- DL manuals

- Suzuki

- Engine

- DF25 2006

- Rigging Manual

Suzuki DF25 2006 Rigging Manual

Summary of DF25 2006

Page 1

99518-03060-01e printed in japan tk 2006 rigging manual df25 -- df250 2006 rigging manu al df25 - - df250 9 9 5 1 8 - 0 3 0 6 0 - 0 1 e 1 1.

Page 2: Group Index

Group index uncrating 1 motor dimensions 2 motor installation 3 remote controls 4 control cable/wiring harness installation on engine side 5 drag link 6 accessories 7 fuel line 8 battery 9 propeller 10 pre-delivery 11 © copyright suzuki motor corporation 2006 foreword this rigging manual details the...

Page 3: How to Use This Manual

How to use this manual to locate what you are looking for: 1. The text of this manual is divided into sections. 2. The section titles are listed on the previous page in a group index. Select the section needed for reference. 3. Holding the manual as shown at the right will allow you to find the firs...

Page 4: General Information

General information warning/caution/note please read this manual and follow its instructions carefully. To emphasize special information, the symbol and the words warning, caution and note have special meanings. Pay special attention to the mes- sages highlighted by these signal words. Indicates a p...

Page 5: Uncrating

1 uncrating 1-1 contents uncrating uncrating procedures .......................................................................1- 2 df200/225/250 .......................................................................................1- 2 5 5.

Page 6: Uncrating Procedures

1-2 uncrating uncrating procedures df200/225/250 the following explains the uncrating procedures for models df200/225/250. The procedures are also applicable to other models packed with steel frame. Metal crates may have sharp edges and may cause injury. The operators should wear appropriate clothin...

Page 7

Uncrating 1-3 5. Remove the bolts d that tighten the steel frame shown with in the illustration at 8 places in total, right and left. 6. Lift the steel frame e by two or more opera- tors to remove it. 7. Remove styrofoam block f. Note: use a hook that has a lifting capacity of at least 450 kg. 8. Re...

Page 8

1-4 uncrating 11. Lift the outboard motor up close to upright position using a hoist or crane so that the end plate l of the base plate p may not be lifted off the floor. 12. Loosen three bolts m marked with in the illustration and remove the fixing bracket n. Make sure to perform this work with two...

Page 9: Lifting Engine

Uncrating 1-5 lifting engine moving the motor in a vertical position all three lifting eyes should be used after the engine has been removed from the crate and is in a vertical position. Do not use front lift eye when uncrating the engine the front lift eye is not designed nor intended to be used fo...

Page 10: Motor Dimensions

2 6 motor dimensions 2-1 contents motor dimensions motor dimensions ....................................................................................2- 2 df4/5/6 ...................................................................................................2- 2 df9.9/15 .........................

Page 11: Motor Dimensions

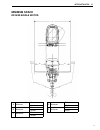

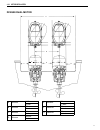

2-2 motor dimensions motor dimensions df4/5/6 unit: mm tilt 1st position: 0˚ tilt 2nd position: 4˚ tilt 3rd position: 8˚ tilt 4th position: 12˚ tilt 5th position: 16˚ shallow 1st position: 32˚ shallow 2nd position: 44˚ maximum tilt: 74˚ 11 11.

Page 12

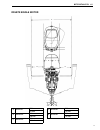

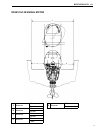

Motor dimensions 2-3 df9.9/15 unit: mm shallow drive 1st position: 27˚ 2nd position: 42˚ 315 315 160 163 12 12.

Page 13

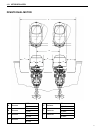

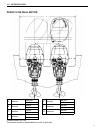

2-4 motor dimensions df25-v2, df25/30, df40/50, df60/70, df90/115/140, df150/175, df200/225/250 unit: mm l3 h4 h5 l5 l4 l2 l1 a1 a2 h3 h2 h1 w3 w1 a3 a4 w2 w4 13 13.

Page 14: Major Dimensions

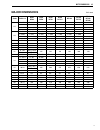

Motor dimensions 2-5 major dimensions unit: mm code df25-v2 df25 df30 df40 df50 df60 df70 df90 df115 df140 df150 df175 df200 df225 df250 h1 s: 117.5 s: 1 215 s: 1 263 l: 1 302.4 l: 1 342 l: 1 390 l: 1 493 l: 1 558 l: 1 611 l: 1 714 x: 1 396.4 x: 1 469 (ul) x: 1 620 (ul) x: 1 683 (ul) x: 1 738 (ul) x...

