- DL manuals

- Suzuki

- Engine

- Engine 2002 GRAND VITARA SQ625

- Service Manual

Suzuki Engine 2002 GRAND VITARA SQ625 Service Manual

Important

WARNING/CAUTION/NOTE

Please read this manual and follow its instructions carefully. To emphasize special information, the words

WARNING, CAUTION and NOTE have special meanings. Pay special attention to the messages highlighted by

these signal words.

The circle with a slash in this manual means “Don’t do this” or “Don’t let this happen”.

WARNING:

Indicates a potential hazard that could result in death or injury.

CAUTION:

Indicates a potential hazard that could result in vehicle damage.

NOTE:

Indicates special information to make maintenance easier or instructions clearer.

WARNING:

This service manual is intended for authorized SUZUKI dealers and qualified service mechanics only.

Inexperienced mechanics or mechanics without the proper tools and equipment may not be able to

properly perform the services described in this manual. Improper repair may result in injury to the

mechanic and may render the vehicle unsafe for the driver and passengers.

WARNING:

For vehicles equipped with a Supplemental Restraint (Air Bag) System :

• Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer.

Refer to “Air Bag System Components and Wiring Location View” under “General Description” in

air bag system section in order to confirm whether you are performing service on or near the air bag

system components or wiring. Please observe all WARNINGS and “Service Precautions” under

“On-Vehicle Service” in air bag system section before performing service on or around the air bag

system components or wiring. Failure to follow WARNINGS could result in unintentional activation

of the system or could render the system inoperative. Either of these two conditions may result in

severe injury.

• If the air bag system and another vehicle system both need repair, SUZUKI recommends that the air

bag system be repaired first, to help avoid unintended air bag system activation.

• Do not modify the steering wheel, instrument panel or any other air bag system component (on or

around air bag system components or wiring). Modifications can adversely affect air bag system

performance and lead to injury.

• If the vehicle will be exposed to temperatures over 93°C (200°F) (for example, during a paint baking

process), remove the air bag system components (air bag (inflator) module, sensing and diagnostic

module (SDM), seat belt pretensioner (if equipped) beforehand to avoid component damage or unin-

tended activation.

Summary of Engine 2002 GRAND VITARA SQ625

Page 1

Important warning/caution/note please read this manual and follow its instructions carefully. To emphasize special information, the words warning, caution and note have special meanings. Pay special attention to the messages highlighted by these signal words. The circle with a slash in this manual m...

Page 2: Foreword

Foreword this manual (volumes 1 and 2) contains procedures for diagnosis, maintenance, adjustments, minor service operations, replacement of components (service) and for disassembly and assembly of major components (unit repair-overhaul). Volume 1 contains chassis, electrical and body sections (all ...

Page 3

Related manual : manual name manual no. Applicability grand vitara/grand vitara xl-7 (sq416/sq420/sq625/ja627) unit repair manual 99501-65d40-01e transmission, transfer and differentials (front and rear) of applicable model mentioned in “foreword” of this manual. Grand vitara/grand vitara xl-7 (sq41...

Page 4: Table Of Contents

Table of contents general information engine 0a 6 general information 0a engine general information and diagnosis (g16/j20) 6 0b 6-1 maintenance and lubrication 0b 6a1 heating and air conditioning engine general information and diagnosis (h25) 6-1 1a 6a2 heater and ventilation 1a 1b 6a4 air conditio...

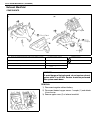

Page 6: Section 6

Engine general information and diagnosis (g16/j20 engines) 6-1 6 section 6 engine general information and diagnosis (g16/j20 engines) engine general information and diagnosis (g16/j20 engines) . . . . . . . . . . . . . . . . . . . . . . . 6-1 engine mechanical (g16 engine) . . . . . . . . . . . . . ...

Page 7

6-2 engine general information and diagnosis (g16/j20 engines) engine diagnosis.............................................. 6-8 general description ........................................ 6-8 on-board diagnostic system (vehicle without diagnosis connector) ......................... 6-8 on-board d...

Page 8

Engine general information and diagnosis (g16/j20 engines) 6-3 table b-8 a/c condenser fan motor relay control system inspection (other than canvas top model, if equipped)......... 6-132 table b-9 a/c compressor relay control system inspection (other than canvas top model, if equipped).................

Page 9: General Information

6-4 engine general information and diagnosis (g16/j20 engines) general information statement of cleanliness and care an automobile engine is a combination of many machined, honed, polished and lapped surfaces with tolerances that are measured in the thousands of an millimeter (ten thousands of inch)...

Page 10

Engine general information and diagnosis (g16/j20 engines) 6-5 general information on engine service the following information on engine service should be noted carefully, as it is important in preventing damage, and in contributing to reli- able engine performance. • when raising or supporting engi...

Page 11

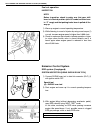

6-6 engine general information and diagnosis (g16/j20 engines) precaution on fuel system service • work must be done with no smoking, in a well-ventilated area and away from any open flames. • as fuel feed line (between fuel pump and fuel pressure regu- lator) is still under high fuel pressure even ...

Page 12

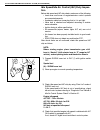

Engine general information and diagnosis (g16/j20 engines) 6-7 fuel pressure relief procedure after making sure that engine is cold, release fuel pressure as fol- lows. 1) place transmission gear shift lever in “neutral” (shift selector lever to “p” range for a/t vehicle), set parking brake, and blo...

Page 13: Engine Diagnosis

6-8 engine general information and diagnosis (g16/j20 engines) engine diagnosis general description this vehicle is equipped with an engine and emission control system which are under control of ecm (pcm). The engine and emission control system in this vehicle are controlled by ecm (pcm). Ecm (pcm) ...

Page 14

Engine general information and diagnosis (g16/j20 engines) 6-9 warm-up cycle a “warm-up cycle” means sufficient vehicle operation such that the coolant temperature has risen by at least 22 ° c (40 ° f) from engine starting and reaches a minimum temperature of 70 ° c (158 ° f). Driving cycle a “drivi...

Page 15

6-10 engine general information and diagnosis (g16/j20 engines) freeze frame date ecm (pcm) stores the engine and driving conditions (in the form of data as shown at the figure) at the moment of the detection of a malfunction in its memory. This data is called “freeze frame data”. Therefore, it is p...

Page 16

Engine general information and diagnosis (g16/j20 engines) 6-11 freeze frame data clearance : the freeze frame data is cleared at the same time as clearance of diagnostic trouble code (dtc). Data link connector (dlc) dlc (1) in compliance with sae j1962 in its installation position, the shape of con...

Page 17

6-12 engine general information and diagnosis (g16/j20 engines) on-board diagnostic system (vehicle with diagnosis connector) ecm diagnosis troubles which may occur in the area including the following parts when the ignition switch is on and the engine is running, and indicates the result by turning...

Page 18

Engine general information and diagnosis (g16/j20 engines) 6-13 data link connector (dlc) dlc (1) is in compliance with saej1962 in its installation posi- tion, the shape of connector and pin assignment. K line of iso 9141 (4) is used for suzuki scan tool to communi- cate with ecm, air bag sdm and a...

Page 19

6-14 engine general information and diagnosis (g16/j20 engines) engine diagnostic flow table refer to the following pages for the details of each step. Step action yes no 1 customer complaint analysis 1) perform customer complaint analysis refer- ring to “customer complaint analysis” in the followin...

Page 20

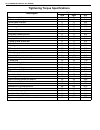

Engine general information and diagnosis (g16/j20 engines) 6-15 1. Customer complaint analysis record details of the problem (failure, complaint) and how it occurred as described by the customer. For this purpose, use of such an inspection form will facilitate collecting information to the point req...

Page 21

6-16 engine general information and diagnosis (g16/j20 engines) 8. Engine basic check and engine diagnosis table perform basic engine check according to the “engine basic check” first. When the end of the flow table has been reached, check the parts of the system suspected as a possible cause referr...

Page 22

Engine general information and diagnosis (g16/j20 engines) 6-17 customer problem inspection form (example) note: the above form is standard sample. It should be modified according to conditions characteristic of each market..

Page 23

6-18 engine general information and diagnosis (g16/j20 engines) malfunction indicator lamp (mil) check 1) turn on ignition switch (but the engine at stop) and check that mil lights. If mil does not light up or dims, go to “diagnostic flow table a-1” for troubleshooting. If mil flushes, go to “diagno...

Page 24

Engine general information and diagnosis (g16/j20 engines) 6-19 [not using suzuki scan tool] (vehicle with monitor con- nector only) 1) check malfunction indicator lamp referring to “malfunction indicator lamp check” in this section. 2) with the ignition switch off position, disconnect suzuki scan t...

Page 25

6-20 engine general information and diagnosis (g16/j20 engines) diagnostic trouble code (dtc) clearance [using scan tool] 1) connect generic scan tool or suzuki scan tool to data link connector in the same manner as when making this connec- tion for dtc check. 2) turn ignition switch off and then on...

