- DL manuals

- SMC Networks

- Chiller

- HRSE012-A

- Operation Manual

SMC Networks HRSE012-A Operation Manual - 5.9.1

HRX-OM-R039

Chapter 5 Display and setting of various functions

5.9 Function to recover from power failure

HRSE Series

5-26

5.9 Function to recover from power failure

5.9.1

Function to recover from power failure

When the power supply is cut due to power failure etc., this function restarts

the operation when the power supply recovers, retaining the conditions

before the power cut.

The [POWER] lamp flashes (5 sec.ON - 0.2 sec.OFF) when the power

failure recovery is set.

The default setting of this function is “OFF”.

Fig 5.9-1 Setting of function to recover from power failure

Summary of HRSE012-A

Page 1

Hrx-om-r039 1 st edition: dec. 2013 rev.E: feb. 2017 operation manual installation・operation original instructions thermo chiller air-cooled refrigerated type hrse012/018/024 series [ hrse012/018/024-a-23(-t) ] keep this manual available whenever necessary © 2017 smc corporation all rights reserved.

Page 2: To The Users

To the users thank you for purchasing smc’s thermo chiller (hereinafter referred to as the “product”). For safety and long life of the product, be sure to read this operation manual (hereinafter referred to as the “manual”) and clearly understand the contents. Be sure to read and follow all instruct...

Page 3: Contents

Hrx-om-r039 contents hrs series contents chapter 1 safety instructions ........................................................... 1-1 1.1 before using the product ........................................................................................ 1-1 1.2 reading the manual .......................

Page 4: Chapter 5

Hrx-om-r039 contents hrs series 4.2.1 power supply ....................................................................................................................... 4-2 4.2.2 setting of circulating fluid temperature .................................................................................

Page 5: Chapter 7

Hrx-om-r039 contents hrs series 6.2 alarm buzzer stop ................................................................................................... 6-2 6.3 troubleshooting ...................................................................................................... 6-3 6.4 other error...

Page 6

Hrx-om-r039 contents hrs series.

Page 7: 1.2 Reading The Manual

Hrx-om-r039 chapter 1 safety instructions hrse series 1.1 before using the product 1-1 chapter 1 safety instructions 1.1 before using the product this chapter is intended to specifically describe the safety related issues for handling the product. Read this before handling the product. The product i...

Page 8: 1.3 Hazards

Hrx-om-r039 chapter 1 safety instructions 1.3 hazards hrse series 1-2 1.3 hazards 1.3.1 level of hazards the instructions given in this manual aim to assure the safe and correct operation of the product, and to prevent injury of operators or damage to the product. These instructions are grouped into...

Page 9: 1.3.3

Hrx-om-r039 chapter 1 safety instructions hrse series 1.3 hazards 1-3 1.3.3 types of hazard labels the product has various potential hazards and they are marked with warning labels. Be sure to read this section before starting any work on the product. warning related to electricity warning relat...

Page 10: 1.3.4

Hrx-om-r039 chapter 1 safety instructions 1.3 hazards hrse series 1-4 1.3.4 locations of hazard labels there are various warning labels on the product to show the potential hazards. Fig. 1.3-1 warning label position fig. 1.3-2 warning label position rear front.

Page 11: 1.4 Other Labels

Hrx-om-r039 chapter 1 safety instructions hrse series 1.4 other labels 1-5 1.4 other labels 1.4.1 product label information about the product, such as serial no. And model no. Can be found on the model label. This information is needed when contacting an smc sales distributor. Fig. 1.4-1 position of...

Page 12: 1.5.2

Hrx-om-r039 chapter 1 safety instructions 1.5 safety measures hrse series 1-6 1.5.2 personal protective equipment this manual specifies personal protective equipment for each work. transport, installing and uninstalling handling of circulating fluid operation always use safety shoes, gloves an...

Page 13: 1.6 Emergency Measures

Hrx-om-r039 chapter 1 safety instructions hrse series 1.6 emergency measures 1-7 1.6 emergency measures in the event of natural disaster, emergency such as fire, earthquake, injury, etc., disconnect the power supply to this product. 1. Disconnect power supply to the product. Fig. 1.6-1 shut off of f...

Page 14: 1.7 Waste Disposal

Hrx-om-r039 chapter 1 safety instructions 1.7 waste disposal hrse series 1-8 1.7 waste disposal 1.7.1 disposal of refrigerant and compressor oil the product uses hydrofluorocarbon type refrigerant (hfc) and compressor oil. Comply with the laws and regulations in each country for the disposal of refr...

