- DL manuals

- SMC Networks

- Chiller

- HRZD020-W1S-W1S

- Operation Manual

SMC Networks HRZD020-W1S-W1S Operation Manual - 10.

HRX-OM-M005

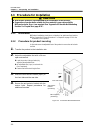

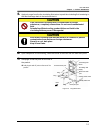

Chapter 3 Transporting and Installation

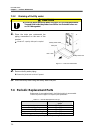

3.3 Procedure for Installation

HRZD Series

3-12

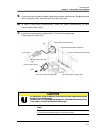

8.

Connect the power cables to the breaker terminal.

Be sure to use a crosshead screwdriver. Recommended torque: 6N•m

9.

Connect the grounding terminal (M8) of

the power cable to the earth bar.

Be sure to use a 13-mm open end wrench.

Recommended torque: 12.5 N•m

[Tips]

See “Table 3-1 Power Cable and Main Breaker (The Product)“ on page 3-7

for torque

value.

10.

Attach the breaker cover to the breaker.

11.

Close the front door.

12.

Connect the power cable to the power breaker on customer side (primary side).

Figure 3-9 Connection of Power Cable and Grounding Terminal

Earth bar

Main

breaker

Grounding

terminal

Power cable

L1

(R)

L2

(S)

L3

(T)

Correct phase rotation is required when attaching the power cable to

the breaker terminal.

Summary of HRZD020-W1S-W1S

Page 1

Hrx-om-m005-e 1 st edition: july 2008 6 th edition: may 2011 operation manual original instructions thermo chiller hrzd020-ws-ws, hrzd020-w1s-w1s hrzd020-w1s-ws, hrzd020-ws-w1s keep this manual available whenever necessary © 2011 smc corporation all rights reserved.

Page 2: To The Users

To the users thank you for purchasing smc’s hrz thermo chiller (hereinafter referred to as the “product”). For safety and long life of the product, be sure to read this operation manual (hereinafter referred to as the “manual”) and clearly understand the contents. • be sure to read and follow all in...

Page 3: Table of Contents

Hrx-om-m005 table of contents hrzd series toc- -1 table of contents chapter 1 safety instructions ............................................................ 1-1 1.1 before using this product ........................................................................................1-1 1.2 hazards ......

Page 4

Hrx-om-m005 table of contents hrz series toc- -2 chapter 4 product startup and shutdown .......................................... 4-1 4.1 pre-check ................................................................................................................... 4-1 4.1.1 installation condition .....

Page 5

Hrx-om-m005 table of contents hrzd series toc- -3 5.3.18 communication setting screen.......................................................................................... 5-27 5.3.19 serial communication setting screen 1 .............................................................................

Page 6

Hrx-om-m005 table of contents hrz series toc- -4 8.6 anchor bolt mounting position ............................................................................. 8-17 8.7 compliance .............................................................................................................. 8-18 8.8...

Page 7

Hrx-om-m005 chapter 1 safety instructions hrzd series 1.1 before using this product 1-1 chapter 1 safety instructions 1.1 before using this product this chapter is intended to specifically describe the safety related issues for handling the unit. Read this before handling the unit. The unit is a coo...

Page 8: 1.2 Hazards

Hrx-om-m005 chapter 1 safety instructions 1.2 hazards hrzd series 1-2 1.2 hazards 1.2.1 hazard levels the instructions given in this manual aim to assure the safe and correct operation of the product, and to prevent injury of operators or damage to the product. These instructions are grouped into th...

Page 9

Hrx-om-m005 chapter 1 safety instructions hrzd series 1.2 hazards 1-3 1.2.3 symbols this manual provides the following symbols in addition to “danger”, “warning”, and “caution” to highlight particular types of hazards. Symbol of electrical hazard symbol of heat hazard symbol of low temperature hazar...

Page 10: 1.3 Hazard Warning Label

Hrx-om-m005 chapter 1 safety instructions 1.3 hazard warning label hrzd series 1-4 1.3 hazard warning label the hazard warning labels are applied to the sections of the product where potential hazards are present during product operation or maintenance. The hazard warning labels are in appropriate s...

Page 11

Hrx-om-m005 chapter 1 safety instructions hrzd series 1.3 hazard warning label 1-5 1.3.2 location of hazard warning label high voltage hazard figure 1-7 high voltage hazard do not peel off or deface the hazard warning labels. Confirm the locations of all hazard warning labels. Read the contents of t...

Page 12

Hrx-om-m005 chapter 1 safety instructions 1.3 hazard warning label hrzd series 1-6 hot/cold surface hazard figure 1-8 hot/cold surface hazard front rear hazard warning label no.5 hazard warning label no.6.

