- DL manuals

- Suzuki

- Motorcycle

- DR 125

- Service Manual

Suzuki DR 125 Service Manual

Summary of DR 125

Page 1

Dr-z125/l 9 9 5 0 0 - 4 1 1 2 5 - 0 1 e.

Page 2: Group Index

Group index general information 1 periodic maintenance 2 engine 3 fuel and lubrication system 4 chassis 5 electrical system 6 servicing information 7 dr-z125/lk4 (’04-model) dr-z125/lk5 (’05-model) 8 dr-z125/lk6 (’06-model) dr-z125/lk7 (’07-model) 9 dr-z125/lk8 (’08-model) 10 foreword this manual co...

Page 3: How To Use This Manual

How to use this manual to locate what you are looking for: 1. The text of this manual is divided into sections. 2. The section titles are listed in the group index. 3. Holding the manual as shown at the right will allow you to find the first page of the section easily. 4. The contents are listed on ...

Page 4

Symbol listed in the table below are the symbols indicating instructions and other information necessary for servic- ing. The meaning of each symbol is also included in the table. Symbol definition symbol definition torque control required. Data beside it indicates specified torque. Apply thread loc...

Page 5: General Information

1 general information 1-1 contents general information warning/caution/note .............................................................. 1- 2 general precautions ................................................................ 1- 2 suzuki dr-z125/lk3 (’03-model) ......................................

Page 6: Warning/caution/note

1-2 general information warning/caution/note please read this manual and follow its instructions carefully. To emphasize special information, the symbol and the words warning, caution and note have special meanings. Pay special attention to the mes- sages highlighted by these signal words. ! Indicat...

Page 7

General information 1-3 " * if parts replacement is necessary, replace the parts with suzuki genuine parts or their equiv- alent. * when removing parts that are to be reused, keep them arranged in an orderly manner so that they may be reinstalled in the proper order and orientation. * be sure to use...

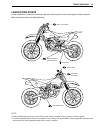

Page 8: Serial Number Location

1-4 general information suzuki dr-z125/lk3 (’03-model) serial number location the frame serial number or v.I.N. (vehicle identification number) 1 is stamped on the right side of the steering head pipe. The engine serial number 2 is located on the left side of the crankcase. These numbers are require...

Page 9: Break-Ln Procedures

General information 1-5 engine oil use a premium quality 4-stroke motor oil to ensure longer ser- vice life of your motorcycle. Use only oils which are rated sf or sg under the api service classification. The recommended viscosity is sae 10w-40. If an sae 10w-40 motor oil is not available, select an...

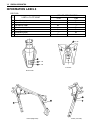

Page 10: Information Labels

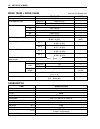

1-6 general information information labels label or plate name no applied specification e-28 e-03 1 noise label — ¡ 2 information label — ¡ 3 fuel caution label ¡ — 4 manual notice label — ¡ 5 warning safety label ¡ ¡ 6 certification plate — ¡ 7 compliance label ¡ — dr-z125/l frame (left side) frame...

Page 11: Specifications

General information 1-7 specifications dimensions and dry mass overall length ...................................................... 1 835 mm (72.2 in) 1 885 mm (74.2 in) ....... Dr-z125l overall width ....................................................... 770 mm (30.3 in) overall height .............

Page 12

1-8 general information chassis front suspension ................................................. Telescopic, coil spring, oil damped, rear suspension .................................................. Link type, coil spring, oil damped, front suspension stroke.........................................

Page 13

General information 1-9 country and area codes the following codes stand for the applicable countries and areas. Code country or area e-03 e-28 usa canada.

Page 14: Periodic Maintenance

2 6 periodic maintenance 2-1 contents periodic maintenance periodic maintenance schedule ............................................2- 2 periodic maintenance chart ...........................................2- 2 lubrication points ...............................................................2- 3 ...

Page 15

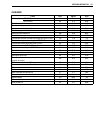

2-2 periodic maintenance periodic maintenance schedule the chart below lists the recommended intervals for all the required periodic service work necessary to keep the motorcycle operating at peak performance and economy. Note: more frequent servicing may be performed on motorcycles that are use und...

Page 16

Periodic maintenance 2-3 lubrication points proper lubrication is important for smooth operation and long life of each working part of the motorcycle. Major lubrication points are indicated below. Note: * before lubricating each part, clean off any rusty spots and wipe off any grease, oil, dirt or g...

Page 17

2-4 periodic maintenance maintenance and tune-up procedures this section describes the servicing procedures for each item in the periodic maintenance chart. Air cleaner if the air cleaner is clogged with dust, intake resistance will be increase, resulting in a decrease in engine output and an increa...

Page 18

Periodic maintenance 2-5 • remove the drain plug 1 to allow any water to drain out. • reinstall the cleaned air cleaner element in the reverse order of removal. ! ! Valve clearance removal • remove the frame covers, seat and fuel tank. ( "5-2) • remove the spark plug. ( "2-7) • remove the valve insp...

Page 19

2-6 periodic maintenance note: * the piston must be at (tdc) on the compression stroke in order to check the valve clearance or to adjust valve clear- ance. * the clearance specification is for cold state. * to turn the crankshaft for clearance checking, rotate in the nor- mal running direction. The...

Page 20

Periodic maintenance 2-7 note: if the cam chain is noisy after having been adjusted, the push rod is probably sticking. Remove the cam chain tension adjuster, clean and lubricate the push rod to obtain smooth movement and proper tensioning action. Spark plug • disconnect the spark plug cap 1 and rem...

Page 21

2-8 periodic maintenance " • tighten the spark plug to the using the special tool. # 09930-10121: spark plug wrench set throttle cable play throttle cable play a should be 2.0 – 4.0 mm (0.08 – 0.16 in) as measured at throttle grip when turning the throttle grip lightly. If the play a is incorrect, a...

Page 22

Periodic maintenance 2-9 • connect the electric tachometer or the multi circuit tester to the high-tension cord. • start the engine and set the engine idle speed between 1 600 and 1 800 r/min by turning the throttle stop screw 1. $ engine idle speed: 1 700 ± 100 r/min # 09900-26006: tachometer, or 0...

Page 23

2-10 periodic maintenance engine oil and oil filter engine oil replacement • place an oil pan below the engine. Drain oil by removing the engine oil drain plug 1 1 1 1. • remove the oil filter cap 2. • tighten the engine oil drain plug 1 to the specified torque. Pour new oil through the oil filler h...

Page 24

Periodic maintenance 2-11 oil filter replacement • drain the engine oil as described in the engine oil replace- ment procedure. • remove the oil filter cap 1 and oil filter 2. • replace the oil filter with a new one. • install the spring 3 correctly. • apply engine oil lightly to the o-ring 4 and 5....

Page 25

2-12 periodic maintenance • remove the spark arrester. • remove carbon deposits from the spark arrester by using a brush. • inspect the spark arrester for damage. If any defects are found, replace the spark arrester with a new one. Drive chain visually inspect the drive chain for the possible defect...

Page 26

Periodic maintenance 2-13 • place the motorcycle on the side-stand. • loosen or tighten both chain adjusters 1 until the chain has 35 – 40 mm (1.4 – 1.6 in) of slack at the middle of the chain between the engine and rear sprockets as shown. The refer- ence marks 2 must be at the same position on the...

Page 27

2-14 periodic maintenance front brake lever play (dr-z125) • turn the adjusting nuts 1 so that the brake lever play a is within specification. $ front brake lever play a a a a : 15 – 25 mm (0.6 – 1.0 in) front disc brake (dr-z125l) brake pads the extent of brake pad wear can be checked by observing ...

Page 28

Periodic maintenance 2-15 air bleeding the brake fluid circuit air trapped in the brake fluid circuit acts like a cushion to absorb a large proportion of the pressure developed by the master cyl- inder and thus interferes with the full braking performance of the brake caliper. The presence of air is...

Page 29

2-16 periodic maintenance front brake lever play check the front brake lever play. If the play is out of specifica- tions, loosen the lock nut 1 and turn the adjuster 2 to obtain the specified play. $ front brake lever play: 0.1 – 0.3 mm (0.004 – 0.012 in) rear brake pedal height • loosen the lock n...

Page 30

Periodic maintenance 2-17 brake shoe wear (rear brake) this motorcycle is equipped with the brake lining wear limit indi- cator on the rear brake. To check wear of the brake lining, perform the following steps. • first, check if the brake system is properly adjusted. • while operating the brake, che...

Page 31

2-18 periodic maintenance tire tread condition operating the motorcycle with excessively worn tires will decrease riding stability and consequently invite a dangerous situation. It is highly recommended to replace a tire when the remaining depth of the tire tread reaches the following specifica- tio...