Page 15

Hrx-om-r039 chapter 2 name and function of parts hrse series 2.1 part number of product 2-1 chapter 2 name and function of parts 2.1 part number of product the product can be ordered with the part number configured as shown below. Refer to “1.4.1 product label” and check the part number of the produ...

Page 16

Hrx-om-r039 chapter 2 name and function of parts 2.2 name and function of parts hrse series 2-2 2.2 name and function of parts fig. 2.2-1 names of each part fig. 2.2-2 names of each part * power supply cable terminal - 100v power supply specification: cable is provided with a plug with ground termin...

Page 17: 2.3 Function of Parts

Hrx-om-r039 chapter 2 name and function of parts hrse series 2.3 function of parts 2-3 table 2-1 accessories list 1 operation manual 2pcs. (jpn: 1pc., eng:1pc.) 2 fitting (for drain port) * 1pc. 2.3 function of parts the function of parts is as follows. Table 2-2 function of parts name function oper...

Page 18

Hrx-om-r039 chapter 2 name and function of parts 2.4 operation display panel hrse series 2-4 2.4 operation display panel the operation panel on the front of the product controls the basic operation of the product. Fig. 2.4-1 operation display panel table 2-3 operation display panel no description fu...

Page 19: 3.1 Transport

Hrx-om-r039 chapter 3 transport and setting up hrse series 3.1 transport 3-1 chapter 3 transport and setting up 3.1 transport the product is heavy and has potential danger at transport. Also, to prevent damage and breakage of the product, be sure to follow these instructions for transport. only pe...

Page 20: 3.1.1

Hrx-om-r039 chapter 3 transport and setting up 3.1 transport hrse series 3-2 3.1.1 transportation using casters 1. Release the lock levers of the front casters. 2. Push the handles on the right/left panel or the corner of the product to move the product to the destination. Do not hold the product by...

Page 21: 3.2 Installation

Hrx-om-r039 chapter 3 transport and setting up hrse series 3.2 installation 3-3 3.2 installation 3.2.1 environment the product must not be operated, installed, stored or transported in the following conditions. Potential malfunction or damage to the product may occur if these instructions are disreg...

Page 22: 3.2.2

Hrx-om-r039 chapter 3 transport and setting up 3.2 installation hrse series 3-4 location that is subjected to strong high frequencies raditation (microwaves). Location that is subjected to potential lightning srtike. Location at altitude of 1000m or higher (except during product storage and transpor...

Page 23: 3.2.3

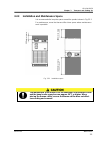

Hrx-om-r039 chapter 3 transport and setting up hrse series 3.2 installation 3-5 3.2.3 installation and maintenance space it is recommended to keep the space around the product shown in fig.3.2-1 for maintenance, move the thermo-chiller into a space where maintenance work is possible. Fig. 3.2-1 inst...

Page 24: 3.3 Installation

Hrx-om-r039 chapter 3 transport and setting up 3.3 installation hrse series 3-6 3.3 installation 3.3.1 mounting mount the product on a flat and stable floor with no vibrations. Refer to ’’8.2 outline dimensions" for dimensional information of the product. how to mount the product 1. Move the produ...

Page 25: 3.3.2

Hrx-om-r039 chapter 3 transport and setting up hrse series 3.3 installation 3-7 3.3.2 electrical wiring power supply cable and earth leakage breaker prepare the power supply shown in the following table. For the connection between the product and power supply, use the power supply cable and earth ...

Page 26: 3.3.3

Hrx-om-r039 chapter 3 transport and setting up 3.3 installation hrse series 3-8 3.3.3 preparation and wiring of power supply cable preparation 【for power supply : 200/230v 】 1. Strip the sheath from the cable of the product. 2. Connect the other end of the cable to a terminal (e.G. Crimped terminal)...

Page 27

Hrx-om-r039 chapter 3 transport and setting up hrse series 3.3 installation 3-9 connecting [for power supply : 100v, 200v and 230v] 1. Connect the plug or crimped terminal to the outlet with ground or to the secondary side of the electrical leakage breaker and to the grounding. 2. Plug the power sup...

