- DL manuals

- Suzuki

- Motorcycle

- 2005 VL1500K5

- Supplementary Service Manual

Suzuki 2005 VL1500K5 Supplementary Service Manual

Summary of 2005 VL1500K5

Page 1

Vl1500 use this manual with: vl1500 service manual (99500-39166-01e).

Page 2: Vl1500K5 (’05-Model)

Vl1500k5 (’05-model) 1 contents vl1500k5 (’05-model) © copyright suzuki motor corporation 2004 this manual describes service specifications, service data and servicing procedures which dif- fer from those of the vl1500k4 (’04-model). Note: • any differences between the vl1500k4 (’04-model) and vl150...

Page 3

2 vl1500k5 (’05-model) switches........................................................................................................ 142 battery.......................................................................................................... 143 wiring harness, cable and hose routing.......

Page 4: Manual

Vl1500k5 (’05-model) 3 abbreviations used in this manual a abdc : after bottom dead center ac : alternating current acl : air cleaner, air cleaner box api : american petroleum institute atdc : after top dead center atm pressure : atmospheric pressure atmospheric pressure sensor (aps) a/f : air fuel ...

Page 5

4 vl1500k5 (’05-model) m mal-code : malfunction code (diagnostic code) max : maximum mil : malfunction indicator lamp (led) min : minimum n nox : nitrogen oxides o ohc : over head camshaft ops : oil pressure switch p pair : pulsed secondary air injection pcv : positive crankcase ventilation (crankca...

Page 6: Specifications

Vl1500k5 (’05-model) 5 specifications dimensions and dry mass overall length ...................................................... 2 525 mm (99.4 in) overall width........................................................ * 995 mm (40.2 in) ............... E-24 overall width.............................

Page 7

6 vl1500k5 (’05-model) chassis front suspension ................................................. Telescopic, coil spring, oil damped rear suspension .................................................. Link type, coil spring, oil damped front suspension stroke....................................... 1...

Page 8

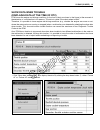

Vl1500k5 (’05-model) 7 periodic maintenance schedule the chart below lists the recommended intervals for all the required periodic service work necessary to keep the motorcycle operating at peak performance and economy. Mileages are expressed in terms of kilome- ters, miles and time for your conveni...

Page 9: Cedures

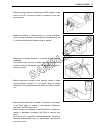

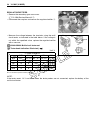

8 vl1500k5 (’05-model) maintenance and tune-up pro- cedures this section describes the servicing procedures for each peri- odic maintenance item which differ from those of the vl1500k4 (’04-model). For details other than the following items, refer to the vl1500 service manual. Fuel hose • remove the...

Page 10

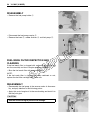

Vl1500k5 (’05-model) 9 lock-nut throttle cable play adjust the throttle cable play a with the following three steps. Minor adjustment first step: • loosen the lock-nut 1 of the throttle returning cable 2 and turn in the adjuster 3 fully into the threads. Second step: • loosen the lock-nut 4 of the t...

Page 11

10 vl1500k5 (’05-model) major adjustment • remove the air cleaner box. ( !Page 103) • loosen the lock-nut 1 of the throttle returning cable. • turn the returning cable adjuster 2 to obtain proper cable play. • loosen the lock-nut 3 of the throttle pulling cable. • turn the pulling cable adjuster 4 i...

Page 12

Vl1500k5 (’05-model) 11 exhaust pipe bolts and muffler bolts • tighten the exhaust pipe bolts and muffler mounting bolts to the specified torque. Tighten initially at 1 000 km (600 miles, 2 month) and every 12 000 km (7 500 miles, 24 months) thereafter. Apply permatex 1372. Apply permatex 1372. & a ...

Page 13

12 vl1500k5 (’05-model) chassis bolts and nuts check that all chassis bolts and nuts are tightened to their specified torque. (refer to vl1500 service manual 2-18 for the locations of the following nuts and bolts.) tighten initially at 1 000 km (600 miles, 2 month) and every 6 000 km (4 000 miles, 1...

Page 14

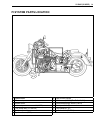

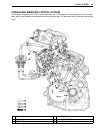

Vl1500k5 (’05-model) 13 engine components removable with engine in place the parts listed below can be removed and reinstalled without removing the engine from the frame. Refer to the page listed in each section for removal and reinstallation instructions. Engine left side engine right side engine c...

Page 15

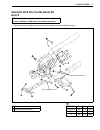

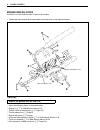

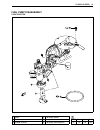

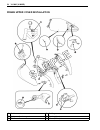

14 vl1500k5 (’05-model) engine removal and installation engine removal the engine removal procedure is different from that of the vl1500k4 (’04-model). For details other than the removal pro- cedure, refer to the vl1500 service manual. • remove the seats. ( !Page 121) • remove the pair cover 1. • di...

Page 16

Vl1500k5 (’05-model) 15 • remove the pair device bracket 7. • remove the no. 1 and no. 2 pair pipes. • remove the air cleaner box. ( !Page 103) • remove the throttle body. ( !Page 104) sa mp le.

Page 17

16 vl1500k5 (’05-model) engine installation installation is in the reverse order of removal procedure. • tighten the exhaust pipe bolts and muffler mounting bolts to the specified torque. ' • adjust the following items to the specification. * engine oil ( !Vl1500 service manual 2-6) * throttle valve...

Page 18: Engine Disassembly And

Vl1500k5 (’05-model) 17 engine disassembly and reassembly the engine disassembly and reassembly procedures are differ- ent from those of the vl1500k4 (’04-model). For details other than the following parts, refer to the vl1500 service manual. Gear position switch removal • remove the gear position s...

Page 19

18 vl1500k5 (’05-model) engine components inspection and servicing camshaft for details other than the following, refer to the vl1500 service manual. Each camshaft i.D. Code has been changed which is stamped on the camshaft end. Cam wear " cam height h service limit (in) : 35.02 mm ( 1.379 in) (ex) ...

Page 20: Precautions In Servicing

Vl1500k5 (’05-model) 19 precautions in servicing when handling the fi component parts or servicing the fi sys- tem, observe the following points for the safety of the system. Connector/coupler • when connecting a connector, be sure to push it in until a click is felt. • with a lock type coupler, be ...

Page 21

20 vl1500k5 (’05-model) • when connecting meter probe from the terminal side of the coupler where (connection from harness side not being possi- ble), use extra care not to force and cause the male terminal to bend or the female terminal to open. Connect the probe as shown to avoid opening of female...

Page 22

Vl1500k5 (’05-model) 21 • when disconnecting and connecting the ecm couplers, make sure to turn off the ignition switch, or electronic parts may get damaged. • battery connection in reverse polarity is strictly prohibited. Such a wrong connection will damage the components of the fi system instantly...

Page 23

22 vl1500k5 (’05-model) electrical circuit inspection procedure while there are various methods for electrical circuit inspection, described here is a general method to check for open and short circuit using an ohmmeter and a voltmeter. Open circuit check possible causes for the open circuit are as ...

Page 24

Vl1500k5 (’05-model) 23 continuity check • measure resistance across coupler b (between a and c in the figure). If no continuity is indicated (infinity or over limit), the circuit is open between terminals a and c. • disconnect the coupler b and measure resistance between couplers a and b. If no con...

Page 25

24 vl1500k5 (’05-model) short circuit check (wire harness to ground) • disconnect the negative cable from the battery. • disconnect the connectors/couplers at both ends of the circuit to be checked. Note: if the circuit to be checked branches to other parts as shown, disconnect all connectors/couple...

