- DL manuals

- Suzuki

- Scooter

- AN650/A

- Supplementary Service Manual

Suzuki AN650/A Supplementary Service Manual

Summary of AN650/A

Page 1

9 9 5 0 1 - 3 6 1 6 0 - 0 1 e an650 / a use this manual with: an650 service manual (99500-36113-01e).

Page 2: An650/ak7 (’07-Model)

An650/ak7 (’07-model) 1 contents an650/ak7 (’07-model) © copyright suzuki motor corporation 2007 this manual describes service data, service specifications, fi and servicing procedures which differ from those of the an650/ak6 (’06-model). Note: • any differences between the an650/ak6 (’06-model) and...

Page 3: An650/ak7 (’07-Model)

2 an650/ak7 (’07-model) an650/ak7 (’07-model) country and area codes the following codes stand for the applicable country(-ies) and area(-s). Model code country or area effective frame no. An650 e-02 e-03 e-19 e-24 e-28 e-33 u.K. U.S.A. (except for california) e.U. Australia canada california (u.S.A...

Page 4: Specifications (An650K7)

An650/ak7 (’07-model) 3 specifications (an650k7) dimensions and dry mass overall length ..................................................................................... 2 260 mm (89.0 in) overall width....................................................................................... 810 mm...

Page 5

4 an650a/k7 (’07-model) capacities fuel tank, including reserve ............................................................... 15.0 l (4.0/3.3 us/imp gal) engine oil, oil change ......................................................................... 2 600 ml (2.7/2.3 us/imp qt) with filter change...

Page 6: Specifications (An650Ak7)

An650/ak7 (’07-model) 5 specifications (an650ak7) dimensions and dry mass overall length ..................................................................................... 2 260 mm (89.0 in) overall width....................................................................................... 810 m...

Page 7

6 an650a/k7 (’07-model) capacities fuel tank, including reserve ............................................................... 15.0 l (4.0/3.3 us/imp gal) engine oil, oil change ......................................................................... 2 600 ml (2.7/2.3 us/imp qt) with filter change...

Page 8: Sds Check

An650/ak7 (’07-model) 7 sds check using sds, sample the data at the time of new and periodic vehicle inspections. After saving the sampled data in the computer, file them by model and by user. The periodically filed data help improve the accuracy of troubleshooting since they can indicate the condit...

Page 9

8 an650a/k7 (’07-model) data at 3 000 r/min under no load data of manifold absolute pressure operation at the time of cold starting approx. 3 000 r/min check the manifold absolute pressure. Xx kpa check the engine coolant temperature. Xx ˚c check the engine r/min. Xxxx r/min check the manifold absol...

Page 10

An650/ak7 (’07-model) 9 data of intake negative pressure during idling (100 °c) data of manifold absolute pressure operation at the time of hot starting check the engine coolant temperature. Approx. 100 ˚c check the manifold absolute pressure. Xx kpa check the manifold absolute pressure. Xx kpa chec...

Page 11

10 an650a/k7 (’07-model) example of trouble three data; value 1 (current data 1), value 2 (past data 2) and value 3 (past data 3); can be made in compar- ison by showing them in the graph. Read the change of value by comparing the current data to the past data that have been saved under the same con...

Page 12: Fi System Wiring Diagram

An650/ak7 (’07-model) 11 fi system wiring diagram crankshaft position sensor(ckps) camshaft position sensor (cmps) combination meter fuel injector #1 fuel injector #2 ignition coil #2 ignition coil #1 m m 30 a 10 a 15 a 40 a *3 *2 ecm/pcm *1 *1 *1 fuel pump intake air pressure sensor (iaps) ambient ...

Page 13: Ecm/pcm Terminal

12 an650a/k7 (’07-model) ecm/pcm terminal ecm terminal no. Circuit k6 k7 1 ignition coil (ig2) ← 2 fuel injector (#1) ← 3 fuel injector (#2) ← 4 shift up switch (up) ← 5 pulley position sensor (pps) ← 6 ptvc heater (ptc) evap system purge control solenoid valve (e-33 only) 7 speed sensor (spd) ← 8 p...

