- DL manuals

- SPX

- Measuring Instruments

- LeakMaster

- Operator's manual

SPX LeakMaster Operator's manual

LeakMaster

™

Evaporative Emissions System Tester with UltraTraceUV

®

dye Technology

Probador del sistema de emisiones de evaporatión y la tecnologia de tinte UltraTraceUV

®

Testeur de système absorbeur de vapeurs de carburant de colorants UltraTraceUV

®

technologie

Part No. 6525

Operator’s Manual

Manual del operador

Manuel de l’opérateur

Summary of LeakMaster

Page 1

Leakmaster ™ evaporative emissions system tester with ultratraceuv ® dye technology probador del sistema de emisiones de evaporatión y la tecnologia de tinte ultratraceuv ® testeur de système absorbeur de vapeurs de carburant de colorants ultratraceuv ® technologie part no. 6525 operator’s manual ma...

Page 2: Table of Contents

1 table of contents table of contents .............................................................................1 safety precautions ............................................................................2 background ..............................................................................

Page 3: Safety Precautions

2 if the operator cannot read these instructions, operating instructions and safety precautions must be read and discussed in the operator’s native language. Warning: to prevent personal injury and / or damage to equipment : • read, understand, and follow all safety precautions and operating procedu...

Page 4: Background

3 the fuel vapor recovery system is the most neglected part of a vehicle’s emission system, according to the environmental protection agency (epa). The vehicle’s evap system is used to collect fuel vapors from the fuel tank. These vapors are stored in a canister filled with activated charcoal. The e...

Page 5: Congratulations!

4 congratulations! You are in possession of the most useful, yet simple to operate, evaporative emissions (evap) system diagnostic tester available today. The leakmaster’s versatile 12-volt design was specifically developed to diagnose vehicle evap systems for leaks. In addition, the leakmaster will...

Page 6: Tester Overview

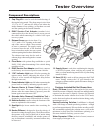

5 tester overview component descriptions 1. Cap plug kit is used to seal the intake ducting of the engine being tested. The plugs range in size from 1-3/4" to 4-1/2", and may be used to seal either the inside diameter of an opening, or flip them over and seal the opening at the outside diameter. 2. ...

Page 7: Setup

6 setup 1. Connect the red power cable from the leakmaster to a 12v dc power supply. If you are using a battery, verify it is in good condition and fully charged. See figure 1. 2. Connect the black ground cable from the leakmaster to the vehicle’s chassis ground. Connect black battery clip to chassi...

Page 8: Phase One

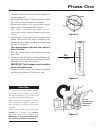

7 phase one 1. Verify the vehicle’s fuel level is below the base of the fuel tank neck. 2. Determine if the vehicle’s evap system is governed by a .040 or .020 acceptable leak standard. 3. Position the selector valve on the tester control panel to the correct standard. See figure 3. The “future” set...

Page 9: Phase One

8 phase one 8. Insert the supply hose from the tester into the evap service port adapter. See figure 6. 9. Close the vehicle’s evap system vent solenoid. 10. Set the tester’s control valve to test. 11. Press the remote start button to activate the tester. At the beginning of the test procedure, the ...

Page 10: Phase Two

9 phase two 1. Verify the vehicle’s fuel level is below the base of the fuel tank neck. 2. Position the selector valve on the tester to smoke. See figure 8. 3. Remove the vehicle’s fuel cap. This saves time when filling the evap system with smoke. 4. Press the remote starter button to activate the t...

Page 11: Vacuum and Induction Leaks

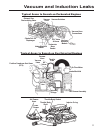

10 1. Seal the system to be tested by selecting the correct size cap plug (supplied) and sealing the engine’s air intake. To inspect the entire system, it is best to seal the engine’s intake as close as possible to the air inlet origin. This is especially important on engines equipped with mass airf...

