- DL manuals

- Suzuki

- Other

- 250

- Service Manual

Suzuki 250 Service Manual

GROUP INDEX

GENERAL INFORMATION

1

PERIODIC MAINTENANCE

2

ENGINE

3

DRIVE TRAIN

4

FUEL SYSTEM

5

LUBRICATION SYSTEM

6

CHASSIS

7

ELECTRICAL SYSTEM

8

SERVICING INFORMATION

9

FOREWORD

This manual contains an introductory description on

the SUZUKI LT-F250 and procedures for its inspec-

tion, service, and overhaul of its main components.

Other information considered as generally known is

not included.

Read the GENERAL INFORMATION section to

familiarize yourself with the vehicle and its mainte-

nance. Use this section as well as other sections as

a guide for proper inspection and service.

This manual will help you know the vehicle better so

that you can assure your customers of fast and reli-

able service.

© COPYRIGHT SUZUKI MOTOR CORPORATION 2001

* This manual has been prepared on the basis

of the latest specifications at the time of publi-

cation. If modifications have been made since

then, differences may exist between the con-

tent of this manual and the actual vehicle.

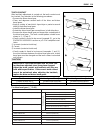

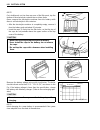

* Illustrations in this manual are used to show

the basic principles of operation and work

procedures. They may not represent the

actual vehicle exactly in detail.

* This manual is written for persons who have

enough knowledge, skills and tools, including

special tools, for servicing SUZUKI vehicles.

If you do not have the proper knowledge and

tools, ask your authorized SUZUKI motorcy-

cle dealer to help you.

Inexperienced mechanics or mechanics

without the proper tools and equipment

may not be able to properly perform the

services described in this manual.

Improper repair may result in injury to the

mechanic and may render the vehicle

unsafe for the rider.

Summary of 250

Page 1

Group index general information 1 periodic maintenance 2 engine 3 drive train 4 fuel system 5 lubrication system 6 chassis 7 electrical system 8 servicing information 9 foreword this manual contains an introductory description on the suzuki lt-f250 and procedures for its inspec- tion, service, and o...

Page 2

03 engine.Book page 105 tuesday, february 28, 2006 3:03 pm.

Page 3: Supplements

Lt-f250k3 (’03-model) 10 lt-f250k4 (’04-model) 11 lt-f250k5 (’05-model) 12 lt-f250k6 (’06-model) 13 lt-f250k7 (’07-model) 14 supplements lt-f250k8 (’08-model) 15 lt-f250k9 (’09-model) 16.

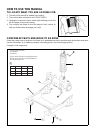

Page 4: How to Use This Manual

How to use this manual to locate what you are looking for: 1. The text of this manual is divided into sections. 2. The section titles are listed in the group index. 3. Holding the manual as shown at the right will allow you to find the first page of the section easily. 4. The contents are listed on ...

Page 5

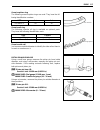

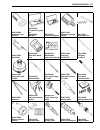

Symbol listed in the table below are the symbols indicating instructions and other information necessary for servic- ing. The meaning of each symbol is also included in the table. Symbol definition symbol definition torque control required. Data beside it indicates specified torque. Apply thread loc...

Page 7: General Information

1 general information 1-1 contents general information warning/caution/note .............................................................. 1- 2 general precautions ................................................................1- 2 suzuki lt-f250k2 (2002-model) ........................................

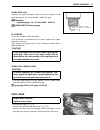

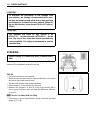

Page 8: Warning/caution/note

1-2 general information warning/caution/note please read this manual and follow its instructions carefully. To emphasize special information, the symbol and the words warning, caution and note have special meanings. Pay special attention to the mes- sages highlighted by these signal words. Indicates...

Page 9

General information 1-3 * if parts replacement is necessary, replace the parts with suzuki genuine parts or their equiv- alent. * when removing parts that are to be reused, keep them arranged in an orderly manner so that they may be reinstalled in the proper order. * be sure to use special tools whe...

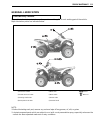

Page 10: Serial Number Location

1-4 general information suzuki lt-f250k2 (2002-model) * difference between photographs and actual vehicles depends on the markets. Serial number location the frame serial number or v.I.N. (vehicle identification number) 1 is stamped on the left side of the rear frame pipe. The engine serial number 2...

Page 11: Break-Ln Procedures

General information 1-5 fuel (for the other countries) use unleaded gasoline that is graded 91 octane or higher by the research method. Engine oil (for usa) suzuki recommends the use of suzuki performance 4 motor oil or oils that meet api service classifications sf or sg and that have a viscosity ra...

Page 12: Information Labels

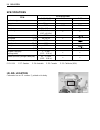

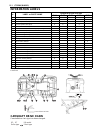

1-6 general information information labels label or plate name no applied specification e-03 e-17 e-24 e-28 e-33 1 certification plate - ¡ — ¡ — ¡ 2 information label - — — — — ¡ 3 gearshift pattern label - ¡ — ¡ — ¡ 4 gearshift pattern label - / . — ¡ — ¡ — 5 tire air pressure label - ¡ ¡ ¡ ¡ ¡ 6 t...

Page 13: Specifications

General information 1-7 specifications dimensions and dry mass overall length ...................................................... 1 800 mm (70.9 in) ....... E-03, 28, 33 1 870 mm (73.6 in) ....... E-17, 24 overall width ....................................................... 1 045 mm (41.1 in)......

Page 14

1-8 general information chassis front suspension .................................................Independent, double wishbone, coil spring, oil damped rear suspension ..................................................Swingarm type, coil spring, oil damped steering angle................................

Page 15: Country and Area Codes

General information 1-9 country and area codes the following codes stand for the applicable countries and areas. Code country or area e-03 e-17 e-24 e-28 e-33 usa sweden australia canada california (usa).

Page 17: Periodic Maintenance

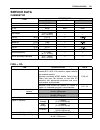

2 6 periodic maintenance 2-1 contents periodic maintenance periodic maintenance schedule ............................................2- 2 periodic maintenance chart ...........................................2- 2 maintenance and tune-up procedures ...............................2- 3 air cleaner .......

Page 18

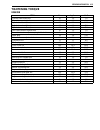

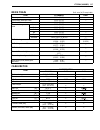

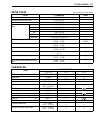

2-2 periodic maintenance periodic maintenance schedule the chart below lists the recommended intervals for all the required periodic service work necessary to keep the vehicle operating at peak performance and economy. Maintenance intervals are expressed in terms of kilometers, miles and months, and...

Page 19

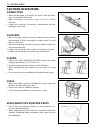

Periodic maintenance 2-3 maintenance and tune-up procedures this section describes the servicing procedures for each item mentioned in the periodic maintenance chart. Air cleaner if the air cleaner is clogged with dust, intake resistance will be increased, with a resultant decrease in power output a...

Page 20

2-4 periodic maintenance • remove the drain cap 1 of the air cleaner box to allow any water to drain out. Exhaust pipe nuts and muffler bolts • tighten the exhaust pipe nuts 1 , muffler connection bolt 2 , and muffler mounting bolts 3 to the specified torque. Exhaust pipe nut: 23 n·m (2.3 kgf-m, 16....

Page 21

Periodic maintenance 2-5 valve clearance excessive valve clearance results in valve noise and insufficient valve clearance results in valve damage and reduced power. Check the intake and exhaust valve clearances at the distances indicated above and adjust the valve clearances to specification, if ne...

Page 22

2-6 periodic maintenance • install the spark plug and tdc plug. Tdc plug: 23 n·m (2.3 kgf-m, 16.5 lb-ft) • apply grease to the o-rings and install the o-rings valve inspection caps. • tighten the valve inspection caps. Spark plug spark plug removal • remove the seat. • remove the fuel tank right sid...

Page 23

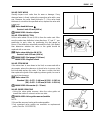

Periodic maintenance 2-7 spark plug gap measure the spark plug gap using a thickness gauge. If the spark plug gap is out of specification, adjust the gap. Standard spark plug gap: 0.6 – 0.7 mm (0.024 – 0.028 in) 09900-20803: thickness gauge electrode check the condition of the electrode. If the elec...

Page 24

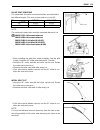

2-8 periodic maintenance throttle cable play adjust the throttle cable play a as follows. • loosen the locknut 1 of the throttle cable. • turn the adjuster 2 in or out to obtain the correct play. Throttle cable play: 3 – 5 mm (0.12 – 0.20 in) • after adjusting the throttle cable play, tighten the lo...

Page 25

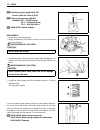

Periodic maintenance 2-9 engine oil replacement • place an oil pan under the drain plug 1 , and then drain out the engine oil by removing the engine oil drain plug 1 and engine oil filler cap 2 . • reinstall the drain plug 1 and the gasket. Tighten the engine oil drain plug 1 to the specicied torque...

Page 26

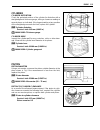

2-10 periodic maintenance final bevel gear oil to change the final bevel gear oil, locate the vehicle on a level position and carry out the following steps. Use sae #90 hypoid gear oil which is rated gl-5 under the api classification system. Use hypoid gear oil sae #80, api grade gl-5, if the vehicl...

Page 27

Periodic maintenance 2-11 spark arrester • remove the bolt 1 . • extract the spark arrester pipe 2 from the muffler. • clean the spark arrester pipe 2 by brush. • reinstall the spark arrester pipe 2 . Clutch • remove the clutch adjuster cap bolt 1 . Note: adjust the clutch release, when the engine i...

