- DL manuals

- Smarter Tools

- Welding System

- ARC-100S

- Operating Manual

Smarter Tools ARC-100S Operating Manual

Summary of ARC-100S

Page 1

Don't work harder. Work smarter. Mig-135 solid wire and flux cored welder revision: ab issue date: march 2011 manual no.: 0-mig1350311 operating manual.

Page 2

We appreciate your business. Thank you and congratulations on choosing smarter tools. Now you can stop working harder and start working smarter. This operating manual has been designed to instruct you on the correct use and operation of your smarter tools’ product. Your satisfaction with this produc...

Page 3

Table of contents section 1: safety instructions and warnings .......................... 1-1 1.1 symbol usage ......................................................................................... 1-1 1.2 arc welding hazards ...........................................................................

Page 4

5.2 troubleshooting ....................................................................................... 5-1 5.3 system schematic ................................................................................... 5-3 5.4 parts list ...................................................................

Page 5: 1.1 Symbol Usage

1-1 section 1: safety instructions and warnings 1.1 symbol usage this manual contains important information that you need to know and understand in order to assure your safety and proper operation of equipment. The following symbols help you recognize this information. Please read the manual and pay...

Page 6: 1.2 Arc Welding Hazards

1-2 1.2 arc welding hazards the symbols shown below are used throughout this manual to call attention to and identify possible hazards. When you see the symbol, watch out, and follow the related instructions to avoid the hazard. The safety information given below is only a summary of the more comple...

Page 7

1-3 • do not drape cables over your body. • if earth grounding of the work-piece is required, ground it directly with a separate cable. • do not touch electrode if you are in contact with the work, ground, or another electrode from a different machine. • use only well-maintained equipment. Repair or...

Page 8

1-4 • work in a confined space only if it is well ventilated, or while wearing an air- supplied respirator. Always have a trained watchperson nearby. Welding fumes and gases can displace air and lower the oxygen level causing injury or death. Be sure the breathing air is safe. • do not weld in locat...

Page 9

1-5 • protect yourself and others from flying sparks and hot metal. • do not weld where flying sparks can strike flammable material. • remove all flammables within 35 ft (10.7 m) of the welding arc. If this is not possible, tightly cover them with approved covers. • be alert that welding sparks and ...

Page 10

1-6 magnetic fields can affect pacemakers. • pacemaker wearers keep away. • wearers should consult their doctor before going near arc welding, gouging, or spot welding operations. Noise can damage hearing. • excessive noise from some processes or equipment can damage hearing. • wear approved ear pro...

Page 11: Maintenance

1-7 • turn face away from valve outlet when opening cylinder valve. • keep protective cap in place over valve except when cylinder is in use or connected for use. • read and follow instructions on compressed gas cylinders, associated equipment, and cga publication p-1 listed in safety standards. 1.3...

Page 12

1-8 moving parts can cause injury. • keep away from moving parts. • keep away from pinch points such as drive rolls. Welding wire can cause injury. • do not press gun trigger until instructed to do so. • do not point gun toward any part of the body, other people, or any metal when threading welding ...

Page 13

1-9 arc welding can cause interference. • electromagnetic energy can interfere with sensitive electronic equipment such as computers and computer-driven equipment such as robots. • be sure all equipment in the welding area is electromagnetically compatible. • to reduce possible interference, keep we...

Page 14: 1.6 Eye Protection

1-10 1.6 eye protection eye and face protectors for welding and related tasks, such as grinding and chipping, should comply with the requirements of ansi z87.1. Look for labels or markings indicating compliance. Depending on the specific work task, appropriate eye/face protection may include safety ...

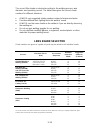

Page 15: Lens Shade Selector

1-11 the correct filter shade is selected according to the welding process, wire diameter, and operating current. The table below gives the correct shade numbers for different situations. • always use suggested shade numbers instead of minimum shades. • provide additional task lighting that suits we...

Page 16: 1.7 Protective Clothing

1-12 1.7 protective clothing like other jobs or careers, welders must wear suitable protective equipment. In general, personal protective equipment (ppe) must protect against hazards such as burns, sparks, spatter, electric shock, and radiation. The use of ppe is a good safe practice and may be requ...