Page 12: Vacuum and Induction Leaks

11 vacuum and induction leaks typical areas to search on fuel injected engines typical areas to search on carbureted engines air cleaner hose loose clamps throttle body shaft throttle body gasket injector o-ring positive crankcase vent hose (pcv) vacuum lines air valves vacuum lines throttle plate a...

Page 13: Vacuum and Induction Leaks

12 vacuum and induction leaks egr valve leaks the exhaust gas recirculating valve is at the heart of the emission control system. Since the egr valve operates in such a hostile environment, it is always susceptible to leakage. During a normal test for vacuum leaks, the egr valve will be exposed to s...

Page 14: Exhaust Leaks

13 exhaust leaks the exhaust cones were developed for the identifi- cation of leaks in a vehicle’s exhaust system. These leaks can be difficult to locate, because they are often hidden by metal shields, or become silenced as the engine warms up. 1. Put the vehicle on a lift to expose the underside. ...

Page 15: Miscellaneous Leaks

14 miscellaneous leaks oil seals and gasket leaks many oil leaks can be located with the leakmaster; however, it is important to understand that the leakmaster will only find leaks that allow air to flow through them, causing the oil to bubble. To find oil leaks, it is necessary to pressurize the cr...

Page 16: Miscellaneous Leaks

15 miscellaneous leaks component testing (radiators, water pumps, valves, etc.) when installing new or rebuilt parts, nothing is more frustrating than to discover, on completion of the job, that the component is faulty or has a leak. It is far easier to inspect a radiator or water pump before it is ...

Page 17: Miscellaneous Leaks

16 miscellaneous leaks wind and water leaks (sunroofs, windows, etc.) the smoke diffuser was developed for quick identification of air and water leaks in a vehicle’s passenger compartment. These leaks can be caused by faulty door and glass seals, windshield or sliding roof seals, or by misalignment ...

Page 18: Maintenance

17 maintenance dipstick low full caution: use only the no. P-0716-uv smoke-producing solution (obtained from the manufacturer) in the leakmaster. Using solutions not recommended by the manufacturer can damage the unit and cause injury to the operator. Checking the smoke solution level check the smok...

Page 19: Parts List

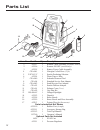

18 parts list 2 3 1 4 5 6 7 8 9 10 11 12 13 14 15 16 17 item no. Part no. Qty. Description 1 6525-7 1 remote cable assembly (includes switch) 2 6525-6 1 remote on/off (switch only) 3 6525-5 1 battery power cable assembly 4 cea-041 1 nitrogen coiled hose (25 ft.) 5 p-0716-uv 1 smoke producing solutio...

Page 20: Troubleshooting

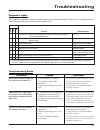

19 troubleshooting diagnostic lights the leakmaster has three diagnostic lights on the control panel that indicate if the tester is working correctly. The following table describes the tester’s trouble codes. Interval probable cause √ constant on (switch in smoke position; smoke venting into atmosph...

Page 21: Fluid Change Record

20 fluid change record date name date name notes.

Page 22: Quick Reference

21 quick reference tester hookup 1. Connect red power cable to 12v dc power. 2. Connect black ground cable to chassis ground. 3. Connect nitrogen to tester. Phase one 1. Set control valve to correct calibration. 2. Press remote button, and align flow meter’s flag with ball. 3. Remove vehicle’s schra...

Page 23: Warranty

22 warranty limited one (1) year warranty champion engineering, inc. Warrants only to the original purchaser that under normal use, care and service, the equipment (except as otherwise provided herein) shall be free from defects in material and workmanship for one year from the date of original invo...

Page 24

Form no. 107360 © 2002 spx corporation (rev. H, october 23, 2008) manufactured by usa & canada patented foreign & other usa patents pending 655 eisenhower drive po box 995 owatonna, mn 55060-0995 usa phone: (507) 455-7000 tech. Serv.: (800) 533-6127 fax: (800) 955-8329 order entry: (800) 533-6127 fa...