- DL manuals

- SMC Networks

- Chiller

- HRS090-A

- Operation Manual

SMC Networks HRS090-A Operation Manual

HRX-OM-S004

1

st

edition: Jul. 2014

2

nd

edition: Nov. 2014

Operation Manual

Installation・Operation

Original Instructions

Thermo chiller

HRS100-A

∗

-20-

∗

HRS150-A

∗

-20-

∗

HRS100-A

∗

-40-

∗

HRS150-A

∗

-40-

∗

HRS100-W

∗

-20-

∗

HRS150-W

∗

-20-

∗

HRS100-W

∗

-40-

∗

HRS150-W

∗

-40-

∗

Keep this manual available whenever necessary

© 2014 SMC CORPORATION All Rights Reserved

Summary of HRS090-A

Page 1

Hrx-om-s004 1 st edition: jul. 2014 2 nd edition: nov. 2014 operation manual installation・operation original instructions thermo chiller hrs100-a ∗ -20- ∗ hrs150-a ∗ -20- ∗ hrs100-a ∗ -40- ∗ hrs150-a ∗ -40- ∗ hrs100-w ∗ -20- ∗ hrs150-w ∗ -20- ∗ hrs100-w ∗ -40- ∗ hrs150-w ∗ -40- ∗ keep this manual av...

Page 2: To The Users

To the users thank you for purchasing smc’s thermo chiller (hereinafter referred to as the “product”). For safety and long life of the product, be sure to read this operation manual (hereinafter referred to as the “manual”) and clearly understand the contents. • be sure to read and follow all instru...

Page 3: Contents

Hrx-om-s004 contents hrs series contents chapter 1 safety instructions .......................................................... 1-1 1.1 before using the product ..........................................................................................1-1 1.2 reading the manual .......................

Page 4

Hrx-om-s004 contents hrs series 3.3.9 rs-232c communication wiring........................................................................................3-26 3.4 piping........................................................................................................................3-27 3.5 ci...

Page 5

Hrx-om-s004 contents hrs series 5.8.1 ready completion (temp ready) signal ....................................................................... 5-19 5.8.2 ready completion (temp ready) signal setting / checking .......................................... 5-20 5.9 offset function .....................

Page 6

Hrx-om-s004 contents hrs series 5.21 communication function.........................................................................................5-69 5.21.1 communication function ...................................................................................................5-69 5.21.2 settin...

Page 7

Hrx-om-s004 contents hrs series 8.4.4 hrs150-w ∗-20/40-∗ .........................................................................................................8-11 8.5 pump capacity..........................................................................................................8-12 8.5.1...

Page 8

Hrx-om-s004 contents hrs series.

Page 9: 1.2 Reading The Manual

Hrx-om-s004 chapter 1 safety instructions hrs series 1.1 before using the product 1-1 chapter 1 safety instructions 1.1 before using the product z this chapter is intended to specifically describe the safety related issues for handling the product. Read this before handling the product. Z the produc...

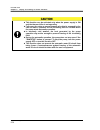

Page 10: 1.3 Hazards

Hrx-om-s004 chapter 1 safety instructions 1.3 hazards hrs series 1-2 1.3 hazards 1.3.1 level of hazards the instructions given in this manual aim to assure the safe and correct operation of the product, and to prevent injury of operators or damage to the product. These instructions are grouped into ...

Page 11: 1.4 Product Label

Hrx-om-s004 chapter 1 safety instructions hrs series 1.4 product label 1-3 1.4 product label information about the product, such as serial no. And model no. Can be found on the product label. This information is needed when contacting an smc sales distributor. How to see the serial number s o 001 (j...

Page 12: 1.5 Safety Measures

Hrx-om-s004 chapter 1 safety instructions 1.5 safety measures hrs series 1-4 1.5 safety measures 1.5.1 safety instructions for use z read and understand this manual carefully before using the product. Z before starting maintenance of the product, be sure to lock out and tag out the breaker of the us...

Page 13: 1.6 Emergency Measures

Hrx-om-s004 chapter 1 safety instructions hrs series 1.6 emergency measures 1-5 1.6 emergency measures when emergency conditions such as natural disaster, fire, earthquake and injury occur, shut off the breaker of the user’s power supply that supplies power to the product. 1.7 waste disposal 1.7.1 d...

Page 14

Hrx-om-s004 chapter 1 safety instructions 1.8 material safety data sheet (msds) hrs series 1-6 1.8 material safety data sheet (msds) if the material safety data sheets of chemicals used in this product are needed, contact an smc's sales distributor. Any chemicals used by the user must be accompanied...

Page 15

Hrx-om-s004 chapter 2 name and function of parts hrs series 2.1 model number of product 2-1 chapter 2 name and function of parts 2.1 model number of product the product can be ordered with the model number configured as shown below. The product needs to be handled in different ways depending on the ...

Page 16

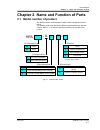

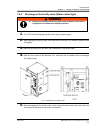

Hrx-om-s004 chapter 2 name and function of parts 2.2 name and function of parts hrs series 2-2 2.2 name and function of parts 2.2.1 hrs100/150-a ∗-20/40 (in case of air cooled type) fig. 2-2 names of the parts (this drawing shows “hrs150-a-20”.) table 2-1 accessory list ① alarm code list label 2pcs....

Page 17

Hrx-om-s004 chapter 2 name and function of parts hrs series 2.2 name and function of parts 2-3 2.2.2 hrs100/150-w ∗-20/40 (in case of water cooled type) fig. 2-3 names of the parts (this drawing shows “hrs150-w-20”.) table 2-2 accessory list ① alarm code list label 2pcs. (english 1pc. /japanese 1pc....

Page 18: 2.3 Function of Parts

Hrx-om-s004 chapter 2 name and function of parts 2.3 function of parts hrs series 2-4 2.3 function of parts the function of parts is as follows. Table 2-3 function of parts name function operation display panel runs and stops the product and performs settings such as the circulating fluid temperatur...

Page 19

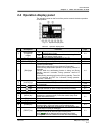

Hrx-om-s004 chapter 2 name and function of parts hrs series 2.4 operation display panel 2-5 2.4 operation display panel the operation panel on the front of the product controls the basic operation of the product. Fig. 2-4 operation display panel table 2-4 operation display panel no description funct...

Page 20

Hrx-om-s004 chapter 2 name and function of parts 2.4 operation display panel hrs series 2-6.

Page 21: 3.1 Transport

Hrx-om-s004 chapter 3 transport and setting up hrs series 3.1 transport 3-1 chapter 3 transport and setting up 3.1 transport the product is heavy and has potential danger at transport. Also, to prevent damage and breakage of the product, be sure to follow the instructions for shown below for transpo...

Page 22

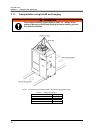

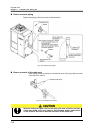

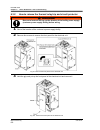

Hrx-om-s004 chapter 3 transport and setting up 3.1 transport hrs series 3-2 3.1.1 transportation using forklift and hanging fig 3-1 fork inserting and hanging position (this drawing is [hrs150-a-20].) table 3-1 weight of the product model weight kg hrs100-a ∗-20/40 approx. 171 hrs150-a ∗-20/40 appro...