Page 17: 1.8 Emf Information

1-13 protect all areas of your body from injury during welding or cutting by wearing the proper protective clothing and equipment. Do not weld or cut unless wearing the necessary ppe as specified in this manual and in ansi z49.1. 1.8 emf information considerations about welding and the effects of lo...

Page 18

1-14 research council concluded that: “the body of evidence, in the committee’s judgment, has not demonstrated that exposure to power-frequency electric and magnetic fields is a human-health hazard.” however, studies are still going forth and evidence continues to be examined. Until the final conclu...

Page 19: 1.1 Símbolo De Uso

1-1a secciÓn 1: instrucciones de seguridad y advertencias 1.1 símbolo de uso este manual contiene información importante que necesita conocer y comprender a fin de garantizar su seguridad y funcionamiento adecuado del equipo. Los símbolos siguientes le ayudarán a reconocer esta información. Por favo...

Page 20

1-2a 1.2 riesgos de soldadura por arco los símbolos se muestra a continuación se utilizan en este manual para llamar la atención e identificar los posibles peligros. Cuando vea el símbolo, tenga cuidado, y siga las instrucciones correspondientes para evitar el peligro. La información de seguridad da...

Page 21

1-3a un alambre desnudo puede matarlo. • apague todo equipo cuando no esté en uso. • no utilice desgastados, rotos, o mal los cables empalmados. • no envuelva los cables alrededor de su cuerpo. • si toma de tierra de la pieza de trabajo se requiere conexión de tierra con un cable separado. • no toqu...

Page 22

1-4a • si la ventilación es mala, use un respirador aprobado con suministro de aire. • lea las hojas de seguridad (msds) y las instrucciones del fabricante para los metales, consumibles, recubrimientos, limpiadores y desengrasantes. • trabajar en un espacio cerrado solamente si está bien ventilado o...

Page 23

1-5a causar chispas, explosión, sobrecalentamiento, o fuego. Revise y asegúrese que el área es segura antes de comenzar a soldar. • protéjase y proteja a otros de las chispas y metal caliente. • no suelde donde las chispas pueden impactar material inflamable. • quite todo material inflamable dentro ...

Page 24

1-6a partes calientes pueden causar quemaduras graves. • no toque las partes calientes sin guantes. • permitir un período de enfriamiento antes de trabajar en la pistola o antorcha. Campos magnÉticos pueden afectar a los marcapasos. • portadores de marcapasos mantenerlos alejados. • el usuario debe ...

Page 25: Mantenimiento

1-7a • use solamente gas protectivo correcto, reguladores, mangueras y accesorios diseñados para la aplicación específica, mantenerlos y sus partes en buen estado. • gire la cara lejos de la salida de la válvula cuando la válvula de cilindro. • mantenga la tapa protectora en su lugar sobre la válvul...

Page 26

1-8a • uso adecuado bolsas anti-estáticas y cajas para almacenar, mover o enviar tarjetas impresas de circuito. Partes que se mueven pueden causar lesiones. • manténgase alejado de las piezas móviles. • aléjese de todo punto que pellizque, tal como rodillos de arrastre. Alambre de soldar puede causa...

Page 27

1-9a • mantenga las puertas de alta frecuencia de la fuente y los paneles cerradas completamente, mantenga los platinos en su fijación correcta y haga tierra y blindaje para minimizar la posibilidad de interferencia. Soldadura de arco puede causar interferencia. • la energía electromagnética puede i...

Page 28

1-10a 1.6 protección de los ojos los ojos y la cara para la soldadura y tareas relacionadas, tales como la molienda y saltar, deberá cumplir con los requisitos de la norma ansi z87.1. Busque las etiquetas o marcas que indiquen el cumplimiento. Dependiendo de la tarea de trabajo específica, adecuada ...

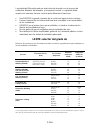

Page 29

1-11a la sombra del filtro adecuado se selecciona de acuerdo con el proceso de soldadura, diámetro del alambre, y la operación actual. La siguiente tabla muestra los números de tono correcto para diferentes situaciones. • use siempre sugerido números de la cortina en lugar de tonos mínimo. • proveer...

Page 30: 1.7 Ropa De Protección

1-12a 1.7 ropa de protección al igual que otros trabajos o carreras, los soldadores deberán usar equipo de protección adecuado. En general, equipo de protección personal (epp) debe proteger contra riesgos tales como quemaduras, chispas, salpicaduras, descargas eléctricas y radiación. La utilización ...