Page 28

2-12 periodic maintenance brakes brake pads • remove the front wheels. ( 7-10) the extent of brake pad wear can be checked by observing the limit line 1 on the side of brake pads. When the wear reaches the limit line, replace the pads with new ones. ( 7-18) brake shoes this vehicle is equipped with ...

Page 29

Periodic maintenance 2-13 • turn the adjuster 1 until the play a is 20 – 30 mm (0.8 – 1.2 in). Rear brake lever • after adjusting the brake pedal, check the rear brake lever play. The brake lever play b as measured at the lever holder should be between 3 – 5 mm (0.1 – 0.2 in) when the lever is light...

Page 30

2-14 periodic maintenance air bleeding the brake fluid circuit air trapped in the brake fluid circuit acts like a cushion absorb a large proportion of the pressure developed by the master cylin- der and thus interferes with the full braking performance of the brake caliper. The presence of air is in...

Page 31

Periodic maintenance 2-15 brake hose • check the brake hoses for leakage, cracks, wear and dam- age. If any damages are found, replace the brake hoses with new ones. Tires tire tread condition operating the vehicle with excessively worn tires will decrease riding stability and consequently invite a ...

Page 32

2-16 periodic maintenance steering steering system should be adjusted properly for smooth manip- ulation of the handlebars and safe running. Toe-in • place the vehicle on level ground. • make sure the tire pressure for right and left tires is the same and set to the proper specification. • set the f...

Page 33

Periodic maintenance 2-17 suspensions • support the vehicle using a jack and wooden blocks. • remove the front and rear wheels. ( 7-10) • inspect the suspension arm and bushing for scratches, wear, or damage. If any damages are found, replace the suspen- sion arm or bushing with a new one. ( 7-30 an...

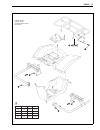

Page 34

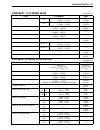

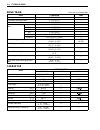

2-18 periodic maintenance chassis bolts and nuts check that all chassis nuts and bolts are tightened to their specified torque. (refer to page 2-19 and 2-20 for the locations of the following nuts and bolts.) tighten initially at 1 month and every 3 months there- after. Item n·m kgf-m lb-ft 1 handle...

Page 35

Periodic maintenance 2-19.

Page 36

2-20 periodic maintenance.

Page 37

Periodic maintenance 2-21 general lubrication proper lubrication is important for smooth operation and long life of each working part of the vehicle. Major lubrication points are indicated below. 1 brake lever holder 5 brake cam grease 2 throttle lever and cable 6 brake cable motor oil 3 steering sh...

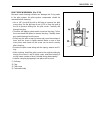

Page 38: Compression Pressure Check

2-22 periodic maintenance compression pressure check the compression pressure reading of a cylinder is a good indicator of its internal condition. The decision to overhaul the cylinder is often based on the results of a compression test. Periodic mainte- nance records kept at your dealership shoud i...

Page 39: Oil Pressure Check

Periodic maintenance 2-23 oil pressure check check the engine oil pressure periodically. This will give a good indication of the condition of the moving parts. Oil pressure: low or high oil pressure can indicate any of the following conditions: low oil pressure * clogged oil filter * oil leakage fro...

Page 40

2-24 periodic maintenance initial engagement and clutch lock-up inspection the lt-f250 is equipped with a centrifugal type automatic clutch. To insure proper performance and longevity of the clutch assemblies, it is essential that the clutches engage smoothly and gradually. Before checking the initi...

Page 41: Engine

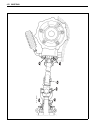

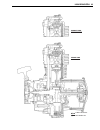

3 6 engine 3-1 contents engine engine components removable with engine in place ...3- 2 engine left side .....................................................................3- 2 engine right side ..................................................................3- 2 engine center .....................

Page 42

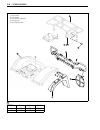

3-2 engine engine components removable with engine in place the parts listed below can be removed and installed without removing the engine from the frame. Refer to the page listed in each section for removal and installation instructions. Engine left side engine right side engine center parts remov...

Page 43

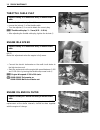

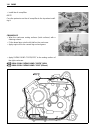

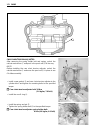

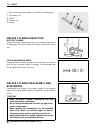

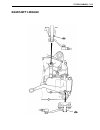

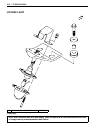

Engine 3-3 engine removal and installation engine removal before taking the engine out of the frame, wash the engine using a steam cleaner. Engine removal is sequentially explained in the following steps. Reinstall the engine by reversing the removal procedure. • drain engine oil. ( 2-9) • remove th...

Page 44

3-4 engine • turn the fuel valve to the “on” position and remove the carbu- retor. Carburetor removal 5-7 • disconnect the engine ground lead wire 1 . • disconnect the neutral switch lead wire coupler 2 . • disconnect the signal generator lead wire coupler 3 and gen- erator lead wire coupler 4 . • r...

Page 45

Engine 3-5 • remove the reverse gearshift arm 1 . • remove the spark plug cap. • remove the right footrest 2 . • remove the brake pedal 3 . • remove the muffler 4 ..

Page 46

3-6 engine • remove the exhaust pipe. • remove the breather hose 1 . • remove the starter motor cover 2 . • remove the starter motor lead wire. • remove the engine mounting bracket a ..

Page 47

Engine 3-7 • remove the engine mounting bolts and nuts. • disconnect the propeller shaft. • remove the engine from the right side..

Page 48

3-8 engine engine installation remount the engine in the reverse order of engine removal. Pay attention to the following points: note: * the engine mounting nuts are self-locking. * once the nut has been removed, it is no longer of any use. Be sure to use new nuts, and then tighten them to the speci...

Page 49

Engine 3-9 • install the new gasket. • apply thread lock “1342” to the muffler mounting bolt a and b . 99000-32050: thread lock “1342” • tighten the exhaust pipe nuts and muffler mounting bolts to the specified torque. Exhaust pipe nut: 23 n·m (2.3 kgf-m, 16.5 lb-ft) muffler connecting bolt: 23 n·m ...

Page 50

3-10 engine • apply thread lock super “1342” to the bolts a and tighten each bolt to the specified torque. Footrest bolt: 8 mm: 26 n·m (2.6 kgf-m, 19.0 lb-ft) 10 mm: 55 n·m (5.5 kgf-m, 40.0 lb-ft) 99000-32050: thread lock “1342” • adjust the brake pedal play b . Brake pedal play b : 20 – 30 mm (0.8 ...

Page 51

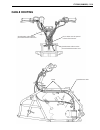

Engine 3-11 • adjust the gearshift lever height a . Gearshift lever height a : 0 – 10 mm (0 – 0.4 in) • after installing the engine, route the wire harness, cables and hoses properly. ( 9-12) • adjust the following items. * engine oil 2-9 * engine idle speed 2-8 * throttle cable play 2-8 engine oil ...

Page 52: Engine Disassembly

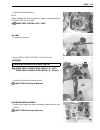

3-12 engine engine disassembly engine top side spark plug • remove the spark plug. 09930-10121: spark plug wrench set starter motor • remove the starter motor. Recoil starter • remove the recoil starter. • remove the valve timing inspection plug 1 . • turn the crankshaft and align the “tdc” line a o...

Page 53

Engine 3-13 cam chain tension adjuster • after removing the spring holder bolt 1 , remove the cam chain tension adjuster. Cylinder head cover • remove the cylinder head cover. Camshaft • remove the c-ring 1 . • flatten the lock washer. • remove the cam chain sprocket bolts and lock washer. • remove ...

Page 54

3-14 engine • remove the cam chain tensioner by removing the bolt. Cylinder head • remove the cylinder head nuts. • remove the cylinder head bolts diagonally. • remove the cylinder head. Cylinder • remove the cylinder nuts. • remove the cam chain guide 1 . • remove the cylinder. Note: be careful not...

Page 55

Engine 3-15 piston • remove the piston by removing the piston pin circlip 1 . Note: place a rag under the piston so as not to drop the piston pin cir- clip into the crankcase. Engine bottom side neutral switch • remove the neutral switch. • remove the springs and pins. Starter cup • remove the start...

Page 56

3-16 engine • remove the generator roter cover. Starter idle gear • remove the starter idle gear. Oil filter • remove the oil filter cover. • remove the oil filter and o-ring 1 . Clutch cover • remove the clutch adjuster cap 1 . • remove the clutch cover..

Page 57

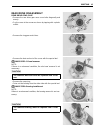

Engine 3-17 • remove the clutch release ball assembly 1 and ball guide 2 . Clutch note: slightly loosen the clutch spring bolts by holding the clutch shoe nut to facilitate later disassembly. • while holding the generator rotor with the special tool, remove the clutch shoe nut. 09930-44520: rotor ho...

Page 58

3-18 engine • install the generator rotor attachment to the crankshaft end. 09930-31921: rotor remover attachment • remove the generator rotor with the special tool. 09930-35010: rotor remover • remove the key 1 . • remove the starter driven gear 2 . Cam chain • remove the cam chain. • remove the pr...

Page 59

Engine 3-19 • remove the clutch release arm 1 . • remove the clutch springs and bolts. • remove the clutch release plate 2 . • remove the clutch sleeve hub nut with the special tool. 09920-53730: clutch sleeve hub holder • remove the primary driven gear assembly. Gearshift • remove the gearshift sha...

