- DL manuals

- Sentry

- Garage Door Opener

- DCC02

- Installation And User Manual

Sentry DCC02 Installation And User Manual

Summary of DCC02

Page 1

Sentry dcc02 roll-up garage door automation installation and user manual.

Page 2: Technical Support

Technical support +27 11 433 4084 for technical queries relating to use/installation of this product! Powered by eng manufactured by martin electronics cc po box 49284, rosettenvile 2130 republic of south africa afr vervaardig deur martin electronics cc posbus 49284, rosettenvile 2130 republiek van ...

Page 3

Table of contents table of contents company profile ........................................................................................... Warnings and cautions for use ................................................................. Introduction ..................................................

Page 4: Martin Electronics Is A

Company profile company profile martin electronics is a respected and well-known manufacturer of rf remote controls and security products and has established itself as the leader in rf remote control for the past 20 years. The company manufactures remote controls, receivers, infrared beams and garag...

Page 5: Warnings And Cautions

Warnings and cautions please read the following warnings and cautions before installing or using the product. Risk of electric shock and/or fire do not touch any components when power is applied 1. Read all instructions and warnings carefully before installing the product 2. The product must only be...

Page 6

Introduction introduction the sentry dcc02 is a second-generation roll-up door automation product designed for domestic and light industrial applications. The product is designed to fit most roll-up garage doors that have plastic or metal spool wheels. It operates by applying a rotational force to o...

Page 7: Operation!

Door types and considerations door types and considerations important - please read this section carefully to ensure that the door you intend to automate, meets the requirements for successful and trouble-free operation! Door brands this product is designed to operate, primarily with common types of...

Page 8: Door Condition Checklist

Door types and considerations door types and considerations doors with bent take-up spools- these are doors with bent spools, that pull the head unit’s driving wheel proportionately skew. The product suffers damage and exhibits all kinds of fault conditions, most commonly that of moving short distan...

Page 9

Required equipment for installation required equipment for installation philips screwdriver & flat screwdriver small side cutter multimeter drill with impact setting masonry drill bit (6 ~ 6.5mm) spanner set (17 ~ 21) tek screws length of angled steel hss drill bits (6 ~ 10mm) length of rectangular ...

Page 10: Correct

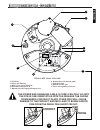

Component detail - head unit component detail - head unit 5 1 2 3 4 8 6 7 1. Dc motor 2. Plastic unit housing 3. Motor wires (green & brown) 4. Head unit controller pcb 5. Manual override engage/disengage lever 6. Manual override lanyard guide 7. Optical pick-up 8. Optical encoder gear 9. Power and ...

Page 11

Component detail - wall console component detail - wall console 1 2 3 7 8 4 5 6 9 10 11 12 13 14 1. Lead-acid battery (12v 1.3ah x 2) 2. Battery interconnects 3. Remote receiver antenna lead (brown) 4. Set button 5. Learn button 6. Transformer wiring loom (6 cores terminated onto molex connector) 7....

Page 12

Wall console - fitting the cables wall console - fitting the cables 2 pin header (ac mains) supplied mains lead with plug (plug fitted varies according to region and local mains voltage) locate the two pin header on the underside of the wall console pcb as shown above. Plug the two pin receptacle on...

Page 13

Wall console - fitting the cables wall console - fitting the cables locate the three pin header on the underside of the wall console pcb as shown above. Plug either end of the interconnecting cable into the receptacle. The moulded grommet, on the cable is designed to slot into a mating receptacle in...

Page 14

Motor head unit installation motor head unit installation the following sections detail how to install the motor head onto the door. Please pay special attention to the various aspects of installation as failure to do so will lead to product failure and/or malfunction. In general, two types of door ...

Page 15

Motor head unit installation motor head unit installation 8 8 factory shipped configuration left hand side install right hand side install brown green brown green l is h e n g 15.

Page 16

Motor head unit installation motor head unit installation once you have determined where you would like to install the motor, and have changed the motor wires accordingly (if necessary) the next step required is to loosen the desired end of the door. The tube is moved away from the door support so t...

Page 17

Motor head unit installation motor head unit installation l is h e n g 3 with the motor gearbox disengaged, push the motor onto the tube until it is supported on the tube. Do not yet push it against the spool wheel. 4 with the motor head unit on the edge of the steel tube, align the two drive hooks ...

