- DL manuals

- Suzuki

- Automobile

- 2006 SX4

- Service Manual

Suzuki 2006 SX4 Service Manual

IMPORTANT

WARNING/CAUTION/NOTE

Please read this manual and follow its instructions carefully. To emphasize special information, the words

,

and

NOTE have special meanings. Pay special attention to the messages high-

lighted by these signal words.

The circle with a slash in this manual means “Don’t do this” or “Don’t let this happen”.

WARNING

!

CAUTION

!

Indicates a potential hazard that could result in death or injury.

WARNING

!

Indicates a potential hazard that could result in vehicle damage.

CAUTION

!

NOTE:

Indicates special information to make maintenance easier or instructions clearer.

This service manual is intended for authorized Suzuki dealers and qualified service technicians only.

Inexperienced technicians or technicians without the proper tools and equipment may not be able to

properly perform the services described in this manual.

Improper repair may result in injury to the technician and may render the vehicle unsafe for the driver

and passengers.

WARNING

!

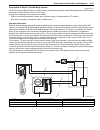

For vehicles equipped with a Supplemental Restraint (Air Bag) System:

• Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

• If the air bag system and another vehicle system both need repair, Suzuki recommends that the air

bag system be repaired first, to help avoid unintended air bag system activation.

• Do not modify the steering wheel, instrument panel or any other air bag system component on or

around air bag system components or wiring. Modifications can adversely affect air bag system

performance and lead to injury.

• If the vehicle will be exposed to temperatures over 93 °C (200 °F), for example, during a paint baking

process, remove the air bag system components, that is air bag (inflator) modules, SDM and/or seat

belt with pretensioner, beforehand to avoid component damage or unintended activation.

WARNING

!

Summary of 2006 SX4

Page 1

Important warning/caution/note please read this manual and follow its instructions carefully. To emphasize special information, the words , and note have special meanings. Pay special attention to the messages high- lighted by these signal words. The circle with a slash in this manual means “don’t d...

Page 3: Foreword

Foreword this manual (volumes 1 and 2) contains procedures for diagnosis, maintenance, adjustments, minor service operations, replacement of components (service) and for disassembly and assembly of major components (unit repair-overhaul). Volume 1 contains general information, engine, suspension, dr...

Page 4

Recommendaton of genuine suzuki parts and accessories use suzuki strongly recommends the use of genuine suzuki parts* and accessories. Genuine suzuki parts and accessories are built to the highest standards of quality and performance, and are designed to fit the vehicle’s exact specifications. A wid...

Page 5: Table of Contents

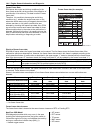

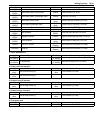

00 0 1 2 3 4 5 6 7 8 9 10 11 volume 1 precautions............................................................... 00-i precautions ............................................................ 00-1 general information ................................................... 0-i general information ...........

Page 7: Section 00

Table of contents 00- i 00 section 00 contents precautions precautions ...............................................00-1 precautions........................................................... 00-1 precautions for vehicles equipped with a supplemental restraint (air bag) system ........ 00-1 genera...

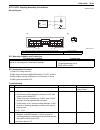

Page 8: Precautions

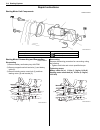

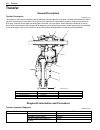

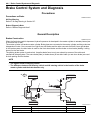

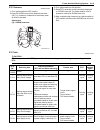

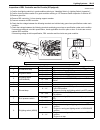

00-1 precautions: precautions precautions precautions precautions for vehicles equipped with a supplemental restraint (air bag) system s6rw0c0000001 warning ! • the configuration of air bag system parts are as shown in the figure. When it is necessary to service (remove, reinstall and inspect) these...

Page 9

Precautions: 00-2 servicing and handling warning ! Many of service procedures require disconnection of “a/b” fuse and all air bag (inflator) module(s) from initiator circuit to avoid an accidental deployment. Driver, passenger, side and curtain air bag (inflator) modules • for handling and storage o...

Page 10

00-3 precautions: warning ! Sdm • for handling and storage of a sdm, select a place where the ambient temperature below 65 °c (150 °f), without high humidity and away from electric noise. • during service procedures, be very careful when handling a sensing and diagnostic module (sdm). Never strike o...

Page 11

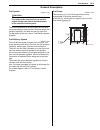

Precautions: 00-4 warning ! • whenever raising a vehicle for service, be sure to follow the instructions under “vehicle lifting points in section 0a”. • when it is necessary to do service work with the engine running, make sure that the parking brake is set fully and the transmission is in neutral (...

Page 12

00-5 precautions: • when removing the battery, be sure to disconnect the negative cable first and then the positive cable. When reconnecting the battery, connect the positive cable first and then the negative cable, and replace the terminal cover. • when removing parts that are to be reused, be sure...

Page 13

Precautions: 00-6 • after servicing fuel, oil, coolant, vacuum, exhaust or brake systems, check all lines related to the system for leaks. • for vehicles equipped with fuel injection systems, never disconnect the fuel line between the fuel pump and injector without first releasing the fuel pressure,...

Page 14

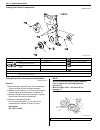

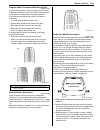

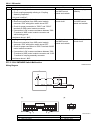

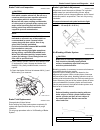

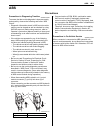

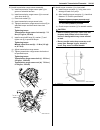

00-7 precautions: precautions in servicing 4wd model s6rw0c0000004 caution ! • never perform any of the following [a], [b] and [c] types of service work. If it is performed while 4wd-auto mode or 4wd-lock mode is selected, front wheels (or rear wheels) drive rear wheels (or front wheels) and vehicle...

Page 15

Precautions: 00-8 precautions for catalytic converter s6rw0c0000005 for vehicles equipped with a catalytic converter, use only unleaded gasoline and be careful not to let a large amount of unburned gasoline enter the converter or it can be damaged. • conduct a spark jump test only when necessary, ma...

Page 16

00-9 precautions: precautions for electrical circuit service s6rw0c0000008 • when replacing a fuse, make sure to use a fuse of the specified capacity. Use of a fuse with a larger capacity will cause a damage to the electrical parts and a fire. • when disconnecting and connecting coupler, make sure t...

Page 17

Precautions: 00-10 • be careful not to touch the electrical terminals of parts which use microcomputers (e.G. Electronic control unit like as ecm, pcm, p/s controller, etc.). The static electricity from your body can damage these parts. • never connect any tester (voltmeter, ohmmeter, or whatever) t...

Page 18

00-11 precautions: air bag warning s6rw0c0000009 warning ! For vehicles equipped with supplemental restraint (air bag) system: • service on and around the air bag system components or wiring must be performed only by an authorized suzuki dealer. Refer to “air bag system components, wiring and connec...

Page 19

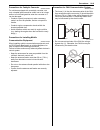

Precautions: 00-12 repair instructions electrical circuit inspection procedure s6rw0c0006001 while there are various electrical circuit inspection methods, described here is a general method to check its open and short circuit by using an ohmmeter and a voltmeter. Open circuit check possible causes ...

Page 20

00-13 precautions: voltage check if voltage is supplied to the circuit being checked, voltage check can be used as circuit check. 1) with all connectors connected and voltage applied to the circuit being checked, measure voltage between each terminal and body ground. A) if measurements were taken as...

Page 21

Precautions: 00-14 intermittent and poor connection inspection s6rw0c0006002 most intermittent are caused by faulty electrical connections or wiring, although a sticking relay or solenoid can occasionally be at fault. When checking it for proper connection, perform careful check of suspect circuits ...

Page 22

00-15 precautions:.

Page 23: Section 0

Table of contents 0- i 0 section 0 contents general information general information ................................ 0a-1 general description .............................................0a-1 abbreviations ...................................................... 0a-1 symbols .............................

Page 24: General Information

0a-1 general information: general information general information general description abbreviations s6rw0c0101001 a: abdc: after bottom dead center abs: anti-lock brake system ac: alternating current a/c: air conditioning a-elr: automatic-emergency locking retractor a/f: air fuel mixture ratio alr: ...

Page 25

General information: 0a-2 s: sae: society of automotive engineers sdm: sensing and diagnostic module (air bag controller, air bag control module) sdt: smart diagnostic tester sfi: sequential multiport fuel injection sohc: single over head camshaft t: tbi: throttle body fuel injection (single-point f...

Page 26

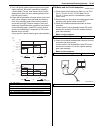

0a-3 general information: there are two kinds of colored wire used in this vehicle. One is single-colored wire and the other is dual-colored (striped) wire. The single-colored wire uses only one color symbol (i.E. “grn”). The dual-colored wire uses two color symbols (i.E. “grn/yel”). The first symbo...

Page 27

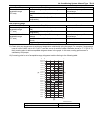

General information: 0a-4 standard tightening torque each fastener should be tightened to the torque specified in each section. If no description or specification is provided, refer to the following tightening torque chart for the applicable torque for each fastener. When a fastener of greater stren...

Page 28

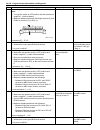

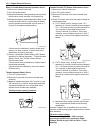

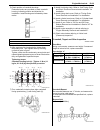

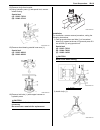

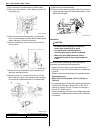

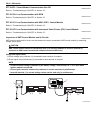

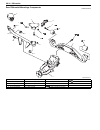

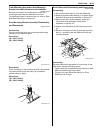

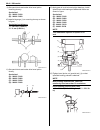

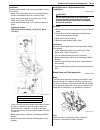

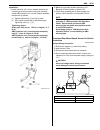

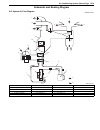

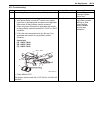

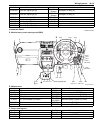

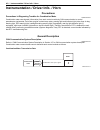

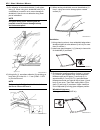

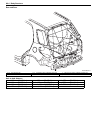

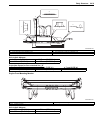

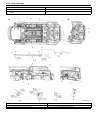

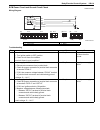

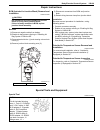

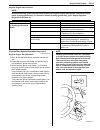

0a-5 general information: vehicle lifting points s6rw0c0101005 warning ! • before applying hoist to underbody, always take vehicle balance throughout service into consideration. Vehicle balance on hoist may change depending on what part to be removed. • before lifting up the vehicle, check to be sur...

