- DL manuals

- Servend

- Beverage Dispenser

- NGF Series

- Installation, Use & Care Manual

Servend NGF Series Installation, Use & Care Manual

Summary of NGF Series

Page 1

Installation, use & care manual this manual is updated as new information and models are released. Visit our website for the latest manual. Www.Manitowocfsg.Com leader in ice & beverage dispensers s, sv, svi, ngf, & quickdraw ™ beverage/ice dispensers part number 020003996 4/12.

Page 2

We reserve the right to make product improvements at any time. Specifications and design are subject to change without notice. Safety notices as you work on manitowoc equipment, be sure to pay close attention to the safety notices in this manual. Disregarding the notices may lead to serious injury a...

Page 3: Table of Contents

Part number 020003996 4/12 i table of contents section 1 general information read this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 unit inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4

Table of contents (continued) ii part number 020003996 4/12 step by step installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15 general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15 speci...

Page 5

Table of contents (continued) part number 020003996 4/12 iii section 4 maintenance cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 daily cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 6

Table of contents (continued) iv part number 020003996 4/12.

Page 7: Section 1

Part number 020003996 4/12 1-1 section 1 general information read this manual manitowoc beverage equipment (mbe) developed this manual as a reference guide for the owner/operator and installer of this equipment. Please read this manual before installation or operation of the machine. A qualified ser...

Page 8

General information section 1 1-2 part number 020003996 4/12 manual fill lid for dispensers with an ice machine if you are top mounting your dispenser with an ice machine, you will require a lid for the manual fill area at the top, front of the dispenser. If you ordered a dispenser and an ice machin...

Page 9: Section 2

Part number 020003996 4/12 2-1 section 2 installation instructions general these instructions are provided to assist the qualified installer. Contact your manitowoc beverage equipment service agent or call manitowoc beverage equipment for information regarding start-up services. Dimensions important...

Page 10

Installation instructions section 2 2-2 part number 020003996 4/12 footprints * includes ngf c a d b minimum area for cutout maximum area for cutout note: footprint for s/sv-175 shown. S & sv maximum minimum a b c d 150 19.00" (48.3 cm) 17.81" (45.2 cm) 8.00" (20.3 cm) 8.00" (20.3 cm) 175 21.00" (53...

Page 11

Section 2 installation instructions part number 020003996 4/12 2-3 location the location selected for the beverage dispenser must meet the following criteria. If any of these criteria are not met, select another location. • the air temperature must be at least 50°f (10°c), but must not exceed 95°f (...

Page 12

Installation instructions section 2 2-4 part number 020003996 4/12 pre-installation checklist when installing any system, first make sure the major components are available. Generally the major components necessary for an installation are: pre-mix system: b-i-b system also: post mix system: bulk syr...

Page 13

Section 2 installation instructions part number 020003996 4/12 2-5 assembly installing baffle for ice machine installations s series baffle 1. Remove both front panels. 2. Examine the ice machine to see if the machine has four screws on the lower front plastic panels. 3. If there are screws, remove ...

Page 14

Installation instructions section 2 2-6 part number 020003996 4/12 electrical general minimum circuit ampacity the minimum circuit ampacity is used to help select the wire size of the electrical supply. (minimum circuit ampacity is not the beverage/ice machine’s running amp load.) the wire size (or ...

Page 15

Section 2 installation instructions part number 020003996 4/12 2-7 pump deck wiring the supply cord is equipped with a three prong 5-15p. When a ground fault circuit interrupter (gfci) is required by code, a breaker type protector must be used. We do not recommend gfic outlets as they are known for ...

Page 16

Installation instructions section 2 2-8 part number 020003996 4/12 water supply recommended plumbing the plumbing diagram is printed on a white vinyl label, located above the inlet tubes for syrup and water. The plumbing diagram label can be accessed by removing the splash panel of the dispenser. Th...

Page 17

Section 2 installation instructions part number 020003996 4/12 2-9 s/sv150 6 valve diagram internal carbonator tank plumbing: 2-1-1-2 manifolding *optional* variety valve on #3 1 – water (thru coldplate) 2 – syrup (ambient) 3 – syrup (ambient) 4 – syrup (thru coldplate) valves “syrup lines not shown...

Page 18

Installation instructions section 2 2-10 part number 020003996 4/12 s/sv175 8 valve diagram 1 internal carbonator tank (optional) plumbing: 3-1-1-1-2 manifolding *optional* variety valve on #4 1 – water (thru coldplate) 2 – syrup (ambient) 3 – syrup (ambient) 4 – syrup (thru coldplate) valves “syrup...

