- DL manuals

- SERO

- Heat Pump

- AWA-SS-10

- Installation And Maintenance Instructions Manual

SERO AWA-SS-10 Installation And Maintenance Instructions Manual - System Description

System description

4

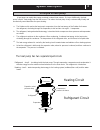

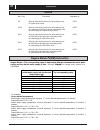

Principle of heat pump

A heat pump can exploit the energy contained in natural heat sources. Or, to put it differently, the heat

pump ”collects” heat energy from the heat source. This makes the heat pump a very environmentally friendly and

economically sound alternative for space heating.

a.

b

The Outdoor unit is used as the heat pump’s evaporator. Here the heat energy of the Outdoor Unit

causes

the refrigerant, circulating through the evaporator, to boil and turn into a gas – it evaporates.

c

The refrigerant, having absorbed heat energy, is circulated to the compressor where pressure and temperature

are raised.

d

The refrigerant continues to the condenser. When condensing, it releases heat energy to the heat carrier,

circulating through the condenser. The temperature of the refrigerant sinks, and it returns to its liquid state.

e

The heat energy released is carried by the heating circuit to water heater and radiator or floor heating

systems.

At last the refrigerant is led through the expansion valve, where its pressure is reduced, and then continues to

the

evaporator

.

The

process

is

restarted.

The

heat pump has

two

separate

liquid circuits

Refrigerant circui

t

– circulating inside the heat pump. Through evaporation, compression and condensation it

absorbs energy from the

outdoor unit and releases it to the heat carrier. The refrigerant is chlorine-free.

Heating circuit

– water transporting heat energy to the heating system (radiators/floor coils) and the water

heater.

Expantion valve/

pressure drop

Refrigerant

Condenser

Compressor/

pressure increase

Evaporator

Heating Circuit

Refrigerant Circuit

Fan

Summary of AWA-SS-10

Page 1

Please read this operation manual before using the heat pump installation and maintenance instructions air source heat pump awa-ss-10 awa-ss-12 awa-ss-16 ( 3x400v / 3 / 50hz ) ( 230v / 50hz ) model : awa-ss-6 awa-ss-8 ( all in one ) july 2009.

Page 3: Contents

Contents 1 system description principle of operation ............................................ 3 control panel layout .................................................................. 5 explanation .......................................................... 5 general information for the installer...

Page 4: System Description

Awa-ss series consists of a heat pump, water heater, electrical module, circulation pumps and a control sys- tem. Awa-ss series is connected to the outdoor unit and heating medium circuits. The heat source of the awa-ss series is provided from air. The outdoor unit of the system is a heat exchanger ...

Page 5: System Description

System description 3 unit description in order to get the best results from the climate system awa-ss series you should read through the section for the system manager in these installation and maintenance instructions. Awa-ss series is a climate system for heating houses and apartment buildings as ...

Page 6: System Description

System description 4 principle of heat pump a heat pump can exploit the energy contained in natural heat sources. Or, to put it differently, the heat pump ”collects” heat energy from the heat source. This makes the heat pump a very environmentally friendly and economically sound alternative for spac...

Page 7: Control Panel

Control panel 5 display left button layout c d button explanation power on/off a up button f down button control panel the control panel of awa-ss features a graphic display control buttons . Beside the control panel you will find the user’s manual, a short description of how to increase and reduce ...

Page 8: Control Panel

Control panel 6 functions the control computer is operated with the help of a user friendly menu system that is displayed on the contr ol panel. There is a main menu and four sub-menus accessible from the main menu. The menus are described in detail further down. To be able to select the desired men...

Page 9: Installation

General information for the installer 7 current regulations require the heating installation to be inspected before it is commissioned. The inspec- tion must be carried out by a suitably qualified person and should be documented. The above applies to closed heating systems. If the heat pump is repla...

Page 10: Pipe Connections

Pipe connections 8 pipe installation must be carried out in accordance with current norms and directives. The heat pump can operate up to a return temperature of about 58* °c and an outgoing temperature of about 70* °c from the heat pump. The compressor produces up to 65* °c, the rest is obtained us...