Page 29

General information: 0a-6 in raising front or rear vehicle end off the floor by jacking, be sure to put the jack against engine front mounting member (1) or rear jacking bracket (2). To perform service with either front or rear vehicle end jacked up, be sure to place safety stands (1) under shaded p...

Page 30

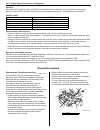

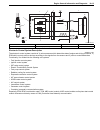

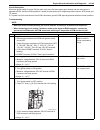

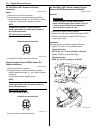

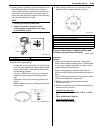

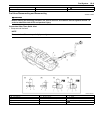

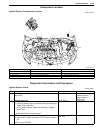

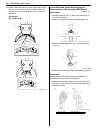

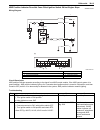

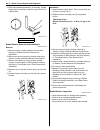

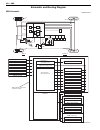

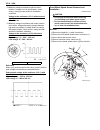

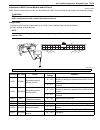

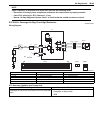

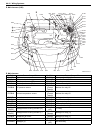

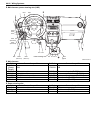

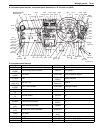

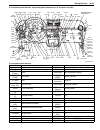

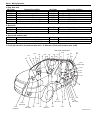

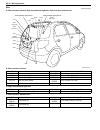

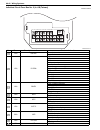

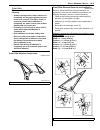

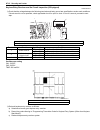

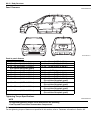

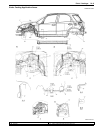

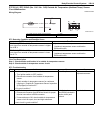

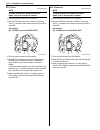

0a-7 general information: component location warning, caution and information labels location s6rw0c0103001 the figure shows main labels among others that are attached to vehicle component parts. When servicing and handling parts, refer to warning / caution instructions printed on labels. If any war...

Page 31

General information: 0a-8 1 2 4 8 6 9 7 3 [a] 5 i6rw0c010001-02 1. Air bag label on driver air bag (inflator) module 6. Air bag label on sdm 2. Air bag label on contact coil assembly 7. Pretensioner label on seat belt retractor 3. Air bag label on passenger air bag (inflator) module 8. Side/curtain ...

Page 32: Maintenance and Lubrication

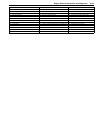

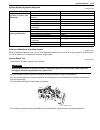

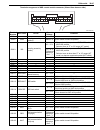

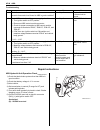

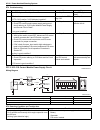

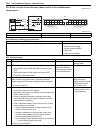

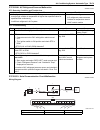

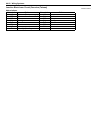

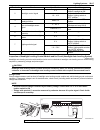

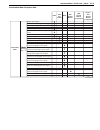

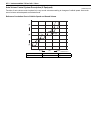

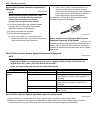

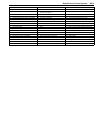

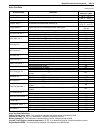

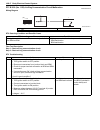

0b-1 maintenance and lubrication: general information maintenance and lubrication precautions precautions for maintenance and lubrication s6rw0c0200001 air bag warning refer to “air bag warning in section 00”. Scheduled maintenance maintenance schedule under normal driving conditions s6rw0c0205001 n...

Page 33

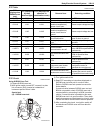

Maintenance and lubrication: 0b-2 note • “r”: replace or change • “i”: inspect and correct, replace or lubricate if necessary • for spark plugs, replace every 50,000 km if the local law requires. • nickel spark plug: bkr6e-11 (ngk) maintenance recommended under severe driving conditions s6rw0c020500...

Page 34

0b-3 maintenance and lubrication: note • “i”: inspect and correct or replace if necessary • “r”: replace or change • *1: inspect or replace more frequently if the vehicle is used under dusty conditions. • *2: clean or replace more frequently if the air from the air conditioning decreases. Repair ins...

Page 35

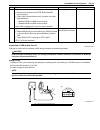

Maintenance and lubrication: 0b-4 fuel evaporative emission control system inspection s6rw0c0206013 check evap canister and fuel vapor hose referring to “evap canister inspection in section 1b” and “vacuum hose and purge valve chamber inspection in section 1b”. Brake discs and pads inspection s6rw0c...

Page 36

0b-5 maintenance and lubrication: hvac air filter (if equipped) inspection s6rw0c0206034 check hvac air filter for dirt and dust referring to “hvac air filter inspection (if equipped) in section 7a”. Hvac air filter (if equipped) replacement s6rw0c0206035 replace hvac air filter with new one referri...

Page 37

Maintenance and lubrication: 0b-6 steering • check to ensure that steering wheel is free from instability, or abnormally heavy feeling. • check that the vehicle does not wander or pull to one side. Engine • check that engine responds readily at all speeds. • check that engine is free from abnormal n...

Page 38

0b-7 maintenance and lubrication:.

Page 39: Section 1

Table of contents 1- i 1 section 1 contents engine precautions .................................................1-1 precautions............................................................. 1-1 precautions for engine.......................................... 1-1 engine general information and diagnos...

Page 40

1-ii table of contents dtc p0171 / p0172: system too lean / too rich (sensor-1, bank-1) .................................1a-81 dtc p0222 / p0223: throttle position sensor (sub) circuit low / high ..................................1a-83 dtc p0300 / p0301 / p0302 / p0303 / p0304: random misfire detect...

Page 41

Table of contents 1-iii accelerator pedal position (app) sensor assembly inspection .........................................1c-5 engine coolant temperature (ect) sensor removal and installation...................................1c-6 engine coolant temperature (ect) sensor inspection...................

Page 42

1-iv table of contents oil pump components ........................................1e-8 oil pump removal and installation .....................1e-9 oil pump disassembly and reassembly ..........1e-10 oil pump inspection ..........................................1e-10 specifications.....................

Page 43

Table of contents 1-v starting motor components ................................. 1i-5 starting motor inspection ..................................... 1i-6 specifications........................................................ 1i-9 cranking system specifications........................... 1i-9 tight...

Page 44: Precautions

1-1 precautions: engine precautions precautions precautions for engine s6rw0c1000001 air bag warning refer to “air bag warning in section 00”. Precautions on engine service refer to “precautions on engine service in section 1a”. Precautions in diagnosing trouble refer to “precautions in diagnosing t...

Page 45

Engine general information and diagnosis: 1a-1 engine engine general information and diagnosis precautions precautions on engine service s6rw0c1100003 the following information on engine service should be noted carefully, as it is important in preventing damage, and in contributing to reliable engin...

Page 46

1a-2 engine general information and diagnosis: • therefore, check both ecm and tcm for dtc when mil lights on. • when checking ecm for dtc, keep in mind that dtc is displayed on the scan tool as follows depending on the scan tool used. – suzuki scan tool displays dtc detected by ecm. – can communica...

Page 47

Engine general information and diagnosis: 1a-3 precaution on can troubleshooting s6rw0c1100008 can schematic and routing diagram outline of troubleshooting when there is a trouble with can, perform “troubleshooting for communication error with scan tool using can” and/ or “troubleshooting for can-dt...

Page 48

1a-4 engine general information and diagnosis: can-dtc even when dtc related to can (= can-dtc) as described below is detected, it is not possible to point out the specific trouble point by can-dtc itself. Be sure to troubleshoot according to “troubleshooting for can-dtc”. Can-dtc table communicatio...

Page 49

Engine general information and diagnosis: 1a-5 engine diagnosis general description s6rw0c1101002 note there are two types of obd system depending on the vehicle specification. For identification, refer to “precaution on on- board diagnostic (obd) system”. The engine and emission control systems in ...

Page 50

1a-6 engine general information and diagnosis: freeze frame data ecm stores the engine and driving conditions (in the form of data as shown) at the moment of the detection of a malfunction in its memory. This data is called “freeze frame data”. Therefore, it is possible to know engine and driving co...

Page 51

Engine general information and diagnosis: 1a-7 • cmp sensor • ckp sensor • knock sensor • wheel speed sensor • cpu (central processing unit) of ecm • app sensor • radiator cooling fan relay • evap canister purge valve • starter relay ecm and mil operate as follows. • mil lights when the ignition swi...

Page 52

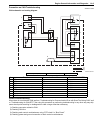

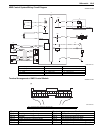

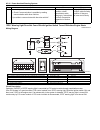

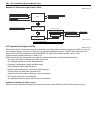

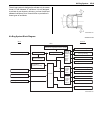

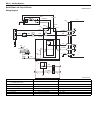

1a-8 engine general information and diagnosis: can communication system description s6rw0c1101015 ecm (2), abs control module (1), tcm (3), bcm (4), 4wd control module (6), combination meter (7) and keyless start control module (5) communicate control data between each control module. Communication ...

Page 53

Engine general information and diagnosis: 1a-9 ecm transmission data engine torque signal accelerator pedal position signal engine speed signal throttle position signal driving cycle active warm up cycle active immobiliz light control signal er indicator mil control signal engine coolant temperature...

Page 54

1a-10 engine general information and diagnosis: ecm reception data air intake system description s6rw0c1101016 the main components of the air intake system are air cleaner (1), air cleaner outlet hose (2), electric throttle body (3) (for the details, refer to “description of electric throttle body s...

Page 55

Engine general information and diagnosis: 1a-11 description of electric throttle body system s6rw0c1101017 the electric throttle body system consists of electric throttle body assembly, accelerator pedal position (app) sensor assembly, ecm and throttle actuator control relay. Among them, assembly co...

Page 56

1a-12 engine general information and diagnosis: description of electric throttle body system calibration s6rw0c1101018 ecm calculates controlled opening of the throttle valve on the basis of the completely closed throttle valve position of the electric throttle body system. The completely closed pos...