Page 28: 3.4 Piping

Hrx-om-r039 chapter 3 transport and setting up 3.4 piping hrse series 3-10 3.4 piping piping port size table 3-3 piping port size name port size* 1 recommended tightening torque recommended proof pressure for piping circulating fluid supply rc1/2 28 to 30n・m 0.3mpa more (for option t [high head pu...

Page 29

Hrx-om-r039 chapter 3 transport and setting up hrse series 3.4 piping 3-11 recommended piping circuit fig. 3.4-2 recommended piping circuit no. Name size 1 valve rc1/2 2 y-shaped strainer or filter rc1/2 (#40) rc1/2 (50 0μm) 3 flow meter 0 to 30 l/min 4 others (pipe, hose, etc.) i.D φ15more circul...

Page 30

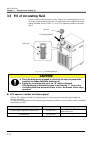

Hrx-om-r039 chapter 3 transport and setting up 3.5 fill of circulating fluid hrse series 3-12 3.5 fill of circulating fluid turn the tank lid anticlockwise to open. Supply the circulating fluid up to the “h” mark on the fluid level indicator. Use tap water which satisfies the water quality standard ...

Page 31: 4.1 Before Starting

Hrx-om-r039 chapter 4 starting the product hrse series 4.1 before starting 4-1 chapter 4 starting the product 4.1 before starting check the following items before starting the product. installation conditions check the product is installed horizontally. Check that there are no heavy objects on the...

Page 32: 4.2.1

Hrx-om-r039 chapter 4 starting the product 4.2 preparation for start hrse series 4-2 4.2 preparation for start 4.2.1 power supply turn on the electrical leakage breaker of the user's equipment, and supply power to the thermo chiller. * for 100 v power supply specification, connect the plug to the ou...

Page 33

Hrx-om-r039 chapter 4 starting the product hrse series 4.3 preparation of circulating fluid 4-3 4.3 preparation of circulating fluid when the circulating fluid tank is filled the user’s machine and piping remains empty. In that condition, the circulating fluid flows out to the user’s machine and pip...

Page 34

Hrx-om-r039 chapter 4 starting the product 4.3 preparation of circulating fluid hrse series 4-4 2. Open the tank lid and supply the circulating fluid up to the “h” mark on the tank. Fig. 4.3-2 filling of circulating fluid confirm that the drain port is closed with a plug or a valve to avoid discha...

Page 35: 4.4.1

Hrx-om-r039 chapter 4 starting the product hrse series 4.4 starting and stopping 4-5 4.4 starting and stopping 4.4.1 starting the product before starting, check the items specified in “4.1 before starting” if any alarm lamp remains on, refer to chapter 6 alarm indication and trouble shooting ” 1. Pr...

Page 36: 4.4.2

Hrx-om-r039 chapter 4 starting the product 4.4 starting and stopping hrse series 4-6 except in case of emergency, do not turn off the power supply switch until the product has stopped completely. Doing so could cause failure. 4.4.2 stopping the product 1. Press the [run/stop] button on the operation...

Page 37

Hrx-om-r039 chapter 4 starting the product hrse series 4.5 check items after starting 4-7 4.5 check items after starting check the following items after starting the product. There is no leakage from piping. There is no drain of circulating fluid from the drain port. The tank level is within the spe...

Page 38

Hrx-om-r039 chapter 4 starting the product 4.6 adjustment of circulating fluid hrse series 4-8.

Page 39: Various Functions

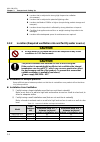

Hrx-om-r039 chapter 5 display and setting of various functions hrse series 5.1 function 5-1 chapter 5 display and setting of various functions 5.1 function 5.1.1 key operations the product can have the displays and settings shown in table 5-1. Table 5-1 list of function no function outline reference...

Page 40: 5.1.2

Hrx-om-r039 chapter 5 display and setting of various functions 5.1 function hrse series 5-2 5.1.2 key operations fig. 5.1-1 “key operation (1/2)” and fig. 5.1-2 “key operation (2/2)” show the operation of keys of the thermo-chiller. Pv sv unused sel main display unused check monitor menu pv sv pv sv...

Page 41

Hrx-om-r039 chapter 5 display and setting of various functions hrse series 5.1 function 5-3 alarm setting menu pv sv pv sv pv sv pv sv pv sv pv sv pv sv pv sv pv sv pv sv pv sv pv sv unused communication setting menu unused unused unused unused unused unused unused unused unused unused unused unused...