Page 11: Pipe Connections

Pipe connections 9 pipe connections for the heat medium side are made at the top. All required safety devices, shut-off valves (as close to the heat pump as possible), and particle filter (supplied) are fitted. When connecting to a system with thermostats on all radiators, a relief valve must be fit...

Page 12: Pipe Connections

Pipe connections 10 how to connect the copper pipes piping connecton attention : when connectiong the pipe, a suitable pitching spanner must be used. If other spanner is used, it may damage the joint due to inappropriate force. 4. Connect the electric cable as per circuit diagram, and bundle it with...

Page 13: Pipe Connections

Pipe connections 11 4. Tighten the cap of two valves. 5. Disconnect the power cable from outdoor unit. 6. Loose the nut of the connect pipe to the outdoor unit valve with 2 spanner, disconnect the connect pipe and the two valves. 1. Start the machine, operate heat pump on state. 2. Remove the cap of...

Page 14: Pipe Connections

Pipe connections 12 pump capacity diagrams, heating medium side kpa awa-ss-8 awa-ss-6 awa-ss-10 available pressure flow awa-ss-12 l/s 1 2 3 0 . 22 0 . 44 0 . 66 0 . 88 1 . 10 1 . 32 80 70 60 50 40 30 20 10 0 1 . 54 1 . 76 0 awa-ss-16 kpa tillgängligt tryck available pressure flow 1 2 3 0.28 0.56 0.8...

Page 15: Pipe Connections

Pipe connections 13 the pump is adjustable to adjust the flow: 1, 2, or 3. The pump is adjustable to adjust the flow: 1, 2, or 3. Wilo rs-25/8 wilo rl-25/7.5 how to adjust the rate of flow.

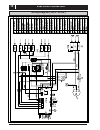

Page 16: Electrical Connection

Electrical connection 14 note! Electrical installation and service must be carried out under the supervision of a qualified electrician in accordance with the stipulations in force. Connect the power cord ( 230v / 50 hz ) ( 3x400v / 3 / 50 hz ) r s l n n n t.

Page 17: Electrical Connection

Electrical connection 15 step1 step3 step2 step1 step3 step2 wiring of the terminal (mode one) wiring of the terminal (mode two).

Page 18: Electrical Connection

Electrical connection 16 connecting the room temperature sensor connecting the outside temperature sensor outp=defrost temperature sensor outdoor unit outp outside air temperature sensor rt oct outside air temperature sensor oct=outside air temperature sensor room temperature sensor rt oct room temp...

Page 19: Electrical Connection

Electrical connection 17 cwt wit outp oct rt wtt c0mp pa.Out hp lp csp gnd ehi n 3wv 4wv n gnd wcp n ofan n gnd gnd wcp2 n layout of the pcb from pcb / con4 /11,12 from pcb / con4 /9,10 from pcb / con4 /7,8 from pcb / con4 /5,6 from pcb / con4 /3,4 from pcb / con4 /1,2 from pcb / con5 /1,2 from pcb ...

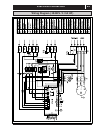

Page 20: Electrical Connection

Electrical connection 18 part of wiring diagram 2.5mm2 terminal connection eh1 eh2 n eh3 n w u v gnd t 3 t 2 t 1 l3 l 2 l1 c 1 u w v cm red white black from ac contactor / l3 from ac contactor / l2 from ac contactor / l1 from from compressor from compressor / v from compressor / u from compressor / ...

Page 21: Electrical Connection

Electrical connection 19 wiring diagram( 230v / 50 hz ).

Page 22: Electrical Connection

Electrical connection 20 wiring diagram ( 3x400v / 3 / 50 hz ).

Page 23: Commissioning and Adjusting

Commissioning and adjusting 21 before starting up the system, check that the heating, hot water circuits are full and thoroughly vented. Check the pipe system for leakage. Preparations filling and venting the heating medium system avt draining sÄv safety valve cw cold water sf particle filter hw hot...

Page 24: Commissioning and Adjusting

Commissioning and adjusting 22 air is initially released from the hot water and venting may be necessary. If bubbling sounds can be heard from the heat pump, the entire system requires further venting. When the system has stabilised (correct pressure and all the air removed) the heating controls can...