Page 57

Engine general information and diagnosis: 1a-13 electronic control system description s6rw0c1101022 the electronic control system consists of 1) various sensors which detect the state of engine and driving conditions, 2) ecm which controls various devices according to the signals from the sensors an...

Page 58

1a-14 engine general information and diagnosis: engine and emission control system flow diagram intak e manif old exhaust manif old exhaust gas air fuel v apor wa rm u p catalyst exhaust pipe ev ap canister purge v alv e fuel injector ect sensor ecm heater control heater control barometr ic pressure...

Page 59

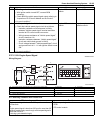

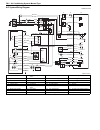

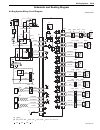

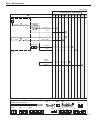

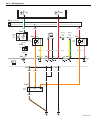

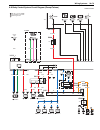

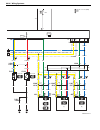

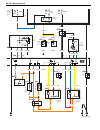

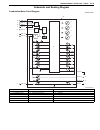

Engine general information and diagnosis: 1a-15 ecm input / output circuit diagram 33 34 35 36 37 +b 59 ig1 +bb ig2 ig2 63 : 64 : 75 74 blu/yel blu/wht blu/red blu/orn blu/blk blk/wht wht/red brn/wht blk/red 67 71 : 5v : 12v 72 60 ig1 e01-29 e01-2 c01-58 e01-1 e01-16 c01-15 c01-30 48 e01-60 yel/blk ...

Page 60

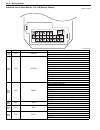

1a-16 engine general information and diagnosis: terminal arrangement of ecm coupler (viewed from harness side) connector: c01 6. Maf and iat sensor 31. Throttle actuator 56. Brake light switch 7. Ect sensor 32. Tp sensor 57. “stop” fuse 8. A/c refrigerant pressure sensor 33. Fuel injector no.1 58. “...

Page 61

Engine general information and diagnosis: 1a-17 connector: e01 20 grn/wht ignition coil no.2 50 red can (high) communication line (active high signal) to tcm 21 grn/yel ignition coil no.1 51 pnk ckp sensor (+) 22 yel/grn starting motor signal 52 red/yel cmp sensor signal 23 — — 53 red output for 5 v...

Page 62

1a-18 engine general information and diagnosis: engine and emission control input / output table s6rw0c1101023 24 yel/red fuel level sensor signal 54 blu ground for app sensor (main) 25 — — 55 grn app sensor (main) signal 26 — — 56 brn output for 5 v power source of app sensor (main) 27 red/blu eps ...

Page 63

Engine general information and diagnosis: 1a-19 idle speed control throttle actuator • ckp sensor • maf sensor • iat sensor • tp sensor • ect sensor • app sensor • wheel speed sensor (vss) • a/c refrigerant pressure sensor • a/c evaporator outlet air temp. Sensor • p/s control module • abs control m...

Page 64

1a-20 engine general information and diagnosis: radiator cooling fan control radiator cooling fan relay no.1, no.2 and no.3 • ignition switch • a/c switch • blower fan selector • wheel speed sensor (vss) • ect sensor • a/c refrigerant pressure sensor • a/c evaporator outlet air temp. Sensor mil cont...

Page 65

Engine general information and diagnosis: 1a-21 a/c condenser cooling fan control a/c condenser cooling fan relay • wheel speed sensor (vss) • a/c refrigerant pressure sensor • a/c evaporator outlet air temp. Sensor • ect sensor • a/c switch • blower fan switch • ignition switch function output inpu...

Page 66

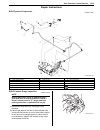

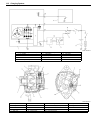

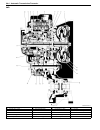

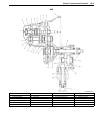

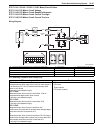

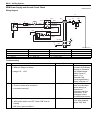

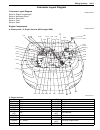

1a-22 engine general information and diagnosis: schematic and routing diagram engine and emission control system diagram s6rw0c1102001 23 29 14 13 15 16 17 11 12 10 1 2 19 20 21 39 42 41 40 38 36 28 3 30 31 37 26 27 32 4 5 22 24 35 34 33 6 7 9 8 25 18 i6rw0c110008-01.

Page 67

Engine general information and diagnosis: 1a-23 1. Air cleaner 15. Ho2s 29. Throttle actuator control relay 2. Maf and iat sensor 16. Warm-up three way catalytic converter 30. Radiator cooling fan relay 3. Tp sensor 17. Three way catalytic converter 31. A/c condenser cooling fan relay 4. Throttle ac...

Page 68

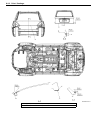

1a-24 engine general information and diagnosis: component location electronic control system components location s6rw0c1103001 note the figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed at the opposite side. 3* h* d b* l 11 f l k 1 b 2 9 4 8 5 6 a...

Page 69

Engine general information and diagnosis: 1a-25 diagnostic information and procedures engine and emission control system check s6rw0c1104001 refer to the following items for the details of each step. Step action yes no 1 ) customer complaint analysis 1) perform customer complaint analysis referring ...

Page 70

1a-26 engine general information and diagnosis: 11 ) final confirmation test 1) clear dtc if any. 2) perform final confirmation test referring to “final confirmation test”. Is there any problem symptom, dtc or abnormal condition? Go to step 6. End. Step action yes no.

Page 71

Engine general information and diagnosis: 1a-27 step 1: customer complaint analysis record details of the problem (failure, complaint) and how it occurred as described by the customer. For this purpose, use of such an inspection form will facilitate collecting information to the point required for p...

Page 72

1a-28 engine general information and diagnosis: step 2: dtc / freeze frame data check, record and clearance first, check dtc (including pending dtc), referring to “dtc check”. If dtc is indicated, print it and freeze frame data or write them down and then clear them by referring to “dtc clearance”. ...

Page 73

Engine general information and diagnosis: 1a-29 dtc check s6rw0c1104003 note • there are two types of obd system depending on the vehicle specification. For identification, refer to “precaution on on-board diagnostic (obd) system”. • the mil is turned on when the ecm and/or tcm detect malfunction(s)...

Page 74

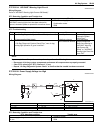

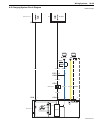

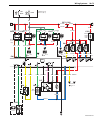

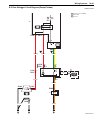

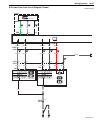

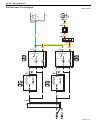

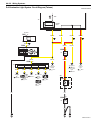

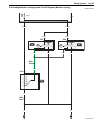

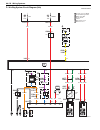

1a-30 engine general information and diagnosis: wiring diagram 5 2 3 4 red wht red wht red wht red wht red wht e01-4 e01-19 e08-1 e08-12 e08-2 e08-13 e04-1 e04-2 g04-4 g04-2 red wht red wht g16-19 g16-18 7 red wht g04-3 g04-1 8 9 red wht g26-23 g26-22 6 red wht g241-9 g241-7 g241-10 g241-6 1 red wht...

Page 75

Engine general information and diagnosis: 1a-31 trouble area • scan tool • connector related to can line (included in dlc) • can line • power or ground circuit of dlc • control module communicated by can – ecm – tcm – abs control module – bcm – combination meter – keyless start control module – 4wd ...

Page 76

1a-32 engine general information and diagnosis: 4 dtc check 1) turn ignition switch to off position. 2) connect scan tool to dlc. 3) check dtc in the following control modules that communicate with scan tool by k-line. • bcm • keyless start control module • 4wd control module is there any dtc other ...

Page 77

Engine general information and diagnosis: 1a-33 7 can line check 1) turn ignition switch to off position. 2) disconnect connectors of all control module communicated by can. 3) check all the following can lines for open, short to power circuit, short to ground circuit, short to other can line and hi...

Page 78

1a-34 engine general information and diagnosis: dtc table s6rw0c1104006 note • there are two types of obd system depending on the vehicle specification. For non-euro-obd model, refer to “precaution on on-board diagnostic (obd) system”. • for non-euro-obd model, some of dtc no. With delta (u) mark in...

Page 79

Engine general information and diagnosis: 1a-35 ) *p0122 throttle/pedal position sensor/switch “a” (main) circuit low output voltage of tp sensor (main) is lower than 0.3 v. 1 driving cycle 1 driving cycle ) *p0123 throttle/pedal position sensor/switch “a” (main) circuit high output voltage of tp se...

Page 80

1a-36 engine general information and diagnosis: ) *p0335 crankshaft position (ckp) sensor “a” circuit ckp sensor signal is not detected for 2 sec. Even though starter is operated. 1 driving cycle 1 driving cycle ) *p0340 camshaft position (cmp) sensor “a” circuit if either of the following condition...

Page 81

Engine general information and diagnosis: 1a-37 ) p0660 intake manifold tuning valve control circuit/ open monitor signal of imt valve is different from command signal for 5 sec. 1 driving cycle not applicable ) p0662 intake manifold tuning valve control circuit high circuit voltage of imt valve is ...

Page 82

1a-38 engine general information and diagnosis: ) u0073 control module communication bus off transmission error that is inconsistent between transmission data and transmission monitor (can bus monitor) data is detected more than 30 times continuously. 1 driving cycle not applicable ) *u0101 ecm lost...

Page 83

Engine general information and diagnosis: 1a-39 for vehicle equipped with a/t note there are two types of obd system depending on the vehicle specification. For identification, refer to “precaution on on-board diagnostic (obd) system”. When using can communication obd generic scan tool, not only the...

Page 84

1a-40 engine general information and diagnosis: fail-safe table s6rw0c1104007 when any of the following dtcs is detected, ecm enters fail-safe mode as long as malfunction continues to exist but that mode is canceled when ecm detects normal condition after that. Dtc no. Detected item fail-safe operat...

Page 85

Engine general information and diagnosis: 1a-41 ) p0327 knock sensor 1 circuit low • ecm stops knock control. • ecm controls fuel cut at specified engine speed. ) p0328 knock sensor 1 circuit high ) p0335 crankshaft position (ckp) sensor “a” circuit • ecm controls ignition timing. • ecm controls fue...