Page 26

Engine general information and diagnosis (g16/j20 engines) 6-21 fail-safe table when any of the following dtcs is detected, ecm (pcm) enters fail-safe mode as long as malfunction continues to exist but that mode is canceled when ecm detects normal condition after that. Dtc no. Trouble area fail safe...

Page 27

6-22 engine general information and diagnosis (g16/j20 engines) diagnostic trouble code (dtc) table dtc no. Detecting item detecting condition (dtc will set when detecting :) mil (vehicle without monitor connector) mil (vehicle with moni- tor connec- tor) p0100 (no.34) mass air flow circuit mal- fun...

Page 28

Engine general information and diagnosis (g16/j20 engines) 6-23 p0172 fuel system too rich short term fuel trim or total fuel trim (short- vand long term added) is smaller thanvspecification for specified time or longer. (fuel trim toward lean side is large.) 2 driving cycles not applica- ble p0300 ...

Page 29

6-24 engine general information and diagnosis (g16/j20 engines) p1451 barometric pressure sen- sor performance problem difference between manifold absolute pressure (map sensor value) and baro- metric pressure (barometric pressure sen- sor value) is larger than specification during cranking. 2 drivi...

Page 30

Engine general information and diagnosis (g16/j20 engines) 6-25 dtc no. Detecting item detecting condition (dtc will set when detecting :) mil p0705 (no.72) transmission range switch circuit malfunc- tion refer to section 7b1 p0715 (no.76) input/turbine speed sensor circuit malfunc- tion p0720 (no.7...

Page 31

6-26 engine general information and diagnosis (g16/j20 engines) scan tool data as the data values given below are standard values estimated on the basis of values obtained from the normally operating vehicles by using a scan tool, use them as reference values. Even when the vehicle is in good condi-...

Page 32

Engine general information and diagnosis (g16/j20 engines) 6-27 inj pulse width (fuel injection pulse width) at specified idle speed with no load after warming up. 1.5 – 4.5 msec ✱ at 2500 r/min. With no load after warming up. 1.5 – 4.5 msec throttle pos (absolute throttle position) ignition switch ...

Page 33

6-28 engine general information and diagnosis (g16/j20 engines) brake sw ignition switch on brake pedal is depress- ing on brake pedal is releas- ing off blower fan ignition switch on blower fan switch on on blower fan switch off off a/c condenser fan ignition switch on a/c not operating off a/c ope...

Page 34

Engine general information and diagnosis (g16/j20 engines) 6-29 scan tool data definitions coolant temp (engine coolant temp., °c/°f) it is detected by engine coolant temp. Sensor. Intake air temp (°c/°f) it is detected by intake air temp. Sensor. Desire idle (desired idle speed rpm) the desired idl...

Page 35

6-30 engine general information and diagnosis (g16/j20 engines) maf (mass air flow rate, g/s, lb/min.) it represents total mass of air entering intake manifold which is measured by mass air flow sensor. Calc load (calculated load value, %) engine load displayed as a percentage of maximum possible lo...

Page 36

Engine general information and diagnosis (g16/j20 engines) 6-31 canist prg duty (evap canister purge flow duty, %) this parameter indicates valve on (valve open) time rate within a certain set cycle of evap canister purge valve which controls the amount of evap purge. Fuel tank level (%) this parame...

Page 37

6-32 engine general information and diagnosis (g16/j20 engines) gear position (1st, 2nd, 3rd or 4th) the gear position is determined on the basis of the command state signals generated from pcm (ecm) to shift solenoids a and b ( # 1 and # 2) and displayed as shown in the table below. Throt pos level...

Page 38

Engine general information and diagnosis (g16/j20 engines) 6-33 mode select sw (power/normal change switch, power/normal) power : switch button is at power position. Normal : switch button is at normal position. 4wd-l sw (4wd-low switch, on/off) on : transfer lever is shifted to 4l position. Off : t...

Page 39

6-34 engine general information and diagnosis (g16/j20 engines) engine basic check this check is very important for troubleshooting when ecm (pcm) has detected no dtc and no abnormality has been found in visual inspection. Follow the flow table carefully. Step action yes no 1 was “engine diag. Flow ...

Page 40

Engine general information and diagnosis (g16/j20 engines) 6-35 engine diagnosis table perform troubleshooting referring to following table when ecm (pcm) has detected no dtc and no abnormality has been found in visual inspection and engine basic inspection previously. Condition possible cause corre...

Page 41

6-36 engine general information and diagnosis (g16/j20 engines) engine has no power engine overheating. Refer to “overheating” in this table. Ignition system out of order. • defective spark plug. “spark plugs” in section 6f1 or 6f2. • faulty ignition coil with ignitor “ignition coil assembly” in sec...

Page 42

Engine general information and diagnosis (g16/j20 engines) 6-37 improper engine idling or engine fails to idle ignition system out of order. • faulty spark plug “spark plugs” in section 6f1 or 6f2. • faulty ignition coil with ignitor “ignition coil assembly” in section 6f1 or 6f2. Fuel system out of...

Page 43

6-38 engine general information and diagnosis (g16/j20 engines) surges (engine power varia- tion under steady throttle or cruise. Feels like the vehicle speeds up and down with no change in the accelerator pedal.) ignition system out of order. • defective spark plug (excess carbon deposits, improper...

Page 44

Engine general information and diagnosis (g16/j20 engines) 6-39 overheating • inoperative thermostat “thermostat” in section 6b. • poor water pump performance “water pump” in section 6b. • clogged or leaky radiator “radiator” in section 6b. • improper engine oil grade “engine oil and oil filter chan...

Page 45

6-40 engine general information and diagnosis (g16/j20 engines) excessive engine oil consumption oil entering combustion chamber • sticky piston ring “pistons, piston rings, connecting rods and cylinders” in section 6a1 or 6a4. • worn piston and cylinder “pistons, piston rings, connecting rods and c...

Page 46

Engine general information and diagnosis (g16/j20 engines) 6-41 engine noise see note below. Valve noise • faulty hydraulic valve lash adjuster “camshafts and valve lash adjuster” in section 6a4. • worn valve stem and guide “valves and cylinder head” in section 6a1 or 6a4. • weak or broken valve spr...

Page 47

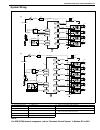

6-42 engine general information and diagnosis (g16/j20 engines) inspection of pcm (ecm) and its circuits pcm (ecm) and its circuits can be checked at pcm (ecm) wiring couplers by measuring voltage, pulse signal and resistance. Voltage check 1) remove pcm (ecm) cover from bracket referring to “engine...

Page 48

Engine general information and diagnosis (g16/j20 engines) 6-43 terminal wire color circuit normal voltage condition e61 1 gry/red output of 5 v power source for co adjusting resistor (if equipped) 4.5 – 5.5 v ignition switch turned on 2 wht power source for ecm internal memory 10 – 14 v regardless ...

Page 49

6-44 engine general information and diagnosis (g16/j20 engines) e61 13 ppl/grn (canvas top model) serial communication line of data link connector 12 v (if equipped) 10 – 14 v ignition switch turned on ppl/red (other than canvas top model) 14 wht/red test switch terminal (if equipped) 10 – 14 v igni...

Page 50

Engine general information and diagnosis (g16/j20 engines) 6-45 e61 22 yel/blu a/c condenser fan motor relay output (canvas top model, if equipped) 10 – 14 v ignition switch turned on, engine coolant temperature under 113°c, 235°f or a/c request signal high input 0 – 1 v ignition switch turned on, e...

Page 51

6-46 engine general information and diagnosis (g16/j20 engines) e61 31 orn/blu selector switch signal of power mode/normal mode for a/t 0 – 1 v ignition switch turned on, a/t power mode/normal mode selector selected at power mode 10 – 14 v ignition switch turned on, a/t power mode/normal mode select...

Page 52

Engine general information and diagnosis (g16/j20 engines) 6-47 c51-3 8 red/wht manifold absolute pressure (map) sensor signal (if equipped) 3.3 – 4.3 v ignition switch turned on with baro- metric pressure at 100kpa, 760mmhg 3.3 – 4.3 v while specified idle speed with barometric pressure at 100kpa, ...

Page 53

6-48 engine general information and diagnosis (g16/j20 engines) c51-3 24 yel/blu a/c condenser fan motor relay output (other than canvas top model, if equipped) 10 – 14 v ignition switch turned on, engine coolant temperature under 113°c, 235°f or a/c request signal high input 0 – 1v ignition switch ...

Page 54

Engine general information and diagnosis (g16/j20 engines) 6-49 c51-1 15 yel/grn “d” position signal for trans- mission range selector switch (a/t) 10 – 14 v ignition switch turned on, selector switch selected at “d” position 0 – 1 v ignition switch turned on, selector switch selected at other than ...

Page 55

6-50 engine general information and diagnosis (g16/j20 engines) c51-1 26 orn/wht 4wd low (4l) switch signal 0 – 1 v ignition switch turned on, transfer selector lever selected at “4l” posi- tion 10 – 14 v ignition switch turned on, transfer selector lever selected at “4h” or “2h” position 27 grn/blu...

