- DL manuals

- SPX

- Power Tool

- TWSL4-046

- Operating manual

SPX TWSL4-046 Operating manual

Summary of TWSL4-046

Page 1

© spx flow, inc. 0 form no. 1000996 rev. 0 oct. 3, 2016 operating manual for: twsl series slimline hydraulic torque wrench original instructions.

Page 2: Table Of Contents

© spx flow, inc. 1 form no. 1000996 rev. 0 oct. 3, 2016 table of contents torque wrench slimline (twsl) ..................................................................................................... 2 safety symbols and definitions ................................................................

Page 3

© spx flow, inc. 2 form no. 1000996 rev. 0 oct. 3, 2016 torque wrench slimline (twsl) description: the twsl torque wrench is a ratchet-type torque tool for tightening nuts and bolts. It uses interchangeable drive links to fit a variety of sizes. It is powered with a 690 bar (10,000 psi) hydraulic pu...

Page 4

© spx flow, inc. 3 form no. 1000996 rev. 0 oct. 3, 2016 safety symbols and definitions the safety signal word designates the degree or level of hazard seriousness. Danger: indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning: indicates a ...

Page 5

Safety precautions continued © spx flow, inc. 4 form no. 1000996 rev. 0 oct. 3, 2016 electric motor warning: to prevent personal injury, electrical work must be performed and tested by a qualified electrician per local directives and standards. Disconnect the pump from the power supply and relieve p...

Page 6: Initial Setup

© spx flow, inc. 5 form no. 1000996 rev. 0 oct. 3, 2016 initial setup each hydraulic torque wrench is supplied completely assembled and ready for use. A hydraulic pump is required to provide the speed and pressure that makes the hydraulic wrench system efficient and accurate. 1. Read and understand ...

Page 7

Initial setup continued © spx flow, inc. 6 form no. 1000996 rev. 0 oct. 3, 2016 torque wrench usage to ensure reasonable life and performance from the torque wrench and system (pump and hoses), these guidelines should be followed: under normal use, the torque wrench should be limited to 75 –80% of i...

Page 8

Initial setup continued © spx flow, inc. 7 form no. 1000996 rev. 0 oct. 3, 2016 safety the twsl hydraulic torque wrench is a high-power hydraulic tool. It is strongly recommended that all users are fully trained and competent in the use of hydraulic torque wrench systems. Incorrect use of the equipm...

Page 9

Initial setup continued © spx flow, inc. 8 form no. 1000996 rev. 0 oct. 3, 2016 preparing the torque wrench for use important: for a copy of the calibration certificate for a specific hydraulic torque wrench, e-mail info@spxboltingsystems.Com with serial number of the hydraulic torque wrench. Cautio...

Page 10

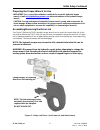

Initial setup continued © spx flow, inc. 9 form no. 1000996 rev. 0 oct. 3, 2016 see figure 2. To assemble a link, position the link onto the body, engaging the keyways on the inner surface of the link sideplates with the keys on the body. Slide the link fully onto the body and push the link retainin...

Page 11

Initial setup continued © spx flow, inc. 10 form no. 1000996 rev. 0 oct. 3, 2016 9. Make sure the hydraulic torque wrench is suitable to deliver the required torque. Should the torque value exceed 80% of the hydraulic torque wrench output, consider using a higher capacity hydraulic torque wrench. 10...

Page 12: Operating Instructions

© spx flow, inc. 11 form no. 1000996 rev. 0 oct. 3, 2016 operating instructions positioning the hydraulic torque wrench on the nut the twsl hydraulic torque wrench fits directly around the nut, with its built in reaction pad designed to brace against an adjacent nut. Figure 4 indicates correct posit...

Page 13

Operating instructions continued © spx flow, inc. 12 form no. 1000996 rev. 0 oct. 3, 2016 use of backing wrenches backing wrenches are often used to prevent the non-tightening nut on the opposite side of the joint assembly from turning during the torquing operation. Verify that the backing wrench is...

Page 14

Operating instructions continued © spx flow, inc. 13 form no. 1000996 rev. 0 oct. 3, 2016 warning: before bolt torquing, verify that: the procedure and data to be used is authorized by a responsible engineer. The joints/pipework being worked on are not live. Joints must be at zero pressure and free ...

Page 15

Operating instructions continued © spx flow, inc. 14 form no. 1000996 rev. 0 oct. 3, 2016 procedure 1. Connect the hydraulic torque wrench to the pump unit. Verify that the couplings are fully screwed together; they are self-sealing and will restrict oil flow if not fully connected. 2. Before applyi...