Page 13

Hrx-om-m005 chapter 1 safety instructions hrzd series 1.4 location of model label 1-7 1.4 location of model label information about the product, such as serial no. And model no. Can be found on the model label. This information is needed when contacting an smc sales distributor. Figure 1-9 location ...

Page 14: 1.5 Safety

Hrx-om-m005 chapter 1 safety instructions 1.5 safety measures hrzd series 1-8 1.5 safety measures 1.5.1 safety precautions while the product is protected by various safety measures including the safety interlocks, the following basic safety precautions should be observed to assure further safe opera...

Page 15

Hrx-om-m005 chapter 1 safety instructions hrzd series 1.5 safety measures 1-9 1.5.2 safety interlock system safety interlock system the function of the safety interlock system is not only to protect personnel by restricting operation that may cause damage to the product or the facility around it but...

Page 16

Hrx-om-m005 chapter 1 safety instructions 1.5 safety measures hrzd series 1-10 1.5.3 lockout/tagout summary lockout of the product disables the main breaker operation to prevent electric shocks. Tagout, to be placed on the locked out main breaker, prevents improper breaker operation (on) conducted b...

Page 17

Hrx-om-m005 chapter 1 safety instructions hrzd series 1.5 safety measures 1-11 lockout procedure 1. Turn the breaker handle to ‘off ’. 2. Turn the breaker handle to ‘reset’. Hold the breaker handle with hand. The handle turns back to ‘off ’ if released. 3. Push the lock pushing part of the breaker h...

Page 18

Hrx-om-m005 chapter 1 safety instructions 1.5 safety measures hrzd series 1-12 1.5.4 protective equipment this manual specifies personal protective equipment for each work. Transport, installing and uninstalling handling of circulating fluid operation always use safety shoes, gloves and head protect...

Page 19: 1.6 Emergency

Hrx-om-m005 chapter 1 safety instructions hrzd series 1.6 emergency measures 1-13 1.6 emergency measures 1.6.1 emergency off [emo] switch press the red emergency off [emo] switch on the front of the product only if the need to shut off the power arises due to emergency such as natural disaster, fire...

Page 20

Hrx-om-m005 chapter 1 safety instructions 1.6 emergency measures hrzd series 1-14 reset of emergency off [emo] switch 1. Before restarting, always make sure that the cause of the emergency off condition (the reason why the emo switch was activated) has been eliminated from the power supplies, the pr...

Page 21: 1.7 Waste

Hrx-om-m005 chapter 1 safety instructions hrzd series 1.7 waste disposal 1-15 1.7 waste disposal 1.7.1 disposal of refrigerant and compressor oil this product uses hydro-fluorocarbon type refrigerant (hfc) and compressor oil. Comply with the law and regulation in each country for the disposal of ref...

Page 22

Hrx-om-m005 chapter 1 safety instructions 1.8 material safety data sheet (msds) hrzd series 1-16 1.7.2 disposal of circulating fluid the disposal of a circulating fluid must be handled by a specialized industrial waste disposal agency. Ensure all circulating fluid is disposed of by such agency. 1.7....

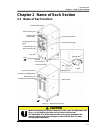

Page 23: 2.1 Name of Each Section

Hrx-om-m005 chapter 2 name of each section hrzd series 2.1 name of each section 2-1 chapter 2 name of each section 2.1 name of each section figure 2-1 name of each section when transporting the product with the casters, raise the adjustable feet (4 pcs.) to the highest position and lock them with th...

Page 24

Hrx-om-m005 chapter 2 name of each section 2.1 name of each section hrzd series 2-2.

Page 25: 3.1 Transporting

Hrx-om-m005 chapter 3 transporting and installation hrzd series 3.1 transporting 3-1 chapter 3 transporting and installation 3.1 transporting the product is heavy and has potential danger during transport. Also, to prevent damage and failure of the product, be sure to follow these instructions for t...

Page 26

Hrx-om-m005 chapter 3 transporting and installation 3.1 transporting hrzd series 3-2 3.1.1 transporting with forklift figure 3-1 transport with forklift rear front forklift insertion side forklift insertion side do not set the product on its side for transportation. Potential damage to this system c...

Page 27: 3.2 Installation

Hrx-om-m005 chapter 3 transporting and installation hrzd series 3.2 installation 3-3 3.1.2 transporting with caster 3.2 installation the product is heavy and requires assistance for this work. Exercise caution and look out for sloped surfaces such as ramps, etc. Product installation should be kept f...

Page 28

Hrx-om-m005 chapter 3 transporting and installation 3.2 installation hrzd series 3-4 3.2.1 installation conditions the product must not be operated, installed, stored or transported in the following conditions. Potential malfunction or damage to the product may occur if disregarded. The product does...

