- DL manuals

- Suzuki

- Motorcycle

- GN125F

- Service Manual

Suzuki GN125F Service Manual

Summary of GN125F

Page 1

Gn125f 99500h3030de001.

Page 2: Foreword

Dachangjiang group co.,ltd. December, 2014 (the 1st edition) ©copyright da 2014 changjiang group co.,ltd. Foreword 8 this manual contains an introductory description on the suzuki and procedures for its inspec- tion/service and overhaul of its main components. Other information considered as general...

Page 3: How To Use This Manual

Component parts and work to be done under the name of each system or unit, is its exploded view. Work instruction and tightening torque, lubricating points and locking points, are provided. Example: front wheel 1 2 3 4 5 6 7 a 8 b n•m kgf•m 18-28 36-52 1.8-2.8 3.6-5.2 front axle shaft spacer dustcov...

Page 4: Symbol

Symbol the following symbols are instructions and necessary information for maintenance. Torque control required. Data beside it indicates specified torque. Apply oil. Use engine oil unless otherwise specified. Apply moly paste 99000-25140 apply or use the absorber oil apply thread lock “1342" 99000...

Page 5

Wire color o/bl o/w o/y r/b r/y w/b w/r y/g y/r y/w orange with blue tracer orange with white tracer orange with yellow tracer red with black tracer red with yellow tracer white with black tracer white with red tracer yellow with green tracer yellow with red tracer yellow with white tracer ............

Page 6: General Information

General information 1 contents 1 1-1 1-1 1-2 1-2 1-2 1-3 warning/caution/note general precautions serial number location fuel and oil recommendation break-in procedure specifications.

Page 7: Warning/caution/note

G e n e r a l i n f o r m at i o n warning/caution/note indicates a potential hazard that could result in death or injury. Indicates a potential hazard that could result in motorcycle damage. Note: indicates special information to make maintenance easier or instructions clearer. General precaution w...

Page 8

1-2 g e n e r a l i n f o r m at i o n note: if parts replacement is necessary, replace the parts with suzuki genuine parts or their equivalent. When removing parts that are to be reused, keep them arranged in an orderly manner so that they may be reinstalled in the proper order and orientation. Be ...

Page 9: Serial Number Locations

Serial number locations the frame serial number or v.I.N. (vehicle identification number) 1 is stamped on the right side of the steering head pipe. The engine serial number 2 is located on the left side of the c r a n k c a s e . T h e s e n u m b e r s a r e r e q u i r e d especially for registeri...

Page 10: Specifications

G e n e r a l i n f o r m at i o n 1-3 specifications dimensions and curb weight 2 000 mm 815 mm 1 100 mm 1 300 mm 175 mm 113 kg overall length overall width overall height wheelbase ground clearance curb weight engine single cylinder, vertical, air-cooled, four stroke 1 57 mm 48.8 mm 124 ml 9.2 : 1...

Page 11

G e n e r a l i n f o r m at i o n 1-4 electric ignition type ignition timing spark plug battery fuse headlight tail light/brake light turn signal light position light cdi 13° b.T.D.C below 2 000 r/min ngk cr8e 12v 7ah 15 a 12v, 35w/35w 12v, 5w/21w 12v, 10w 12v, 5w chassis front absorber rear absorb...

Page 12: Periodic Maintenance

Periodic maintenance periodic maintenance maintenance procedures contents 2 2-1 2-3 2-3 2-4 2-5 2-5 2-5 2-6 2-7 2-7 2-8 2-8 2-8 2-9 2-9 2-9 2-10 2-11 2-14 2-14 2-14 2-15 2-15 2-17 2-18 battery/fuse air filter muffler nut and bolt cylinder head, cylinder bolts and nuts valve clearance spark plug engi...