Page 26

Vl1500k5 (’05-model) 25 using the multi-circuit tester • use the suzuki multi-circuit tester (09900-25008). • use well-charged batteries in the tester. • be sure to set the tester to the correct testing range. Using the tester • incorrectly connecting the + and - probes may cause the inside of the t...

Page 27

26 vl1500k5 (’05-model) fi system technical features injection time (injection volume) the factors to determine the injection time include the basic fuel injection time which is calculated on the basis of the intake air pressure, engine speed and throttle opening angle, and various compensations. Th...

Page 28

Vl1500k5 (’05-model) 27 compensation of injection time (volume) the following different signals are output from the respective sensors for compensation of the fuel injection time (volume). Injection stop control signal description engine oil temperature sensor signal when engine oil temperature is l...

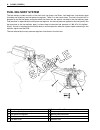

Page 29: Fuel Delivery System

28 vl1500k5 (’05-model) fuel delivery system the fuel delivery system consists of the fuel tank, fuel pump, fuel filters, fuel feed hose, fuel delivery pipe (including fuel injectors) and fuel pressure regulator. There is no fuel return hose. The fuel in the fuel tank is pumped up by the fuel pump a...

Page 30: Fi System Parts Location

Vl1500k5 (’05-model) 29 fi system parts location ecm a speedometer h gear position switch b starter relay i ho2 sensor (ho2s) [for e-02, 19, 24] c starter motor j crankshaft position sensor (ckps) d intake air pressure sensor #1 (iaps) k fuel injector #2 (fi) e fuel pump relay (fp relay) l fuel inje...

Page 31

30 vl1500k5 (’05-model) ecm n intake air pressure sensor #2 (iaps) s decompression solenoid o secondary throttle position sensor (stps) t intake air temperature sensor (iats) p throttle position sensor (tps) u ignition coil #2 (ig coil) q secondary throttle valve actuator (stva) v pair solenoid valv...

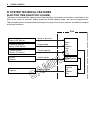

Page 32: Fi System Wiring Diagram

Vl1500k5 (’05-model) 31 fi system wiring diagram speedometer fuel injector (fi) fuel pump rela y fuel pump engine stop s witch 10 a 15 a 10 a side-stand rela y neutr al indicator light side-stand s witch star ter rela y star ter motor secondar y throttle v alv e actuator (stv a) clutch le v e r posi...

Page 33: Ecm Terminal

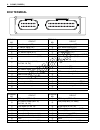

32 vl1500k5 (’05-model) ecm terminal terminal no. Circuit terminal no. Circuit 1 gp switch signal (gp) h ignition switch signal (at) 2 iat sensor signal (iat) i eot sensor signal (eot) 3 rear cylinder iap sensor signal (iap. R) j to sensor signal (tos) 4 stp sensor signal (stp) k tp sensor signal (t...

Page 34: Self-Diagnosis Function

Vl1500k5 (’05-model) 33 self-diagnosis function the self-diagnosis function is incorporated in the ecm. The function has two modes, “user mode” and “dealer mode”. The user can only be notified by the lcd (display) panel and led (fi light). To check the function of the individual fi system devices, t...

Page 35

34 vl1500k5 (’05-model) dealer mode the defective function is memorized in the computer. Use the special tool’s coupler to connect to the dealer mode coupler. The memorized malfunction code is displayed on the lcd (display) panel. Malfunction means that the ecm does not receive signal from the devic...

Page 36

Vl1500k5 (’05-model) 35 in the lcd (display) panel, the malfunction code is indicated from small code to large code. *1 to get the proper signal from the throttle position sensor, the sensor basic position is indicated in the lcd (display) panel. The malfunction code is indicated in three digits. In...

Page 37

36 vl1500k5 (’05-model) tps adjustment 1. Warm up the engine and adjust the engine idle speed to 1 000 ± 100 r/min. ( !Page 8) 2. Connect the special tool (mode select switch) and select the dealer mode. 3. Remove the right frame upper cover. ( !Vl1500 service manual 6-3) 4. Loosen the screw and tur...

Page 38: Fail-Safe Function

Vl1500k5 (’05-model) 37 fail-safe function fi system is provided with fail-safe function to allow the engine to start and the motorcycle to run in a mini- mum performance necessary even under malfunction condition. The engine can start and can run even if the above signal is not received from each s...

Page 39: Fi System Troubleshooting

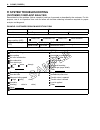

38 vl1500k5 (’05-model) fi system troubleshooting customer complaint analysis record details of the problem (failure, complaint) and how it occurred as described by the customer. For this purpose, use of an inspection form such as below will facilitate collecting information required for proper anal...

Page 40

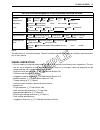

Vl1500k5 (’05-model) 39 note: the above form is a standard sample. The form should be modified according to conditions and characteris- tics of each market. Visual inspection • prior to diagnosis using the mode select switch or sds, perform the following visual inspections. The rea- son for visual i...

Page 41

40 vl1500k5 (’05-model) self-diagnostic procedures note: * don’t disconnect couplers from the ecm, the battery cable from the battery, ecm ground wire harness from the engine or main fuse before confirming the malfunction code (self-diag- nostic trouble code) stored in memory. Such disconnection wil...

Page 42

Vl1500k5 (’05-model) 41 use of sds diagnostic procedures * don’t disconnect couplers from ecm, the battery cable from the battery, ecm ground wire harness from the engine or main fuse before confirming the malfunction code (self-diagnostic trouble code) stored in memory. Such disconnection will eras...

Page 43

42 vl1500k5 (’05-model) use of sds diagnosis reset proce- dure • after repairing the trouble, turn off the ignition switch and turn on again. • click the dtc inspection button 1. • check the dtc. • the previous malfunction history code (past dtc) still remains stored in the ecm. Therefore, erase the...

Page 44

Vl1500k5 (’05-model) 43 show data when trouble (displaing data at the time of dtc) ecm stores the engine and driving conditions (in the form of data as shown in the figure) at the moment of the detection of a malfunction in its memory. This data is called “show data when trouble”. Therefore, it is p...

Page 45

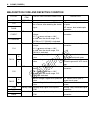

44 vl1500k5 (’05-model) malfunction code and defective condition dtc no. Detected item detected failure condition check for c00 no fault ––––––––––– ––––––––––– c12 ckp sensor the signal does not reach ecm for 3 sec. Or more, after receiving the starter signal. Ckp sensor wiring and mechan- ical par...

Page 46

Vl1500k5 (’05-model) 45 dtc no. Detected item detected failure condition check for c21 iat sensor the sensor voltage should be the fol- lowing. 0.1 v sensor voltage in other than the above range, c21 (p0110) is indicated. Iat sensor, lead wire/coupler connection. P0110 h sensor voltage is higher tha...

Page 47

46 vl1500k5 (’05-model) dtc no. Detected item detected failure condition check for c31 gear posi- tion signal gear position signal voltage should be higher than the following for 3 seconds and more. Gear position sensor voltage > 0.6 v if lower than the above value, c31 (p0705) is indicated. Gp swit...

Page 48

Vl1500k5 (’05-model) 47 “c12” (p0335) ckp sensor circuit malfunction inspection step 1 1) remove the seats. ( !Page 121) 2) remove the left and right frame upper covers. ( !Vl1500 service manual 6-3) 3) remove the speedometer and fuel inlet cover. ( !Vl1500 service manual 6-3) 4) turn the ignition s...