Page 16: Performance Specifications

© spx flow, inc. 15 form no. 1000996 rev. 0 oct. 3, 2016 performance specifications technical specifications the following technical data is applicable to all twsl hydraulic torque wrenches: link maximum torque: see link table below body maximum pressure: advance - 690 bar (10,000 psi) retract - 103...

Page 17

© spx flow, inc. 16 form no. 1000996 rev. 0 oct. 3, 2016 twsl4 pressure/torque conversion chart link maximum pressures (1) – twsl4-046 (2) – twsl4-050 (3) – twsl4-055 (4) – twsl4-060 pump pressure torque output bar psi nm ft-lb 83 1200 685 505 97 1400 799 589 110 1600 913 674 124 1800 1027 758 138 2...

Page 18: General Maintenance

© spx flow, inc. 17 form no. 1000996 rev. 0 oct. 3, 2016 general maintenance maintenance maintenance should follow each period of use to keep the twsl hydraulic torque wrench in good working condition. Twsl torque wrench 1. Wipe away any debris that may have accumulated, particularly around the swiv...

Page 19

General maintenance continued © spx flow, inc. 18 form no. 1000996 rev. 0 oct. 3, 2016 figure 6. Right hand sideplate removal 5. See figure 7 and parts list. Remove the drive assembly and lubricate the link components using revol r5 moly anti seize : lh and rh sideplate recesses, bores and inside fa...

Page 20

General maintenance continued © spx flow, inc. 19 form no. 1000996 rev. 0 oct. 3, 2016 6. Rebuild the link ensuring the slider pin correctly locates in the lh sideplate groove and that the crank is correctly located in the slider. 7. Re-assemble the link onto the body for storage to prevent debris f...

Page 21

© spx flow, inc. 20 form no. 1000996 rev. 0 oct. 3, 2016 troubleshooting fault possible cause remedy cylinder will not advance. 1. Coupling not fully mated. 1. Check coupling. Cylinder will not retract. 2. Cylinder seal leakage. 2. Replace seal. 3. Pump unit. 3. Check pump unit. 4. Faulty coupling. ...

Page 22: Repair Procedures

© spx flow, inc. 21 form no. 1000996 rev. 0 oct. 3, 2016 repair procedures it is recommended that full servicing is carried out on an annual basis by the manufacturer or approved service agent (other than maintenance, lubrication, and emergency seal replacement). All components shall be inspected an...

Page 23

Repair procedures continued © spx flow, inc. 22 form no. 1000996 rev. 0 oct. 3, 2016 teeth for damage, cracks etc. Any substandard component must be replaced immediately using genuine parts supplied by spx bolting systems. Link assembly see figure 9. Before assembly, apply a liberal coat of revol r5...

Page 24

Repair procedures continued © spx flow, inc. 23 form no. 1000996 rev. 0 oct. 3, 2016 figure 10. Link component assembly 5. See parts list. Assemble the rh sideplate ensuring that the crank stop locates correctly into the rh sideplate. 6. See figure 11. Apply revol r5 moly anti seize or general greas...

Page 25

Repair procedures continued © spx flow, inc. 24 form no. 1000996 rev. 0 oct. 3, 2016 link size screw 1 screw 2 screw 3 nm lb-in nm lb-in nm lb-in twsl 4 20 177 10.2 90 10.2 90 7. Manually rotate the ratchet verifying free movement and correct ratcheting. Following strip down and/or lubrication, the ...

Page 26

© spx flow, inc. 25 form no. 1000996 rev. 0 oct. 3, 2016 multiswivel manifold assembly note: all seals should be new and lubricated with clean hydraulic oil or seal assembly paste before installation. 1. Install the new port o-ring seals into the base of the multiswivel post. 2. Apply loctite® 243 o...

Page 27

Repair procedures continued © spx flow, inc. 26 form no. 1000996 rev. 0 oct. 3, 2016 item description 1 shuttle 2 piston rod 3 gland 4 body figure 15. Gland location 5. See figure 16. Withdraw the entire piston assembly out of the body. Item description 1 piston seal 2 piston 3 gland 4 shuttle 5 gla...

Page 28

Repair procedures continued © spx flow, inc. 27 form no. 1000996 rev. 0 oct. 3, 2016 hydraulic body assembly note: all seals should be new and lubricated with clean hydraulic oil or seal assembly paste before installation. 1. Assemble a new rod seal and a new o-ring seal onto the gland. Assemble a n...

