- DL manuals

- SPX

- Heat Pump

- Votator II

- Instruction Manual

SPX Votator II Instruction Manual

Summary of Votator II

Page 1

Fpo instruction manual votator ® ii scraped surface heat exchanger form no.: 95-03057 revision: 11/2012 read and understand this manual prior to operating or servicing this product..

Page 2

Information contained in this manual is subject to change without notice and does not represent a commitment on the part of spx corporation. No part of this manual may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying and recording, for any pu...

Page 3

11/2012 95-03057 page 1 waukesha cherry-burrell table of contents warranty ......................................................................................................4 shipping damage or loss ...........................................................................4 warranty claim ........

Page 4

Page 2 95-03057 11/2012 table of contents waukesha cherry-burrell special considerations for vertical votator ii ..............................................24 minimum height - vertical votator ii ...........................................................24 mounting pole - vertical votator ii ......

Page 5

11/2012 95-03057 page 3 waukesha cherry-burrell table of contents heat exchanger tube removal - horizontal unit ...................................... 50 heat exchanger tube installation - horizontal unit ................................... 51 maintenance of vertical votator ii ........................

Page 6: Warranty

Warranty waukesha cherry-burrell page 4 95-03057 11/2012 warranty seller warrants its products to be free from defect in materials and workmanship for a period of one (1) year from the date of shipment. This warranty shall not apply to products which require repair or replacement due to normal wear ...

Page 7: Safety

Waukesha cherry-burrell safety 11/2012 95-03057 page 5 safety read and understand this manual prior to installing, operating or servicing this equipment spx recommends users of our equipment and designs follow the latest industrial safety standards. At a mini- mum, these should include the industria...

Page 8: Care of Stainless Steel

Care of stainless steel waukesha cherry-burrell page 6 95-03057 11/2012 care of stainless steel stainless steel corrosion corrosion resistance is greatest when a layer of oxide film is formed on the surface of stainless steel. If film is disturbed or destroyed, stainless steel becomes much less resi...

Page 9: Introduction

Waukesha cherry-burrell introduction 11/2012 95-03057 page 7 introduction models and specifications the votator ii can be furnished for horizontal or vertical installation, available in the following models: model heat transfer area jacket type 6 x 84 11 ft 2 (1.0 m 2 ) steam/liquid refrigeration 6 ...

Page 10

Introduction waukesha cherry-burrell page 8 95-03057 11/2012 votator ii media configurations the votator ii is available in the following configurations: • bws-brine/water/steam for liquid and steam heating and cooling applications. • liquid for water or glycol. • vapor for steam or refrigeration. S...

Page 11: Installation

Waukesha cherry-burrell installation 11/2012 95-03057 page 9 installation site selection considerations foundation & drainage the votator ii should be located on a firm foundation, angled to allow liquids to drain away from the unit. Clearances • the rear and sides of the unit, or unit cluster, shou...

Page 12

Installation waukesha cherry-burrell page 10 95-03057 11/2012 • refrigeration valves: liquid feed solenoid valve dual pressure regulating valve level switch hot gas pressure regulating valve hot gas solenoid valve • freeze protection components (if furnished): current sensing relay instrument curren...

Page 13

Waukesha cherry-burrell installation 11/2012 95-03057 page 11 2005 mechanical seal design units furnished between 2005 and 2012 have a one-piece chrome-oxide coated rotating body running against a stationary ceramic head insert. It can easily be converted to a double mechanical seal by adding second...

Page 14

Installation waukesha cherry-burrell page 12 95-03057 11/2012 flush fluid requirements the double mechanical seal must be flushed, using the threaded flush ports, anytime the mutator shaft is rotated. Failure to do this will result in rapid seal failure due to excessive contaminate and heat buildup....

Page 15

Figure 8- suggested media piping, steam s pi tc ty te pi pi 1 2 4 3 5 6 7 9 8 10 11 12 he100-056 waukesha cherry-burrell installation 11/2012 95-03057 page 13 suggested media piping for water or liquid the media piping should flow counter-current to the product flow, and should be circulating at a r...

Page 16

Installation waukesha cherry-burrell page 14 95-03057 11/2012 refrigeration piping installation analyze plant refrigeration load capacity thoroughly. The system must be sized to adequately support the additional capacity of this cylinder. All pipes must be clean and free of oil, chips and sealant re...