Page 49

48 vl1500k5 (’05-model) 7) if ok, then check the continuity between each terminal and ground. " ckp sensor continuity: ∞Ω (infinity) (blue – ground) (green – ground) # 09900-25008: multi-circuit tester set ) tester knob indication: resistance (Ω) are the resistance and continuity ok? 8) after repair...

Page 50

Vl1500k5 (’05-model) 49 “c13” (p1750) or “c17” (p0105) iap sensor circuit malfunction inspection step 1 (when indicating c13/p1750 for iap sensor #2) 1) remove the right frame upper cover. ( !Vl1500 service manual 6-3) for the other inspection procedures are the same as c17/ p0105. (when indicating ...

Page 51

50 vl1500k5 (’05-model) is the voltage ok? 8) after repairing the trouble, clear the dtc using sds tool. ( !Page 42) step 2 1) connect the iap sensor coupler. 2) insert the needle pointed probes to the lead wire coupler. 3) start the engine at idle speed and measure the iap sensor output voltage at ...

Page 52

Vl1500k5 (’05-model) 51 step 3 1) turn the ignition switch off. 2) remove the iap sensor. ( !Page 118) 3) connect the vacuum pump gauge to the vacuum port of the iap sensor. 4) arrange 3 new 1.5 v batteries in series 1 (check that total - voltage is 4.5 – 5.0 v) and connect - terminal to the ground ...

Page 53

52 vl1500k5 (’05-model) output voltage (vcc voltage 4.5 – 5.0 v, ambient temp. 20 – 30 °c, 68 – 86 °f) altitude (reference) atmospheric pressure output voltage (ft) (m) (mmhg) kpa (v) 0 2 000 0 610 760 707 100 94 3.4 – 4.0 2 001 5 000 611 1 524 707 634 94 85 2.8 – 3.7 5 001 8 000 1 525 2 438 634 567...

Page 54

Vl1500k5 (’05-model) 53 “c14” (p0120-h/l) tp sensor circuit malfunction inspection step 1 (when indicating c14:) 1) remove the right frame upper cover. ( !Vl1500 service manual 6-3) 2) turn the ignition switch off. 3) check the tp sensor coupler for loose or poor contacts. If ok, then measure the tp...

Page 55

54 vl1500k5 (’05-model) step 1 (when indicating p0120-h:) 1) remove the right frame upper cover. ( !Vl1500 service manual 6-3) 2) turn the ignition switch off. 3) check the tp sensor coupler for loose or poor contacts. If ok, then check the tp sensor lead wire continuity. 4) disconnect the tp sensor...

Page 56

Vl1500k5 (’05-model) 55 step 1 (when indicating p0120-l:) 1) remove the right frame upper cover. ( !Vl1500 service manual 6-3) 2) turn the ignition switch off. 3) check the tp sensor coupler for loose or poor contacts. If ok, then measure the tp sensor lead wire continuity. 4) disconnect the tp sens...

Page 57

56 vl1500k5 (’05-model) step 2 1) turn the ignition switch off. 2) disconnect the tp sensor coupler. 3) install the test harness to the tp sensor. 4) check the continuity between terminal a and ground. " tp sensor continuity: ∞Ω (infinity) (terminal a – ground) 5) if ok, then measure the tp sensor r...

Page 58

Vl1500k5 (’05-model) 57 step 3 1) connect the tp sensor coupler 1 to the test harness. 2) turn the ignition switch on. 3) measure the tp sensor output voltage at the coupler (between + bi/b and - b/br) by turning the throttle grip. " tp sensor output voltage throttle valve is closed: approx. 1.12 v ...

Page 59

58 vl1500k5 (’05-model) “c15” (p0115-h/l) eot sensor circuit malfunction inspection step 1 (when indicating c15:) 1) turn the ignition switch off. 2) check the eot sensor coupler for loose or poor contacts. If ok, then measure the eot sensor voltage at the wire side coupler. 3) disconnect the eot se...

Page 60

Vl1500k5 (’05-model) 59 step 1 (when indicating p0115-h:) 1) turn the ignition switch off. 2) check the eot sensor coupler for loose or poor contacts. If ok, then check the eot sensor lead wire continuity. 7 3) remove the left frame upper cover. ( !Vl1500 service manual 6-3) 4) disconnect the eot se...

Page 61

60 vl1500k5 (’05-model) step 1 (when indicating p0115-l:) 1) turn the ignition switch off. 2) check the eot sensor coupler for loose or poor contacts. If ok, then check the eot sensor lead wire continuity. 3) disconnect the eot sensor coupler. 4) check the continuity between b/bl wire 1 and ground. ...

Page 62

Vl1500k5 (’05-model) 61 step 2 1) turn the ignition switch off. 2) disconnect the eot sensor coupler. 3) measure the eot sensor resistance. " eot sensor resistance: approx. 61.3 k Ω at 20 °c (68 °f) (white – white) # 09900-25008: multi-circuit tester set ) tester knob indication: resistance (Ω) refe...

Page 63

62 vl1500k5 (’05-model) eot sensor inspection • remove the eot sensor. ( !Page 119) • check the eot sensor by testing it at the bench as shown in the figure. Connect the eot sensor 1 to a circuit tester and place it in the oil 2 contained in a pan, which is placed on a stove. • heat the oil to raise...

Page 64

Vl1500k5 (’05-model) 63 “c18” (p1751) decomp. Relay circuit malfunction inspection step 1 1) remove the right frame upper cover. ( !Vl1500 service manual 6-3) 2) turn the ignition switch off. 3) check the decomp. Relay coupler for loose or poor contacts. If ok, then check the decomp. Relay. ( !Vl150...

Page 65

64 vl1500k5 (’05-model) active control inspection 1) set up the sds tool. (refer to the sds operation manual for further details) 2) turn the ignition switch on. 3) click “decomp sol operating control” 1. 4) with the engine starter button pushed, click “on” button 2. At this time, if an operation so...

Page 66

Vl1500k5 (’05-model) 65 “c19” (p0615) starter relay circuit malfunction inspection step 1 1) remove the left frame upper cover. ( !Vl1500 service manual 6-3) 2) turn the ignition switch off. 3) check the starter relay coupler for loose or poor contacts. If ok, then inspection the starter relay. ( !V...

Page 67

66 vl1500k5 (’05-model) “c21” (p0110-h/l) iat sensor circuit malfunction inspection step 1(when indicating c21:) 1) remove the right frame upper cover. ( !Vl1500 service manual 6-3) 2) turn the ignition switch off. 3) check the iat sensor coupler for loose or poor contacts. If ok, then measure the i...

Page 68

Vl1500k5 (’05-model) 67 step 1 (when indicating p0110-h:) 1) remove the right frame upper cover. ( !Vl1500 service manual 6-3) 2) turn the ignition switch off. 3) check the iat sensor coupler for loose or poor contacts. If ok, then check the iat sensor lead wire continuity. 4) remove the left frame ...

Page 69

68 vl1500k5 (’05-model) step 1 (when indicating p0110-l:) 1) remove the right frame upper cover. ( !Vl1500 service manual 6-3) 2) turn the ignition switch off. 3) check the iat sensor coupler for loose or poor contacts. If ok, then check the iat sensor lead wire continuity. 4) disconnect the iat sen...

Page 70

Vl1500k5 (’05-model) 69 step 2 1) turn the ignition switch off. 2) measure the iat sensor resistance. " iat sensor resistance: approx. 2.45 kΩ at 20 °c (68 °f) (terminal – terminal) # 09900-25008: multi-circuit tester set ) tester knob indication: resistance (Ω) is the resistance ok? " iat sensor sp...

