- DL manuals

- Sequoia Aircraft Corporation

- Aircrafts

- F.8L Falco

- Construction Manual

Sequoia Aircraft Corporation F.8L Falco Construction Manual

Summary of F.8L Falco

Page 1

F.8l falco construction manual.

Page 2

F.8l falco construction manual sequoia aircraft corporation 2000 tomlynn street, p.O. Box 6861 • richmond, virginia 23230 • 804/353-1713 • fax 804/359-2618 • www.Seqair.Com.

Page 3

Copyright 2002 sequoia aircraft corporation. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form by any means, electronic, mechanical, photocopying, recording, or otherwise, without prior written permission of sequoia aircraft...

Page 4

L f.8l falco construction manual revision 4, march 1, 2002 list of effective pages revision 4 march 1, 2002 the f.8l falco construction manual was originally written in 1984, and since then portions of the manual have been revised in 1986 and 1989 to correct minor deficiencies. At the time of these ...

Page 5

L f.8l falco construction manual revision 4, march 1, 2002 12-1 thru 12-4 4 march 1, 2002 13-1 thru 13-4 4 march 1, 2002 14-1 thru 14-12 4 march 1, 2002 15-1 thru 15-4 4 march 1, 2002 16-1 thru 16-14 4 march 1, 2002 17-1 thru 17-10 4 march 1, 2002 18-1 thru 18-12 4 march 1, 2002 19-1 thru 19-8 4 mar...

Page 6

L f.8l falco construction manual revision 4, march 1, 2002 preface it is customary to acknowledge those who have assisted in the writing of a book, however this manual is the result of assistance from hundreds of falco builders. Indeed, it is a rare builder who has not made some contribution to our ...

Page 7

L f.8l falco construction manual revision 4, march 1, 2002.

Page 8

L f.8l falco construction manual i revision 4, march 1, 2002 table of contents chapter 1 preparing for construction welcome! 1-1 where to start? 1-1 family and friends 1-1 your shop 1-1 what to make? 1-2 setting standards 1-2 modifications 1-3 visit a falco builder 1-5 plan ahead 1-5 in search of ex...

Page 9

L f.8l falco construction manual ii revision 4, march 1, 2002 scarfing jig 4-5 air compressor 4-5 pneumatic staple gun 4-5 hand-operated stapler 4-6 staple lifter 4-6 die grinders 4-6 electric hand sander 4-6 carbide abraders 4-7 sanding blocks 4-7 gil-bilt power tool kits 4-7 laminate trimmer 4-7 o...

Page 10

L f.8l falco construction manual iii revision 4, march 1, 2002 aerolite 8-5 penacolite g-1131 resorcinol 8-5 plastic resin glues 8-6 epoxy glues 8-6 test blocks 8-9 chapter 9 moisture protection of wood introduction 9-1 requirements of finishes 9-1 protective power of wood finishes 9-1 the 1950’s te...

Page 11

L f.8l falco construction manual iv revision 4, march 1, 2002 chapter 14 antenna installation no. 1 communications antenna installation 14-1 no. 2 communications antenna installation 14-2 vhf navigation antenna installation 14-3 marker beacon antenna installation 14-3 transponder antenna installatio...

Page 12

L f.8l falco construction manual v revision 4, march 1, 2002 chapter 23 wing, preliminary assembly kits on hand 23-1 other materials 23-1 spar fittings installation 23-1 main wing spar/fuselage frame no. 4 23-8 forward wing spar/fuselage frame no. 3 23-12 fuselage frame no. 5 23-17 fuselage frame no...

Page 13

L f.8l falco construction manual vi revision 4, march 1, 2002 chapter 28 fuselage assembly, part 3 kits on hand 28-1 bottom forward fuselage skin 28-19 aft top fuselage section 28-21 forward top fuselage section 28-24 appendix a sources woodworking tools a-1 general tools, metal & wood a-3 aircraft ...

Page 14

L f.8l falco construction manual 1–1 revision 4, march 1, 2002 chapter 1 preparing for construction “perfection is finally attained not when there is no longer anything to add, but when there is no longer anything to take away.” antoine de saint exupéry wind, sand and stars welcome! Welcome to the f...

Page 15

L f.8l falco construction manual 1–2 revision 4, march 1, 2002 from the project will become a problem, and your family will come to resent the thing that keeps you from them. What to make? One of your early decisions will be which kits to buy and which parts to make. For most builders, the decision ...

Page 16

L f.8l falco construction manual 1–3 revision 4, march 1, 2002 if you take great care to do everything well, you will enjoy the construction of the aircraft much more than if you are sloppy. When your falco is finished, you will find it difficult to look at the airplane without seeing the errors. Yo...

Page 17

L f.8l falco construction manual 1–4 revision 4, march 1, 2002 you understand, but you will not. After the instrument panel and the electrical system are installed, you will have a very good idea. You will not completely understand the degree of systems integration until you have the falco ready to ...

Page 18

L f.8l falco construction manual 1–5 revision 4, march 1, 2002 problems. If you are not prepared to spend the time and money on engineering, then you should not expect us to be enthusiastic about the design change. Also, to do this type of thing properly will involve a lot of our time. We do not hav...

Page 19

L f.8l falco construction manual 1–6 revision 4, march 1, 2002 among the ranks of the chapter members; however, our experience is that the true experts tend to be lone wolves. They do not tend to be joiners or socializers. You must seek them out, and you can expect their enthusiasm to rise only afte...

Page 20

L f.8l falco construction manual 1–7 revision 4, march 1, 2002 request. For your information, the price of the falco plans is broken down as follows: roughly $100.00 covers the cost of printing the drawings and construction manual, $100.00 goes to mr. Frati (his only compensation), and $200.00 remai...

Page 21

L f.8l falco construction manual 1–8 revision 4, march 1, 2002.

Page 22

L f.8l falco construction manual 2–1 revision 4, march 1, 2002 chapter 2 reading the plans the falco plans you may not be aware of it, but almost everything you purchase has been made from plans—your car, your house, the pen you write with, etc. Over the years, manufacturers have found that a drawin...

Page 23

L f.8l falco construction manual 2–2 revision 4, march 1, 2002 important it is that you have complete details. There is an old saying that something is only as hard to build as the plans are poor. There is a great deal of truth to this. You will find that your greatest difficulties will arise when y...

Page 24

L f.8l falco construction manual 2–3 revision 4, march 1, 2002 sections & views now take a look at drawing no. 838-2. Here we have something new. In this case there are two views, but the thing that looks like a side view doesn't make any sense. This is known as a section. A section is a view throug...

Page 25

L f.8l falco construction manual 2–4 revision 4, march 1, 2002 a view is just like a section, but the part is not cut through. A view is a designer's way of saying “this is what the part would look like if you looked at it from here”. Figure 3 shows an example of a view of our little house. Dimensio...

Page 26

L f.8l falco construction manual 2–5 revision 4, march 1, 2002 dimensions given do not match the part as drawn, and when a dimension is underlined you are being alerted to the discrepancy. In such cases you are to pay attention to the actual size of the drawn part but to use the dimension given. Eve...

Page 27

L f.8l falco construction manual 2–6 revision 4, march 1, 2002 a mold line will not be seen often, but it is the same pattern as is used for section and view lines, except that the line is a lightweight line. We will point out these and other special types of lines as they are used. A few symbols a ...

Page 28

L f.8l falco construction manual 2–7 revision 4, march 1, 2002 need more help? You will find that the drawings will be easy to understand. If you should have trouble with them, ask someone to come over and give you a quick lesson. Engineers or machinists would be the best people to ask. Architects u...

Page 29

L f.8l falco construction manual 2–8 revision 4, march 1, 2002.

Page 30

L f.8l falco construction manual 3–1 revision 4, march 1, 2002 chapter 3 your shop close to home the most important thing about your shop is that it be located as close to home as possible. Working in a shop should be a pleasure, and it is no fun at all to have to pack off to the airport. If your sh...

Page 31

L f.8l falco construction manual 3–2 revision 4, march 1, 2002 you will also find that if the shop is painted white, it will make the shop seem much brighter. Temperature control the glues that are used for aircraft woodwork require a minimum temperature. Resorcinol requires 70°f, as does epoxy. Som...

Page 32

L f.8l falco construction manual 4–1 revision 4, march 1, 2002 chapter 4 tools introduction the availability of proper tools will make a huge difference in the speed that you build your falco. If you visit a number of falco builders, you will be amazed at the variety of tools that are used. Some bui...

Page 33

L f.8l falco construction manual 4–2 revision 4, march 1, 2002 a dial or vernier caliper is extremely handy. We prefer the dial type, and we have one in inches only. For conversions we use a hand-held calculator. You will find such a calculator extremely handy. We prefer the hewlett-packard hp11c pr...

Page 34

L f.8l falco construction manual 4–3 revision 4, march 1, 2002 clamps oh, boy! Are you going to need clamps! Rare is the builder who has enough of them. Generally, you will need many different types. The c-clamp is the most common type and is available almost everywhere. A better alternative for sma...