Page 18

Motor head unit installation motor head unit installation l is h e n g 5 with the two drive hooks aligned as shown in the previous step, gently press the motor and the spool wheel together as shown. The motor must fit snugly against the spool wheel. Lift the door tube back onto the platform, the ste...

Page 19

Motor head unit installation motor head unit installation l is h e n g 19 6 looking at the opposite side of the motor, that is, from the driving wheel side, ensure that both drive hooks fit snugly as shown in the above diagram. The maximum amount of clearance between the surfaces of the spool wheel ...

Page 20

Motor head unit installation motor head unit installation l is h e n g 20 tightening the motor and tube assembly for platform type (wispeco™) doors, replace the original u-bolt. Inspect the washers and nuts and replace if needed for other types of doors, you will need to use the supplied u-bolt, cut...

Page 21

21 motor head unit installation motor head unit installation l is h e n g when fitting the cover, route the motor wires and the interconnecting cable through the slots in the cover as shown. The cover is a press-fit, it is not affixed with screws. 10 once the motor is attached to the door, the u-bol...

Page 22: (Krazi-Door, Etc..)

Motor head unit installation motor head unit installation l is h e n g 22 tightening the motor unit on a door with side plates (krazi-door, etc..) for krazi door (and other similar doors) it is necessary to fabricate a steel baseplate and use it in conjunction with the supplied u-bolt. This configur...

Page 23

Motor head unit installation motor head unit installation l is h e n g 23 the above figure shows how the u-bolt fits over the tube, and restrains the motor unit to the tube, without reliance on a platform or interfering with the side plates. The motor can be mounted, on these kinds of doors, in any ...

Page 24

24 l is h e n g motor head unit installation motor head unit installation 1 2 3 5 4 step 1 - fit the u-bolt over the motor unit stem as shown step 2 - fasten the u-bolt to the tube by means of a tek screw (a hole will now be made in the tube, locking the u-bolt securely in place) step 3 - fit the ba...

Page 25: Mounting Template

Wall console installation wall console installation 25 l is h e n g the wall console is designed to be affixed to any surface using a variety of screws. Four keyhole style mounting holes are provided in the base of the wall console for easy mounting on a variety of surfaces. In most cases the unit w...

Page 26

26 l is h e n g wall console installation wall console installation for typical masonry (brick wall) mounting, it is recommended to install the nail in anchors as shown. The plastic sleeves are inserted into the wall first after being drilled with the hammer drill. 1 2 once the sleeves are inserted ...

Page 27: Enhanced Installation Detail

L is h e n g 27 system commissioning system commissioning system commissioning procedure this section explains the steps to be followed to commission the dcc02 post fitment and installation on the door. Commissioning involves powering the system for the first time, programming the limits, as well as...

Page 28

28 l is h e n g system commissioning - external rcvr system commissioning - external rcvr connection diagram for external receiver close up of wall console ancillary terminals external receiver grn blk red red grn blk cable: 4 core “comms” cable note that the common of the relay contact on the recei...

Page 29

L is h e n g system commissioning - beams system commissioning - beams connection diagram for infra-red safety beams 29 close up of wall console ancillary terminals 24 12 0 nc n o c om receiver transmitter sentry ir beam wall console terminals beam tx beam rx 24 12 0 24 12 0 nc no com trg bm com b+ ...

Page 30

30 l is h e n g system commissioning - remote led system commissioning - remote led close up of wall console ancillary terminals grn connection diagram for installing a remote status led a remote status led allows the user to know the status of the garage door (open, closed or trouble) from a remote...

Page 31: Powering Up The System

System commissioning - powering up system commissioning - powering up l is h e n g 31 powering up the system once installation is complete, and, if applicable, the connections to beams and/or an external receiver has been made, the system can be powered up by connecting the batteries first (linking ...

Page 32: Powering Up (Cont..)

L is h e n g system commissioning - powering up system commissioning - powering up 32 powering up (cont..) if the system has powered up correctly, there will be no further beeps. However, if there is a problem, the system will emit error beeps and flash an error code on the status led. These issues ...