Page 13: Periodic Maintenance

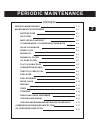

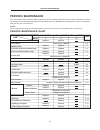

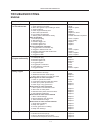

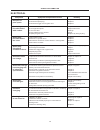

Periodic maintenance 2-1 periodic maintenance the chart below lists recommended intervals for all the required periodic service work necessary to keep the motorcycle operating at peak performance and economy. Mileages are expressed in terms of kilometer and time for your convenience. Note: more freq...

Page 14: Lubrication Chart

P e r i o d i c m a i n t e n a n c e 2-2 lubrication chart throttle cable throttle grip clutch cable drive chain tachometer cable brake cam shaft steering swing arm bearings initial and every 5 000 engine oil engine oil motor oil, every 1 000 km every 10 000 grease grease grease every 2 years or 20...

Page 15: Maintenance Procedures

P e r i o d i c m a i n t e n a n c e 2-3 maintenance procedures battery / fuse inspect initial 1 000 km and every 5 000 km when installing the battery lead wires, fix the lead first and lead last. 09900-28403 : hydrometer fuse battery the battery must be removed to check the electrolyte level and s...

Page 16

P e r i o d i c m a i n t e n a n c e 2-4 air cleaner clean every 3 000 km do not twist or wring the element because it will tear or the individual cells of the element will be damaged. If driving under dusty condition clean the air cleaner element more frequently. , make sure the drain plug is fitt...

Page 17

P e r i o d i c m a i n t e n a n c e 2-5 muffler bolts muffler bolt : 11~15 n•m inspect initial 1 000 km and tighten every 5 000 km inspect initial 1 000 km and every 5 000 km. Cylinder head nut: 21~25 n•m tighten the muffler bolts to the specified torque. Tighten four m10 nuts to the specified tor...

Page 18

P e r i o d i c m a i n t e n a n c e 2-6 09900 20803 thickness gauge 11f14-017: valve adjust spring - : valve clearance specifications hook the valve rocker arm with the special tool, insert the thickness gauge to the valve stem end and the adjusting screw on the rocker arm. If the clearance is off...

Page 19

P e r i o d i c m a i n t e n a n c e 2-7 engine oil change initial 1 000 km and every 3 000 km engine oil should be changed while the engine is hot. Start up the engine and allow it to run for several minutes at idling speed. Shut down the engine and wait about two minute. Then check the oil level ...

Page 20

P e r i o d i c m a i n t e n a n c e 2-8 oil sump filter clean every 10 000 km clean the sump filter to remove any foreign matter that may be collected there. Inspect the screen to insure that it is free of any sign of damage. Clutch inspect initial 1 000 km and every 5 000 km. 4mm 4mm the clutch p...

Page 21

P e r i o d i c m a i n t e n a n c e 2-9 fuel hose inspect initial 1 000 km and every 5 000 km. Replace every 4 years. Fuel strainer clean initial 1 000 km and every 5 000 km. Inspect the fuel hose and connections for damage and fuel leakage. If any defects are found, the fuel hose must be replaced...

Page 22

P e r i o d i c m a i n t e n a n c e 2-10 drive chain clean and lubricate every 1 000 km drive chain / sprocket cleaning and lubrication drive chain adjustment too much chain slack can cause the chain to come off the sprocket, resulting in an accident or serious damage to the motorcycle. Inspect an...

Page 23

P e r i o d i c m a i n t e n a n c e 2-11 brakes inspect initially at 1 000 km and every 5 000 km. Replace hose every 4 years. Change fluid every 2 years. Front brake(disc type) brake fluid level specification and classification: dot 3 or dot 4 the brake system of this motorcycle is filled with a g...

Page 24

P e r i o d i c m a i n t e n a n c e 2-12 air bleeding the brake fluid circuit handle the brake fluid with care: the fluid reacts chemically with paint, plastics, rubber materials, etc. Replenish the brake fluid reservoir as necessary while bleeding the brake system. Make sure that there is always ...

Page 25

P e r i o d i c m a i n t e n a n c e 2-13 rear brake h rear brake pedal height rear brake pedal travel adjust the brake pedal limit screw to set the brake pedal at the position of 10-20mm higher than the footrest, then tighten the locking nut . Rear brake travel is the distance from stepping on the...