Page 86

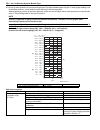

1a-42 engine general information and diagnosis: scan tool data s6rw0c1104008 as the data values are standard values estimated on the basis of values obtained from the normally operating vehicles by using a scan tool, use them as reference values. Even when the vehicle is in good condition, there may...

Page 87

Engine general information and diagnosis: 1a-43 * ) long ft b1 (long term fuel trim) at specified idle speed after warming up –20 – +20% ) total ft b1 (total fuel trim) at specified idle speed after warming up –35 – +35% * ) a/f b1 s1 current (a/f sensor output current) at specified idle speed after...

Page 88

1a-44 engine general information and diagnosis: scan tool data definitions coolant temp (engine coolant temperature, °c, °f) it is detected by engine coolant temp. Sensor. Intake air temp. ( °c, °f) it is detected by intake air temp. Sensor. Engine speed (rpm) it is computed by reference pulses from...

Page 89

Engine general information and diagnosis: 1a-45 maf (mass air flow rate, g/s, lb/min.) it represents total mass of air entering intake manifold which is measured by mass air flow sensor. Calc load (calculated load value, %) engine load displayed as a percentage of maximum possible load. Value is cal...

Page 90

1a-46 engine general information and diagnosis: starter sw (starter switch, on / off) this parameter indicates condition of starting motor relay output. On: starting motor relay is on off: starting motor relay is off a/c pressure (a/c refrigerant absolute pressure, kpa) this parameter indicates a/c ...

Page 91

Engine general information and diagnosis: 1a-47 visual inspection s6rw0c1104009 visually check the following parts and systems. Engine basic inspection s6rw0c1104010 this check is very important for troubleshooting when ecm has detected no dtc and no abnormality has been found in “visual inspection”...

Page 92

1a-48 engine general information and diagnosis: 5 is engine cranked? Go to step 6. Go to “cranking system symptom diagnosis in section 1i”. 6 does engine start? Go to step 7. Go to step 9. 7 check idle speed 1) check engine idle speed referring to “idle speed and iac throttle valve opening inspectio...

Page 93

Engine general information and diagnosis: 1a-49 engine symptom diagnosis s6rw0c1104011 perform troubleshooting referring to the followings when ecm has detected no dtc and no abnormality has been found in “visual inspection” and “engine basic inspection”. Condition possible cause correction / refere...

Page 94

1a-50 engine general information and diagnosis: engine noise – piston, ring and cylinder noise note before checking mechanical noise, make sure that: • specified spark plug is used. • specified fuel is used. Worn piston, ring and cylinder bore “pistons, piston rings, connecting rods and cylinders in...

Page 95

Engine general information and diagnosis: 1a-51 poor gasoline mileage faulty spark plug (improper gap, heavy deposits and burned electrodes, etc.) “spark plug inspection in section 1h” high idle speed condition “improper engine idling or engine fails to idle” poor performance of ect sensor or maf se...

Page 96

1a-52 engine general information and diagnosis: surge – engine power variation under steady throttle or cruise. Feels like vehicle speeds up and down with no change in accelerator pedal faulty spark plug (excess carbon deposits, improper gap, burned electrodes, etc.) “spark plug inspection in sectio...

Page 97

Engine general information and diagnosis: 1a-53 engine has no power faulty spark plug “spark plug inspection in section 1h” faulty ignition coil with ignitor “ignition coil assembly (including ignitor) inspection in section 1h” faulty knock sensor “dtc p0327 / p0328: knock sensor circuit low / high”...

Page 98

1a-54 engine general information and diagnosis: excessive hydrocarbon (hc) emission or carbon monoxide (co) faulty spark plug “spark plug inspection in section 1h” faulty ignition coil with ignitor “ignition coil assembly (including ignitor) inspection in section 1h” low compression “compression che...

Page 99

Engine general information and diagnosis: 1a-55 mil does not come on with ignition switch on and engine stop (but engine can be started) s6rw0c1104012 wiring diagram circuit description when the ignition switch is turned on, ecm causes the main relay to turn on (close the contact point). Then, ecm b...

Page 100

1a-56 engine general information and diagnosis: troubleshooting note when measuring circuit voltage, resistance and/or pulse signal at ecm connector, connect the special tool to ecm and/or the ecm connectors referring to “inspection of ecm and its circuits”. Step action yes no 1 mil power supply che...

Page 101

Engine general information and diagnosis: 1a-57 mil remains on after engine starts s6rw0c1104013 wiring diagram refer to “mil does not come on with ignition switch on and engine stop (but engine can be started)”. Circuit description when the ignition switch is turned on, ecm causes the main relay to...

Page 102

1a-58 engine general information and diagnosis: dtc p0030: ho2s heater control circuit (sensor-1, bank-1) s6rw0c1104014 wiring diagram a/f sensor description refer to “a/f sensor description”. Dtc detecting condition and trouble area dtc confirmation procedure 1) with ignition switch turned off, con...

Page 103

Engine general information and diagnosis: 1a-59 dtc troubleshooting dtc p0031 / p0032: ho2s heater control circuit low / high (sensor-1, bank-1) s6rw0c1104015 wiring diagram refer to “dtc p0030: ho2s heater control circuit (sensor-1, bank-1)”. A/f sensor description refer to “a/f sensor description”...

Page 104

1a-60 engine general information and diagnosis: dtc troubleshooting step action yes no 1 was “engine and emission control system check” performed? Go to step 2. Go to “engine and emission control system check”. 2 a/f sensor heater circuit check 1) disconnect connector from a/f sensor with ignition s...

Page 105

Engine general information and diagnosis: 1a-61 dtc p0037 / p0038: ho2s heater control circuit low / high (sensor-2, bank-1) s6rw0c1104016 wiring diagram refer to “dtc p0030: ho2s heater control circuit (sensor-1, bank-1)”. Dtc detecting condition and trouble area dtc confirmation procedure 1) with ...

Page 106

1a-62 engine general information and diagnosis: dtc p0101: mass or volume air flow circuit range / performance s6rw0c1104017 wiring diagram 4 ho2s heater circuit check 1) disconnect connectors from ecm and check for proper terminal connection to ecm connector. 2) if connections are ok, check that ho...

Page 107

Engine general information and diagnosis: 1a-63 dtc detecting condition and trouble area dtc confirmation procedure note check to make sure that the following conditions are satisfied when using this “dtc confirmation procedure”. • intake air temperature at engine start: –10 °c (14 °f) to 80 °c (176...

Page 108

1a-64 engine general information and diagnosis: dtc p0102 / p0103: mass or volume air flow circuit low / high input s6rw0c1104018 wiring diagram refer to “dtc p0101: mass or volume air flow circuit range / performance”. Dtc detecting condition and trouble area dtc confirmation procedure 1) with igni...

Page 109

Engine general information and diagnosis: 1a-65 3 maf sensor power supply voltage check 1) disconnect connector from maf sensor with ignition switch turned off. 2) check for proper terminal connection to maf sensor and ecm connectors. 3) if connections are ok, turn ignition switch to on position. 4)...

Page 110

1a-66 engine general information and diagnosis: dtc p0111: intake air temperature sensor 1 circuit range / performance s6rw0c1104019 wiring diagram refer to “dtc p0101: mass or volume air flow circuit range / performance”. Dtc detecting condition and trouble area dtc confirmation procedure note chec...

Page 111

Engine general information and diagnosis: 1a-67 dtc detecting condition and trouble area dtc confirmation procedure 1) with ignition switch off, connect scan tool. 2) turn on ignition switch and clear dtc by using scan tool. 3) start engine and run it for 10 sec. 4) check dtc. Dtc troubleshooting no...

Page 112

1a-68 engine general information and diagnosis: dtc p0116: engine coolant temperature circuit range / performance s6rw0c1104021 wiring diagram dtc detecting condition and trouble area dtc confirmation procedure warning ! • when performing a road test, select a place where there is no traffic or poss...

Page 113

Engine general information and diagnosis: 1a-69 dtc troubleshooting step action yes no 1 was “engine and emission control system check” performed? Go to step 2. Go to “engine and emission control system check”. 2 dtc check is there dtc(s) other than p0116? Go to applicable dtc diag.Flow. Go to step ...

Page 114

1a-70 engine general information and diagnosis: dtc p0117 / p0118: engine coolant temperature circuit low / high s6rw0c1104022 wiring diagram refer to “dtc p0116: engine coolant temperature circuit range / performance”. Dtc detecting condition and trouble area dtc confirmation procedure 1) with igni...

Page 115

Engine general information and diagnosis: 1a-71 dtc p0122 / p0123: throttle / pedal position sensor / switch “a” circuit low / high s6rw0c1104023 wiring diagram 4 ect sensor check 1) check ect sensor for performance referring to “engine coolant temperature (ect) sensor inspection in section 1c”. Is ...

Page 116

1a-72 engine general information and diagnosis: dtc detecting condition and trouble area dtc confirmation procedure 1) with ignition switch off, connect scan tool. 2) turn on ignition switch and clear dtc by using scan tool. 3) start engine and run it for 10 sec. 4) check dtc. Dtc troubleshooting no...

Page 117

Engine general information and diagnosis: 1a-73 3 wire harness check 1) turn ignition switch off position. 2) disconnect connectors from tp sensor and ecm. 3) check for proper terminal connection to electric throttle body assembly and ecm connectors. 4) if connections are ok, check that tp sensor (m...

Page 118

1a-74 engine general information and diagnosis: dtc p0131 / p0132: o2 sensor circuit low voltage / high voltage (sensor-1, bank-1) s6rw0c1104026 wiring diagram refer to “dtc p0030: ho2s heater control circuit (sensor-1, bank-1)”. Dtc detecting condition and trouble area dtc confirmation procedure no...

Page 119

Engine general information and diagnosis: 1a-75 dtc p0133: o2 sensor circuit slow response / performance (sensor-1, bank-1) s6rw0c1104027 wiring diagram refer to “dtc p0030: ho2s heater control circuit (sensor-1, bank-1)”. A/f sensor description refer to “a/f sensor description”. Dtc detecting condi...

Page 120

1a-76 engine general information and diagnosis: dtc confirmation procedure warning ! • when performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident. • road test should be carried out b...