Page 56

Engine general information and diagnosis (g16/j20 engines) 6-51 c51-2 7 red 4wd air pump assembly output 10 – 14 v ignition switch turned on, transfer selector selected at “4l” or “4h” position 0 – 1 v ignition switch turned on, transfer selector selected at “2h” position 8 pnk/blu fuel injector no....

Page 57

6-52 engine general information and diagnosis (g16/j20 engines) c51-2 15 lt grn/ wht egr valve (stepper motor coil 2) output (if equipped) 10 – 14 v ignition switch turned on *0 – 1 v ↑ ↓ 8 – 14 v (repeated indicator) while engine running (output signal is active low duty pulse. Pulse generated time...

Page 58

Engine general information and diagnosis (g16/j20 engines) 6-53 c51-2 21 brn/yel ignition coil no.4 output (for j20 engine) 0 – 0.6 v ignition switch turned on *0 – 0.6 v ↑ ↓ 2 – 4 v (repeated indicator) engine running (output signal is active high pulse. Pulse frequency varies depending on engine s...

Page 59

6-54 engine general information and diagnosis (g16/j20 engines) resistance check 1) disconnect couplers from ecm/pcm with ignition switch off. 2) check resistance between each pair of terminals of discon- nected couplers as listed in the following table. Caution: never touch terminals of ecm/pcm its...

Page 60

Engine general information and diagnosis (g16/j20 engines) 6-55 terminals circuit standard resistance condition e61-3 and c51-3-20 heater of ho2s-2 (if equipped) 11.7 – 14.3 Ω – e61-9 and e61-2 main relay 79 – 95 Ω (canvas top model) 160 – 240 Ω (other than canvas top model) – e61-22 and c51-3-20 a/...

Page 61

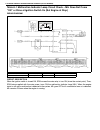

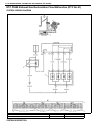

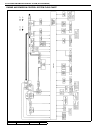

6-56 engine general information and diagnosis (g16/j20 engines) table a-1 malfunction indicator lamp circuit check – mil does not come “on” or dims at ignition switch on (but engine at stop) wiring diagram circuit description when the ignition switch is turned on, ecm causes the main relay to turn o...

Page 62

Engine general information and diagnosis (g16/j20 engines) 6-57 inspection table a-2 malfunction indicator lamp circuit check – mil remains “on” after engine starts wiring diagram/circuit descrition refer to table a-1. Inspection step action yes no 1 mil power supply check : 1) turn ignition switch ...

Page 63

6-58 engine general information and diagnosis (g16/j20 engines) table a-3 mil check – mil flashes at ignition switch on (vehicle with monitor connector) wiring diagram/circuit description refer to table a-1. Inspection table a-4 mil check – mil does not flash or just remains on even with grounding d...

Page 64

Engine general information and diagnosis (g16/j20 engines) 6-59 table a-5 ecm (pcm) power and ground circuit check – mil doesn’t light at ignition switch on and engine doesn’t start though it is cranked up. Wiring diagram circuit description when the ignition switch is turned on, the main relay turn...

Page 65

6-60 engine general information and diagnosis (g16/j20 engines) inspection step action yes no 1 main relay operating sound check : is operating sound of main relay heard at igni- tion switch on? Go to step 5. Go to step 2. 2 fuse check : is main “fi” fuse in good condition? Go to step 3. Check for s...

Page 66

Engine general information and diagnosis (g16/j20 engines) 6-61 dtc p0100 (dtc no.33, 34) mass air flow circuit malfunction wiring diagram dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and clear dt...

Page 67

6-62 engine general information and diagnosis (g16/j20 engines) troubleshooting step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 maf sensor check : 1) connect scan tool to dlc with ignition switch off. 2) start engine and check maf value ...

Page 68

Engine general information and diagnosis (g16/j20 engines) 6-63 dtc p0110 (dtc no.23, 25) intake air temp. (iat) circuit malfunction wiring diagram dtc detecting condition and trouble area dtc confirmation rpocedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and...

Page 69

6-64 engine general information and diagnosis (g16/j20 engines) troubleshooting step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check iat sensor and its circuit. 1) connect scan tool with ignition switch off. 2) turn ignition switch on. ...

Page 70

Engine general information and diagnosis (g16/j20 engines) 6-65 dtc p0115 (dtc no.14, 15) engine coolant temp. Sensor circuit malfunction wiring diagram dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switc...

Page 71

6-66 engine general information and diagnosis (g16/j20 engines) troubleshooting step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check ect sensor and its circuit. 1) connect scan tool with ignition switch off. 2) turn ignition switch on. ...

Page 72

Engine general information and diagnosis (g16/j20 engines) 6-67 dtc p0120 (dtc no.21, 22) throttle position circuit malfunction wiring diagram dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and clea...

Page 73

6-68 engine general information and diagnosis (g16/j20 engines) troubleshooting step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check tp sensor and its circuit. 1) connect scan tool to dlc with ignition switch off and then turn ignition ...

Page 74

Engine general information and diagnosis (g16/j20 engines) 6-69 dtc p0121 throttle position range/performance problem wiring diagram refer to dtc p0120. Dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switc...

Page 75

6-70 engine general information and diagnosis (g16/j20 engines) troubleshooting (dtc p0121) fig. For step 4 and 5 step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 is there a dtc related to tp sensor (dtc p0120)? Go to applicable dtc diag....

Page 76

Engine general information and diagnosis (g16/j20 engines) 6-71 dtc p0130 (dtc no.13) ho2s-1 circuit malfunction wiring diagram dtc detecting condition and trouble area 1. To ignition switch 3. Fuse box 2. Ho2s-1 4. Ecm (pcm) dtc detecting condition trouble area following conditions are detected in ...

Page 77

6-72 engine general information and diagnosis (g16/j20 engines) dtc confirmation proceudre 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and clear dtc, pending dtc and freeze frame data by using scan tool and start engine. 3) increase vehicle speed to 55 km/h (35 m...

Page 78

Engine general information and diagnosis (g16/j20 engines) 6-73 troubleshooting (dtc p0130) fig. 1 for step 2 step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 ho2s-1 output voltage check : 1) connect scan tool to dlc with ignition switch ...

Page 79

6-74 engine general information and diagnosis (g16/j20 engines) dtc p0133 ho2s-1 circuit slow response wiring diagram refer to dtc p0130. Dtc detecting condition and trouble area dtc cconfirmation procedure refer to dtc p0130. Troubleshooting dtc detecting condition trouble area following conditions...

Page 80

Engine general information and diagnosis (g16/j20 engines) 6-75 dtc p0134 ho2s-1 no activity detected wiring diagram refer to dtc p0130. Dtc detecting condition and trouble area dtc confirmation procedure refer to dtc p0130. Troubleshooting dtc detecting condition trouble area following conditions a...

Page 81

6-76 engine general information and diagnosis (g16/j20 engines) dtc p0135 ho2s-1 heater circuit malfunction wiring diagram refer to dtc p0130. Dtc detecting conditin and trouble area dtc confirmation procedure 1) connect scan tool with ignition switch off. 2) turn on ignition switch and clear dtc, p...

Page 82

Engine general information and diagnosis (g16/j20 engines) 6-77 troubleshooting (dtc p0135) step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 ho2s-1 heater check : 1) disconnect ho2s-1 coupler with ignition switch off. 2) check resistance ...

Page 83

6-78 engine general information and diagnosis (g16/j20 engines) dtc p0136 ho2s-2 circuit malfunction wiring diagram dtc detecting condition and trouble area dtc confirmation procedure [a] : canvas top model 1. To ignition switch 3. Fuse box [b] : other than canvas top model 2. Ho2s-2 4. Ecm (pcm) dt...

Page 84

Engine general information and diagnosis (g16/j20 engines) 6-79 1) connect scan tool with ignition switch off. 2) turn on ignition switch and clear dtc, pending dtc and freeze frame data in ecm memory by using scan tool and start engine. 3) increase vehicle speed to 55 km/h (40 mph) or more. 4) keep...

Page 85

6-80 engine general information and diagnosis (g16/j20 engines) dtc p0141 ho2s-2 heater circuit malfunction wiring diagram refer to dtc p0136. Dtc detecting condition and trouble are dtc confirmation procedure 1) connect scan tool with ignition switch off. 2) turn on ignition switch and clear dtc, p...

Page 86

Engine general information and diagnosis (g16/j20 engines) 6-81 troubleshooting (dtc p0141) step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 ho2s-2 heater check : 1) disconnect ho2s-2 coupler with ignition switch off. 2) check resistance ...

Page 87

6-82 engine general information and diagnosis (g16/j20 engines) dtc p0171 fuel system too lean dtc p0172 fuel system too rich system diagram refer to “electronic control system description” in section 6e1. Dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool to dl...

Page 88

Engine general information and diagnosis (g16/j20 engines) 6-83 troubleshooting (dtc p0171/p0172) step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 is there dtc(s) other than “dtc p0171/ p0172”? Go to applicable “dtc flow table”. Go to ste...