Page 26

P e r i o d i c m a i n t e n a n c e 2-14 check the tire pressure and surface during the maintenance. There are serial marks t.W.I. (tire wear indicator) in the edge of the tire. Check the block of t.W.I. In the tread near the mark. If the tire wears off to reach the boss, the tire should be replac...

Page 27

P e r i o d i c m a i n t e n a n c e 2-15 inspect initial 1 000 km and every 5 000 km rear absorber lighting and signal inspect the headlight, left and right turn signal light, tail light / brake light and dashboard signal light, replace the light if there is something unusual. (refer to page 6-7) ...

Page 28

P e r i o d i c m a i n t e n a n c e 2-16.

Page 29

Compression pressure a low compression pressure may indicate any of the following malfunctions: excessively worn cylinder wall. Worn piston or piston rings. Piston rings stuck in the grooves. Poor seating contact of valves. Defective cylinder head gasket. Note: before testing the engine for compress...

Page 30

Oil pressure support the motorcycle with the main stand; install the oil pressure gauge in the position shown in the illustration. Warm up the engine as follows. Summer: approx. 10 min. At 2 000 r/min. Winter: approx. 20 min. At 2 000 r/min. After the warming up operation, increase the engine speed ...

Page 31: Engine

Engine contents removable engine parts with engine in place engine removal and remounting cylinder head and valve cylinder and piston clutch oil pump gear shifting shaft generator and starting clutch crankshaft, transmission and kick starter device 3 3-1 3-2 3-6 3-17 3-21 3-25 3-26 3-27 3-31.

Page 32

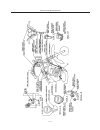

Removing engine parts with engine in place e n g i n e 3-1 upper side of engine right side of engine left side of engine chain tensioner cam shaft cylinder head cover cylinder head cylinder piston oil filter clutch cover clutch oil pump gear shifting shaft sprocket cover starting motor generator rot...

Page 33

E n g i n e 3-2 engine removal and installation engine removal before taking the engine out of the frame, wash the engine with a suitable cleaner. The procedure of engine removal is sequentially explained in the following steps: support the motorcycle with main stand. Drain the engine oil. Remove th...

Page 34

E n g i n e 3-3 remove the generator and gear indication light coupler 5 and . Disconnect the carburetor balancer pipe by unscrewing the clamp screws. Take off the engine sprocket cover disconnect the ground wire from the crankcase. Take off the drive chain by removing the clip . . Remove the crankc...

Page 35

E n g i n e 3-4 remove the lead wire of starter motor wire. Take off the spark plug cap . Remove the muffler mounting bolt . Remove the muffler mounting bolts then take off the muffler. , remove the engine front mounting bolt and engine lower hanging plate bolt , take off the engine lower hanging pl...

Page 36

E n g i n e 3-5 engine remounting the engine can be mounted in the reverse order of removal. Engine mounting nut : 33-39 n•m engine lower hanging nut : 22-33 n•m swing arm nut :50-80 n•m muffler bolt :11-15 n•m install the drive chain and drive chain clip . Align the release arm slit surface with th...

Page 37: Cylinder Head And Valve

E n g i n e 3-6 cylinder head and valve when removing cylinder head cover piston must be at top dead center on compression stroke. , removal drain the engine oil, take off the engine. (refer to page 3-2) remove the generator cover cap and valve timing inspect- ing plug . Bring the piston to top dead...

Page 38

E n g i n e 3-7 do not drop camshaft drive chain, pin and sprocket into the crankcase. . The cam chain tensioner bolt is to be removed only when disassembling the engine a a remove the camshaft sprocket bolts and detach the cam- shaft. Remove the cylinder head side nuts and cylinder side nuts. Loose...