Page 42: 5.1.3

Hrx-om-r039 chapter 5 display and setting of various functions 5.1 function hrse series 5-4 5.1.3 list of parameters table 5.1-2 “list of parameter (1/3)” and table 5.1-4“list of parameter (3/3)” show the parameters of the thermo-chiller. Table 5.1-2 list of parameter (1/3) display item initial valu...

Page 43

Hrx-om-r039 chapter 5 display and setting of various functions hrse series 5.1 function 5-5 table 5.1-3 list of parameter (2/3) display item initial value (default setting) reference page category alarm buzzer sound on 5.5 alarm setting menu unused - 5.6 changing of circulating fluid discharge tempe...

Page 44

Hrx-om-r039 chapter 5 display and setting of various functions 5.1 function hrse series 5-6 table 5.1-4 list of parameter (3/3) display item initial value (default setting) reference page category unused - - - unused - unused - unused - unused - unused - unused - unused - unused - unused -.

Page 45: 5.2 Main Screen

Hrx-om-r039 chapter 5 display and setting of various functions hrse series 5.2 main screen 5-7 5.2 main screen 5.2.1 main screen displays the current temperature and the set temperature of the circulating fluid. The set temperature can be changed on this screen. 5.2.2 display on the main screen the ...

Page 46: 5.3

Hrx-om-r039 chapter 5 display and setting of various functions 5.3 alarm display menu hrse series 5-8 5.3 alarm display menu 5.3.1 alarm display menu the alarm display screen appears when an alarm is generated. The alarm display menu cannot be accessed when no alarm has been generated. Refer to “cha...

Page 47: 5.4.1

Hrx-om-r039 chapter 5 display and setting of various functions hrse series 5.4 inspection monitor menu 5-9 5.4 inspection monitor menu 5.4.1 inspection monitor menu as a part of the daily inspection, the temperature, pressure and accumulated operating time can be checked. Please use this for confirm...

Page 48

Hrx-om-r039 chapter 5 display and setting of various functions 5.4 inspection monitor menu hrse series 5-10 check of the temperature of the inlet of the compressor. 3. Press the [sel] key once. The temperature of the refrigerant circuit compressor inlet is displayed on the digital display. Pv sv dis...

Page 49: 10.

Hrx-om-r039 chapter 5 display and setting of various functions hrse series 5.4 inspection monitor menu 5-11 check of the accumulated operation time of the pump 8. Press the [sel] key once. The accumulated operation time of the pump is displayed on the digital display. Pv sv displays the accumulated ...

Page 50: 5.5.1

Hrx-om-r039 chapter 5 display and setting of various functions 5.5 alarm buzzer sound setting hrse series 5-12 5.5 alarm buzzer sound setting 5.5.1 alarm buzzer sound setting this sets whether a warning sound is made or not when alarm signal is output. The default setting is buzzer sound on. 5.5.2 a...

Page 51: 5.6.1

Hrx-om-r039 chapter 5 display and setting of various functions hrse series 5.6 alarm customize function 5-13 5.6 alarm customize function 5.6.1 alarm customize function the operation and the threshold when alarm signal is output can be customized. Customers should set them depending on their applica...

Page 52

Hrx-om-r039 chapter 5 display and setting of various functions 5.6 alarm customize function hrse series 5-14 table 5.6-2 list of set alarm customize function(2/2) display item contents initial value (default setting) monitoring start timer alarm will not be generated during the set period of time af...

Page 53

Hrx-om-r039 chapter 5 display and setting of various functions hrse series 5.6 alarm customize function 5-15 detection temperature for circulating fluid discharge temperature rise setting and checking 5. Press the [sel] key once. The set screen of detection temperature for circulating fluid discharg...

Page 54: 10.

Hrx-om-r039 chapter 5 display and setting of various functions 5.6 alarm customize function hrse series 5-16 10. Select detection temperature for circulating fluid discharge temperature drop from the table below with [ ▲] key or [▼] key, and confirm by pressing “sel”. Table 5.6-6 list of set value s...

Page 55: 15.

Hrx-om-r039 chapter 5 display and setting of various functions hrse series 5.6 alarm customize function 5-17 15. Press the [sel] key once. "as11" is displayed, but this feature is not available on this product. Pv sv 16. Press the [sel] key once. "as12" is displayed, but this feature is not availabl...

Page 56: 21.