Page 23

Hrx-om-s004 chapter 3 transport and setting up hrs series 3.1 transport 3-3 3.1.2 transportation using casters (hrs-ks001 / ks002) separately and after fastening it to the product.> fig. 3-2 transportation using casters (this drawing is [hrs150-a-20].) raise the adjuster feet and push the corners of...

Page 24: 3.2 Installation

Hrx-om-s004 chapter 3 transport and setting up 3.2 installation hrs series 3-4 3.2 installation 3.2.1 environment the product must not be operated, installed, stored or transported in the following conditions. Potential malfunction or damage to the product may occur if these instructions are disrega...

Page 25

Hrx-om-s004 chapter 3 transport and setting up hrs series 3.2 installation 3-5 z location that is subjected to static electricity, or conditions where static electricity can discharge to the product. Z location that is subjected to strong high frequencies raditation (microwaves). Z location that is ...

Page 26

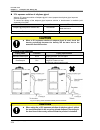

Hrx-om-s004 chapter 3 transport and setting up 3.2 installation hrs series 3-6 3.2.2 location installation of multiple products keep sufficient space between products so that the air vented from one product will not be taken in by other products. Installation at indoor site 1 in case of facility hav...

Page 27

Hrx-om-s004 chapter 3 transport and setting up hrs series 3.2 installation 3-7 required facility water system table 3-3 heat radiation model heat radiation kw facility water specifications hrs100-w ∗-20/40-∗ approx. 19 hrs150-w ∗-20/40-∗ approx. 28 refer to [8.1 specifications]. Installation at indo...

Page 28

Hrx-om-s004 chapter 3 transport and setting up 3.2 installation hrs series 3-8 3.2.3 installation and maintenance space it is recommended to keep the space around the product shown in fig. 3-3. Fig. 3-3 installation space (this drawing is [hrs150-a-20].) have an enough space for the ventilation for ...

Page 29: 3.3 Installation

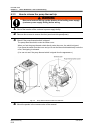

Hrx-om-s004 chapter 3 transport and setting up hrs series 3.3 installation 3-9 3.3 installation 3.3.1 installation how to mount the product 1. Insert the product to the anchor bolts that were previously driven on the level floor. 2. Fasten the nuts to the anchor bolts. 3. Make sure that there is no ...

Page 30

Hrx-om-s004 chapter 3 transport and setting up 3.3 installation hrs series 3-10 〈in case of purchasing option a or [caster adjuster-foot kit] (hrs-ks002/ks003)〉 refer to the operation manual for the separately sold accessory for the further details of the swivel caster and the adjuster foot set. Fig...

Page 31

Hrx-om-s004 chapter 3 transport and setting up hrs series 3.3 installation 3-11 3.3.2 electrical wiring do not modify the intenal electrical wiring of the product. Incorrect wiring may cause electrical shock or fire. Also, modifing the internal wiring will void the product’s warranty. Never connect ...

Page 32

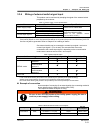

Hrx-om-s004 chapter 3 transport and setting up 3.3 installation hrs series 3-12 power supply specifications, power supply cable and earth leakage breaker prepare the power supply shown in the following table. For the connection between the product and power supply, use the power supply cable and ear...

Page 33

Hrx-om-s004 chapter 3 transport and setting up hrs series 3.3 installation 3-13 3.3.3 preparation and wiring of power supply cable be sure to lock out and tag out the breaker of the facility power supply (customer power supply facility) before wiring. Z the electrical facilities should be installed ...

Page 34

Hrx-om-s004 chapter 3 transport and setting up 3.3 installation hrs series 3-14 in case of option b [earth leakage breaker],hrs ∗∗∗-∗∗-40-∗ a breaker that has the operating characteristic below is installed. Please use a breaker that has the same or longer operating time as/than this for the user’s ...

Page 35

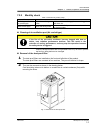

Hrx-om-s004 chapter 3 transport and setting up hrs series 3.3 installation 3-15 preparation for operation 1. Remove four screws to remove the front panel for the electrical unit. Fig. 3-6 remove the front panel for the electrical unit (this drawing shows air cooled type.) fig. 3-7 remove the front p...

Page 36

Hrx-om-s004 chapter 3 transport and setting up 3.3 installation hrs series 3-16 2. Hold the handle and put up the front panel of the electrical unit, and remove it. Fig. 3-8 remove the front panel of the electrical unit (this drawing shows air cooled type.) fig. 3-9 remove the front panel of the ele...

Page 37

Hrx-om-s004 chapter 3 transport and setting up hrs series 3.3 installation 3-17 3. Connect the power supply and the ground cable as shown in the figure below. Fig. 3-10 wiring of power supply cable ∗ connect over current protection to the user’s side (primary side) to avoid hazard..

Page 38

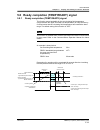

Hrx-om-s004 chapter 3 transport and setting up 3.3 installation hrs series 3-18 3.3.4 contact input/output communicatin wiring the product has a contact input/output communication function as shown below. Connect cables referring to the applicable chapter for each function. (for details of the funct...

Page 39

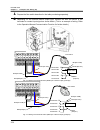

Hrx-om-s004 chapter 3 transport and setting up hrs series 3.3 installation 3-19 3.3.5 wiring of run/stop signal input・remote signal input run/stop signal input and remote signal input enable the product to operate/stop or switched dio remote and dio local remotely by applying a contact signal input....

Page 40

Hrx-om-s004 chapter 3 transport and setting up 3.3 installation hrs series 3-20 2. Connect the signal cable and switch to the terminal as follows. (this wiring is an example.) fig. 3-11 wiring of run/stop signal input・remote signal input (example) terminal no. 5 terminal no.13 terminal no.11 termina...

Page 41

Hrx-om-s004 chapter 3 transport and setting up hrs series 3.3 installation 3-21 3.3.6 wiring of external switch signal input this product can be monitored by sampling the signal of the external switch prepared by the customer. Table 3-7 power supply, contact specifications name terminal no. Specific...

Page 42

Hrx-om-s004 chapter 3 transport and setting up 3.3 installation hrs series 3-22 flow switch 3 6 5 11 terminal no. 14 blue(dc com) brown(dc 24v) black (output1) 11 6 13 3 14 terminal no. Terminal no. Terminal no. Terminal no. Blue(dc com) brown(dc 24v) black (output1) terminal no. Terminal no. Termin...

Page 43

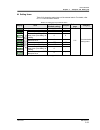

Hrx-om-s004 chapter 3 transport and setting up hrs series 3.3 installation 3-23 setting items table 3-10 shows the setting items of the external switch. For details, refer to 5.21 communication function. Table 3-10 setting list of the external switch display item initial value (default setting) exam...

Page 44

Hrx-om-s004 chapter 3 transport and setting up 3.3 installation hrs series 3-24 3.3.7 wiring of contact output signal contact output signals are the signals that output the status of this product. Contact specification of each signal output is shown below the specifications of the contact for each s...

Page 45

Hrx-om-s004 chapter 3 transport and setting up hrs series 3.3 installation 3-25 3.3.8 rs-485 communication wiring serial communication rs-485, operation start/stop, setting and reading of circulating fluid temperature, and reading of alarm condition can be done by remote control. Refer to the operat...

Page 46

Hrx-om-s004 chapter 3 transport and setting up 3.3 installation hrs series 3-26 3.3.9 rs-232c communication wiring serial communication rs-232c, operation start/stop, setting and reading of circulating fluid temperature, and reading of alarm condition can be performed by remote control. Refer to the...