Page 39

E n g i n e 3-8 take off the valve cotters from the valve stem. Take out the valve spring retainers inner springs and outer springs. Pull out the valves from the other side. , remove the oil seal. Remove the spring lower retainer . After removed the sealant from the fitting surface of the cylinder h...

Page 40

E n g i n e 3-9 rocker arm h 09900 20605: caliper gauge - 09900-22302: plastigage (0.051 – 0.152 mm) check the inside diameter of the valve rocker arm and wear of the camshaft contacting surface. The camshaft should be checked for runout and also for wear of cams and journals if the engine has been ...

Page 41

E n g i n e 3-10 valve spring 09900 20103: vernier calipers - measure the valve spring free length. Measure the thickness , and if the thickness is found to have been reduced to the limit, replace the valve. Check the spark plug hole and valve of combustion chamber part for scratch. Check the gasket...

Page 42

E n g i n e 3-11 place the dial gauge at right angles to the valve head, and measure the valve head radial runout. If it measures more the limit, replace the valve . 09900-20606: dial gauge (1/100 mm) 09900-20701: magnetic stand 09900-21304: v-block ( 100 mm) valve stem runout limit: 0.03 mm support...

Page 43

E n g i n e 3-12 valve seat angle valve width intake exhaust 30 , 45 o o 15 , 45 o o 0.9-1.1mm check the contact surface institute. If found any defective, service the valve seat. 45 o 15 o exhaust side n-122 n-121 45 o 30 o 60 o intake side n-122 n-126 n-111 09916-21110: valve reamer set damaged su...

Page 44

Width valve seat width: 0.9-1.1 mm 45 o 3-13 e n g i n e 09900-20103: vernier calipers check the contact width. If contact width is too small, cut the valve seat with a 45 reamer to raise. O after the desired seat position and width is achieved, apply a layer of lapping compound and use the reamer v...

Page 45

E n g i n e 3-14 cylinder head assembly gasoline is very explosive, be sure to keep the work area well ventilated. Keep away from fire and spark. Clean and assemble cylinder head and valve components. Fill intake and exhaust ports with gasoline to check for leaks and worn seals. If any leaks occur, ...

Page 46

E n g i n e 3-15 11f14 018: valve spring tools - cylinder head cover assembly reassembly do not let dirt and dust get into the engine. Install the valve cotters with the special tool. Clean the cylinder head cover throughly with detergent. Lubricate the rocker arm shaft with engine oil. Mount the ro...

Page 47

E n g i n e 3-16 cylinder head nut: 21-25 n•m install the four nuts and washers, tighten the nuts to specified torque. Cylinder side nut: 8-12 n•m install the four cylinder side nuts, tighten the nuts to the specified torque. Inspect the valve clearance. (refer to page 2-5) bring the piston to top d...

Page 48: Cylinder And Piston

E n g i n e 3-17 cylinder and piston cylinder removal inspection 09900-20803: thickness gauge 09900-20508: cylinder gauge set 09910 34510: piston pin remover - piston removal and inspection removal place a clean rag over the cylinder base to prevent piston pin circlip from dropping into crankcase. H...

Page 49

E n g i n e 3-18 inspection 09900-20803: thickness gauge using a soft-metal scrapper or discarded piston ring to decarbon the ring grooves of the piston. Do not use the steel brush or the piston will be scratched. 09900-20203: micrometer (50~75 mm) 09900-20605: caliper gauge 09900-20205: micrometer ...

Page 50

E n g i n e 3-19 make sure to fit the piston ring in the cylinder evenly with the piston head. 09900-20803 thickness gauge : reassembly hold each piston ring with the piston rings properly spaced and insert them into the cylinder. Check to insure that piston rings are properly inserted in the the cy...

Page 51

E n g i n e 3-20 hold each piston ring with their properly spaced and insert them into the cylinder. Check to insure that the piston rings are properly inserted into the cylinder skirt. Before assembling the cylinder head, apply oil to conrod big end, small end and piston sliding part. Install the d...