Page 32

Periodic maintenance 2-19 exhaust pipe bolts and muffler mounting bolt cylinder head nuts, when they are not tightened to the specified torque, may result in leakage of the compressed mixture and reduce output. • tighten the exhaust pipe bolts and muffler mounting bolt to the specified torque. & exh...

Page 33

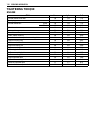

2-20 periodic maintenance chassis bolts and nuts check that all chassis bolts and nuts are tightened to their specified torque. (refer to page 2-21 for the loca- tions of the following bolts and nuts on the motorcycle.) tighten initially at 1 month and every 6 months thereafter. Item n·m kgf-m lb-ft...

Page 34

Periodic maintenance 2-21.

Page 35: Compression Pressure Check

2-22 periodic maintenance compression pressure check the compression pressure reading of a cylinder is a good indicator of its internal condition. The decision to overhaul the cylinder is often based on the results of a compression test. Periodic mainte- nance records kept at your dealership shoud i...

Page 36: Oil Pressure Check

Periodic maintenance 2-23 oil pressure check check the engine oil pressure periodically. This will give a good indication of the condition of the moving parts. ! Oil pressure: low or high oil pressure can indicate any of the following conditions: low oil pressure * clogged oil filter * oil leakage f...

Page 37: Engine

3 6 engine 3-1 contents engine engine components removable with engine in place ...3- 2 engine left side .....................................................................3- 2 engine right side ..................................................................3- 2 engine center .....................

Page 38

3-2 engine engine components removable with engine in place the parts listed below can be removed and reinstalled without removing the engine from the frame. Refer to the pages listed in each section for removal and reinstallation instructions. Engine left side engine right side engine center parts ...

Page 39

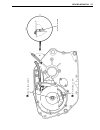

Engine 3-3 engine removal and reinstallation engine removal • remove the seat. ( ! 5-2) • remove the fuel tank. ( ! 4-2) • remove the carburetor. ( ! 4-5) • drain engine oil. ( ! 2-10) • disconnect the plug cap. • remove the exhaust pipe bolts. • remove the muffler connecting bolt 1 and mounting bol...

Page 40

3-4 engine • remove the gearshift cam lever. • loosen the rear axle nut 1 and chain adjuster nuts 2 (left and right). Make sure that the drive chain has enough slack. • remove the engine sprocket 3. Note: when loosening the engine sprocket bolt, depress the brake pedal. • remove the clutch release a...

Page 41

Engine 3-5 • remove the rear engine mounting nut and bolt. • remove the front engine mounting bolts and bracket. • remove the upper engine mounting bolts and bracket. Note: when removing the upper mounting bolts and nuts, support the engine with a jack. • remove the swingarm pivot nut and washer. • ...

Page 42

3-6 engine engine reinstallation reinstall the engine in the reverse order of engine removal. • install the engine mounting bolts and nuts as shown in the following illustration. • tighten the engine mounting nuts to the specified torque. Note: the engine mounting nuts are self-locking. Once the nut...

Page 43

Engine 3-7 • install the clutch release arm as shown in the illustration. Note: align the release arm slit surface a with the notch mark b on the release camshaft. • install the engine sprocket with drive chain as shown. # • tighten the engine sprocket bolt to the specified torque. " engine sprocket...

Page 44

3-8 engine • tighten the muffler mounting bolts 1, clamp bolt 2 and exhaust pipe bolts 3 to the specified torque. ! Muffler mounting bolt 1:23 n·m (2.3 kgf-m, 16.5 lb-ft) muffler connecting bolt 2:23 n·m (2.3 kgf-m, 16.5 lb-ft) exhaust pipe bolt 3:11 n·m (1.1 kgf-m, 8.0 lb-ft) • position the carbure...

Page 45

Engine 3-9 engine disassembly the procedure for engine disassembly is sequentially explained in the following steps. • remove the spark plug. & 09930-10121: spark plug wrench set kick starter lever • remove the kick starter lever. • remove the timing inspection plug 1 and generator cover plug 2. • r...

Page 46

3-10 engine cam chain tension adjuster • remove the cam chain tension adjuster 1. Camshaft • remove the camshaft end cap 2. • flatten the lock washer and remove the camshaft sprocket bolts. • remove the camshaft 3 and camshaft sprocket 4. # • remove the c-ring 6. # cylinder head • remove the cylinde...

Page 47

Engine 3-11 • remove the cylinder head bolts diagonally. • remove the cylinder head. Note: if the cylinder head does not come off, lightly tap on the finless portion of it with a plastic hammer. Cylinder • remove the gasket 1. • remove the cam chain guide 2. • remove the cylinder by removing the nut...

Page 48

3-12 engine clutch cover • remove the clutch cover. Clutch • while holding the generator rotor nut, remove the clutch spring mounting bolts in a crisscross pattern, and remove the clutch springs and clutch pressure plate 1. • remove the clutch drive and driven plates. • remove the washer 2, bearing ...

Page 49

Engine 3-13 • remove the washer and primary driven gear assembly 1. • remove the spacer 2 and washer. Gearshift • remove the kick starter drive gear 3 and waher. • remove the gearshift shaft 4. • remove the pawl lifter 5 and cam guide 6. • remove the gearshift cam driven gear 7. Note: when removing ...

Page 50

3-14 engine • remove the pin 1. • remove the oil pump 2. # primary drive gear • flatten the lock washer of the primary drive gear nut. • remove the primary drive gear/oil pump drive gear nut with the special tool. & 09930-40113: rotor holder # • remove the oil pump drive gear 3 and primary drive gea...

Page 51

Engine 3-15 generator rotor • remove the generator rotor nut with the special tools. & 09930-40113: rotor holder • remove the generator rotor with the special tools. & 09930-30161: rotor remover attachment 09930-30102: sliding shaft generator stator • remove the generator stator 1. Cam chain • remov...

Page 52

3-16 engine • remove the gearshift cam stopper. • remove the crankcase bolts. • separate the left and right crankcases with the special tool. & 09920-13120: crankcase separator note: * fit the crankcase separator, so that the tool arms are in paral- lel with the side of crankcase. * the crankshaft a...

Page 53

Engine 3-17 • remove the driveshaft and countershaft. • remove the gearshift cam stopper 1. Crankshaft • remove the crankshaft with the special tool. & 09920-13120: crankcase separator.

Page 54

3-18 engine engine components inspection and service cylinder head cover # disassembly • remove the inspection caps 1. • remove the rocker arm shaft bolts 2. • remove the rocker arm shafts 3. • remove the rocker arms 4 and wave washers 5. Cylinder head cover distortion after removing sealant from th...

Page 55

Engine 3-19 rocker arm i.D. Measure the inside diameter of the rocker arm and check the wear of the camshaft contacting surface. $ rocker arm i.D. Standard (in. & ex.): 12.000 – 12.018 mm (0.4724 – 0.4731 in) & 09900-20605: dial calipers reassembly reassemble the cylinder head cover in the reverse o...

Page 56

3-20 engine cylinder head # disassembly • remove the cam chain tensioner 1. • remove the intake pipe 2. • compress the valve spring with the special tools. & 09916-14510: valve lifter 09916-14910: valve lifter attachment • remove the valve cotters 1 from the valve stem. & 09916-84511: tweezers • rem...

Page 57

Engine 3-21 • remove the valve from the combustion chamber side. • remove the valve stem seal 1. • remove the valve spring seat 2. Cylinder head distortion decarbon the combustion chamber. Check the gasket surface of the cylinder head for distortion using a straightedge and thickness gauge. Take cle...

Page 58

3-22 engine valve head radial runout place the dial gauge at a right angle to the valve head face and measure the valve head radial runout. If it measures more than the service limit, replace the valve. $ valve head radial runout service limit: 0.03 mm (0.001 in) & 09900-20606: dial gauge (1/100 mm)...

Page 59

Engine 3-23 • re-finish the valve guide holes in the cylinder head using the special tools. & 09916-34561: valve guide reamer (11.3 mm) 09916-34542: handle note: insert the reamer from the combustion chamber side and always turn the reamer handle clockwise. • oil the stem hole of each valve guide an...

Page 60

3-24 engine valve seat service the valve seats for both intake and exhaust valves are machined to two different angles. (the seat contact surface is cut at 45°.) & 09916-21111: valve seat cutter set 09916-24480: solid pilot (n-140-5.5) 09916-24900: valve seat cutter set note: use the solid pilot (n-...