Page 89

6-84 engine general information and diagnosis (g16/j20 engines) dtc p0300 random misfire detected dtc p0301 cylinder 1 misfire detected dtc p0302 cylinder 2 misfire detected dtc p0303 cylinder 3 misfire detected dtc p0304 cylinder 4 misfire detected system description ecm (pcm) measures the angle sp...

Page 90

Engine general information and diagnosis (g16/j20 engines) 6-85 troubleshooting (dtc p0300/p0301/p0302/p0303/p0304) step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 ignition system inspection : 1) check spark plug and ignition spark of cy...

Page 91

6-86 engine general information and diagnosis (g16/j20 engines) dtc p0325 (dtc no.43) knock sensor circuit malfunction wiring diagram dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool to dlc with ignition off. 2) turn on ignition switch and clear dtc by using s...

Page 92

Engine general information and diagnosis (g16/j20 engines) 6-87 fig. 1 for step 3 3 1) stop engine. 2) with ignition switch at off position, discon- nect knock sensor connector. 3) with ignition switch at on position, check voltage from “red/blu” to body ground ter- minal of knock sensor connector. ...

Page 93

6-88 engine general information and diagnosis (g16/j20 engines) dtc p0335 crankshaft position sensor circuit malfunction wiring diagram reference connect oscilloscope between terminals c51-2-19 (+) and c51-2-20 (–) of ecm (pcm) connector connected to ecm (pcm) and check ckp sensor signal. Oscillosco...

Page 94

Engine general information and diagnosis (g16/j20 engines) 6-89 dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and clear dtc, pending dtc and freeze frame data by using scan tool and run engine at i...

Page 95

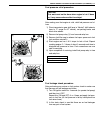

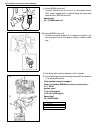

6-90 engine general information and diagnosis (g16/j20 engines) [a] fig. For step 3 / [b] fig. For step 4 / [c] fig. For step 4. 4 ckp sensor visual inspection : 1) check visually ckp sensor and signal rotor (crankshaft timing belt pulley for g16 or ckp sensor plate (4) on crankshaft for j20) for th...

Page 96

Engine general information and diagnosis (g16/j20 engines) 6-91 dtc p0340 (dtc no.42) camshaft position sensor circuit malfunction wiring diagram reference connect oscilloscope between terminals c51-2-26 and c51-3-26 (ground) of ecm (pcm) connector connected to ecm (pcm) and check cmp sensor signal....

Page 97

6-92 engine general information and diagnosis (g16/j20 engines) dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and clear dtc, pending dtc and freeze frame data by using scan tool. 3) crank engine for 3 seconds or more and keep it at idle f...

Page 98

Engine general information and diagnosis (g16/j20 engines) 6-93 8 check cmp sensor (2) for operation as follows. 1) remove cmp sensor (2) from sensor case. 2) remove metal particles on end face of cmp sen- sor (2), if any. 3) connect connector to cmp sensor (2). Disconnect connectors from ignition c...

Page 99

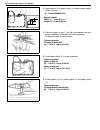

6-94 engine general information and diagnosis (g16/j20 engines) [a] fig. For step 5 / [b] fig. For step 8 g16 / [c] fig. For step 10 j20 / [d] fig. For step 9 g16 / [e] fig. For step 11 j20

Page 100

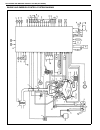

Engine general information and diagnosis (g16/j20 engines) 6-95 dtc p0400 exhaust gas recirculation flow malfunction system / wiring diagram [a] : canvas top model 2. Intake manifold 5. Main fuse 8. Fuse box [b] : other than canvas top model 3. Exhaust gas 6. Main relay 9. Ecm (pcm) 1. Egr valve 4. ...

Page 101

6-96 engine general information and diagnosis (g16/j20 engines) dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and clear dtc, pending dtc and freeze frame data by using scan tool and warm up engine ...

Page 102

Engine general information and diagnosis (g16/j20 engines) 6-97 troubleshooting (dtc p0400) step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 is there dtc p0403 (egr circuit malfunction)? Go to dtc p0403 diag. Flow table. Go to step 3. 3 d...

Page 103

6-98 engine general information and diagnosis (g16/j20 engines) dtc p0403 (dtc no.51) exhaust gas recirculation circuit malfunction wiring diagram dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and ...

Page 104

Engine general information and diagnosis (g16/j20 engines) 6-99 troubleshooting (dtc p0403/dtc no.51) step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 egr valve check : 1) with ignition switch off, disconnect con- nector from egr valve. 2...

Page 105

6-100 engine general information and diagnosis (g16/j20 engines) dtc p0420 catalyst system efficiency below threshold system diagram circuit description exhaust oxygen concentration at the pre-twc and the post-twc is detected from ho2s-1 and ho2s-2 respectively and accordingly ecm (pcm) controls the...

Page 106

Engine general information and diagnosis (g16/j20 engines) 6-101 dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and clear dtc, pending dtc and freeze frame data by using scan tool. 3) increase vehicle speed to 80 – 90 km/h (50 – 56 mph). 4...

Page 107

6-102 engine general information and diagnosis (g16/j20 engines) dtc p0443 evap control system purge control valve circuit malfunction wiring diagram dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch a...

Page 108

Engine general information and diagnosis (g16/j20 engines) 6-103 troubleshooting (dtc p0443) evap canister purge system check 1) warm up engine to normal operating temperature. 2) hoist vehicle so that all wheels rotate freely. 3) set m/t in “neutral” or a/t in “p” position and parking brake. 4) dis...

Page 109

6-104 engine general information and diagnosis (g16/j20 engines) evap canister purge valve inspection 1) with ignition switch off, disconnect coupler from canister purge valve. 2) check resistance between two terminals of evap canister purge valve. If resistance is as specified, proceed to next oper...

Page 110

Engine general information and diagnosis (g16/j20 engines) 6-105 dtc p0460 fuel level sensor circuit high input wiring diagram dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and clear dtc, pending d...

Page 111

6-106 engine general information and diagnosis (g16/j20 engines) troubleshooting step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table” in this section. 2 does fuel level meter in combination meter indi- cate “e” (empty)? Replenish fuel tank with ...

Page 112

Engine general information and diagnosis (g16/j20 engines) 6-107 dtc p0500 (dtc no.24) vehicle speed sensor malfunction wiring diagram dtc detecting condition and trouble area dtc comfirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and clear dtc, p...

Page 113

6-108 engine general information and diagnosis (g16/j20 engines) troubleshooting (dtc p0500/dtc no.24) step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 does speedometer indicate vehicle speed? Faulty “blu/yel” wire or poor c51-2-25 connec...

Page 114

Engine general information and diagnosis (g16/j20 engines) 6-109 dtc p0505 idle air control system malfunction system / wiring diagram dtc detecting condition and trouble area 1. Throttle body 3. Ecm (pcm) 5. Main fuse 7. Fuse box 2. Idle air control valve 4. Sensed information 6. Main relay 8. Ecm ...

Page 115

6-110 engine general information and diagnosis (g16/j20 engines) dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and clear dtc, pending dtc and freeze frame data by using scan tool and warm up engine completely. 3) run engine at idle speed ...

Page 116

Engine general information and diagnosis (g16/j20 engines) 6-111 6 was idle speed higher than specification in step 2? Check abnormal air inhal- ing from intake manifold, throttle body, pcv valve and evap canister purge control system. Check parts or system which can cause engine low idle. • air inh...

Page 117

6-112 engine general information and diagnosis (g16/j20 engines) dtc p0601 (dtc no.71) internal control module memory check sum error system description internal control module is installed in ecm (pcm). Dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool to dlc ...

Page 118

Engine general information and diagnosis (g16/j20 engines) 6-113 dtc p1408 manifold absolute pressure sensor circuit malfunction wiring diagram dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and cle...

Page 119

6-114 engine general information and diagnosis (g16/j20 engines) troubleshooting (dtc p1408) step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 map sensor signal check : 1) remove ecm (pcm) cover. 2) check voltage between c51-3-8 and c51-3-...

Page 120

Engine general information and diagnosis (g16/j20 engines) 6-115 dtc p1450 barometric pressure sensor circuit malfunction dtc p1451 barometric pressure sensor performance problem system description barometric pressure sensor is installed in ecm (pcm). Dtc detecting condition and trouble area dtc con...

Page 121

6-116 engine general information and diagnosis (g16/j20 engines) dtc p1500 engine starter signal circuit malfunction wiring diagram dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and clear dtc by us...

Page 122

Engine general information and diagnosis (g16/j20 engines) 6-117 dtc p1510 ecm back-up power supply malfunction wiring diagram circuit description battery voltage is supplied to keep dtc memory, values that ecm has learned to control engine, etc. In ecm even when ignition switch is turned off. Dtc d...

Page 123

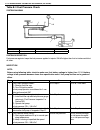

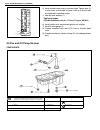

6-118 engine general information and diagnosis (g16/j20 engines) table b-1 fuel pump circuit inspection wiring diagram inspection [a] : canvas top model and other than canvas top model with immobilizer control system 2. Fuel pump relay 5. Fuel pump [b] : other than canvas top model with immobilizer ...