Page 52: Clutch

E n g i n e 3-21 clutch drain the engine oil remove the oil filter cover nuts, take off the oil filter cover remove the oil filter. . . Remove the clutch cover screws diagonally, take off the clutch cover . Remove the gasket and dowel pins. Removal remove the clutch spring bolts diagonally. Remove c...

Page 53

E n g i n e 3-22 flatten the lock washer.. Hold the clutch hub with the special tool, remove the clutch hub nut and lock washer. 09920-53710: clutch sleeve hub holder remove the clutch hub and washer. Remove the primary driven gear, spacer and washer. Measure the thickness and claw width of each dri...

Page 54

E n g i n e 3-23 measure each driven plate for distortion with a thickness gauge. Replace all driven plates if any of them exceeds the limit. 09900 20803: thickness gauge - replace the drive and drive plates as a whole set which exceed the limit. Drive plate claw width limit: 11.0 mm driven plate di...

Page 55

E n g i n e 3-24 reassembly reassemble the clutch in the reverse order of removal, pay attention to the following points: clutch sleeve hub nut: 30-50 n·m 09920 53710: clutch driven hub holder - bend the clutch sleeve hub washer to the nuts. Install the clutch drive plates and driven plates. Install...

Page 56: Oil Pump

E n g i n e 3-25 reassembly apply a small quantity of engine oil to the inside the oil pump before assembly. Apply thethread lock “1342” to the oil pump mounting bolts and tighten the bolts . 99000-32050: thread lock "1342" removal oil pump remove the clip, oil pump driven gear and oil pump driven g...

Page 57: Gear Shifting Shaft

E n g i n e 3-26 gear shifting shaft removal reassemble the gear shifting shaft in the reverse order of removal, pay attention to the following points: check the return spring for damage, gear shifting shaft 8 for wear or bending. Remove the gear shifting shaft remove the screws, gear shifting cam g...

Page 58

E n g i n e 3-27 generator & starting clutch removal remove the generator rotor nut while holding the generator rotor with the special tool. Remove the generator cover remove the gasket and dowel pins. Remove the starting motor by removing the bolts . Remove the engine sprocket cover . Disconnect th...

Page 59

E n g i n e 3-28 remove the generator stator remove the trigger coil . . Hold the generator rotor with the special tool, remove the starting clutch bolt. Remove the roller , push piece , and spring from the starting clutch. Remove the starter clutch gear. Remove the generator rotor and key with the ...

Page 60

E n g i n e 3-29 inspection install the starter driven gear to the starter clutch and turn the starter driven gear by hand to inspect the starter clutch for a smooth movement. The gear turns one direction only. If a large resistance is felt to rotation, inspect the starter clutch for damage or inspe...

Page 61

E n g i n e 3-30 fit the key in the crankshaft key slot. When installing the rotor, align the rotor key slot with the key on the crankshaft. Install the generator nut, tighten the nut to the specified torque. When installing the key, take care not to damage the key slot and crankshaft. Generator nut...

Page 62

E n g i n e 3-31 crankshaft, transmission and kickstarterset. Removal remove the cylinder head and cylinder. (refer to page 3-7) remove the clutch and gear shifting shaft.(refer to page 3- 21) remove the generator rotor and starting clutch. (refer to page 3-27) remove the neutral locate screw plug a...

Page 63

E n g i n e 3-32 fit the crankcase separator, so that the tool plate is parallel with the end face of the crankcase. Remove the right crankcase with the special tool. Remove the gear shifting hub fixing spring. Remove the gear shifting shafts, take off the forks. Remove the gear shifting hub. Remove...

Page 64

E n g i n e 3-33 inspection support the crankshaft with “v” blocks as shown. Measure the crankshaft runout with the dial gauge. Measure the big end of the conrod side clearance with a thickness gauge. 09900-20803: thickness gauge 09900-20606: dial gauge (1/100 mm) 09900-20701: magnetic stand 09900-2...