Page 17

Waukesha cherry-burrell installation 11/2012 95-03057 page 15 refrigeration valves liquid feed solenoid valve liquid feed solenoid valve is for on/off control of liquid refrigerant flow. Valve is closed when de-energized. Dual pressure regulating valve dual pressure regulating valve is shipped loose...

Page 18

Installation waukesha cherry-burrell page 16 95-03057 11/2012 hot gas pressure regulating valve systems with hot gas include a solenoid-operated pressure regulating valve for introducing and maintaining constant downstream pressure for hot gas inlet. Pumped refrigeration systems include a solenoid o...

Page 19

Table 3: call outs for figure 10 (on page 16) 1. Safety relief valve 10. Dual pressure regulating valve (includes items 4, 8 and 9) 2. Product in 11. To refrigerant low pressure receiver 3. Product out 12. Hot gas purge valve 4. Low pressure solenoid valve, see item 10 13. Flow control valve 5. Hot ...

Page 20

Figure 12- suggested media piping, gravity refrigeration - vertical 1 2 3 4 5 6 7 9 10 11 12 13 14 15 16 17 18 19 20 pi s s s pi he100-060a pi 1 10 12 11 11 13 level switch control or level master control table 4: call outs for figure 11 (page 17) and figure 12 1. Safety relief valve (dual) 12. Liqu...

Page 21

Waukesha cherry-burrell installation 11/2012 95-03057 page 19 electrical equipment the electrical components, if furnished by waukesha cherry- burrell, are loose and require installation by customer.The list below is keyed to the suggested wiring diagrams on the following pages and describe typical ...

Page 22

Installation waukesha cherry-burrell page 20 95-03057 11/2012 refrigeration wiring schematics freeze protection components figure 13- suggested electrical schematic - freeze protection components cu rr e n t se n s e re l a y cu rre nt me t e r ii- x x 1 2 34 567 9 8 10 11 tr ip c u r r e n t = ad j...

Page 23

Waukesha cherry-burrell installation 11/2012 95-03057 page 21 gravity refrigeration with level master control (lmc) figure 14- suggested electrical schematic - gravity refrigeration with level master control (lmc) he100-101a.

Page 24

Installation waukesha cherry-burrell page 22 95-03057 11/2012 gravity refrigeration with level switch figure 15- suggested electrical schematic - gravity refrigeration with level switch he100-108.

Page 25

Waukesha cherry-burrell installation 11/2012 95-03057 page 23 liquid overfeed refrigeration system figure 16- suggested electrical schematic - liquid overfeed refrigeration system he100-102.

Page 26

Installation waukesha cherry-burrell page 24 95-03057 11/2012 media system check danger: refrigeration controls should be operated and serviced only by trained and qualified personnel. Each cylinder is tested for leaks at the factory. However, vibrations and handling during shipping can loosen pipin...

Page 27

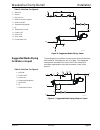

Waukesha cherry-burrell installation 11/2012 95-03057 page 25 mounting scrape cylinders - vertical votator ii using a crane or other lift device, lift cylinder from pedestal (drive) end. Lifting in any other manner may damage cylinder. Secure scrape cylinders in place with four (4) stainless steel 5...

Page 28

Installation waukesha cherry-burrell page 26 95-03057 11/2012 check balance and pressure settings balance and pressure settings should be checked prior to start- up as follows: 1. Start hydraulic pump. Note: the hydraulic pump must be wired to an on/off switch device. Pump rotation is clockwise when...

Page 29

Waukesha cherry-burrell installation 11/2012 95-03057 page 27 gravity refrigeration system - vertical votator ii the gravity refrigeration system includes the following items that must be installed: • accumulator • media piping • valves the accumulator, refrigeration piping, and valves are shipped l...

Page 30

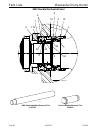

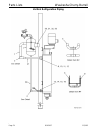

Installation waukesha cherry-burrell page 28 95-03057 11/2012 typical dimensional data and hydraulic lift system votator ii general assembly v o tator ii general assembly 95 r e q' d f o r s h af t r e mo v a l 7-3/1 6 ” (18 3 mm) 7 -1/4” (1 8 1 mm) 21-5/16 ” di m "c " di m "b " 9” d im " a" (app ro...