Hrx-om-r039 chapter 5 display and setting of various functions 5.6 alarm customize function hrse series 5-18 21. Press the [sel] key once. "as17" is displayed, but this feature is not available on this product. Pv sv 22. Press the [sel] key once. "as18" is displayed, but this feature is not availabl...

Page 57: 26.

Hrx-om-r039 chapter 5 display and setting of various functions hrse series 5.6 alarm customize function 5-19 26. Select temperature alarm monitoring method from the table below with [ ▲] key or [▼] key, and confirm by pressing “sel”. Table 5.6-7 list of set value set value item explanation initial v...

Page 58: 29.

Hrx-om-r039 chapter 5 display and setting of various functions 5.6 alarm customize function hrse series 5-20 to sets the time when alarm monitoring starts setting unit is 1 minute. Settings of this function and example of alarm generating timing for 5.6.3 "setting of temperature alarm monitoring met...

Page 59: 5.6.3

Hrx-om-r039 chapter 5 display and setting of various functions hrse series 5.6 alarm customize function 5-21 5.6.3 setting of temperature alarm monitoring method and alarm generation timing examples of temperature alarm monitoring method setting and alarm generation timing are shown below. when "a...

Page 60

Hrx-om-r039 chapter 5 display and setting of various functions 5.6 alarm customize function hrse series 5-22 when "automatic monitoring + monitoring start timer" is selected [1] circulating fluid temperature when starting operation: approximately 25 o c [2] circulating fluid set temperature : 15 o...

Page 61: 5.7 Data Reset Function

Hrx-om-r039 chapter 5 display and setting of various functions hrse series 5.7 data reset function 5-23 5.7 data reset function 5.7.1 data reset function values set by customer are reset to default values. Accumulated operating time is not reset. 5.7.2 method of resetting data reset function the tab...

Page 62: 5.8.1

Hrx-om-r039 chapter 5 display and setting of various functions 5.8 accumulated time reset function hrse series 5-24 5.8 accumulated time reset function 5.8.1 accumulated time reset function the alarms below are generated to notify the maintenance time. The product is not stopped for alarm. Pump main...

Page 63

Hrx-om-r039 chapter 5 display and setting of various functions hrse series 5.8 accumulated time reset function 5-25 3. Select from the table below with [▲] key or [▼] key, and confirm by pressing “sel”. Select , then the accumulated operating time of the pump is reset. The display returns to the mai...

Page 64: 5.9.1

Hrx-om-r039 chapter 5 display and setting of various functions 5.9 function to recover from power failure hrse series 5-26 5.9 function to recover from power failure 5.9.1 function to recover from power failure when the power supply is cut due to power failure etc., this function restarts the operat...

Page 65: 5.9.2

Hrx-om-r039 chapter 5 display and setting of various functions hrse series 5.9 function to recover from power failure 5-27 5.9.2 function to recover from power failure setting and checking the table below explains the setting items of the power recovery function and the initial values. Table 5.9-1 l...

Page 66

Hrx-om-r039 chapter 5 display and setting of various functions 5.9 function to recover from power failure hrse series 5-28.

Page 67: Shooting

Hrx-om-r039 chapter 6 alarm indication and trouble shooting hrse series 6.1 alarm display 6-1 chapter 6 alarm indication and trouble shooting 6.1 alarm display when any alarm occurs, the product responds with the following conditions. The [alarm] lamp will flash. The alarm buzzer sounds. The alarm n...

Page 68: 6.2 Alarm Buzzer Stop

Hrx-om-r039 chapter 6 alarm indication and trouble shooting 6.2 alarm buzzer stop hrse series 6-2 6.2 alarm buzzer stop the alarm buzzer sounds to notify when the alarm signal is output. How to stop the alarm buzzer. Ensure that the alarm display screen is displayed. The alarm buzzer can only be sto...

Page 69: 6.3 Troubleshooting

Hrx-om-r039 chapter 6 alarm indication and trouble shooting hrse series 6.3 troubleshooting 6-3 6.3 troubleshooting the troubleshooting method depends which alarm has been generated. Refer to ’’ table 6-1 alarm coce list and troubleshooting ’’. This page explains how to reset the alarm signal condit...

Page 70: 6.4 Other Errors

Hrx-om-r039 chapter 6 alarm indication and trouble shooting 6.4 other errors hrse series 6-4 table 6-1 alarm code list and troubleshooting code descriptioin operation cause / remedy (press the reset key after eliminating the cause.) al02 high circulating fluid discharge temp. Stop - reduce the ambie...