Page 19

Section 2 installation instructions part number 020003996 4/12 2-11 s/sv200/250/sv-250qd 8 valve diagram 1 plumbing: 3-1-1-1-2 manifolding *optional* variety valve on #4 1 – water (thru coldplate) 2 – syrup (ambient) 3 – syrup (ambient) 4 – syrup (thru coldplate) note: syrup lines not shown pre-chil...

Page 20

Installation instructions section 2 2-12 part number 020003996 4/12 s/sv200/250 10 valve diagram internal carbonator tank (optional) plumbing: 3-1-2-1-3 manifolding pre-chill out to carbonator 8 7 6 5 4 3 3 2 1 1, 2, 3 4 5, 6 7 valves circuits co 2 manifold: change to carbonated or non-carbonated wa...

Page 21

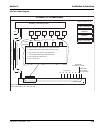

Section 2 installation instructions part number 020003996 4/12 2-13 ngf-250 & ngf-250qd 8 valve diagram w-water valves circuits carbona tor out to post -chill pre-chill out to carbona tor syrup #12 syrup #1 1 syrup #10 syrup #9 syrup #7 syrup #6 syrup #4 syrup #8 syrup #5 syrup #3 syrup #2 syrup #1 ...

Page 22

Installation instructions section 2 2-14 part number 020003996 4/12 co 2 supply routing internal carb tank purge tube some models are equipped with an internal carbonation tank. These models require that the purge/pressure relief tubing be routed to a drain. 1. Remove the splash panel. 2. Uncoil tub...

Page 23

Section 2 installation instructions part number 020003996 4/12 2-15 step by step installation general s/sv/svi/ngf series dispensers have a stainless steel cabinet and lighted merchandiser standard. Beverage valves, coldplate connections, drain connections and electrical components are front service...

Page 24

Installation instructions section 2 2-16 part number 020003996 4/12 d. Mount the collector box to the bracket by sliding the right and left bracket tabs into the slots on the collector box. E. Be sure the 90° rubber ice bin drain elbows are routed into the collector box. F. Reinstall the extended sp...

Page 25

Section 2 installation instructions part number 020003996 4/12 2-17 ada key pads these instructions are for installations with this option. 1. Remove power from the unit. Merchandiser removal 2. Loosen the two knurled fasteners located in the top of the merchandiser that hold the merchandiser in pla...

Page 26

Installation instructions section 2 2-18 part number 020003996 4/12 ada key pad matrix finish installation 12. Put the splash panel and merchandiser back onto the unit and reinstall the screws that hold them in place. 13. Restore power to the unit. Starting your beverage system & dispenser upon comp...

Page 27: Section 3

Part number 020003996 4/12 3-1 section 3 operation general system overview typical internal carbonation beverage dispensing system typical external carbonation (ambient) beverage dispensing system 1800 75 60 dispenser carbonator tank carbonate, non-carbonate beverage manifold counter top syrup tap w...

Page 28

Operation section 3 3-2 part number 020003996 4/12 component identification merchandiser soda valves key switch carb/non-carb water manifold and syrup/soda inlet (behind splash panel) drainpan grid drainpan splash panel counter.

Page 29

Section 3 operation part number 020003996 4/12 3-3 sequence of operation ice recommended for dispensing dispensers are designed to dispense hard, cube ice up to one-inch square. The ice shapes and sizes listed above are recommended for dispensing. Warm “super cooled” ice before dispensing: “super co...

Page 30

Operation section 3 3-4 part number 020003996 4/12 operation carbon dioxide (co 2 ) leaves the storage tank and arrives at the carbonator tank through the gas inlet. Water supply enters the carbonator pump inlet at regular street water line pressure (minimum 20 psi, maximum 80 psi, dynamic or flowin...

Page 31

Section 3 operation part number 020003996 4/12 3-5 7. Primary pressure regulator – lowers the co 2 gas pressure, to 100 psi, so the co 2 gas will be at the proper pressure to enter the carbonator regulator. 8. Lowered outgoing pressure – set for 75 psi. Gauge indicates lowered outgoing pressure from...

Page 32

Operation section 3 3-6 part number 020003996 4/12 figal system figal refers to the stainless steel tanks of pre-mix beverage or post-mix syrup. A small co 2 tank pushes the beverage out of the figal tank. Figal tanks the stainless steel figal beverage tanks are easy to store and connect. When using...

Page 33

Section 3 operation part number 020003996 4/12 3-7 operation checks and adjustments rocking chute ice delivery switch adjustment to properly adjust the switch, first unplug the power cord to the unit then remove the merchandiser. This will give you access to the ice delivery switch located on the le...

Page 34

Operation section 3 3-8 part number 020003996 4/12 quickdraw ice portion adjustments the quickdraw ice dispensing system has adjustable ice portion sizes. Follow the directions below to set the ice portion size. Each portion size must be checked according to customer specification at the time of ins...