Page 61

Engine 3-25 initial seat cut • using the 45° cutter, descale and clean up the seat. Rotate the cutter one or two turns. • measure the valve seat width w after every cut. • if the valve seat is pitted or burned, use the 45° cutter to con- dition the seat some more. Note: cut only the minimum amount n...

Page 62

3-26 engine # note: after servicing the valve seats, be sure to check the valve clear- ance after the cylinder head has been reinstalled. ( ! 2-7) valve seat sealing condition inspection with the valve and valve spring assembled, pour a small quan- tity of gasoline into the intake or exhaust port. C...

Page 63

Engine 3-27 $ valve spring tension (in. & ex.) standard inner : 76 – 90 n/32.5 mm (7.8 – 9.2 kgf/32.5 mm, 17.2 – 20.3 lbs/1.28 in) outer: 186 – 219 n/36.0 mm (18.9 – 22.3 kgf/36.0 mm, 41.7 – 49.2 lbs/1.42 in) reassembly reassemble the cylinder head in the reverse order of disassem- bly. Pay attentio...

Page 64

3-28 engine • install the valve spring retainer 1, press down the spring using the valve lifter and then install the cotter halves onto the valve stem end. Then, release the valve lifter to allow the cot- ters 2 to wedge between the retainer and the valve stem. Be sure that the rounded lip 3 of the ...

Page 65

Engine 3-29 camshaft camshaft inspection if the engine produces abnormal noises, vibration or lacks power, a camshaft may be distorted or worn to the service limit. The camshaft runout should be checked. Also, check the cams and journals for wear or damage. Cam wear worn-down cams are often the caus...

Page 66

3-30 engine if the camshaft journal oil clearance exceeds the limit, measure the inside diameter of the camshaft journal holder and outside diameter of the camshaft journal. Replace the camshaft or the cylinder head depending upon which one exceeds the specifica- tion. ! Camshaft journal holder i.D....

Page 67

Engine 3-31 cylinder bore measure the cylinder bore diameter at six places. If any one of the measurements exceed the limit, overhaul the cylinder and replace the piston with an oversize piston, or replace the cylinder. $ cylinder bore service limit: 57.110 mm (2.2484 in) & 09900-20508: cylinder gau...

Page 68

3-32 engine $ piston ring groove width standard 1st : 1.21 – 1.23 mm (0.047 – 0.048 in) 2nd : 1.21 – 1.23 mm (0.047 – 0.048 in) oil : 2.51 – 2.53 mm (0.099 – 0.110 in) $ piston ring thickness standard 1st : 1.175 – 1.190 mm (0.0463 – 0.0469 in) 2nd : 1.170 – 1.190 mm (0.0461 – 0.0469 in) note: remov...

Page 69

Engine 3-33 oversize rings oversize piston ring the following oversize piston ring is used. It bears the following identification number. Piston ring 1st and 2nd 0.5 mm: 50 oversize oil ring the following oversize oil ring is used. It bears the following identification mark. Oil ring 0.5 mm: painted...

Page 70

3-34 engine crankshaft and conrod conrod small end i.D. Measure the conrod small end inside diameter using the dial cal- ipers. If the conrod small end inside diameter exceeds the ser- vice limit, replace the conrod. $ conrod small end i.D. Service limit: 14.040 mm (0.5528 in) & 09900-20605: dial ca...

Page 71

Engine 3-35 conrod deflection and conrod big end side clearance wear on the big end of the conrod can be estimated by checking the movement of the small end of the rod. This method can also check the extent of wear on the parts of the conrod’s big end. $ conrod deflection service limit: 3.0 mm (0.12...

Page 72

3-36 engine transmission disassembly • disassemble the transmission gears as shown in the illustration. Note: when removing the 2nd drive gear, use a gear puller and a proper attachment. Reassembly assemble the countershaft and driveshaft in the reverse order of disassembly. Pay attention to the fol...

Page 73

Engine 3-37 • when installing a new snap ring, pay attention to the direction of the snap ring. Fit the snap ring to the side where the thrust is as shown in the illustration. The rounded side should be against the gear surface. • press fitted 2nd drive gear onto the countershaft. Before reassem- bl...

Page 74

3-38 engine gearshift forks measure the gearshift fork clearance in the groove of its respec- tive gear using the thickness gauge. The clearance for each of the two gearshift forks plays an impor- tant role in the smoothness and positiveness of the shifting action. Each fork has its prongs fitted in...

Page 75

Engine 3-39 clutch clutch drive plates measure the thickness and claw width of the clutch drive plates using vernier calipers. If a clutch drive plate is not within the ser- vice limit, replace the clutch plates as a set. $ clutch drive plate thickness service limit: 2.6 mm (0.102 in) & 09900-20101:...

Page 76

3-40 engine oil filter • remove the oil filter cap 1. • remove the oil filter 2 and install a new one. Note: before installing the new oil filter and oil filter cap, make sure that the spring 3 and new o-rings ( 4 , 5 ) are installed cor- rectly. • applyb engine oil to the o-ring 4 and 5. • install ...

Page 77

Engine 3-41 kick starter removal • remove the snap ring 1. • remove the spring guide 2. • remove the kick starter shaft return spring 3. & 09900-06107: snap ring pliers • remove the kick starter shaft 4, kick starter 5, spring 6 and washer 7. 1 kick starter lever 2 kick starter drive gear 3 kick sta...

Page 78

3-42 engine reassembly reassemble the kick starter in the reverse order of removal. Pay attention to the following points. • aligh the punch mark a on the kick starter 1 with the punch mark b on the kick starter shaft 2. • insert the kick starter shaft into the crankcase. • engage the kick starter 1...

Page 79

Engine 3-43 crankcase bearings bearing inspection while the bearing is in the crankcase, rotate its inner race and check to see that it turns smoothly. If it does not turn quietly and smoothly, or if there are signs of any abnormalities, the bearing is defective and must be replaced as follows. Bear...

Page 80

3-44 engine crankshaft bearing installation • install the crankshaft bearings with the special tool. & 09913-70210: bearing installer set driveshaft bearing installation • install the driveshaft bearings using the special tool. & 09913-70210: bearing installer set • install the washer 1. • apply a s...

Page 81

Engine 3-45 • install the bearing retainer 1. Note: apply a small quantity of thread lock “1342” to the bearing retainer screws. ! 99000-32050: thread lock “1342” clutch release camshaft removal • remove the oil seal retainer 1. • remove the clutch release camshaft 2. Reassembly • install the clutch...

Page 82: Engine Reassembly

3-46 engine engine reassembly reassemble the engine in the reverse order of disassembly. The following steps require special attention or precautionary measures should be taken. Note: apply engine oil to each running and sliding part before reassembling. Crankshaft • when installing the crankshaft i...

Page 83

Engine 3-47 note: two kinds of gearshift forks ( a, b) are used. They resemble each other very closely in external appearance and configura- tion. Carefully examine the illustration for correct installing posi- tions and directions. Note: position the gearshift cam as shown so that the gearshift for...

Page 84

3-48 engine • tighten the crankcase bolts to the specified torque. ! Crankcase bolt: 10 n·m (1.0 kgf-m, 7.0 lb-ft) note: * after the crankcase bolts have been tightened, make sure that the crankshaft, countershaft and driveshaft rotate smoothly. * if these shafts do not rotate smoothly, try to free ...

Page 85

Engine 3-49 • install the generator stator. • generator rotor • install the generator rotor securely. • tighten the generator rotor nut to the specified torque with the special tool. ! 09930-40113: rotor holder " generator rotor nut: 55 n·m (5.5 kgf-m, 40.0 lb-ft) • install the kick starter idle gea...

Page 86

3-50 engine • install the washer and primary drive gear/oil pump drive gear nut. Note: this nut 1 has left hand threads. • tighten the primary drive gear/oil pump drive gear nut 1 to the specified torque with the special tool. & 09930-40113: rotor holder " primary drive gear/oil pump drive gear nut:...

Page 87

Engine 3-51 • install each pawl into the gearshift cam driven gear. 1 gearshift pawl 2 pin 3 spring 4 gearshift cam driven gear note: the large shoulder a must face to the outside. • install the gearshift cam driven gear assembly. • install the pawl lifter 5 and cam guide 6. Note: apply a small quan...

Page 88

3-52 engine clutch • install the washer 1 and spacer 2 onto the countershaft. Note: apply engine oil to the inside and outside surfaces of the spacer. • install the primary driven gear assembly 3 and washer 4 onto the countershaft. Note: when engaging the primary drive and driven gears, turn the pri...