Page 60

3-20 engine • remove the shift cam shaft 1 . • remove the gearshift cam plate and stopper. Oil pump drive gear • remove the oil pump drive gear 1 and pin 2 . Oil pump • remove the circlip. • remove the oil pump driven gear 1 . • remove the pin 2 and washer 3 . • remove the oil pump..

Page 61

Engine 3-21 • remove the left crankcase bolts. • remove the right crankcase bolts. • separate the crankcase with the special tool. Note: * the crankcase separator plate is parallel with the end face of the crankcase. * the crankshaft must remain in the left crankcase half. 09920-13120: crankcase sep...

Page 62

3-22 engine • remove the gearshift cam and forks. • remove the shift cam lock shaft 1 . • remove the reverse driven gear 2 and reverse dog 3 . • remove the crankshaft with the special tool. 09920-13120: crankcase separator drive bevel gear • using a chisel, unlock the nut..

Page 63

Engine 3-23 • fit the special tool onto the driveshaft. 09930-73150: output shaft holder • remove the secondary drive bevel gear and nut by holding the special tool with a vise. • remove the driveshaft and countershaft..

Page 64

3-24 engine engine components inspection and servicing cylinder head cover disassembly • remove the rocker arm shaft. Cylinder head cover distortion after removing sealant from the fitting surface of the cylinder head cover, place the cylinder head cover on a surface plate and check for distortion w...

Page 65

Engine 3-25 rocker arm i.D. When checking the valve rocker arm, the inside diameter of the valve rocker arm and wear of the camshaft contacting surface should be checked. Rocker arm i.D. Standard: 12.000 – 12.018 mm (0.4724 – 0.4731 in) 09900-20605: dial calipers reassembly • install the new o-ring ...

Page 66

3-26 engine • remove the oil seal with long-nose pliers. • remove the valve spring seat. Note: removal of valves completes ordinary disassembling work. If valve guides have to be removed for replacement after inspect- ing the related parts, carry out the steps shown in the valve guide servicing. Cyl...

Page 67

Engine 3-27 valve face wear visually inspect each valve face for wear or damage. If any abnormal wear is found, replace the respective valve with a new one. Measure the valve head thickness t . If the valve head thickness is not within the specified value, replace the value with a new one. Valve hea...

Page 68

3-28 engine • re-finish the valve guide holes in the cylinder head with the reamer and handle. 09916-34561: valve guide reamer (11.3 mm) 09916-34542: reamer handle • install a ring onto each valve guide. Be sure to use new rings. • oil the stem hole of each valve guide and drive the guide into the g...

Page 69

Engine 3-29 valve seat servicing the valve seats for intake and exhaust valves are machined to two different angles. The seat contact surface is cut at 45°. Note: the valve seat contact area must be inspected after each cut. 09916-21111: valve seat cutter set 09916-24900: valve seat cutter set 09916...

Page 70

3-30 engine top narrowing cut • if the contact area w is too high on the valve, or if it is too wide, use the 15° cutter to lower and narrow the contact area. Final seat cut • if the contact area w is too low or too narrow, use the 45° cut- ter to raise and widen the contact area. Note: after cuttin...

Page 71

Engine 3-31 • after the desired seat position and width is achieved, use the 45° cutter very lightly to clean up any burrs caused by the pre- vious cutting operations. Note: after servicing the valve seats, be sure to check the valve clear- ance after the cylinder head has been reinstalled. ( 2-5) •...

Page 72

3-32 engine valve spring free length (in & ex) service limit : 41.0 mm (1.63 in) valve spring tension (in & ex) standard: 236 – 287 n/36.8 mm (24.1 – 29.3 kgf/36.8 mm, 53.1 – 64.6 kgf/1.45 in) 09900-20101: vernier calipers reassembly • install each valve spring seat. • apply molybdenum oil solution ...

Page 73

Engine 3-33 camshaft the camshaft should be checked for wear and also for runout of cams and journals if the engine has been noted to produce abnormal noise or vibration or to lack output power. Any of these malconditions could be caused by a worn camshaft. Camshaft cam wear worn-down cams are often...

Page 74

3-34 engine if the camshaft journal oil clearance measured exceeds the limit, measure the outside diameter of camshaft. Replace either the cylinder head set or the camshaft if the clear- ance is incorrect. Camshaft journal o.D. Standard: 21.959 – 21.976 mm (0.8645 – 0.8652 in) 09900-20205: micromete...

Page 75

Engine 3-35 cylinder cylinder distortion check the gasketed surface of the cylinder for distortion with a straightedge and thickness gauge, taking a clearance reading at several places as indicated. If the largest reading at any position of the straightedge exceeds the limit, replace the cylinder. C...

Page 76

3-36 engine piston ring to groove clearance using a thickness gauge, measure the side clearances of the 1st and 2nd rings. If any of the clearances exceeds the limit, replace both piston and piston rings. Piston ring to groove clearance service limit (1st) : 0.18 mm (0.0071 in) (2nd): 0.15 mm (0.005...

Page 77

Engine 3-37 oversize piston ring the following oversize piston rings are used. They bear the fol- lowing identification numbers. Oversize oil ring the following oversize oil ring is available as optional parts. They bear the following identification mark. Oversize side rail just measure outside diam...

Page 78

3-38 engine conrod/crankshaft conrod small end i.D. Using a caliper gauge, measure the conrod small end inside diameter. Conrod small end i.D. Service limit: 16.040 mm (0.6315 in) 09900-20605: dial calipers (10 – 34 mm) 09900-22401: small bore gauge (10 – 18 mm) if the conrod small end inside diamet...

Page 79

Engine 3-39 clutch clutch drive plates note: wipe off engine oil from the clutch drive plates with a clean rag. • measure the thickness of drive plates with a vernier calipers. • if each drive plate is not within the standard range, replace it with a new one. Drive plate thickness standard : 2.7 – 2...

Page 80

3-40 engine clutch shoes inspect the clutch shoes for chips, cracks, uneven wear, and heat discoloration. Also, check the depth of the grooves on the clutch shoes. If there is no groove at any part of the shoes, replace the shoes as a set. Note: the clutch shoes must always be changed as a set. Clut...

Page 81

Engine 3-41 • apply thread lock super “1303” to the bolts, and then tighten them to the specified torque with a offset wrench. Starter clutch bolt: 26 n·m (2.6 kgf-m, 19.0 lb-ft) 99000-32030: thread lock super “1303” 09930-44520: rotor holder • install the starter driven gear to the starter clutch. ...

Page 82

3-42 engine transmission disassembly • insert the special tool between the 2nd drive gear and 4th drive gear. • remove the 2nd drive gear by a hydraulic press. 09950-81910: remover • disassemble the transmission as shown. 1 reverse driven gear 2 reverse gear dog 3 1st driven gear 4 5th driven gear 5...

Page 83

Engine 3-43 reassembly assemble the transfer in the reverse order of disassembly. Pay attention to the following points: note: * always use new snap rings. * before installing the gears, coat lightly engine oil to the shafts and gears. • when installing a new snap ring, pay attention to the directio...

Page 84

3-44 engine • when installing the bushings, align the shaft hole with the bushing hole..

Page 85

Engine 3-45 gearshift fork shift fork to groove clearance using a thickness gauge, check the shifting fork clearance in the groove of its gear. The clearance for each of the three shifting forks plays an impor- tant role in the smoothness and positiveness of shifting action. If the clearance exceeds...

Page 86

3-46 engine generator cover disassembly • remove the generator stator. • remove the oil seal. Reassembly • install the oil seal with the special tool. • install the generator stator. Replace the removed oil seal with a new one..

Page 87

Engine 3-47 clutch cover disassembly • remove the clutch release outer guide. • remove the bearing with the special tool. 09921-20240: bearing remover set note: if there is no abnormal noise, the bearing removal is not neces- sary. Inspection rotate the balls by hand to inspect for an abnormal noise...

Page 88

3-48 engine crankcase bearing inspection rotate the bearing inner race by finger to inspect for abnormal play, noise and smooth rotation while the bearings are in the crankcase. Replace the bearing in the following procedure if there is any- thing unusual. Bearing removal • remove the bearing retain...

Page 89

Engine 3-49 • install the bearing retainers. Note: when installing the bearing retainers, apply a small quantity of thread lock to the screws. 09900-32050: thread lock “1342” oil seal • remove the oil seal. • apply suzuki super grease “a” to the oil seal. 99000-25030: suzuki super grease “a” (usa) 9...

Page 90

3-50 engine crankshaft disassembly reassembly • determine the width between the webs referring to the figure when rebuilding the crankshaft. Crank web to web width standard: 53.0 ± 0.1mm (2.087 ± 0.004 in) crankshaft (r) crank pin ! Bearing " conrod # crankshaft (l).

Page 91

Engine 3-51 recoil starter disassembly • after removing the nut 1 , take out the recoil starter related parts from the housing. 1 nut 6 spring 2 friction plate 7 spacer 3 ratchet guide 8 pin 4 ratchet 9 reel 5 spring cover 1 ratchet set 2 reel 3 spiral spring 4 rope assembly wear hand and eye protec...

Page 92

3-52 engine reassembly reassemble the recoil starter in the reverse order of disassem- bly. Pay attention to the following points: • when installing the spiral spring, hook the spiral spring end 1 with the recoil starter case. • apply suzuki super grease “a” to the spiral spring. 99000-25030: suzuki...

Page 93

Engine 3-53 • pull the rope and check that the ratchet is pushed out..

