- DL manuals

- SMC Networks

- Control Unit

- EX250-SPR1

- Operation Manual

SMC Networks EX250-SPR1 Operation Manual - Table of Contents

Summary of EX250-SPR1

Page 1

No.Ex※※-ome0014-f product name fieldbus system (si unit – profibus dp compatible) model / series / product number ex250-spr1.

Page 2: Table of Contents

-1- no.Ex※※-ome0014-f table of contents safety instructions 2 model indication and how to order 8 summary of product parts 8 mounting and installation 9 installation 9 wiring 10 setting 15 troubleshooting 22 specification 28 specifications 28 dimensions 29.

Page 3: Safety Instructions

-2- no.Ex※※-ome0014-f safety instructions these safety instructions are intended to prevent hazardous situations and/or equipment damage. These instructions indicate the level of potential hazard with the labels of "caution", "warning" or "danger". They are all important notes for safety and must be...

Page 4: Caution

-3- no.Ex※※-ome0014-f caution the product is provided for use in manufacturing industries. The product herein described is basically provided for peaceful use in manufacturing industries. If considering using the product in other industries, consult smc beforehand and exchange specifications or a co...

Page 5: Operator

-4- no.Ex※※-ome0014-f operator this operation manual is intended for those who have knowledge of machinery using pneumatic equipment, and have sufficient knowledge of assembly, operation and maintenance of such equipment. Only those persons are allowed to perform assembly, operation and maintenance...

Page 6

-5- no.Ex※※-ome0014-f ■ note ○follow the instructions given below when designing, selecting and handling the product. The instructions on design and selection (installation, wiring, environment, adjustment, operation, maintenance, etc.) described below must also be followed. product specifications ...

Page 7

-6- no.Ex※※-ome0014-f product handling installation •do not drop, hit or apply excessive shock to the si unit. Otherwise damage to the product can result, causing malfunction. •tighten to the specified tightening torque. If the tightening torque is exceeded the mounting screws may be broken. Ip67 p...

Page 8

-7- no.Ex※※-ome0014-f •mount the product in a place that is not exposed to vibration or impact. Otherwise failure or malfunction can result. •do not use the product in an environment that is exposed to temperature cycle. Heat cycles other than ordinary changes in temperature can adversely affect the...

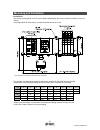

Page 9: Summary of Product Parts

-8- no.Ex※※-ome0014-f model indication and how to order ex250-spr1 communication protocol pr1 profibus dp summary of product parts no. Element description 1 communication connector connect with profibus dp communication line. 1 2 power supply connector supplies power to the solenoid valve, the outp...

Page 10: Mounting and Installation

-9- no.Ex※※-ome0014-f mounting and installation ■ installation not having mounting hole, it can’t be set to bus independently. Be sure to connect manifold to si unit for setting. And if input block is unnecessary, connect end plate directly to si unit. : the size when connecting bus tee with the si...

Page 11

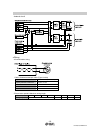

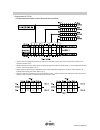

-10- no.Ex※※-ome0014-f internal circuit ■ wiring communication wiring cable: shielded twisted pair cable (type-a cable) impedance 135 to 165 ohm(3 to 20 mhz) capacity between conductors 30 pf/m or less conductor resistance 110 Ω/km or less cable diameter 0.64 mm or more conductor area 0.34 mm 2 or...

Page 12

-11- no.Ex※※-ome0014-f terminator it is necessary to attach bus terminator resistance to the units located at the ends of transmission line. : contact each manufacture about communication cable and bus tee..

Page 13

-12- no.Ex※※-ome0014-f power supply wiring power supply line inside the unit has individual power supplies for solenoid valve actuation (sv power supply) and for control parts and input block (si . Sw power supply). Supply 24 vdc for each of them. Either single or dual power supply is available. :...

Page 14

-13- no.Ex※※-ome0014-f communication connector m12 5-pin reverse (socket) example of connected bus tee: turck vb2/fsw/fkw/fsw45 etc. Pin no. Description function 1 vp supply voltage for terming resistor 2 a-n minus to send/receive data 3 dgnd ground for terminating resistor 4 b-p plus to send/recei...

Page 15

-14- no.Ex※※-ome0014-f ○maintenance addition of input block remove screws from end plate. mount attached tie rod. connect additional input block. connect end plate and tighten removed screws by specified tightening torque. (0.6 nm) exchange of si unit remove screws from end plate and release co...

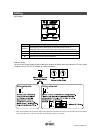

Page 16: Setting

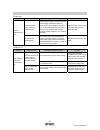

-15- no.Ex※※-ome0014-f setting led display indication contents pwr(v) green lights up when power supply for solenoid valves is turned on. Disappear when solenoid valve power supply voltage decreases below 19v. Run green lights up during operation(when power supply for si unit is turned on.) dia red...