Page 124

Engine general information and diagnosis (g16/j20 engines) 6-119 fig. For step 2 [a] : left hand steering vehicle (canvas top model) [b] : right hand steering vehicle (canvas top model) [c] : left hand steering vehicle (other than canvas top model) [d] : right hand steering vehicle (other than canva...

Page 125

6-120 engine general information and diagnosis (g16/j20 engines) table b-2 fuel injectors and circuit inspection wiring diagram inspection 1. Main relay 3. Injector no.2 5. Injector no.4 7. Ecm (pcm) 2. Injector no.1 4. Injector no.3 6. To ignition switch step action yes no 1 check injector for oper...

Page 126

Engine general information and diagnosis (g16/j20 engines) 6-121 4 check power circuit of injectors for open and short. Is it normal? Check all 4 injectors for resistance respectively. If resistance is ok, substi- tute a known-good ecm (pcm) and recheck. Power circuit open or short. Step action yes ...

Page 127

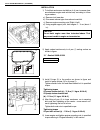

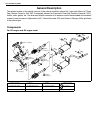

6-122 engine general information and diagnosis (g16/j20 engines) table b-3 fuel pressure inspection system diagram inspection (a) : gauge (c) : attachment 2. Delivery pipe 4. Fuel filter (b) : hose 1. Injector 3. Fuel pressure regulator 5. Fuel pump note: before using following flow table, check to ...

Page 128

Engine general information and diagnosis (g16/j20 engines) 6-123 7 was no fuel pressure applied in step 1? Go to step 8. Go to step 9. (low pressure is mea- sured.) 8 with fuel pump operated and fuel return hose blocked by pinching it, is fuel pressure applied? Faulty fuel pressure regu- lator. Shor...

Page 129

6-124 engine general information and diagnosis (g16/j20 engines) table b-4 idle air control system inspection wiring diagram inspection 1. Throttle body 3. Ecm (pcm) 5. Main relay 2. Idle air control valve 4. Sensed information 6. Ecm (pcm) step action yes no 1 check engine idle speed and iac duty r...

Page 130

Engine general information and diagnosis (g16/j20 engines) 6-125 3 check iac valve referring to “iac valve inspection” in section 6e1. Is check result as specified? Go to step 4. Iac valve malfunction, “blu/ blk”, “lt grn/blk”, “ppl/ blk”, “gry/blu” or “ppl/ yel” wire open or short or poor coupler c...

Page 131

6-126 engine general information and diagnosis (g16/j20 engines) 10 was iac duty more than about 30% in step 1 of this table? Check parts or system which can cause engine low idle. • air inhaling from between throttle body and maf sensor. • egr valve malfunction (leakage from valve seat) • accessory...

Page 132

Engine general information and diagnosis (g16/j20 engines) 6-127 table b-5 a/c signal circuits inspection (for canvas top model, if equipped) wiring diagram inspection 1. A/c control module (amplifier) 2. Ecm (pcm) step action yes no 1 check a/c signal circuit. 1) check voltage at terminal e61-17 wi...

Page 133

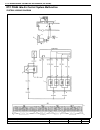

6-128 engine general information and diagnosis (g16/j20 engines) table b-6 a/c signal circuits inspection (other than canvas top model, if equipped) wiring diagram circuit description hvac control module outputs a/c on signal to ecm (pcm) when a/c switch and heater blower motor are turned on. Then c...

Page 134

Engine general information and diagnosis (g16/j20 engines) 6-129 inspection step action yes no 1 a/c switch signal circuit check : 1) remove ecm (pcm) cover. 2) check voltage between e61-17 and ground under following conditions. A/c switch signal specification ignition switch on and a/c switch and/o...

Page 135

6-130 engine general information and diagnosis (g16/j20 engines) table b-7 a/c condenser fan motor relay control system inspection (canvas top model, if equipped) wiring diagram inspection 1. To ignition switch 5. A/c condenser fan motor relay 2. “rear defg” fuse for canvas top model, “heater” fuse ...

Page 136

Engine general information and diagnosis (g16/j20 engines) 6-131 3 1) remove ecm (pcm) cover. 2) check voltage between e61-22 terminal of ecm (pcm) connected coupler and ground. Other than conditions a and b in step 2 : 10 – 14 v under condition a or b in step 2 : 0 – 1 v is check result as specifie...

Page 137

6-132 engine general information and diagnosis (g16/j20 engines) table b-8 a/c condenser fan motor relay control system inspection (other than canvas top model, if equipped) wiring diagram circuit description a/c condenser fan is turned on by ecm (pcm) when engine coolant temperature is higher than ...

Page 138

Engine general information and diagnosis (g16/j20 engines) 6-133 step action yes no 1 a/c condenser fan motor control circuit check 1) remove ecm (pcm) cover. 2) measure voltage between c51-3-24 and vehicle body ground with ignition turned on. Is voltage 10 – 14? Go to step 3. Go to step 2. 2 a/c co...

Page 139

6-134 engine general information and diagnosis (g16/j20 engines) table b-9 a/c compressor relay control system inspection (other than can- vas top model, if equipped) wiring diagram circuit description a/c compressor relay is turned on by ecm (pcm) when a/c signal inputted to ecm (pcm) and engine co...

Page 140

Engine general information and diagnosis (g16/j20 engines) 6-135 2 a/c compressor control circuit check 1) turn off ignition switch. 2) check for fuse blowout at “htr 15 a” fuse. 3) if ok, check a/c compressor relay referring to “a/c compressor relay and condenser fan motor relay” in section 6e1. Is...

Page 141: Special Tool

6-136 engine general information and diagnosis (g16/j20 engines) special tool 09917-47010 09930-88530 see note “a”. Vacuum pump gauge injector test lead tech 2 kit (suzuki scan tool) (see note “b”.) note: • “a” : this kit includes the following items. 1. Pressure gauge 09912-58441, 2. Pressure hose ...

Page 142: Section 6-1

Engine general information and diagnosis (h25 engine) 6-1-1 6-1 10 10a 10b section 6-1 engine general information and diagnosis (h25 engine) engine general information and diagnosis (h25 engine) ................................................... 6-1-1 engine mechanical ................................

Page 143

6-1-2 engine general information and diagnosis (h25 engine) on-board diagnostic system (vehicle with diagnosis connector) ........... 6-1-12 precaution in diagnosing trouble.............. 6-1-13 engine diagnostic flow table ................... 6-1-14 malfunction indicator lamp (mil) check..............

Page 144

Engine general information and diagnosis (h25 engine) 6-1-3 dtc p0601 internal control module memory check sum error........................ 6-1-129 dtc p1408 manifold absolute pressure sensor circuit malfunction........ 6-1-130 dtc p1450 barometric pressure sensor circuit malfunction dtc p1451 baro...

Page 145: General Information

6-1-4 engine general information and diagnosis (h25 engine) general information statement of cleanliness and care an automobile engine is a combination of many machined, honed, polished and lapped surfaces with tolerances that are measured in the thousands of an millimeter (ten thousands of inch). A...

Page 146

Engine general information and diagnosis (h25 engine) 6-1-5 general information on engine service the following information on engine service should be noted carefully, as it is important in preventing damage, and in contributing to reli- able engine performance. • when raising or supporting engine ...

Page 147

6-1-6 engine general information and diagnosis (h25 engine) precaution on fuel system service • work must be done with no smoking, in a well-ventilated area and away from any open flames. • as fuel feed line (between fuel pump and fuel pressure regu- lator) is still under high fuel pressure even aft...

Page 148

Engine general information and diagnosis (h25 engine) 6-1-7 fuel pressure relief procedure after making sure that engine is cold, relief fuel pressure as fol- lows. 1) place transmission gear shift lever in “neutral” (shift selector lever to “p” range for a/t vehicle), set parking brake, and block d...

Page 149: Engine Diagnosis

6-1-8 engine general information and diagnosis (h25 engine) engine diagnosis general description this vehicle is equipped with an engine and emission control system which are under control of ecm (pcm). The engine and emission control system in this vehicle are controlled by ecm (pcm). Ecm (pcm) has...

Page 150

Engine general information and diagnosis (h25 engine) 6-1-9 warm-up cycle a warm-up cycle means sufficient vehicle operation such that the coolant temperature has risen by at least 22°c (40°f) from engine starting and reaches a minimum temperature of 70°c (158°f). Driving cycle a “driving cycle” con...

Page 151

6-1-10 engine general information and diagnosis (h25 engine) freeze frame data ecm (pcm) stores the engine and driving conditions (in the form of data as shown at the figure) at the moment of the detection of a malfunction in its memory. This data is called “freeze frame data”. Therefore, it is poss...

Page 152

Engine general information and diagnosis (h25 engine) 6-1-11 freeze frame data clearance : the freeze frame data is cleared at the same time as clearance of dtc. Data link connector (dlc) dlc (1) is in compliance with saej1962 in its installation posi- tion, the shape of connector and pin assignment...

Page 153

6-1-12 engine general information and diagnosis (h25 engine) on-board diagnostic system (vehicle with diagnosis connector) ecm diagnosis troubles which may occur in the area including the following parts when the ignition switch is on and the engine is running, and indicates the result by turning on...