Page 14

An650/ak7 (’07-model) 13 ecm terminal no. Circuit k6 k7 v — — w battery (batt) ← x — — y ground (e1) ← z ckp sensor (n-) ← [ cmp sensor (g+) ← \ ho2 sensor heater (oxh) ← ] immobilizer (txck) (for e-02, 19, 24) ← ^ immobilizer (rxck) (for e-02, 19, 24) ← a immobilizer led (meter) (for e-02, 19, 24) ...

Page 15

14 an650a/k7 (’07-model) fail-safe function fi system is provided with fail-safe function to allow the engine to start and the motorcycle to run in a mini- mum performance necessary even under malfunction condition. The engine can start and can run even if the above signal is not received from each ...

Page 16

An650/ak7 (’07-model) 15 malfunction code and defective condition dtc no. Detected item detected failure condition check for c00 no fault ––––––––––– ––––––––––– c40 (p0505) isc valve although current is flowing though the isc valve motor, the current detection is not possible. Isc valve circuit ope...

Page 17

16 an650a/k7 (’07-model) “c40” (p0505 or p0506 and p0507) isc valve circuit malfunction " inspection step 1 1) turn the ignition switch off. 2) remove the maintenance lid. ( #an650k3 9-13) 3) check the isc valve coupler 1 for loose or poor contacts. If ok, then check the isc valve lead wire continui...

Page 18

An650/ak7 (’07-model) 17 4) remove the front panel. ( #an650k3 9-8) 5) disconnect the isc valve coupler and ecm couplers. 6) check the continuity between terminals a (b/lg) and m, ter- minals b (p/w) and t, terminals c (g) and s, terminals d (w/b) and r. $ isc valve lead wire continuity: continuity ...

Page 19

18 an650a/k7 (’07-model) active control inspection (isc rpm control) check 1 1) place the motorcycle on the center stand. 2) pull the parking brake lever and make sure that the rear wheel is locked. 3) set up the sds tool. (refer to the sds operation manual for further details.) 4) check that the en...

Page 20

An650/ak7 (’07-model) 19 check 2 1) click the button 1 and decrease the “spec” 2 to 1 050 rpm slowly. 2) check that the “desired idle speed” 3 is nearly equal to the “spec” 2. At the same time, check that the number of steps 4 in the isc valve position decreases . Note: it takes a few seconds for “d...

Page 21

20 an650a/k7 (’07-model) check 4 1) increase the “spec” 1 to 1 500 rpm. 2) check that the “desired idle speed” 2 is approx. 1 500 rpm. 3) check that the “engine speed” 3 is close to 1 500 rpm. Note: be careful not to increase the “spec” to more than 1 600 rpm, or the “engine speed” may reach the upp...

Page 22

An650/ak7 (’07-model) 21 “c41” (p2505) ecm/pcm power input circuit malfunction " inspection step 1 (when indicating c41:) 1) turn the ignition switch off. 2) remove the front panel. ( #an650k3 9-8) 3) check the ecm couplers 1 for loose or poor contacts. If ok, then measure the ecm input voltage. 4) ...

Page 23

22 an650a/k7 (’07-model) is the voltage ok? 6) after repairing the trouble, clear the dtc using sds tool. (refer to the sds operation manual for further details.) yes • fuel pump related circuit malfunction. • r/bl wire open or shorted or poor terminal w connection. • battery voltage to ecm (batt) s...

Page 24

An650/ak7 (’07-model) 23 “c44” (p0130/p0135) ho2 sensor (ho2s) circuit malfunction " inspection step 1 (when indicating c44/p0130:) 1) turn the ignition switch off. 2) remove the footboard. ( #an650k3 9-18) 3) check the ho2 sensor coupler 1 for loose or poor contacts. If ok, then check the ho2 senso...