Page 121

Engine general information and diagnosis: 1a-77 dtc p0134: o2 sensor circuit no activity detected (sensor-1, bank-1) s6rw0c1104028 wiring diagram refer to “dtc p0030: ho2s heater control circuit (sensor-1, bank-1)”. A/f sensor description refer to “a/f sensor description”. Dtc detecting condition an...

Page 122

1a-78 engine general information and diagnosis: dtc p0137 / p0138: o2 sensor (ho2s) circuit low voltage / high voltage (sensor-2, bank-1) s6rw0c1104030 wiring diagram refer to “dtc p0030: ho2s heater control circuit (sensor-1, bank-1)”. Dtc detecting condition and trouble area dtc confirmation proce...

Page 123

Engine general information and diagnosis: 1a-79 6) repeat step 4). 7) keep above vehicle speed for 8 min. Or more. (throttle valve opening is kept constant in this step.) 8) repeat step 5). 9) check dtc and pending dtc. Dtc troubleshooting step action yes no 1 was “engine and emission control system...

Page 124

1a-80 engine general information and diagnosis: dtc p0140: o2 sensor (ho2s) circuit no activity detected (sensor-2, bank-1) s6rw0c1104032 wiring diagram refer to “dtc p0030: ho2s heater control circuit (sensor-1, bank-1)”. Dtc detecting condition and trouble area dtc confirmation procedure note chec...

Page 125

Engine general information and diagnosis: 1a-81 dtc p0171 / p0172: system too lean / too rich (sensor-1, bank-1) s6rw0c1104033 wiring diagram refer to “dtc p0030: ho2s heater control circuit (sensor-1, bank-1)”. A/f sensor description refer to “a/f sensor description”. Dtc detecting condition and tr...

Page 126

1a-82 engine general information and diagnosis: dtc troubleshooting step action yes no 1 was “engine and emission control system check” performed? Go to step 2. Go to “engine and emission control system check”. 2 is there dtc(s) other than fuel system (dtc p0171 / p0172 / 2195 / 2196)? Go to applica...

Page 127

Engine general information and diagnosis: 1a-83 dtc p0222 / p0223: throttle position sensor (sub) circuit low / high s6rw0c1104034 wiring diagram refer to “dtc p0122 / p0123: throttle / pedal position sensor / switch “a” circuit low / high”. Dtc detecting condition and trouble area dtc confirmation ...

Page 128

1a-84 engine general information and diagnosis: 3 wire harness check 1) turn ignition switch off position. 2) disconnect connectors from tp sensor and ecm. 3) check for proper terminal connection to electric throttle body assembly and ecm connectors. 4) if connections are ok, check that tp sensor (s...

Page 129

Engine general information and diagnosis: 1a-85 dtc p0300 / p0301 / p0302 / p0303 / p0304: random misfire detected / cylinder 1 / cylinder 2 / cylinder 3 / cylinder 4 misfire detected s6rw0c1104035 system description ecm measure the angle of the crankshaft based on the pulse signal from the ckp sens...

Page 130

1a-86 engine general information and diagnosis: dtc troubleshooting step action yes no 1 was “engine and emission control system check” performed? Go to step 2. Go to “engine and emission control system check”. 2 does fuel level meter indicate “e” level (empty)? Add fuel and recheck. Go to step 3. 3...

Page 131

Engine general information and diagnosis: 1a-87 dtc p0327 / p0328: knock sensor circuit low / high s6rw0c1104036 wiring diagram dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool to dlc with ignition switch turned off. 2) turn on ignition switch and clear dtc pe...

Page 132

1a-88 engine general information and diagnosis: dtc p0335: crankshaft position sensor “a” circuit s6rw0c1104037 wiring diagram dtc detecting condition and trouble area 3 wire harness check 1) disconnect connector from ecm with ignition switch turned off. 2) check that knock sensor signal circuit is ...

Page 133

Engine general information and diagnosis: 1a-89 dtc confirmation procedure note check to make sure that the following conditions are satisfied when using this “dtc confirmation procedure”. • the following dtcs are not detected: dtcs related to starter relay 1) with ignition switch off, connect scan ...

Page 134

1a-90 engine general information and diagnosis: dtc p0340: camshaft position sensor “a” circuit s6rw0c1104038 wiring diagram system description the cmp sensor located on the cylinder head cover consists of the signal generator (magnetic sensor) and signal rotor (intake camshaft portion). The signal ...

Page 135

Engine general information and diagnosis: 1a-91 dtc confirmation procedure note check to make sure that the following conditions are satisfied when using this “dtc confirmation procedure”. • the following dtcs are not detected: dtcs related to ckp sensor 1) with ignition switch off, connect scan too...

Page 136

1a-92 engine general information and diagnosis: dtc p0420: catalyst system efficiency below threshold (bank-1) s6rw0c1104039 system and wiring diagram system description ecm monitors oxygen concentration in the exhaust gas which has passed the warm up three way catalytic converter by ho2s. When the ...

Page 137

Engine general information and diagnosis: 1a-93 dtc confirmation procedure warning ! • when performing a road test, select a place where there is no traffic or possibility of a traffic accident and very careful during testing to avoid occurrence of an accident. • road test should be carried out with...

Page 138

1a-94 engine general information and diagnosis: dtc p0443: evap emission system purge control valve circuit s6rw0c1104041 wiring diagram dtc detecting condition and trouble area dtc confirmation procedure warning ! • when performing a road test, select a place where there is no traffic or possibilit...

Page 139

Engine general information and diagnosis: 1a-95 dtc troubleshooting step action yes no 1 was “engine and emission control system check” performed? Go to step 2. Go to “engine and emission control system check”. 2 evap canister purge valve power supply voltage check 1) disconnect connector from evap ...

Page 140

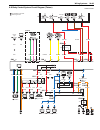

1a-96 engine general information and diagnosis: dtc p0462 / p0463: fuel level sensor circuit low / high s6rw0c1104045 wiring diagram dtc detecting condition and trouble area e01 c01 3 4 18 19 5 6 7 10 11 17 20 47 46 49 50 51 21 22 52 16 25 9 24 14 29 55 57 54 53 59 60 58 2 26 27 28 15 30 56 48 32 31...

Page 141

Engine general information and diagnosis: 1a-97 dtc confirmation procedure 1) with ignition switch off, connect scan tool. 2) turn on ignition switch and clear dtc by using scan tool. 3) start engine and run it for 10 sec. 4) check dtc and pending dtc. Dtc troubleshooting step action yes no 1 was “e...

Page 142

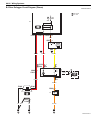

1a-98 engine general information and diagnosis: dtc p0480: fan 1 control circuit s6rw0c1104046 wiring diagram dtc detecting condition and trouble area dtc confirmation procedure 1) with ignition switch turned off, connect scan tool. 2) turn on ignition switch and clear dtc by using scan tool. 3) sta...

Page 143

Engine general information and diagnosis: 1a-99 dtc troubleshooting step action yes no 1 was “engine and emission control system check” performed? Go to step 2. Go to “engine and emission control system check”. 2 wire harness check 1) turn ignition switch to off position. 2) check for proper termina...

Page 144

1a-100 engine general information and diagnosis: 5 radiator cooling fan control circuit voltage check 1) turn ignition switch to off position. 2) remove radiator cooling fan relay no.1 (1), no.2 (2) or no.3 (3). 3) turn ignition switch on position. 4) check that radiator cooling fan relay (no.1, no....

Page 145

Engine general information and diagnosis: 1a-101 dtc p0481: fan 2 control circuit s6rw0c1104048 wiring diagram dtc detecting condition and trouble area dtc confirmation procedure 1) with ignition switch turned off, connect scan tool. 2) turn on ignition switch and clear dtc by using scan tool. 3) st...

Page 146

1a-102 engine general information and diagnosis: dtc troubleshooting step action yes no 1 was “engine and emission control system check” performed? Go to step 2. Go to “engine and emission control system check”. 2 wire harness check 1) turn ignition switch to off position. 2) check for proper termin...

Page 147

Engine general information and diagnosis: 1a-103 dtc p0500: vehicle speed sensor “a” s6rw0c1104050 wiring diagram dtc detecting condition and trouble area dtc confirmation procedure warning ! • when performing a road test, select a place where there is no traffic or possibility of a traffic accident...

Page 148

1a-104 engine general information and diagnosis: dtc troubleshooting note make sure that dtc of can communication is not detected by ecm. Dtc p0504: brake switch “a”/“b” correlation s6rw0c1104051 wiring diagram step action yes no 1 was “engine and emission control system check” performed? Go to step...

Page 149

Engine general information and diagnosis: 1a-105 dtc detecting condition and trouble area dtc confirmation procedure warning ! • when performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an acc...

Page 150

1a-106 engine general information and diagnosis: dtc p0532 / p0533: a/c refrigerant pressure sensor circuit low / high s6rw0c1104053 wiring diagram 4 brake switch signal circuit check 1) disconnect connectors from ecm with ignition switch turned off. 2) check for proper connection of each switch cir...

Page 151

Engine general information and diagnosis: 1a-107 dtc detecting condition and trouble area dtc confirmation procedure 1) with ignition switch turned off, connect scan tool. 2) turn on ignition switch and clear dtc by using scan tool. 3) check dtc. Dtc troubleshooting dtc p0601 / p0602 / p0607: intern...

Page 152

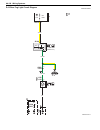

1a-108 engine general information and diagnosis: dtc troubleshooting dtc p0616 / p0617: starter relay circuit low / high s6rw0c1104055 wiring diagram circuit description engine start signal is sent from engine starter circuit while engine cranking. Step action yes no 1 dtc recheck 1) clear dtc refer...

Page 153

Engine general information and diagnosis: 1a-109 dtc detecting condition and trouble area dtc confirmation procedure 1) with ignition switch off, connect scan tool. 2) turn on ignition switch and clear dtc by using scan tool. 3) start engine and run it for 1 minute. 4) check dtc and pending dtc. Dtc...

Page 154

1a-110 engine general information and diagnosis: dtc p0660 / p0662: intake manifold tuning valve control circuit open / high s6rw0c1104057 wiring diagram dtc detecting condition and trouble area dtc confirmation procedure note check to make sure that the following conditions are satisfied when using...