Page 71

70 vl1500k5 (’05-model) “c23” (p1651-h/l) to sensor circuit malfunction inspection step 1 (when indicating c23:) 1) remove the seats. ( !Page 121) 2) turn the ignition switch off. 3) check the to sensor coupler for loose or poor contacts. If ok, then measure the to sensor resistance. 4) disconnect t...

Page 72

Vl1500k5 (’05-model) 71 step 1 (when indicating p1651-h:) 1) remove the seats. ( !Page 121) 2) turn the ignition switch off. 3) check the to sensor coupler for loose or poor contacts. If ok, then check the to sensor lead wire continuity. 4) disconnect the to sensor coupler. 5) check the continuity b...

Page 73

72 vl1500k5 (’05-model) step 1 (when indicating p1651-l:) 1) remove the seats. ( !Page 121) 2) turn the ignition switch off. 3) check the to sensor coupler for loose or poor contacts. If ok, then check the to sensor lead wire continuity. 4) disconnect the to sensor coupler. 5) check the continuity b...

Page 74

Vl1500k5 (’05-model) 73 step 2 1) connect the to sensor coupler. 2) insert the needle pointed probes to the lead wire coupler. 3) turn the ignition switch on. 4) measure the voltage at the wire side coupler between black and b/br wires. " to sensor voltage (normal): 0.4 – 1.4 v ( + br/w – - b/br) al...

Page 75

74 vl1500k5 (’05-model) “c28” (p1655) stv actuator circuit malfunction inspection step 1 1) remove the air cleaner box. ( !Page 103) 2) turn the ignition switch off. 3) check the stva lead wire coupler for loose or poor contacts. 4) turn the ignition switch on to check the stv operation. (stv operat...

Page 76

Vl1500k5 (’05-model) 75 step 2 1) turn the ignition switch off. 2) disconnect the stva lead wire coupler. 3) check the continuity between each terminal and ground. " stva continuity: ∞Ω (infinity) (terminal – ground) 4) if ok, then measure the stva resistance (between black wire a and pink wire b) a...

Page 77

76 vl1500k5 (’05-model) active control inspection 1) set up the sds tool. (refer to the sds operation manual for further details.) 2) turn the ignition switch on. 3) click “secondary throttle operating control” 1. 4) click each button 2. At this time, if an operation sound is heard from the stva, th...

Page 78

Vl1500k5 (’05-model) 77 “c29” (p1654-h/l) stp sensor circuit malfunction inspection step 1 (when indicating c29:) 1) remove the air cleaner box. ( !Page 103) 2) turn the ignition switch off. 3) check the stp sensor coupler for loose or poor contacts. If ok, then measure the stp sensor input voltage....

Page 79

78 vl1500k5 (’05-model) step 1 (when indicating p1654-h:) 1) remove the air cleaner box. ( !Page 103) 2) turn the ignition switch off. 3) check the stp sensor coupler for loose or poor contacts. If ok, then check the stp sensor lead wire continuity. 4) disconnect the stp sensor coupler. 5) check the...

Page 80

Vl1500k5 (’05-model) 79 step 1 (when indicating p1654-l:) 1) remove the air cleaner box. ( !Page 103) 2) turn the ignition switch off. 3) check the stp sensor coupler for loose or poor contacts. If ok, then check the stp sensor lead wire continuity. 4) disconnect the to sensor coupler. 5) check the ...

Page 81

80 vl1500k5 (’05-model) step 2 1) turn the ignition switch off. 2) remove the air cleaner box. ( !Page 103) 3) disconnect the stp sensor coupler. 4) check the continuity between each terminal and ground. " stp sensor continuity: ∞Ω (infinity) (terminal – ground) 5) if ok, then measure the stp sensor...

Page 82

Vl1500k5 (’05-model) 81 step 3 1) turn the ignition switch off. 2) connect the stp sensor coupler. 3) insert the needle pointed probes to the stp sensor coupler. 4) disconnect the stva lead wire coupler. 5) turn the ignition switch on. 6) measure the stp sensor output voltage at the coupler (between...

Page 83

82 vl1500k5 (’05-model) “c31” (p0705) gp switch circuit malfunction inspection step 1 1) remove the secondary gear case cover. ( !Vl1500 service manual 3-7) 2) turn the ignition switch off. 3) check the gp switch coupler for loose or poor contacts. If ok, then measure the gp switch voltage. 4) suppo...

Page 84

Vl1500k5 (’05-model) 83 is the voltage ok? 10)after repairing the trouble, clear the dtc using sds tool. ( !Page 42) yes • red or r/b wire open or shorted to ground. • if wire and connection are ok, intermittent trou- ble or faulty ecm. • recheck each terminal and wire harness for open circuit and p...

Page 85

84 vl1500k5 (’05-model) “c32” (p0201) or “c33” (p0202) fuel injector circuit malfunction inspection (when indicating c32/p0201 for fuel injector #1) (when indicating c33/p0202 for fuel injector #2) step 1 1) remove the air cleaner box. ( !Page 103) 2) turn the ignition switch off. 3) check the injec...

Page 86

Vl1500k5 (’05-model) 85 5) if ok, then check the continuity between each terminal and ground. " stp sensor continuity: ∞Ω (infinity) # 09900-25008: multi-circuit tester set ) tester knob indication: resistance (Ω) are the resistance and continuity ok? 6) after repairing the trouble, clear the dtc us...

Page 87

86 vl1500k5 (’05-model) “c41” (p0230) fp relay circuit malfunction inspection step 1 1) remove the right frame upper cover. ( !Vl1500 service manual 6-3) 2) turn the ignition switch off. 3) check the fp relay coupler for loose or poor contacts. If ok, then check the fp relay. ( !Page 96) is the fp r...

Page 88

Vl1500k5 (’05-model) 87 “c44” (p0130/p0135) ho2 sensor (ho2s) circuit malfunction (for e-02, 19, 24) inspection step 1 (when indicating c44/p0130:) 1) remove the seats. ( !Page 121) 2) turn the ignition switch off. 3) check the ho2 sensor for loose or poor contacts. If ok, then check the ho2 sensor ...

Page 89

88 vl1500k5 (’05-model) 7) remove the left frame upper cover. ( !Vl1500 service manual 6-3) and disconnect the ecm coupler. 8) check the continuity between w/g wire a and terminal 7. 9) also, check the continuity between b/br wire b and terminal d. " ho2s lead wire continuity: continuity (,) # 09900...

Page 90

Vl1500k5 (’05-model) 89 is the voltage ok? 6) after repairing the trouble, clear the dtc using sds tool. ( !Page 42) step 1 (when indicating c44/p0135:) 1) remove the seats. ( !Page 121) 2) turn the ignition switch off. 3) check the ho2 sensor for loose or poor contacts. If ok, then measure the ho2 ...

Page 91

90 vl1500k5 (’05-model) step 2 (when indicating c44/p0135:) 1) connect the ho2 sensor coupler. 2) insert the needle pointed probes to the ho2 sensor coupler. 3) turn the ignition switch on and measure the heater voltage between w/b wire and ground. 4) if the tester voltage indicates the battery volt...

Page 92

Vl1500k5 (’05-model) 91 “c49” (p1656) pair control solenoid valve circuit malfunction inspection step 1 1) turn the ignition switch off. 2) check the pair control solenoid valve coupler for loose or poor contacts. If ok, then measure the pair control solenoid valve resis- tance. 3) disconnect the pa...