Page 25

24 an650a/k7 (’07-model) 7) remove the front panel. ( #an650k3 9-8) 8) disconnect the ecm coupler. 9) check the continuity between b/g wire a and terminal e. 10)also, check the continuity between b/br wire b and terminal n. $ ho2s lead wire continuity: continuity (%) ! 09900-25008: multi-circuit tes...

Page 26

An650/ak7 (’07-model) 25 is the voltage ok? 6) after repairing the trouble, clear the dtc using sds tool. (refer to the sds operation manual for further details.) step 1 (when indicating c44/p0135:) 1) turn the ignition switch off. 2) remove the footboard. ( #an650k3 9-18) 3) check the ho2 sensor co...

Page 27

26 an650a/k7 (’07-model) step 2 (when indicating c44/p0135:) 1) connect the ho2 sensor coupler. 2) insert the needle pointed probe to the ho2 sensor coupler. 3) turn the ignition switch on and measure the heater voltage between b (o/w) wire and ground. 4) if the tester voltage indicates the battery ...

Page 28

An650/ak7 (’07-model) 27 “c49” (p1656) pair control solenoid valve circuit malfunction inspection step 1 1) turn the ignition switch off. 2) remove the lower leg shield. ( #an650k3 9-10) 3) check the pair control solenoid valve coupler 1 for loose or poor contacts. If ok, then measure the pair contr...

Page 29

28 an650a/k7 (’07-model) step 2 1) turn the ignition switch on. 2) measure the voltage between o/w wire and ground. $ pair control solenoid valve voltage:battery voltage ( + o/w – - ground) ! 09900-25008: multi-circuit tester set ' tester knob indication: voltage (() is the voltage ok? 3) after repa...

Page 30

An650/ak7 (’07-model) 29 isc valve removal • remove the front box. ( #an650k3 9-18) • disconnect the isc valve coupler 1. " • remove the isc valve 2. Isc valve inspection • inspect the isc valve for carbon deposition or damage. • clean or replace the isc valve if necessary. Note: the isc valve can b...

Page 31

30 an650a/k7 (’07-model) isc valve pre-set when removing or replacing the isc valve, set the isc valve in the following procedures: 1) turn the ignition switch on. 2) set up the sds tool. (refer to the sds operation manual for further details.) 3) click “active control”. 4) click “isc learned value ...

Page 32

An650/ak7 (’07-model) 31 throttle valve synchronization check and adjust the throttle valve synchronization between two cylinders. Step 1 • remove the front box. ( #an650k3 9-18) • disconnect the respective vacuum hoses 1 from vacuum nip- ples. • disconnect the iap sensor coupler 2. • connect the re...

Page 33

32 an650a/k7 (’07-model) • click “active control”. • click “isc air volume control” 1. • click “on” 2 to fix the isc air volume of two cylinders. Note: when making this synchronization, be sure that the water tem- perature is within 80 – 100 °c (176 – 212 °f). A engine speed: approx. 1 200 rpm b isc...

Page 34

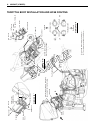

An650/ak7 (’07-model) 33 wiring harness, cable and hose routing wiring harness routing pass the each relay lead wire outside the parking brake cable. Center stand switch cvt revolution sensor pully position sensor cvt motor ho2 sensor ap sensor parking brake cable power source fuse fuse box clamp cl...

Page 35

34 an650a/k7 (’07-model) throttle body installation and hose routing fuel pump fix ed with clamp fuel f eed hose clamp a b isc hose pa ir hose a : the end of the clamp should f a ce .... B : the clamp scre w head should f a ce .... View of “b” ia t sensor ap sensor p a ir control solenoid v a lv e a...

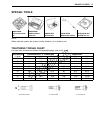

Page 36: Special Tools

An650/ak7 (’07-model) 35 special tools note: when order the special tool, please confirm whether it is available or not. Tightening torque chart for other nuts and bolts not listed in the preceding page, refer to this chart: 09900-25008 multi-circuit tester set 09900-25009 needle pointed probe set 0...