Page 31

Waukesha cherry-burrell installation 11/2012 95-03057 page 29 horizontal refrigeration assembly d im " a " d im " b " d im " c " d im " d " d im " e " d im " f " di m " g " di m "h " d im " j " d im " k " d im " l " 1 . A c c u m u l a t o r s b e a r s a .S .M .E . S t a m p f o r c o m p l ia n c ...

Page 32

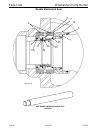

Installation waukesha cherry-burrell page 30 95-03057 11/2012 vertical refrigeration system 1 5 -1 5 /1 6 ” r e f (4 0 5 m m ) 1 7 -7 /1 6 ” (4 4 3 m m ) 2 6 -5 /8 ” r e f (6 7 6 m m ) 4 ' 4 -1 /2 " m in (1 3 3 3 m m ) 2 '1 -3 /4 " r e f (6 5 4 m m ) 1 '- 6 " r e f (4 5 7 m m ) 8 " r e f (2 0 3 m m ...

Page 33

Waukesha cherry-burrell installation 11/2012 95-03057 page 31 horizontal frame options 10 ” di m "a " dim "b" dim "d" dim "e" di m "f" 2 d im " g " a d j u s t . L e g 5 " - 6 " (1 2 7 -1 5 2 m m ) d im " k " dim "c" di m " j " di m "h" 1 cyl co nf ig u r a t io n (between c enters) di m "b " d im "...

Page 34

Installation waukesha cherry-burrell page 32 95-03057 11/2012 vertical mounting pole/hydraulics v o tator ii v e rtical mounting po le/hydraulics dim " a " 3-15 /1 6” (100 mm ) 12 -5 /8 ” (32 1 mm) front view side view 1. T o p o f th e pole t o b e a t t ac h ed/suppor t ed by the cust o m e r . 2 ...

Page 35

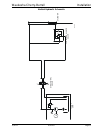

Waukesha cherry-burrell installation 11/2012 95-03057 page 33 vertical hydraulic schematic b a p t m c y l in d e r directional va lv e power un it counter balanc e va lv e h e 1 0 0 -0 5 1.

Page 36: Operation

Operation waukesha cherry-burrell page 34 95-03057 11/2012 operation pre-startup check these instructions are general and should be used only as a guide. It may be necessary to modify them to conform to actual in-plant requirements. Changes should be documented by plant personnel. Before starting vo...

Page 37

Waukesha cherry-burrell operation 11/2012 95-03057 page 35 startup procedure heating/liquid cooling applications 1. Start product pump using product or compatible liquid, such as water. 2. After product flow is established, start votator ii mutator shaft motor. Do not run votator ii without product ...

Page 38

Operation waukesha cherry-burrell page 36 95-03057 11/2012 shutdown procedure caution: the steam or refrigeration supply valves must be shut off before stopping product flow. Failure to do this could result in product burn-on or freezing in heat exchanger cylinders. These instructions are general an...

Page 39: Maintenance

Waukesha cherry-burrell maintenance 11/2012 95-03057 page 37 maintenance routine maintenance checklist - vertical votator ii 1. Tools required: • rubber or plastic mallet • large adjustable wrench (2-3/8 inch) or wcb model 79-2 sanitary wrench for removing the shaft locknut • two adjustable or open-...

Page 40

Maintenance waukesha cherry-burrell page 38 95-03057 11/2012 • when assembling the double mechanical seal, place the wave spring on the shaft and then the seal body with o-ring. Position the seal body and install the keeper o- ring, followed by the secondary seal and wave spring. • check all seal as...

Page 41

Waukesha cherry-burrell maintenance 11/2012 95-03057 page 39 caution: failing to use the head removal tool can result in damage to the seal face. Use of the hrt prevents chipping the stationary seal face on the end of the shaft during removal or replacement of the head. 8. Insert the head removal to...

Page 42

Maintenance waukesha cherry-burrell page 40 95-03057 11/2012 end of the shaft. Slide the bearing race over the tool and onto the shaft to protect the stationary seal face during assembly. 16. Seat the bearing in the head, using a plastic mallet, if required. 17. Install shaft locknut and bearing cap...

Page 43

Waukesha cherry-burrell maintenance 11/2012 95-03057 page 41 preventive maintenance • correct problems as soon as they are discovered. • inspect equipment frequently following changes in product formulation, processing conditions or cip regimen. • always note and report any abnormal or unusual condi...