Page 89

Engine 3-53 • install the clutch sleeve hub nut, and tighten it to the specified torque with the special tool. ! Clutch sleeve hub nut: 50 n·m (5.0 kgf-m, 36.0 lb-ft) " 09920-53740: clutch sleeve hub holder • bend the lock washer 1 securely. • install the clutch push rod 2 as shown in the illustrati...

Page 90

3-54 engine clutch cover • install the two dowel pins and new gasket 1. • tighten the clutch cover bolts and oil filter cap nut securely. # generator cover • install the new gasket 1. • install the generator cover 2 and tighten the bolts securely. Install the new gasket washer to the bolt a ..

Page 91

Engine 3-55 piston/piston ring • first, install a spacer 1 into the oil ring groove and then install the two side rails 2. The spacer and side rails do not have a specific top or bottom when they are new. When reassem- bling used parts, install them in their original place and direc- tion. # • insta...

Page 92

3-56 engine the followings are reminders for piston installation: • before installing the piston pin, apply molybdenum oil solution onto its surface. • apply engine oil to the big and small ends of the conrod. • place a clean rag over the cylinder base to prevent the piston pin circlip from dropping...

Page 93

Engine 3-57 cylinder head • install the dowel pins into the cylinder and then install the cyl- inder head gasket 1 onto the cylinder. ! • place the cylinder head onto the cylinder. • cylinder head bolts and washers must be installed correctly as shown in the photograph. A long bolt + copper washer b...

Page 95

Engine 3-59 • bend the lock washer securely. 1 camshaft 2 pin 3 bolt 4 lock washer 5 camshaft sprocket cylinder head cover • pour engine oil in each oil pocket in the cylinder head. • install the camshaft end cap 1. • clean the mating surfaces of the cylinder head and head cover. • install the dowel...

Page 96

3-60 engine • tighten the cylinder head cover bolts to the specified torque with a torque wrench diagonally. $ cylinder head cover bolt: 10 n·m (1.0 kgf-m, 7.0 lb-ft) ! ! Cam chain tension adjuster install the cam chain tension adjuster following the procedure below. • after loosening the locknut 1,...

Page 97

2 4 6 fuel and lubrication system 4-1 contents fuel and lubrication system fuel tank ..........................................................................................4- 2 fuel tank removal ..............................................................4- 2 fuel valve ...........................

Page 98: Fuel Tank

4-2 fuel and lubrication system fuel tank fuel tank removal • remove the frame covers and seat. ( !5-2) • turn the fuel valve to “off” position and disconnect the fuel hose 1 from the fuel valve. • remove the fuel tank. " gasoline is highly flammable and explosive. Keep heat, spark and flame away..

Page 99: Fuel Valve

Fuel and lubrication system 4-3 fuel valve fuel valve/fuel filter removal • remove the seat. ( !5-2) • remove the fuel tank. ( !4-2) • remove the fuel valve by removing the mounting bolts. " fuel filter inspection and cleaning if the fuel filter is dirty with sediment or rust, fuel will not flow smo...

Page 100: Carburetor

4-4 fuel and lubrication system carburetor construction 1 plate 2 throttle valve return spring 3 jet needle 4 starter plunger 5 throttle valve 6 main air jet 7 pilot air jet 8 diaphragm 9 throttle stop screw 0 o-ring a washer b spring c pilot screw d pilot jet e needle jet f main jet holder g plate ...

Page 101

Fuel and lubrication system 4-5 specifications e-03: usa e-28: canada i.D. No. Location carburetor has i.D. Number 1 printed on the carburetor body according to its specification. Removal • remove the seat. ( !5-2) • turn the fuel valve to “off” position. • remove the fuel tank. ( !4-2) • disconnect...

Page 102

4-6 fuel and lubrication system disassembly • remove the throttle valve 1 and spring 2. • remove the carburetor top cap 3. • remove the float chamber body 4. • remove the float assembly 5 by removing the float pin 6. Note: remove the float assembly together with the needle valve. $ • remove the need...

Page 103

Fuel and lubrication system 4-7 • remove the main jet holder 1, valve seat 2 and pilot jet 3. A main jet 1 main jet holder 2 valve seat 3 pilot jet • slowly turn the pilot screw 4 in clockwise and count the num- ber of turns until the screw is lightly seated. Make a note of how many turns were made ...

Page 104

4-8 fuel and lubrication system • remove the starter plunger. $ cleaning " • clean all jets with a spray-type carburetor cleaner and blow dry with compressed air. • clean all circuits of the carburetor thoroughly - not just the perceived problem area. Clean the circuits in the carburetor body with a...

Page 105

Fuel and lubrication system 4-9 inspection check following items for any damage or clogging. * pilot jet * needle valve * main jet * main air jet * gasket and o-ring * pilot air jet * throttle valve * needle jet air bleeding hole * pilot outlet and by-pass needle valve inspection if foreign matter i...

Page 106: Engine Lubrication System

4-10 fuel and lubrication system engine lubrication system engine lubrication system chart oil pump oil filter crankshaft cylinder wall conrod small end by-pass primary driven gear spacer countershaft and gears countershaft left side bearing oil sump filter cam faces rocker arm shafts conrod big end...

Page 107: Oil Pressure

Fuel and lubrication system 4-11 oil pressure ( !2-23) oil filter ( !2-10) oil sump filter ( !3-41) note: when separating the crankcase, wash the oil sump filter with cleaning solvent, and then blow compressed air through it to dry off solvent..

Page 108: Chassis

5 chassis 5-1 contents chassis exterior parts .............................................................................5- 2 removal .................................................................................... 5- 2 remounting ..................................................................

Page 109: Exterior Parts

5-2 chassis exterior parts removal frame covers • remove the frame covers 1 and 2. Seat • remove the frame covers. • remove the bolts a (left and right). • remove the seat 1. Fuel tank covers • remove the tank covers 1 and 2. Front number plate • pull out the fuel vent hose and untie the belt. • rem...

Page 110

Chassis 5-3 front wheel and front brake (dr-z125) removal • loosen the front brake adjusting nut 1. • remove the front brake cable 2. • remove the cotter pin 3 and front axle nut 4. • raise the front wheel off the ground with a jack or wooden block. • remove the front wheel with the front brake pane...

Page 111

5-4 chassis • remove the front brake panel 1. • remove the brake shoes 2 from the brake panel. • remove the brake cam lever bolt and nut. • remove the brake cam lever 3. • remove the spring 4, washer 5, o-ring 6 and brake cam- shaft 7..

Page 112

Chassis 5-5 inspection and disassembly tire ......................................................................... !2-17 spoke nipples..................................................... !2-18 wheel bearings inspect the play a of the wheel bearings by hand while they are in the wheel. Rotate the...

Page 113

5-6 chassis brake drum inspect the brake drum and measure the brake drum i.D. To determine the extent of wear. Replace the brake drum if the measurement exceeds the service limit. The value of this limit is indicated inside the brake drum. " 09900-20102: venier calipers $ brake drum i.D. Service lim...

Page 114

Chassis 5-7 • install the new o-ring 1, washer 2 and spring 3. • install the brake cam lever as shown. • tighten the brake cam lever nut to the specified torque. & brake cam lever nut: 11 n·m (1.1 kgf-m, 8.0 lb-ft) • apply suzuki super grease “a” to the brake cam and pin, and install the brake shoes...

Page 115: Front Wheel (Dr-Z125L)

5-8 chassis front wheel (dr-z125l) removal • remove the cotter pin 1. • remove the front axle nut 2. • raise the front wheel off the ground with a jack or wooden block. • remove the front axle shaft and front wheel. ! 1 bearing 2 spacer 3 bearing 4 brake disc 5 front axle a front axle nut b brake di...

Page 116

Chassis 5-9 inspection and disassembly tire ........................................................................... "2-17 spoke nipples....................................................... "2-18 wheel bearings ................................................... "5- 5 axle shaft ..................

Page 117: Front Brake (Dr-Z125L)

5-10 chassis front brake (dr-z125l) ' # 1 caliper holder 2 caliper 3 brake pad 4 shim 5 spring 6 dust seal 7 piston seal 8 piston 9 cap 0 diaphragm a master cylinder b brake hose a brake caliper mounting bolt b air bleeder valve c master cylinder mounting bolt d brake hose adapter e brake hose union...

Page 118

Chassis 5-11 brake pad replacement removal • remove the brake caliper 1. • remove the brake pads 2 and shim by removing the brake pad mounting pin 3. # installation • remont the brake pad mounting pin 1. • install the pin 2. • tighten the brake caliper mounting bolts to the specified torque. & brake...

Page 119

5-12 chassis brake fluid replacement • place the motorcycle on a level surface and keep the handle- bars straight. • remove the master cylinder reservoir cap and diaphragm. • remove as much old brake fluid as possible. • fill the reservoir with new brake fluid. ) specification and classification: do...