Page 15: Code Definition

2-6 motor dimensions code definition code definition and description a1 minimum angle from transom board and bracket clamp (transom angle) note: abyc recommends boat transom angle be 14° ± 2° a2 maximum tilt-up angle a3 maximum steering angle on stbd side from centerline of motor body a4 maximum ste...

Page 16: Motor Installation

3 6 motor installation 3-1 contents motor installation horsepower selection .........................................................................3- 2 clamp bracket dimensions ..................................................................3- 3 df4/5/6 .............................................

Page 17: Horsepower Selection

3-2 motor installation horsepower selection • states the maximum horsepower of outboard motor that can be safely used on that boat. There is severe product liability potential connected with rigging and selling a boat with an outboard motor exceeding the horsepower capacity limitation. • the rig sho...

Page 18: Clamp Bracket Dimensions

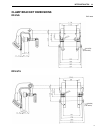

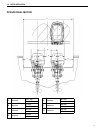

Motor installation 3-3 clamp bracket dimensions df4/5/6 unit: mm df9.9/15 (holes) (2 places) (holes) (2 places) 18 18.

Page 19

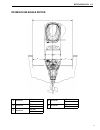

3-4 motor installation df25-v2 unit: mm df25/30, df40/50 (holes) (4 places) (holes) (8 places) 19 19.

Page 20

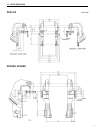

Motor installation 3-5 df60/70, df90/115 unit: mm df140 holes (10 places) holes (2 places) holes (2 places) holes (10 places) holes (2 places) holes (2 places) 20 20

Page 21

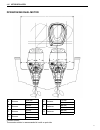

3-6 motor installation df150/175 unit: mm df200/225/250 holes (20 places) holes (20 places) 21 21.

Page 22: Minimum Space

Motor installation 3-7 minimum space df25/30 single motor a minimum 840 mm d minimum 230 mm 33 inch 9 inch b maximum 190 mm e minimum 230 mm 7.4 inch 9 inch c maximum 190 mm 7.4 inch a d e b c 22 22.

Page 23

3-8 motor installation df25/30 dual motor a minimum 1 401 mm e minimum 181 mm 55 inch 7.1 inch b minimum 561 mm f maximum 190 mm 22 inch 7.4 inch c minimum 230 mm g maximum 190 mm 9 inch 7.4 inch d minimum 230 mm 9 inch a d e f g b c f g 23 23.

Page 24

Motor installation 3-9 df40/50 single motor a minimum 838 mm d minimum 230 mm 33 inch 9 inch b maximum 189 mm e minimum 230 mm 7.4 inch 9 inch c maximum 189 mm 7.4 inch a d e b c 24 24.

Page 25

3-10 motor installation df40/50 dual motor a minimum 1 397 mm e minimum 181 mm 55 inch 7.1 inch b minimum 559 mm f maximum 189 mm 22 inch 7.4 inch c minimum 230 mm g maximum 189 mm 9 inch 7.4 inch d minimum 230 mm 9 inch a d e f g b c f g 25 25.

Page 26

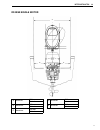

Motor installation 3-11 df60/70 single motor a minimum 838 mm d minimum 200 mm 33 inch 7.9 inch b maximum 219 mm e minimum 200 mm 8.6 inch 7.9 inch c maximum 219 mm 8.6 inch a d e b c 26 26.

Page 27

3-12 motor installation df60/70 dual motor a minimum 1 397 mm e minimum 121 mm 55 inch 4.8 inch b minimum 559 mm f maximum 219 mm 22 inch 8.6 inch c minimum 200 mm g maximum 219 mm 7.9 inch 8.6 inch d minimum 200 mm 7.9 inch a d e f g b c f g 27 27.

Page 28

Motor installation 3-13 df90/115/140 single motor a minimum 838 mm e minimum 179 mm 33 inch 7 inch b maximum 240 mm 9.4 inch c maximum 240 mm 9.4 inch d minimum 179 mm 7 inch a d e b c 28 28.

Page 29

3-14 motor installation df90/115/140 dual motor counter-rotation (df140) the counter-rotation is recommended to install on port-side a minimum 1 498 mm e minimum 180 mm 59 inch 7 inch b minimum 660 mm f maximum 240 mm 26 inch 9.4 inch c minimum 179 mm g maximum 240 mm 7 inch 9.4 inch d minimum 179 m...

Page 30

Motor installation 3-15 df200/225/250 single motor a minimum 940 mm d minimum 184 mm 37 inch 7.2 inch b maximum 286 mm e minimum 184 mm 11.3 inch 7.2 inch c maximum 286 mm 11.3 inch a d e b c 30 30

Page 31

3-16 motor installation df200/225/250 dual motor counter-rotation the counter-rotation is recommended to install on port-side a minimum 1 626 mm e minimum 114 mm 64 inch 4.5 inch b minimum 686 mm f maximum 286 mm 27 inch 11.3 inch c minimum 184 mm g maximum 286 mm 7.2 inch 11.3 inch d minimum 184 mm...