Page 17

-16- no.Ex※※-ome0014-f diagnosis information diagnosis information of the si unit is composed of 6 bytes standard diagnosis information and 7 bytes si unit status information, 13 bytes in total, as specified in profibus dp. When the si unit is in a non-standard state, it will send an error message ...

Page 18

-17- no.Ex※※-ome0014-f byte1: station status 2 bit 7 0 0 x x x 0 1 0 x byte2: station status 3 bit 7 0 0 x x x x x x x byte3: diag.Master_add indicates the master address. Byte4, 5: ident_number indicates id no. Of si unit. Byte6: diag.Header indicates how many bits the enhancing diagnosis data has....

Page 19

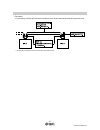

-18- no.Ex※※-ome0014-f set-up steps in profibus dp, a device database file called the generic station description (gsd) file provides configuration information specific to the device (id number, data format, baud rate...). The gsd file of the product depends on the address setting mode (selected by...

Page 20

-19- no.Ex※※-ome0014-f i/o configuration i/o configuration of si unit is shown below. (refer to manuals or other information of master for details such as definition of numbers.) byte (slot) no. Type length unit 0 163 (a3h) output 4 byte 1 147 (93h) input 4 byte.

Page 21

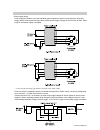

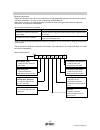

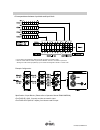

-20- no.Ex※※-ome0014-f assignment of i/o no. Correspondence between output data and valve manifold : output numbers are assigned to stations from side d to u of manifold in order. (see manual of each valve manifold for the directions of side d and u) : standard manifold is wired in double. Output...

Page 22

-21- no.Ex※※-ome0014-f correspondence between input data and input block : input numbers are assigned to stations from si unit side to input side in order. : each bit of data read into master 4 bytes shows on/off of sensor connected to input block. Starting from lsb of first byte (offset 0), inpu...

Page 23: Troubleshooting

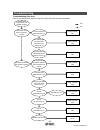

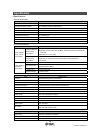

-22- no.Ex※※-ome0014-f troubleshooting troubleshooting flow chart if the si unit malfunctions, select the specific trouble with the flow chart stated below. A reduced wiring system does not operate normally a solenoids valve does not operate normally only the solenoid valve led turns on the inputs t...

Page 24

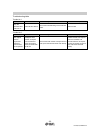

-23- no.Ex※※-ome0014-f troubleshooting table trouble no.1 trouble possible cause investigation method of cause remedy only the solenoid valve led turn on. Solenoid valve failure. Check the troubleshooting for the solenoid valve. Same as left. Trouble no.2 trouble possible cause investigation method ...

Page 25

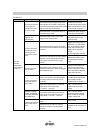

-24- no.Ex※※-ome0014-f trouble no.3 trouble possible cause investigation method of cause remedy check that the power supply cable for the solenoid valve is not broken, and that the connection between the power supply cable and connector has not loosened. Review the connection condition of the power ...

Page 26

-25- no.Ex※※-ome0014-f trouble no.4 trouble possible cause investigation method of cause remedy the inputs that are beyond the maximum point number do not operate. Inadequate total number of inputs from the input block connected with the si unit. Check if the total number of inputs is 32 or less. El...

Page 27

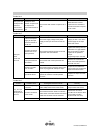

-26- no.Ex※※-ome0014-f trouble no.7 trouble possible cause investigation method of cause remedy incorrect wiring of the power supply for control and input block of the product. Confirm there is no incorrect connection between input and si unit controlling part power supply and si unit power supply c...

Page 28

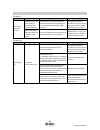

-27- no.Ex※※-ome0014-f trouble no.9 trouble possible cause investigation method of cause remedy decreased power supply voltage for solenoid valves. Check supply voltage of the solenoid valve power supply. (information about the solenoid valve power supply is sent to the plc as extended diagnostic in...

Page 29: Specification

-28- no.Ex※※-ome0014-f specification ■ specifications general specification item specification operating ambient temp. -10 to +50 o c operating ambient humidity 35 to 85%rh (no dew condensation) storage ambient temp. -20 to +60 o c withstand voltage 500 vac for 1 min. Insulation resistance 500 vdc 1...

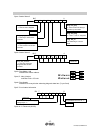

Page 30: Dimensions

Dimensions -29- no.Ex※※-ome0014-f.

Page 31

No.Ex※※-ome0014-f revision history a: add some contents b: correct an error in writing c: make an overall revision d: correct an error in writing e: revision f: correct an error in writing note: specifications are subject to change without prior notice and any obligation on the part of the manufactu...