Page 35

L f.8l falco construction manual 4–4 revision 4, march 1, 2002 you will need an assortment of drill bits for both metal and wood. You will not want to build a falco without a set of brad point bits. These bits cut a very clean, smooth hole in wood, unlike normal twist bits which tear their way throu...

Page 36

L f.8l falco construction manual 4–5 revision 4, march 1, 2002 the frame and tightened with a knurled knob. “a highly recommended tool for those fed up with k-mart coping saws”. Stationary belt/disc sander this is an essential tool, which you will use very often. It is not particularly important whe...

Page 37

L f.8l falco construction manual 4–6 revision 4, march 1, 2002 trigger, and you want to be sure to get a staple gun that will shoot fine-wire staples that will not split the wood. The premier manufacturer is senco products, and they have two staplers which shoot fine-wire staples. The senco bo4, bo6...

Page 38

L f.8l falco construction manual 4–7 revision 4, march 1, 2002 products makes a line of perma-grit tools. Most are round or triangular file-like devices but they also sell flat sheets of thin steel with carbide brazed to them. The flat sheets can be bonded to a board and this makes a great float-san...

Page 39

L f.8l falco construction manual 4–8 revision 4, march 1, 2002 torque wrench you will need one torque wrench during the construction of your falco. This will be required eventually for the spark plugs for your engine. Check with your local fbo for a recommended type. Gluing supplies when you work wi...

Page 40

L f.8l falco construction manual 5–1 revision 4, march 1, 2002 chapter 5 planning ahead the faa and you the federal aviation administration (faa) is part of the united states department of transportation. As a pilot, you are aware of its role in certifying production aircraft, licensing pilots, oper...

Page 41

L f.8l falco construction manual 5–2 revision 4, march 1, 2002 to keep rascals from producing aircraft on production lines and licensing them in the amateur- built category, the regulations state that a builder must do the majority of the work himself. This has been widely interpreted as the now-com...

Page 42

L f.8l falco construction manual 5–3 revision 4, march 1, 2002 new friend who is offering a few suggestions and telling you about the horrible thing he saw the other day. Perhaps the most telling experience was that of a falco builder who had the head of the local gado office do his inspection. The ...

Page 43

L f.8l falco construction manual 5–4 revision 4, march 1, 2002.

Page 44

L f.8l falco construction manual 6–1 revision 4, march 1, 2002 chapter 6 machining, welding & fabrication introduction this chapter is devoted to the construction of the various parts which are included in the kits that we offer. Accordingly, if you purchase these kits, this chapter may be skipped. ...

Page 45

L f.8l falco construction manual 6–2 revision 4, march 1, 2002 built up, and the part must be stress relieved after welding. Failure to stress relieve any welded part can cause it to fail prematurely. There are a few heat treated 4130 parts in the falco. The normal heat treatment specification is to...

Page 46

L f.8l falco construction manual 6–3 revision 4, march 1, 2002 because of their function in the aircraft, the installation and tolerances of the bushings is important. The bushings, in particular, must not be allowed to fit loosely in the hinges. (to guard against the possibility of the bushings bei...

Page 47

L f.8l falco construction manual 6–4 revision 4, march 1, 2002 main landing gear legs if you make your own landing gear legs, you will find that the bearing surfaces of the upper tube will warp slightly during welding. For this reason, it is best to weld the upper tube completely, with the oleo brac...

Page 48

L f.8l falco construction manual 7–1 revision 4, march 1, 2002 chapter 7 corrosion protection introduction the protection of aluminum, bronze and steel parts is a very complicated subject. For a complete discussion, the best publication is painting aircraft for corrosion control by ray stits. This m...

Page 49

L f.8l falco construction manual 7–2 revision 4, march 1, 2002 other parts which will be exposed to the elements. Zinc chromate primers do not have good adhesion. The primer is available in yellow or green. We prefer the yellow, simply because the lighter color makes inspection easier. Zinc chromate...

Page 50

L f.8l falco construction manual 8–1 revision 4, march 1, 2002 chapter 8 aircraft woodwork, materials spruce the falco was originally designed and built with sitka spruce for all of the spar caps. Poplar was used for the ribs, fuselage frames and all other places where we now use spruce. We are in t...

Page 51

L f.8l falco construction manual 8–2 revision 4, march 1, 2002 conditions is shown in figure 1. Note that under constant temperature conditions the moisture content increases as the relative humidity increases, and that under constant relative humidity conditions the moisture content decreases as th...

Page 52

L f.8l falco construction manual 8–3 revision 4, march 1, 2002 widely separated cities in the united states at different times of the year. Similar seasonal variations occur in other parts of the world. In tropical and subtropical areas, where long rainy seasons are followed by long dry spells, the ...

Page 53

L f.8l falco construction manual 8–4 revision 4, march 1, 2002 content, typically around 5 to 7%. If you use the plywood immediately, the plywood will be drier than the spruce. In time, the plywood will pick up moisture and expand. For most parts, this is of little consequence. If the plywood is use...

Page 54

L f.8l falco construction manual 8–5 revision 4, march 1, 2002 production falcos were built entirely with aerolite. Aerolite is highly recommended. For those jobs where a longer working time is needed, we recommend koppers penacolite g-1131 resorcinol adhesive. Resorcinols are the most durable room-...

Page 55

L f.8l falco construction manual 8–6 revision 4, march 1, 2002 70°f is required, and this glue does not fill gaps as aerolite does, thus the surfaces of the pieces of wood must be machined surfaces. Glue pressures are important with resorcinols and penacolite is less sensitive to glue pressures that...

Page 56

L f.8l falco construction manual 8–7 revision 4, march 1, 2002 30° 40° 50° 60° 70° 80° 90° 100° 110° ambient air temperature (°f) 70° 80° 90° 100° 110° 120° 130° 140° 150° 160° 170° 180° 190° 200° 210° 220° 230° 240° peak surface temperature (°f) (soaring september 1975) black brown red & green oran...

Page 57

L f.8l falco construction manual 8–8 revision 4, march 1, 2002 the effects of epoxy are cumulative. When you first work with epoxy you will not be bothered, and you will wonder what all the fuss is about—then one day you will become sensitized. When that happens, you will have burns on your hands fr...

Page 58

L f.8l falco construction manual 8–9 revision 4, march 1, 2002 the west system epoxies are low viscosity resins, designed primarily as a moisture protection coating that is adapted for use as a wood glue. They have little resistance to glue starvation caused by clamping, and gougeon recommends the a...

Page 59

L f.8l falco construction manual 8–10 revision 4, march 1, 2002 consider. Mark each test block for the faa inspector to see. The normal test used for wood aircraft is known as the “block shear test”. This is described in anc-19 and many other texts. You will not be able to duplicate this test withou...

Page 60

L f.8l falco construction manual 9–1 revision 4, march 1, 2002 chapter 9 moisture protection of wood introduction all of the interior and exterior wood surfaces must be covered with a coating to prevent the absorption of moisture. This chapter will deal only with the interior surfaces. A complete di...

Page 61

L f.8l falco construction manual 9–2 revision 4, march 1, 2002 the surface of wood is vascular and moderately absorptive of liquids. Wood surfaces, therefore, must be rendered nonabsorptive by applying sealer or primer, which penetrates only far enough to close the openings in the surface, before a ...

Page 62

L f.8l falco construction manual 9–3 revision 4, march 1, 2002 the final coat only is aluminized the moisture-excluding effectiveness sometimes is no greater than that obtainable with the clear vehicle without the aluminum. Recent developments in the past decade, polyurethane paints have been develo...

Page 63

L f.8l falco construction manual 9–4 revision 4, march 1, 2002 note that aluminum pigmented varnish is still superior to polyurethane and epoxy paints. This does not take into account the greater life of polyurethane and epoxy coatings. We recommend that epoxy or polyurethane coatings be used on the...

Page 64

L f.8l falco construction manual 9–5 revision 4, march 1, 2002 the method you will use is to complete the assembly to a point at which the plywood skin has been glued on the top or bottom of the wing and the second skin has been cut and fitted accurately but has not yet been glued down. All glue lin...

Page 65

L f.8l falco construction manual 9–6 revision 4, march 1, 2002.

Page 66

L f.8l falco construction manual 10–1 revision 4, march 1, 2002 chapter 10 woodworking methods introduction this chapter will cover the basic techniques you will be using to build the falco. We will discuss methods that have been used for years, and we will also tell you about many techniques that f...

Page 67

L f.8l falco construction manual 10–2 revision 4, march 1, 2002 be made in the general direction of the grain slope. The object is to make the cut in such a way as to minimize the amount of end grain showing on the face of the scarf joint. Figure 1 shows this requirement, but please note that the gr...

Page 68

L f.8l falco construction manual 10–3 revision 4, march 1, 2002 making a scarf joint every builder ends up using his own version of a scarfing jig. There are a huge number of such arrangements and these are shown in the many reference books listed in appendix b. Figure 3 the simplest way to scarf pl...

Page 69

L f.8l falco construction manual 10–4 revision 4, march 1, 2002 rolling table lower tenoner head hold down bar piece being scarfed jig figure 4 there are many other methods of scarfing plywood. A tenoner may be used as shown in figure 4. This method may be used for spruce or plywood. While few falco...