Page 71: Cleaning

Hrx-om-r039 chapter 9 product warrantycontrol, inspection and cleaning hrse series 7.1 control of circulating fluid quality 7-1 chapter 7 control, inspection and cleaning 7.1 control of circulating fluid quality table 7-1 quality standard for fresh water (tap water) item product standard value for c...

Page 72: 7.2.1

Hrx-om-r039 chapter 8 documents 7.2 inspection and cleaning hrse series 7-2 7.2 inspection and cleaning 7.2.1 daily check check the items listed below. If any abnormality is found, stop the operation, remove the plug of the power supply cable from the outlet, and ask for maintenance. Table 7-2 conte...

Page 73: 7.2.2

Hrx-om-r039 chapter 9 product warrantycontrol, inspection and cleaning hrse series 7.2 inspection and cleaning 7-3 7.2.2 monthly check cleaning of air vent use a long bristled brush or air gun to clean the condenser to prevent the fins from being deformed or damaged. removal of the dustproof fil...

Page 74: 7.2.3

Hrx-om-r039 chapter 8 documents 1.1 hrse series 7-4 cleaning of filter use a long bristled brush or air gun to clean the condenser. Fig 7.2-2 cleaning of filter mounting of dustproof filter insert the collar in reverse order of removal, then mount the dustproof filter. (the magnet clicks when mo...

Page 75: 7.3 Consumables

Hrx-om-r039 chapter 9 product warrantycontrol, inspection and cleaning hrse series 7.3 consumables 7-5 7.3 consumables replace the following parts depending on their condition. Table 7-3 consumables part number name qty. Remarks hrs-s0001 dustproof filter 1 for spare 7.4 stop for a long time if ther...

Page 76

Hrx-om-r039 chapter 8 documents 7.4 stop for a long time hrse series 7-6 2. Remove the tank lid. 3. Remove the drain plug on the drain port on the piping to discharge the fluid. An o ring is used for the drain plug. Take care not to damage the o ring. 4. Confirm that a sufficient amount of the circu...

Page 77: Example)

Hrx-om-r039 chapter 9 product warrantycontrol, inspection and cleaning hrse series 7.4 stop for a long time 7-7 fitting for the drain port (accessory) the thermo-chiller includes the fitting for the drain port shown in fig 7.4-3 . Discharging of the drain will be easier if customer prepares a valv...

Page 78

Hrx-om-r039 chapter 8 documents 7.4 stop for a long time hrse series 7-8.

Page 79: Chapter 8 Documents

Hrx-om-r039 chapter 9 product warrantydocuments hrse series product warranty 8-1 chapter 8 documents 8.1 specifications list 8.1.1 product specification table 8-1 specifications list [hrse - -10-(t)] model hrse012-a-10-(t) hrse018-a-10-(t) cooling method air-cooled refrigerated type refrigerant r407...

Page 80

Hrx-om-r039 chapter 9 product warranty product warranty hrse series 8-2 table 8-2 specifications list[hrse -a-20-(t)] model hrse012-a-20-(t) hrse018-a-20-(t) hrse024-a-20-(t) cooling method air-cooled refrigerated type refrigerant r407c(hfc) quantity of refrigerant kg 0.32 0.33 0.34 control method c...

Page 81

Hrx-om-r039 chapter 9 product warrantydocuments hrse series product warranty 8-3 table 8-3 specifications list[hrse -a-23-(t)] model hrse012-a-23-(t) hrse018-a-23-(t) hrse024-a-23-(t) cooling method air-cooled refrigerated type refrigerant r407c(hfc) quantity of refrigerant kg 0.32 0.33 0.34 control...

Page 82: 8.1.2

Hrx-om-r039 chapter 9 product warranty product warranty hrse series 8-4 8.1.2 refrigerant with gwp reference table8-4 refrigerant with gwp reference refrigerant global warming potential (gwp) regulation (eu) no 517/2014 (based on the ipcc ar4) revised fluorocarbons recovery and destruction law (japa...

Page 83: 8.2 Outline Dimensions

Hrx-om-r039 chapter 9 product warrantydocuments hrse series product warranty 8-5 8.2 outline dimensions fig. 8.2-1 outline dimensions fig. 8.2-2 outline dimensions * power supply cable terminal configuration - 100v power supply specification: cable is provided with a plug with ground terminal (jis c...