Page 65

E n g i n e 3-34 ● inspect the gear shifting hub guide slot. Replace the gear shifting hub if the guide slot is damage. Inspect each bush, gear inner surface and gear teeth face for abnormal wear or poor lubrication. Remove the bearing locating plates on left and right crankcase. Rotate the inner ra...

Page 66

E n g i n e 3-35 install the bearings on the left and right crankcase with the special tool. Reassemble in the reverse order of removal, pay attention to the following points: reassmebly 09913-70210: bearing installer bearing crankshaft decide the width between the webs when rebuilding the crankshaf...

Page 67

E n g i n e 3-36 never fit the crankshaft into the crankcase by striking it with a plastic hammer always use the special tool otherwise crankshaft alignment accuracy will be affected. . , transmission never reuse a circlip. After a circlip has been removed from a shaft, it should be discarded and a ...

Page 68

E n g i n e 3-37 press-fit 2nd drive gear onto the counter shaft. Before reassembling, coat the internal face of the 2nd drive gear with thread lock super “1303b”and install it so that the length as shown in fig. A a 99000-32030: thread lock super "1303" the procedure may be performed only twice bef...

Page 69

E n g i n e 3-38 , note: two kinds of gear shifting forks, and are used. They resemble each other very closely in extermal appearance and configuration. Carefully examine the i l l u s t r a t i o n f o r c o r r e c t i n s t a l l i n g p o s i t i o n s a n d directions. Crankcase coat super grea...

Page 70: Fuel And Lubrication

Fuel and lubrication contents fuel cock carburetor lubrication system 4-1 4-3 4-7 4.

Page 71

F u e l a n d l u b r i c at i o n s y s t e m 4-1 fuel cock and fuel filter turn the fuel cock to ” ” position shown in photo and disconnect fuel hose from the fuel cock. Place a clean pan under the fuel cock assembly, turn fuel cock to “ ” position and drain the gasoline. Remove the fuel filter. R...

Page 72

F u e l a n d l u b r i c at i o n s y s t e m 4-2 reassembly reassemble the fuel cock or fuel filter in the reverse order of removal. Pay attention to the following points: install the fuel cock . Install the fuel filter. Gasket must be replaced with a new one to prevent leakage. Gasket do not miss...

Page 73: Carburetor

F u e l a n d l u b r i c at i o n s y s t e m 4-3 carburetor carburetor construction a e b c d item specification item specification carburetor type i.D. No. Main jet bubbling jet needle needle jet idle jet idle air screw idle air jet # 12.5 -0(390) p 4dh41-2 Ø 3 # 110 054g bs26 1400 100 r/min ± 2,...

Page 74

F u e l a n d l u b r i c at i o n s y s t e m 4-4 removal and disassembly disconnect the carburetor balance pipe . Remove the carburetor clamp screw . Remove the throttle cable remove the fuel hose remove the carburetor. . . Remove the carburetor diaphragm cover. Remove the spring, diaphragm and pi...

Page 75

F u e l a n d l u b r i c at i o n s y s t e m 4-5 remove the float pin screws. Pull out the float pin and remove the float and needle valve. Remove the main jet remove the bubbling jet . Remove the idle jet . . B c a b c needle valve inspection if foreign matter is caught between the valve seat and...

Page 76

F u e l a n d l u b r i c at i o n s y s t e m 4-6 remounting remount the carburetor by reversing the sequence of removal steps, and following adjustments and inspection are necessary after remounting the carburetor. Throttle cable play adjust the throttle cable play to be 0.5-1.0 mm. Adjust the thr...

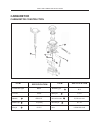

Page 77: Lubrication System

F u e l a n d l u b r i c at i o n s y s t e m 4-7 lubrication system rocker arm shaft camshaft journal and cam face camshaft conrod small end bearing cylinder wall conrod big end bearing driveshaft bearing drive shaft and gears clutch plates primary driven gear spacer countershaft and gears counter...