Page 120

Chassis 5-13 • remove the brake pads and shim. ( ! 5-11) • remove the brake caliper holder. • remove the spring 1. • place a rag over the brake caliper piston to prevent it from popping out, and then force out the piston using compressed air. # • remove the dust seal 2 and piston seal 3. # brake cal...

Page 121

5-14 chassis brake caliper reassembly and remounting reassemble and remount the brake caliper in the reverse order of removal and disassembly. Pay attention to the following points: • wash the caliper bore and piston with the specified brake fluid. Thoroughly wash the dust seal groove and piston sea...

Page 122

Chassis 5-15 • install the brake pads and shim. ( !5-11) • tighten the brake caliper mounting bolts 1, brake hose union bolt 2 to the specified torque. & brake caliper mounting bolt: 23 n·m (2.3 kgf-m, 16.5 lb-ft) brake hose union bolt: 23 n·m (2.3 kgf-m, 16.5 lb-ft) note: before remounting the brak...

Page 123

5-16 chassis master cylinder removal and disas- sembly • remove the brake lever cover 1. • place a rag underneath the brake hose union bolt 2 on the master cylinder to catch any spilt brake fluid. Loosen the brake hose union bolt and disconnect the brake hose. # • remove the master cylinder assembly...

Page 124

Chassis 5-17 • pull out the dust seal boot 1 and remove the snap ring 2. " 09900-06108: snap ring pliers • remove the washer 3, piston 4 and spring 5. Master cylinder inspection master cylinder inspect the master cylinder bore for any scratches or damage. If any damages are found, replace the master...

Page 125

5-18 chassis # ) specification and classification: dot4 • when remounting the master cylinder on the handlebars, align the master cylinder holder’s mating surface 1 with the punched mark 2 on the handlebars, and then tighten the upper clamp bolt first. & master cylinder mounting bolt: 23 n·m (2.3 kg...

Page 126: Front Fork

Chassis 5-19 front fork removal and disassembly • remove the front brake cable. (dr-z125) • remove the brake caliper. (dr-z125l) • remove the front wheel. ( ! 5-3 or -8) # • loosen the upper and lower clamp bolts. • pull down the front fork assembly. 1 o-ring 2 front fork spring 3 damper rod 4 inner...

Page 127

5-20 chassis • remove the boot. # • remove the cap bolt and spring. • invert the fork and stroke it several times to drain out the fork oil. Under this condition (inverted condition), hold the fork for a few minutes. • remove the damper rod bolt 1. • remove the damper rod 2. Replace the removed boot...

Page 128

Chassis 5-21 • remove the oil seal stopper ring. • slowly pull out the inner tube. • remove the oil lock piece 1. • remove the oil seal 2, oil seal retainer 3, outer tube antifric- tion metal 4 and inner tube antifriction metal 5. # the outer and inner tube’s antifriction metals must be replaced alo...

Page 129

5-22 chassis inspection fork spring measure the fork spring free length. If the fork spring free length is shorter than the service limit, replace the fork spring with a new one. $ front fork spring free length service limit: 587 mm (23.1 in) inner and outer tube inspect the inner tube sliding surfa...

Page 130

Chassis 5-23 • insert the oil lock piece, inner tube and damper rod into the outer tube and install the oil seal by using the special tool. " 09940-52861: front fork oil seal installer set • install the oil seal stopper ring. # damper rod bolt • apply a small quantity of thread lock 1342 to the thre...

Page 131

5-24 chassis • install the spring as shown. • tighten the front fork cap bolt to the specified torque. & front fork cap bolt: 23 n·m (2.3 kgf-m, 16.5 lb-ft) • install the boot. • tighten the upper clamp bolt 1 to the specified torque. • tighten the lower clamp bolt 2 to the specified torque. & front...

Page 132: Steering

Chassis 5-25 steering removal and disassembly • remove the front number plate. ( ! 5-2) • remove the front fender. ( ! 5-2) • remove the front wheel. ( ! 5-3 or -8) • remove the front brake lever. (dr-z125) • remove the front brake master cylinder and brake caliper. (dr-z125l) • remove the front for...

Page 133

5-26 chassis • remove the clutch lever holder 1 and engine stop button 2. • remove the throttle grip case 3 and grip. • remove the handlebars 4. • remove the steering stem upper bracket 5 by removing the steering stem head nut. • remove the steering stem nut 6 by using the special tool. " 09940-1493...

Page 134

Chassis 5-27 inspection inspect the removed parts for the following abnormalities. If any damages are found, replace the respective part with a new one. * steering race wear and brinelling * bearing wear or damage * abnormal bearing noise * distortion of steering stem or handlebars • remove the stee...

Page 135

5-28 chassis • apply suzuki super grease ‘‘a’’ to the steering stem upper and lower bearings. ! 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (others) steering stem nut • tighten the steering stem nut to the specified torque by using the special tools. " 09940-14930...

Page 136

Chassis 5-29 • set the throttle grip case to match its mating face to the punched mark 1 on the handlebars. • apply suzuki super grease “a” to the end of throttle cables. % 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (others) • set the clutch lever holder to match...

Page 137

5-30 chassis note: hold the front fork legs, move them back and forth and make sure that the steering is not loose. # after performing the adjustment and installing the handlebars, “rock” the front wheel assembly forward and backward to ensure that there is no play and that the procedure was accompl...

Page 138: Rear Wheel And Rear Brake

Chassis 5-31 rear wheel and rear brake removal • remove the rear brake adjusting nut 1. • loosen the chain adjuster nuts 2 (right and left). • remove the cotter pin 3 and the rear axle nut 4. • raise the rear wheel off the ground with a jack or wooden block. • remove the rear axle 5. • disengage the...

Page 139

5-32 chassis • remove the rear brake panel 1. • remove the rear sprocket 2. • remove the brake shoes 3 from the brake panel. • remove the brake cam lever 4. • remove the washer 5, o-ring 6 and brake camshaft 7..

Page 140

Chassis 5-33 inspection and disassembly tire ......................................................................... !2-17 spoke nipples ....................................................... ! 2-18 wheel bearings...................................................... ! 5- 5 axle shaft ..............

Page 141

5-34 chassis rear wheel • tighten the rear axle nut to the specified torgue. & rear axle nut: 45 n·m (4.5 kgf-m, 32.5 lb-ft) • install the new cotter pin. • adjust the drive chain slack after installing the rear wheel. ( !2-12) • adjust the rear brake pedal free travel. ( ! 2-16).

Page 142

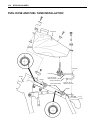

Chassis 5-35 rear swingarm and suspension 1 rear shock absorber 2 rear cushion rod 3 rear cushion lever 4 swingarm 5 drive chain case 6 chain buffer 7 chain guide a rear shock absorber mounting bolt b rear shock absorber mounting nut c swingarm pivot nut d cushion lever bolt (front) e cushion lever ...

Page 143

5-36 chassis removal • remove the rear wheel. ( ! 5-31) • remove the chain guide 1. • remove the right frame cover. ( ! 5-2) • remove the rear shock absorber upper mounting bolt 2. • remove the cushion lever nut 3 and bolt. • remove the swingarm pivot nut 4 and shaft. • remove the swingarm assembly....

Page 144

Chassis 5-37 • remove the cushion rod nut 1 and bolt. • remove the cushion lever nut 2 and bolt. Inspection and disassembly spacers • remove the dust seal covers, washers and spacers from the swingarm, cushion lever and cushion rod. Inspect the spacers for any flaws or other damage. If any dam- ages...

Page 145

5-38 chassis • remove the swingarm bushings by using the special tools. " 09923-74510: bearing remover 09930-30102: sliding shaft # swingarm inspect the swingarm for damage. If any damages are found, replace the swingarm with a new one. Needle bearings • remove the dust seals. " 09913-50121: oil sea...

Page 146

Chassis 5-39 insert the spacers into the needle bearings, move the spacer up and down check for any play. If there is excessive play, replace the bearing with new ones. • remove the needle bearings by using the special tools. " 09923-73210: bearing remover 09930-30102: sliding shaft # chain buffer i...

Page 147

5-40 chassis rear shock absorber inspect the rear shock absorber and bushing for damage and oil leakage. If any damages are found, replace the rear shock absorber with a new one. # swingarm pivot shaft measure the pivot shaft runout using the dial gauge. If the runout exceeds the service limit, repl...

Page 148

Chassis 5-41 note: press the bearing at 4.0 mm (0.16 in) depth from the cushion lever and rod edge. Needle bearings • apply suzuki super grease “a” to the spacers and nee- dle bearings before installing. % 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (others) • pre...