Page 25: Control

Control 23 general information menu navigation the right-hand button on the control panel is used to open the desired menu. The left-ha nd button is used to return to the pr evious menu . The up and down buttons are used to navigate between the parameters of a menu. A cursor (arrow) on the left-hand...

Page 26: Control

Control 24 menus main menu information to open the main menu information, press the right- or left-hand button once. To select the desired sub-menu use the up or down button. Open the menu by pressing the right-hand button once. To return to the main menu, press the left-hand button once. Informatio...

Page 27: Control

Control 25 • operation off heat pump is turned off. The following text is displayed on the control panel: “operation off “ if the heat pump will be put in operation off mode during winter, please remember to let out all the water the heating system to avoid any damage caused by freezing. Menus if yo...

Page 28: Control

Control 26 sub-menu temperature this menu shows the different temperatures of the heating system. All temperature changes registered over the last 60 minutes are stored in the control system and can be viewed in the shape of graphs. Table 2: menu temperature menu text description adjustable by: out ...

Page 29: Control

Control 27 menus menu text description adjustable by: cmp.A add1 add 2 user user user user add 3 off when the value (testing) reaches the value setting by user, user the system will be closed. When the value (testing) reaches the value setting by user, the compressor will be start-up.And the value(t...

Page 30: Control

Control 28 before the degree minute reach - 60 (adjustable) ,the compressor is off, but when the degree minute reach - 60 (adjustable) ,the compressor automatic start,and the flow teperature will begin increase. ( higher than desired temperature) when the actual water supply temperature reach / high...

Page 31: Operation

Sub-menu operating time operation time heatpump add1 add2 add3 warmwt 2 h 1 h 0 h 0 h 0 h table 3: menu operating time menu text description adjustable : heatpump total operating hours of heat pump since user installation. Operating time will not be reset to zero. Add 1 total operating hours of auxi...

Page 32: Control

Control 30 most settings will be made by the installation contractor in connection with installation. Adjustments to be made regularly by the user are the following: • selection of operating mode • adjustment of desired room temperature by changing the room value. • adjustment of heat curve • adjust...

Page 33: Control

Control 31 adjustments to be made regularly adjustment of the curve value the heat curve will be adjusted by the curve value. This value indicates the supply line temperature to the radiators at 0°c outside temperature. At outside air tempe- ratures lower than 0°c, the water sent to the radiators wi...

Page 34: Control

Control 32 adjustments to be made regularly when enter ‘room heat’ mode, user could control compressor and electrical heater through regulate heat curve or dm (degree minute). Under a certain ambient temperature ,the time start of compressor is determined by degree minute(dm). Now we are giving two ...

Page 35: Control

Control 33 adjustments to be made regularly adjus t men t of room value as mentioned above, you can also adjust heat curve and indoor temperature by changing the room value. If you use room value to adjust the heat curve, the gradient does not change, i.E. It doesn’t become steeper or flatter. Inste...

Page 36: Adjustment

Adjustments to be made regularly adjustment of part of the heat curve at outdoor temperatures between -5°c and +5°c part of the heat curve may need adjusting if the indoor temperature does not stay at the preset room value. For this reason, the control system includes a function adjust- ing the curv...

Page 37: Adjustment

Adjustments to be made regularly adjustment of the min and max value the min and max value is the lowest respectively highest value that is allowed for the supply line temperature. Adjusting the minimum and maximum supply line temperature is particularly important if your home has floor heating.If y...

Page 38: Control

Control 36 adjustments to be made regularly graph of recent changes in temperature all temperatures registered during the last hour can be viewed in the sub-menu temperature in the shape of a graph. This will enable you to monitor changes in the different system temperatures . There is a graph avail...

Page 39: Control

Control 37 maximum return line temperature the maximum return line temperature, i.E. Temperature of the water returning from the heating system, should be adapted to each individual installation. The correct temperature value for your system will be entered by your installation contractor in connect...