Page 35

Section 3 operation part number 020003996 4/12 3-9 sensor beam sensor beam sequence of operation 1. Ice fills the ice chute until it interrupts the beam. 2. Paddlewheel stops. 3. Ready for the next portioned dispense. Adjustment 1. Loosen screws on left & right side of assembly. 2. Adjust sensor boa...

Page 36

Operation section 3 3-10 part number 020003996 4/12 brix check step 1 - gather tools tools you will need; brix cup and s tube. Note: follow instructions on 2a or 2b depending on valve type that is being checked. Step 2a - attaching s tube to multi-flavor valve • remove nozzle and syrup diffuser from...

Page 37: Section 4

Part number 020003996 4/12 4-1 section 4 maintenance cleaning daily cleaning all cleaning must meet your local health department regulations. The following cleaning instructions are provided as a guide. Clean the exterior and drain pan: 1. Turn off the key switch located on either right or left side...

Page 38

Maintenance section 4 4-2 part number 020003996 4/12 monthly cleaning clean and sanitize the ice bin: 1. Unplug unit and remove all ice from the ice bin. 2. Mix a solution of mild detergent to clean the dispenser bin and components. 3. Wash the ice bin using a sponge and the mild detergent solution....

Page 39

Section 4 maintenance part number 020003996 4/12 4-3 preventive maintenance preventative maintenance is a vital part of keeping your dispenser in top condition. Following the guidelines below will assist you in continued trouble-free operation of your unit. 1. Conduct daily maintenance of the machin...

Page 40

Maintenance section 4 4-4 part number 020003996 4/12 7. Remove agitator arm and paddlewheel pin. Non-front serviceable motor a. Rotate the agitator arm so the paddle wheel pin handle is pointing up, toward the ceiling. B. Prepare agitator pin for removal by removing the stainless steel split ring. C...

Page 41

Section 4 maintenance part number 020003996 4/12 4-5 quickdraw components 1. Turn the beverage valve switch on the front left side to the off position. 2. Place a receptacle (bucket or large cup) under the ice dispense chute. 3. Place the ice dispense switch to manual mode. The door will open and ic...

Page 42

Maintenance section 4 4-6 part number 020003996 4/12 5. The ice chamber must be sanitized with a soft bristle brush to adequately clean the drainage area. 9. Reverse the procedure to reassemble the quickdraw mechanism. 10. Place the ice dispense switch to the auto position, and place the beverage va...

Page 43

Section 4 maintenance part number 020003996 4/12 4-7 front serviceable gear motor removal these instructions are provided as a guide for the removal of the gear motor. Depending on the model number of your dispenser, these instructions may vary slightly. 1. Unplug the dispenser. 2. Unplug the motor....

Page 44

Maintenance section 4 4-8 part number 020003996 4/12 sanitizing beverage system cleaning sanitize the beverage system at initial start-up as well as regularly scheduled cleaning. The drain pan must be in place under soda valves, to carry away detergent and sanitizing agents that will be flushed thro...

Page 45

Section 4 maintenance part number 020003996 4/12 4-9 5. Draw rinse water through system until clean water is dispensed. Most beverage valves allow the syrup side to be manually activated by depressing the syrup pallet. 6. Connect bucket 2 to system. 7. Draw detergent solution through system until so...

Page 46

Maintenance section 4 4-10 part number 020003996 4/12 this page intentionally left blank.

Page 47: Section 5

Part number 020003996 4/12 5-1 section 5 before calling for service checklist if a problem arises during operation of your dispenser, follow the checklist below before calling service. Routine adjustments and maintenance procedures are not covered by the warranty. Problem possible cause to correct d...

Page 48

Before calling for service section 5 5-2 part number 020003996 4/12 drink troubleshooting condition investigation check correction water only dispensing no pressure regulator(s) out of adjustment check/adjust regulator(s). Out of co 2 install fresh tank. Defective regulator(s) check/repair/replace r...

Page 49

Section 5 before calling for service part number 020003996 4/12 5-3 pump troubleshooting quickdraw mechanism troubleshooting problem possible cause corrective action pump motor does not shut off problem with probe or probe harness pump motor intermittent problem with probe or probe harness pump moto...

Page 50

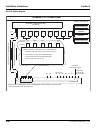

Before calling for service section 5 5-4 part number 020003996 4/12 quickdraw ice portion control program supply power on switch in auto mode power up displays “8888” then “____” dispense chute filled w/ ice auto mode press any size button to dispense programmed size fixed maximum time is 6 sec if p...

Page 52

Manitowoc beverage systems 2100 future drive sellersburg, in 47172, usa ph: 812-246-7000 fax: 812-246-7024 visit us online at: www.Manitowocfsg.Com © 2012 manitowoc continuing product improvements may necessitate change of specifications without notice. Part number 020003996 4/12.