Page 29

© spx flow, inc. 28 form no. 1000996 rev. 0 oct. 3, 2016 parts lists.

Page 30

Parts lists continued © spx flow, inc. 29 form no. 1000996 rev. 0 oct. 3, 2016 twlc4 torque wrench parts list item no part number qty description 1 ldfas040002 1 twlc body assembly 1.1 stdfa000070 1 - plug 1.2 ldfbd040001 1 - twlc body 2 dftas010001 1 multiswivel manifold assembly 2.1 stdhc000005 1 ...

Page 31

© spx flow, inc. 30 form no. 1000996 rev. 0 oct. 3, 2016.

Page 32

© spx flow, inc. 31 form no. 1000996 rev. 0 oct. 3, 2016 twsl4 torque wrench: link parts list link ref: twsl4-2 twsl4-046 item no. Part no. Qty description 1 dfthp040001 1 twl4 head pin 2 twslpl040046 1 twsl4 left sideplate 46mm / 1-13/16" a/f 3 stdfa000062 1 screw 4 twslcs040001 1 twsl4 crank stop ...

Page 33

Parts lists continued © spx flow, inc. 32 form no. 1000996 rev. 0 oct. 3, 2016 link ref: twsl4-3 twsl4-050 item no. Part no. Qty description 1 dfthp040001 1 twl4 head pin 2 twslpl040050 1 twsl4 left sideplate 50mm / 2" a/f 3 stdfa000062 1 screw 4 twslcs040001 1 twsl4 crank stop 5 dftsl040001 1 twl4 ...

Page 34

Parts lists continued © spx flow, inc. 33 form no. 1000996 rev. 0 oct. 3, 2016 link ref: twsl4-4 twsl4-055 item no. Part no. Qty description 1 dfthp040001 1 twl4 head pin 2 twslpl040055 1 twsl4 left sideplate 55mm / 2-3/16" a/f 3 stdfa000062 1 screw 4 twslcs040001 1 twsl4 crank stop 5 dftsl040001 1 ...

Page 35

Parts lists continued © spx flow, inc. 34 form no. 1000996 rev. 0 oct. 3, 2016 link ref: twsl4-5 twsl4-060 item no. Part no. Qty description 1 dfthp040001 1 twl4 head pin 2 twslpl040060 1 twsl4 left sideplate 60mm / 2-3/8" a/f 3 stdfa000062 1 screw 4 twslcs040001 1 twsl4 crank stop 5 dftsl040001 1 t...

Page 36

Parts lists continued © spx flow, inc. 35 form no. 1000996 rev. 0 oct. 3, 2016 link ref: twsl4-6 twsl4-065 item no. Part no. Qty description 1 dfthp040001 1 twl4 head pin 2 twslpl040065 1 twsl4 left sideplate 65mm / 2-9/16" a/f 3 stdfa000062 1 screw 4 twslcs040001 1 twsl4 crank stop 5 dftsl040001 1 ...

Page 37

Parts lists continued © spx flow, inc. 36 form no. 1000996 rev. 0 oct. 3, 2016 link ref: twsl4-7 twsl4-070 item no. Part no. Qty description 1 dfthp040001 1 twl4 head pin 2 twslpl040070 1 twsl4 left sideplate 70mm / 2-3/4" a/f 3 stdfa000062 1 screw 4 twslcs040001 1 twsl4 crank stop 5 dftsl040001 1 t...

Page 38

Parts lists continued © spx flow, inc. 37 form no. 1000996 rev. 0 oct. 3, 2016 link ref: twsl4-8 twsl4-075 item no. Part no. Qty description 1 dfthp040001 1 twl4 head pin 2 twslpl040075 1 twsl4 left sideplate 75mm / 2-15/16" a/f 3 stdfa000062 1 screw 4 twslcs040001 1 twsl4 crank stop 5 dftsl040001 1...

Page 39

Parts lists continued © spx flow, inc. 38 form no. 1000996 rev. 0 oct. 3, 2016 link ref: twsl4-9 twsl4-080 item no. Part no. Qty description 1 dfthp040001 1 twl4 head pin 2 twslpl040080 1 twsl4 left sideplate 80mm / 3-1/8" a/f 3 stdfa000062 1 screw 4 twslcs040001 1 twsl4 crank stop 5 dftsl040001 1 t...

Page 40

© spx flow, inc. 39 form no. 1000996 rev. 0 oct. 3, 2016.