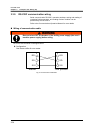

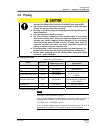

Page 47: 3.4 Piping

Hrx-om-s004 chapter 3 transport and setting up hrs series 3.4 piping 3-27 z connect piping firmly. Incorrect piping might cause leakage of supplied or drained fluid and wet surrounding area and facility. Z use caution not to allow dust and foreign matter to enter the water circuit, etc. During conne...

Page 48

Hrx-om-s004 chapter 3 transport and setting up 3.4 piping hrs series 3-28 how to connect piping tighten the piping to each connection as follows below. Fig. 3-16 tightening of piping how to connect to the drain port when piping the pump drain port, hold the ball valve of the pump drain port with a w...

Page 49

Hrx-om-s004 chapter 3 transport and setting up hrs series 3.4 piping 3-29 recommended piping circuit thermo chiller facility water outlet port (water cooled type) facility water inlet port (water cooled type) automatic flui-fill port circulationg fluid outlet port circulationg fluid return port over...

Page 50

Hrx-om-s004 chapter 3 transport and setting up 3.4 piping hrs series 3-30 install the drain pan for the pump this product uses the pump that uses mechanical seal. Install the of accessory under the pump. If the leakage is found, replace the mechanical seal. Order the mechanical seal described in “7....

Page 51

Hrx-om-s004 chapter 3 transport and setting up hrs series 3.5 circulating fluid supply 3-31 3.5 circulating fluid supply 3.5.1 automatic fluid-fill function open the fluid supply valve that is connected to the automatic water fill port. Fluid supply starts and stops automatically with the ball tap i...

Page 52

Hrx-om-s004 chapter 3 transport and setting up 3.5 circulating fluid supply hrs series 3-32 15% aqueous solution of ethylene glycol when a 15% aqueous solution of ethylene glycol is used, prepare the ethylene glycol aqueous solution separately. To control the density of the ethylene glycol aqueous s...

Page 53

Hrx-om-s004 chapter 3 transport and setting up hrs series 3.5 circulating fluid supply 3-33 3.5.2 fill of fluid without using auto fluid-fill function to supply the circulating fluid without using automatic fluid-fill function, remove the upper panel on the right side, and supply the fluid to the fl...

Page 54

Hrx-om-s004 chapter 3 transport and setting up 3.5 circulating fluid supply hrs series 3-34 3. Supply the circulating fluid to the water fill port. Please supply the circulating fluid to the fluid level between “high” and “low” levels of the fluid level gauge. Fig. 3-24 supplying the fluid to the fl...

Page 55

Hrx-om-s004 chapter 3 transport and setting up hrs series 3.5 circulating fluid supply 3-35 3.5.3 for option k “fluid-fill port” open the cap of the fluid-fill port and supply the circulating fluid to the fluid level between “high” and “low” levels of the fluid level gauge. Close the cap after suppl...

Page 56

Hrx-om-s004 chapter 3 transport and setting up 3.5 circulating fluid supply hrs series 3-36.

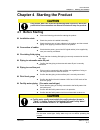

Page 57: 4.1 Before Starting

Hrx-om-s004 chapter 4 starting the product hrs series 4.1 before starting 4-1 chapter 4 starting the product 4.1 before starting z check the following points before starting the product. Installation state z check the product is installed horizontally. Z check that there are no heavy objects on the ...

Page 58: 4.2 Preparation For Start

Hrx-om-s004 chapter 4 starting the product 4.2 preparation for start hrs series 4-2 4.2 preparation for start 4.2.1 power supply turn on the breaker of the user’s power supply. When the product is switched on, the operation panel display operates as shown below: z the initial screen (hello screen) i...

Page 59

Hrx-om-s004 chapter 4 starting the product hrs series 4.2 preparation for start 4-3 press 4.2.3 for hrs100/150-**-40 turn on the breaker handle. The status will become the clause 4.2.1 power supply. Fig. 4-2 position of the breaker handle (this drawing shows “hrs150-a-40”.) 4.2.4 setting of circulat...

Page 60

Hrx-om-s004 chapter 4 starting the product 4.3 preparation of circulating fluid hrs series 4-4 4.3 preparation of circulating fluid circulating fluid is supplied only inside of the product at the time of installation of the thermo-chiller. When the product starts operation in this condition, circula...

Page 61

Hrx-om-s004 chapter 4 starting the product hrs series 4.3 preparation of circulating fluid 4-5 5. Press the [reset] button (press the [▼] and [▲] buttons simultaneously) to stop the alarm buzzer. Fig. 4-6 alarm receipt 6. Fluid supply using automatic water fill function has been started. Operation s...

Page 62

Hrx-om-s004 chapter 4 starting the product 4.3 preparation of circulating fluid hrs series 4-6 7. Press the [reset] button (press the [▼] and [▲] buttons simultaneously) to reset the alarm. Pressing these buttons at the same time resets the alarm (low level in tank) and turns off the [alarm] led (re...

Page 63

Hrx-om-s004 chapter 4 starting the product hrs series 4.4 operation start and stop 4-7 4.4 operation start and stop 4.4.1 starting the product before starting, check the items specified in “4.1 before starting” if any alarm light remains on, refer to chapter 6 alarm notification and troubleshooting”...

Page 64

Hrx-om-s004 chapter 4 starting the product 4.4 operation start and stop hrs series 4-8 except in case of emergency, do not turn off the breaker until the product has stopped completely. Otherwise it may cause a failure. 4.4.2 stopping the product 1. Press the [run/stop] button on the operation panel...

Page 65

Hrx-om-s004 chapter 4 starting the product hrs series 4.5 check items during startup 4-9 4.5 check items during startup check the following items after starting the product. Z confirm that there is leakage from the piping. Z confirm that no circulating fluid is discharged from the pump drain port. Z...

Page 66

Hrx-om-s004 chapter 4 starting the product 4.6 adjustment of circulating fluid flow rate hrs series 4-10

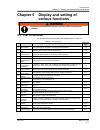

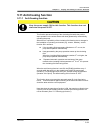

Page 67: Various Functions

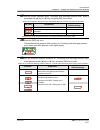

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.1 list of function 5-1 chapter 5 display and setting of various functions 5.1 list of function the product can have the displays and settings shown in table 5-1. Table 5-1 list of function no function outline reference page ...

Page 68: 5.2 Function

Hrx-om-s004 chapter 5 display and setting of various functions 5.2 function hrs series 5-2 5.2 function 5.2.1 key operations fig. “key operation (1/2)” and “key operation (2/2)” shows the operation of keys of the thermo-chiller. By pressing the “sel” key for 2 seconds, the pv display blinks and func...

Page 69

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.2 function 5-3 menu changing of contact input signal 1 detection alarm buzzer sound changing of low tank level changing of circulating fluid discharge temperature rise detection temperature for circulating fluid discharge te...

Page 70

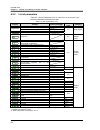

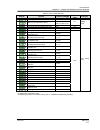

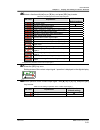

Hrx-om-s004 chapter 5 display and setting of various functions 5.2 function hrs series 5-4 5.2.2 list of parameters “table 5.2-1 list of parameters (1/3)” to “ table 5.2-3 list of parameter (3/3) ” show the parameters of the thermo-chiller. Table 5.2-1 list of parameters (1/3) display content defaul...