Page 78: Chassis

Chassis contents front wheel front absorber steering stem front brake rear wheel and rear brake rear absorber and rear swing arm 5-1 5-6 5-12 5-18 5-24 5-30 5.

Page 79: Front Wheel

C h a s s i s 5-1 front wheel item n•m kgf•m a 36-52 3.6-5.2 18-28 1.8-2.8 b b front axle front axle nut oil seal brake disc bolt spacer dust seal washer brake disc roller bearing spacer front tire front rim speedometer gear driver oil seal speedometer gear box construction a 10 11 12 13.

Page 80

C h a s s i s 5-2 removal and disassembly support the motorcycle by the center stand. Disconnect the front brake and speedometer cable . Remove the front axle nut , take off the front wheel . Remove the speedometer gearbox assembly . Remove the front axle spacer and front wheel assembly dust seal . ...

Page 81

C h a s s i s 5-3 remove the bearings on both sides with the special tool, take off the spacer. 09921-20240: bearing remover tool inspection inspect the oil seal for wear or damage, replace the oil seal if there are any defects. Using the special tools check the axle shaft for runout and replace it ...

Page 82

C h a s s i s 5-4 reassembly reassemble and remount the front wheel in reverse order of removal. Pay special attention to the following points. Apply super grease ”a” to bearings before reassembly. 99000-25010: super grease ”a” the sealed cover of the bearing must face outside. 09924-84521: bearing ...

Page 83

C h a s s i s 5-5 brake disc make sure that the brake disc is clean and free of any greasy matter. Install the brake disc, tighten to the brake disc bolts to the specified torque. Bend the lock washer to the brake disc bolt. Front brake disc bolt: 18~28 n•m front axle shaft install the front wheel a...

Page 84: Front Absorber

C h a s s i s 5-6 front absorber construction b 3 9 10 11 o-ring plug tube oil lock piece oil seal item n•m kgf•m a 4 5 6 12 13 washer rebound spring ring oil seal outer tube 7 8 14 a b damper rod inner tube front axle pinch bolt oil seal stopper ring seal ring damper rod bolt b 35-55 3.5-5.5 20-26 ...

Page 85

C h a s s i s 5-7 removal and disassembly remove the front wheel (refer to page 5-2). Remove the two bolts and dismount the front caliper . Remove the cap bolt and draw out the spacer and absorber spring. 1 remove the four bolts and take off the front fender . Remove the four handlebar holder clamp ...

Page 86

C h a s s i s 5-8 11f14 010: front absorber tools - invert the absorber and stroke it several times to remove the oil. Remove the damper rod bolt by using the special tools and hexagon wrench . Remove the oil lock piece and damper rod with rebound spring. Separate the inner tube from the outer tube....

Page 87

C h a s s i s 5-9 inspection damper rod ring inner tube and outer tube spring thread lock inspect the damper rod ring for wear and damage . Inspect the inner tube and outer tube sliding surface for any scuffing or flaws. Measure the spring free length. If it is shorter than the service limit, replac...

Page 88

C h a s s i s 5-10 oil seal install the oil seal to the outer tube by using the special tool as shown . 09940-50112: absorber oil seal installer apply super grease lightly on the oil seal lip. Upside downside front absorber spring when installing the front fork spring, the close pitch end should pos...

Page 89

C h a s s i s 5-11 reassembly reassemble the front absorbers in the reverser order of removal. Pay attention to the following points: absorber oil type: #34 apply a small quantity of absorber oil to the o-ring on the front absorber. Tighten the front absorber lower bracket clamp bolts to the specifi...

Page 90: Steering Stem

C h a s s i s 5-12 steering stem construction item n•m kgf•m a b c 35~55 3.5~5.5 12~20 1.2~2.0 25~35 2.5~3.5 11 12 13 14 15 16 a steering stem nut dust seal handlebar clamp bolt lower bracket clamp bolt 8 9 b c upper bearing outer race 10 steering stem bolt washer ball upper bearing inner race lower...