Page 29

Hrx-om-m005 chapter 3 transporting and installation hrzd series 3.2 installation 3-5 3.2.2 installation location and maintenance work area the product does not have any ventilating hole on the right and left sides. Although it can be installed directly contacting walls or other devices, installation...

Page 30

Hrx-om-m005 chapter 3 transporting and installation 3.3 procedure for installation hrzd series 3-6 3.3 procedure for installation 3.3.1 installation product installation should be on a vibration-free, stable and level surface. See “appendix 8.2 outer dimensions” in chapter 8 on page 8-11 for the dim...

Page 31

Hrx-om-m005 chapter 3 transporting and installation hrzd series 3.3 procedure for installation 3-7 3.3.3 wiring installation power cable the power cables are to be prepared under your responsibility, referring to the following table. Table 3-1 power cable and main breaker (the product) item hrzd020-...

Page 32

Hrx-om-m005 chapter 3 transporting and installation 3.3 procedure for installation hrzd series 3-8 selection of the breaker for the customer’s equipment (primary side) this product is equipped with a breaker which has different operating characteristics depending on each model. For the customer’s eq...

Page 33

Hrx-om-m005 chapter 3 transporting and installation hrzd series 3.3 procedure for installation 3-9 3.3.4 procedures for wiring installation 1. Turn off the power breaker on customer side (primary side), and then use the assigned procedures to peform lockout/tagout. [tips] connection of the power cab...

Page 34

Hrx-om-m005 chapter 3 transporting and installation 3.3 procedure for installation hrzd series 3-10 4. Undo the screws (2 pcs.) to remove the breaker cover. [tips] make sure the breaker is at the ‘off’ position. Otherwise, the opening of the front door is not possible. Front front door screw breaker...

Page 35

Hrx-om-m005 chapter 3 transporting and installation hrzd series 3.3 procedure for installation 3-11 5. Loosen the cap and insert the power cable from the power cable access. Retighten the cap after inserting the cable, and make sure the cable is secured. 6. In case of using serial communication, mou...

Page 36: 10.

Hrx-om-m005 chapter 3 transporting and installation 3.3 procedure for installation hrzd series 3-12 8. Connect the power cables to the breaker terminal. Be sure to use a crosshead screwdriver. Recommended torque: 6n•m 9. Connect the grounding terminal (m8) of the power cable to the earth bar. Be sur...

Page 37

Hrx-om-m005 chapter 3 transporting and installation hrzd series 3.3 procedure for installation 3-13 3.3.5 installation of circulating fluid and facility water piping pipe diameter table 3-3 pipe diameter pipe diameter recommended torque (material: ss* vs ss) facility water inlet rc1/2 28 to 30n•m (2...

Page 38

Hrx-om-m005 chapter 3 transporting and installation 3.3 procedure for installation hrzd series 3-14 procedure for piping installation secure the pipe coupling section with a pipe wrench, and provide proper tightening to the pipe. Recommended piping installation table 3-4 recommended pipe no. Name si...

Page 39: 4.1 Pre-Check

Hrx-om-m005 chapter 4 product startup and shutdown hrzd series 4.1 pre-check 4-1 chapter 4 product startup and shutdown 4.1 pre-check check the following items prior to starting up the product. 4.1.1 installation condition make sure that the product is installed in a horizontal position. No heavy ob...

Page 40

Hrx-om-m005 chapter 4 product startup and shutdown 4.3 filling of circulating fluid hrzd series 4-2 背面 循環液規定レベル 4.3 filling of circulating fluid 4.3.1 preparation of circulating fluid when the circulating fluid is a fluorinated fluid when the circulating fluid is a 60% ethylene glycol aqueous soluti...

Page 41

Hrx-om-m005 chapter 4 product startup and shutdown hrzd series 4.3 filling of circulating fluid 4-3 4.3.2 supply of circulating fluid remove the circulating fluid fill cap, and fill the circulating fluid until it reaches its specified level. The circulating fluid specified level is a range between “...

Page 42

Hrx-om-m005 chapter 4 product startup and shutdown 4.4 requirement for product startup hrzd series 4-4 4.4 requirement for product startup 4.4.1 turning on power 1. Make sure that the main breaker for the product is off, and release lockout/tagout of the power breaker on customer side (primary side)...

Page 43

Hrx-om-m005 chapter 4 product startup and shutdown hrzd series 4.5 product startup and shutdown 4-5 4.4.2 circulating fluid temperature setting from the “setting data screen” on the operation touch panel, set the circulating fluid at any temperature. See section 5.3.4 “ch1(2) setting data screen 1, ...

Page 44

Hrx-om-m005 chapter 4 product startup and shutdown 4.5 product startup and shutdown hrzd series 4-6.