Page 70

L f.8l falco construction manual 10–5 revision 4, march 1, 2002 will be 12mm wide. Measure off the 12mm dimension and draw a line. The scarf can then be sanded to this line. If you are very careful and skillful, you can do most of the scarf with a power sander. You should finish off the scarf with a...

Page 71

L f.8l falco construction manual 10–6 revision 4, march 1, 2002 because the excess moisture around glue joints expands the wood, machining of the wood should be postponed until after the wood has been conditioned. Machining immediately after gluing will result in a depression at the glue joint after...

Page 72

L f.8l falco construction manual 10–7 revision 4, march 1, 2002 the same guidelines would apply to staples. We have already suggested in the chapter on tools the two recommended staplers. Nails are difficult to handle and slow to install. Staples and nails are used to hold the wood in place during g...

Page 73

L f.8l falco construction manual 10–8 revision 4, march 1, 2002 the wood. The rib capstrips must be soaked overnight in water, then put into a bending jig until dry. It is not necessary to bend the wood precisely as there is still plenty of “flex” left in wood. The birch plywood is bent in a similar...

Page 74

L f.8l falco construction manual 10–9 revision 4, march 1, 2002 60" 50" 40" 30" 20" 10" 8" 6" 4" 3" 2" 1" .40" .30" .20" .10" .05" .04" .03" .02" .01" .02" .04" .06" .10" .20".30" .60" 1" 90° angle-10% moisture content 0° angle-10% moisture content 90° angle-hot soaked 0° angle-hot soaked thickness ...

Page 75

L f.8l falco construction manual 10–10 revision 4, march 1, 2002 figure 9 the leading edges of the wing, tail and control surfaces are the most common plywood bending exercise in the falco. There are several methods that may be used. One of these is to pre-bend the plywood over a mandrel as shown in...

Page 76

L f.8l falco construction manual 10–11 revision 4, march 1, 2002 quite long, and this is desirable. To bend the plywood, lace the rubber bands back and forth over the nails of the two 20x20 pine pieces. The first couple of lacings will do little to bend the plywood, but as you work your way down the...

Page 77

L f.8l falco construction manual 10–12 revision 4, march 1, 2002 figure 12 for many of the wing ribs you can use the rubber bands to clamp the ribs in place. These are the “open” ribs; that is, they do not have plywood glued to the face of the rib. To clamp a corner block in place, the method shown ...

Page 78

L f.8l falco construction manual 10–13 revision 4, march 1, 2002 figure 14 when you glue the leading edge skins on the elevator or rudder, you can use the method shown in figure 15. These custom band clamps are made of aluminum and a bolt is used as a jack-screw to apply the pressure. The nut may be...

Page 79

L f.8l falco construction manual 10–14 revision 4, march 1, 2002 figure 16 a simpler method is to use the large rubber bands to clamp the skins in place. For the upper leading edge skin of the aileron, you may use the same type of method shown in figure 11. Drilling holes most of the fittings (suppl...

Page 80

L f.8l falco construction manual 10–15 revision 4, march 1, 2002 bolt torques with a metal airplane, all bolts are expected to be torqued to a specific value. This is not true of a wood airplane. The bolts are expected to be tight but not so tight that the wood is crushed. You will notice that the m...

Page 81

L f.8l falco construction manual 10–16 revision 4, march 1, 2002.

Page 82

L f.8l falco construction manual 11–1 revision 4, march 1, 2002 chapter 11 making ribs this chapter is devoted entirely to making the wing and tail ribs. If you are purchasing the ribs, you may skip this chapter. If you are going to make all of your wood components you should start with the ribs. It...

Page 83

L f.8l falco construction manual 11–2 revision 4, march 1, 2002 the drawings for the rudder ribs are badly out of scale. As noted in the revisions, the lightening holes in the nose ribs are to be omitted. Jigs ribs require some type of jig during their construction to insure accurate contours and di...

Page 84

L f.8l falco construction manual 11–3 revision 4, march 1, 2002 glue is dry. This usually means overnight, and you will have to repeat the process for the gussets on the opposite side. One method of making rib jigs is to drill large holes at each joint intersection. The purpose of this is that the r...

Page 85

L f.8l falco construction manual 11–4 revision 4, march 1, 2002 one method that you can use to speed up the construction of the ribs is to make two ribs at one time. You will need to make the rib slightly more than twice the normal width. Use a band saw to resaw the ribs in two pieces. You will have...

Page 86

L f.8l falco construction manual 12–1 revision 4, march 1, 2002 chapter 12 making the fuselage frames this chapter is devoted entirely to making the fuselage frames. If you are purchasing these frames, you may skip this chapter. As with the ribs, it is best to start with the simplest of the fuselage...

Page 87

L f.8l falco construction manual 12–2 revision 4, march 1, 2002 glue, for example, will gum up a sanding belt very quickly. When the lamination is removed from the mold, the lower side is usually flat. Some builders put a fence on a band saw and carefully saw the extra wood off. Others put a router ...

Page 88

L f.8l falco construction manual 12–3 revision 4, march 1, 2002 not always given at the face with the larger overall dimensions. For most of the fuselage frames in the tail section, this is inconsequential, but if you wish, you may work out the larger dimensions using trigonometry and a calculator. ...

Page 89

L f.8l falco construction manual 12–4 revision 4, march 1, 2002 this same formula can be solved for either x or y. These two formulas are: x = a 1 − 1 − 1 − y b 2 y = b 1 − 1 − 1 − x a 2 if you have a hewlett-packard hp-11c programmable calculator you may use the program shown in figure 2. Figure 2 ...

Page 90

L f.8l falco construction manual 13–1 revision 4, march 1, 2002 chapter 13 making the spars this chapter is devoted entirely to making the spars. If you are purchasing the spars, you may skip this chapter. As always, it is best to start with the simplest parts and work your way up to the most diffic...

Page 91

L f.8l falco construction manual 13–2 revision 4, march 1, 2002 plywood scarf joints some of the spars have several thicknesses of plywood on the faces of the spars. The plywood joints are scarf joints, of course, but they are drawn in an exaggerated manner for clarity. On the faces of the spars, th...

Page 92

L f.8l falco construction manual 13–3 revision 4, march 1, 2002 start by laying out the dimensions of the spar on the jig table. As always, work carefully. This is one part of the airplane that you do not want to make twice, so measure everything three times. The upper and lower spar booms will be l...

Page 93

L f.8l falco construction manual 13–4 revision 4, march 1, 2002 to draw the inside framework of the spar on the outside faces of the plywood. Glue on the plywood..

Page 94

L f.8l falco construction manual 14–1 revision 4, march 1, 2002 chapter 14 antenna installation the internal antenna system described in this chapter provides for the installation of antennas for dual vhf com, dual vhf nav (vor-loc-gs), dme, adf, transponder, and marker beacon within the wooden stru...

Page 95

L f.8l falco construction manual 14–2 revision 4, march 1, 2002 if only one communications antenna is installed, it should be this antenna since the radio waves from unicom radio antennas are vertically polarized to a greater extent than other communications (atc, fss, tower, ground, etc.). Material...

Page 96

L f.8l falco construction manual 14–3 revision 4, march 1, 2002 vhf navigation antenna installation see drawings no. 160 and 161. The vhf navigation antenna is a nearly-identical mirror image of the no. 2 com antenna, but in the right wing. The elements are run parallel to the wing spar to the ribs ...

Page 97

L f.8l falco construction manual 14–4 revision 4, march 1, 2002 materials required: 1 rst ferrite-foil antenna kit 1 ug88 (male) bnc connector 1 ug89 (female) bnc connector 20’ rg58 coaxial cable (includes 3’ extra) since this system was designed, the location of the marker beacon receiver has been ...

Page 98

L f.8l falco construction manual 14–5 revision 4, march 1, 2002 may be run to a remote receiver on the aft face of frame no. 6. This installation will provide the extra cable needed. Adf antenna installation no special antenna is offered by radio systems technology since most new radios are supplied...

Page 99

L f.8l falco construction manual 14–6 revision 4, march 1, 2002 loran antenna design requirements loran systems were originally developed for marine navigation. Ships and boats use a vertical whip antenna, usually 5 or 10 feet high. The antenna does not require a specific tuned length like the other...

Page 100

L f.8l falco construction manual 14–7 revision 4, march 1, 2002 you must install the antenna coupler. The antenna coupler is sold with the loran and is optimized to work with the specific radio. You should not try to use a loran coupler from another manufacturer or to use an adf coupler. The apollo ...

Page 101

L f.8l falco construction manual 14–8 revision 4, march 1, 2002 the antenna coupler may be installed either vertically or horizontally. The coupler may be installed in several places. The most convenient place is inside the access door for the rudder cable pulley. Figure 2 see drawing no. 410, secti...

Page 102

L f.8l falco construction manual 14–9 revision 4, march 1, 2002 the ground plane in layman’s terms, the object of the ground plane is to make the loran antenna think it is installed on a metal airplane. The loran antenna is easy to fool, so you will only need a few wires. The ground plane will consi...