Page 71

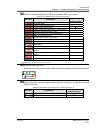

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.2 function 5-5 table 5.2-2 list of parameter (2/3) display content default setting ∗4 reference page category warming up function off warming up temperature setting ---- (20.0 o c (68.0 ゚ f) ∗6 5.17 anti-snow coverage functi...

Page 72

Hrx-om-s004 chapter 5 display and setting of various functions 5.2 function hrs series 5-6 table 5.2-3 list of parameter (3/3) display content default setting reference page category changing of circulating fluid pressure sensor error a.Stp changing of the pump maintenance a.Stp changing of the fan ...

Page 73: 5.3 Main Display

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.3 main display 5-7 5.3 main display 5.3.1 main display the current temperature and the set temperature of the circulating fluid are shown on the main display, and the main display allows the set temperature to be changed. 5....

Page 74: 5.4

Hrx-om-s004 chapter 5 display and setting of various functions 5.4 alarm menu hrs series 5-8 5.4 alarm menu 5.4.1 alarm menu the alarm display appears when an alarm is generated. ∗ the alarm menu is not be accessible when no alarm has been generated. ∗ refer to “chapter 6 alarm notification and trou...

Page 75: 5.5 Check Monitor Menu

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.5 check monitor menu 5-9 5.5 check monitor menu 5.5.1 check monitor menu as a part of the daily inspection, the temperature, pressure and accumulated operating time can be checked. Please use this for confirmation of your da...

Page 76

Hrx-om-s004 chapter 5 display and setting of various functions 5.5 check monitor menu hrs series 5-10 checking: circulating fluid temperature at the heat exchanger inlet 2. Press the [sel] key once. Display of the circulating fluid temperature returned to the return port appears on the digital displ...

Page 77

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.5 check monitor menu 5-11 checking: refrigerant circuit pressure on the low pressure side 6. Press the [sel] key once. Display of the refrigerant circuit pressure on the low pressure side appears on the digital display. Chec...

Page 78: 10.

Hrx-om-s004 chapter 5 display and setting of various functions 5.5 check monitor menu hrs series 5-12 checking: accumulated operating time of the compressor 9. Press the [sel] key once. Display of the accumulated operating time of the compressor appears on the digital display. Pv sv refer to “ table...

Page 79: 5.6 Key-Lock

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.6 key-lock 5-13 5.6 key-lock 5.6.1 key-lock the buttons can be locked to prevent the settings being changed by an operator error. Operation can be started/stopped by operating the “run/stop” key even when the button-lock is ...

Page 80

Hrx-om-s004 chapter 5 display and setting of various functions 5.6 key-lock hrs series 5-14 5.6.2 key-lock setting / checking the table below explains the setting items of the key-lock function and the initial values. Table 5.6-1 set items for key -lock display item contents default key-lock sets th...

Page 81

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.7 run timer, stop timer function 5-15 5.7 run timer, stop timer function 5.7.1 run timer and stop timer function this function starts or stops operation of the product automatically when the set time has passed. The time can...

Page 82

Hrx-om-s004 chapter 5 display and setting of various functions 5.7 run timer, stop timer function hrs series 5-16 timer setting example now 1h 2h 3h 4h 5h 6h 7h 8h stopped operating ・・・ run timer set to start after 3hours ↑operating now 1h 2h 3h 4h 5h 6h 7h 8h operating stopped ・・・ stop timer set to...

Page 83

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.7 run timer, stop timer function 5-17 5.7.2 setting and checking of run timer and stop timer function the table below explains the setting items of the run/stop timer and the initial values. Table 5.7-1 setting of run timer ...

Page 84

Hrx-om-s004 chapter 5 display and setting of various functions 5.7 run timer, stop timer function hrs series 5-18 setting/checking: stop timer 4. Press the [sel] key once. Setting screen of the stop timer appears on the digital display. Pv sv 5. Select stop timer with the [▲] key or the [▼] key, and...

Page 85

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.8 ready completion (temp ready) signal 5-19 5.8 ready completion (temp ready) signal 5.8.1 ready completion (temp ready) signal this function sets a bandwidth for the set circulating fluid temperature (range between the uppe...

Page 86

Hrx-om-s004 chapter 5 display and setting of various functions 5.8 ready completion (temp ready) signal hrs series 5-20 5.8.2 ready completion (temp ready) signal setting / checking the table below shows explanation and default of the set items for ready completion (temp ready) signal. Table 5.8-1 s...

Page 87

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.8 ready completion (temp ready) signal 5-21 5. Select ready bandwidth with [▲] key or [▼] key, and enter by pressing the [sel] key. Table 5.8-3 set value for ready mode set value explanation default sets ready bandwidth (ran...

Page 88: 5.9 Offset Function

Hrx-om-s004 chapter 5 display and setting of various functions 5.9 offset function hrs series 5-22 5.9 offset function 5.9.1 offset function this is a function that controls the "circulating fluid display temperature" and the "target temperature for chiller temperature control" by shifting the tempe...

Page 89

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.9 offset function 5-23 5.9.2 usage example of offset function suppose that the circulating fluid discharge temperature of this thermo-chiller is 30 o c and the circulating fluid temperature that enters the user's equipment i...

Page 90

Hrx-om-s004 chapter 5 display and setting of various functions 5.9 offset function hrs series 5-24 ■ when only the "displayed circulating fluid temperature" needs to be the same as the circulating temperature supplied to the user's equipment: use "mode 2" of the offset function, and set the offset t...

Page 91

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.9 offset function 5-25 5.9.3 setting/checking of offset function the table below shows the set items of the offset function and the default values. Table 5.9-2 set items for offset function display item contents default offs...

Page 92

Hrx-om-s004 chapter 5 display and setting of various functions 5.9 offset function hrs series 5-26 setting/checking: offset temperature 4. Press the [sel] key once. Setting screen of offset temperature appears on the digital display. Pv sv 5. Set offset temperature with [▲] key or [▼] key, and press...

Page 93

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.10 operation restoration after power failure 5-27 5.10 operation restoration after power failure 5.10.1 operation restoration function after power failure when the power supply is cut due to power failure, etc., this functio...

Page 94

Hrx-om-s004 chapter 5 display and setting of various functions 5.10 operation restoration after power failure hrs series 5-28 5.10.2 setting/checking of the operation restoration function the table below shows the setting items of the operation restoration after power failure function and the defaul...

Page 95: 5.11 Anti-Freezing Function

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.11 anti-freezing function 5-29 5.11 anti-freezing function 5.11.1 anti-freezing function this function prevents freezing of the circulating fluid while the product stops operation in the winter season with heat generated by ...

Page 96

Hrx-om-s004 chapter 5 display and setting of various functions 5.11 anti-freezing function hrs series 5-30 z this function can be activated only when the power supply is on and the thermo-chiller is not operating. Z fully open the valve or manual bypass valve that is arranged by the user to make it ...

Page 97

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.11 anti-freezing function 5-31 5.11.2 setting/checking of anti-freezing function the table below shows the set item of the anti-freezing function and the default setting. Table 5.11-1 set item for anti-freezing function disp...

