- DL manuals

- Sera

- Control Unit

- PROFIBUS

- Technical Manual

Sera PROFIBUS Technical Manual

Summary of PROFIBUS

Page 1

Technical manual translation of original technical manual en profibus interface module.

Page 2

Introduction 2 www.Sera-web.Com note keep the operating manual for future use! Attention subject to technical modifications! About this instructions special notes in these instructions are marked with text and danger symbols. Note notes or instructions that faciliate work and ensure a safe operation...

Page 3

Contents www.Sera-web.Com 3 safety instructions .............................................................................................................4 personnel qualification and training ...........................................................................................................

Page 4

Safety instructions 4 www.Sera-web.Com warning before commissioning, installating and during operation of the sera dosing pump the respective regulations valid at the place of installation are to be observed! Compliance with these operating instructions and, in particular, the safety instructions, h...

Page 5

Www.Sera-web.Com 5 transport / storage general sera products are checked for perfect condition and function previous to shipment. Check for transport damage immediately after arrival of goods. If damage is found, this is to be reported immediately to the responsible carrier and the manufacturer. Sto...

Page 6

Product description 6 www.Sera-web.Com the interface module must only be used as communication interface between a controllable sera dosing pump and a profibus network. A proprietary sera protocol is used for the internal communication between interface module and dosing pump. Note the sera dosing p...

Page 7

Technical data www.Sera-web.Com 7 technical data electrical data profibus interface profibus dp-v1 (slave) gsd file sera sera0fa2.Gsd transmission rate 9.6/19.2/45.45/93.75/187.5/500 kbit/s 1.5/3/6/12 mbit/s automatic baud rate detection supply voltage 24 v dc max. Power consumption 1 w ambient cond...

Page 8

8 www.Sera-web.Com electrical connections interface assignment function 1 level connection 8-pole pre-alarm and dry run- ning protection 2 profibus output * 5-pole connection to the profibus network or terminating resistor (5) 3 profibus input * 5-pole connection to the profibus network 4 pump conne...

Page 9

Www.Sera-web.Com 9 electrical connections the field bus box modules are connected via the supplied connection cable. The interface module has a socket and a plug, whereby no y-connector is necessary. The supply voltage (+5 v dc) for the terminating resistor is only applied on the socket. The termina...

Page 10

10 www.Sera-web.Com electrical connections master slave slave repeater slave slave slave slave slave slave slave slave slave terminating resistor anschluss pumpe (4) pin no. Function pin 1 +24 v supply voltage pin 2 communication im1 pin 3 communication im2 pin 4 not assigned pin 5 communication im3...

Page 11

Www.Sera-web.Com 11 electrical connections transmission rate total of stub cables * > 1.5 mbit/s none 1.5 mbit/s 6.7 m 500 kbit/s 20 m 187.5 kbit/s 33 m 93.75 kbit/s 100 m 19.2 kbit/s 500 m * total of all stub cables within a segment for profibus cable of 30 pf/m stub cables are never allowed if the...

Page 12

12 www.Sera-web.Com ■ disconnect voltage. ■ connect interface module (1) to the sera pump (2) (see „electrical connections). Observe earthing. ■ apply voltage. ■ pump starts. ■ module status (3) lights green. ■ the “interface” operating mode must be enabled and can be selected for operating modes. ■...

Page 13

Www.Sera-web.Com 13 operation operation window interface module is initialised. No bus/network connection is established or there is no data exchange. Bus/network connection established. Data exchange is present. No operating mode has been selected in the pump_control module. No valid process data e...

Page 14

14 www.Sera-web.Com operation operating modes the following operating modes are possible in interface ope- ration: ■ manual ■ impulse ■ analog ■ batch modules thanks to use of the modular design, every sera dosing pump connected to the interface module can be parametrised ac- cording to their own re...

Page 15

Www.Sera-web.Com 15 operation modules / input pump_control this module is always necessary for the control of the pump irrespective of operating mode. The external stop bit that is valid in all operating modes can be set with this module. Other functions are the setting of the operating mode, reset ...

Page 16

16 www.Sera-web.Com operation parameter adresse 001...125 modules / output pump_state statuses of the pump. All operating modes of the pump are displayed here. Even if the pump is not in the interface mode. Flow_state current delivery rate of the pump in litres / hour or strokes. Valid across operat...

Page 17

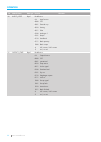

Www.Sera-web.Com 17 operation the control and parametrisation of the pump are performed using modules that are described in the following table: no. Module name data type function comment 1 pump_control byte 1 bit definition: must always be implemented to select the ope- rating mode. If a valid inte...