Page 149

5-42 chassis • tighten the swingarm pivot nut to the specified torque. & swingarm pivot nut: 65 n·m (6.5 kgf-m, 47.0 lb-ft) after installing the rear wheel, adjust the following before riding. Drive chain.......................................................... !2-12 tire..............................

Page 150

Chassis 5-43 rear shock absorber disposal ' gas pressure release • mark the drill hole with a center punch. • cover the rear shock absorber with a transparent plastic bag 1. • hold the shock absorber 2 with a vice. • make a hole with a drill. ' * the rear shock absorber unit contains high-pressure n...

Page 151: Electrical System

6 electrical system 6-1 contents electrical system cautions in servicing ................................................................6- 2 connectors ............................................................................6- 2 couplers ............................................................

Page 152: Cautions In Servicing

6-2 electrical system cautions in servicing connectors • when disconnecting a connector, be sure to hold the termi- nals; do not pull the lead wires. • when connecting a connector, push it in so it is firmly attached. • inspect the connector for corrosion, contamination and any breakage in the cover...

Page 153

Electrical system 6-3 using the multi circuit tester • properly use the multi circuit tester + and - probes. Improper use can cause damage to the vehicle and tester. • if the voltage and current values are not known, begin mea- suring in the highest range. • when measuring the resistance, make sure ...

Page 154: Ignition System

6-4 electrical system ignition system description the ignition system is shown in the diagram below. Troubleshooting g/b b/y b/w b/bl b b/r g/b b/y b/w b/bl b b/r generator engine stop switch spark plug cdi unit.

Page 155

Electrical system 6-5 inspection ignition coil primary peak voltage • remove the fuel tank. ( !4-2) • remove the spark plug cap and spark plug. • connect a new spark plug to spark plug cap and ground it to the cylinder head. Note: make sure that the spark plug cap and spark plug are connected proper...

Page 156

6-6 electrical system • shift the transmission into neutral. • kick the kick starter lever and allow the engine to crank for a few times, and then measure the ignition coil primary peak voltage. • repeat the above procedure a few times and measure the highest ignition coil primary peak voltage. Note...

Page 157

Electrical system 6-7 pick-up coil peak voltage note: make sure all of the couplers are connected properly. • disconnect the wire harness coupler 1. Measure the pick-up coil peak voltage in the following proce- dure. • connect the multi circuit tester with the peak volt adaptor as follows. Pick-up c...

Page 158

6-8 electrical system stator coil resistance • remove the fuel tank. • disconnect the stator coil lead wire coupler 1. Measure the resistance between the two lead wires using the multi circuit tester. If the resistance is not within the specified value, replace the stator coil with a new one. Also, ...

Page 159: Servicing Information

7 servicing information 7-1 contents servicing information troubleshooting ........................................................................ 7- 2 engine ........................................................................................ 7- 2 carburetor ......................................

Page 160: Troubleshooting

7-2 servicing information troubleshooting engine complaint symptom and possible causes remedy engine will not start or is hard to start. Compression too low 1. Worn cylinder. 2. Worn piston ring. 3. Worn valve guide or improper valve seating. 4. Loose spark plug. 5. Broken, cracked, or damaged pisto...

Page 161

Servicing information 7-3 complaint symptom and possible causes remedy engine is noisy. Excessive valve chatter 1. Excessive valve clearance. 2. Weak or broken valve spring. 3. Worn camshaft. 4. Worn or burnt camshaft journal. Noise seems to come from the piston 1. Worn piston. 2. Worn cylinder. 3. ...

Page 162

7-4 servicing information complaint symptom and possible causes remedy transmission jumps out of gear. 1. Worn gear. 2. Worn or distorted gearshift fork. 3. Weakened gearshift stopper spring. 4. Worn gearshift pawl. Replace. Replace. Replace. Replace. Engine idles poorly. 1. Valve clearance out of a...

Page 163

Servicing information 7-5 carburetor complaint symptom and possible causes remedy engine overheats. 1. Carbon buildup on piston crown. 2. Insufficient amount of engine oil. 3. Defective oil pump. 4. Clogged oil circuit. 5. Float chamber fuel level too low. 6. Air leakage from intake pipe. 7. Incorre...

Page 164

7-6 servicing information chassis complaint symptom and possible causes remedy steering is heavy. 1. Overtightened steering stem nut. 2. Broken bearing in steering stem. 3. Distorted steering stem. 4. Low tire pressure. Adjust. Replace. Replace. Regulate. Handlebar wobbles. 1. Loss of balance betwee...

Page 165

Servicing information 7-7 brakes complaint symptom and possible causes remedy brake power insuffi- cient. 1. Worn brake shoe. 2. Oil in brake shoe surfaces. 3. Excessively worn brake drum. 4. Excessive brake lever/pedal play. Replace. Clean. Replace. Adjust. Brake power insuffi- cient. (dr-z125l) 1....

Page 166

7-8 servicing information electrical complaint symptom and possible causes remedy no sparking or poor sparking. 1. Defective ignition coil. 2. Defective spark plug. 3. Defective generator. 4. Defective cdi unit. Replace. Replace. Replace. Replace. Spark plug is wet or quickly becomes fouled with car...

Page 167: Wiring Diagram

Servicing information 7-9 wiring diagram.

Page 168

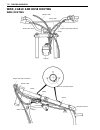

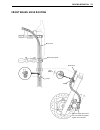

7-10 servicing information wire, cable and hose routing wire routing throttle cable front brake cable clutch cable engine stop switch lead wire clamp cdi unit clamp clamp clamp clamp throttle cable engine stop switch lead wire clutch cable face the clamp end down. Gnerator lead wire.

Page 169

Servicing information 7-11 gener ator lead wire 5 n . M (0.5 kgf-m, 3.7 lb-ft) @ 55 n . M (5.5 kgf-m, 40 lb-ft) @ 90˚.

Page 170

7-12 servicing information cable routing front brake cable front brake cable clamp clamp wire harness face the circlip end down. Clutch cable clutch cable throttle cable steering stem upper bracket.

Page 171

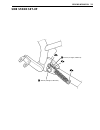

Servicing information 7-13 brake hose brake hose guide clamp 1 mm (0.04 in) brake hose clamp after the brake hose union has contacted the stopper, tighten the union bolt. Front brake hose routing.

Page 172

7-14 servicing information fuel valve face the clamp end down. Face the clamp end outside. @ 4.4 n.M (0.44 kgf-m, 3.0 lb-ft) frame cut the clamp end after tightening. Face the clamp end to the right. Fuel hose and fuel tank mounting.

Page 173: Side Stand Set-Up

Servicing information 7-15 55 n.M (5.5 kgf-m, 40.0 lb-ft) @ 50 n.M (5.0 kgf-m, 36.0 lb-ft) @ side stand set-up.

Page 174

7-16 servicing information carburetor installation/hose routing f ace the clip end to the to the r ight side . Air v ent hose breather hose air v ent hose carb uretor o v erflo w hose view a p ass the air v ent hose betw een the fr ame and engine co v e r. Clamp clamp aa air v ent hose breather hose...

Page 175: Special Tools

Servicing information 7-17 special tools 09900-00401 hexagon wrench set 09900-00410 hexagon wrench set 09900-06107 snap ring pliers 09900-06108 snap ring pliers 09900-09004 impact driver set 09900-20101 vernier calipers 09900-20102 vernier calipers 09900-20202 micrometer (25 – 50 mm) 09900-20203 mic...

Page 176

7-18 servicing information 09910-34510 piston pin puller 09913-50121 oil seal remover 09913-70210 bearing installer set 09915-63310 adaptor 09915-64510 compression gauge set 09915-70610 adaptor 09915-74510 oil pressure gauge set 09916-10911 valve lapper set 09916-14510 valve lifter 09916-14910 attac...

Page 177

Servicing information 7-19 note: when ordering a special tool, please confirm whether it is available or not. 09924-84521 bearing installer set 09925-18011 steering bearing installer 09930-10121 spark plug wrench set 09930-30102 sliding shaft 09930-40113 rotor holder 09940-14930 steering stem nut so...

Page 178: Tightening Torque

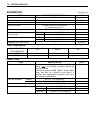

7-20 servicing information tightening torque engine item n·m kgf-m lb-ft cylinder head cover bolt 10 1.0 7.0 spark plug 11 1.1 8.0 cylinder head bolt initial 10 1.0 7.0 final 27 2.7 19.5 cylinder nut 10 1.0 7.0 primary drive gear nut 50 5.0 36.0 generator rotor nut 55 5.5 40.0 clutch sleeve hub nut ...