Page 94

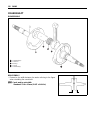

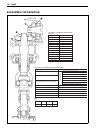

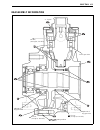

3-54 engine drive train secondary bevel gears construction 1 bearing 2 shim 3 secondary bevel drive gear 4 washer 5 washer 6 secondary bevel driven gear 7 shim 8 bearing 9 secondary bevel gear shaft 0 bearing a oil seal b o-ring c water proof cover d snap ring item n·m kgf-m lb-ft a , b 100 10.0 72....

Page 95

Engine 3-55 secondary driven bevel gear removal the following components must be removed in the described order before removing the secondary driven bevel gear. Note: refer to the following pages for the details of each step. • remove the rear wheel. ( 7-10) • remove the swingarm. ( 7-54) • remove t...

Page 96

3-56 engine inspection inspect the removed parts for the following abnormalities. * drive and driven bevel gears damage or wear * improper tooth contact * abnormal noise of bearings * bearing damage or wear * oil seal damage or wear secondary driven bevel gear reassembly • install the bearing. Note:...

Page 97

Engine 3-57 • apply 4 – 5 gram of water resistance grease to the outside of the seal lip groove. • apply grease to the seal lip groove and install it. 99000-25160: water resistance grease 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (others) • apply grease to the o...

Page 98

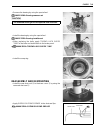

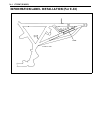

3-58 engine secondary gear shims adjustment • remove the secondary bevel gear cover. • hold the bearings with the special tool. 09921-21910: bearing holder • set a dial gauge on the driven bevel gear as shown. Measure the backlash by turning the driven bevel gear shaft in each direction, reading the...

Page 99

Engine 3-59 tooth contact after backlash adjustment is carried out, the tooth contact must be checked. Pay attention to the following procedures: • remove the driven bevel gear. • clean and degrease several teeth of the drive and driven bevel gears. • apply a coating of machinist’s layout dye or pas...

Page 100

3-60 engine reassembly information item n·m kgf-m lb-ft 1 2 100 10.0 72.5 " part no. Shim thickness list of shims a available for the drive bevel gear side. 24935-19b00-025: 0.25 mm (0.0098 in) 24935-19b00-030: 0.30 mm (0.0118 in) 24935-19b00-035: 0.35 mm (0.0138 in) 24935-19b00-115 0.30+0.30=0.60 m...

Page 101: Engine Reassembly

Engine 3-61 engine reassembly reassemble the engine in the reverse order of disassembly. Pay special attention to the following points: note: apply engine oil to each running and sliding part before reas- sembling. Engine bottom side drive train • install the driveshaft and countershaft. • install t...

Page 102

3-62 engine crankshaft • when mounting the crankshaft in the crankcase, it is neces- sary to pull its left end into the crankcase with the special tool. Note: use the proper bars. 09910-32812: crankshaft installer • install the reverse dog and washer 1 . • install the reverse driven gear and washer ...

Page 103

Engine 3-63 • install the transmission related parts. Note: each fork has own embossed letters. 1 05g-1b (for reverse/1st gear) 2 05g-2b (for 2nd/3rd gear) 3 19b-3j (for 4th/5th gear) • install the reverse idle gear shaft 4 . • install the snap ring 5 , washer 6 and spacer 7 . 09900-06107: snap ring...

Page 104

3-64 engine • install the oil sump filter. Note: face the protrusion on the oil sump filter to the top when install- ing it. Crankcase • wipe the crankcase mating surfaces (both surfaces) with a cleaning solvent. • fit the dowel pins onto the left half on the crankcase. • apply engine oil to the con...

Page 105

Engine 3-65 • assemble the crankcase within few minutes. Note: fit the clamp to the bolt a . Oil pump • install the oil pump. • install the washer 1 and pin 2 . • install the oil pump driven gear by installing the snap ring. Oil pump drive gear • install the pin 1 . • install the oil pump drive gear...

Page 106

3-66 engine gearshift • install the spring 1 , washer 2 and gearshift cam stopper 3 . Note: fit the spring end to the stopper properly. • install the the gearshift cam plate 4 . • apply thread lock “1342” to the bolt and install the gear- shift cam plate guide. 99000-32050: thread lock “1342” • inst...

Page 107

Engine 3-67 clutch • install the clutch drive plates and driven plates one by one onto the clutch sleeve hub 1 . Drive plate ...........6 pcs driven plate ........5 pcs • install the clutch pressure plate 2 . • install the washer 3 onto the countershaft. • install the primary driven gear assembly. •...

Page 108

3-68 engine • install the washer and clutch sleeve hub nut. Note: the convex side of the washer faces outside. • tighten the clutch sleeve hub nut to the specified torque with the special tool. Clutch sleeve hub nut: 70 n·m (7.0 kgf-m, 50.5 lb-ft) 09920-53730: clutch sleeve hub holder • stake the cl...

Page 109

Engine 3-69 cam chain • install the cam chain. Generator • install the starter driven gear 1 . • install the key 2 . Note: degrease the tapered portion of the generator rotor assembly and also the crankshaft. Use nonflammable cleaning solvent to wipe off the oily or greasy matter to make these surfa...

Page 110

3-70 engine • install the clutch shoe and washer. • before installing the clutch shoe nut, apply engine oil to the thread and inside surface of the nut. • install the clutch shoe nut. • tighten the clutch shoe nut to the specified torque while hold- ing the generator rotor with the special tool. 099...

Page 111

Engine 3-71 • install the clutch cover. Oil filter • before installing the oil filter, fit the new o-rings and apply engine oil lightly to them. • install the spring 1 and oil filter. Starter idle gear • install the idle driven gear. • install the dowel pins and new gasket. • tighten the generator c...

Page 112

3-72 engine secondary driven bevel gear • install the secondary driven bevel gear shaft assembly. • install the dowel pins. • apply suzuki bond “1207b/1215” to the mating surface of the right crankcase. 99104-31140: suzuki bond “1207b” (usa) 99000-31110: suzuki bond “1215” (others) • install the sec...

Page 113

Engine 3-73 neutral switch • install the springs and switch contacts. • install the neutral switch. Engine top side piston • install the piston rings in the order of oil ring, 2nd ring and 1st ring. • the first member to go into the oil ring groove is a spacer 1 . After placing the spacer, fit the t...

Page 114

3-74 engine • position the gaps of the three rings as shown. Before inserting the piston into the cylinder, check that the gaps are so located. • apply a light coat of molybdnum oil solution to the piston pin. Molybdnum oil solution • install the piston and piston pin. Note: when installing the pist...

Page 115

Engine 3-75 • hold each piston ring with properly position, insert the piston into the cylinder. • tighten the cylinder base nuts temporarily. Note: fit the clamp to the bolt b . Cylinder head • install the cam chain guide 1 . • fit the dowel pins and new cylinder head gasket. • install the cylinder...

Page 116

3-76 engine • install the cam chain tensioner. Camshaft • align the line a on the generator rotor with the index mark b on the crankcase. • align the marks c on the camshaft so that they are parallel with the surface of the cylinder head. Note: do not rotate the generator while doing this. When the ...

Page 117

Engine 3-77 • bend up the washer tongue positively to lock the bolts. • install the c-ring 1 . Cylinder head cover • clean the mating surface of the cylinder head and head cover before matching. • install the dowel pins to the cylinder head. • apply suzuki bond “1216b” to the mating surface of the c...

Page 118

3-78 engine cam chain tension adjuster after removing the spring holder bolt and spring, unlock the ratchet mechanism 1 and push in the push rod 2 all the way. Note: before installing the cam chain tension adjuster, unlock the ratchet mechanism 1 and move the push rod 2 in place to see if it slides ...

Page 119

Engine 3-79 • apply grease to the new o-rings and install the valve inspec- tion caps. 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (others) • install the valve timing inspection plug. Recoil starter • apply a small quantity of thread lock “1342” to the bolts. • in...

Page 120

3-80 engine • install the spark plug. 09930-10121: spark plug wrench set clutch release adjustment • temporarily install the gear shift lever. • loosen the clutch release outer guide nuts 1 . • loosen the locknut 2 . • turn the adjusting screw 3 clockwise until it stops. • check that the gearshift l...

Page 121: Drive Train

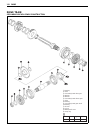

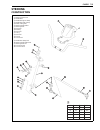

2 4 6 drive train 4-1 contents drive train rear driving system ....................................................................4- 2 rear drive removal .............................................................4- 3 rear drive disassembly .....................................................4- ...

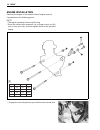

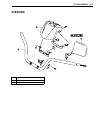

Page 122: Rear Driving System

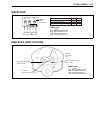

4-2 drive train rear driving system 1 rear drive gear case cover 2 shim, lh 3 bevel ring gear 4 shim, rh 5 rear drive gear case 6 shim 7 bevel pinion gear 8 pinion gear shaft coupling joint 9 propeller shaft 0 universal joint.

Page 123

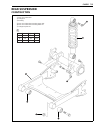

Drive train 4-3 rear drive removal • remove the rear wheels. ( 7-10) • disconnect the rear brake cables and brake drum air vent hose. • remove the left wheel hub. ( 7-11) • remove the rear drive gear case under cover. • drain the gear oil. ( 2-10) • remove the shock absorber mounting bolt. • remove ...

