SMC Networks IDU15E1-23 SERIES Operation Manual - Troubleshooting

5. Troubleshooting

5 - 1

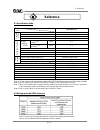

5.1 Troubleshooting

If any error is found in the product, investigate the following points. If the error cannot be solved, turn off the

power supply and contact your local supplier or SMC sales representative.

Trouble

Possible cause

Remedy

Although the

switch with lamp

is turned on, the

lamp does not

light up and the

product does not

start operating.

The power supply cable has been

loosened or disconnected.

- Reconnect it firmly.

The ground fault circuit

interrupter is not turned on.

Check the capacity of the ground fault circuit interrupter.

- Check the product was not restarted within 3 minutes after

being stopped.

- Turn on the ground fault circuit interrupter and try to

operate.

If the ground fault circuit interrupter turns back off, the

insulation failure of the product is suspected. Turn off the

power supply and contact SMC.

Running lamp

extinguishes

and compressor

stops during

operation but

resumes normal

operation

illuminating the

lamp after

aperiod of time.

The product is installed in an

inappropriate location.

Ambient temperature is excessive.

- Improve ventilation condition and reduce the ambient

temperature as much as possible.

The ventilation port is obstructed

by a wall or clogged with dust.

- Keep the product 60cm or more away from the surrounding

walls.

- Clean the ventilation ports once every month.

The compressed air temperature is

too high.

- Improve the ventilation in the location where the air

compressor is installed, or decrease the ambient

temperature to allow the discharge air temperature of the

air compressor to go down.

- Install an aftercooler after the air compressor to reduce the

temperature.

The fluctuation of the power supply

voltage is too large.

- Install a power supply transformer or use a different power

supply to provide appropriate voltage.

- The fluctuation of the power supply voltage should be kept

within +/-10% of the rated voltage.

The evaporation

thermometer is

over the green

area without hot

air coming from

the ventilation

port (exhaust

port).

(The compressor

for refrigeration

has stopped with

the lamp lit up.

The product is installed in an

inappropriate location.

Ambient temperature is excessive.

- Improve ventilation condition and reduce the ambient

temperature as much as possible.

The ventilation port is obstructed

by a wall or clogged with dust.

- Keep the product 60cm or more away from the

surrounding walls.

- Clean the ventilation ports once every month.

The compressed air temperature is

excessive.

- Improve the ventilation in the location where the air

compressor is installed, or decrease the ambient

temperature to allow the discharge air temperature of the

air compressor to go down.

- Install an aftercooler after the air compressor to reduce the

temperature.

The fluctuation of the power supply

voltage is too large.

- Install a power supply transformer or use a different power

supply to provide appropriate voltage.

- The fluctuation of the power supply voltage should be kept

within +/-10% of the rated voltage.

The built-in overload relay of the

compressor for refrigeration has

started.

- Check the product was not restarted within 3 minutes after

being stopped.

Troubleshooting

5