Page 155

Engine general information and diagnosis: 1a-111 dtc troubleshooting dtc p1510: ecm back-up power supply malfunction s6rw0c1104063 wiring diagram step action yes no 1 was “engine and emission control system check” performed? Go to step 2. Go to “engine and emission control system check”. 2 imt valve...

Page 156

1a-112 engine general information and diagnosis: circuit description battery voltage is supplied so that dtc memory, values for engine control learned by ecm, etc. Are kept in ecm even when the ignition switch is turned off. Dtc detecting condition and trouble area dtc confirmation procedure 1) with...

Page 157

Engine general information and diagnosis: 1a-113 dtc troubleshooting dtc p2102: throttle actuator control motor circuit low s6rw0c1104066 wiring diagram refer to “dtc p0122 / p0123: throttle / pedal position sensor / switch “a” circuit low / high”. Dtc detecting condition and trouble area dtc confir...

Page 158

1a-114 engine general information and diagnosis: dtc troubleshooting step action yes no 1 was “engine and emission control system check” performed? Go to step 2. Go to “engine and emission control system check”. 2 throttle actuator control relay circuit check 1) remove throttle actuator control rela...

Page 159

Engine general information and diagnosis: 1a-115 dtc p2103: throttle actuator control motor circuit high s6rw0c1104067 wiring diagram refer to “dtc p0122 / p0123: throttle / pedal position sensor / switch “a” circuit low / high”. Dtc detecting condition and trouble area dtc confirmation procedure 1)...

Page 160

1a-116 engine general information and diagnosis: dtc troubleshooting dtc p2119: throttle actuator control throttle body range / performance s6rw0c1104069 wiring diagram refer to “dtc p0122 / p0123: throttle / pedal position sensor / switch “a” circuit low / high”. Dtc detecting condition and trouble...

Page 161

Engine general information and diagnosis: 1a-117 dtc p2122 / p2123: throttle / pedal position sensor / switch “d” circuit low / high s6rw0c1104070 wiring diagram 3 wire harness check 1) disconnect connectors from electric throttle body assembly and ecm with ignition switch turned off. 2) check for p...

Page 162

1a-118 engine general information and diagnosis: dtc detecting condition and trouble area dtc confirmation procedure 1) with ignition switch turned off, connect scan tool. 2) turn on ignition switch and clear dtc by using scan tool. 3) keep the accelerator pedal at idle position for 2 sec. 4) keep t...

Page 163

Engine general information and diagnosis: 1a-119 dtc p2127 / p2128: throttle / pedal position sensor / switch “e” circuit low / high input s6rw0c1104071 wiring diagram refer to “dtc p2122 / p2123: throttle / pedal position sensor / switch “d” circuit low / high”. Dtc detecting condition and trouble ...

Page 164

1a-120 engine general information and diagnosis: dtc confirmation procedure 1) with ignition switch turned off, connect scan tool. 2) turn on ignition switch and clear dtc by using scan tool. 3) keep the accelerator pedal at idle position for 2 sec. 4) keep the accelerator pedal at fully depressed p...

Page 165

Engine general information and diagnosis: 1a-121 dtc p2135: throttle / pedal position sensor / switch “a” / “b” voltage correction s6rw0c1104072 wiring diagram refer to “dtc p0122 / p0123: throttle / pedal position sensor / switch “a” circuit low / high”. Dtc detecting condition and trouble area dtc...

Page 166

1a-122 engine general information and diagnosis: dtc p2138: pedal position sensor (main / sub) voltage correction s6rw0c1104073 wiring diagram refer to “dtc p0122 / p0123: throttle / pedal position sensor / switch “a” circuit low / high”. Dtc detecting condition and trouble area dtc confirmation pro...

Page 167

Engine general information and diagnosis: 1a-123 dtc p2195 / p2196: o2 sensor signal stuck lean / stuck rich (sensor-1, bank-1) s6rw0c1104074 wiring diagram refer to “dtc p0030: ho2s heater control circuit (sensor-1, bank-1)”. A/f sensor description refer to “a/f sensor description”. Dtc detecting c...

Page 168

1a-124 engine general information and diagnosis: dtc troubleshooting dtc p2227 / p2228 / p2229: barometric pressure circuit performance / low / high s6rw0c1104077 system description barometric pressure sensor is installed in ecm. Dtc detecting condition and trouble area dtc confirmation procedure dt...

Page 169

Engine general information and diagnosis: 1a-125 dtc u0073: control module communication bus off s6rw0c1104081 refer to “troubleshooting for can-dtc”. Dtc u0101: lost communication with tcm s6rw0c1104082 refer to “troubleshooting for can-dtc”. Dtc u0121: lost communication with abs / esp ® control m...

Page 170

1a-126 engine general information and diagnosis: troubleshooting step action yes no 1 dtc check 1) turn ignition switch to off position. 2) connect scan tool to dlc. 3) check dtc in the following control modules. • ecm • tcm • bcm • keyless start control module • 4wd control module is there any dtc ...

Page 171

Engine general information and diagnosis: 1a-127 3 can line check 1) turn ignition switch to off position. 2) disconnect connectors of all control module communicated by can. 3) check all the following can lines for open, short to power circuit, short to ground circuit, short to other can line and h...

Page 172

1a-128 engine general information and diagnosis: 6 terminating resistance check in ecm and combination meter 1) turn ignition switch to off position and then disconnect negative (–) cable at battery. 2) measure resistance between can high terminal (2) and can low terminal (3) on dlc (1). If resistan...

Page 173

Engine general information and diagnosis: 1a-129 12 can communication check of tcm 1) turn ignition switch to off position. 2) connect tcm connectors. 3) perform “communication bus check” under “bus check” using suzuki-sdt with ignition switch turned on. Are all of bcm, ecm, abs control module, comb...

Page 174

1a-130 engine general information and diagnosis: inspection of ecm and its circuits s6rw0c1104086 ecm and its circuits can be checked by measuring voltage, pulse signal and resistance with special tool connected. Caution ! Ecm cannot be checked by itself. It is strictly prohibited to connect voltmet...

Page 175

Engine general information and diagnosis: 1a-131 terminal no. Wire color circuit normal voltage condition remarks c01-1 blu/ yel fuel injector no.1 10 – 14 v ig switch: on — *0 – 0.6 v ↑↓ 10 – 14 v (“reference waveform no.1: ”, “reference waveform no.2: ” and “reference waveform no.24: ”) engine: id...

Page 176

1a-132 engine general information and diagnosis: c01-15 blk ground for ecm below 0.3 v ig switch: on — c01-16 blu/ red fuel injector no.3 10 – 14 v ig switch: on — *0 – 0.6 v ↑↓ 10 – 14 v (“reference waveform no.1: ” and “reference waveform no.7: ”) engine: idle speed after warming up output signal ...

Page 177

Engine general information and diagnosis: 1a-133 c01-24 lt grn ect sensor signal 3.3 – 3.8 v ig switch: on ect: 0 °c (32 °f) — 1.38 – 1.72 v ig switch: on ect: 50 °c (122 °f) 0.40 – 0.53 v ig switch: on ect: 100 °c (212 °f) c01-25 lt grn/ blk iat sensor signal 3.18 – 3.67 v ig switch: on iat: 0 °c (...

Page 178

1a-134 engine general information and diagnosis: c01-40 wht tp sensor (sub) signal 1.33 – 1.63 v ig switch: on engine: after warmed up accelerator pedal: released — 3.67 – 4.67 v ig switch: on engine: after warmed up accelerator pedal: depressed fully c01-41 blk ground for tp sensor below 0.3 v ig s...

Page 179

Engine general information and diagnosis: 1a-135 c01-49 wht can (low) communication line (active low signal) to tcm 1.5 – 2.5 v (“reference waveform no.25: ”) engine: stop ig switch: on can communication signal is serial communication signal pulse. Pulse signal displayed with a regular frequency var...

Page 180

1a-136 engine general information and diagnosis: terminal no. Wire color circuit normal voltage condition remarks e01-1 blk/ red main power supply 10 – 14 v ig switch: on — e01-2 wht/ red power source for ecm internal memory 10 – 14 v ig switch: on — e01-3 — — — — — e01-4 red can (high) communicatio...

Page 181

Engine general information and diagnosis: 1a-137 e01-22 lt grn cruise control command switch signal 4 – 6 v ig switch: on — e01-23 — — — — — e01-24 yel/ red fuel level sensor signal 0 – 6 v ig switch: on voltage varies depends on fuel level e01-25 — — — — — e01-26 — — — — — e01-27 red/ blu eps activ...

Page 182

1a-138 engine general information and diagnosis: e01-44 brn engine speed signal output for p/ s control module *0 – 1 v ↑ ↓ 8 – 14 v (“reference waveform no.26: ” and “reference waveform no.27: ”) while engine running. Output signal is pulse. Pulse frequency varies depending on engine speed. (2 puls...

Page 183

Engine general information and diagnosis: 1a-139 reference waveform no.1 fuel injector signal (1) with engine idling reference waveform no.2 no.1 fuel injector signal (2) with engine idling e01-52 yel app sensor (sub) signal 0.17 – 0.58 v ig switch: on engine: after warmed up accelerator pedal: rele...

Page 184

1a-140 engine general information and diagnosis: reference waveform no.3 no.2 fuel injector signal (2) with engine idling reference waveform no.4 ho2s signal (1) with engine idling reference waveform no.5 ho2s signal (1) with engine racing reference waveform no.6 evap canister purge valve signal mea...

Page 185

Engine general information and diagnosis: 1a-141 reference waveform no.7 no.3 fuel injector signal (2) with engine idling reference waveform no.8 no.4 fuel injector signal (2) with engine idling reference waveform no.9 ignition coil signal (1) with engine idling reference waveform no.10 ignition coi...

Page 186

1a-142 engine general information and diagnosis: reference waveform no.11 ignition coil no.3 signal (2) with engine idling reference waveform no.12 ignition coil no.2 signal (1) with engine idling reference waveform no.13 ignition coil no.1 signal (1) with engine idling reference waveform no.14 maf ...

Page 187

Engine general information and diagnosis: 1a-143 reference waveform no.15 a/f sensor signal with engine idling reference waveform no.16 imt valve actuator signal with engine racing reference waveform no.17 cmp sensor signal with engine idling reference waveform no.18 cmp sensor signal with engine id...