Page 44

Maintenance waukesha cherry-burrell page 42 95-03057 11/2012 shafts all shaft surfaces, especially in seal and bearing areas, should be kept smooth and clean. Special care should be taken while cleaning and maintaining seals and bearings to assure that these areas of the shaft are not scratched or d...

Page 45

Waukesha cherry-burrell maintenance 11/2012 95-03057 page 43 inspected for flaking of the chrome. Normally, tubes will develop phonographic patterns from blade contact and rotation; this phonographic pattern is generally visible to the eye but is not significant unless detectable by touch. Scoring i...

Page 46

Maintenance waukesha cherry-burrell page 44 95-03057 11/2012 regulations, depending on the location of your facility. It is also a requirement of most business insurance carriers, so you are helping to protect your company against potential fines and uninsured losses. With stakes this high, tube rep...

Page 47

Waukesha cherry-burrell maintenance 11/2012 95-03057 page 45 jacket side for units using steam, water, or liquid the jacket side of the heat transfer tube has a sealed cover that allows the media flow to circulate around the tube. If it becomes coated with foreign matter and heat transfer is reduced...

Page 48

Maintenance waukesha cherry-burrell page 46 95-03057 11/2012 scraper blade removal & replacement 1. Remove scraper blades by lifting up and pulling them from the pins. Peek blades have a locking groove. 2. After lifting, push to the right before pulling them from the pins. Note: blades should be kep...

Page 49

Waukesha cherry-burrell maintenance 11/2012 95-03057 page 47 maintenance of horizontal votator ii danger: before doing any maintenance work on the votator ii, lock out and tag out equipment. Shaft removal - horizontal unit 1. Check to make sure all supply lines to unit are closed, locked out and tag...

Page 50

Maintenance waukesha cherry-burrell page 48 95-03057 11/2012 11. Remove scraper blades and service as necessary. See “scraper blade maintenance” on page 45 note: blades should be kept in the same position on the mutator shaft throughout the life of blade. Make sure blades are removed and reinstalled...

Page 51

Waukesha cherry-burrell maintenance 11/2012 95-03057 page 49 10. Make sure o-ring (see figure 35, item a) is installed in the opposite drive end head. Lubricate lightly 11. Install opposite drive end head by reversing procedure for removal of head. 12. Install shaft bearing in head. Install hrt into...

Page 52

Maintenance waukesha cherry-burrell page 50 95-03057 11/2012 heat exchanger tube removal - horizontal unit danger: before doing any maintenance work on the votator ii, lock out and tag out equipment. 1. Check to insure all supply lines to unit are closed and locked and tagged out. 2. Make sure that ...

Page 53

Waukesha cherry-burrell maintenance 11/2012 95-03057 page 51 heat exchanger tube installation - horizontal unit 1. Inspect jacket cylinder interior and wipe out all dirt and impurities. 2. Lubricate sealing surfaces inside jacket cylinder and install new o-rings in the tube. 3. Carefully insert tube...

Page 54

Maintenance waukesha cherry-burrell page 52 95-03057 11/2012 6. Unlatch locking latch. 7. The head has an on-off engraving on the rim, located just above product outlet. Rotate head in off direction until head disengages. 8. Lower head until hydraulic rod is fully extended. See figure 44. 9. Once sh...

Page 55

Waukesha cherry-burrell maintenance 11/2012 95-03057 page 53 7. If optional blade aligning tool is used, install it on the bayonet ring of heat transfer tube. Place each half of the ring on the bayonet and rotate it as one piece. 8. Raise shaft slowly, tucking blades into shaft while shaft and blade...

Page 56

Maintenance waukesha cherry-burrell page 54 95-03057 11/2012 5. Remove the three (3) bolts holding front jacket cover in place. 6. Remove the non-driven product head from mutator shaft. 7. Reattach head to tube. See figure 50. Reattach shaft nut cover and clamp, and use lift to position non-driven e...

Page 57

Waukesha cherry-burrell maintenance 11/2012 95-03057 page 55 12. Lower head and tube assembly and service as required. 13. Lubricate and install new o-rings on both ends of tube. 14. Install new packing ring (on steam or liquid tubes). 15. To reinstall tube, reverse the procedure. 16. Torque bolts t...