Page 45: 5.1 Operation Touch Panel

Hrx-om-m005 chapter 5 product operation hrzd series 5.1 operation touch panel 5-1 chapter 5 product operation 5.1 operation touch panel use the operation touch panel located in front of the product for the basic operations. Figure 5-1 operation touch panel [stop] key used to stop the operation. Oper...

Page 46

Hrx-om-m005 chapter 5 product operation 5.2 flow chart of operation screen hrzd series 5-2 main screen setting data screen 1 detail setting screen 1 detail setting screen 2 alarm list screen alarm history screen 通信モード選択画面 status screen 1 status screen 2 status screen 3 status screen 4 status screen ...

Page 47

Hrx-om-m005 chapter 5 product operation hrzd series 5.2 flow chart of operation screen 5-3 5.2.2 flow chart of operation screen (2) figure 5-3 flow chart of operation screen (2) table 5-2 descriptions of operation screens (2) screen descriptions reference display setting screen 1 allows the changing...

Page 48: 5.3 Operation

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-4 5.3 operation screen 5.3.1 initial screen figure 5-4 “initial screen” the “initial screen” is displayed upon power-on of this product. This screen remains on for approx. 30 seconds and is automatically switched to the “main...

Page 49

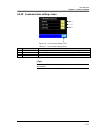

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-5 5.3.2 main screen figure 5-5 “main screen” table 5-4 “main screen” no. Item descriptions p.E pump eco limit : be available c.E compressor eco limit : be available md1 offset mode 1 1 cnt: rmt remote 2 pv discharge temperatu...

Page 50

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-6 5.3.3 special mode the indicator lamp is designed to flash when the product goes into special mode, as shown below. Figure 5-6 “main screen” table 5-5 special mode indicator lamp mode descriptions pump up your piping is sup...

Page 51

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-7 5.3.4 ch1(2) setting data screen 1, 2 figure 5-7 “ch1(2) setting data screen 1” figure 5-8 “ch1(2) setting data screen 2” table 5-6 “ch1(2) setting data screen 1, 2” no. Item descriptions factory default 1 temp sp allows th...

Page 52

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-8 5.3.5 ch1(2) setting data screen 3 figure 5-9 “ch1(2) setting data screen 3” table 5-7 “ch1(2) setting data screen 3” no. Item descriptions factory default 1 di sp allows the setting of sp of the circulating fluid electric ...

Page 53

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-9 ten-key screen the “ten-key screen” appears with the touch of the [set] key of each item on the ch1(2) setting screens 1, 2, and 3, which enables the setting of set values. Figure 5-11 “ten-key screen” table 5-8 “ten-key sc...

Page 54

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-10 procedure for changing circulating fluid set temperature 1. Touch the [setting] key in “ch2” on the “main screen”. The “ch2 setting data screen 1” is displayed. Figure 5-12 “main screen” 2. Touch the [set] key for “temp sp...

Page 55

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-11 5.3.6 mode selection screen figure 5-15 “mode selection screen” this screen enables the selection of the communication mode. The procedures for product start/stop and set value setting may vary with the communication mode....

Page 56

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-12 procedure for changing communication mode 1. Touch the [comm] key on the “main screen". The “mode selection screen” is displayed. Figure 5-16 “main screen” 2. Touch “serial” on the “mode selection screen”. The name of “ser...

Page 57

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-13 4. Touch the [yes] key. The “serial” mode is established, instead of “local”, and the “main screen” is displayed accordingly. Figure 5-19 “message screen” [tips] with the touch of the [no] key, the screen is switched to th...

Page 58

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-14 5.3.7 status screen 1 figure 5-20 “status screen 1” table 5-10 “status screen 1” no. Item descriptions 1 temp pv discharge temperature of the circulating fluid (a value derived according to the offset *1 if applied) 2 temp...

Page 59

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-15 5.3.8 status screen 2 figure 5-21 “status screen 2” table 5-11 “status screen 2” no. Item descriptions 1 - limiting value for the compressor and pump with limited abilities (on is selected on the setting screen) settings o...

Page 60

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-16 5.3.9 status screen 3, 4 the “status screen 3” and “status screen 4” enable the recording of the operational status of ch1 and ch2 respectively. The explanation proceeds taking the “status screen 3” as an example (the “sta...

Page 61

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-17 procedure for deleting logging data 1. Touch the [clear] key. The “message screen” is displayed. Figure 5-23 “status screen 3” 2. Touch the [yes] key. Logging data deletion takes place as to data displayed on the “status s...

Page 62

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-18 5.3.10 status screen 5 figure 5-25 “status screen 5” table 5-13 “status screen 5” no. Item descriptions 1 di pv di level of the circulating fluid 2 di sp set di level 3 di sv status of the di solenoid valve (open/close) 4 ...