Page 93

92 vl1500k5 (’05-model) step 2 1) turn the ignition switch on. 2) measure the voltage between o/w wire and ground. " pair valve voltage: battery voltage ( + o/w – - ground) # 09900-25008: multi-circuit tester set * tester knob indication: voltage (+) is the voltage ok? 3) after repairing the trouble...

Page 94: Fuel System

Vl1500k5 (’05-model) 93 fuel system fuel tank removal • remove the seats 1. ( !Page 121) • remove the speedometer and fuel inlet cover 2. ( !Vl1500 service manual 6-3) • remove the frame head covers 3 and frame upper covers 4. ( !Vl1500 service manual 6-3) • remove the frame covers 5. ( !Vl1500 serv...

Page 95

94 vl1500k5 (’05-model) fuel pressure inspection • remove the seats. ( !Page 121) • remove the speedometer and fuel inlet cover. ( !Vl1500 service manual 6-3) • remove the left frame head cover and left frame upper cover. ( !Vl1500 service manual 6-3) • place a rag under the fuel feed hose. • remove...

Page 96

Vl1500k5 (’05-model) 95 fuel pump inspection turn the ignition switch on and check that the fuel pump operates for few seconds. If the fuel pump motor does not make operating sound, inspect the fuel pump circuit connections or inspect the fuel pump relay and tip-over sensor. If the fuel pump relay, ...

Page 97

96 vl1500k5 (’05-model) • connect a proper lead wire into the fuel pump lead wire cou- pler (fuel pump side) and apply 12 volts to the fuel pump (between y/r wire and b/w wire) for 10 seconds and mea- sure the amount of fuel discharged. Battery + terminal (yellow with red tracer) battery - terminal ...

Page 98

Vl1500k5 (’05-model) 97 • remove the fuel feed hose 5. $ • disconnect the fuel pump coupler 6. • remove the fuel pump mounting bolts diagonally. • lift up the rear part a and turn the fuel pump mounting plate counterclockwise to approx. 90°. • pull out the fuel pump mounting plate until the fuel pre...

Page 99

98 vl1500k5 (’05-model) • pull the fuel pump mounting plate until the fuel filter 8 comes out from the fuel tank. • set the fuel pump mounting plate to the horizontal line. • turn the fuel pump mounting plate counterclockwise to approx. 90°. • pull the fuel pump mounting plate until the fuel pump ba...

Page 100

Vl1500k5 (’05-model) 99 fuel pump disassembly construction 1 band 4 fuel pump holder & 2 fuel pump 5 o-ring item n·m kgf-m lb-ft 3 rubber cushion a fuel pump mounting bolt a 10 1.0 7.0 sa mp le.

Page 101

100 vl1500k5 (’05-model) disassembly • remove the fuel pump holder 1. • disconnect the fuel pump coupler 2. • remove the band 3, rubber cushion 4 and fuel pump 5. Fuel mesh filter inspection and cleaning if the fuel mesh filter is clogged with sediment or rust, fuel will not flow smoothly and loss i...

Page 102

Vl1500k5 (’05-model) 101 installation • install the fuel pump in the reverse order of removal, and pay attention to the following points: • install the new o-ring and apply grease to it. $ ( 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (others) • install the fuel p...

Page 103: Throttle Body

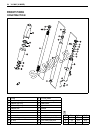

102 vl1500k5 (’05-model) throttle body construction 1 stp sensor 9 fast idle screw 2 tp sensor 0 iap sensor 3 fuel delivery pipe a stp sensor mounting screw & 4 fuel delivery pipe joint hose b tp sensor mounting screw item n·m kgf-m lb-ft 5 fuel injector c fuel delivery pipe joint hose a 3.5 0.35 2....

Page 104

Vl1500k5 (’05-model) 103 air cleaner box removal • remove the seats 1. ( !Page 121) • remove the speedometer and fuel inlet cover 2, frame head covers 3, and frame upper covers 4. ( !Vl1500 service manual 6-3) • loosen the throttle body clamp screws. • disconnect the iat sensor coupler 5. • disconne...

Page 105

104 vl1500k5 (’05-model) throttle body removal • remove the air cleaner box. ( !Page 103) • disconnect the throttle cables from their drum. ' • disconnect the stp sensor coupler 1 and stva coupler 2. • place a rag under the fuel feed hose and disconnect the fuel feed hose 3 from the delivery pipe. •...

Page 106

Vl1500k5 (’05-model) 105 • disconnect the tp sensor coupler 4 and iap sensor vacuum hoses 5. • remove the throttle body assembly. Throttle body disassembly • remove the fuel delivery pipe joint hose 1. • remove the fuel delivery pipes 2 • remove the fuel injectors. Sa mp le.

Page 107

106 vl1500k5 (’05-model) • remove the tp sensor 3 and stp sensor 4 with the special tool. # 09930-11950: torx wrench note: prior to disassembly, mark each sensor’s original position with a paint or scribe for accurate reinstallation. ' ' ' ' never remove the stva 5 from the throttle body. Never remo...

Page 108

Vl1500k5 (’05-model) 107 throttle body cleaning $ • clean all passageways with a spray-type carburetor cleaner and blow dry with compressed air. ' inspection check following items for any damage or clogging. * o-ring * throttle valve * secondary throttle valve * vacuum hose * delivery pipe joint hos...

Page 109

108 vl1500k5 (’05-model) throttle body reassembly reassemble the throttle body in the reverse order of disassem- bly. Pay attention to the following points: • with the stv fully open, install the stp sensor 1 and tighten the stp sensor mounting screw to the specified torque. Note: * apply thin coat ...

Page 110

Vl1500k5 (’05-model) 109 • apply thin coat of the engine oil to the new fuel injector cush- ion seal 3, and install it to the fuel injector. ' • install the o-ring 4 to the fuel injector. • apply thin coat of the engine oil to the new o-ring 4. • install the fuel injector 5 by pushing it straight to...

Page 111

110 vl1500k5 (’05-model) throttle body installation installation is in the reverse order of removal. Pay attention to the following points: • connect the throttle pulling cable 1 and throttle returning cable 2 to the throttle cable drum. • loosen each throttle cable lock-nut. • turn in each throttle...

Page 112

Vl1500k5 (’05-model) 111 • if the stp sensor resistance is out of specification, loosen the stp sensor mounting screw and adjust the stp sensor resis- tance to specification. • tighten the stp sensor mounting screw. # 09930-11950: torx wrench & stp sensor mounting screw: 3.5 n·m (0.35 kgf-m, 2.5 lb-...

Page 113

112 vl1500k5 (’05-model) fast idle the fast idle system is automatic type. When the fast idle cam is turned by the secondary throttle valve actuator, the cam pushes the lever on the throttle valve shaft causing the throttle valve to open and raise the engine speed. When the engine has warmed up, dep...

Page 114

Vl1500k5 (’05-model) 113 • turn the ignition switch on. • open the secondary throttle valve fully by turning it with your finger. • with the secondary throttle valve held at this position, mea- sure the output voltage of the tp sensor as shown. • calculate the voltage difference between tp sensor ou...

Page 115

114 vl1500k5 (’05-model) throttle valve synchronization check and adjust the throttle valve synchronization among two cylinders. Use of digital vacuum tester step 1 • remove the seats. ( !Page 121) • remove the speedometer and fuel inlet cover, frame head covers and upper frame covers. ( !Vl1500 ser...