Page 37: Service Data (An650K7)

36 an650a/k7 (’07-model) service data (an650k7) valve + guide unit: mm (in) item standard limit valve diam. In. 29.5 (1.16) — ex. 25.0 (0.98) — tappet clearance (when cold) in. 0.10 – 0.20 (0.0039 – 0.0079) — ex. 0.20 – 0.30 (0.0079 – 0.0118) — valve guide to valve stem clearance in. 0.010 – 0.040 (...

Page 38

An650/ak7 (’07-model) 37 camshaft + cylinder head unit: mm (in) cylinder + piston + piston ring unit: mm (in) item standard limit cam height in. 35.38 – 35.43 (1.393 – 1.395) 35.10 (1.382) ex. 33.98 – 34.03 (1.338 – 1.340) 33.70 (1.327) camshaft journal oil clearance in. & ex. 0.032– 0.066 (0.0013 –...

Page 39

38 an650a/k7 (’07-model) conrod + crankshaft unit: mm (in) oil pump item standard limit piston ring thickness 1st 0.97 – 0.99 (0.038 – 0.039) — 2nd 0.97 – 0.99 (0.038 – 0.039) — piston pin bore 16.002 – 16.008 (0.6300 – 0.6302) 16.030 (0.6311) piston pin o.D. 15.995 – 16.000 (0.6297 – 0.6299) 15.980...

Page 40

An650/ak7 (’07-model) 39 clutch unit: mm (in) injector + fuel pump + fuel pressure regulator fi/cvt-sensors item standard limit drive plate thickness 2.92 – 3.08 (0.115 – 0.121) 2.62 (0.103) drive plate claw width 13.85 – 13.96 (0.545 – 0.550) 13.05 (0.514) driven plate no. 2 thickness 2.42 – 2.58 (...

Page 41

40 an650a/k7 (’07-model) throttle body thermostat + radiator + fan + coolant item specification note to sensor resistance 19.1 – 19.7 k Ω to sensor output voltage normal 0.4 – 1.4 v +: gr/r -: b/br leaning 3.7 – 4.4 v +: gr/r -: b/br ignition coil primary peak voltage more than 80 v (when cranking) ...

Page 42

An650/ak7 (’07-model) 41 electrical unit: mm (in) item standard/specification limit engine coolant type use an anti-freeze/coolant compatible with alumi- num radiator, mixed with distilled water only, at the ratio of 50:50. — engine coolant including reserve reverse tank side approx. 250 ml (0.264/0...

Page 43

42 an650a/k7 (’07-model) wattage unit: w brake + wheel unit: mm (in) item std/spec. E-02, 19 e-03, 24, 28, 33 headlight hi 60 + 55 60 × 2 lo 55 55 × 2 parking or position light 5 × 2 brake light/taillight 21/5 × 2 ← turn signal light 21 × 4 ← license plate light 5 ← instrument panel light 1.4 × 2 ← ...

Page 44

An650/ak7 (’07-model) 43 suspension unit: mm (in) tire item standard limit wheel rim runout axial — 2.0 (0.08) radial — 2.0 (0.08) wheel axle runout front — 0.25 (0.010) rear — 0.25 (0.010) wheel rim size front 15 m/c × mt3.50 — rear 14 m/c × mt4.50 — item standard limit front fork stroke 110 (4.3) ...

Page 45

44 an650a/k7 (’07-model) fuel + oil item specification note fuel type use only unleaded gasoline of at least 87 pump octane (r/2 + m/2) or 91 octane or higher rated by the research method. Gasoline containing mtbe (methyl tertiary butyl ether), less than 10% ethanol, or less than 5% methanol with ap...

Page 46: Service Data (An650Ak7)

An650/ak7 (’07-model) 45 service data (an650ak7) valve + guide unit: mm (in) item standard limit valve diam. In. 29.5 (1.16) — ex. 25.0 (0.98) — tappet clearance (when cold) in. 0.10 – 0.20 (0.0039 – 0.0079) — ex. 0.20 – 0.30 (0.0079 – 0.0118) — valve guide to valve stem clearance in. 0.010 – 0.040 ...