Page 33: Limit Programming

L is h e n g 33 system commissioning - limits system commissioning - limits limit programming before the garage door operator can be used, the door limits have to be programmed. This is an automated process, that involves little user input. Assuming the system has powered up correctly (no beeping) t...

Page 34: Limit Programming (Cont)

Limit programming (cont) the door will open slowly until the end-stop is encountered. When the endstop is encountered, the door will stop for a few seconds, then close at full speed, then stop. It will wait for a few seconds and then open fully at full speed. This is done in order to measure various...

Page 35

System commissioning - limits system commissioning - limits l is h e n g 35 3 door closes at full rated speed once the upper limit has been registered (stall against endstop) the door will close automatically at full speed. The door will slow down and stop fully closed. 4 door opens at full rated sp...

Page 36

System commissioning - limits system commissioning - limits l is h e n g 36 adding weight to very light doors in general, when the roll-up door is very light, a number of symptoms may become apparent and cause temporary malfunctions of the product. These include stopping after moving short distances...

Page 37

37 l is h e n g system commissioning - programming remotes system commissioning - programming remotes programming remote controls into the system the dcc02 is supplied with two four code-hopping remote controls which are intended for use with this product. The user can purchase additional remote con...

Page 38

38 l is h e n g system commissioning - programming remotes system commissioning - programming remotes as shown on the previous page, pressing and releasing the lrn button, switches the system into remote programming mode. A single beep indicates this. When in learn mode, the current slot selected is...

Page 39

39 l is h e n g system commissioning - programming remotes system commissioning - programming remotes once the desired slot has been selected, operate the desired button on the remote control, to program it into the system. Upon successful learning, the wall console will issue two confirmation beeps...

Page 40

40 l is h e n g system commissioning - erasing remotes system commissioning - erasing remotes erasing all the remote controls in the system to erase all the remote controls in the system, in cases where there has been a security breach or to reset the remote control storage to factory defaults, the ...

Page 41: Advanced Features

41 l is h e n g advanced features advanced features advanced features the dcc02 is equipped with a programmable auto-close timer, which is accessible via a menu termed the “advanced features menu”. The structure of this menu is shown as follows: set e press and release set button e x1 advanced featu...

Page 42

42 l is h e n g advanced features - auto-close selection advanced features - auto-close selection auto-close function enable/disable the auto-close function can be enabled/disabled as follows. Please be aware that when auto-close is enabled, there must be a safety beam present. Auto-close option men...

Page 43: Auto-Close Timer Adjustment

43 l is h e n g advanced features - auto-close timer advanced features - auto-close timer auto-close timer adjustment when enabled, the auto-close timer can be adjusted for time-out periods between 10 seconds and 250 seconds. Adjustment below or above this range will result in an error indication. T...

Page 44: Troubleshooting Guide

L is h e n g troubleshooting guide troubleshooting guide troubleshooting guide the following is a thorough guide to solving problems that occur with the dcc02. It is split into two sections, one for diagnosing troubles during limit programming, the other for diagnosing problems during normal running...

Page 45

45 l is h e n g section a: limit set-up troubleshooting (cont) troubleshooting guide troubleshooting guide problem likely cause(s) possible solution(s) the door moves slowly, reaches the endstop and then fails to stop with a loud “clack clack clack” noise. • door too light • endstops not secure enou...

Page 46

46 l is h e n g troubleshooting guide troubleshooting guide section b: general operating mode troubleshooting problem likely cause(s) possible solution(s) cannot enter limit programming • door not closed fully • ensure the door has been closed fully, if not the cause, power cycle the system and then...

Page 47

47 l is h e n g troubleshooting guide - error and status codes troubleshooting guide - error and status codes normal operation off = door closed status led slow flash = door opening on = door fully/partially open or partially closed fast flash = door closing error condition (only indicated when door...

Page 48: Product Type:

48 l is h e n g product specification product specification product type: dc drive reduction gear motor for roll up doors voltage: 24 volts dc power source: 200 - 250v ac 50/60hz 120va battery back-up: internal 12v 1.3ah batteries (2 pcs) max lift mass: equivalent to 6kg receiver frequency: 433.92mh...

Page 49

49 this page intentionally left blank.

Page 50

Ref: dcc02 user manual rev1_1.Cdr.