Page 116

Vl1500k5 (’05-model) 115 note: during balancing the throttle valves, always set the engine rpm at 1 000 r/min, using throttle stop screw. Step 3 • turn in all the idle air screws to the complete close position. • check for difference of vacuum between no. 1 and no. 2. • equalize these two by gradual...

Page 117

116 vl1500k5 (’05-model) • connect one of the vacuum balancer gauge hose 2 to the vacuum nipple on the no. 1 throttle body. # 09913-13121: vacuum balancer gauge • connect a tachometer. • start up the engine and keep it running at 1 000 r/min by turn- ing throttle stop screw 3. # 09900-25008: multi-c...

Page 118

Vl1500k5 (’05-model) 117 throttle valve synchronization using the vacuum balancer gauge, inspect the throttle valve synchronization in the same manner as the digital vacuum tester. Pay attention to the following points: the vacuum gauge is positioned approx. 45° from the horizontal level, and in thi...

Page 119: Sensors

118 vl1500k5 (’05-model) sensors iap sensor inspection the intake air pressure sensor is located at the rear side of the air cleaner box. ( !Page 49) iap sensor removal/installation • remove the frame head covers and frame upper covers. ( !Vl1500%service manual 6-3) • remove the iap sensors 1 and di...

Page 120

Vl1500k5 (’05-model) 119 ckp sensor inspection the signal rotor is mounted on the generator rotor and crank- shaft position sensor is installed at the inside of the generator cover. ( !Vl1500%service manual 3-16) ckp sensor removal/installation ( !Vl1500%service manual 3d-4) iat sensor inspection th...

Page 121

120 vl1500k5 (’05-model) to sensor inspection the tip-over sensor is located under the front seat. ( !Page 70) to sensor removal/installation • remove the seats. ( !Page 121) • disconnect the coupler 1 and remove the to sensor. • installation is in the reverse order of removal. Note: when installing...

Page 122: Exterior Parts

Vl1500k5 (’05-model) 121 exterior parts seat removal this section gives only exterior parts removal procedure which differ from that of the vl1500k4 (’04-model). For details refer to the chapter 6 of service manual. • remove the rear seat 1. ' • remove the seat bracket 2 and front seat 3. Seat insta...

Page 123: Front Fork

122 vl1500k5 (’05-model) front fork construction 1 o-ring b oil lock piece 2 front fork spring c inner tube cover guide 3 damper rod ring d outer tube 4 rebound spring e upper inner tube cover 5 damper rod f rubber 6 inner tube g washer 7 slide metal h lower inner tube cover & 8 dust seal i inner tu...

Page 124

Vl1500k5 (’05-model) 123 removal and disassembly the front fork removal and disassembly procedures are different from those of the vl1500k4 (’04-model). For details other than the following, refer to the vl1500 service manual. • remove the front wheel, front fender and front brake calipers. ( !Vl150...

Page 125

124 vl1500k5 (’05-model) • remove the front fork cap bolts 7. Inspection for details other than the following, refer to the vl1500 service manual. Fork spring " front fork spring free length service limit: 589 mm (23.2 in) reassembly and remounting the front fork reassembly and remounting procedures...

Page 126

Vl1500k5 (’05-model) 125 • install the front fork cap bolt. • install the inner tube cover stopper 1 at 284.3 mm (11.19 in) a from the upper surface of the inner tube. • set the washer 2 and rubber 3 to the inner tube. • install the upper inner tube cover 4. Note: when installing the front fork inne...

Page 127

126 vl1500k5 (’05-model) • when installing the front fork assembly, align the upper sur- face d of the inner tube with the surface e of the steering upper bracket. • tighten the front fork lower clamp bolts 5 to the specified torque. & front fork lower clamp bolt: 23 n·m (2.3 kgf-m, 16.5 lb-ft) • ti...

Page 128

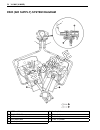

Vl1500k5 (’05-model) 127 location of electrical components 1 fuel pump and level gauge ( !Page 95) 9 to sensor ( !Page 70) 2 tp sensor ( !Page 53) 0 starter motor 3 iap sensor (front) ( !Page 49) a oil pressure switch 4 ignition coil (#2) b eot sensor ( !Page 58) 5 horn (** except for e-03, 24, 28 a...

Page 129

128 vl1500k5 (’05-model) 1 fuel injector (#1 & #2)( !Page 84) 9 gp switch ( !Page 82) 2 stp sensor ( !Page 77) 0 ho2 sensor (for e-02, 19, 24) ( !Page 87) 3 stv actuator ( !Page 74) a ignition coil (#1) 4 iap sensor (rear) ( !Page 49) b regulator/rectifier 5 ecm (engine control module) c generator 6...

Page 130: Charging System

Vl1500k5 (’05-model) 129 charging system inspection generator coil resistance • remove the seats. ( !Page 121) • remove the speedometer and fuel inlet cover, frame head covers and frame upper covers. ( !Vl1500 service manual 6-3) • disconnect the generator coupler 1. • measure the resistance among t...

Page 131

130 vl1500k5 (’05-model) regulator/rectifier • remove the secondary gear case cover. ( !Vl1500 service manual 3-7) • disconnect the couplers and remove the regulator/rectifier 1. • measure the voltage between the terminals using the multi circuit tester as indicated in the table below. If the voltag...

Page 132

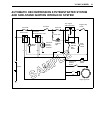

Vl1500k5 (’05-model) 131 automatic decompression system/starter system and side-stand ignition interlock system y/g m g/r battery fuse 30a automatic decompression relay automatic decom- pression solenoid starter relay starter motor starter button clutch lever position switch ig. Switch fuse 15a turn...

Page 133

132 vl1500k5 (’05-model) side-stand/ignition interlock system parts inspection check the interlock system for proper operation. If the interlock system does not operate properly, check each component for damage or abnormalities. If any abnormality is found, replace the component with a new one. Gear...

Page 134: Ignition System

Vl1500k5 (’05-model) 133 ignition system note: the fuel cut-off circuit is incorporated in this ecm in order to prevent over-running of engine. When engine speed reaches 5 800 – 6 000 r/min during running, this circuit cuts off fuel at the fuel injector. Troubleshooting no spark or poor spark note: ...

Page 135

134 vl1500k5 (’05-model) step 2 1) measure the battery voltage between input lead wires at the ecm with the ignition switch in the “on” position. (e-02, 19, 24: o/g and b/w, e-03, 28, 33: o/w and b/w) is the voltage ok? Step 3 1) measure the ignition coil primary peak voltage. ( !Page 135) note: thi...

Page 136

Vl1500k5 (’05-model) 135 inspection ignition coil primary peak voltage • remove the frame head covers and frame upper covers. ( !Vl1500 service manual 6-3) • remove the cylinder head side caps and disconnect the spark plug caps. ( !Vl1500%service manual 3-8) • connect new spark plugs to each spark p...

Page 137

136 vl1500k5 (’05-model) ignition coil resistance • remove the frame head covers and frame upper covers. ( !Vl1500 service manual 6-3) • remove the cylinder head side caps and disconnect the spark plug caps. ( !Vl1500%service manual 3-8) • measure the ignition coil resistance in both the primary and...

Page 138

Vl1500k5 (’05-model) 137 • shift the transmission into the neutral and turn ignition switch “on”. • crank the engine a few seconds with the starter motor by depressing starter button and check the ckp sensor peak voltage. • repeat the above procedure a few times and measure the highest peak voltage....

Page 139: Speedometer

138 vl1500k5 (’05-model) speedometer description this speedometer mainly consists of the stepping motor, lcd (liquid crystal display) and led (light emit- ting diode). This speedometer is light, thin and of high response compared to those currently in use because of this composition. The speedometer...