Page 63

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-19 5.3.11 alarm list screen in the event of an error in the product, the alarm buzzer sounds *1 and the current screen is switched to the “alarm list screen”. The alarm lamp on the “alarm list screen” flashes, and the relevan...

Page 64

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-20 5.3.12 alarm history screen the alarm history screen lists alarms that have been raised in the product (alarm occurrence date, alarm code, and alarm message). Figure 5-27 “alarm history screen” table 5-15 “alarm history sc...

Page 65

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-21 procedure for deleting alarm history data 1. Touch the [clear] key. The “message screen” is displayed. Figure 5-28 “alarm history screen” 2. Touch the [yes] key. Alarm history data deletion takes place. Figure 5-29 “messag...

Page 66

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-22 5.3.13 detail setting screen 1 figure 5-30 “detail setting screen 1” table 5-16 “detail setting screen 1” no. Item descriptions 1 display set used to display the “display setting screen 1” on page 5-24. 2 communication set...

Page 67

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-23 5.3.14 detail setting screen 2 figure 5-31 “detail setting screen 2” table 5-17 “detail setting screen 2” no. Item descriptions 1 auto purge used to display the “purge mode screen” on page 5-52. 2 [next] key used to displa...

Page 68

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-24 5.3.15 display setting screen 1 figure 5-32 “display setting screen 1” table 5-18 “display setting screen 1” no. Item setting range descriptions factory default 1 language english, japanese, korean allows the selection of ...

Page 69

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-25 5.3.16 display setting screen 2 figure 5-33 “display setting screen 2” table 5-19 “display setting screen 2” no. Item descriptions 1 time used to display the “time setting screen” on page 5-25. 2 [next] key used to display...

Page 70

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-26 procedure for setting time 1. Touch the [+] or [-] key. The cursor appears flashing, and a relevant number is incremented or decremented. Figure 5-35 “time setting screen” 2. Touch the [enter] key. The “message screen” is ...

Page 71

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-27 5.3.18 communication setting screen figure 5-38 “communication setting screen” table 5-21 “communication setting screen” no. Item descriptions 1 serial used to display the “serial communication setting screen 1” on page 5-...

Page 72

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-28 5.3.19 serial communication setting screen 1 figure 5-39 “serial communication setting screen 1” table 5-22 “serial communication setting screen 1” no. Item descriptions factory default 1 spec communication specifications ...

Page 73

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-29 5.3.20 serial communication setting screen 2 figure 5-40 “serial communication setting screen 2” table 5-23 “serial communication setting screen 2” no. Item setting range descriptions factory default 1 [sel] key rs485, rs2...

Page 74

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-30 procedure for specifying communication specifications and baud rate 1. Touch the [sel] key. The box appears flashing. A set value changes with each touch of the key. Figure 5-41 “serial communication setting screen 2” [tip...

Page 75

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-31 procedure for initializing communication specifications and baud rate 1. Touch the [initial] key. The “message screen” is displayed. Figure 5-44 “serial communication setting screen 2” 2. Touch the [yes] key. Initializatio...

Page 76

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-32 5.3.21 ch1(2)dio communication setting screen 1 figure 5-46 “ch1(2)dio communication setting screen 1” table 5-24 “ch1(2)dio communication setting screen 1” no. Item descriptions 1 dio used to display the “ch1(2)dio commun...

Page 77

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-33 5.3.22 ch1(2)dio communication setting screen 2 figure 5-47 “ch1(2)dio communication setting screen 2” table 5-25 “ch1(2)dio communication setting screen 2” no. Item setting range descriptions factory default 1 run a_1, m_...

Page 78

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-34 procedure for setting run, remote, and out1 to out6 1. Touch the arrow [▲][▼] keys ([▲] key only for run and remote). The box appears flashing. A set value changes with each touch of the key. Figure 5-48 “ch1(2)dio communi...

Page 79

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-35 procedure for initializing run, remote, and out1 to out6 settings 1. Touch the [initial] key. The “message screen” is displayed. Figure 5-51 “ch1(2)dio communication setting screen 2” 2. Touch the [yes] key. Initialization...

Page 80

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-36 5.3.23 ch1(2) analog input setting screen figure 5-53 “ch1(2) analog input setting screen 1” table 5-26 “ch1(2) analog input setting screen 1” no. Item setting range descriptions factory default 1 [type] key di sp, n/a, te...

Page 81

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-37 procedure for setting analog input signal type 1. Touch the [type] key. The box appears flashing. A set value changes with each touch of the key. Figure 5-54 “ch1(2) analog input setting screen 1” [tips] the setting has no...