Page 98

Hrx-om-s004 chapter 5 display and setting of various functions 5.12 key operation sound setting hrs series 5-32 5.12 key operation sound setting 5.12.1 key operation sound setting operation sound (click sound) of the buttons on the operation panel can be set on/off. Default setting is button operati...

Page 99

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.13 temperature unit change 5-33 5.13 temperature unit change 5.13.1 temperature unit change the temperature unit used for the thermo-chiller can be selected celsius ( o c) or fahrenheit ( o f). This setting determines the te...

Page 100: 5.14 Pressure Unit Change

Hrx-om-s004 chapter 5 display and setting of various functions 5.14 pressure unit change hrs series 5-34 5.14 pressure unit change 5.14.1 pressure unit change pressure unit used for the thermo-chiller can be selected mpa or psi. This setting determines the pressure unit which is displayed/output. Th...

Page 101: 5.15 Data Reset Function

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.15 data reset function 5-35 5.15 data reset function 5.15.1 data reset function resets the values set by user to the default values. Note that the accumulated operating time will not be reset. 5.15.2 how to operate reset fun...

Page 102

Hrx-om-s004 chapter 5 display and setting of various functions 5.16 accumulated operating time reset function hrs series 5-36 5.16 accumulated operating time reset function 5.16.1 accumulated operating time reset function the alarms shown below will be generated to notify the maintenance timing. The...

Page 103

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.16 accumulated operating time reset function 5-37 2. Press the [sel] key 14 times. Resetting screen of the pump accumulated operating time appears on the digital display. Pv sv 3. Select with [▲] key or [▼] key, and press [s...

Page 104

Hrx-om-s004 chapter 5 display and setting of various functions 5.16 accumulated operating time reset function hrs series 5-38 reset of accumulated operating time 7. Press and hold the [menu] key for approximately 2 seconds. Repeat pressing the key until the button-lock setting screen [ ] appears on ...

Page 105: 10.

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.16 accumulated operating time reset function 5-39 reset of the accumulated operating time of the dust-proof filter 10. Press and hold the [menu] key for approximately 2 seconds. Repeat pressing the key until the button-lock ...

Page 106: 5.17 Warming Up Function

Hrx-om-s004 chapter 5 display and setting of various functions 5.17 warming up function hrs series 5-40 5.17 warming up function 5.17.1 warming up function this function maintains the circulating fluid temperature to the set warming-up temperature with heat generated by automatically operating the p...

Page 107

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.17 warming up function 5-41 5.17.2 setting/checking of warming up function the table below shows the setting items of the warming up function and the default setting. Table 5.17-1 set item for warming up function display ite...

Page 108

Hrx-om-s004 chapter 5 display and setting of various functions 5.17 warming up function hrs series 5-42 5. Set the warming up temperature with [▲] key or [▼] key, and press [sel] key to enter. Table 5.17-3 setting of warming up temperature set value explanation initial value (default setting) settin...

Page 109

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.18 anti-snow coverage function 5-43 5.18 anti-snow coverage function 5.18.1 anti-snow coverage function this function prevents snow coverage on the exhaust port on top of the product during the winter time by automatically o...

Page 110

Hrx-om-s004 chapter 5 display and setting of various functions 5.18 anti-snow coverage function hrs series 5-44 5.18.2 setting/checking of anti-snow coverage function the table below shows the set item of the anti-snow coverage function and the default setting. Table 5.18-1 set item for anti-snow co...

Page 111

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.19 alarm buzzer sound setting 5-45 5.19 alarm buzzer sound setting 5.19.1 alarm buzzer sound setting this sets whether a warning sound is made or not when alarm signal is output. The default setting is buzzer sound on. 5.19....

Page 112

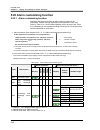

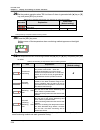

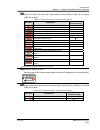

Hrx-om-s004 chapter 5 display and setting of various functions 5.20 alarm customizing function hrs series 5-46 5.20 alarm customizing function 5.20.1 alarm customizing function operation and trigger level when an alarm signal is output can be customized. Perform settings depending on the application...

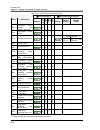

Page 113

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.20 alarm customizing function 5-47 table 5.20-2 alarm setting and customizing (2/4) ① alarm operations ② alarm threshold and others ∗4 code alarm name display a.Stp a.R un p.Run off display default setting settable range set...

Page 114

Hrx-om-s004 chapter 5 display and setting of various functions 5.20 alarm customizing function hrs series 5-48 table 5.20-3 alarm setting and customizing (2/4) ① alarm operations ② alarm threshold and others code alarm name display a.Stp a.R u n p.Ru n off display default setting settable range al17...

Page 115

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.20 alarm customizing function 5-49 table 5.20-4 alarm setting and customizing (2/4) ① alarm operations ② alarm threshold and others code alarm name display a.Stp a.R un p.Run off display default setting settable range al40 d...

Page 116

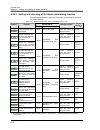

Hrx-om-s004 chapter 5 display and setting of various functions 5.20 alarm customizing function hrs series 5-50 5.20.2 setting and checking of the alarm customizing function the table below shows the set items of the alarm customizing function and the default settings. Table 5.20-5 default settings o...

Page 117

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.20 alarm customizing function 5-51 table 5.20-6 default settings of the alarm customizing function (2/3) object alarm display content code alarm name change content default setting operation setting when "dc line fuse cut" a...

Page 118

Hrx-om-s004 chapter 5 display and setting of various functions 5.20 alarm customizing function hrs series 5-52 table 5.20-7 default settings of the alarm customizing function (3/3) object alarm display content code alarm name change content initial setting operation setting when "circulating fluid d...

Page 119

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.20 alarm customizing function 5-53 1. Press and hold the [menu] key for approximately 2 seconds. Repeat pressing the key until the alarm buzzer sound setting screen [ ] appears on the digital display. Pv sv pv sv pv sv pv sv...

Page 120

Hrx-om-s004 chapter 5 display and setting of various functions 5.20 alarm customizing function hrs series 5-54 setting/checking: threshold temperature setting for "detection temp. For the circulating fluid discharge temp. Increase" alarm 6. Press the [sel] key once. Threshold detecting temperature s...

Page 121: 10.

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.20 alarm customizing function 5-55 setting/checking: threshold detecting temperature setting for "circulating fluid discharge temp. Drop" alarm generation 10. Press the [sel] key once. Threshold detecting temperature setting...

Page 122: 14.

Hrx-om-s004 chapter 5 display and setting of various functions 5.20 alarm customizing function hrs series 5-56 setting/checking: threshold pressure setting for "circulating fluid discharge pressure rise" alarm 14. Press the [sel] key once. Threshold detecting pressure setting screen for "circulating...

Page 123: 17.

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.20 alarm customizing function 5-57 17. Set the product operation when "circulating fluid discharge pressure drop" alarm is generated with [▲] key or [▼] key, and press [sel] key to enter. Table 5.20-15 operation setting when...

Page 124: 20.

Hrx-om-s004 chapter 5 display and setting of various functions 5.20 alarm customizing function hrs series 5-58 setting/checking: operation setting when "communication error" alarm is generated 20. Press the [sel] key once. Operation setting screen when "communication error" alarm is generated appear...

Page 125: 25.

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.20 alarm customizing function 5-59 25. Set the product operation when "contact input 1 signal detection" alarm is generated with [▲] key or [▼] key, and press [sel] key to enter. Table 5.20-19 operation setting when "contact...