Page 58

Maintenance waukesha cherry-burrell page 56 95-03057 11/2012 mechanical seal maintenance the mechanical seals on the votator ii are the same on both the non-driven and driven ends of the unit. The o-rings and seal materials have been selected for the product specifications. Various options are shown...

Page 59

Waukesha cherry-burrell maintenance 11/2012 95-03057 page 57 single mechanical seal installation after the head insert and the body insert are installed, the remaining components are installed as follows: 1. Place wavy washer spring (see figure 56, item a) on shaft. 2. Install seal back-up ring. (se...

Page 60

Maintenance waukesha cherry-burrell page 58 95-03057 11/2012 to install a new primary or secondary insert, lubricate o-rings and the inside bore. Insert in the head with an even distribution of force on face. Protect the face with plastic to avoid damage. 2012 primary/secondary seal head insert remo...

Page 61

Waukesha cherry-burrell maintenance 11/2012 95-03057 page 59 one-piece primary seal body (rotating seal face) see figure 63. Removable seal body insert (rotating seal face) the rotating seal face is referred to as the seal body insert. This part is designed to wear at a greater frequency than the se...

Page 62

Maintenance waukesha cherry-burrell page 60 95-03057 11/2012 assembly of secondary seal body (for double mechanical seal only) the secondary seal body has one o-ring that holds the insert stationary in the body. To install the insert in the seal body: 1. Place o-ring in body (no lubrication). 2. Pus...

Page 63

Waukesha cherry-burrell maintenance 11/2012 95-03057 page 61 7. Slide seal body over seal body drive pin so that o-ring in body seats in groove in mutator shaft. 8. Check seal to insure that it will move freely with spring and that drive pins hold it stationary with respect to shaft. Servicing mecha...

Page 64

Maintenance waukesha cherry-burrell page 62 95-03057 11/2012 8. Remove clamp on head. (see figure 74, item a) and shaft nut guard. 9. While supporting head, remove shaft nut. (nut is left hand threaded.) 10. Grasp head with both hands, remove it from shaft. 11. Seals can now be serviced. See “mechan...

Page 65: Parts Lists

Waukesha cherry-burrell parts lists 11/2012 95-03057 page 63 parts lists latch product heads caution: product heads comply with the asme pressure vessel code and must not be changed between units of the same design. Also, a concentric head is not interchangeable with an eccentric/oval design. Item #...

Page 66

Parts lists waukesha cherry-burrell page 64 95-03057 11/2012 cylinder assembly he100-039b 19 20 21 23 22 13 15 12 14 16,36 24 25 19 20 21 22 23 extra heavy duty bearing option- b 23 21 19 20 he100-124 b 26 22 24 spider head option obsolete after 2009 extra heavy duty bearing option (current design).

Page 67

Waukesha cherry-burrell parts lists 11/2012 95-03057 page 65 cylinder assembly * for the extra heavy duty bearing option (current design) only, xhd bearing assembly (128472+) includes: item 22, bearing (128473+); item 24, bearing sleeve (128474+); and item 26, stator (128475+). Order part number 128...

Page 68

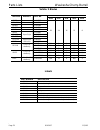

Description size part # shaft skid (horizontal votator only) 6 x 24 ll934744 6 x 36 6 x 48 6 x 72 ll934394 6 x 84 parts lists waukesha cherry-burrell page 66 95-03057 11/2012 cylinder assembly - shaft size seal type shaft model part # seal type shaft model part # 6 x 24 single mechanical 5-1/4" dia ...

Page 69

Waukesha cherry-burrell parts lists 11/2012 95-03057 page 67 cylinder assembly - removable tube size application code type description part # 6 x 24 bws um 316 ss tw/wo rings ll936879 um 316 ss cr 130906+ um ni/cr ll122763 vapor um 316 ss tw/w rings ll118829 um ni/cr ll118909 6 x 36 bws um ni/cr ll9...

Page 70

Parts lists waukesha cherry-burrell page 68 95-03057 11/2012 2012 double mechanical seal 32 4 11a 44 3 1 5 7 45 6 7a 9 10 8 11 he100-113 43 he100-116 he100-115 ode head installation/removal tool ll121191 seal installation/removal tool 130007+.

Page 71

Waukesha cherry-burrell parts lists 11/2012 95-03057 page 69 2012 single and double mechanical seal note: seal face material options (items 7a and 8): permissible material combinations are: carbon/ceramic; carbon/silicon carbide; silicon carbide/silicon carbide; and tungsten carbide/silicon carbide....