Page 31: 1.8 Información Del Emf

1-13a proteger a todas las áreas de su cuerpo de las lesiones durante la soldadura o el corte con el uso de la ropa adecuada y equipo de protección. No suelde o corte a menos que use el ppe necesario tal como se especifica en este manual y en la norma ansi z49.1. 1.8 información del emf consideracio...

Page 32

1-14a eléctricos y magnéticos es un peligro para la salud humana." sin embargo, los estudios todavía están haciéndose y la evidencia continua siendo examinada. Hasta que las conclusiones finales de la investigación se alcanzan, es posible que desee reducir al mínimo su exposición a los campos electr...

Page 33: 20A-135A

2-1 section 2: introduction and specifications 2.1 equipment identification the unit’s identification number (specification or part number), model, and serial number usually appear on a nameplate attached to the machine. Equipment which does not have a nameplate attached to the machine is identified...

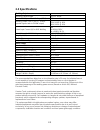

Page 34: 2.3 Specifications

2-2 2.3 specifications welding output welding current range 20-135 amps nominal dc open circuit voltage (ocv) 33v welding output, 104º f (40º c), 10 min. (quoted figures refer to smaw output) 40a /16v @ 100% 52a /16.6v @ 60% 90a /18.5v @ 20% rated input current (a) for mig welding 9a io=90a@18.5v i ...

Page 35: 2.4 Duty Cycle

2-3 2.4 duty cycle the rated duty cycle of a welding power source, is a statement of the time it may be operated at its rated welding current output without exceeding the temperature limits of the insulation of the component parts. To explain the 10 minute duty cycle period the following example is ...

Page 36: 3.1 Selecting A Location

3-1 section 3: installation 3.1 selecting a location be sure to locate the welder according to the following guidelines: • in areas, free from moisture and dust. • ambient temperature between 32°f (0°c) to 104° f (40° c). • in areas, free from oil, steam and corrosive gases. • in areas, not subjecte...

Page 37

3-2 the mig-135 should be operated from a single- phase 60hz, ac power supply. The input voltage should match the electrical input voltages shown on the input data label on the unit nameplate. See section 2.1 for example do not attempt to cut off the ground pin to fit it to a 1–15r outlet or extensi...

Page 38

3-3 3.4 electromagnetic compatibility extra precautions for electromagnetic compatibility may be required when this welding power source is used in a domestic situation. A. Installation and use - users responsibility the user is responsible for installing and using the welding equipment according to...

Page 39

3-4 welding equipment should be connected to the mains supply according to the manufacturer’s recommendations. If interference occurs, it may be necessary to take additional precautions such as filtering of the mains supply. Consideration should be given to shielding the supply cable of permanently ...

Page 40: 3.5 Setup For Welding

3-5 3.5 setup for welding conventional operating procedures apply when using the welding power source, i.E. Connect work lead directly to work piece and electrode lead is used to hold electrode. Wide safety margins provided by the design ensure that the welding power source will withstand short-term...

Page 41

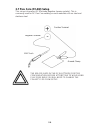

3-6 3.7 flux core (fcaw) setup this set up is known as dc electrode negative (reverse polarity). This is commonly used for dc flux core welding on most materials such as steel and stainless steel. The mig-135 ships in the dc electrode positive configuration. Before attempting to weld using flux core...

Page 42: 3.9 Installing Wire Rolls

3-7 3.8 changing between processes the mig (gmaw) and flux core (fcaw) processes utilize different polarities (dcep and dcen). To change between them follow these instructions: 1. Make sure the machine is unplugged from the power receptacle. 2. Open the door to the machine. 3. Remove the polarity te...

Page 43

3-8.

Page 44: 4.1 General Operation

4-1 section 4: operation 4.1 general operation conventional operating procedures apply when using the welding power source, i.E. Connect work lead directly to work piece and electrode lead is used to hold the electrode. The welding current range values should be used as a guide only. Current deliver...

Page 45

4-2 a) amp adjustment switches the amp adjustment switches allow for adjustment between four different amp settings. Switch settings welding current in volts max-2 34v max-1 28v min-2 24v min-1 21v b) over heat indicator the welding power source is protected by a self resetting thermostat. The indic...

Page 46: 4.3 Selecting Wire Types

4-3 4.3 selecting wire types for thin metals, use a smaller diameter wire. For thicker metal use a larger wire and a larger machine. See machine recommendations for welding capacity. Use the correct wire type for the base metal being welded. Use stainless steel wires for stainless steel, aluminum wi...