Page 82

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-38 procedure for setting analog input signal scaling 1. Touch the [v lo] key or [v lo] key. The “ten-key screen” is displayed. Figure 5-57 “ch1(2) analog input setting screen 1” 2. Use the ten-key to input a set value, and to...

Page 83

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-39 4. Touch the [yes] key. The setting takes effect. Figure 5-60 “message screen” [tips] the setting is not performed when the [no] key is touched, which causes the “ch1(2) analog input setting screen 1” where the box is flas...

Page 84

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-40 5.3.24 ch1(2) analog output setting screen 1, 2 the “ch* analog output setting screen 1” can set output1 and the “ch* analog output setting screen 2” can set output 2. Figure 5-63 “ch1(2) analog output setting screen 1, 2”...

Page 85

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-41 procedure for setting analog output signal type 1. Touch the [type] key. The box appears flashing. A set value changes with each touch of the key. Figure 5-64 “ch1(2) analog output setting screen 1, 2” [tips] the setting h...

Page 86

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-42 procedure for setting analog output signal scaling 1. Touch the [v lo] key or [v lo] key. The “ten-key screen” is displayed. Figure 5-67 “ch1(2) analog output setting screen 1, 2” 2. Use the ten-key to input a set value, a...

Page 87

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-43 4. Touch the [yes] key. The setting takes effect. Figure 5-70 “message screen” [tips] the setting is not performed when the [no] key is touched, which causes the “ch1(2) analog output setting screen 1, 2” where the box is ...

Page 88

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-44 5.3.25 control setting screen figure 5-73 “control setting screen” table 5-28 “control setting screen” no. Item descriptions 1 ch1 control used to display the “ch1 control setting screen” on page 5-44. 2 ch2 control used t...

Page 89

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-45 5.3.27 ch1(2) compressor eco limit setting screen the compressor eco limit setting screen enables the setting of a limit to compressor performance. Figure 5-75 “compressor eco limit setting screen” table 5-30 “compressor e...

Page 90

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-46 5.3.28 ch1(2) pump eco limit setting screen the pump eco limit setting screen enables the setting of a limit to pump performance. If the setting of the circulating fluid discharge pressure limit is valid, the discharge pre...

Page 91

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-47 5.3.29 ch1(2) offset setting screen the offset setting screen enables the selection of offset mode. Figure 5-77 “offset setting screen” table 5-32 “offset setting screen” no. Item setting range descriptions factory default...

Page 92

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-48 5.3.30 ch1(2) circulating fluid discharge pressure limit setting screen the circulating fluid discharge pressure limit setting screen enables the setting of a limit to discharge pressure of the circulating fluid. The setti...

Page 93

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-49 5.3.31 maintenance screen figure 5-79 “maintenance screen” table 5-34 “maintenance screen” no. Item descriptions 1 auto tuning used to display the “auto tuning screen” on page 5-50. 2 ev adjust used to display the “ev open...

Page 94

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-50 5.3.32 auto tuning screen figure 5-80 “auto tuning screen” table 5-35 “auto tuning screen” no. Item descriptions 1 [start] key used to display the “message screen” to perform auto tuning of ch1. Tunning: during auto tuning...

Page 95

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-51 5.3.33 ev opening adjustment screen figure 5-81 “auto opening adjustment screen” table 5-36 “auto opening adjustment screen” no. Item descriptions 1 [ev1] to [ev3] key used to display the “message screen” to adjust the ori...

Page 96

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-52 5.3.34 purge mode screen figure 5-82 “purge mode screen” table 5-37 “purge mode screen” no. Item descriptions stop collection stopped purging during collection 1 finish collection completed successfully circulating fluid c...

Page 97

Hrx-om-m005 chapter 5 product operation hrzd series 5.3 operation screen 5-53 in the event of an error the error window shown below is displayed when an error occurs that results in the termination of ongoing circulating fluid recovery. Fluid collection is stopped accordingly. Figure 5-83 “purge mod...

Page 98

Hrx-om-m005 chapter 5 product operation 5.3 operation screen hrzd series 5-54.

Page 99: Troubleshooting

Hrx-om-m005 chapter 6 error message and troubleshooting hrzd series 6.1 error message 6-1 chapter 6 error message and troubleshooting 6.1 error message the following events happen when the product has an error. The “alarm” lamp comes on. Alarm buzzer comes on. The “alarm display screen” is displayed...

Page 100: 6.2 Troubleshooting

Hrx-om-m005 chapter 6 error message and troubleshooting 6.2 troubleshooting hrzd series 6-2 6.2 troubleshooting the procedure for error recovery varies with alarm types. Alarm code.01 to 21, 22, 24, 25, 28: eliminate the error cause, then press the [reset] key on the operation display panel or power...