Page 40: Control

Control 38 regular checks check of operating mode in the event of an alarm, the background light of lcd will flash and an alarm message will be displayed. Check the alarm indicator regularly to make sure that the heat pump works properly. You would not always notice if there is something wrong, as t...

Page 41: Control

Control 39 regular checks checking the safety valves both safety valves of the heating system should be checked at least four times a year to prevent lime deposits to clog the mechanism. To find out where the safety valves are located. The safety valve of the water heater protects the closed heater ...

Page 42: Control

Control 40 alarm messages in the event of an alarm message, try to re-start the unit with the safety switch. If this does not work, try to solve the problem with the help of the table below. Call your installation contractor if you need help. Table : alarm messages message signification cause action...

Page 43: Control

Control 41 terminology and abbreviations evaporate the evaporator, energy from the heat source is absorbed by the refrigerant passing through the evaporator. The refrigerant turns into gas. (see ”heat pump principle” on p. 4). Integral is the heat balance of the heating system. Production of heat is...

Page 44: Function

Description of the switch board function initial state a0 1 aa m ba m switch board a0 1 : control the compressor; aa m : control the water cycle pump; ba m : control the fan motor of outdoor unit. Note! The manual switch board is use only if the necessary for test or repair. When the machine is runn...

Page 45: Dealing With Malfunctions

Dealing with malfunctions 43 fighter 1220 close the shut-off valves in heating medium system. Open the drain valve (73 , 74). A small amount of water runs out, however, to fully empty the heating medium side requires the connector that joins the heating medium side and the connection on the heat pum...

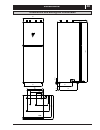

Page 46: Component Placement

44 1 11 3 2 4 5 6 7 9 10 12 13 14 8 9 component placement please note : the picture for reference only !.

Page 47: Component Placement

26 23 24 25 55 56 57 58 59 60 61 62 63 64 65 66 67 69 15 18 17 16 20 19 21 22 68 rt component placement 45 27 31 33 32 34 35 37 36 38 39 40 47 46 48 42 50 51 53 52 54 28 oct outp 43 29 30 41 44 45 49 please note : the picture for reference only !.

Page 48: Component Placement

Component placement 3x400 v / 3 / 50 hz 230 v /50 hz 70 71 70 71 46 please note : the picture for reference only !.

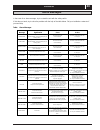

Page 49: List of Components

List of components 37 adjustable pressure switch 38 valve for adjustable pressure switch 47 2 right side board 3 left side board 4 glass upper door 5 glass lower door 6 front board 7 board for fixing control panel 8 the back board 9 hole for copper pipe connection 10 stainless steel adjustable feet ...

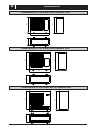

Page 50: Dimensions

Dimensions and setting-out coordinates 7 2 0 6 7 0 5 0 3 0 -5 0 4 5 5 2 7 0 7 8 9 0 480 482 384 208 62 540 1 8 0 0 544 60 600 5 4 440 dimensions 48.

Page 51: Dimensions

Dimensions dimensions of the awa-ss-6 outdoor unit 6 9 0 830 3 1 0 7 2 0 dimensions of the awa-ss-10 outdoor unit 7 7 0 880 3 6 0 8 0 0 49 dimensions of the awa-ss-8 outdoor unit 5 9 0 2 8 5 6 1 0 840

Page 52: Dimensions

Dimensions dimensions of the awa-ss-12 outdoor unit dimensions of the awa-ss-16 outdoor unit 1 2 0 0 830 3 1 0 1 2 3 0 1 2 2 0 930 3 9 0 1 2 5 0 50

Page 53: Accessories

Accessories fighter 1220 outside air temperature sensor room temperature sensor 78 77 80 79 enclosed kit 81 82 51.

Page 54: Technical Specifications

Technical specifications technical specifications 230v / 3 x 400 v 52 operating curr. Incl. Immersion heater 6 / 9 kw (a) connection heating flow, o.D. ø max pressure in storage heater (mpa) 0.9 (9 bar) refrigerant quantity (r410a) (kg) max temp. (flow/return circuit) (°c) 68/55 ip 21 volume, water ...