Page 188

1a-144 engine general information and diagnosis: reference waveform no.19 throttle actuator output signal with ignition switch turned on reference waveform no.20 throttle actuator output signal with ignition switch turned on reference waveform no.21 knock sensor signal at engine speed 4000 r/min. Me...

Page 189

Engine general information and diagnosis: 1a-145 reference waveform no.22 knock sensor signal at engine speed 4000 r/min. Reference waveform no.23 can communication line signal from abs / esp ® control module with ignition switch turned on reference waveform no.24 ignition coil signal and fuel injec...

Page 190

1a-146 engine general information and diagnosis: reference waveform no.26 ignition pulse (engine revolution) signal (2) with engine idling reference waveform no.27 ignition pulse (engine revolution) signal (2) with engine idling measurement terminal ch1: “c01-52” to “c01-58” ch2: “e01-44” to “c01-58...

Page 191

Engine general information and diagnosis: 1a-147 resistance check 1) remove ecm from its bracket referring to “engine control module (ecm) removal and installation in section 1c”. Caution ! Never touch terminals of ecm itself or connect voltmeter or ohmmeter (2). 2) connect special tool to ecm conne...

Page 192

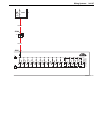

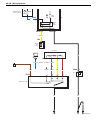

1a-148 engine general information and diagnosis: ecm power and ground circuit check s6rw0c1104087 wiring diagram e01 c01 3 4 18 19 5 6 7 10 11 17 20 47 46 49 50 51 21 22 52 16 25 9 24 14 29 55 57 54 53 59 60 58 2 26 27 28 15 30 56 48 32 31 34 35 36 37 40 42 39 38 44 45 43 41 33 1 12 13 23 8 3 4 18 1...

Page 193

Engine general information and diagnosis: 1a-149 circuit description when the ignition switch is turned on, the main relay turns on (the contact point closes) and the main power is supplied to ecm. And then ecm supplies 5 v power to each sensor (a/c refrigerant pressure sensor, app sensor and tp sen...

Page 194

1a-150 engine general information and diagnosis: 5 main relay circuit check 1) connect connectors to ecm with ignition switch turned off. 2) turn ignition switch to on position. 3) measure voltage between “e01-60” terminal of ecm connector and body ground. Is voltage 0 – 1 v? Go to step 7. Go to ste...

Page 195

Engine general information and diagnosis: 1a-151 fuel injector circuit check s6rw0c1104088 wiring diagram 10 main relay check 1) check main relay referring to “engine and emission control system relay inspection in section 1c”. Is main relay in good condition? “brn/wht” wire is open or high resistan...

Page 196

1a-152 engine general information and diagnosis: troubleshooting note • before performed troubleshooting, be sure to read the “precautions of ecm circuit inspection”. • when measuring circuit voltage, resistance and/or pulse signal at ecm connector, connect the special tool to ecm and/or the ecm con...

Page 197

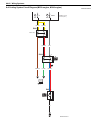

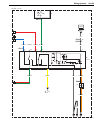

Engine general information and diagnosis: 1a-153 fuel pump and its circuit check s6rw0c1104089 wiring diagram e01-1 e01-60 e01-15 brn/wht blk/yel blk/yel e01-29 blk/wht grn/wht blk/wht blk/wht pnk blk wht grn 7 6 4 3 2 5 e01 c01 3 4 18 19 5 6 7 10 11 17 20 47 46 49 50 51 21 22 52 16 25 9 24 14 29 55...

Page 198

1a-154 engine general information and diagnosis: troubleshooting note • before performed troubleshooting, be sure to read the “precautions of ecm circuit inspection”. • when measuring circuit voltage, resistance and/or pulse signal at ecm connector, connect the special tool to ecm and/or the ecm con...

Page 199

Engine general information and diagnosis: 1a-155 6 fuel pump relay drive signal check 1) measure voltage within 2 sec. After ignition switch is turned on. Is voltage 0 – 1 v? Go to step 7. Substitute a known- good ecm and recheck. 7 wire circuit check 1) turn off ignition switch. 2) detach fuel tank...

Page 200

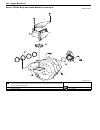

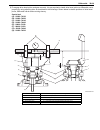

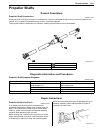

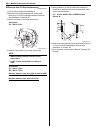

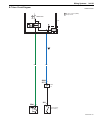

1a-156 engine general information and diagnosis: fuel pressure check s6rw0c1104090 system diagram special tool (a): 09912–58442 (b): 09912–58432 (c): 09912–58490 i7rw01110038-01 1. Injector 2. Delivery pipe 3. Fuel pump 4. Fuel filter 5. Fuel pressure regulator.

Page 201

Engine general information and diagnosis: 1a-157 troubleshooting note before using the following flow chart, chart check to make sure that battery voltage is higher than 11 v. If battery voltage is low, pressure becomes lower than specification even if fuel pump and line are in good condition. Step ...

Page 202

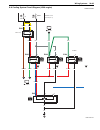

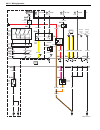

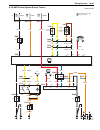

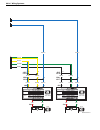

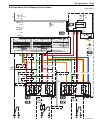

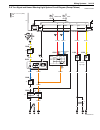

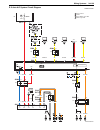

1a-158 engine general information and diagnosis: a/c condenser cooling fan control system inspection s6rw0c1104091 wiring diagram troubleshooting e01 c01 3 4 18 19 5 6 7 10 11 17 20 47 46 49 50 51 21 22 52 16 25 9 24 14 29 55 57 54 53 59 60 58 2 26 27 28 15 30 56 48 32 31 34 35 36 37 40 42 39 38 44 ...

Page 203

Engine general information and diagnosis: 1a-159 4 check wire circuit 1) disconnect a/c condenser cooling fan relay from fuse box no.2 with ignition switch turned off. 2) turn on ignition switch, measure voltage between engine ground and “blu/yel” wire terminal of a/c condenser cooling fan relay con...

Page 204

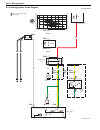

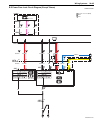

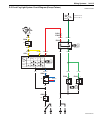

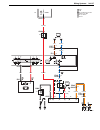

1a-160 engine general information and diagnosis: a/c system circuits check s6rw0c1104092 wiring diagram blk/wht blk/red wht blu brn/wht 12v 5v 14 17 10 8 e01-29 e01-1 e01-60 c01-15 c01-29 c01-48 c01-58 c01-30 blk/yel blk/yel blk blk blk blk/orn blk/orn red blk 11 wht 9 3 4 blk/red red/blk blk/red bl...

Page 205

Engine general information and diagnosis: 1a-161 troubleshooting note • before performed troubleshooting, be sure to read the “precautions of ecm circuit inspection”. • when measuring circuit voltage, resistance and/or pulse signal at ecm connector, connect the special tool to ecm and/or the ecm con...

Page 206

1a-162 engine general information and diagnosis: 9 a/c evaporator temperature sensor check 1) check a/c evaporator temperature sensor referring to “evaporator temperature sensor inspection in section 7b”. Is resistance within specification? Go to step 10. Faulty a/c evaporator temperature sensor. 10...

Page 207

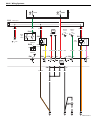

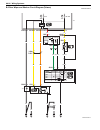

Engine general information and diagnosis: 1a-163 electric load signal circuit check s6rw0c1104093 wiring diagram e01 c01 3 4 18 19 5 6 7 10 11 17 20 47 46 49 50 51 21 22 52 16 25 9 24 14 29 55 57 54 53 59 60 58 2 26 27 28 15 30 56 48 32 31 34 35 36 37 40 42 39 38 44 45 43 41 33 1 12 13 23 8 3 4 18 1...

Page 208

1a-164 engine general information and diagnosis: troubleshooting note • before performed troubleshooting, be sure to read the “precautions of ecm circuit inspection”. • when measuring circuit voltage, resistance and/or pulse signal at ecm connector, connect the special tool to ecm and/or the ecm con...

Page 209

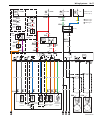

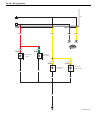

Engine general information and diagnosis: 1a-165 radiator cooling fan low speed control system check s6rw0c1104094 wiring diagram e01 c01 3 4 18 19 5 6 7 10 11 17 20 47 46 49 50 51 21 22 52 16 25 9 24 14 29 55 57 54 53 59 60 58 2 26 27 28 15 30 56 48 32 31 34 35 36 37 40 42 39 38 44 45 43 41 33 1 12...

Page 210

1a-166 engine general information and diagnosis: troubleshooting warning ! Keep hands, tools, and clothing away from radiator cooling fan to help prevent personal injury. This fan is electric and can come on whether or not the engine is running. The fan can start automatically in response to the ect...

Page 211

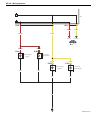

Engine general information and diagnosis: 1a-167 radiator cooling fan high speed control system check s6rw0c1104095 wiring diagram refer to “radiator cooling fan low speed control system check”. Troubleshooting warning ! Keep hands, tools, and clothing away from radiator cooling fan to help prevent ...

Page 212

1a-168 engine general information and diagnosis: repair instructions idle speed and iac throttle valve opening inspection s6rw0c1106001 before idle speed check, make sure of the following. • lead wires and hoses of electronic fuel injection and engine and emission control systems are connected secur...

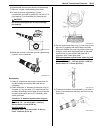

Page 213

Engine general information and diagnosis: 1a-169 special tools and equipment special tool s6rw0c1108001 09912–58432 09912–58442 fuel pressure gauge hose fuel pressure gauge this tool is included in fuel pressure gauge set (09912- 58413). ) this tool is included in fuel pressure gauge set (09912- 584...

Page 214

1b-1 aux. Emission control devices: engine aux. Emission control devices diagnostic information and procedures evap canister purge system inspection s6rw0c1204003 1) warm up engine to normal operating temperature. 2) hoist vehicle so that all wheels rotate freely. 3) set m/t in “neutral” or a/t in “...

Page 215

Aux. Emission control devices: 1b-2 repair instructions evap system components s6rw0c1206001 evap canister purge inspection s6rw0c1206002 note before inspection, check to make sure that gear shift lever is in neutral position (with a/t model, selector lever in “p” range) and that parking brake lever...