Page 124

4-4 drive train • remove the rear drive gear case together with the propeller shaft. • remove the propeller shaft from the rear drive gear case. • remove the axle housing bolts and nuts. • remove the rear axle together with the axle housing..

Page 125

Drive train 4-5 rear drive disassembly rear drive gear case • remove the rear drive gear case cover bolts diagonally and evenly. • pry the cover at the arrows as shown by tapping with a plastic mallet. • remove the ring gear and shims. • remove the dust seal out of the cover with the special tool. 0...

Page 126

4-6 drive train • remove the bearing and oil seal out of the cover with a suit- able tool. Note: if there is no abnormal condition, the bearing/oil seal removal is not necessary. • remove the oil seal out of the case with a suitable tool. Note: if there is no abnormal condition, the oil seal removal...

Page 127

Drive train 4-7 • unstake the bearing locknut with a small chisel or drill. • remove the bearing locknut with the special tool. 09921-21820: bearing lock nut wrench • remove the pinion gear assembly and shim out of the case. • remove the o-ring 1 from the pinion gear shaft. • remove the bearing from...

Page 128

4-8 drive train • remove the pinion gear pilot bearing with the special tools. 09921-20210: bearing puller 09930-30104: sliding shaft note: if there is no abnormal condition, the bearing removal is not nec- essary. Universal joint • remove the c-rings from the universal joint. • remove the bearings ...

Page 129

Drive train 4-9 rear drive inspection propeller shaft inspect the splines of the propeller shaft for wear or damage. Also, inspect the boot for cuts or damage. If any defects are found, replace the propeller shaft and its boot with the new ones. Universal joint inspect the universal joint and outer ...

Page 130

4-10 drive train check the outer race play and smooth rotation of the bearing by hand while it is on the pinion gear shaft. Inspect the pinion gear for wear or damage. If the pinion gear is damaged, inspect the ring gear also. If any defects are found, replace the bearing and gear with the new ones....

Page 131

Drive train 4-11 rear axle inspect the splines of the rear axle and splines of the ring gear for wear or damage. If any wear or damage is found, replace the rear axle and ring gear with the new ones. Rear drive reassembly reassemble the rear drive in the reverse order of disassembly. Pay attention t...

Page 132

4-12 drive train gear case bearing • drive the bearings into the gear case and case cover with the special tool. 09913-70210: bearing installer set dust seal • fix the bearing race with the snap ring. • apply grease to the bearing. 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super...

Page 133

Drive train 4-13 bevel pinion gear shaft bearing • drive the bearing onto the shaft with the special tool. 09913-70210: bearing installer set bevel pinion gear/shim/locknut [final assembly] • install the new o-ring 1 onto the pinion gear shaft. • install the shim, pinion gear assembly and new bearin...

Page 134

4-14 drive train • apply grease to the splines of the pinion gear shaft and install the pinion gear shaft coupling joint by tapping with a plastic mallet. 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (others) • apply 4 – 5 gram of water resistance grease to the out...

Page 135

Drive train 4-15 universal joint • apply grease to the bearing and its dust seal lip. 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (others) • install the universal joint and bearings with the special tool. 09913-70210: bearing installer set • install the c-rings by...

Page 136

4-16 drive train rear drive installation install the rear drive in the reverse order of removal. Pay atten- tion to the following points: • coat a new o-ring with grease and install it into the groove in the gear case. 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (...

Page 137

Drive train 4-17 • tighten the axle housing mounting bolts to the specified torque. Axle housing mounting bolt: 60 n·m (6.0 kgf-m, 43.5 lb-ft) • tighten the shock absorber mounting bolt to the specified torque. Shock absorber mounting bolt: 50 n·m (5.0 kgf-m, 36.0 lb-ft) • install the rear drive gea...

Page 138

4-18 drive train shim adjustment backlash • install the pinion gear assembly, removed shim and new bearing locknut. ( 4-13) • tighten the bearing locknut to the specified torque. ( 4-13) note: at this time, it is not necessary to stake the bearing locknut. ( 4-13) • install the removed right side sh...

Page 139

Drive train 4-19 • install the gear case cover and tighten its bolts to the speci- fied torque in a crisscross pattern. ( 4-14) note: * do not install the new o-ring to the gear case cover at this time. * do not apply a thread lock to the case cover bolts at this time. Gear case cover bolt: 25 n·m (...

Page 140

4-20 drive train tooth contact after backlash adjustment and left shim selection are carried out, the tooth contact must be checked. Pay attention to the fol- lowing procedures: • remove the ring gear. • clean and degrease several teeth on the ring gear and pinion gear, and then apply a coating of m...

Page 141

Drive train 4-21 reassembly information pinion gear shim right side of ring gear shim mating surfaces 27 n·m (2.7 kgf-m, 19.5 lb-ft) 25 n·m (2.5 kgf-m, 18.0 lb-ft) left side of ring gear shim 4 – 5 gram 100 n.M (10.0 kgf.M, 72.5 lb-ft).

Page 142

4-22 drive train 4 – 5 g ram.

Page 143: Fuel System

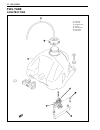

5 fuel system 5-1 contents fuel system fuel tank ........................................................................................5- 2 construction .........................................................................5- 2 fuel line inspection .................................................

Page 144: Fuel Tank

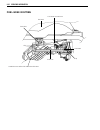

5-2 fuel system fuel tank construction 1 fuel tank 2 fuel cap 3 breather hose 4 gasket 5 seal washer 6 fuel valve 7 fuel hose.

Page 145

Fuel system 5-3 fuel line inspection inspect the fuel lines, fuel tank and fuel tank cap for damage and fuel leakage. If any damages are found, replace the defective parts with the new ones. • remove the front fender. ( 7-5) • turn the fuel valve to the “on” position. • disconnect the fuel hose 1 an...

Page 146: Fuel Valve

5-4 fuel system fuel valve removal and inspection • remove the fuel tank. ( 5-3) • remove the fuel valve. Fuel strainer if the fuel strainer is dirty with sediment or rust, fuel will not flow smoothly and loss in engine power may result. Clean the fuel strainer with compressed air. Remounting remoun...

Page 147: Carburetor

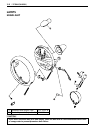

Fuel system 5-5 carburetor construction 1 diaphragm 2 air vent hose 3 ring 4 piston valve 5 air jet 6 throttle lever cap 7 o-ring 8 top cover 9 spring 0 stopper plate a spring b washer c spacer d jet needle e carburetor body f coasting enrichment valve g spring h cover i fuel hose j starter plunger ...

Page 148

5-6 fuel system specifications e-03: usa e-17: sweden e-24: australia e-28: canada e-33: california (usa) i.D. No. Location carburetor has an i.D. Number 1 printed on its body. Item specification e-03, 24, 28 e-17 e-33 carburetor type mikuni bs29 ← ← bore size 29 mm ← ← i.D. No. 05g0 05g2 05g1 idle ...

Page 149

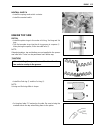

Fuel system 5-7 removal • remove the fuel tank side covers. ( 7-5) • disconnect the fuei hose 1 and vacuum hose 2 . • loosen the carburetor clamp screws • remove the carburetor side cap 3 . • remove the o-ring 4 . • disconnect the throttle cable 5 . • remove the carburetor. • disconnect the starter ...

Page 150

5-8 fuel system disassembly • remove the fuel hose 1 , air vent hose 2 and vacuum hose 3 . • remove the coasting enrichment valve cover 4 , spring 5 . • remove the coasting enrichment valve 6 . • remove the carburetor top cap. • remove the spring 7 and diaphragm assembiy 8 . Do not use compressed ai...

Page 151

Fuel system 5-9 • remove the stopper plate 1 . • remove the following parts. 2 jet needle 3 washer 4 spring • remove the diaphragm by removing the ring 5 . • remove the throttle stop screw holder 6 . • remove the float chamber 7 . • remove the throttle stop screw 8 ..

Page 152

5-10 fuel system • remove the o-ring 1 . • remove the float pin 2 , float 3 and needle valve 4 . • remove the following parts. 1 main jet 2 needle jet holder, o-ring and needle jet 3 pilot jet 4 pilot screw 5 air jet note: before removing the pilot screw 4 , its setting must be deter- mined. Slowly ...

Page 153

Fuel system 5-11 pilot screw removal (for e-33) because harsh cleaning solvents can damage the o-ring seals in the pilot system, the pilot system components should be removed before cleaning. • use a 1/8" size drill bit with a drill-stop to remove the pilot screw plug. Set the drill-stop 4 mm (0.16 ...

Page 154

5-12 fuel system cleaning • clean all jets with a spray-type carburetor cleaner and dry them using compressed air. • clean all circuits of the carburetor thoroughly – not just the perceived problem area. Clean the circuits in the carburetor body with a spray-type cleaner. If necessary, soak each cir...

Page 155

Fuel system 5-13 inspection check the following items for any damage or clogging. If any damages are found, replace the damaged parts with new ones. * pilot jet * valve seat * main jet * piston valve * piiot air jet * starter jet * needle jet air bleeding hole * o-ring * float * throttle valve * nee...

Page 156

5-14 fuel system reassembly reassemble the carburetor in the reverse order of disassembly. Pay attention to the following points: needle jet • install the needle jet with the bigger i.D. Portion of the needle jet facing upward. Pilot screw • after cleaning, install the pilot screw 1 to the original ...