Page 103

L f.8l falco construction manual 14–10 revision 4, march 1, 2002 a partial list of things to be grounded: the firewall, all control cables, aileron pushrods, elevator pushrod, seat tracks, flap torque tube, firewall, landing gear retraction system, the engine mount, main landing gear, nose gear, all...

Page 104

L f.8l falco construction manual 14–11 revision 4, march 1, 2002 ❏ fray the shielding braid and strip the inner insulation 3/32” (2.4mm). Tin the center conductor; that is, coat the conductor with solder to make the delicate job of soldering the contact easier. Clamp gasket nut washer figure 5 ❏ pin...

Page 105

L f.8l falco construction manual 14–12 revision 4, march 1, 2002 figure 8 ❏push the assembly into the body as far as it will go. Slide the nut into the body and screw in place with a wrench until tight. For this operation, hold the cable and shell rigid and rotate the nut..

Page 106

L f.8l falco construction manual 15–1 revision 4, march 1, 2002 chapter 15 electrical system the electrical system is installed in accordance with the drawings and manual supplied with the electrical system kit. These drawings and the manual are not available separately. This chapter will provide yo...

Page 107

L f.8l falco construction manual 15–2 revision 4, march 1, 2002 frame no. 3 : compass (internally lighted) oat probe (on right fuselage skin, forward of the frame) center console panel : flap position switch throttle position switch landing gear warning horn control sticks : microphone push-to-talk ...

Page 108

L f.8l falco construction manual 15–3 revision 4, march 1, 2002 rudder : tail light wing : wing tip lights heated pitot wire bundle routing the instrument panel has three large plugs which are installed on the forward face of the panel. The wires from these plugs go down and then split into two bund...

Page 109

L f.8l falco construction manual 15–4 revision 4, march 1, 2002.

Page 110

L f.8l falco construction manual 16–1 revision 4, march 1, 2002 chapter 16 tail group assembly preparations kits on hand to assemble the tail group you should have the following kits: kit no. 801-1 tail group equipment kit no. 806 trim tab control equipment kit no. 402 tail group kit no. 405 tail gr...

Page 111

L f.8l falco construction manual 16–2 revision 4, march 1, 2002 until late in the construction, you will need “six fingers and an eyeball on a string” to get the parts in the airplane. In addition to fittings, there are a lot of little pieces of wood which are easily installed early in the game. The...

Page 112

L f.8l falco construction manual 16–3 revision 4, march 1, 2002 figure 1 if you wish, you can make plywood plates for each end of the assembly at hand. A vertical line can be drawn on the plate and the plate used to support alignment strings for the leading edge, trailing edge, or any other part of ...

Page 113

L f.8l falco construction manual 16–4 revision 4, march 1, 2002 drawing notes this chapter describes the assembly of the tail group in accordance with the tail group drawings issued in june 1985. These drawings have a number of changes from the earlier drawings issued in 1979. Many of you may be wor...

Page 114

L f.8l falco construction manual 16–5 revision 4, march 1, 2002 humidity. The rib drawings show a number of new details. There are now rib drawings for the sta. 0 ribs for the stabilizer rib, for example. The original drawings did not show the fairings for the tail group. These new drawings now show...

Page 115

L f.8l falco construction manual 16–6 revision 4, march 1, 2002 the forward fin spar has been changed to include a triangular block of spruce to allow for the installation of the terminal block just mentioned. The opening at the bottom has been changed slightly (the 30r dimensions) to provide cleara...

Page 116

L f.8l falco construction manual 16–7 revision 4, march 1, 2002 when you install sheet metal screws in the wood, drill a small pilot hole to keep the screw from splitting the wood. Preparatory work each of the steps listed has a box for you to check as you do the step. Main fin spar ❏ review drawing...

Page 117

L f.8l falco construction manual 16–8 revision 4, march 1, 2002 forward fin spar ❏ review drawing no. 412. If your spar has been made to the older drawings, you should add the 25x25x13 spruce triangle to the right side. ❏ if your spar has been made to the older drawings, you should change the radius...

Page 118

L f.8l falco construction manual 16–9 revision 4, march 1, 2002 ❏ drill the 1/4”Ø hole for the tail light wires. ❏ if necessary, trim the end of the spar as shown for p/n 415-2. Main stabilizer spar ❏ review drawing no. 406. If your spar has been made to the older drawings, you should add an extra b...

Page 119

L f.8l falco construction manual 16–10 revision 4, march 1, 2002 elevator spar ❏ see drawing no. 406. Install plywood pads on forward and aft face of the spar as shown. At the center of the aircraft, the 2mm plywood extends to b.L. 100. This is because ribs will be glued to the aft face of the spar ...

Page 120

L f.8l falco construction manual 16–11 revision 4, march 1, 2002 ❏ install the 20x18 spruce block on the r.H. Sta. 1 elevator rib. See drawing no. 402, section c-c and g-g. Note that the plywood face of this rib is outboard. Scuff-sand the plywood prior to gluing. ❏ install p/n 117-11 clamp on this ...

Page 121

L f.8l falco construction manual 16–12 revision 4, march 1, 2002 230 1270 350 grain elevator trailing edge skin 230 1270 350 grain elevator trailing edge skin 1270 350 grain elevator trailing edge skin 230 1270 350 grain elevator trailing edge skin 230 figure 3 ❏ use one 50”x50”sheet of 1.2mm birch ...

Page 122

L f.8l falco construction manual 16–13 revision 4, march 1, 2002 660 330 1270 grain stabilizer skin 660 330 1270 grain stabilizer skin 660 330 1270 grain stabilizer skin 660 330 1270 grain stabilizer skin figure 5 ❏ use two 50”x50”sheets of 1.5mm birch plywood and cut in accordance with figure 5. 88...

Page 123

L f.8l falco construction manual 16–14 revision 4, march 1, 2002 660 grain stabilizer skin 660 grain stabilizer skin 660 grain stabilizer skin 660 grain stabilizer skin 225 225 225 225 100 100 100 100 690 (typ) 660 figure 7 ❏ use one 50”x50”sheet of 1.5mm birch plywood and cut in accordance with fig...

Page 124

L f.8l falco construction manual 17–1 revision 4, march 1, 2002 chapter 17 tail group hinge installation elevator hinge installation for the control hinge installation, you will have to ream the bronze bushings with a 1/4”Ø reamer. Do this on a drill press. You can use a 1/4”Ø drill bit, but a reame...

Page 125

L f.8l falco construction manual 17–2 revision 4, march 1, 2002 figure 1 ❏ when you have the hinges in the correct position, remove the 1/4”Ø hinge bolts and carefully drill the 3/16”Ø holes for p/n 750. Use a drill press for all hinge bolt holes through the spars. ❏ install the channel-nuts for p/n...

Page 126

L f.8l falco construction manual 17–3 revision 4, march 1, 2002 ❏ remove the 1/4” hinge bolts and carefully drill the 3/16”Ø holes for the two p/n 755 hinges on the left side. ❏ install the channel-nuts for p/n 755. To keep from moving anything at this critical stage, the screws for the channel-nuts...

Page 127

L f.8l falco construction manual 17–4 revision 4, march 1, 2002 temporary shim under the channel-nut. The screws for the channel-nuts should not be installed at this time. ❏ re-assemble the hinges with the hinge bolts. Check the alignment of all of the hinges. ❏ when you have the hinges in the corre...

Page 128

L f.8l falco construction manual 17–5 revision 4, march 1, 2002 you should understand that the elevator balance weight cannot be installed from the aft end of the airplane through the spar—it simply will not fit (you may be able to get the weight only through, but once the arms are riveted in positi...

Page 129

L f.8l falco construction manual 17–6 revision 4, march 1, 2002 figure 5 ❏ drill p/n 750 with a 5/32”Ø drill at 37mm below the hinge line. See figure 5. Drill only one hole at this time. Insure that this hole is 14mm from the base of the hinge (see drawing no. 750). The holes for the attachment of t...

Page 130

L f.8l falco construction manual 17–7 revision 4, march 1, 2002 figure 7 ❏ install both balance weight arms (with spacers) on p/n 750. See figure 7. Use a 5/32”Ø drill bit to align the one hole already drilled. You may also use a no. 8 machine screw or one of the ms20470ad5-16 rivets. If a rivet is ...

Page 131

L f.8l falco construction manual 17–8 revision 4, march 1, 2002 figure 9 ❏ rivet the balance weight in place. See figure 9. To prevent any corrosion, you should bed the arms down in wet zinc chromate primer or bond with epoxy. Note: in the next few steps you will install the balance weight and arms ...

Page 132

L f.8l falco construction manual 17–9 revision 4, march 1, 2002 ❏ as stated above, ream the upper 3/16”Ø bolt hole through p/n 750 and install the bolt. See figure 10. Figure 11 ❏ as stated above, drill the lower hole through p/n 750 with a 5/32”Ø drill, ream up to 3/16”Ø and install the bolt. See f...

Page 133

L f.8l falco construction manual 17–10 revision 4, march 1, 2002.

Page 134

L f.8l falco construction manual 18–1 revision 4, march 1, 2002 chapter 18 elevator assembly ❏ if not already done, cut the elevator leading edge ribs for the 8x8 leading edge strip. Note: in the following steps, the leading edge ribs and the leading edge strip will be installed on the elevator. The...