Page 47

46 an650a/k7 (’07-model) camshaft + cylinder head unit: mm (in) cylinder + piston + piston ring unit: mm (in) item standard limit cam height in. 35.38 – 35.43 (1.393 – 1.395) 35.10 (1.382) ex. 33.98 – 34.03 (1.338 – 1.340) 33.70 (1.327) camshaft journal oil clearance in. & ex. 0.032– 0.066 (0.0013 –...

Page 48

An650/ak7 (’07-model) 47 conrod + crankshaft unit: mm (in) oil pump item standard limit piston ring thickness 1st 0.97 – 0.99 (0.038 – 0.039) — 2nd 0.97 – 0.99 (0.038 – 0.039) — piston pin bore 16.002 – 16.008 (0.6300 – 0.6302) 16.030 (0.6311) piston pin o.D. 15.995 – 16.000 (0.6297 – 0.6299) 15.980...

Page 49

48 an650a/k7 (’07-model) clutch unit: mm (in) injector + fuel pump + fuel pressure regulator fi/cvt-sensors item standard limit drive plate thickness 2.92 – 3.08 (0.115 – 0.121) 2.62 (0.103) drive plate claw width 13.85 – 13.96 (0.545 – 0.550) 13.05 (0.514) driven plate no. 2 thickness 2.42 – 2.58 (...

Page 50

An650/ak7 (’07-model) 49 throttle body thermostat + radiator + fan + coolant item specification note to sensor resistance 19.1 – 19.7 k Ω to sensor output voltage normal 0.4 – 1.4 v +: gr/r -: b/br leaning 3.7 – 4.4 v +: gr/r -: b/br ignition coil primary peak voltage more than 80 v (when cranking) ...

Page 51

50 an650a/k7 (’07-model) electrical unit: mm (in) item standard/specification limit engine coolant type use an anti-freeze/coolant compatible with alumi- num radiator, mixed with distilled water only, at the ratio of 50:50. — engine coolant including reserve reverse tank side approx. 250 ml (0.264/0...

Page 52

An650/ak7 (’07-model) 51 wattage unit: w brake + wheel unit: mm (in) item std/spec. E-02, 19, 51 e-03, 24, 28, 33 headlight hi 60 + 55 60 × 2 lo 55 55 × 2 parking or position light 5 × 2 brake light/taillight 21/5 × 2 ← turn signal light 21 × 4 ← license plate light 5 ← instrument panel light 1.4 × ...

Page 53

52 an650a/k7 (’07-model) suspension unit: mm (in) tire item standard limit wheel rim runout axial — 2.0 (0.08) radial — 2.0 (0.08) wheel axle runout front — 0.25 (0.010) rear — 0.25 (0.010) wheel rim size front 15 m/c × mt3.50 — rear 14 m/c × mt4.50 — item standard limit front fork stroke 110 (4.3) ...

Page 54

An650/ak7 (’07-model) 53 fuel + oil item specification note fuel type gasoline used should be graded 91 octane or higher. An unleaded gasoline is recommended. Fuel tank capacity including reserve 15.0 l (4.0/3.3 us/lmp gal) fuel meter mark flickering approx. 3.0 l (0.79/0.66 us/lmp gal) fuel meter m...

Page 55

Wiring diagram an650k7 (e-02, 19) – sa mp le.

Page 56

An650k7 (e-24) – sa mp le.

Page 57

An650k7 (e-03, 28, 33) – sa mp le.

Page 58

An650ak7 (e-02, 19, 51) – sa mp le.

Page 59

An650ak7 (e-24) – sa mp le.

Page 60

An650ak7 (e-03, 28, 33) – sa mp le.

Page 61

Prepared by february, 2007 part no. 99501-36160-01e printed in japan 56 sa mp le.

Page 62

Printed in japan k7.