Page 157

Fuel system 5-15 • install the jet needle to the piston valve with the projection c on the jet needle ring inserted in the hole d on the piston valve. Note: touch the spacer 4 with the e-ring 5 . • install the diaphragm assembly to the carburetor. Note: when installing the piston vaive, make sure th...

Page 158

5-16 fuel system remounting remount the carburetor assembly in the reverse order of removal. Pay attention to the following points: • align the lug on the carburetor with the intake pipe’s cutout. • make sure that the carburetor hoses are routed properly. ( 9-17) after the carburetor assembly has be...

Page 159: Lubrication System

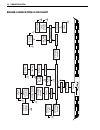

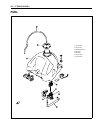

6 lubrication system 6-1 contents lubrication system lubrication system ....................................................................6- 2 engine lubrication circuit ...............................................6- 2 engine lubrication flow chart .....................................6- 4 oil ...

Page 160: Lubrication System

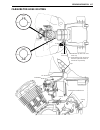

6-2 lubrication system lubrication system engine lubrication circuit oil pump oil filter lubrication oil returned oil.

Page 161

Lubrication system 6-3 intake side lubrication oil returned oil exhaust side.

Page 162

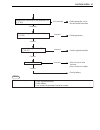

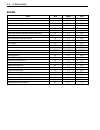

6-4 lubrication system engine lubrication flow chart oil sump fil ter orifice orifice oil fil ter oil pump cylinder driveshaft right end bearing clutch release bearing crankshaft right end bearing driveshaft b ushings/ gears conr od big end bearing cylinder w all & pist on r ocker arms & shafts cams...

Page 163: Oil Pressure

Lubrication system 6-5 oil pressure ( 2-23) oil filter ( 2-9) oil strainer ( 3-21, 63, 64) oil pump ( 3-20, 3-65).

Page 165: Chassis

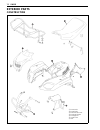

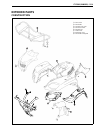

7 chassis 7-1 contents chassis exterior parts .................................................................................................................... 7- 2 construction ............................................................................................................. 7- 2 remo...

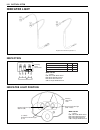

Page 166: Exterior Parts

7-2 chassis exterior parts construction 1 front carrier 2 front fender 3 fuel tank side cover 4 front inner fender 5 front grip bar 6 center cover 7 seat.

Page 167

Chassis 7-3 1 rear carrier 2 rear fender 3 footrest mud guard 4 footrest item n·m kgf-m lb-ft a 55 5.5 40.0 b 26 2.6 19.0 c 28 2.8 20.5 d 55 5.5 40.0 ".

Page 168

7-4 chassis removal seat • remove the seat by pulling the lever. Front carrier • remove the front carrier 1 . Front grip bar • remove the bolts. • remove the front grip bar 1 ..

Page 169

Chassis 7-5 fuel tank side cover • remove the seat. ( 7-4) • remove the fuel tank side covers by removing the fasteners. Front fender • remove the seat. ( 7-4) • remove the fuel tank side covers. ( see above) • remove the fasteners which connect the front fender and mud guard. • remove the fasteners...

Page 170

7-6 chassis • remove the front inner fenders. • disconnect the headlight couplers. • remove the fasteners. • remove the fuel tank cap. • remove the front fender. Note: when removing the front fender, take the front fender backward with the forehead of the front fender opened out. • remove the center...

Page 171

Chassis 7-7 footrest mud guard • remove the fuel tank side cover. ( 7-5) • remove the footrest mud guard 1 . Note: the fastener a on the rear fender consists of screw, washer and nut. Footrest • remove the seat. ( 7-4) • remove the fuel tank side cover. ( 7-5) • remove the footrest mud guard. ( 7-7)...

Page 172

7-8 chassis rear fender • remove the seat. ( 7-4) • remove the fuel tank side covers. ( 7-5) • remove the rear carrier. ( 7-7) • remove the battery 1 . • remove the rear fender mounting bolts. • disconnect the cdi unit coupler. • remove the rear fender. Note: the fastener a on the rear fender consis...

Page 173

Chassis 7-9 remounting remount the exterior parts in the reverse order of removal. Pay attention to the following points: rear carrier • apply thread lock super “1303” and “1322” to the rear carrier mounting bolts 1 . 99000-32030: thread lock super “1303” (usa) 99000-32110: thread lock super “1322” ...

Page 174: Front and Rear Wheels

7-10 chassis front and rear wheels construction removal front and rear wheels • place the vehicle on level ground. • support the vehicle with a jack or wooden block. • remove the wheel. Front wheel hub • remove the front wheel. ( see above) • remove the cotter pin, then loosen the wheel hub nut by a...

Page 175

Chassis 7-11 rear wheel hub • remove the rear wheel. ( 7-10) • remove the cotter pin and loosen the wheel hub nut by apply- ing the rear brake. • remove the wheel hub nut and washer and then remove the wheel hub 1 . Inspection and disassembly dust seal inspect the dust seal lips for wear or damege. ...

Page 176

7-12 chassis remounting and remounting front and rear wheels remount the wheels in the reverse order of removal. Pay atten- tion to the following points: • tighten the wheel set nuts to the specified torque. Front and rear wheel set nut: 50 n·m (5.0 kgf-m, 36.0 lb-ft) note: when installing each whee...

Page 177

Chassis 7-13 • install the dust seals 1 into the front wheel hub with stamped mark facing to outside by using the special tool. 09913-70210: bearing installer set • apply suzuki super grease “a” to the dust seal’s lip. 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (...

Page 178

7-14 chassis rear wheel hub • apply small amount of suzuki super grease “a” to the left wheel hub’s spline. 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (others) • install the rear wheel hub, washer and nut. • tighten the rear wheel hub nut to the specified torque....

Page 179: Tires

Chassis 7-15 tires tire replacement • remove the front and rear wheels. ( 7-10) • after removing the air valve cap, release the tire pressure by depressing the valve. • dismount the bead from the rim completely as shown. • separate the tire from the rim by using a set of tire levers and rim protecto...

Page 180

7-16 chassis • when installing each tire, make sure the arrow a on the tire points in the direction of rotation. Also, make sure the outer side of the wheel rim is facing outward. Note: for inspecting the tire refer to page 2-15. Inspect the valve core, before installation. • inflate the tire to sea...

Page 181: Front Brake

Chassis 7-17 front brake construction * this brake system is filled with an ethylene glycol-based dot 4 brake fluid. Do not use or mix different types of fluid, such as silicone-based or petroleum-based brake fluids. * do not use any brake fluid taken from old, used or unsealed containers. Never reu...

Page 182

7-18 chassis brake pad replacement • remove the front wheel. ( 7-10) • remove the brake caliper mounting bolts 1 and brake pad mounting pins 2 . • remove the brake pads. • install the new brake pads. Note: the shim must be installed to the caliper piston side pad. • tighten the brake pad mounting pi...

Page 183

Chassis 7-19 brake fluid replacement • place the vehicle on a level surface and keep the handlebar straight. • remove the master cylinder reservoir cap and diaphragm. • suck up the old brake fluid as much as possible. • fill the reservoir with new brake fluid. Specification and classification: dot 4...

Page 184

7-20 chassis • remove the spring 1 . • place a rag over the brake caliper piston to prevent the piston from popping out and then force out the piston using com- pressed air. • remove the dust seal and piston seal. • remove the cap 2 and loosen the brake caliper holder slide pin 3 . • remove the brak...

Page 185

Chassis 7-21 brake caliper inspection brake caliper inspect the brake caliper cylinder wall for nicks, scratches or other damage. If any damages are found, replace the brake cal- iper with a new one. Brake caliper piston inspect the brake caliper piston for any scratches or other dam- age. If any da...

Page 186

7-22 chassis brake caliper reassembly and remounting reassemble and remount the brake caliper in the reverse order of removal and disassembly. Pay attention to the following points: • wash the caliper bore and piston with the specified brake fluid. Thoroughly wash the dust seal grooves and piston se...

Page 187

Chassis 7-23 • apply suzuki silicone grease to the brake caliper holder slide pin. 99000-25100: suzuki silicone grease • install the pin 1 , washer 2 and caliper holder 3 to the cali- per. • apply thread lock super “1360” to the pin 1 . 99000-32130: thread lock super “1360” • tighten the pin 1 to th...

Page 188

7-24 chassis brake disc removal and disassembly • remove the front wheel. ( 7-10) • remove the front wheel hub. ( 7-10) • remove the brake disc. Brake disc inspection • remove the front wheel. ( 7-10) • remove the caliper. ( 7-19) inspect the brake disc for cracks or damage and measure the thickness...

Page 189

Chassis 7-25 master cylinder removal and disassembly • place a rag underneath the brake hose union bolt on the mas- ter cylinder to catch any spilt brake fluid. Remove the brake hose union bolt and disconnect the brake hose. • remove the master cylinder assembly. • disconnect the brake switch couple...

Page 190

7-26 chassis • remove the piston/secondary cup, primary cup and spring. 7 secondary cup 8 piston 9 primary cup 0 spring master cylinder inspection master cylinder inspect the master cylinder bore for any scratches or damage. If any damages are found, replace the master cylinder with a new one. Pisto...

Page 191

Chassis 7-27 • align the master cylinder holder’s mating surface 1 with the punched mark 2 on the handlebars and tighten the upper clamp bolt first. Master cylinder clamp bolt: 10 n·m (1.0 kgf-m, 7.0 lb-ft) a master cylinder b master cylinder upper clamp bolt c handlebar d clearance • tighten the br...