Page 179

Servicing information 7-21 chassis item n·m kgf-m lb-ft front axle nut (dr-z125) 35 3.5 25.5 (dr-z125l) 44 4.4 32.0 front fork cap bolt 23 2.3 16.5 front fork damper rod bolt 20 2.0 14.5 front fork lower clamp bolt 33 3.3 24.0 front fork upper clamp bolt 29 2.9 21.0 steering stem head nut 90 9.0 65....

Page 180

7-22 servicing information tightening torque chart for other nuts and bolts not listed in the preceding page, refer to this chart: bolt diameter a a a a (mm) conventional or “4” marked bolt “7” marked bolt n·m kgf-m lb-ft n·m kgf-m lb-ft 4 1.5 0.15 1.0 2.3 0.23 1.5 5 3 0.3 2.0 4.5 0.45 3.0 6 5.5 0.5...

Page 181: Service Data

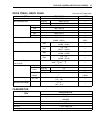

Servicing information 7-23 service data 4 stroke valve + guide unit: mm (in) item standard limit valve diam. In. 30 (1.2) — ex. 26 (1.0) — valve clearance (when cold) in. 0.08 – 0.13 (0.003 – 0.005) — ex. 0.13 – 0.18 (0.005 – 0.007) — valve guide to valve stem clearance in. 0.010 – 0.037 (0.0004 – 0...

Page 182

7-24 servicing information camshaft + cylinder head unit: mm (in) item standard limit cam height in. & ex. 33.13 – 33.17 (1.304 – 1.306) 32.83 (1.293) camshaft journal oil clearance in. & ex. 0.032 – 0.066 (0.0013 – 0.0026) 0.150 (0.0059) camshaft journal holder i.D. In. & ex. 22.012 – 22.025 (0.866...

Page 183

Servicing information 7-25 cylinder + piston + piston ring unit: mm (in) item standard limit compression pressure 1 200 – 1 600 kpa (12 – 16 kgf/cm 2 , 171 – 228 psi) 1 000 kpa (10 kgf/cm 2 , 142 psi) piston-to-cylinder clearance 0.020 – 0.030 (0.0008 – 0.0012) 0.120 (0.0047) cylinder bore 57.000 – ...

Page 184

7-26 servicing information conrod + crankshaft unit: mm (in) oil pump clutch unit: mm (in) item standard limit conrod small end i.D. 14.004 – 14.012 (0.5513 – 0.5517) 14.040 (0.5528) conrod deflection — 3.0 (0.12) conrod big end side clearance 0.10 – 0.45 (0.004 – 0.018) 1.0 (0.04) conrod big end wi...

Page 185

Servicing information 7-27 drive train + drive chain unit: mm (in) except ratio carburetor item standard limit primary reduction ratio 3.470 (59/17) — final reduction ratio dr-z125 3.642 (51/14) — dr-z125l 4.071 (57/14) — gear ratios low 3.000 (33/11) — 2nd 1.857 (26/14) — 3rd 1.368 (26/19) — 4th 1....

Page 186

7-28 servicing information electrical item specification e-03, 28 main jet (m.J.) #102.5 jet needle (j.N.) 5hgm74-1 needle jet (n.J.) n-6m throttle valve (th.V.) #2.5 pilot jet (p.J.) #17.5 pilot screw (p.S.) pre-set (2 ! Turns back) throttle cable play 2.0 – 4.0 mm (0.08 – 0.16 in) item specificati...

Page 187

Servicing information 7-29 brake + wheel unit: mm (in) item standard/specification limit brake lever play dr-z125 15 – 25 (0.6 – 1.0) — dr-z125l 0.1 – 0.3 (0.004 – 0.012) — rear brake pedal free travel 20 – 30 (0.8 – 1.2) — rear brake pedal height -10 – 0 (-0.4 – 0) — brake drum i.D. Rear — 110.7 (4...

Page 188

7-30 servicing information suspension unit: mm (in) tire pressure fuel + oil item standard/specification limit front fork stroke 180 (7.1) — front fork spring free length — 587 (23.1) front fork oil level 173.0 (6.81) — front fork oil type suzuki fork oil ss-08 (#10) or an equivalent fork oli — fron...

Page 189: Dr-Z125/lk5 (’05-Model)

2 4 6 8 dr-z125/lk4 (’04-model) and dr-z125/lk5 (’05-model) 8-1 contents dr-z125/lk5 (’05-model) this chapter describes service specifications, service data and servicing procedures which dif- fer from those of the dr-z125/lk3 (’03-model). Note: * any differences between the dr-z125/lk3 (’03-model) ...

Page 190: Specifications

8-2 dr-z125/lk4 (’04-model) and dr-z125/lk5 (’05-model) specifications dimensions and dry mass overall length ...................................................................................... 1 835 mm (72.2 in) 1 885 mm (74.2 in)..........Large wheel overall width .................................

Page 191: Service Data

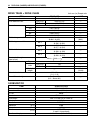

Dr-z125/lk4 (’04-model) and dr-z125/lk5 (’05-model) 8-3 service data valve + guide unit: mm (in) item standard limit valve diam. In. 30 (1.2) — ex. 26 (1.0) — valve clearance (when cold) in. 0.08 – 0.13 (0.003 – 0.005) — ex. 0.13 – 0.18 (0.005 – 0.007) — valve guide to valve stem clearance in. 0.010...

Page 192

8-4 dr-z125/lk4 (’04-model) and dr-z125/lk5 (’05-model) camshaft + cylinder head unit: mm (in) item standard limit cam height in. & ex. 33.13 – 33.17 (1.304 – 1.306) 32.83 (1.29) camshaft journal oil clearance in. & ex. 0.032 – 0.066 (0.0013 – 0.0026) 0.150 (0.0059) camshaft journal holder i.D. In. ...

Page 193

Dr-z125/lk4 (’04-model) and dr-z125/lk5 (’05-model) 8-5 cylinder + piston + piston ring unit: mm (in) item standard limit compression pressure 1 200 – 1 600 kpa (12 – 16 kgf/cm 2 , 171 – 228 psi) 1 000 kpa (10 kgf/cm 2 , 142 psi) piston to cylinder clearance 0.020 – 0.030 (0.0008 – 0.0012) 0.120 (0....

Page 194

8-6 dr-z125/lk4 (’04-model) and dr-z125/lk5 (’05-model) conrod + crankshaft unit: mm (in) oil pump clutch unit: mm (in) item standard limit conrod small end i.D. 14.004 – 14.012 (0.5513 – 0.5517) 14.040 (0.5528) conrod deflection — 3.0 (0.12) conrod big end side clearance 0.10 – 0.45 (0.004 – 0.018)...

Page 195

Dr-z125/lk4 (’04-model) and dr-z125/lk5 (’05-model) 8-7 drive train + drive chain unit: mm (in) except ratio carburetor item standard limit primary reduction ratio 3.470 (59/17) — final reduction ratio dr-z125 3.642 (51/14) — dr-z125l 4.071 (57/14) — gear ratios low 3.000 (33/11) — 2nd 1.857 (26/14)...

Page 196

8-8 dr-z125/lk4 (’04-model) and dr-z125/lk5 (’05-model) electrical item specification e-03, 28 main jet (m.J.) #102.5 jet needle (j.N.) 5hgm74-1 needle jet (n.J.) n-6m throttle valve (th.V.) #2.5 pilot jet (p.J.) #17.5 pilot screw (p.S.) pre-set (2 and 1/4 turns back) throttle cable play 2.0 – 4.0 m...

Page 197

Dr-z125/lk4 (’04-model) and dr-z125/lk5 (’05-model) 8-9 brake + wheel unit: mm (in) item standard/specification limit brake lever play dr-z125 15 – 25 (0.6 – 1.0) — dr-z125 0.1 – 0.3 (0.004 – 0.012) — rear brake pedal free travel 20 – 30 (0.8 – 1.2) — rear brake pedal height –10 – 0 (–0.4 – 0) — bra...

Page 198

8-10 dr-z125/lk4 (’04-model) and dr-z125/lk5 (’05-model) suspension unit: mm (in) tire pressure fuel + oil item standard/specification limit front fork stroke 180 (7.1) — front fork spring free length — 587 (23.1) front fork oil level 173.0 (6.81) — front fork oil type suzuki fork oil ss-08 (#10) or...

Page 199: Tightening Torque

Dr-z125/lk4 (’04-model) and dr-z125/lk5 (’05-model) 8-11 tightening torque chassis item n·m kgf-m lb-ft front axle nut (dr-z125) 35 3.5 25.5 (dr-z125l) 44 4.4 32.0 front fork cap bolt 23 2.3 16.5 front fork damper rod bolt 20 2.0 14.5 front fork lower clamp bolt 33 3.3 24.0 front fork upper clamp bo...