Page 216

1b-3 aux. Emission control devices: evap canister purge valve and its circuit inspection s6rw0c1206003 warning ! Do not apply vacuum by mouth; otherwise harmful fuel vapor can be breathed in. Caution ! Do not apply vacuum more than –86 kpa (– 12.47 psi); otherwise evap canister purge valve could be ...

Page 217

Aux. Emission control devices: 1b-4 vacuum passage inspection s6rw0c1206004 start engine and run it at idle speed. Disconnect purge hose no.3 (1) from evap canister purge valve (2). With finger placed against disconnected hose, check that vacuum is applied. If it is not applied, clean vacuum passage...

Page 218

1b-5 aux. Emission control devices: evap canister removal and installation s6rw0c1206010 removal 1) disconnect negative cable at battery. 2) hoist vehicle. 3) remove evap canister as follows. A) disconnect hoses (1) from evap canister (2). B) remove evap canister bracket (3) with evap canister from ...

Page 219

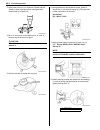

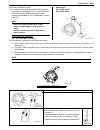

Aux. Emission control devices: 1b-6 pcv valve inspection s6rw0c1206016 1) remove pcv valve referring to “pcv valve removal and installation”. 2) connect pcv valve to hose and install plug to cylinder head cover hole. 3) run engine at idle. 4) place your finger over end of pcv valve (1) to check for ...

Page 220: Engine Electrical Devices

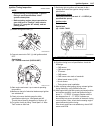

1c-1 engine electrical devices: engine engine electrical devices repair instructions engine control module (ecm) removal and installation s6rw0c1306001 caution ! As ecm consists of precision parts, be careful not to expose it to excessive shock. Note for vehicle equipped with immobilizer control sys...

Page 221

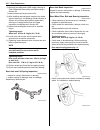

Engine electrical devices: 1c-2 electric throttle body assembly on-vehicle inspection s6rw0c1306004 warning ! Never touch throttle valve with finger while ignition switch is turned on and accelerator pedal is depressed. Otherwise, injury may result by pinching the finger between throttle valve and t...

Page 222

1c-3 engine electrical devices: electric throttle body assembly operation check 1) remove air cleaner outlet hose. 2) turn on ignition switch. 3) depress accelerator pedal gradually and check that throttle valve moves smoothly until it opens fully. 4) release accelerator pedal depressed in step 3) a...

Page 223

Engine electrical devices: 1c-4 tp sensor (sub) [b]: 1.33 – 5.007 v, varying according to throttle valve opening by finger (voltage should vary by about 0.032 v for each 1 ° valve opening) electric throttle body system calibration s6rw0c1306005 note if the service described under the “precautions of...

Page 224

1c-5 engine electrical devices: accelerator pedal position (app) sensor assembly removal and installation s6rw0c1306007 caution ! • do not expose app sensor assembly to excessive shock like a dropping it. If app sensor assembly has been exposed to excessive shock, it should be replaced. • be careful...

Page 225

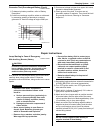

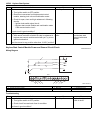

Engine electrical devices: 1c-6 3) measure output voltage variation while accelerator pedal is released and fully depressed as the following graph. If sensor voltage is out of specified value or does not vary linearly as the following graph, replace app sensor assembly. Engine coolant temperature (e...

Page 226

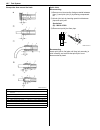

1c-7 engine electrical devices: air fuel ratio (a/f) sensor on-vehicle inspection s6rw0c1306011 heater 1) disconnect a/f sensor connector. 2) using ohmmeter, measure resistance of sensor heater between terminals “v b ” and “gnd” at sensor connector. If found faulty, replace a/f sensor. Note temperat...

Page 227

Engine electrical devices: 1c-8 camshaft position (cmp) sensor removal and installation s6rw0c1306014 removal 1) disconnect negative cable at battery. 2) remove air cleaner case referring to “air cleaner assembly removal and installation in section 1d”. 3) disconnect connector from cmp sensor. 4) re...

Page 228

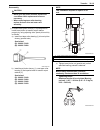

1c-9 engine electrical devices: installation reverse removal procedure noting the following. • apply engine oil to o-ring of sensor. • tighten ckp sensor bolt to specified torque. Tightening torque ckp sensor bolt (a): 11 n·m (1.1 kgf-m, 8.0 lb-ft) • connect connector and fix wire harness with clamp...

Page 229

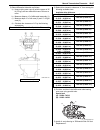

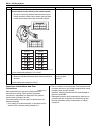

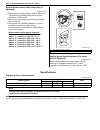

Engine electrical devices: 1c-10 engine and emission control system relay inspection s6rw0c1306019 main, fuel pump, starting motor control, throttle actuator control and radiator cooling fan relays 1) disconnect negative cable at battery. 2) remove main relay (1), fuel pump relay (3), starting motor...

Page 230

1c-11 engine electrical devices: mass air flow (maf) and intake air temperature (iat) sensor removal and installation s6rw0c1306021 caution ! • do not disassemble maf and iat sensor. • do not expose maf and iat sensor to any shock. • do not clean maf and iat sensor. • if maf and iat sensor has been ...

Page 231

Engine electrical devices: 1c-12 imt valve actuator inspection s6rw0c1306023 caution ! Be sure not to apply battery voltage to imt valve actuator for 10 seconds or more. 1) connect battery positive (+) and negative (–) terminals to imt valve actuator (1) as shown in table below. If it does not opera...

Page 232: Engine Mechanical

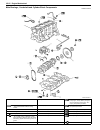

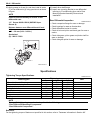

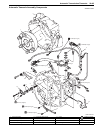

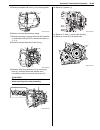

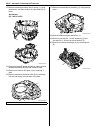

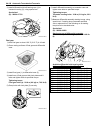

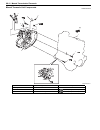

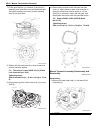

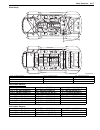

1d-1 engine mechanical: engine engine mechanical general description engine construction s6rw0c1401001 the engine is water-cooled, in line 4 cylinders, 4 stroke cycle gasoline unit with its dohc (double over head camshaft) valve mechanism arranged for “v” type valve configuration consisting of 16 va...

Page 233

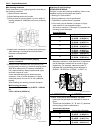

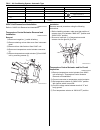

Engine mechanical: 1d-2 imt (intake manifold tuning) system s6rw0c1401002 imt (intake manifold tuning) system varies effective length of intake pipe by opening and closing imt valve in order to improve air volumetric efficiency. As intake valve in cylinder head is opened and closed repeatedly, intak...

Page 234

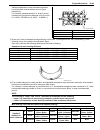

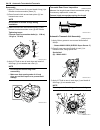

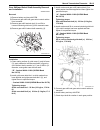

1d-3 engine mechanical: diagnostic information and procedures compression check s6rw0c1404001 check compression pressure on all 4 cylinders as follows: 1) warm up engine. 2) stop engine after warming up. Note after warming up engine, place transmission gear shift lever in “neutral” (shift selector l...

Page 235

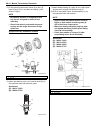

Engine mechanical: 1d-4 engine vacuum check s6rw0c1404002 the engine vacuum that develops in the intake line is a good indicator of the condition of the engine. The vacuum checking procedure is as follows: 1) warm up engine to normal operating temperature. Note after warming up engine, be sure to pl...

Page 236

1d-5 engine mechanical: 5) check valve lashes with thickness gauge (1) according to the following procedure. A) check valve lashes of cylinder no.1. B) turn crankshaft pulley by 180 ° clockwise. C) check valve lashes of cylinder no.3. D) in the same manner as b) – c), check valve lashes of cylinder ...

Page 237

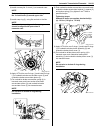

Engine mechanical: 1d-6 4) turn camshaft by approximately 90 ° clockwise and remove shim (3). Warning ! Never put in the hand between camshaft and tappet. 5) using a micrometer (2), measure the thickness of the removed shim (1), and determine replacement shim by calculating the thickness of new shim...

Page 238

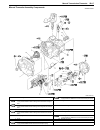

1d-7 engine mechanical: 9) install camshaft housing (1) and tighten bolts to specified torque. Tightening torque camshaft housing bolt (a): 11 n·m (1.1 kgf-m, 8.0 lb-ft) 10) turn crankshaft pulley more than 4 rotations. 11) check valve clearance again. 12) after checking and adjusting all valves, in...

Page 239

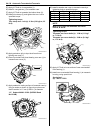

Engine mechanical: 1d-8 air cleaner assembly removal and installation s6rw0c1406002 removal 1) remove air cleaner inlet hose (2) and outlet hose. 2) disconnect maf sensor connector (3). 3) remove air cleaner case (1). Installation 1) install air cleaner case (1). 2) connect maf sensor connector (3),...

Page 240

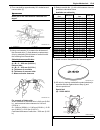

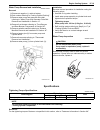

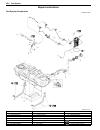

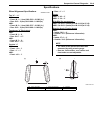

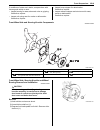

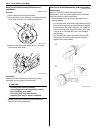

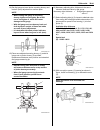

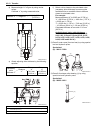

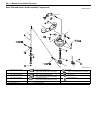

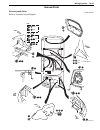

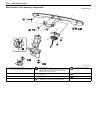

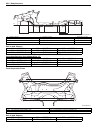

1d-9 engine mechanical: electric throttle body and intake manifold components s6rw0c1406005 (a) 4 2 2 2 1 3 i7rw01140021-03 1. Intake manifold : never disassemble intake manifold. Disassembly will spoil its original performance. If faulty condition is found, replace it with new one. 4. Electric thro...

Page 241

Engine mechanical: 1d-10 electric throttle body on-vehicle inspection s6rw0c1406006 check electric throttle body assembly referring to “throttle valve operation check” and “electric throttle body assembly operation check” under “electric throttle body assembly on-vehicle inspection in section 1c”. E...

Page 242