Page 135

L f.8l falco construction manual 18–2 revision 4, march 1, 2002 edge strip as a continuous strip of spruce on the right side of the aircraft and cut it out later. This makes the alignment of the trailing edge strip inboard of the trim tab much easier. The ribs should be aligned with a string. The us...

Page 136

L f.8l falco construction manual 18–3 revision 4, march 1, 2002 ❏ drill the 1/8”Ø vent hole through p/n 404-7 and p/n 403-4 ribs on the left side of the aircraft. We do not suggest drilling this hole on the right side due to the increased possibility of moisture entering around the elevator trim tab...

Page 137

L f.8l falco construction manual 18–4 revision 4, march 1, 2002 some builders have built the trim tab completely separately. After the trailing edge strip and the 10x15 spruce pieces from the trailing edge strip to b.L. 70 are glued in place, the trailing edge for the trim tab is cut out of the elev...

Page 138

L f.8l falco construction manual 18–5 revision 4, march 1, 2002 same hardware store that sells the sanding belts. Auto body shops and auto paint stores also sell a variety of sanding strips intended for use with special sanding blocks, and you might try these as well. Initial sanding should be done ...

Page 139

L f.8l falco construction manual 18–6 revision 4, march 1, 2002 strip, sticky side out. These pieces will also stick to the tape on the ribs. Place the skin in position and push it down so that the masking tape adheres to the inside of the skin. Remove all extra pieces of masking tape used to adhere...

Page 140

L f.8l falco construction manual 18–7 revision 4, march 1, 2002 figure 10 ❏ fit and bend the leading edge skin outboard of sta. 5. See figure 10. Note: this skin is a little tricky. If you attempt to skin this area with a single piece of plywood wrapped around the leading edge, you will find that th...

Page 141

L f.8l falco construction manual 18–8 revision 4, march 1, 2002 plywood. This can be sanded with a drum sander in an electric drill (work very carefully!) and finished off with a sanding block. ❏ turn the elevator over, and fit the 2mm skin over the trailing edge inboard of sta. 1. The plywood must ...

Page 142

L f.8l falco construction manual 18–9 revision 4, march 1, 2002 ❏ fit the lower skins and draw the outline of the ribs and spars for gluing. It will not be necessary to varnish the inside of these skins before gluing. Draw the internal structure on the skin for stapling or nailing during the skinnin...

Page 143

L f.8l falco construction manual 18–10 revision 4, march 1, 2002 ❏ cut away the plywood on the bottom between the elevator and the trim tab. It is not essential that you cut all of the plywood away at this time, but you should cut enough out so that you can drill up through the top skin to locate th...

Page 144

L f.8l falco construction manual 18–11 revision 4, march 1, 2002 ❏ trace the outline of the fairing skins on the 2mm skin of the elevator, then varnish the inside of the fairing skins and that area of the 2mm skin which will be enclosed by the fairing skins. ❏ glue the fairing skins in place. Scuff ...

Page 145

L f.8l falco construction manual 18–12 revision 4, march 1, 2002.

Page 146

L f.8l falco construction manual 19-1 revision 4, march 1, 2002 chapter 19 stabilizer assembly stabilizer assembly many builders inquire if the ribs should be installed with the plywood web inboard or outboard. It doesn't matter, and you may install the ribs either way; however, we prefer to see the...

Page 147

L f.8l falco construction manual 19-2 revision 4, march 1, 2002 figure 2 ❏ place the main stabilizer spar in the jig table, forward face up, and level the spar. It is imperative that the spar remain straight during the assembly process to insure that the hinges on the stabilizer will remain aligned ...

Page 148

L f.8l falco construction manual 19-3 revision 4, march 1, 2002 since the plywood on the aft face of the main stabilizer spar is stepped, the 350mm dimension would only apply to the center of the aircraft. For sta. 3, you must make allowance for the thinner plywood, so the proper dimension is 349mm ...

Page 149

L f.8l falco construction manual 19-4 revision 4, march 1, 2002 figure 7 ❏ sand the ribs to the correct angle for the leading edge strip. ❏ glue the leading edge ribs for sta. 1 and 6 in place. ❏ stretch a string across the ribs at sta. 1 and 6. This is to align the remaining ribs. See figure 7. Fig...

Page 150

L f.8l falco construction manual 19-5 revision 4, march 1, 2002 note: when the leading edge strip is finally installed, it will be somewhat difficult to clamp. Because of the angle between the ribs and leading edge strip, the ribs will tend to “squirt” inboard. To keep this from happening, it is bes...

Page 151

L f.8l falco construction manual 19-6 revision 4, march 1, 2002 ❏ the stabilizer may now be removed from the jig. Figure 12 ❏ install the trim tab control cable tube in the horizontal stabilizer. See figure 12. Bend the tube as required to fit in the intermediate rib and forward stabilizer spar. The...

Page 152

L f.8l falco construction manual 19-7 revision 4, march 1, 2002 figure 13 ❏ soak the skins in water and bend around the leading edge strip. Do this for the top and bottom skins. At the tip, you should use a steam iron and pull the plywood down around the stabilizer tip bow to get the compound bend n...

Page 153

L f.8l falco construction manual 19-8 revision 4, march 1, 2002 ❏ install the channel-nuts for the outboard stabilizer hinges. To prevent moisture from getting under the channel-nuts, they should be bedded down with wet zinc chromate primer or epoxy. ❏ glue on the bottom stabilizer skin. This skin w...

Page 154

L f.8l falco construction manual 20–1 revision 4, march 1, 2002 chapter 20 rudder assembly fin and rudder assembly notes see chapter 14 for the installation of the loran antenna. In particular, the loran antenna coupler, the installation of the antenna coaxial cable and the installation of the groun...

Page 155

L f.8l falco construction manual 20–2 revision 4, march 1, 2002 rudder assembly in the following steps, the leading edge ribs and the leading edge strip will be installed on the rudder. The leading edge strip may be fitted to the ribs before gluing on the ribs. Some builders prefer to glue the leadi...

Page 156

L f.8l falco construction manual 20–3 revision 4, march 1, 2002 trailing edge rib installation in the following steps, the trailing edge ribs will be installed on the spar. It will be important that you maintain the alignment of the trailing edge. You will find that once things are glued in place, t...

Page 157

L f.8l falco construction manual 20–4 revision 4, march 1, 2002 ❏ glue the trailing edge ribs for sta. 1, 2, 3 and 4 in place. Scuff-sand the plywood before gluing. ❏ fit the two spar doublers to the aft face of the spar. These are shown on drawing no. 411, section b-b. Figure 7 ❏ fit the sta. 0 dia...

Page 158

L f.8l falco construction manual 20–5 revision 4, march 1, 2002 figure 8 ❏ fit and glue the rudder tip bow, p/n 415-2, in place at the top of the rudder. See figure 9. Figure 9 ❏ install the strip of spruce at the bottom of the rudder, between the rudder spar and the trailing edge strip. See figure ...

Page 159

L f.8l falco construction manual 20–6 revision 4, march 1, 2002 figure 10 ❏ scarf the plywood for the joint that will occur with the leading edge skin above sta. 4-1/2. (if you wish, you may skip this step and install the skin so that it extends just to the lower surface of the sta. 4-1/2 rib, then ...

Page 160

L f.8l falco construction manual 20–7 revision 4, march 1, 2002 figure 11 ❏ after you have bent and fitted the skin for the upper leading edge, mask the skin on the inside and varnish. ❏ glue the upper leading edge skin in place. Scuff-sand the plywood prior to gluing. ❏ cover the two hinge “opening...

Page 161

L f.8l falco construction manual 20–8 revision 4, march 1, 2002 ❏ cut out the two hinge openings in the leading edge skin. See figure 14. Figure 14 ❏ install all of the channel-nuts. Since wood rot most often occurs under metal fittings, you should bed the channel-nuts in epoxy or wet zinc chromate ...

Page 162

L f.8l falco construction manual 20–9 revision 4, march 1, 2002 ❏ glue the left trailing edge skin on the rudder. Use long straight boards and clamp them on either side of the rudder to support the thin trailing edge strip, or staple through the trailing edge into a long straight board. Scuff-sand t...

Page 163

L f.8l falco construction manual 20–10 revision 4, march 1, 2002 figure 17 ❏ install the tail light. Note: the tail light is installed with two small machine screws (with 4-40 screw threads, we understand). The simplest installation is to epoxy the nuts in the wood. As an alternative, you could dril...

Page 164

L f.8l falco construction manual 21–1 revision 4, march 1, 2002 chapter 21 fin assembly the fin is assembled just like the stabilizer, elevator and rudder. You have to make sure that the fin spars will match the stabilizer spars. This can be accomplished in three ways: one way is to glue the main st...

Page 165

L f.8l falco construction manual 21–2 revision 4, march 1, 2002 them in place and then cut off the excess. These strips are shown on drawings no. 413 and 415, which are very accurately drawn. Thus, we suggest that you take the necessary measurements from these drawings. See figure 2, chapter 19. Fig...