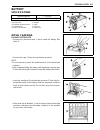

Page 192: Front Suspension

7-28 chassis front suspension construction 1 front shock absorber 2 upper wishbone arm 3 bushing 4 lower wishbone arm 5 steering knuckle 6 snap ring 7 knuckle end a shock absorber mounting upper nut b shock absorber mounting lower bolt c wishbone arm pivot nut d steering knuckle nut e tie rod end nu...

Page 193

Chassis 7-29 removal and disassembly • remove the wheel hub. ( 7-10) • remove the brake hose clamp 1 . • disconnect the brake hose at the hose clamp. • remove the front disc cover 2 . • remove the cotter pin and tie rod end nut. • remove the shock absorber lower mounting bolt 3 . • remove the wishbo...

Page 194

7-30 chassis • remove the cotter pins and nuts. • remove the steering knuckle 1 with a commercially available ball bearing joint remover 2 . Inspection front shock absorber inspect the shock absorber for oil leakage or damage. If any damages are found, replace the front shock absorber with a new one...

Page 195

Chassis 7-31 knuckle end inspect the knuckle end boot for wear or damage. If any dam- ages are found, replace the knuckle end with a new one. Inspect the knucle end for smooth movement. If there are any abnormalities, replace the tie rod end with a new one. • remove the snap ring. • remove the knuck...

Page 196

7-32 chassis brake disc cover inspect the brake disc cover for damage. If any damages are found, replace the brake disc cover with a new one. Reassembly and remounting reassemble and remount the front suspension in the reverse order of removal and disassembly. Pay attention to the following points: ...

Page 197

Chassis 7-33 • degrease the tapered portion of knuckle and also knuckle end with nonflammable cleaning solvent. • install the wishbone arms to the knuckle and tigten the knuckle nuts to the specified torque. Knuckle nut: 45 n·m (4.5 kgf-m, 32.5 lb-ft) • install the cotter pins. • apply thread lock s...

Page 198

7-34 chassis • tighten the tie rod end nut to the specified torque. Tie rod end nut: 35 n·m (3.5 kgf-m, 25.5 lb-ft) • install the cotter pin. Replace the removed cotter pin with a new one..

Page 199: Steering

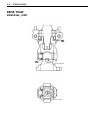

Chassis 7-35 steering construction item n·m kgf-m lb-ft a 23 2.3 16.5 b 23 2.3 16.5 c 49 4.9 35.5 d 35 3.5 25.5 e 29 2.9 21.0 " 1 steering head cover 2 handlebars 3 handlebar upper clamp 4 handlebar lower clamp 5 brake cable guide 6 steering shaft holder 7 steering shaft 8 dust seal 9 bushing 0 dust...

Page 200

7-36 chassis removal • remove the front fender and center cover. ( 7-5) • remove the master cylinder assembly from the handlebars. ( 7-25) • remove the throttle lever case 1 . • disconnect the rear brake cable 2 and remove the handlebar switch 3 . • loosen the locknut and remove the reverse lock rel...

Page 201

Chassis 7-37 • remove the cotter pins and tie rod end nuts. • remove the cotter pin and steering shaft nut 1 , washer 2 and dust seal 3 . • remove the o-ring 4 . • remove the steering shaft holder bolts. • remove the steering shaft holder half. Replace the removed cotter pins with new ones. Replace ...

Page 202

7-38 chassis • remove the steering shaft 1 . • remove the dust seals 2 from the steering shaft. • remove the steering shaft holder half 3 . • remove the steering shaft. • remove the dust seal 4 from the steering shaft. Inspection and disassembly inspect the removed parts for the following abnormalit...

Page 203

Chassis 7-39 tie rod end inspect the tie rod ends for smooth movement. If there are any abnormalities, replace the tie rod end with a new one. Inspect the tie rod end boot for wear or damage. If any damages are found, replace the tie rod end with a new one. Steering shaft inspect the steering shaft ...

Page 204

7-40 chassis • install the steering shaft bushing with the special tool. 09924-84510: bearing installer set reassembly and remounting reassemble and remount the steering stem in the reverse order of removal and disassembly. Pay attention to the following points: steering shaft • apply suzuki super g...

Page 205

Chassis 7-41 • apply suzuki super grease “a” to the steering shaft holders and dust seals before remounting the steering shaft holders. 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (others) • tighten the steering shaft holder bolts to the specified torque. Steering...

Page 206

7-42 chassis handlebars when installing the lower handlebar holder 1 to the steering shaft, the higher mating portion must face to forward. • set the handlebars to match its punched mark 2 to the mat- ing face of the handlebar clamps. • first tighten the bolts 3 to the specified torque and then tigh...

Page 207

Chassis 7-43 toe-in adjustment adjust the toe-in as follows: • place the vehicle on level ground and set the handlebars straight. Make sure all the tires are inflated to the standard pressure. ( 2-15) • place 75 kg (165 lbs) of weight on the seat. • loosen the locknuts ( 1 , 2 ) on each tie rod. • m...

Page 208

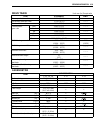

7-44 chassis front wheel, front brake, front suspension and steering reassembling information item n·m kgf-m lb-ft 1 23 2.3 16.5 2 23 2.3 16.5 3 49 4.9 35.5 4 29 2.9 21.0 5 35 3.5 25.5 6 57 5.7 41.0 " " item n·m kgf-m lb-ft 7 55 5.5 40.0 8 65 6.5 47.0 9 45 4.5 32.5 0 50 5.0 36.0 a 75 7.5 54.0 b 23 2...

Page 209: Rear Brake

Chassis 7-45 rear brake construction item n·m kgf-m lb-ft a 60 6.0 43.5 b 11 1.1 8.0 c 11 1.1 8.0 " 1 dust seal 7 bearing a brake panel bolt 2 drum cover 8 brake camshaft b brake cam lever nut 3 brake drum 9 o-ring 4 brake shoe 0 o-ring 5 o-ring a brake panel 6 snap ring b brake cam lever.

Page 210

7-46 chassis removal and disassembly • remove the rear wheel. ( 7-10) • remove the rear hub. ( 7-11) • disconnect the brake cables. • remove the drum cover bolts. • remove the drum cover 1 by using the slotted screwdriver. • remove the brake drum 2 . • remove the brake shoes 3 and springs 4 . Note: ...

Page 211

Chassis 7-47 • remove the o-ring 1 . • disconnect the brake breather hose 2 . • remove the brake panel. • remove the o-ring 3 . • remove the brake cam lever 4 . • remove the washer 5 and spring 6 . • remove the brake camshaft 7 and o-rings 8 from the brake panel..

Page 212

7-48 chassis inspection brake drum measure the brake drum i.D. To determine the extent of wear. If the measurement value exceeds the service limit, replace the brake drum with a new one. Brake drum i.D. Service limit: 140.7 mm (5.54 in) brake shoe inspect the brake shoes for wear or damage. If any w...

Page 213

Chassis 7-49 • remove the bearing by using the special tool. 09921-20240: bearing remover set • install the bearing by using the special tool. 09913-70210: bearing installer set • when replacing the bolts, apply thread lock super “1360” to the bolts and install them to the brake panel. 99000-32130: ...

Page 214

7-50 chassis • apply suzuki super grease “a” to the o-rings and brake camshaft. • install the new o-rings and brake camshaft to the anchor panel. 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (others) • install the washer 1 . • install the spring 2 with the spring e...

Page 215

Chassis 7-51 • install the new o-ring to the brake panel. • apply suzuki super grease “a” to the anchor pin and brake camshaft sliding surface lightly. 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (others) • install the brake shoes and springs to the brake panel. N...

Page 216

7-52 chassis • install the brake drum. Note: before installing the brake drum, make sure that the brake drum is clean and free of any greasey matter. • install the drum cover and tighten the bolts. Note: when installing the drum cover, make sure that the o-ring must be fitted into the groove on the ...

Page 217: Rear Suspension

Chassis 7-53 rear suspension construction item n·m kgf-m lb-ft a 55 5.5 40.0 b 60 6.0 41.0 c 85 8.5 61.5 " 1 rear shock absorber 2 swingarm 3 bushing a rear shock absorber mounting upper bolt b rear shock absorber mounting lower nut c swingarm pivot nut.

Page 218

7-54 chassis removal • remove the rear wheel. ( 7-10) • remove the rear brake. ( 7-46) • remove the rear drive gear case, drive shaft and rear axle housing. ( 4-3) • remove the rear shock absorbers 1 . • disconnect the brake breather hose from the swingarm. • loosen the swingarm pivot nut 2 . • remo...

Page 219

Chassis 7-55 reassembly and remounting reassembly and remount the rear swingarm and suspension in the reverse order of removal and disassembly. Pay attention to the following points: • install the swingarm and rear shock absorber. • tighten the swingarm pivot bolts and shock absorber mount- ing bolt...

Page 220: Rear Axle

7-56 chassis rear axle construction 1 rear axle 2 rear axle housing.

Page 221

Chassis 7-57 removal • remove the trailer towing. (e17, e24 only) • remove the right and left rear wheels. ( 7-10) • remove the rear wheel right and left hubs. ( 7-11) • remove the rear brake. ( 7-46) • support the rear drive gear case with a jack or wooden block. • remove the rear axle housing moun...

Page 222

7-58 chassis inspection rear axle shaft inspect the rear axle shaft visually for distortion or damages. If any damages are found, replace the rear axle shaft with a new one. Using a dial gauge, check the axle shaft for runout and replace it if the runout exceeds the limit. 09900-20607: dial gauge (1...