Page 47

4-4 solid carbon-steel er70s-6 • must be used with co2 or 75% argon/25% (c-25) shielding gas • co2 gas is economical and provides deeper penetration • 75% argon/25% co2 has less spatter and a better bead appearance • indoor use with no wind • for auto body and manufacturing fabrication • welds thinn...

Page 48

4-5 4.4 back panel/gas connector when using the mig (gmaw) welding process (solid wire) a shielding gas is required. Familiarize yourself with the location of the “back panel” tapered nozzle gas connector before attempting to operate. A stainless steel hose clamp is recommended to ensure a leak-proo...

Page 49

4-6 1. Using a secured gmaw shielding gas cylinder, slowly crack open then close the cylinder valve while standing off to the side of the valve. This will remove any debris that may be around the valve & regulator seat area. 2. Install the regulator and tighten with a wrench. 3. Connect the gas hose...

Page 50: 4.1 Funcionamiento General

4-1a sección 4: operación 4.1 funcionamiento general los procedimientos convencionales de servicio son aplicables cuando se utiliza la fuente de energía de la soldadura, el trabajo de conectar es decir, conducen directamente a la pieza de trabajo y el cable del electrodo se utiliza para sostener el ...

Page 51

4-2a e) ajuste amp interruptores los interruptores de ajuste de amplificador permitir el ajuste entre cuatro ajustes diferentes amplificador. Switch settings welding current in volts max-2 34v max-1 28v min-2 24v min-1 21v f) en indicador de calor el equipo de soldadura está protegido por un termost...

Page 52

4-3a 4.3 selección de tipos de cables para los metales delgado, utilice un cable de menor diámetro. Para más gruesas de metal utilizar un cable más grande y una máquina más grande. Véanse las recomendaciones de la máquina para la capacidad de soldadura. Utilice el tipo de cable correcto para ser la ...

Page 53

4-4a solid carbon-steel er70s-6 • must be used with co2 or 75% argon/25% (c-25) shielding gas • co2 gas is economical and provides deeper penetration • 75% argon/25% co2 has less spatter and a better bead appearance • indoor use with no wind • for auto body and manufacturing fabrication • welds thin...

Page 54

4-5a una abrazadera de manguera de acero inoxidable se recomienda para asegurar una conexión a prueba de fugas. 1. El uso de un blindaje garantizado gmaw cilindro de gas, poco a poco grieta abierta a continuación, cierre la válvula del cilindro, mientras que de pie a un lado de la válvula. Esto quit...

Page 55: Posicionamiento

4-6a 4.5 holding y la pistola de soldadura de posicionamiento alambre de soldadura se activa cuando pistola es presionado. Antes de descenso de casco y oprimir el gatillo, cable se que hay mÁs de 1 / 2 pulg (13 mm) fin pasado de punta y punta de alambre está colocado correctamente en la costura. 1. ...

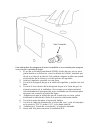

Page 56: 5.1 Maintenance

5-1 section 5: maintenance and troubleshooting 5.1 maintenance the only routine maintenance required is a thorough cleaning and inspection, with frequency being dependent upon the usage and the operating environment. This product contains exremely dangerous voltages. Turn off the power switch, unplu...

Page 57

5-2 trouble remedy no weld output; fan does not run. Place power switch in on position (see section 4.3). Reset circuit breaker at electrical panel (see section 3.3). Check for proper input power connections (see section 3.3). No weld output; fan on. Unit overheated. Duty cycle exceeded. Allow unit ...

Page 58: 5.1 Mantenimiento

5-1a secciÓn 5: mantenimiento y resoluciÓn de problemas 5.1 mantenimiento el único mantenimiento de rutina a una limpieza a fondo y de inspección, con la frecuencia que depende del uso y el entorno operativo. Este producto contiene tensiones exremely peligroso. Apague el interruptor de alimentación,...

Page 59

5-2a trouble remedy no hay salida de soldadura; ventilador no funciona. Coloque el interruptor en posición de encendido (ver sección 4.3). Reajuste el disyuntor en el panel eléctrico (ver sección 3.3). Verifique las conexiones de entrada de energía (ver sección 3.3). No hay salida de soldadura; vent...