Page 126: 29.

Hrx-om-s004 chapter 5 display and setting of various functions 5.20 alarm customizing function hrs series 5-60 29. Set the product operation when "dc line fuse cut" alarm is generated with [▲] key or [▼] key, and press [sel] key to enter. Table 5.20-21 operation setting when "dc line fuse cut" alarm...

Page 127: 32.

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.20 alarm customizing function 5-61 setting/checking: monitoring start timer 32. Press the [sel] key once. Setting screen of the monitoring start timer is displayed on the digital display. Pv sv 33. Set monitoring start timer...

Page 128

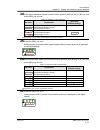

Hrx-om-s004 chapter 5 display and setting of various functions 5.20 alarm customizing function hrs series 5-62 5.20.3 setting of temperature alarm monitoring method and alarm generation timing examples of temperature alarm monitoring method setting and alarm generation timing are shown below. When "...

Page 129

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.20 alarm customizing function 5-63 when "automatic monitoring + monitoring start timer" is selected [1] circulating fluid temperature when starting operation: approximately 20 o c [2] circulating fluid set temperature : 15 o...

Page 130: 36.

Hrx-om-s004 chapter 5 display and setting of various functions 5.20 alarm customizing function hrs series 5-64 setting/checking: operation when compressor related alarms are generated 36. Press the [sel] key once. Setting screen of the product operation when compressor related alarms are generated a...

Page 131: 38.

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.20 alarm customizing function 5-65 setting/checking: operation setting when "circulating fluid discharge pressure sensor error" alarm is generated 38. Press the [sel] key once. Operation setting screen when "circulating flui...

Page 132: 42.

Hrx-om-s004 chapter 5 display and setting of various functions 5.20 alarm customizing function hrs series 5-66 setting/checking: operation setting when "fan maintenance" alarm is generated 42. Press the [sel] key once. Operation setting screen when "fan maintenance" alarm is generated appears on the...

Page 133: 46.

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.20 alarm customizing function 5-67 setting/checking: operation setting when "dust-proof filter maintenance" alarm is generated 46. Press the [sel] key once. Operation setting screen when "dust-proof filter maintenance" alarm...

Page 134: 50.

Hrx-om-s004 chapter 5 display and setting of various functions 5.20 alarm customizing function hrs series 5-68 setting/checking: monitoring time for maintenance of dustproof filter 50. Press the [sel] key once. Setting screen of the monitoring time before "dust-proof filter maintenance" alarm is gen...

Page 135

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.21 communication function 5-69 5.21 communication function 5.21.1 communication function contact input/output and serial communication can be performed. Refer to the operation manual communication function for more details 5...

Page 136

Hrx-om-s004 chapter 5 display and setting of various functions 5.21 communication function hrs series 5-70 setting/checking: communication mode 1. Press and hold the [menu] key for approximately 2 seconds. Repeat pressing the button until the communication mode setting screen [ ] appears on the digi...

Page 137

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.21 communication function 5-71 4. Select a serial communication protocol with [▲] key or [▼] key, and press [sel] key to enter. Table 5.21-3 setting of serial communication protocol set value explanation initial value (defau...

Page 138: 10.

Hrx-om-s004 chapter 5 display and setting of various functions 5.21 communication function hrs series 5-72 setting/checking: slave addresses (modbus) 9. Press the [sel] key once. Setting screen of slave addresses (modbus) is displayed on the digital display. Pv sv 10. Set slave addresses (modbus) wi...

Page 139: 14.

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.21 communication function 5-73 14. S set slave addresses (simple communication protocol) with [▲] key or [▼] key, and press [sel] key to enter. Table 5.21-8 setting of slave addresses set value explanation initial value (def...

Page 140: 18.

Hrx-om-s004 chapter 5 display and setting of various functions 5.21 communication function hrs series 5-74 18. Set bcc (simple communication protocol) with [▲] key or [▼] key, and press [sel] key to enter. Table 5.21-10 bcc setting set value explanation initial value (default setting) setting/checki...

Page 141: 22.

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.21 communication function 5-75 22. Perform setting for parity check (simple communication protocol) with [▲] key or [▼] key, and press [sel] key to enter. Table 5.21-12 parity check setting set value explanation initial valu...

Page 142: 26.

Hrx-om-s004 chapter 5 display and setting of various functions 5.21 communication function hrs series 5-76 26. Set responce delay time (simple communication protocol) with [▲] key or [▼] key, and press [sel] key to enter. Table 5.21-14 setting of response delay time set value explanation initial val...

Page 143: 30.

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.21 communication function 5-77 30. Perform setting for the contact input signal 1 with [▲] key or [▼] key, and press [sel] key to enter. Table 5.21-16 setting for contact input signal 1 set value explanation initial value (d...

Page 144: 34.

Hrx-om-s004 chapter 5 display and setting of various functions 5.21 communication function hrs series 5-78 34. Set time delay for the contact input signal 1 delay timer for reading with [▲] key or [▼] key, and press [sel] key to enter. Table 5.21-18 setting of time delay for contact input signal del...

Page 145: 38.

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.21 communication function 5-79 38. Perform setting of the contact input signal 2 with [▲] key or [▼] key, and press [sel] key to enter. Table 5.21-20 setting of the contact input signal 2 set value explanation initial value ...

Page 146: 42.

Hrx-om-s004 chapter 5 display and setting of various functions 5.21 communication function hrs series 5-80 42. Set time delay for the contact input signal 2 delay timer for reading with [▲] key or [▼] key, and press [sel] key to enter. Table 5.21-22 setting of time delay for the contact input signal...

Page 147: 46.

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.21 communication function 5-81 46. Select a function with [▲] key or [▼] key, and press [sel] key to enter. Table 5.21-24 setting for the contact output signal 1 set value explanation initial value (default setting) no signa...

Page 148: 49.

Hrx-om-s004 chapter 5 display and setting of various functions 5.21 communication function hrs series 5-82 setting/checking: selected alarm for contact output signal 1 49. Press the [sel] key once. Setting screen of selected alarm of the contact output signal 1 is displayed on the digital display. P...

Page 149: 52.

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.21 communication function 5-83 52. Select a function with [▲] key or [▼] key, and press [sel] key to enter. Table 5.21-27 setting for the contact output signal 2 set value explanation initial value (default setting) no signa...

Page 150: 55.

Hrx-om-s004 chapter 5 display and setting of various functions 5.21 communication function hrs series 5-84 setting/checking: selected alarm for contact output signal 2 55. Press the [sel] key once. Setting screen of selected alarm of the contact output signal 2 is displayed on the digital display. P...

Page 151: 58.

Hrx-om-s004 chapter 5 display and setting of various functions hrs series 5.21 communication function 5-85 58. Select a function for the contact output signal 3 with [▲] key or [▼] key, and press [sel] key to enter. Table 5.21-30 function setting for the contact output signal 3 set value explanation...

Page 152: 61.

Hrx-om-s004 chapter 5 display and setting of various functions 5.21 communication function hrs series 5-86 setting/checking: selected alarm for contact output signal 3 61. Press the [sel] key once. Setting screen of the selected alarm of the contact output signal 3 is displayed on the digital displa...