Page 84: 8.3 Flow Chart

Hrx-om-r039 chapter 9 product warranty product warranty hrse series 8-6 8.3 flow chart circulating fluid circuit refrigeration circuit tank comp press sensor (for high pressure) expansion temp. Sensor (for compressor inlet) pump temp sensor (for outlet) ventilation circulating fluid return port rc1/...

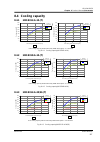

Page 85: 8.4 Cooling Capacity

Hrx-om-r039 chapter 9 product warrantydocuments hrse series product warranty 8-7 8.4 cooling capacity 8.4.1 hrse012-a-10-(t) fig. 8.4-1 cooling capacity(hrse012-a-10) 8.4.2 hrse018-a-10-(t) fig. 8.4-2 cooling capacity(hrse018-a-10) 8.4.3 hrse012-a-20/23-(t) fig. 8.4-3 cooling capacity(hrse012-a-20/2...

Page 86: 8.4.4

Hrx-om-r039 chapter 9 product warranty product warranty hrse series 8-8 8.4.4 hrse018-a-20/23-(t) fig. 8.4-4 cooling capacity(hrse018-a-20/23) 8.4.5 hrse024-a-20/23-(t) fig. 8.4-5 cooling capacity(hrse024-a-20/23) 50hz 0 500 1000 1500 2000 0 10 20 30 40 circurating fluid temperature[℃] co o lin g c ...

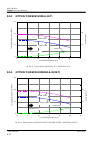

Page 87: 8.5 Pump Capacity

Hrx-om-r039 chapter 9 product warrantydocuments hrse series product warranty 8-9 8.5 pump capacity 8.5.1 hrse012/018-a-10 fig. 8.5-1 pump capacity (hrse012-a-10, hrse018-a-10) 8.5.2 hrse012/018/024-a-20/23 fig. 8.5-2 pump capacity (hrse012-a-20/23, hrse018-a-20/23, hrse024-a-20/23) 0.00 0.02 0.04 0....

Page 88: 8.5.3

Hrx-om-r039 chapter 9 product warranty product warranty hrse series 8-10 8.5.3 option-t (hrse012/018-a-10-t) fig. 8.5-3 pump capacity (hrse012-a-10-t, hrse018-a-10-t) 8.5.4 option-t (hrse012/018/024-a-20/23-t) fig. 8.5-4 pump capacity (hrse012-a-20/23-t, hrse018-a-20/23-t, hrse024-a-20/23-t) 0 0.05 ...

Page 89: “-23”Only)

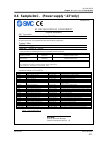

Hrx-om-r039 chapter 9 product warrantydocuments hrse series product warranty 8-11 8.6 sample doc. (power supply “-23”only) sample doc. Ec declaration of conformity original declaration smc corporation _ 4-14-1 soto-kanda, chiyoda-ku, tokyo 101-0021 japan declares under our sole responsibility that t...

Page 90: 8.7 Daily Check Sheet

Hrx-om-r039 chapter 9 product warranty product warranty hrse series 8-12 8.7 daily check sheet chapter 9 for inf or ma tion a bo ut h ow t o pe rf or m da ily c he ck s of t he t he rmo c hi lle r, re fe r to s ec tion “ 8. 2. 1 d ail y c he ck ” of th e op er at io n man u a l. C h e c k a n d r e ...

Page 91

Hrx-om-r039 chapter 9 product warranty hrse series product warranty 9-13 chapter 9 product warranty 1. Period the warranty period of the product is 1 year in service or 1.5 years after the product is delivered, whichever is first. 2. Scope for any failure reported within the warranty period which is...

Page 92

Hrx-om-r039 chapter 9 product warranty product warranty hrse series 9-14 6. Request to customers proper use and maintenance are essential to assure safe use of this product. Be sure to satisfy the following preconditions. Please note that we may refuse to carry out warranted repair if these precondi...

Page 93

4-14-1, sotokanda, chiyoda-ku, tokyo 101-0021 japan tel: + 81 3 5207 8249 fax: +81 3 5298 5362 url http://www.Smcworld.Com note: specifications are subject to change without prior notice and any obligation on the part of the manufacturer. © 2017 smc corporation all rights reserved.