Page 140

Vl1500k5 (’05-model) 139 removal and disassembly • remove the seats. ( !Page 121) • remove the speedometer and fuel inlet cover. ( !Vl1500 service manual 6-3) • remove the speedometer 1. ' • disassemble the speedometer as follows. ' when disconnecting and reconnecting the speedome- ter coupler, make...

Page 141

140 vl1500k5 (’05-model) inspection led (light emitting diode) check that the leds illuminate (fi light and oil pressure indica- tor light) immediately after turning the ignition switch on. Also, check the other leds for their lighting (neutral indicator light, high-beam indicator light and turn sig...

Page 142: Relays

Vl1500k5 (’05-model) 141 speedometer if the speedometer, odometer or trip meter does not function properly, inspect the speedometer sensor and connection of coupler 1. If the speedometer sensor and connection are all right, replace the meter with a new one. Speedometer sensor • remove the right fram...

Page 143: Switches

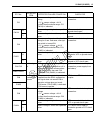

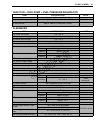

142 vl1500k5 (’05-model) switches inspect each switch for continuity with the multi-circuittester. If any abnormality is found, replace the respec- tive switch assemblies with new ones. # 09900-25008: multi-circuit tester set b/y ground on (engine is stopped) off (engine is running) color position b...

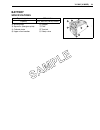

Page 144: Battery

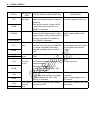

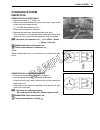

Vl1500k5 (’05-model) 143 battery specifications a anode plates e stopper b separator (fiberglass plate) f filter c cathode plates g terminal d upper cover breather h safety valve type designation ftz16-bs-1 capacity 12 v, 64.8 kc (18 ah)/10 hr sa mp le.

Page 145

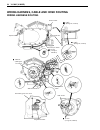

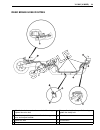

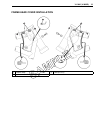

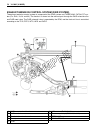

144 vl1500k5 (’05-model) wiring harness, cable and hose routing wiring harness routing speed sensor starter motor ground wire oil pressure switch 6 n.M (0.6 kgf-m, 4.5 lb-ft) 6 n.M (0.6 kgf-m, 4.5 lb-ft) 160 n.M (16.0 kgf-m, 115.5 lb-ft) 14 n.M (1.4 kgf-m, 10.0 lb-ft) side-stand switch gear position...

Page 146

Vl1500k5 (’05-model) 145 clamp ho2 sensor (for e-02, 19, 24) wiring harness clutch hose frame high-tension cord generator coupler clamp wiring harness (except to sensor) to sensor set the “ up ” mark to the top. Don’t set lead wire on pipe. Brake hose pass through the high-tension cord inside of the...

Page 147

146 vl1500k5 (’05-model) clamp handle switch (r, l) clamp wiring harness front turn (r, l) clamp boots clutch hose brake hose handle switch clamp horn (for e-03, 24, 28, 33) horn lead wire (for e-03, 24, 28, 33) horn lead wire (for e-02, 19) generator lead wire put lead wire into the space. Ignition...

Page 148

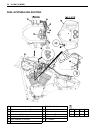

Vl1500k5 (’05-model) 147 cable and hose routing throttle cable no. 1 throttle cable no. 2 wiring harness clutch hose brake hose wiring harness 40 mm (1.57 in) 160 mm (6.30 in) throttle cable no. 1 clutch hose throttle cable no. 2 wiring harness clutch hose throttle cable no. 1 throttle cable no. 2 w...

Page 149

148 vl1500k5 (’05-model) front brake hose routing 1 after the brake hose union has contacted the stopper, tighten the union bolt to the specified torque. 4 pass through the brake hose inside of the hose guide. 2 after positioning the hose clamp with stopper, tighten the clamp bolt. 5 bind the brake ...

Page 150

Vl1500k5 (’05-model) 149 rear brake hose routing 42 ˚ 1 after the brake hose union has contacted the stopper, tighten the union bolt. 5 after positioning the clamp with the stopper, tighten the clamp bolt. 2 brake hose must be passed over the brake support boss and caliper bracket. 6 brake hose 3 re...

Page 151

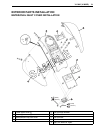

150 vl1500k5 (’05-model) fuel system hose routing 1 fuel feed hose 8 pcv (breather) hose & 2 iap sensor vacuum hose (rear cylinder) 9 air cleaner box item n·m kgf-m lb-ft 3 iap sensor vacuum hose (front cylinder) 0 iat sensor 0 20 2.0 14.4 4 purge hose (e-33 only) a iap sensor (front cylinder) c 22 ...

Page 152

Vl1500k5 (’05-model) 151 the clamp bolt head sould face downward. 15 n.M (0.15 kgf-m, 1.0 lb-ft) 10 n.M (1.0 kgf-m, 7.0 lb-ft) 5 n.M (0.5 kgf-m, 3.7 lb-ft) the ends of the clamp should face right side. The ends of the clamp should face left side. Water drain hose fuel feed hose the ends of the clamp...

Page 153

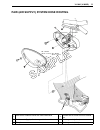

152 vl1500k5 (’05-model) pair (air supply) system hose routing 1 pair control solenoid valve with pair reed valve *1 connect the air hose to the air cleaner box. 2 cushion seat (apply an adhesive agent to the cushion seat.) *2 matching mark (yellow) 3 wiring harness *3 matching mark (white) *1 *2 *3...

Page 154: Exterior Parts Installation

Vl1500k5 (’05-model) 153 exterior parts installation meter/fuel inlet cover installation (usa) (others) (usa) (others) *1 *2 1 frame upper cover (l) 5 fuel lid hinge bracket 2 frame upper cover (r) 6 fuel lid 3 speedometer/fuel inlet cover 7 fuel lid cover 4 speedometer switch cover *1 outside *2 ap...

Page 155

154 vl1500k5 (’05-model) frame upper cover installation 1 cushion seat 4 molding 2 apply an adhesive agent. 5 bend up the stay. 3 cushion rubber 6 50 mm (2.0 in) sa mp le.

Page 156

Vl1500k5 (’05-model) 155 frame head cover installation 1 cushion seat 3 3 mm (0.12 in) 2 apply an adhesive agent. Sa mp le.

Page 157

156 vl1500k5 (’05-model) grease-up points brake pedal installation 50 n.M (5.0 kgf-m, 36.0 lb-ft) h × × × × × × h brake pedal height: 98 mm (3.86 in) × apply an adhesive agent. Sa mp le.

Page 158: Special Tools

Vl1500k5 (’05-model) 157 special tools note: when order the special tool, please confirm whether it is available or not. 09900-25009 needle pointed probe set 09900-28630 tps test wire har- ness 09904-41010 sds set tool 99565-01010-004 cd-rom ver. 4 09915-74511 oil pressure gauge 09940-40211 fuel pre...

Page 159: Tightening Torque

158 vl1500k5 (’05-model) tightening torque * fi system and intake air system * chassis item n·m kgf-m lb-ft iat sensor 20 2.0 14.4 ho2 sensor (for e-02, 19, 24) 25 2.5 18.0 eot sensor 22 2.2 16.0 fuel pump mounting bolt 10 1.0 7.0 stps mounting screw 3.5 0.35 2.5 tps mounting screw 3.5 0.35 2.5 fuel...