Page 101

Hrx-om-m005 chapter 6 error message and troubleshooting hrzd series 6.2 troubleshooting 6-3 table 6-1 troubleshooting (2/3) code error message product condition cause remedies ch1-15 ch2-15 pump breaker trip flt stop the breaker for the circulating pump power line was tripped. Check that the power s...

Page 102

Hrx-om-m005 chapter 6 error message and troubleshooting 6.2 troubleshooting hrzd series 6-4 table 6-1 troubleshooting (3/3) code error message product condition cause remedies ch1-28 ch2-28 cprsr inv error flt-f0 stop an error was detected in the inverter for compressor. Contact the product supplier...

Page 103

Hrx-om-m005 chapter 7 product maintenance hrzd series 7.1 water quality management 7-1 chapter 7 product maintenance 7.1 water quality management table 7-1 water quality standards substance facility water spec. Circulating water spec. Ph (25°c) 6.5 to 8.2 6.0 to 8.0 electrical conductivity (25°c) (µ...

Page 104

Hrx-om-m005 chapter 7 product maintenance 7.2 inspection and cleaning hrzd series 7-2 7.2 inspection and cleaning 7.2.1 daily inspection table 7-2 daily inspection inspection item inspection method no heavy object is placed on this product. This product should not be subjected to external force. Ins...

Page 105: 7.3 Storage

Hrx-om-m005 chapter 7 product maintenance hrzd series 7.3 storage 7-3 7.2.2 quarterly inspection table 7-3 quarterly inspection inspection item inspection method circulating fluid is to be drained for check. Fluid should be free of particles, moisture *1 and foreign substances. For ethylene glycol s...

Page 106

Hrx-om-m005 chapter 7 product maintenance 7.3 storage hrzd series 7-4 7.3.1 draining of circulating fluid out of tank the refrigerating tank is designed to drain the circulating fluid from the drain port at the back of the product. The water-cooled tank is designed to drain the circulating fluid fro...

Page 107

Hrx-om-m005 chapter 7 product maintenance hrzd series 7.3 storage 7-5 5. Apply air purge from the the circulating fluid return to push the circulating fluid remaining in the heat exchange back in the tank and drain it. 6. Upon completion of fluid draining, close the valves of the main and sub tank d...

Page 108

Hrx-om-m005 chapter 7 product maintenance 7.4 periodic replacement parts hrzd series 7-6 7.3.2 draining of facility water 1. Place the drain pan underneath the piping connections on the rear of the product. At least a 7l capacity drain pan is required. 2. Remove facility water piping. Remove the joi...

Page 109: Chapter 8 Appendix

Hrx-om-m005 chapter 8 appendix hrzd series 8.1 specification 8-1 chapter 8 appendix 8.1 specification 8.1.1 product specification specification for fluorinated fluid (wide temperature) double inverter (hrzd020-ws-ws) table 8-1 specification for fluorinated fluid (wide temperature) double inverter (h...

Page 110

Hrx-om-m005 chapter 8 appendix 8.1 specification hrzd series 8-2 approx. 1 to 2l/min of facility water. *10: the rated flow is a required flow rate to maintain cooling capacity and temperature stability. Always use the accessory “by-pass piping set” if the fluid falls below the rated flow. *11: this...

Page 111

Hrx-om-m005 chapter 8 appendix hrzd series 8.1 specification 8-3 specification for ethylene glycol solution (wide temperature) double inverter (hrzd020-w1s-w1s) table 8-2 specification for ethylene glycol solution (wide temperature) double inverter (hrzd020-w1s-w1s) model hrzd020-w1s-w1s channel 1 2...

Page 112

Hrx-om-m005 chapter 8 appendix 8.1 specification hrzd series 8-4 specification for ethylene glycol solution/ fluorinated fluid (wide temperature) double inverter (hrzd020-w1s-ws) table 8-3 specification for ethylene glycol solution/ fluorinated fluid (wide temperature) double inverter (hrzd020-w1s-w...

Page 113

Hrx-om-m005 chapter 8 appendix hrzd series 8.1 specification 8-5 *11: this is the dimensions of panels, which is derived without protrusions such as a breaker handle. *12: this is the mass of the system when it contains no circulating fluid. *13: if the difference of elevation measures more than 10m...

Page 114

Hrx-om-m005 chapter 8 appendix 8.1 specification hrzd series 8-6 specification for fluorinated fluid / ethylene glycol solution (wide temperature) double inverter (hrzd020-ws-w1s) table 8-4 specification for fluorinated fluid / ethylene glycol solution (wide temperature) double inverter (hrzd020-ws-...