Page 72

Parts lists waukesha cherry-burrell page 70 95-03057 11/2012 double mechanical seal 6 4 11a 11 32 44 43 45 1 3 10 7 5 he100-114 he100-116 ode head installation/removal tool ll121191.

Page 73

Waukesha cherry-burrell parts lists 11/2012 95-03057 page 71 one piece single & double mechanical seal note: use ode head installation tool ll121191 to protect head insert when installing or removing the opposite drive end product head. Item # description qty per seal material option part # 1 wavy w...

Page 74

Parts lists waukesha cherry-burrell page 72 95-03057 11/2012 single mechanical seal.

Page 75

Waukesha cherry-burrell parts lists 11/2012 95-03057 page 73 single mechanical seal note: use ode head installation tool ll121191 to protect head insert when installing or removing the opposite drive end product head. Note: items 4, 5, 11, 11a, 32, 43, and 44 are required when the seal must be flush...

Page 76

Parts lists waukesha cherry-burrell page 74 95-03057 11/2012 vertical refrigeration piping.

Page 77

Waukesha cherry-burrell parts lists 11/2012 95-03057 page 75 vertical refrigeration piping item # description qty per acc notes part # 1 accumulator 1 16" diameter ll929516 2 refrigeration piping 1 upper accumulator piping ll930348 4 refrigeration piping 1 lower accumulator piping ll930349 5 weld ca...

Page 78

Item # description qty per pole model part # 3 hydraulic valve 1 all ll928736 4 push - pull handle 1 all ll929343 5 hydraulic power assembly 1 3/4 hp clr ll928737 pump/adapter kit only 1 ll928737-1 16 shaft stop clamp 1 4” shaft ll935529 4-1/2” shaft ll931279 5-1/4” shaft ll935191 22 hydraulic cylin...

Page 79

Item # description model qty part # 20 shaft nut guard all 1 ll929346 21 shaft locknut all 1 ll119275a 46 gasket all 1 ll117720 47 o-ring all 1 n70222-674 48 shaft heater pipe 6 x 24 cylinder 1 ll123001 6 x 36 cylinder 1 ll112278e 6 x 48 cylinder 6 x 72 cylinder 6 x 84 cylinder 49 heater pipe suppor...

Page 80

6x84 6x72 6x48 6x36 6x24 410ss ll900127 celcon ll900129 brass ll916284 17-7 ss ll900124 peek ll118683 410ss ll125801 brass ll918089 17-7 ss ll919100 celcon ll900133 peek ll121856 128675+ n/a 8 4 n/a 2 128675m1 n/a 2 2 n/a n/a 128675m2 n/a 2 2 n/a n/a ll926752 n/a 8 4 n/a 2 ll926752m1 n/a 2 2 n/a n/a...

Page 81: Troubleshooting

Waukesha cherry-burrell troubleshooting 11/2012 95-03057 page 79 troubleshooting problem possible cause suggested action freeze-up. Power failure. Check power supply. Product outlet temperature too low. Adjust process to raise product outlet temperature. Product flow rate too low. Adjust process to ...

Page 82

Troubleshooting waukesha cherry-burrell page 80 95-03057 11/2012 increased gas discharge temperature. Air in refrigeration system. Refer to “water and air in refrigeration system” on page 82. Seal head will not install properly. Twisted when installed. Lubricate before installing. Installed wrong si...

Page 83

Waukesha cherry-burrell troubleshooting 11/2012 95-03057 page 81 product leaking: • between lapped or polished surfaces of seal head insert and seal body. • around o-rings of interface of head and seal head insert. • around interface of seal body and shaft. Seal insert cocked when installed. Remove ...

Page 84

Troubleshooting waukesha cherry-burrell page 82 95-03057 11/2012 unthawing a frozen system to unthaw a system that has frozen-up, perform the following procedures. The cause of freeze-up must be corrected before operation is restarted. See the troubleshooting chart starting on page 79 for cause and ...

Page 86

Votator ® ii scraped surface heat exchanger spx flow technology 611 sugar creek road delavan, wi 53115 p: (262) 728-1900 or (800) 252-5200 f: (262) 728-4904 or (800) 252-5012 e: wcb@spx.Com spx reserves the right to incorporate our latest design and material changes without notice or obligation. Des...