Page 166

L f.8l falco construction manual 21–3 revision 4, march 1, 2002 figure 3 ❏ fit the intermediate rib for sta. 3, p/n 413-4, to the main fin spar. Clamp in place. See drawing no. 411 and figure 3. Note: in the following steps, you will be looping a string over this rib to align the sta. 2 rib. Since t...

Page 167

L f.8l falco construction manual 21–4 revision 4, march 1, 2002 the stabilizer already made, it is too late to change anything now. If you are off this dimension, you will have to adjust the lengths of the intermediate fin ribs. ❏ glue the intermediate rib for sta. 3 to the main fin spar ❏ loop a st...

Page 168

L f.8l falco construction manual 21–5 revision 4, march 1, 2002 figure 6 ❏ fit the leading edge ribs for sta. 2 and 5 (p/n 413-3 and 415-6) in place. These ribs must be placed very accurately, since they will be used to align all of the ribs in between. See figure 7. Figure 7 ❏ sand the ribs to the ...

Page 169

L f.8l falco construction manual 21–6 revision 4, march 1, 2002 figure 8 ❏ fit the remaining ribs. See figure 8. If you wish, you may fit the sta. 1 ribs (see drawing no. 410), but these ribs are not installed until after the fuselage skin is installed. Figure 9 ❏ fit the leading edge strip to the r...

Page 170

L f.8l falco construction manual 21–7 revision 4, march 1, 2002 ❏ glue the remaining ribs in place on the forward fin spar and the main fin spar. Do not glue the ribs for sta. 1 at this time. Scuff-sand the plywood before gluing. ❏ glue the optional piece of 1mm birch plywood to the upper end of the...

Page 171

L f.8l falco construction manual 21–8 revision 4, march 1, 2002 ❏ use small nails as alignment pins and mask off the left skin for varnishing. You should also draw the internal structure of the fin on the outside of the skins. This will make it easier to use nails or staples when you glue on the ski...

Page 172

L f.8l falco construction manual 21–9 revision 4, march 1, 2002 figure 12 ❏ glue on the right skin. See figure 12. This skin will extend from the top of the fin to the rib at sta. 2. Scuff-sand the plywood before gluing. ❏ install the ferrite balun assembly and the coaxial cable for the com antenna ...

Page 173

L f.8l falco construction manual 21–10 revision 4, march 1, 2002.

Page 174

L f.8l falco construction manual 22–1 revision 4, march 1, 2002 chapter 22 aileron/flap assembly this chapter will cover the assembly of the aileron and flaps and the installation of their hinges. If you wish, you may do this work simultaneously with the work covered in chapter 23 “wing, preliminary...

Page 175

L f.8l falco construction manual 22–2 revision 4, march 1, 2002 aileron/flap hinge installation ❏ draw the chord lines on the forward and aft face of the aft wing spars. ❏ draw the wing stations on the aft face of the aft wing spar. See drawing no. 206. ❏ draw the wing stations on the forward face o...

Page 176

L f.8l falco construction manual 22–3 revision 4, march 1, 2002 ❏ re-assemble the hinges with the hinge bolts and check for smooth operation of the hinges. ❏ remove the hinge bolts and drill the 3/16” bolt holes for p/n 747. ❏ install the channel-nuts for p/n 747. Do not install the screws for the c...

Page 177

L f.8l falco construction manual 22–4 revision 4, march 1, 2002 ❏ drill four 1/8”Ø vent holes in the aileron/flap spar as shown on drawing no. 206. ❏ install the plywood pads under the channel-nuts as shown on drawing no. 204. You can glue on the pads and then re-drill the bolt holes through the ply...

Page 178

L f.8l falco construction manual 22–5 revision 4, march 1, 2002 280 1100 aileron upper trailing edge skin sta. 10-14 300 1100 flap upper trailing edge skin sta. 2-6 300 1100 flap upper trailing edge skin sta. 2-6 300 1100 aileron/flap upper trailing edge skin sta. 6-10 300 1100 aileron/flap upper tr...

Page 179

L f.8l falco construction manual 22–6 revision 4, march 1, 2002 figure 5 ❏ make the notched wooden strip for the 95% chord station. Use a piece of 15x15 pine about 3400mm or 11-1/2’ long—it isn’t structural so you can piece it together from shorter scrap pieces. It is important that the strip of woo...

Page 180

L f.8l falco construction manual 22–7 revision 4, march 1, 2002 spar. You might as well make a lot of these angle guides so that you will not be slowed down by a lack of them—12 would be ideal. You should also make two angle guides with an angle of 98.9° to clamp against the outboard face of the sta...

Page 181

L f.8l falco construction manual 22–8 revision 4, march 1, 2002 the notched strip of wood will correctly position the trailing edge rib at the 95% chord station, but at the aft face of the spar you should refer to the rib drawings to note the correct position. This is not as simple as it sounds sinc...

Page 182

L f.8l falco construction manual 22–9 revision 4, march 1, 2002 ❏ fit and install the leading edge strips into the flap and aileron leading edge ribs. See figure 11. The notching already done in the leading edge ribs may be all that is required, although you may have to sand or shim in a few places....

Page 183

L f.8l falco construction manual 22–10 revision 4, march 1, 2002 ❏ turn the aileron/flap assembly over and support the trailing edge with a long straight board as shown in figure 13. The trailing edge strip can be closer to the table than shown and the long straight board need only keep the trailing...

Page 184

L f.8l falco construction manual 22–11 revision 4, march 1, 2002 ❏ trace the outline of the spar, ribs and leading edge strip on the under surface of the upper leading edge skins in preparation for varnishing. Locate each skin with a couple of “alignment pins”—little nails driven through the skin an...

Page 185

L f.8l falco construction manual 22–12 revision 4, march 1, 2002 ❏ fit and install the lower leading edge skin between sta. 6 and 10. See figure 18. Before installation, scarf for the joint for the trailing edge skin and the next outboard skin. Figure 19 ❏ fit and install the lower leading edge skin...

Page 186

L f.8l falco construction manual 22–13 revision 4, march 1, 2002 figure 21 ❏ turn the aileron/flap assembly around so that its lower surface faces toward the jig table as shown in figure 21. Clamp in place and check the alignment. It is particularly important that you make sure that the aileron/flap...

Page 187

L f.8l falco construction manual 22–14 revision 4, march 1, 2002 ❏ install the upper leading edge skin between sta. 6 and 10. See figure 23. Scarf for the joint for the next outboard skin, but do not scarf for the trailing edge skin. Figure 24 ❏ fit and install the upper leading edge skin between st...

Page 188

L f.8l falco construction manual 22–15 revision 4, march 1, 2002 figure 27 ❏ fit and install the lower trailing edge skin between sta. 2 and 6. See figure 27. Although the aileron/flap assembly is torsionally rigid at this stage of construction, the trailing edge can still be bowed and made into a w...

Page 189

L f.8l falco construction manual 22–16 revision 4, march 1, 2002 figure 30 ❏ install the upper trailing edge skin between sta. 2 and 6. See figure 30. Figure 31 ❏ install the upper trailing edge skin between sta. 6 and 10. See figure 31. Figure 32 ❏ install the upper trailing edge skin between sta. ...

Page 190

L f.8l falco construction manual 23–1 revision 4, march 1, 2002 chapter 23 wing, preliminary assembly this chapter will cover the preliminary assembly of the wing. If you wish, you may do this work simultaneously with the work covered in chapter 22 “aileron/flap assembly” and chapter 25 “fuselage, p...

Page 191

L f.8l falco construction manual 23–2 revision 4, march 1, 2002 that will be used for the electrical wiring, fuel line, brake lines, antenna cables, etc. These holes were originally 20x40 but that size proved to be too small. These holes should be positioned so that they are just above the lower spa...

Page 192

L f.8l falco construction manual 23–3 revision 4, march 1, 2002 figure 1 ❏ locate and mark the wing rib chord line on the forward face of the spar at sta. 14. This point should be relative to the chord line on the aft face of the spar. The best way to do this is shown in figure 1. Use a piece of ply...

Page 193

L f.8l falco construction manual 23–4 revision 4, march 1, 2002 w.L. –420 is the top of the center portion of the forward wing spar, and this matches the top of the center section of frame no. 3, to which it is glued. The landing gear is installed as shown on drawing no. 102. With the spar made to p...

Page 194

L f.8l falco construction manual 23–5 revision 4, march 1, 2002 ❏ using the dimensions drawn on the spar—b.L. 927.5 and the landing gear water line—install p/n 767 on the front wing spar. See drawing no. 102 and figure 2. Drill the holes with a drill press. Be sure to install the fittings with the g...

Page 195

L f.8l falco construction manual 23–6 revision 4, march 1, 2002 figure 5 ❏ when the epoxy has set, remove the front wing spar and drill the holes for p/n 766 through the main wing spar as shown in figure 5. Note: the best way to drill these holes is with a vertical milling machine or with a radial a...

Page 196

L f.8l falco construction manual 23–7 revision 4, march 1, 2002 ❏ lay out the position of p/n 772-1 as shown in figure 6. See drawing no. 102. The centerline of p/n 772-1 should be perpendicular to the chord line drawn on the aft face of the spar. Note: remember that the spar is tapered. P/n 773 spa...