Page 223

Chassis 7-59 • tighten the rear axle housing bolts/nuts 1 and rear shock absorber mounting bolt 2 to the specified torque. Rear shock absorber mounting nut (lower): 60 n·m (6.0 kgf-m, 43.5 lb-ft) • tighten the axle housing mounting nuts 3 . • install the trailer towing. ( see below) a hole hole clea...

Page 224

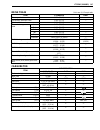

7-60 chassis rear wheel, rear brake, rear suspension, rear swin- garm and rear axle shaft reassembling information item n·m kgf-m lb-ft 1 85 8.5 61.5 2 55 5.5 40.0 3 60 6.0 43.5 4 60 6.0 43.5 " item n·m kgf-m lb-ft 5 50 5.0 36.0 6 100 10.0 72.5 7 11 1.1 8.0 bend the cotter pin securely f or f ear th...

Page 225: Reverse Lock Release Cable

Chassis 7-61 reverse lock release cable removal and installation • take the boot 1 off. • loosen the locknut 2 . • remove the clip 3 and pin 4 . • loosen the locknuts 5 and remove the reverse lock release cable. • remount the reverse lock release cable in the reverse order of removal. After remounti...

Page 227: Electrical System

8 electrical system 8-1 contents electrical system cautions in servicing ................................................................8- 2 connectors ............................................................................8- 2 couplers ............................................................

Page 228: Cautions In Servicing

8-2 electrical system cautions in servicing connectors • when disconnecting a connector, be sure to hold the termi- nals; do not pull the lead wires. • when connecting a connector, push it in so it is firmly attached. • inspect the connector for corrosion, contamination and any breakage in the cover...

Page 229

Electrical system 8-3 battery • the mf battery used in this vehicle does not require mainte- nance (e.G., electrolyte level inspection, distilled water replen- ishment). • during normal charging, no hydrogen gas is produced. How- ever, if the battery is overcharged, hydrogen gas may be pro- duced. T...

Page 230

8-4 electrical system location of electrical components battery parking brake switch handlebar switch (l) horn button (e-17, 24) ignition switch emergency switch (e-17) brake light pedal switch starter motor.

Page 231

Electrical system 8-5 horn (e-17, 24) ignition coil neutral switch diode fuse starter relay generator neutral switch regulator/rectifier neutral relay cdi unit.

Page 232: Charging System

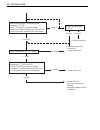

8-6 electrical system charging system troubleshooting generator regulator/rectifier ignition switch fuse battery load no accessories no current leaks incorrect continued on next page • remove accessories • short circuit of wire harness • faulty electrical equipment • faulty battery • abnormal drivin...

Page 233

Electrical system 8-7 • faulty generator coil or disconnected lead wires • faulty generator • faulty regulator/rectifier measure the continuity of the generator coil. ( 8-9) measure the generator no-load voltage. ( 8-9) continuity correct inspect the regulator/rectifier. ( 8-10) correct inspect the ...

Page 234

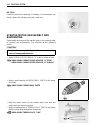

8-8 electrical system inspection battery current leakage • remove the seat. ( 7-4) • turn the ignition switch to the “off” position. • disconnect the - battery lead wire. Measure the current between - battery terminal and the - bat- tery lead wire using the multi circuit tester. If the reading excee...

Page 235

Electrical system 8-9 generator coil resistance • remove the fuel tank left side cover. ( 7-5) • disconnect the generator coupler. Measure the resistance between the three lead wires. If the resistance is not specified value, replace the stator coil with a new one. Also, check that the generator cor...

Page 236

8-10 electrical system regulator/rectifier • remove the regulator/rectifier. Measure the voltage between the terminals using the multi cir- cuit tester, as indicated in the table below. If the voltage is not within the specified value, replace the regu- lator/rectifier with a new one. 09900-25008: m...

Page 237: Starter System

Electrical system 8-11 starter system troubleshooting starter motor fuse starter relay b/w y/b neutral relay starter button engine stop switch emergency switch (e-17) ignition switch cdi parking brake switch neutral indicator light o/y y/g batter y reverse indicator light neutral switch bl b/bl b r/...

Page 238

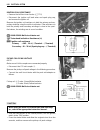

8-12 electrical system starter motor removal and disassembly • remove the right front inner fender. ( 7-5) • remove the right footrest mud guard. ( 7-7) • remove the starter motor cover 1 . • remove the starter motor lead wire 2 . • remove the starter motor 3 . Incorrect • faulty starter relay corre...

Page 239

Electrical system 8-13 • disassembly the starter motor, as shown. Starter motor inspection carbon brushes inspect the carbon brushes for abnormal wear, cracks, or smoothness in the brush holder. If any damages are found, replace the brush assembly with a new one. Commutator inspect the commutator fo...

Page 240

8-14 electrical system oil seal check the seal lip for damage or leakage. If any damages are found, replace the starter motor with a new one. Starter motor reassembly and remounting reassemble and remount the starter motor in the reverse order of removal and disassembly. Pay attention to the followi...

Page 241

Electrical system 8-15 • apply suzuki super grease “a” to the o-ring . 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (others) starter relay inspection • remove the seat. ( 7-4) • remove the fuel tank left side cover. ( 7-5) • disconnect the battery - lead wire at ba...

Page 242

8-16 electrical system measure the relay coil resistance between the terminals using the multi circuit tester. If the resistance is not within the specified value, replace the starter relay with a new one. 09900-25008: multi circuit tester set tester knob indication: resistance ( Ω ) starter relay r...

Page 243: Ignition System

Electrical system 8-17 ignition system troubleshooting spark plug ignition coil dc-dc converter ignition power source circuit wave form arrangment circuit cpu driver scr c cdi unit emergency switch (e-17) ignition switch fuse battery generator parking brake switch neutral relay neutral switch engine...

Page 244

8-18 electrical system measure the ignition coil primary peak voltage. ( 8-19) note: the ignition coil peak voltage inspection method is applicable only with the multi circuit tester and the peak volt adaptor. Inspect the ignition coil. ( 8-20) measure the pickup coil peak voltage and resistance. ( ...

Page 245

Electrical system 8-19 inspection ignition coil primary peak voltage • remove the fuel tank left side cover. ( 7-5) • remove the left front inner fender. ( 7-5) • remove the spark plug cap. • connect a new spark plug to spark plug cap and ground it to the cylinder head. Note: make sure that the spar...

Page 246

8-20 electrical system ignition coil resistance • remove the left front inner fender. ( 7-5) • disconnect the ignition coil lead wires and spark plug cap, and remove the ignition oil. Measure the ignition coil resistance in both the primary and sec- ondary windings using the multi circuit tester. If...

Page 247

Electrical system 8-21 • repeat the above procedure a few times and measure the highest pickup coil peak voltage. Tester knob indication: voltage ( ) pickup coil peak voltage: more than 4.0 v if the peak voltage measured on the cdi unit coupler is lower than the standard value, measure the peak volt...

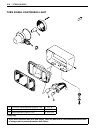

Page 248: Lamps

8-22 electrical system lamps headlight headlight bulb replacement • remove the socket covers ( 1 , 2 ). • remove the socket 3 . • remove the bulb. • install the new bulb in the reverse order of removal. Headlight beam adjustment • adjust the headlight vertical beam by loosening the screw 1 . Install...

Page 249

Electrical system 8-23 brake light/taillight bulb replacement • remove the socket. • remove the bulb. • install the new bulb in the reverse order of removal. Brake light/taillight: 12 v 21/5 w if you touch the bulb with your bare hands, clean the bulb with a cloth moistened with alcohol or soapy wat...

Page 250: Indicator Light

8-24 electrical system indicator light inspection indicator light position high beam indicator light (e-17) re hi nu bl/r o/bl bl/b b/w y steering stem head cover item + - re: reverse indicator light o/bl bl/r nu: neutral indicator light o/bl bl/b hi: high beam indicator light (e-17) y b/w y b/w bl/...

Page 251: Diode

Electrical system 8-25 diode • remove the fuel tank left side cover. ( 7-5) • remove the neutral switch diode. Measure the voltage between the terminals using the multi cir- cuit tester as indicated in the table below. 09900-25008: multi circuit tester set tester knob indication: diode test ( ) ✽ mo...

Page 252: Switches

8-26 electrical system switches measure each switch for continuity using a multi circuit tester. If any abnormality is found, replace the respective switch assemblies with a new one. 09900-25008: multi circuit tester set ignition switch dimmer switch engine stop switch starter button brake light lev...

Page 253: Battery

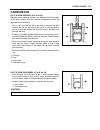

Electrical system 8-27 battery specifications a anode plates e stopper b separator (fiberglass plate) f filter c cathode plates g terminal d upper cover breather h safty valve initial charging filling electrolyte • remove the aluminum tape 1 which seals the battery filler holes 2 . • remove the caps...

Page 254

8-28 electrical system note: if air bubbles do not rise from any one of the filler ports, tap the bottom of the electrolyte container two or three times. Never remove the electrolyte container from the battery while there is still electrolyte in the container. • after the electrolyte container is co...

Page 255

Electrical system 8-29 servicing visually inspect the surface of the battery container. If any signs of cracking or electrolyte leakage from the sides of the battery have occurred, replace the battery with a new one. If the battery terminals are found to be coated with rust or an acidic white powder...

Page 257: Servicing Information

9 servicing information 9-1 contents servicing information troubleshooting ........................................................................ 9- 2 engine ........................................................................................9- 2 drive train ......................................