Page 115

Hrx-om-m005 chapter 8 appendix hrzd series 8.1 specification 8-7 *11: this is the dimensions of panels, which is derived without protrusions such as a breaker handle. *12: this is the mass of the system when it contains no circulating fluid. *13: if the difference of elevation measures more than 10m...

Page 116

Hrx-om-m005 chapter 8 appendix 8.1 specification hrzd series 8-8 8.1.2 communication specification this section provides the general outline of communications utilized in this product. For detail specification, we provide a separate product manual “communication specification”, which is available th...

Page 117

Hrx-om-m005 chapter 8 appendix hrzd series 8.1 specification 8-9 serial rs-485, rs-232c table 8-6 serial rs-485, rs-232c item specification connector no. P3 connector type (this product) d-sub9p female connector (m2.6 ×0.45) standard eia rs-485, rs-232c protocol modicon modbus circuit block diagram ...

Page 118

Hrx-om-m005 chapter 8 appendix 8.1 specification hrzd series 8-10 8.1.3 alarm signal selection user can designate alarm signal separately for contact signal (out1 to out6). See section 5.3.22 “ch1(2)dio communication setting screen 2” in “chapter 5 product operation” on page 5-33 for signal selectin...

Page 119: 8.2 Outer

Hrx-om-m005 chapter 8 appendix hrzd series 8.2 outer dimensions 8-11 8.2 outer dimensions figure 8-1 outer dimensions (dimensional tolerance: ±10mm) top left rear front.

Page 120: 8.3 Flow

Hrx-om-m005 chapter 8 appendix 8.3 flow chart hrzd series 8-12 8.3 flow chart 8.3.1 hrzd020-ws-ws, hrzd020-w1s-w1s, hrzd020-w1s-ws, hrzd020-ws-w1s drain pan drain pan port (rc3/8 w/ plug) facility water circuit (single system for ch1 and ch2) circulating fluid circuit thermal fuse internal pump circ...

Page 121: 8.4 Offset

Hrx-om-m005 chapter 8 appendix hrzd series 8.4 offset function 8-13 8.4 offset function potential deviations in temperature between this product and your system may occur depending on the installation environment. The offset function has three types (mode1 to 3) to calibrate any deviations in temper...

Page 122

Hrx-om-m005 chapter 8 appendix 8.4 offset function hrzd series 8-14 8.4.1 example of offset function when the discharge temperature of the circulating fluid is at 30°c, heat is dissipated by 1°c so the circulating fluid in your system to be 29°c. Under the above condition, the following process is t...

Page 123

Hrx-om-m005 chapter 8 appendix hrzd series 8.4 offset function 8-15 when mode2 is selected with offset value set at -1°c, temp pv and communication data shows “29°c” (circulating fluid discharge temp. Value + offset value) that agrees with the temperature of the circulating fluid in your system. Fig...

Page 124: 8.5 Band/ready

Hrx-om-m005 chapter 8 appendix 8.5 band/ready function hrzd series 8-16 8.5 band/ready function sets band to temp sp value, and notifies temp pv value reaches within band range by the operation display panel or the communication. See section 5.3.4 “ch1(2) setting data screen 1, 2” in “chapter 5 prod...

Page 125

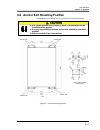

Hrx-om-m005 chapter 8 appendix hrzd series 8.6 anchor bolt mounting position 8-17 8.6 anchor bolt mounting position adjust and secure the adjuster foot of the product to the anti-seismic bracket. Figure 8-8 anchor bolt mounting position anti-seismic bracket is an accessory, which is recommended for ...

Page 126: 8.7 Compliance

Hrx-om-m005 chapter 8 appendix 8.7 compliance hrzd series 8-18 8.7 compliance this product conforms to the following standards. Table 8-8 compliance emc directive 2004/108/ec low voltage directive 2006/95/ec machinery directive 2006/42/ec overvoltage category category 2 (iec60664-1) ce marking pollu...

Page 127: 8.8

Hrx-om-m005 chapter 8 appendix hrzd series 8.8 thermo chiller daily inspection sheet 8-19 8.8 thermo chiller daily inspection sheet circulat ing f luid supply port cap looseness in pr ess. Flowrate te m p. O perat ing condit ion e rro r circulat ing flu id flo w ra te circulat ing f luid out let pre...

Page 128

Hrx-om-m005 chapter 8 appendix 8.8 thermo chiller daily inspection sheet hrzd series 8-20

Page 129: Product Warranty

Product warranty 1. Conditions of warranty when a nonconformance should take place to our thermo-cooler, we will repair the unit without charge in accordance with our current terms and conditions. This free repair covers the replacement of all nonconforming parts, their adjustment and checks. Please...