Page 197

L f.8l falco construction manual 23–8 revision 4, march 1, 2002 ❏ clamp p/n 759a and 759b on the forward face of the main wing spar. See drawing no. 201 sheet 4. Install the aileron bellcranks to make sure that the spacing between the support brackets is correct. ❏ drill the holes through the main w...

Page 198

L f.8l falco construction manual 23–9 revision 4, march 1, 2002 ❏ place frame no. 4 on the forward face of the wing spar. The top of the inside of the fuselage frame and the top of the main wing spar should line up. Line up the centerline of the fuselage frame and the main wing spar. ❏ trace the out...

Page 199

L f.8l falco construction manual 23–10 revision 4, march 1, 2002 figure 11 ❏ install p/n 520-2 on the aft face of the main wing spar at the aircraft centerline. See drawing no. 102. Note that the upper bolt holes are located 18mm below the top of the spar. This will require that the spar be sanded s...

Page 200

L f.8l falco construction manual 23–11 revision 4, march 1, 2002 figure 12 ❏ for the wheel well door installation—install the 25x25 spruce triangle for the 30x15 and 60x15 seat track supports on the aft face of the main wing spar. See figure 12. The locations for the seat track supports are shown at...

Page 201

L f.8l falco construction manual 23–12 revision 4, march 1, 2002 supports. The top of this piece is located at w.L. –420. A good view of this piece is shown on drawing no. 202. ❏ install the 10x10 spruce triangles for the inside side walls on the forward face of frame no. 4. See figure 13. These are...

Page 202

L f.8l falco construction manual 23–13 revision 4, march 1, 2002 figure 15 ❏ glue fuselage frame no. 3 to the forward wing spar. See figure 15. It is very important that the fuselage frame be properly located on the wing spar. For this gluing operation, we suggest that the landing gear fittings be a...

Page 203

L f.8l falco construction manual 23–14 revision 4, march 1, 2002 ❏ assemble p/n 701 with four p/n 764 as shown on drawing no. 126. ❏ make the two spruce blocks that are used as mounting pads for p/n 764 as shown on drawing no. 126. ❏ install these two blocks on the aft face of the front wing spar. T...

Page 204

L f.8l falco construction manual 23–15 revision 4, march 1, 2002 figure 18 ❏ install the saddle gussets for the four 30x15 floor supports that are installed between frame no. 3 and 4. See figure 7. These gussets are shown on drawing no. 315 and 155. The overall dimensions of the gussets should be 25...

Page 205

L f.8l falco construction manual 23–16 revision 4, march 1, 2002 ❏ if you wish, you may install the gluing strips and other wood pieces discussed in the note above. ❏ install two 10x10 spruce strips on the aft face of fuselage frame no. 3 as shown in figure 19. These strips will pick up the inside c...

Page 206

L f.8l falco construction manual 23–17 revision 4, march 1, 2002 position, particularly if you have very large feet. (builder comment: says either channel- nut or spruce flooring support on the aircraft’s right side interferes with drilling p/n 717.) fuselage frame no. 5 figure 21 ❏ glue plywood on ...

Page 207

L f.8l falco construction manual 23–18 revision 4, march 1, 2002 figure 22 ❏ install the rudder cable pulleys on the front face of fuselage frame no. 5 as shown in figure 22. See detail a, drawing no. 310. You will find detail a on the right side of the sheet. We forgot to put a "see detail a" on th...

Page 208

L f.8l falco construction manual 23–19 revision 4, march 1, 2002 157 forward face 160 aft face 563 forward face 560 aft face 15 20 figure 24 ❏ for “open air” wheel well installation—cut out for four 30x15 seat track supports as shown in figure 24. See drawing no. 310. ❏ for “open air” wheel well ins...

Page 209

L f.8l falco construction manual 23–20 revision 4, march 1, 2002 15 20 563 forward face 560 aft face figure 25 ❏ for the wheel well door installation—cut out for 30x15 and 60x15 seat track supports as shown in figure 25. See drawing no. 310. ❏ for the wheel well door installation—cut out for the two...

Page 210

L f.8l falco construction manual 23–21 revision 4, march 1, 2002 ❏ mask off the inside of the closing plywood for varnishing. ❏ varnish the inside of the frame and the inner face of the closing plywood. ❏ glue on the plywood to close the frame. Figure 26 ❏ cut the five longeron cutouts in fuselage f...

Page 211

L f.8l falco construction manual 23–22 revision 4, march 1, 2002 ❏ since the holes in p/n 762 are not likely to be exactly the same, you should mark them so that you can install them in the correct position. One method is to use a center punch and mark the upper outside of the part. ❏ drill the two ...

Page 212

L f.8l falco construction manual 23–23 revision 4, march 1, 2002 ❏ on the forward face, install the 10x10 rectangular (or triangular) spruce strips for the inside fuselage side walls as shown on figure 28. See drawing no. 315. Note: it is important that the inside fuselage side wall be as wide as po...

Page 213

L f.8l falco construction manual 23–24 revision 4, march 1, 2002 figure 30 ❏ clamp the gluing strip in place on the aft face of frame no. 6 and trace its outline on frame no. 6. See figure 30. The strip should not be installed until it is sanded to the angle required for the fuselage skin. This glui...

Page 214

L f.8l falco construction manual 23–25 revision 4, march 1, 2002 figure 32 ❏ install the two control sticks on p/n 701 as shown in figure 32. See drawing no. 126. ❏ install p/n 718 on the two control sticks. See drawing no. 126 and 718. Note on drawing no. 718 that the ends of the control stick conn...

Page 215

L f.8l falco construction manual 23–26 revision 4, march 1, 2002 figure 33 ❏ install the miter gear and shaft, p/n 520-4, in p/n 520-2 housing as shown in figure 33. See drawing no. 102 for all details for the assembly of this gearbox. ❏ install ms20271-b14 universal joint on p/n 520-4. P/n 520-4 an...

Page 216

L f.8l falco construction manual 23–27 revision 4, march 1, 2002 figure 34 ❏ slip the lower p/n 520-7 miter gear and p/n 520-3 spur gear on 520-6a vertical shaft as shown in figure 35 these two gears must have a snug fit against the inner race of the bearings, since this is what holds the gears in p...

Page 217

L f.8l falco construction manual 23–28 revision 4, march 1, 2002 ❏ trial fit the horizontal shaft and miter gear as shown in figure 41. If it is necessary to achieve a proper meshing of the gear teeth, grind/sand the hub of the miter gear on the vertical shaft—a number of builders have reported that...

Page 218

L f.8l falco construction manual 23–29 revision 4, march 1, 2002 figure 36 ❏ install p/n 821-2 spindle on p/n 520-6a shaft, drill and ream for the roll pin and install the roll pin as shown in figure 36. Note: it is important for all of the screwjacks to be synchronized exactly. The springs on the e...

Page 219

L f.8l falco construction manual 23–30 revision 4, march 1, 2002 note: the hole must first be drilled with a 3/16”Ø drill, then reamed with a brown & sharpe no. 1 tapered reamer. The small end of the tapered shank shall not extend more than 1/16” above the surface of the universal joint. ! Caution i...

Page 220

L f.8l falco construction manual 23–31 revision 4, march 1, 2002 figure 40 ❏ install the screwjack sleeves on the screwjacks. See figure 40. Screw the screwjacks all the way so that they bottom on the end of the universal joints. Be careful to keep the left and right sides properly identified. Figur...

Page 221

L f.8l falco construction manual 23–32 revision 4, march 1, 2002 installed) in place. See figure 42. Be sure you install the screwjack with the left hand threads on the right side and the screwjack with the right hand threads on the left side. Use shims, clamps, or any other means to hold the shaft ...

Page 222

L f.8l falco construction manual 23–33 revision 4, march 1, 2002 necessary, eliminate the washer, sand the bottom of the handle or deepen the counterbore to achieve the free rotation of the handle. ❏ the gears, screwjacks and all other parts of this retraction system should be lubricated with mil-g-...

Page 223

L f.8l falco construction manual 23–34 revision 4, march 1, 2002 hex with a wrench before pressing on the strut valve. Sand the 37.9Ø ridge of the piston until the piston will fit into the oleo nut, then carefully clean the piston to remove all sanding grit. Oil the piston and reassemble the oleo st...

Page 224

L f.8l falco construction manual 23–35 revision 4, march 1, 2002 main landing gear bushings installation the main landing gear mount fittings have grease fittings installed for lubrication. There are two installations. For the first parts we made, straight grease fittings are installed, and we have ...

Page 225

L f.8l falco construction manual 23–36 revision 4, march 1, 2002 base—it is held in place with loctite—and then reinstalled with loctite after the base is screwed in place. ❏ trial fit the main landing gear in the fittings mounted on the spars. The bushings compress slightly when they are installed ...

Page 226

L f.8l falco construction manual 23–37 revision 4, march 1, 2002 • wing walk and wheel well framing between sta. 1 and 2 and more wheel well framing inboard of sta. 1. • flap torque tube support blocks on sta. 2 rib. • landing gear nut access door between sta. 2 and 3—forward of the front wing spar....