Page 18

18 www.Sera-web.Com operation no. Module name data type function comment 4 analog_ control byte 1 bit definition: input2_control or input3_control must be set as analogue input for the analogue operation. 0-2 analogue signal 00 0-20 ma 01 4-20 ma 10 standardised byte 2 analogue i1 bytes 2-5 are only...

Page 19

Www.Sera-web.Com 19 operation no. Module name data type function comment 7 input2_control byte 1 bit definition: the function of the inputs / outputs can be set in bus operation by using the respective mo- dule. Otherwise, the functionality on delivery is applicable. 0-3 input function 0000 off 0001...

Page 20

20 www.Sera-web.Com operation no. Module name data type function comment 10 output2_ control byte 1 bit definition: the function of the inputs / outputs can be set in bus operation by using the respective mo- dule. Otherwise, the functionality on delivery is applicable. 0-3 output function 0000 off ...

Page 21

Www.Sera-web.Com 21 operation no. Module name data type function comment 13 speedlimit_ control byte 1 speed limit 30-100% 14 slowmode_ control byte 1 bit definition: 0-1 suction stroke 00 100% 01 75% 10 50% 11 25% 15 dosing_ control byte 1 bit definition: 0-3 sensor type 000 off 001 type 8x9x.1 010...

Page 22

22 www.Sera-web.Com operation no. Module name data type function comment 18 time_control byte 1 bit definition: 0. Set time the time is applied when changing the bit from 0 to 1. Byte 2 day 1-31 byte 3 month 1-12 byte 4 year year starting from 2000. 0 cor- responds to the year 2000. 16 corresponds t...

Page 23

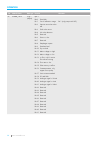

Www.Sera-web.Com 23 operation no. Module name data type function comment 22 pump_state byte 1 bit definition: 0-3 operation mode 0000 interface operation fail safe 0001 manual interface 0010 pulse interface 0011 analogue interface 0100 batch interface 0101 manual 0110 pulse 0111 analogue 1000 batch ...

Page 24

24 www.Sera-web.Com operation no. Module name data type function comment 24 counter_state float 1 current delivered quantity not calibrated: strokes since switching on or reset calibrated litres since switching on or reset long 2 (4-byte) total delivered quantity in litres, since delivery of the pum...

Page 25

Www.Sera-web.Com 25 operation no. Module name data type function comment 27 analogue_state byte 1 bit definition: 0-2 analogue signal 00 0-20 ma 01 4-20 ma 10 standardised byte 2 analogue i1 0-200 byte 3 analogue frequency f1 0-100% byte 4 analogue i2 0-200 byte 5 analogue frequency f2 0= 0 ma 150= ...

Page 26

26 www.Sera-web.Com operation no. Module name data type function comment 30 input3_state byte 1 bit definition: 0-3 input function 0000 off 0001 external stop 0010 venting 0011 pulse 0100 analogue 1 0101 recipe 0110 start batch 0111 batch quantity 1000 batch output 4. Nc contact / no contact 5. Set ...

Page 27

Www.Sera-web.Com 27 operation no. Module name data type function comment 32 output2_state byte 1 bit definition: 0-3 output function 0000 off 0001 operational 0010 pump active 0011 stroke signal 0100 pre-alarm level 0101 dry run 0110 diaphragm rupture 0111 no flow 1000 group signal 1001 group fault ...

Page 28

28 www.Sera-web.Com operation 36 alarm_state long 1 (4-byte) byte 1 bit 0 drive fault bit 1 out of calibration range bit 1 (only pumps with hle) bit 2 setpoint cannot be achie- ved bit 3 fault stroke sensor bit 4 no stroke detection bit 5 reserved bit 6 drive too slow bit 7 reserved bit 8 diaphragm ...

Page 29

Www.Sera-web.Com 29 diagnostics signals the sera interface module has two diagnostics messages that are output in the network-specific protocol (profibus / pro- finet). A present message is indicated by flashing once for a short time of the module status led. The messages can be read in plain text u...

Page 30

30 www.Sera-web.Com maintenance and cleaning the interface module is maintenance-free. Clean with a moist cloth. Rub dry afterwards. Attention do not use any solvents! These can attack the surfaces. Decommissioning ■ disconnect device from the power supply. ■ detach electrical connections. ■ take de...

Page 31

Www.Sera-web.Com 31.

Page 32

Ta05-00 en 180228 sera ® is a registered trademark by sera gmbh. Subject to change without notice. Sera accepts no liability for errors or misprints. Sera prodos gmbh sera-str. 1 34376 immenhausen germany tel. +49 5673 999 02 fax +49 5673 999 03 info-prodos@sera-web.Com www.Sera-web.Com follow us.