Page 154

Engine general information and diagnosis (h25 engine) 6-1-13 data link connector (dlc) dlc (1) in compliance with sae j1962 in its installation position, the shape of connector and pin assignment. K line of iso 9141 (4) is used for suzuki scan tool to communi- cation with ecm (pcm), airbag sdm and a...

Page 155

6-1-14 engine general information and diagnosis (h25 engine) engine diagnostic flow table refer to following pages for the detail of each step. Step action yes no 1 customer complaint analysis 1) perform customer complaint analysis refer- ring to “customer complaint analysis” in the following. Was c...

Page 156

Engine general information and diagnosis (h25 engine) 6-1-15 11 final confirmation test 1) clear dtc if any. 2) perform final confirmation test referring to “final confirmation test” in the following. Is there any problem symptom, malfunction dtc or abnormal condition? Go to step 6. End. Step action...

Page 157

6-1-16 engine general information and diagnosis (h25 engine) 1. Customer complaint analysis record details of the problem (failure, complaint) and how it occurred as described by the customer. For this purpose, use of such an inspection form will facilitate collecting information to the point requir...

Page 158

Engine general information and diagnosis (h25 engine) 6-1-17 2. Diagnostic trouble code (dtc)/freeze frame data check first, check dtc, referring to “diagnostic trouble code check” in this section. If dtc is indicated, record dtc and freeze frame data. • after that clear dtc referring to “diagnostic...

Page 159

6-1-18 engine general information and diagnosis (h25 engine) 5. Trouble symptom confirmation based on information obtained in step 1 “customer complaint analysis” and step 2 “dtc/freeze frame data check”, confirm trouble symptoms. Also, reconfirm dtc according to “dtc conformation procedure” describ...

Page 160

Engine general information and diagnosis (h25 engine) 6-1-19 9. Troubleshooting for dtc based on the dtc indicated in step 6 or 7 and referring to the applicable dtc diag. Flow table in this section, locate the cause of the trouble, namely in a sensor, switch, wire harness, connector, actuator, ecm ...

Page 161

6-1-20 engine general information and diagnosis (h25 engine) malfunction indicator lamp (mil) check 1) turn on ignition switch (but the engine at stop) and check that mil (1) lights. If mil does not light up, go to “diagnostic flow table a-1” for troubleshooting. 2) start engine and check that mil t...

Page 162

Engine general information and diagnosis (h25 engine) 6-1-21 [not using suzuki scan tool] (vehicle with monitor connec- tor) 1) check malfunction indicator lamp referring to “malfunction indicator lamp check” in this section. 2) with the ignition switch off position, disconnect suzuki scan tool if c...

Page 163

6-1-22 engine general information and diagnosis (h25 engine) diagnostic trouble code (dtc) clearance [using scan tool] 1) with ignition switch off, connect generic scan tool or suzuki scan tool to data link connector (dlc). 2) turn ignition switch on. 3) erase dtc according to instructions displayed...

Page 164

Engine general information and diagnosis (h25 engine) 6-1-23 diagnostic trouble code (dtc) table dtc no. Detecting item detecting condition (dtc will set when detecting : ) mil vehicle without monitor connector mil (vehicle with monitor connector) p0100 (no.34) mass air flow circuit malfunction sens...

Page 165

6-1-24 engine general information and diagnosis (h25 engine) p0154 (vehicle without diagno- sis connector)/ p0150 (vehicle with diagnosis connector) (no.26) ho2s (bank 2 – sensor 1) no activity detected output voltage of ho2s-1 fails to go above specification (or ho2s-1 circuit open). 2 driving cycl...

Page 166

Engine general information and diagnosis (h25 engine) 6-1-25 p0335 crankshaft position sensor circuit malfunction no signal for 2 sec. During engine cranking 1 driving cycle not applicable p0340 (no.42) camshaft position sensor circuit malfunction no signal during engine running. 1 driving cycle 1 d...

Page 167

6-1-26 engine general information and diagnosis (h25 engine) dtc no. Detecting item detecting condition (dtc will set when detecting : ) mil p0705 (no.72) transmission range circuit malfunction refer to section 7b1 p0715 (no.76) input/turbine speed sensor circuit malfunction p0720 (no.75) a/t vss si...

Page 168

Engine general information and diagnosis (h25 engine) 6-1-27 fail-safe table when any of the following dtcs is detected, ecm enters fall-safe mode as long as malfunction continues to exist but that mode is canceled when ecm detects normal condition after that. Dtc no. Trouble area fail safe operatio...

Page 169

6-1-28 engine general information and diagnosis (h25 engine) scan tool data as the data values given below are standard values estimated on the basis of values obtained from the normally operating vehicles by using a scan tool, use them as reference values. Even when the vehicle is in good condi- ti...

Page 170

Engine general information and diagnosis (h25 engine) 6-1-29 oxygen sensor b1 s2 (ho2s2 output voltage) when engine is running at 2000 r/min. For 3 min or longer after warming up. 0.05 – 0.95 v oxygen sensor b2 s1 (ho2s2 output voltage) when engine is running at 2000 r/min. For 3 min or longer after...

Page 171

6-1-30 engine general information and diagnosis (h25 engine) trans range ignition switch on, selector lever is at “r”, “n”, “d”, “2” or “l” range. R, n, d, 2 or l ✱ brake sw (brake, stop lamp, switch) ignition switch on, brake pedal is released. Off ✱ ignition switch on, brake pedal is depressed. On...

Page 172

Engine general information and diagnosis (h25 engine) 6-1-31 scan tool data definitions coolant temp (engine coolant temp., °c/°f) it is detected by engine coolant temp. Sensor. Intake air temp (°c/°f) it is detected by intake air temp. Sensor. Desire idle (desired idle speed rpm) the desired idle s...

Page 173

6-1-32 engine general information and diagnosis (h25 engine) throttle pos (absolute throttle position, %) when throttle position sensor is fully closed position, throttle opening is indicated as 0% and 100% for full open position. Tp sensor volt (tp sensor output voltage, v) throttle position sensor...

Page 174

Engine general information and diagnosis (h25 engine) 6-1-33 egr valve (%) this parameter indicates opening rate of egr valve which controls the amount of egr flow. A/c switch (on/off) on : command for operation being output from a/c amplifier to compressor. Off : command for operation not being out...

Page 175

6-1-34 engine general information and diagnosis (h25 engine) shift sol # 1 con/mon (shift solenoid # 1, a command/monitor, on/off) con-on : on command being output to shift solenoid # 1, a. Con-off : on command not being output. Mon-on : electricity being passed to shift solenoid # 1, a. Mon-off : e...

Page 176

Engine general information and diagnosis (h25 engine) 6-1-35 engine diagnosis table perform troubleshooting referring to following table when ecm (pcm) has detected no dtc and no abnormality has been found in visual inspection and engine basic inspection previously. Condition possible cause correcti...

Page 177

6-1-36 engine general information and diagnosis (h25 engine) engine has no power engine overheating. Refer to “overheating” in this table. Ignition system out of order. • defective spark plug “spark plugs” in section 6f2. • faulty ignition coil with ignitor “ignition coil assembly” in section 6f2. F...

Page 178

Engine general information and diagnosis (h25 engine) 6-1-37 engine hesitates (momentary lack of response as the accelerator is depressed. Can occur at all vehicle speeds. Usually most severe when first trying to make the vehicle move, as from a stop sign.) ignition system out of order. • spark plug...

Page 179

6-1-38 engine general information and diagnosis (h25 engine) excessive detona- tion (the engine makes sharp metallic knocks that change with throttle opening. Sounds like pop corn popping.) engine overheating refer to “overheating” in this table. Ignition system out of order. • faulty spark plug “sp...

Page 180

Engine general information and diagnosis (h25 engine) 6-1-39 poor gasoline mile- age ignition system out of order. • faulty spark plug (improper gap, heavy deposits, and burned electrodes, etc.) “spark plugs” in section 6f2. Engine and emission control system out of order. • fuel pressure out of spe...

Page 181

6-1-40 engine general information and diagnosis (h25 engine) engine noise see note below. Valve noise • faulty hydraulic valve lash adjuster “camshaft and valve lash adjuster” in sec- tion 6a2. • worn valve stem and guide “valves and cylinder heads” in section 6a2. • weak or broken valve spring “val...

Page 182

Engine general information and diagnosis (h25 engine) 6-1-41 ecm (pcm) substitution when substituting a known-good ecm (pcm), check for following conditions. Neglecting this check may cause damage to known- good ecm (pcm). • resistance value of all relays, actuators is as specified respectively. • m...

Page 183

6-1-42 engine general information and diagnosis (h25 engine) 1. Ecm (pcm) 2. Connector (viewed from harness side) terminal number wire color circuit normal voltage condition e61-1 wht/grn fuel pump relay output (with- out immobilizer control sys- tem) 0 – 2.5 v while 3 sec. After ignition switch tur...