Page 227

L f.8l falco construction manual 23–38 revision 4, march 1, 2002 280 grain direction grain direction 280 330 330 870 870 870 870 530 530 310 310 wing walk wing walk outboard seat skin outboard seat skin inboard seat skin inboard seat skin 285 480 upper wing skin sta. 1 inboard 285 480 upper wing ski...

Page 228

L f.8l falco construction manual 23–39 revision 4, march 1, 2002 grain direction sta. 6 to sta. 10 bottom wing skin 680 250 wing tip skin figure 49 ❏ use two 50”x50” sheets of 1.5mm birch plywood as shown in figure 49. Cut the wing tip skins and then cut the wing skin to fit the aircraft. Grain dire...

Page 229

L f.8l falco construction manual 23–40 revision 4, march 1, 2002.

Page 230

L f.8l falco construction manual 24–1 revision 4, march 1, 2002 chapter 24 wing assembly this chapter will cover the assembly of the wing. If you wish, you may do this work simultaneously with the work covered in chapter 25 “fuselage, preliminary assembly”. Kits on hand to do the work covered in thi...

Page 231

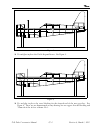

L f.8l falco construction manual 24–2 revision 4, march 1, 2002 the wing will be assembled with the leading edge up as may be seen in many illustrations in this chapter. The four slots in the centerboard will support the forward wing spar, main wing spar, fuselage frame no. 5 and fuselage frame no. ...

Page 232

L f.8l falco construction manual 24–3 revision 4, march 1, 2002 500 100 1365 145 255 100 260 170 255 70 20 1600 35 offset chord line offset chord line wing rib horizontal reference line figure 3 the template for wing sta. 1 is shown in figure 3. The shop floor is shown to the right side of the illus...

Page 233

L f.8l falco construction manual 24–4 revision 4, march 1, 2002 used the sta. 14 template to supply all bracing for side loads. The centerboard and other templates were screwed to the shop floor with shelf brackets. Wires and turnbuckles were used to hold the top of the templates in place. When the ...

Page 234

L f.8l falco construction manual 24–5 revision 4, march 1, 2002 wing assembly figure 5 ❏ set up the fuselage centerboard. ❏ put fuselage frame no. 6 in the fuselage centerboard. ❏ put fuselage frame no. 5 in the fuselage centerboard. ❏ put fuselage frame no. 4 and the main wing spar in the fuselage ...

Page 235

L f.8l falco construction manual 24–6 revision 4, march 1, 2002 aft face of the spar at the center of the aircraft—the tips are actually 1.5mm higher than at the center because of the thinner plywood. ❏ fix the templates at wing sta. 14 in place. Use the offset chord line to align the template from ...

Page 236

L f.8l falco construction manual 24–7 revision 4, march 1, 2002 figure 6 ❏ clamp the intermediate leading edge ribs (those ribs between the main wing spar and the front wing spar) for wing sta. 1, 2, 3 and 4 to the main wing spar as shown in figure 6. Do not sand the ends of the ribs at this time. U...

Page 237

L f.8l falco construction manual 24–8 revision 4, march 1, 2002 figure 7 ❏ clamp the leading edge ribs for sta. 1, 2, 3 and 4 in place as shown in figure 7. Sand the aft faces of the ribs as necessary for alignment with the leading edge alignment string. Figure 8 ❏ clamp the remaining leading edge r...

Page 238

L f.8l falco construction manual 24–9 revision 4, march 1, 2002 figure 9 ❏ clamp the leading edge strip in place as shown in figure 9. Sand the ribs as necessary to match the angle of the leading edge strip. During this and later operations, you will find it helpful to clamp a long board along the t...

Page 239

L f.8l falco construction manual 24–10 revision 4, march 1, 2002 ❏ install the framing for the landing gear inspection doors. See figure 10. Do not install the corner blocks at this time. Note: some builders have installed inspection doors for the aileron pulleys. If you wish to do so, you may, but ...

Page 240

L f.8l falco construction manual 24–11 revision 4, march 1, 2002 figure 12 ❏ clamp all intermediate trailing edge ribs (the ribs between the main wing spar and the aft wing spar) to the main wing spar as shown in figure 12. The sta. 2-1/2 wing rib must be installed with the plywood face inboard. ❏ a...

Page 241

L f.8l falco construction manual 24–12 revision 4, march 1, 2002 figure 14 ❏ cut four wedge-shaped spruce blocks for p/n 765 as indicated on drawing no. 201, sheet 4, section w-w. These blocks should be cut oversized and clamped in place. ❏ clamp the flap supports (p/n 765) and the flap torque tube ...

Page 242

L f.8l falco construction manual 24–13 revision 4, march 1, 2002 also have to check the alignment and placement of the flap torque tube and the flap pushrod. You should use a small nail as an alignment pin to correctly locate the aft wing spar on fuselage frame no. 6. One alternative is to drill thr...

Page 243

L f.8l falco construction manual 24–14 revision 4, march 1, 2002 ❏ check the alignment of the flap pushrod with the flap hinge. You will have to file on the inside of the fork end of p/n 713a and on p/n 743 for clearance when the flaps are all the way down. At this time, you are primarily concerned ...

Page 244

L f.8l falco construction manual 24–15 revision 4, march 1, 2002 figure 18 ❏ install the aileron/flap assembly on the aft wing spar as shown in figure 18. All hinges must be installed. ❏ fit the trailing edge strip to the trailing edge rib at wing sta. 1 and 14. ❏ fit the trailing edge rib for wing ...

Page 245

L f.8l falco construction manual 24–16 revision 4, march 1, 2002 figure 19 ❏ glue the two 20x20 stringers on the bottom of the fuselage. See figure 19. At the forward end, the stringers are glued to the bottom of the main wing spar, and at the aft end they are glued to the two saddle gussets on the ...

Page 246

L f.8l falco construction manual 24–17 revision 4, march 1, 2002 ❏ as shown in figure 20, glue the 17 cove ribs to the aft face of the aft wing spar and install the wing gap trailing edge strip, p/n 206-5. See drawing no. 201 sheet 2. Figure 21 ❏ for “open air” wheel well installation—fit the four 3...

Page 247

L f.8l falco construction manual 24–18 revision 4, march 1, 2002 rings at the correct angle—5.5° nose high from horizontal, in case you wondered. After this is done, the rings should be notched for the outboard seat supports. ❏ for “open air” wheel well installation—sand the upper wheel well rings t...

Page 248

L f.8l falco construction manual 24–19 revision 4, march 1, 2002 ❏ for wheel well door installation—fit the 75x15 spruce strip between the inboard and outboard seat support as shown in figure 25. This is shown in detail a, drawing no. 201. Figure 25 ❏ for wheel well door installation—glue the 60x15 ...

Page 249

L f.8l falco construction manual 24–20 revision 4, march 1, 2002 ❏ for wheel well door installation—glue the upper wheel well ring and outboard seat supports in place. Figure 27 ❏ for wheel well door installation—fit and install the lower wheel well ring. See figure 27. At the aft end of the wheel w...

Page 250

L f.8l falco construction manual 24–21 revision 4, march 1, 2002 figure 29 ❏ install the seven wing walk supports between sta. 1 and 2 as shown in figure 29. See drawing no. 201, sheet 1. Note carefully that one of these pieces forms the aft upper end of the opening for the landing gear—install this...

Page 251

L f.8l falco construction manual 24–22 revision 4, march 1, 2002 cross piece at the top of the wing. All of this may be seen on detail s and t of drawing no. 201 sheet 4. Figure 31 ❏ fit the wing tip bow in place. See drawing no. 202. ❏ fit the 10mm thick piece of spruce (p/n 202-3) at the aft end o...

Page 252

L f.8l falco construction manual 24–23 revision 4, march 1, 2002 figure 32 ❏ install the control stick assembly on the aft face of the front wing spar. ❏ install the aileron control cables. The control cable assemblies are shown on drawing no. 150-2 and -3. The installation of the control cables are...

Page 253

L f.8l falco construction manual 24–24 revision 4, march 1, 2002 ❏ drill one rivet hole for p/n 714 with a #30 (.128”Ø) drill. See drawing no. 781. Remove the aileron pushrod from the airplane and drill the second rivet hole for p/n 714. Install the rivets for p/n 714. Note: the normal practice when...

Page 254

L f.8l falco construction manual 24–25 revision 4, march 1, 2002 note: for the wiring conduit, 3/8”o.D. Plastic tubing has been supplied with the kits. A number of builders have pointed out that the wires will not fit in this size tubing, thus we suggest that 1/2” tubing be used in its place. The tu...

Page 255

L f.8l falco construction manual 24–26 revision 4, march 1, 2002 installed in the same holes with the coaxial cables or in separate holes. Both the fuel tank vent lines and the antenna coaxial cable must be installed so that they are not fouled by the flap torque tube or the flap pushrod. Figure 36 ...

Page 256

L f.8l falco construction manual 24–27 revision 4, march 1, 2002 ❏ install the nav antenna coaxial cable in the wing. The location for the cable is shown in the wing rib drawings. At sta. 4 inboard, the transponder coaxial cable witll be routed with it—see next step ❏ install the coaxial cable for t...