Page 200: Dr-Z125/lk7 (’07-Model)

2 4 6 9 dr-z125/lk6 (’06-model) and dr-z125/lk7 (’07-model) 9-1 contents this chapter describes service specifications, service data and servicing procedures which differ from those of the dr-z125/lk4 (’04-model), dr-z125/lk5 (’05-model). Note: * any differences between the dr-z125/lk4 (’04-model), ...

Page 201: Specifications

9-2 dr-z125/lk6 (’06-model) and dr-z125/lk7 (’07-model) specifications dimensions and dry mass overall length ...................................................................................... 1 835 mm (72.2 in) 1 885 mm (74.2 in).......... Large wheel overall width ................................

Page 202: Service Data

Dr-z125/lk6 (’06-model) and dr-z125/lk7 (’07-model) 9-3 service data valve + guide unit: mm (in) item standard limit valve diam. In. 30 (1.2) — ex. 26 (1.0) — valve clearance (when cold) in. 0.08 – 0.13 (0.003 – 0.005) — ex. 0.13 – 0.18 (0.005 – 0.007) — valve guide to valve stem clearance in. 0.010...

Page 203

9-4 dr-z125/lk6 (’06-model) and dr-z125/lk7 (’07-model) camshaft + cylinder head unit: mm (in) cylinder + piston + piston ring unit: mm (in) item standard limit cam height in. & ex. 33.13 – 33.17 (1.304 – 1.306) 32.83 (1.29) camshaft journal oil clearance in. & ex. 0.032 – 0.066 (0.0013 – 0.0026) 0....

Page 204

Dr-z125/lk6 (’06-model) and dr-z125/lk7 (’07-model) 9-5 conrod + crankshaft unit: mm (in) oil pump clutch unit: mm (in) item standard limit piston ring thickness 1st 1.175 – 1.190 (0.0463 – 0.0469) — 2nd 1.170 – 1.190 (0.0461 – 0.0469) — piston pin bore 14.002 – 14.008 (0.5513 – 0.5515) 14.030 (0.55...

Page 205

9-6 dr-z125/lk6 (’06-model) and dr-z125/lk7 (’07-model) drive train + drive chain unit: mm (in) except ratio carburetor item standard limit primary reduction ratio 3.470 (59/17) — final reduction ratio dr-z125 3.642 (51/14) — dr-z125l 4.071 (57/14) — gear ratios low 3.000 (33/11) — 2nd 1.857 (26/14)...

Page 206

Dr-z125/lk6 (’06-model) and dr-z125/lk7 (’07-model) 9-7 electrical brake + wheel unit: mm (in) item specification note spark plug type denso: x24esr-u ngk: dr8ea gap 0.6 – 0.8 mm (0.024 – 0.031 in) spark performance over 8 mm (0.3 in) at 1 atm. Ignition coil resistance primary 0.1 – 0.8 Ω w/bl – b/w...

Page 207

9-8 dr-z125/lk6 (’06-model) and dr-z125/lk7 (’07-model) suspension unit: mm (in) tire pressure item standard/specification limit wheel rim size front dr-z125 j17 × 1.40 — dr-z125l j19 × 1.40 — rear dr-z125 j14 × 1.60 — dr-z125l j16 × 1.60 — tire size front dr-z125 70/100-17 40m — dr-z125l 70/100-19 ...

Page 208

Dr-z125/lk6 (’06-model) and dr-z125/lk7 (’07-model) 9-9 fuel + oil item specification note fuel type use only unleaded gasoline of at least 87 pump octane (r/2 + m/2) or 91 octane or higher rated by the research method. Gasoline containing mtbe (methyl tertiary butyl ether), less than 10% ethanol, o...

Page 209: Dr-Z125/lk8 (’08-Model)

Contents 2 4 6 10 dr-z125/lk8 (’08-model) 10-1 this chapter describes service specifications, service data and servicing procedures which differ from those of the dr-z125/lk6 (’06-model), dr-z125/lk7 (’07-model). Note: * any differences between the dr-z125/lk6 (’06-model), dr-z125/lk7 (’07-model) an...

Page 210: Specifications

10-2 dr-z125/lk8 (’08-model) specifications dimensions and dry mass overall length ...................................................................................... 1 835 mm (72.2 in) 1 885 mm (74.2 in) ............. Large wheel overall width .......................................................

Page 211: Service Data

Dr-z125/lk8 (’08-model) 10-3 service data valve + guide unit: mm (in) item standard limit valve diam. In. 30 (1.2) — ex. 26 (1.0) — valve clearance (when cold) in. 0.08 – 0.13 (0.003 – 0.005) — ex. 0.13 – 0.18 (0.005 – 0.007) — valve guide to valve stem clearance in. 0.010 – 0.037 (0.0004 – 0.0015) ...

Page 212

10-4 dr-z125/lk8 (’08-model) camshaft + cylinder head unit: mm (in) cylinder + piston + piston ring unit: mm (in) item standard limit cam height in. & ex. 33.13 – 33.17 (1.304 – 1.306) 32.83 (1.29) camshaft journal oil clearance in. & ex. 0.032 – 0.066 (0.0013 – 0.0026) 0.150 (0.0059) camshaft journ...

Page 213

Dr-z125/lk8 (’08-model) 10-5 conrod + crankshaft unit: mm (in) oil pump clutch unit: mm (in) item standard limit piston ring thickness 1st 1.175 – 1.190 (0.0463 – 0.0469) — 2nd 1.170 – 1.190 (0.0461 – 0.0469) — piston pin bore 14.002 – 14.008 (0.5513 – 0.5515) 14.030 (0.5524) piston pin o.D. 13.994 ...

Page 214

10-6 dr-z125/lk8 (’08-model) drive train + drive chain unit: mm (in) except ratio carburetor item standard limit primary reduction ratio 3.470 (59/17) — final reduction ratio dr-z125 3.642 (51/14) — dr-z125l 4.071 (57/14) — gear ratios low 3.000 (33/11) — 2nd 1.857 (26/14) — 3rd 1.368 (26/19) — 4th ...

Page 215

Dr-z125/lk8 (’08-model) 10-7 electrical brake + wheel unit: mm (in) item specification note spark plug type denso: x24esr-u ngk: dr8ea gap 0.6 – 0.8 mm (0.024 – 0.031 in) spark performance over 8 mm (0.3 in) at 1 atm. Ignition coil resistance primary 0.1 – 0.8 Ω w/bl – b/w secondary 13 – 18 k Ω plug...

Page 216

10-8 dr-z125/lk8 (’08-model) suspension unit: mm (in) tire pressure item standard/specification limit wheel rim size front dr-z125 j17 × 1.40 — dr-z125l j19 × 1.40 — rear dr-z125 j14 × 1.60 — dr-z125l j16 × 1.60 — tire size front dr-z125 70/100-17 40m — dr-z125l 70/100-19 42m — rear dr-z125 90/100-1...

Page 217

Dr-z125/lk8 (’08-model) 10-9 fuel + oil item specification note fuel type use only unleaded gasoline of at least 87 pump octane (r/2 + m/2) or 91 octane or higher rated by the research method. Gasoline containing mtbe (methyl tertiary butyl ether), less than 10% ethanol, or less than 5% methanol wit...

Page 218: Tightening Torque

10-10 dr-z125/lk8 (’08-model) tightening torque chassis item n·m kgf-m lb-ft front axle nut (dr-z125) * 42 * 4.2 * 30.5 (dr-z125l) * 49 * 4.9 * 35.5 front fork cap bolt 23 2.3 16.5 front fork damper rod bolt 20 2.0 14.5 front fork lower clamp bolt 33 3.3 24.0 front fork upper clamp bolt 29 2.9 21.0 ...

Page 219: Cable Routing

Dr-z125/lk8 (’08-model) 10-11 cable routing front brake cable front brake cable clamp clamp wire harness face the circlip end down. Clutch cable clutch cable throttle cable steering stem upper bracket.

Page 220

10-12 dr-z125/lk8 (’08-model) fuel hose and fuel tank installation fuel tank frame clamp clamp fuel tank cushion fuel valve fuel hose face the tip of clamp to lower. Face the tip of clamp to outside. Face the tip of clamp to outside. To the carburetor.

Page 221

Prepared by 6th ed. May, 2008 may, 2008 1st ed. March, 2002 part no. 99500-41125-01e printed in japan 228.

Page 222

Printed in japan k3 k4 k5 k6 k7 k8.