Page 184

Engine general information and diagnosis (h25 engine) 6-1-43 e61-9 orn/blu selector switch signal of power mode/normal mode for a/t 0 – 1 v ignition switch turned on, a/t power mode/normal mode selector selected at power mode 10 – 14 v ignition switch turned on, a/t power mode/normal mode selector s...

Page 185

6-1-44 engine general information and diagnosis (h25 engine) e61-23 ppl duty output terminal (if equipped) 0 – 1 v ignition switch turned on immobilizer indicator lamp output (if equipped) 10 – 14 v while engine running 0 – 1 v ignition switch turned on with engine stop e61-24 ppl/wht serial communi...

Page 186

Engine general information and diagnosis (h25 engine) 6-1-45 c51-3-2 orn/blu ckp sensor signal (–) (if equipped) 0 – 1 v ignition switch turned on ✱ 4 – 6 v ↑↓ –4 – –6 v (repeated indicator) engine running at idling after warming up between ckp sensor signal (–) and (+). (input signal is sinusoidal ...

Page 187

6-1-46 engine general information and diagnosis (h25 engine) c51-3-10 yel/blu reference signal for cmp sensor ✱ 0 – 0.6 v ↑↓ 4 – 6 v (repeated indicator) engine running at idling after warming up. (sensor signal is pulse. Pulse fre- quency varies depending on engine speed. (4 pulses are generated pa...

Page 188

Engine general information and diagnosis (h25 engine) 6-1-47 c51-3-19 yel/wht ect sensor signal for combi- nation meter ✱ 0 – 0.6 v ↑↓ 4 – 6 v (repeated indicator) ignition switch turned on (output signal is 1 hz active low duty pulse. Duty ratio varies depending on ect.) ect 40°c = 45% on duty ect ...

Page 189

6-1-48 engine general information and diagnosis (h25 engine) c51-1-7 orn/blk “4wd” lamp output 0 – 1 v ignition switch turned on, transfer selector selected at “4h” or “4l” range 10 – 14 v ignition switch turned on, transfer selector selected at “2h” range c51-1-8 blu/grn a/t input shaft speed senso...

Page 190

Engine general information and diagnosis (h25 engine) 6-1-49 c51-1-15 red 4wd air pump assembly out- put 10 – 14 v ignition switch turned on, transfer selector selected at “4l” or “4h” position 0 – 1 v ignition switch turned on, transfer selector selected at “2h” position c51-1-16 blu/yel a/t input ...

Page 191

6-1-50 engine general information and diagnosis (h25 engine) c51-2-4 lt grn/ wht egr valve (stepper motor coil 2) output (if equipped) 10 – 14 v ignition switch turned on ✱ 0 – 1 v ↑↓ 8 – 14 v (repeated indicator) while engine running. (output signal is active low duty pulse. Pulse generated time de...

Page 192

Engine general information and diagnosis (h25 engine) 6-1-51 c51-2-13 brn ignition coil no.1 output 0 – 0.6 v ignition switch turned on ✱ 0 – 0.6 v ↑↓ 2 – 4 v (repeated indicator) engine running (output signal is active high pulse. Pulse frequency varies depending on engine speed.) c51-2-14 ppl/blk ...

Page 193

6-1-52 engine general information and diagnosis (h25 engine) c51-2-22 blk/brn ignition coil no.6 output 0 – 0.6 v ignition switch turned on ✱ 0 – 0.6 v ↑↓ 2 – 4 v (repeated indicator) engine running (output signal is active high pulse. Pulse frequency varies depending on engine speed.) c51-2-23 brn/...

Page 194

Engine general information and diagnosis (h25 engine) 6-1-53 resistance check 1) disconnect ecm couplers (1) from ecm with ignition switch off. 2) check resistance between each pair of terminals of discon- nected couplers as listed in following table. Caution: never touch terminals of ecm itself or ...

Page 195

6-1-54 engine general information and diagnosis (h25 engine) c51-2-7 – c51-2-20 fuel injector no.1 10 – 14 Ω – c51-2-6 – c51-2-20 fuel injector no.2 c51-2-19 – c51-2-20 fuel injector no.3 c51-2-18 – c51-2-20 fuel injector no.4 c51-2-28 – c51-2-20 fuel injector no.5 c51-2-27 – c51-2-20 fuel injector ...

Page 196

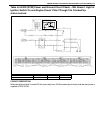

Engine general information and diagnosis (h25 engine) 6-1-55 table a-1 malfunction indicator lamp circuit check mil does not come on or mil dimms at ignition switch on leaving engine off wiring diagram circuit description when the ignition switch is turned on, ignition switch signal is sent to ecm. ...

Page 197

6-1-56 engine general information and diagnosis (h25 engine) troubleshooting step action yes no 1 test switch terminal check (vehicle with moni- tor connector) : 1) check test switch terminal of monitor con- nector for being grounded. 2) with ignition switch on leaving engine off, measure voltage be...

Page 198

Engine general information and diagnosis (h25 engine) 6-1-57 table a-2 malfunction indicator lamp circuit check mil remains on after engine starts wiring diagram/circuit description refer to table a-1. Troubleshooting table a-3 malfunction indicator lamp check mil flashes at ignition switch on (vehi...

Page 199

6-1-58 engine general information and diagnosis (h25 engine) table a-4 malfunction indicator lamp check mil does not flash or just remains on even with grounding diagnosis switch terminal (vehi- cle with monitor connector) wiring diagram/circuit description refer to table a-1. Troubleshooting step a...

Page 200

Engine general information and diagnosis (h25 engine) 6-1-59 table a-5 ecm (pcm) power and ground circuit check mil does not light at ignition switch on and engine does not start though it is cranked up. Wiring diagram circuit description when the ignition switch is turned on, the main relay turns o...

Page 201

6-1-60 engine general information and diagnosis (h25 engine) troubleshooting step action yes no 1 main relay operating sound check : is operating sound of main relay heard at igni- tion switch on? Go to step 5. Go to step 2. 2 fuse check : is main fuse in good condition? Go to step 3. Check for shor...

Page 202

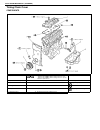

Engine general information and diagnosis (h25 engine) 6-1-61 dtc p0100 mass air flow sensor circuit malfunction (dtc no.33, 34) wiring diagram dtc detecting condition and trouble area [a] : terminal arrangement of ecm (pcm) coupler viewed from harness side 1. Main relay 2. Mass air flow sensor dtc d...

Page 203

6-1-62 engine general information and diagnosis (h25 engine) dtc confirmation procedure • intake air temperature : between –14°c and 70°c (6.8°f and 158°f) • atmospheric pressure : higher than 560 mmhg (altitude : lower than 2790 m (9150 ft)) 1) with ignition switch off, connect scan tool. 2) turn o...

Page 204

Engine general information and diagnosis (h25 engine) 6-1-63 dtc p0110 intake air temp. Circuit malfunction (dtc no.23, 25) wiring diagram dtc detecting condition and trouble area dtc confirmation procedure [a] : terminal arrangement of ecm (pcm) coupler viewed from harness side 1. Iat sensor dtc de...

Page 205

6-1-64 engine general information and diagnosis (h25 engine) • intake air temperature : between –14°c and 70°c (68°f and 158°f) • atmospheric pressure : higher than 560 mmhg (altitude : lower than 2790 m (9150 ft)) 1) with ignition switch off, connect scan tool. 2) turn on ignition switch, clear dtc...

Page 206

Engine general information and diagnosis (h25 engine) 6-1-65 dtc p0115 engine coolant temp. Circuit malfunction (dtc no.14, 15) wiring diagram dtc detecting condition and trouble area dtc confirmation procedure [a] : terminal arrangement of ecm (pcm) coupler viewed from harness side 1. Ect sensor dt...

Page 207

6-1-66 engine general information and diagnosis (h25 engine) • atmospheric pressure : higher than 560 mmhg (altitude : lower than 2790 m (9150 ft)) • intake air temperature : between –14°c and 70°c (6.8°f and 158°f) 1) with ignition switch off, connect scan tool. 2) turn on ignition switch, clear dt...

Page 208

Engine general information and diagnosis (h25 engine) 6-1-67 dtc p0120 throttle position circuit malfunction (dtc no.21, 22) wiring diagram dtc detecting condition and trouble area dtc confirmation procedure 1) with ignition switch off, connect scan tool. 2) turn on ignition switch and clear dtc by ...

Page 209

6-1-68 engine general information and diagnosis (h25 engine) dtc troubleshooting fig. For step 2 step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 tp sensor reference voltage check : 1) wit ignition switch off, disconnect tp sen- sor coupl...

Page 210

Engine general information and diagnosis (h25 engine) 6-1-69 dtc p0121 throttle position circuit performance problem wiring diagram refer to dtc p0120 (dtc no.21, 22). Dtc detecting condition and trouble area dtc confirmation procedure 1) with ignition switch off, connect scan tool. 2) turn on ignit...

Page 211

6-1-70 engine general information and diagnosis (h25 engine) dtc troubleshooting fig. For step 5 step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 tp sensor signal check : 1) remove ecm (pcm) cover. 2) start engine and warm up for normal o...