Page 153: Troubleshooting

Hrx-om-s004 chapter 6 alarm notification and troubleshooting hrs series 6.1 alarm notification 6-1 chapter 6 alarm notification and troubleshooting 6.1 alarm notification z the product makes notification in the order shown below when any alarm is generated. The [alarm] light blinks. Z the alarm buzz...

Page 154

Hrx-om-s004 chapter 6 alarm notification and troubleshooting 6.1 alarm notification hrs series 6-2 z when multiple alarms are generated, the alarm codes are displayed one by one by pressing the [sel] button alarm with the number ”1” in the sv window on the digital display is the latest alarm. The al...

Page 155: 6.2 Alarm Buzzer Stop

Hrx-om-s004 chapter 6 alarm notification and troubleshooting hrs series 6.2 alarm buzzer stop 6-3 6.2 alarm buzzer stop an alarm buzzer sounds to notify when any alarms are generated. How to stop the alarm buzzer is explained below. Z confirm that the alarm display is shown. The alarm buzzer can be ...

Page 156: 6.3 Troubleshooting

Hrx-om-s004 chapter 6 alarm notification and troubleshooting 6.3 troubleshooting hrs series 6-4 6.3 troubleshooting 6.3.1 alarm contents, causes, and troubleshooting troubleshooting method varies depending on which alarm has been generated. Refer to ’’ table 6-1 to table 6-3 ’’. Instructions to rese...

Page 157

Hrx-om-s004 chapter 6 alarm notification and troubleshooting hrs series 6.3 troubleshooting 6-5 table 6-1 alarm codes and troubleshooting (1/3) code alarm name alarm operation (default setting) cause / remedy (press the reset key after eliminating the cause.) al01 low level in tank a.Run fluid level...

Page 158

Hrx-om-s004 chapter 6 alarm notification and troubleshooting 6.3 troubleshooting hrs series 6-6 table 6-2 alarm codes and troubleshooting (2/3) code alarm name alarm operation*1 (default setting) cause / remedy (press the reset key after eliminating the cause.) al18 compressor running failure p.Run ...

Page 159

Hrx-om-s004 chapter 6 alarm notification and troubleshooting hrs series 6.3 troubleshooting 6-7 table 6-3 alarm codes and troubleshooting (3/3) code alarm name alarm operation*1 (default setting) cause / remedy (press the reset key after eliminating the cause.) al41 power stoppage a.Stp power supply...

Page 160

Hrx-om-s004 chapter 6 alarm notification and troubleshooting 6.3 troubleshooting hrs series 6-8 6.3.2 how to release the thermal relay trip and circuit protector 1. Shut of the breaker of the customer’s power supply facility. 2. Remove four screws to remove the front panel for the electrical unit. F...

Page 161

Hrx-om-s004 chapter 6 alarm notification and troubleshooting hrs series 6.3 troubleshooting 6-9 4. Confirm if the thermal relay or the circuit protector are tripped. If the thermal relay tripped, push the reset buttan. If the circuit protector tripped, make it on by pushing up the lever. Fig. 6-3 th...

Page 162

Hrx-om-s004 chapter 6 alarm notification and troubleshooting 6.3 troubleshooting hrs series 6-10 6.3.3 how to release the pump thermal trip 1. Shut of the breaker of the customer’s power supply facility. 2. Remove four screws to remove the front panel and side panel(lower). 3. Check if the pump ther...

Page 163: 6.4 Other Errors

Hrx-om-s004 chapter 6 alarm notification and troubleshooting hrs series 6.4 other errors 6-11 6.4 other errors how to check other errors the causes and remedies for failures that are not indicated by alarm numbers are shown in ’’table 6-5 ’’. Table 6-5 possible causes and countermeasures for failure...

Page 165: Cleaning

Hrx-om-s004 chapter 7 control, inspection and cleaning hrs series 7.1 quality control of circulating fluid and facility water 7-1 chapter 7 control, inspection and cleaning 7.1 quality control of circulating fluid and facility water table 7-1 quality criteria for clean water (tap water) standard val...

Page 166

Hrx-om-s004 chapter 7 control, inspection and cleaning 7.2 inspection and cleaning hrs series 7-2 7.2 inspection and cleaning 7.2.1 daily check check the items listed below. If any abnormality is found, stop the operation of the product and turn the power supply off, and ask for service. Table 7-2 d...

Page 167

Hrx-om-s004 chapter 7 control, inspection and cleaning hrs series 7.2 inspection and cleaning 7-3 7.2.2 monthly check table 7-3 contents of monthly check item contents of check ventilating condition (air cooled type) clean the ventilating grilles. Make sure the ventilating grilles are not clogged wi...

Page 168

Hrx-om-s004 chapter 7 control, inspection and cleaning 7.2 inspection and cleaning hrs series 7-4 cleaning of dust-proof filter clean the dust-proof filters with a long bristled brush or by air blow. Fig. 7-2 cleaning of the dust-proof filter mounting of dust-proof filters reassemble the filters in ...

Page 169

Hrx-om-s004 chapter 7 control, inspection and cleaning hrs series 7.2 inspection and cleaning 7-5 replacement of circulating fluid z replace the circulating fluid with new clean fluid periodically, or it may get algae or decompose. Z circulating fluid to be supplied in the tank should satisfy the wa...

Page 170

Hrx-om-s004 chapter 7 control, inspection and cleaning 7.2 inspection and cleaning hrs series 7-6 7.2.4 inspection every 6 months check for water leakage from pump remove the panel and check the pump for excessive leakage. If the leakage is found, replace the mechanical seal. Order the mechanical se...

Page 171: 7.3 Consumables

Hrx-om-s004 chapter 7 control, inspection and cleaning hrs series 7.3 consumables 7-7 7.2.5 inspection during winter season anti-freezing function this function prevents freezing of the circulating fluid while the product stops operation in the winter season with heat generated by automatically oper...

Page 172

Hrx-om-s004 chapter 7 control, inspection and cleaning 7.4 operation stop for an extended period of time hrs series 7-8 7.4 operation stop for an extended period of time if there is a concern that the product will not be operated for an extended period of time or there is a possibility of freezing i...

Page 173

Hrx-om-s004 chapter 7 control, inspection and cleaning hrs series 7.4 operation stop for an extended period of time 7-9 7.4.2 discharge of the facility water (water-cooled type) 1. Turn off the earth leakage breaker of the user’s power supply. 2. Stop supplying the facility water, and make sure that...

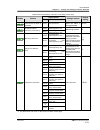

Page 175: Chapter 8 Documents

Hrx-om-s004 chapter 8 documents hrs series 8.1 specifications 8-1 chapter 8 documents 8.1 specifications 8.1.1 hrs100/150-a ∗-20-∗ table 8-1 specifications [hrs100/150-a ∗-20-∗] model hrs100-a ∗-20-∗ hrs150-a ∗-20-∗ cooling method air-cooled refrigerated type refrigerant r410a (hfc) control method p...

Page 176

Hrx-om-s004 chapter 8 documents 8.1 specifications hrs series 8-2 8.1.2 hrs100/150-a ∗-40-∗ table 8-2 specifications [hrs100/150-a ∗-40-∗] model hrs100-a ∗-40-∗ hrs150-a ∗-40-∗ cooling method air-cooled refrigerated type refrigerant r410a (hfc) control method pidcontrol ambient temperature ∗1 o c -5...