Page 32: Transom Centerline

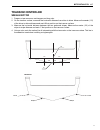

Motor installation 3-17 transom centerline single motor 1. Prepare a tape measure, marking pen and long ruler. 2. On the transom surface, measure the horizontal distance from chine to chine. Measure the center (1/2) of the chine-to-chine distance and mark b that position on the transom surface. 3. M...

Page 33

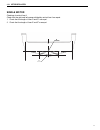

3-18 motor installation single motor checking of vertical line a. Check that the right and left spaces divided by vertical line a are equal. 1. Check that the length of lines d and d” are equal. 2. Check that the length of lines e and e” are equal. A d” e” d e b c 33 33.

Page 34

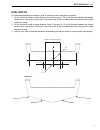

Motor installation 3-19 dual motor for the distance between the centers, refer to minimum space of the previous section. 1. On the horizontal chine-to-chine distance, mark b the point at 1/2 of the distance between the engine centers away from and on each side of the vertical line a that has been pr...

Page 35

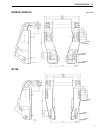

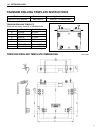

3-20 motor installation transom drilling template instructions transom drilling template there are two sizes, a and b, of the drilled hole. Transom drilling template dimensions unit: mm tool name part number applicable model transom drilling template 09914-89510 df25/30 – df200/225/250 hole name mod...

Page 36

Motor installation 3-21 df25/30, df40/50 bolt hole position unit: mm df60/70, df90/115, df140 bolt hole position df25/30, df40/50 clamp bracket df60/70, df90/115, df140 clamp bracket.

Page 37

3-22 motor installation df150/175 bolt hole position unit: mm df200/225/250 bolt hole position df150/175 clamp bracket df200/225/250 clamp bracket.

Page 38

Motor installation 3-23 use of transom drilling template 1. Get ready for a tape measure, water-based marking pen and long ruler. 2. On the transom surface, measure the horizontal distance from chine to chine. Measure the center (1/2) of the chine-to-chine distance and mark that position on the tran...

Page 39

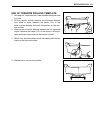

3-24 motor installation 6. Install the transom drilling template to transom board so that its center two holes are fitted to the vertical centerline a. 7. Adjust the height and horizontal position of transom drilling template with its wing bolts. 8. Tighten the transom clamp arm nut to secure the tr...

Page 40

Motor installation 3-25 9. Recheck the transom height from the upper edge of the tran- som board where there is a cutout of transom drilling tem- plate using a tape measure. • in other words, confirm the position of the anti-cavitation plate. 10. Drill the bolt holes into the transom board through t...

Page 41: Lifting Motor

3-26 motor installation lifting motor moving the motor in a vertical position all three lifting eyes should be used after the engine has been removed from the crate and is in a vertical position. Weight by model specification do not use front lift eye when uncrating the motor the front lift eye is n...

Page 42: Engine Mount

Motor installation 3-27 engine mount mounting to the transom df25v2 contained parts nut d: 40 n·m (4.0 kgf-m, 29.0 lb-ft) note: • clamp bracket top side of two bolt holes is optional. • drill the top holes at lest 25 mm(1.0 in) away from the transom top surface. • drill the mounting holes vertical...

Page 43

3-28 motor installation mounting to the transom df60/70, df90/115, df140 contained parts nut d: 55 n·m (5.5 kgf-m, 40.0 lb-ft) note: • drill the upper holes center at least 25 mm (1.0 in) away from the transom top surface. • install the large diameter washer b on the transom board side. • to ensur...

Page 44

Motor installation 3-29 six bolts to mount to the boat transom. nut d: 80 n·m (8.0 kgf-m, 58.0 lb-ft) note: • drill the mounting holes vertically to the transom board face. • drill the upper holes center at least 25 mm (1.0 in) down from the transom top surface. • to ensure a water-tightness, seal...

Page 45

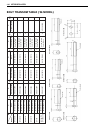

3-30 motor installation bolt transom table (’06 model) item model df25/30 df40/50 df60/70 df90/115 df140 df150/175 df200/225/250 09160-12044 09160-12044 09160-12044 09160-12044 09160-12044 09160-13017 4 4 4 4 4 6 09160-12110 09160-12110 09160-12110 09160-12110 09160-12110 09160-13016 4 4 4 4 4 6 091...