Summary of DL1000

Page 1

Dl1000

Page 2: Group Index

Group index general information 1 periodic maintenance 2 engine 3 fi system 4 cooling and lubrication system 5 chassis 6 electrical system 7 servicing information 8 emission control information 9 wiring diagram 10 © copyright suzuki motor corporation 2002 foreword this manual contains an introductor...

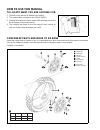

Page 3: How To Use This Manual

How to use this manual to locate what you are looking for: 1. The text of this manual is divided into sections. 2. The section titles are listed in the group index. 3. Holding the manual as shown at the right will allow you to find the first page of the section easily. 4. The contents are listed on ...

Page 4

Symbol listed in the table below are the symbols indicating instructions and other information necessary for servic- ing. The meaning of each symbol is also included in the table. Symbol definition symbol definition torque control required. Data beside it indicates specified torque. Apply thread loc...

Page 5: Manual

Abbreviations used in this manual a abdc : after bottom dead center ac : alternating current acl : air cleaner, air cleaner box api : american petroleum institute atdc : after top dead center atm pressure: atmospheric pressure atmospheric pressure sensor (aps) a/f : air fuel mixture b bbdc : before ...

Page 6

M mal-code : malfunction code (diagnostic code) max : maximum mil : malfunction indicator lamp (led) min : minimum n nox : nitrogen oxides o ohc : over head camshaft ops : oil pressure switch p pcv : positive crankcase ventilation (crankcase breather) r rh : right hand rom : read only memory s sae :...

Page 7: General Information

1 general information 1-1 contents general information warning/caution/note ...............................................................1- 2 general precautions ................................................................1- 2 suzuki dl1000k2 (’02-model) ..........................................

Page 8: Warning/caution/note

1-2 general information warning/caution/note please read this manual and follow its instructions carefully. To emphasize special information, the symbol and the words warning, caution and note have special meanings. Pay special attention to the mes- sages highlighted by these signal words. ! Indicat...

Page 9

General information 1-3 " * if parts replacement is necessary, replace the parts with suzuki genuine parts or their equiva- lent. * when removing parts that are to be reused, keep them arranged in an orderly manner so that they may be reinstalled in the proper order and orientation. * be sure to use...

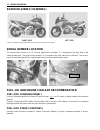

Page 10: Serial Number Location

1-4 general information suzuki dl1000k2 (’02-model) * difference between photographs and actual motorcycles depends on the markets. Serial number location the frame serial number or v.I.N. (vehicle identification number) 1 is stamped on the right side of the steering head pipe. The engine serial num...

Page 11

General information 1-5 engine oil use a premium quality 4-stroke motor oil to ensure longer ser- vice life of your motorcycle. Use only oils which are rated sf or sg under the api service classification. The recommended vis- cosity is sae 10w-40. If an sae 10w-40 motor oil is not avail- able, selec...

Page 12: Break-Ln Procedures

1-6 general information break-ln procedures during manufacture only the best possible materials are used and all machined parts are finished to a very high standard but it is still necessary to allow the moving parts to “break-in” before subjecting the engine to maximum stresses. The future performa...

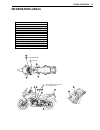

Page 13: Information Labels

General information 1-7 information labels 1 noise label (for e-03, 24, 33) 2 information label (for e-03, 28, 33) 3 ices canada label (for e-28) 4 vacuum hose routing label (for e-33) 5 fuel caution label (for e-02, 24) 6 manual notice label (for e-03, 33) 7 tire pressure label 8 warning safety lab...

Page 14: Specifications

1-8 general information specifications dimensions and dry mass overall length....................................................... 2 295 mm (90.4 in) overall width ........................................................ 865 mm (34.1 in) overall height.................................................

Page 15

General information 1-9 chassis front suspension................................................. Inverted telescopic, coil spring, oil damped rear suspension ................................................. Link type, coil spring, oil damped steering angle ............................................

Page 16: Country And Area Codes

1-10 general information country and area codes the following codes stand for the applicable country(-ies) and area(-s). Code country or area e-02 e-03 e-19 e-24 e-28 e-33 u. K. U. S. A. (except for california) eu australia canada california (u. S. A.).

Page 17: Periodic Maintenance

2 6 periodic maintenance 2-1 contents periodic maintenance periodic maintenance schedule ............................................2- 2 periodic maintenance chart ...........................................2- 2 lubrication points ...............................................................2- 3 ...

Page 18

2-2 periodic maintenance periodic maintenance schedule the chart below lists the recommended intervals for all the required periodic service work necessary to keep the motorcycle operating at peak performance and economy. Mileages are expressed in terms of kilome- ters, miles and time for your conve...

Page 19

Periodic maintenance 2-3 lubrication points proper lubrication is important for smooth operation and long life of each working part of the motorcycle. Major lubrication points are indicated below. Note: * before lubricating each part, clean off any rusty spots and wipe off any grease, oil, dirt or g...

Page 20: Cedures

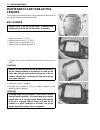

2-4 periodic maintenance maintenance and tune-up pro- cedures this section describes the servicing procedures for each item of the periodic maintenance requirements. Air cleaner • remove the seat. ( ! 6-4) • remove the fuel tank. ( ! 4-52) • remove the air cleaner box cap 1 . • remove the air cleane...

Page 21

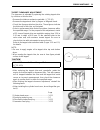

Periodic maintenance 2-5 note: when cleaning the air cleaner element, drain water from the air cleaner by removing the drain plug. Spark plug no.1 (front) spark plug removal • remove the spark plug mounting bolts a and b . • move the radiator forward. • remove the spark plug cap 1 . Note: be careful...

Page 22

2-6 periodic maintenance no.2 (rear) spark plug removal • remove the seat. ( ! 6-4) • lift and support the fuel tank. ( ! 4-51) • remove the spark plug cap. • remove the spark plug with a spark plug wrench. Heat range • check to see the heat range of the plug. Carbon deposit • check to see if there ...

Page 23

Periodic maintenance 2-7 spark plug and plug cap installation " • install the spark plugs to the cylinder heads by finger tight, and then tighten them to the specified torque. & spark plug: 11 n·m (1.1 kgf-m, 8.0 lb-ft) note: when fitting the spark plug caps, front and rear, face the triangle mark a...

Page 25

Periodic maintenance 2-9 tappet clearance adjustment the clearance is adjusted by replacing the existing tappet shim by a thicker or thinner shim. • remove the intake or exhaust camshafts. ( ! 3-20) • remove the tappet and shim by fingers or magnetic hand. • check the figures printed on the shim. Th...

Page 26

2-10 periodic maintenance (intake side).

Page 27

Periodic maintenance 2-11 (exhaust side).

Page 28

2-12 periodic maintenance fuel hose inspect the fuel feed hose a for damage and fuel leakage. If any defects are found, the fuel hoses must be replaced. Engine oil and oil filter oil should be changed while the engine is warm. Oil filter replacement at the above intervals, should be done together wi...

Page 29

Periodic maintenance 2-13 • start up the engine and allow it to run for several minutes at idling speed. • turn off the engine and wait about one minute, then check the oil level through the inspection window a . If the level is below mark “l”, add oil to “f” level. If the level is above mark “f”, d...