Page 160: Service Data

Vl1500k5 (’05-model) 159 service data valve + guide unit: mm (in) item standard limit valve diam. In. 33 (1.3) — ex. 40 (1.6) — lash-adjuster plunger stroke 0 – 0.5 (0 – 0.02) — valve guide to valve stem clearance in. 0.010 – 0.037 (0.0004 – 0.0015) — ex. 0.040 – 0.070 (0.0016 – 0.0028) — valve stem...

Page 161

160 vl1500k5 (’05-model) camshaft + cylinder head unit: mm (in) cylinder + piston + piston ring unit: mm (in) item standard limit cam height in. * 35.320 – 35.370 (1.3905 – 1.3925) * 35.02 (1.379) ex. 36.880 – 36.930 (1.4521 – 1.4537) 36.58 (1.440) camshaft journal oil clearance in. & ex. 0.032 – 0....

Page 162

Vl1500k5 (’05-model) 161 conrod + crankshaft unit: mm (in) item standard limit piston ring end gap 1st 0.30 – 0.45 (0.012 – 0.018) 0.70 (0.028) 2nd 0.45 – 0.60 (0.018 – 0.024) 1.00 (0.039) piston ring to groove clearance 1st — 0.180 (0.007) 2nd — 0.150 (0.006) piston ring groove width 1st 1.210 – 1....

Page 163

162 vl1500k5 (’05-model) oil pump clutch unit: mm (in) drive train unit: mm (in) except ratio item standard limit oil pump reduction ratio 1.154 (76/51 × 31/40) — oil pressure (at 60 °c, 140 °f) above 350 kpa (3.5 kgf/cm 2 , 50 psi) below 650 kpa (6.5 kgf/cm 2 , 92 psi) at 3 000 r/min — item standar...

Page 164

Vl1500k5 (’05-model) 163 * injector + fuel pump + fuel pressure regurator * fi-sensors item specification note injector resistance approx. 11.7 Ω at 20 °c (68 °f) fuel pump discharge amount 168 ml (5.7/5.9 us/lmp oz) and more/10 sec. Fuel pressure regulator operat- ing set pressure approx. 300 kpa (...

Page 165

164 vl1500k5 (’05-model) * throttle body electrical unit: mm (in) item specification id no. 10f0 (for e-02, 19, 03, 24, 28), 10f1 (for e-33) bore size 36 mm fast idle r/min 1 400 – 2 000 r/min when cold engine idle r/min 1 000 ± 100 r/min throttle cable play 2.0 – 4.0 mm (0.08 – 0.16 in) item specif...

Page 166

Vl1500k5 (’05-model) 165 wattage unit: w brake + wheel unit: mm (in) item specification e-03, 28, 33 e-24 others headlight hi 60 ← ← lo 55 ← ← position/parking light * 12/5 brake light/taillight 21/5 ← ← turn signal light front 21/5 21 ← rear 21 ← ← speedometer light * led ← ← turn signal indicator ...

Page 167

166 vl1500k5 (’05-model) suspension unit: mm (in) tire pressure fuel + oil item standard limit wheel rim size front 16 × mt3.50, 16m/c × mt3.50 — rear 15m/c × mt5.00 — tire size front 150/80-16 71h, 150/80-16m/c 71h — rear 180/70-15m/c 76h — tire tread depth front — 1.6 (0.06) rear — 2.0 (0.08) item...

Page 168

Vl1500k5 (’05-model) 167 item standard limit front fork oil capacity (each leg) *416 ml (14.1/14.6 us/lmp oz) bevel gear oil type hypoid gear oil #90 api gl-5 bevel gear oil capacity final 200 – 220 ml (6.8/7.0 – 7.4/7.7 us/lmp oz) brake fluid type dot 4 sa mp le.

Page 169: Emission Control Systems

168 vl1500k5 (’05-model) emission control systems fuel injection system vl1500k5 motorcycles are equipped with a fuel injection system for emission level control. This fuel injection system is precision designed, manufactured and adjusted to comply with the applicable emission limits. 1 fuel tank 7 ...

Page 170

Vl1500k5 (’05-model) 169 crankcase emission control system the engine is equipped with a pcv system. Blow-by gas in the engine is constantly drawn into the crank- case, which is returned to the combustion chamber through the pcv (breather) hose, air cleaner and throttle body. 1 pair control solenoid...

Page 171

170 vl1500k5 (’05-model) exhaust emission control system (pair system) the exhaust emission control system is composed of the pair system and three-way catalyst sys- tem (for e-02, 19, 24 and 33). The fresh air is drawn into the exhaust port through the pair solenoid valve and pair reed valve. The p...

Page 172

Vl1500k5 (’05-model) 171 noise emission control system tampering with the noise control system prohibited: local law prohibits the following acts or the causing thereof: 1. The removal or rendering inoperative by any person, other than for purposes of maintenance, repair or replacement, of any devic...

Page 173

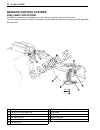

172 vl1500k5 (’05-model) pair (air supply) system inspection hoses and pipes • remove the pair cover. ( !Page 14) • inspect the hoses for wear or damage. • inspect that the hoses for secure connection. Pair reed valve • remove the pair control solenoid valve. ( !Page 14) • remove the reed valve case...

Page 174

Vl1500k5 (’05-model) 173 • connect the 12 v battery to the pair control solenoid valve terminals and check the air flow. • if air does not flow out, the solenoid valve is in normal condi- tion. • check the resistance between the terminals of the pair con- trol solenoid valve. " resistance: 20 – 24 Ω...

Page 175

174 vl1500k5 (’05-model) pair (air supply) system diagram *1 *2 *3 a fresh air 4 no. 2 cylinder b exhaust gas *1 from air cleaner 1 pair control solenoid valve *2 to no. 1 cylinder 2 pair reed valve *3 to no. 2 cylinder 3 no. 1 cylinder sa mp le.

Page 176

Vl1500k5 (’05-model) 175 pair (air supply) system hose routing *1 *2 *3 20 – 40 mm (0.79 – 1.57 in) 20 – 40 mm (0.79 – 1.57 in) 15 – 20 mm (0.59 – 0.79 in) 15 – 20 mm (0.59 – 0.79 in) 1 pair control solenoid valve with pair reed valve *1 connect the air hose to the air cleaner box. 2 cushion seat (a...

Page 177

176 vl1500k5 (’05-model) heated oxgen sensor (ho2s) inspection (for e-02, 19, 24) the ho2 sensor coupler is located at the rear side of the fuel tank. ( !Page 87) • inspect the ho2 sensor and its circuit referring to flow table of the malfunction code c44 (p0130/p0135). • check the resistance betwee...

Page 178

Wiring diagram e-02, 19, 24 lbl b/w lbl b/w lg b/w lg b/w o/y p b/w o/y p b/w r bl/b b/br r bl/b b/br o/w b/br w/g w/b o/w b/br w/g w/b o/w g/r w r o/w g/r w r r br/w b/br r br/w b/br y/r b/w y/b y/r b/w y/b y/r b/w r/b y/r b/w r/b y o/w r/w y/r y o/w r/w y/r w gr b w w gr b w o/w w o/w w o/w b/y o/...

Page 179

E-03, 28, 33 headlight front turn signal light (r) front turn signal light (l) speedometer off run off on push handlebar switch (r) handlebar switch (l) starter button front brake light switch speed sensor side-stand switch push free on off ecm brake light/ taillight battery starter motor starter re...

Page 180

Prepared by may, 2004 part no. 99501-39550-01e printed in japan 176 sa mp le.

Page 181

Printed in japan k5.