Page 212

Engine general information and diagnosis (h25 engine) 6-1-71 dtc p0130 (vehicle without diagnosis connector) ho2s (bank-1 sensor-1) circuit malfunction wiring diagram dtc detecting condition and trouble area [a] : terminal arrangement of ecm (pcm) coupler viewed form harness side 2. Ho2s 4. “ig coil...

Page 213

6-1-72 engine general information and diagnosis (h25 engine) dtc confirmation procedure 1) with ignition switch off, connect scan tool. 2) turn on ignition switch and clear dtc by using scan tool if any. 3) start engine and warm up to normal operating temperature. 4) increase vehicle speed till engi...

Page 214

Engine general information and diagnosis (h25 engine) 6-1-73 6 fuel injector inspection : 1) inspect fuel injectors (no.1, 3, 5) referring to “fuel injector” in section 6e2. Are they in good condition? Go to step 7. Faulty fuel injector(s). 7 fuel pressure inspection : 1) check fuel pressure referri...

Page 215

6-1-74 engine general information and diagnosis (h25 engine) dtc p0133 ho2s (bank-1 sensor-1) circuit slow response wiring diagram refer to dtc p0130. Dtc detecting condition and trouble area dtc confirmation procedure 1) with ignition switch off, connect scan tool. 2) turn on ignition switch and cl...

Page 216

Engine general information and diagnosis (h25 engine) 6-1-75 dtc p0134 (vehicle without diagnosis connector)/p0130 (vehicle with diagno- sis connector) ho2s (bank-1 sensor-1) no activity detected (dtc no.13) wiring diagram refer to dtc p0130. Dtc detecting condition and trouble area dtc confirmation...

Page 217

6-1-76 engine general information and diagnosis (h25 engine) 3 ho2s voltage check : 1) remove ecm (pcm) cover. 2) start engine and check voltage between c51- 3-4 and c51-3-20 while repeating racing engine. Does the voltage indicate 0.5 v or more even at once? Poor c51-3-4 and/or c51- 3-20 terminal c...

Page 218

Engine general information and diagnosis (h25 engine) 6-1-77 dtc p0135 ho2s (bank-1 sensor-1) heater circuit malfunction wiring diagram refer to dtc p0130. Dtc detecting condition and trouble area dtc confirmation procedure 1) with ignition switch off, connect scan tool. 2) turn on ignition switch a...

Page 219

6-1-78 engine general information and diagnosis (h25 engine) fig. For step 2, 3 4 ho2s heater control circuit check : 1) with ignition switch off, install ho2s heater relay. 2) with ignition switch on leaving engine off, check voltage between c51-3-6 and ground. Is the voltage 10 – 14 v? Substitute ...

Page 220

Engine general information and diagnosis (h25 engine) 6-1-79 dtc p0136 ho2s (bank-1 sensor-2) circuit malfunction wiring diagram dtc detecting condition and trouble area dtc confirmation procedure [a] : terminal arrangement of ecm (pcm) coupler viewed from harness side 2. Ho2s 4. “ig coil” fuse 1. H...

Page 221

6-1-80 engine general information and diagnosis (h25 engine) • intake air temperature : between –14°c and 70°c (6.8°f and 158°f) • atmospheric pressure : higher than 560 mmhg (altitude : lower than 2790 m (9150 ft)) • following dtcs are not detected : p0110 (no.23, 25), p0335, p0460, p1450 and p1451...

Page 222

Engine general information and diagnosis (h25 engine) 6-1-81 dtc p0141 ho2s (bank-1 sensor-2) heater circuit malfunction wiring diagram refer to dtc p0136. Dtc detecting condition and trouble area dtc confirmation procedure • intake air temperature : between –14°c and 70°c (6.8°f and 158°f) • atmosp...

Page 223

6-1-82 engine general information and diagnosis (h25 engine) fig. For step 2, 3 4 ho2s heater control circuit check : 1) with ignition switch off, install ho2s heater relay. 2) with ignition switch on leaving engine off, check voltage between c51-3-17 and ground. Is the voltage 10 – 14 v? Substitute...

Page 224

Engine general information and diagnosis (h25 engine) 6-1-83 dtc p0150 (vehicle without diagnosis connector) ho2s (bank-2 sensor-1) circuit malfunction wiring diagram dtc detecting condition and trouble area [a] : terminal arrangement of ecm (pcm) coupler viewed from harness side 2. Ho2s 4. “ig coil...

Page 225

6-1-84 engine general information and diagnosis (h25 engine) dtc confirmation procedure • intake air temperature : between –14°c and 70°c (6.8°f and 158°f) • atmospheric pressure : higher than 560 mmhg (altitude : lower than 2790 m (9150 ft)) • following dtc is not detected : p0135 1) with ignition ...

Page 226

Engine general information and diagnosis (h25 engine) 6-1-85 6 fuel injector inspection : 1) inspect fuel injectors (no.2, 4, 6) referring to “fuel injector” in section 6e2. Are they in good condition? Go to step 7. Faulty fuel injector(s). 7 fuel pressure inspection : 1) check fuel pressure referri...

Page 227

6-1-86 engine general information and diagnosis (h25 engine) dtc p0153 ho2s (bank-2 sensor-1) circuit slow response wiring diagram refer to dtc p0150. Dtc detecting condition and trouble area dtc confirmation procedure • intake air temperature : between –14°c and 70°c (6.8°f and 158°f) • atmospheric...

Page 228

Engine general information and diagnosis (h25 engine) 6-1-87 dtc p0154 (vehicle without diagnosis connector)/p0150 (vehicle with diag- nosis connector) ho2s (bank-2 sensor-1) no activity detected (dtc no.26) wiring diagram refer to dtc p0150. Dtc detecting condition and trouble area dtc confirmation...

Page 229

6-1-88 engine general information and diagnosis (h25 engine) 3 ho2s voltage check : 1) remove ecm (pcm) cover. 2) start engine and check voltage between c51- 3-15 and c51-3-20 while repeating racing engine. Does the voltage indicate 0.5 v or more even at once? Poor c51-3-15 and/or c51-3- 20 terminal...

Page 230

Engine general information and diagnosis (h25 engine) 6-1-89 dtc p0155 ho2s (bank-2 sensor-1) heater circuit malfunction wiring diagram refer to dtc p0150. Dtc detecting condition and trouble area dtc confirmation procedure • intake air temperature : between –14°c and 70°c (6.8°f and 158°f) • atmosp...

Page 231

6-1-90 engine general information and diagnosis (h25 engine) fig. For step 2, 3 4 ho2s heater control circuit check : 1) with ignition switch off, install ho2s heater relay. 2) with ignition switch on leaving engine off, check voltage between c51-3-5 and ground. Is the voltage 10 – 14 v? Substitute ...

Page 232

Engine general information and diagnosis (h25 engine) 6-1-91 dtc p0156 ho2s (bank-2 sensor-2) circuit malfunction wiring diagram dtc detecting condition and trouble area dtc confirmation procedure [a] : terminal arrangement of ecm (pcm) coupler viewed from harness side 2. Ho2s 4. “ig coil” fuse 1. H...

Page 233

6-1-92 engine general information and diagnosis (h25 engine) • intake air temperature : between –14°c and 70°c (6.8°f and 158°f) • atmospheric pressure : higher than 560 mmhg (altitude : lower than 2790 m (9150 ft)) • following dtcs are not detected : p0110 (no.23, 25), p0335, p0460, p01450 and p014...

Page 234

Engine general information and diagnosis (h25 engine) 6-1-93 dtc p0161 ho2s (bank-2 sensor-2) heater circuit malfunction wiring diagram refer to dtc p0156. Dtc detecting condition and trouble area dtc confirmation procedure • intake air temperature : between –14°c and 70°c (6.8°f and 158°f) • atmosp...

Page 235

6-1-94 engine general information and diagnosis (h25 engine) fig. For step 2, 3 and 4 4 ho2s heater control circuit check : 1) with ignition switch off, install ho2s heater relay (1). 2) with ignition switch on leaving engine off, check voltage between c51-3-16 and ground. Is the voltage 10 – 14 v? ...

Page 236

Engine general information and diagnosis (h25 engine) 6-1-95 dtc p0171 fuel system too lean (bank-1) dtc p0172 fuel system too rich (bank-1) dtc detecting condition and trouble area dtc confirmation procedure • intake air temperature : between –14°c and 70°c (6.8°f and 158°f) • atmospheric pressure ...

Page 237

6-1-96 engine general information and diagnosis (h25 engine) 6 check fuel injector circuit referring to “table b- 3” in this section. Is it in good condition? Go to step 7. Repair or replace. 7 check fuel level sensor referring to step 3 of “dtc p0460 diag. Flow table” in this section. Is check resu...

Page 238

Engine general information and diagnosis (h25 engine) 6-1-97 dtc p0174 fuel system too lean (bank-2) dtc p0175 fuel system too rich (bank-2) dtc detecting condition and trouble area dtc confirmation procedure • intake air temperature : between –14°c and 70°c (6.8°f and 158°f) • atmospheric pressure ...

Page 239