Page 177

Hrx-om-s004 chapter 8 documents hrs series 8.1 specifications 8-3 8.1.3 hrs100/150-w ∗-20-∗ table 8-3 specifications[hrs100/150-w ∗-20-∗] model hrs100-w ∗-20-∗ hrs150-w ∗-20-∗ cooling method water-cooled refrigerated type refrigerant r410a (hfc) control method pidcontrol ambient temperature ∗1 o c 2...

Page 178

Hrx-om-s004 chapter 8 documents 8.1 specifications hrs series 8-4 8.1.4 hrs100/150-w ∗-40-∗ table 8-4 specifications[hrs100/150-w ∗-40-∗] model hrs100-w ∗-40-∗ hrs150-w ∗-40-∗ cooling method water-cooled refrigerated type refrigerant r410a (hfc) control method pidcontrol ambient temperature ∗1 o c 2...

Page 179

Hrx-om-s004 chapter 8 documents hrs series 8.1 specifications 8-5 8.1.5 communication specification regarding the communication specification, refer to the operation manual communication function, hrx-om-s010..

Page 180: 8.2 Outline Dimensions

Hrx-om-s004 chapter 8 documents 8.2 outline dimensions hrs series 8-6 8.2 outline dimensions 8.2.1 hrs100/150-a ∗-20/40-∗ fig. 8-1 outline dimensions dimensions for the positions of the anchor bolts (view a-a) in case of hrs150 954mm(37.6in) 616mm(24.3in) 1434 mm( 5 6.5 in) a a 954mm(37.6in) 670mm(2...

Page 181

Hrx-om-s004 chapter 8 documents hrs series 8.2 outline dimensions 8-7 8.2.2 hrs100/150-w ∗-20/40-∗ fig. 8-2 outline dimensions dimensions for the positions of the anchor bolts (view a-a) 715mm(28.1in) 687mm(27in) 12 35 mm (48 .6i n ) a a 687mm(27in) 715mm(28.1in) 12 35 mm (48 .6 in ) 687mm(27in ) 61...

Page 182: 8.3 Flow Diagram

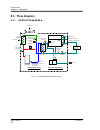

Hrx-om-s004 chapter 8 documents 8.3 flow diagram hrs series 8-8 8.3 flow diagram 8.3.1 hrs100/150-a ∗-20/40-∗ compressor expansion valve b expansion valve a dryer press. Sensor (ref. High press.) heat exchanger press. Sensor (ref. Low press.) fan level switch ball tap press. Sensor (outlet) temp. Se...

Page 183

Hrx-om-s004 chapter 8 documents hrs series 8.3 flow diagram 8-9 8.3.2 hrs100/150-w ∗-20/40-∗ compressor expansion valve b expansion valve a dryer press. Sensor (ref. High press.) heat exchanger press. Sensor (ref. Low press.) level switch ball tap press. Sensor (outlet) temp. Sensor (outlet) fluid l...

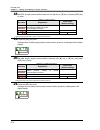

Page 184: 8.4 Cooling Capacity

Hrx-om-s004 chapter 8 documents 8.4 cooling capacity hrs series 8-10 8.4 cooling capacity 8.4.1 hrs100-a ∗-20/40-∗ fig. 8-5 cooling capacity(hrs100-a ∗-20/40-∗) 8.4.2 hrs150-a ∗-20/40-∗ fig. 8-6 cooling capacity(hrs150-a ∗-20/40-∗) : ambient temperature: 32 o c : ambient temperature: 40 o c : ambien...

Page 185

Hrx-om-s004 chapter 8 documents hrs series 8.4 cooling capacity 8-11 8.4.3 hrs100-w ∗-20/40-∗ fig. 8-7 cooling capacity(hrs100-w ∗-20/40-∗) 8.4.4 hrs150-w ∗-20/40-∗ fig. 8-8 cooling capacity(hrs150-w ∗-20/40-∗) : facility water temperature 32 o c : facility water temperature 40 o c 50hz 60hz 50hz 60...

Page 186: 8.5 Pump Capacity

Hrx-om-s004 chapter 8 documents 8.5 pump capacity hrs series 8-12 8.5 pump capacity 8.5.1 hrs100/150-a/w ∗-20/40-∗ fig. 8-9 pump capacity (hrs100/150-a/w ∗-20/40-∗) 0 0.1 0.2 0.3 0.4 0.5 0 10 20 30 40 50 60 70 circulating fluid flow [l/min] p re ss u re [m p a ] 0 10 20 30 40 50 li fti ng he ad [ m ...

Page 187: ∗∗∗-∗∗-40-∗)

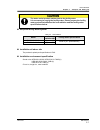

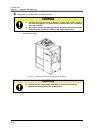

Hrx-om-s004 chapter 8 documents hrs series 8.6 types of hazard labels (hrs - -40- ) 8-13 8.6 types of hazard labels (hrs ∗∗∗-∗∗-40-∗) to ensure the safety of the operators, potential hazards are classified and marked with warning labels. Read this section before starting any work on the product. Ele...

Page 188

Hrx-om-s004 chapter 8 documents 8.6 types of hazard labels (hrs - -40- ) hrs series 8-14 8.6.1 positions of danger warning label confirm the positions of the danger warning labels on the product to show the potential danger before starting operation. Fig. 8-10 positions of danger warning label fig. ...

Page 189: 8.7 Standards

Hrx-om-s004 chapter 8 documents hrs series 8.7 standards 8-15 8.7 standards this product complies with the standards shown below: table 8-5 standards standard model emc directive 2004/108/ec ce mark machinery directive 2006/42/ec hrs ∗∗∗-∗∗-40-∗.

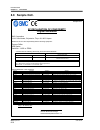

Page 190: 8.8 Sample Doc.

Hrx-om-s004 chapter 8 documents 8.8 sample doc. Hrs series 8-16 8.8 sample doc. Sample doc. Ec declaration of conformity original declaration smc corporation 4-14-1 soto-kanda, chiyoda-ku, tokyo 101-0021 japan declares under our sole responsibility that the following equipment: thermo chiller hrs se...

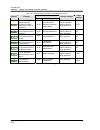

Page 191: 8.9 Daily Check Sheet

Hrx-om-s004 chapter 8 documents hrs series 8.9 daily check sheet 8-17 8.9 daily check sheet for inform ation a bout how to perf orm daily checks of the therm o chiller , refer to section “7.2.1 daily check” of the ope ration manual. Check and recor d the condition at st art right af te r s etting up...

Page 192

Hrx-om-s004 chapter 8 documents 8.9 daily check sheet hrs series 8-18.

Page 193: Chapter 9 Product Warranty

Hrx-om-s004 chapter 9 product warranty hrs series product warranty 9-1 chapter 9 product warranty 1. Period the warranty period of the product is 1 year in service or 1.5 years after the product is delivered whichever comes first. 2. Scope for any failure reported within the warranty period which is...

Page 194

Hrx-om-s004 chapter 9 product warranty product warranty hrs series 9-2 6. Request to customers proper use and maintenance are essential to assure safe use of this product. Be sure to satisfy the following preconditions. Please note that we may refuse to carry out warranted repair if these preconditi...

Page 196

4-14-1, sotokanda, chiyoda-ku, tokyo 101-0021 japan tel: + 81 3 5207 8249 fax: +81 3 5298 5362 url http://www.Smcworld.Com note: specifications are subject to change without prior notice and any obligation on the part of the manufacturer. © 2014 smc corporation all rights reserved.