Page 91

C h a s s i s 5-13 removal disconnect the couplers and lead wires. Remove the lead wires from the headlight housing. Remove the two bolts and take off the headlight housing. Remove the two nuts and take off the turn signal lights, right and left. Loosen the lower bracket bolts. Remove the tachometer...

Page 92

C h a s s i s 5-14 remove the two bolts and take off the dashboard assembly. Remove the ignition switch cover. Remove the handlebar holder clamp bolts, take off the handlebar . Remove the front absorber cap bolts and steering stem nut, take off the upper bracket. Take off the front absorbers. 1 1 re...

Page 93

C h a s s i s 5-15 inspection . Handlebars distortion. Handlebars clamp wear. Race wear and brinelling worn or damaged steel balls. Distortion of steering stem. Remove the upper and lower steel balls. Remove the outer race fitted on the steering stem. This can be down with a chisel. Draw out the two...

Page 94

C h a s s i s 5-16 reassembly inner races outer race 09940-34513: steering race installer 09941-74910 : steering bearing installer steel ball reassemble and remount the steering stem in the reverse order of removal, and carry out the following steps: press in the upper and lower inner races with a s...

Page 95

C h a s s i s 5-17 turn back the stem nut by 1/4-1/2 turn. 1/4-1/2 turn back the adjustment will vary from motorcycle to another. Tighten the steering stem head bolts to the specified torque. Set the handlebar to match its punched mark to the mating face of the holder. Secure the each handlebar clam...

Page 96: Front Break

C h a s s i s 5-18 front break construction 1 b 2 c 3 4 5 a brake lever piston cup set brake light switch brake hose pad set master cylinder clamping bolt brake hose union bolt air bleeder valve item n•m kgf•m a b 8-12 0.8-1.2 20-25 2.0-2.5 c 6-9 0.6-0.9 a b b c.

Page 97

C h a s s i s 5-19 the brake system of this motorcycle is filled with a suzuki brake fluid. Do not use or mix different types of fuid such as silicone-based and petroleum-based fluid for refilling the system, otherwise serious damage will be caused. Do not use any brake fluid taken from old or used ...

Page 98

C h a s s i s 5-20 caliper disconnect the brake hose from the caliper catch the brake fluid in a suitable receptacle. Remove the caliper mounting bolts and then take off the caliper. Remove the brake pads. Place a rag over the piston to prevent popping up. Force out the piston by using air gun. Remo...

Page 99

C h a s s i s 5-21 piston inspect the piston surface for scratches or other damage. Inspect the rubber parts for cracks and damage. If any defects are found, replace the affected parts. Visually inspect brake disc for cracks or damage, and measure brake disc thickness with a micrometer. Measure the ...

Page 100

C h a s s i s 5-22 tighten the brake hose union bolt to the specific torque. Bleed air from the brake fluid circuit after reassembly the cliper. (refer to page 2-13) brake hose union bolt: 20~25 n•m brake fluid, if it leaks, will interfere with safe running and immediately discolor painted surfaces....

Page 101

C h a s s i s 5-23 i n s p e c t i o n inspect the master cylinder bore for any scratches or other damage. Inspect the piston surface for scratches or other damage. Inspect the primary cup, secondary cup and dust seal boot for wear or damage. Wash the master cylinder components with fresh brake flui...

Page 102

C h a s s i s 5-24 rear wheel and rear brake construction 1 2 3 4 5 6 7 8 9 rear axle shaft rear sprocket tire roller bearing spacer oil seal roller bearing rear sprocket drum retainer rear sprocket drum brake rod brake shoe rear break anchor panel brake cam lever rear wheel roller bearing spacer re...

Page 103

C h a s s i s 5-25 removal and disassembly support the motorcycle by the center stand. Remove the rear brake adjuster nut. Puff off the cotter pin, remove the torque link nut and bolt. Remove the rear axle nut. Loosen the chain adjuster lock nut and adjuster bolt, right and left. Draw out the axle s...

Page 104

C h a s s i s 5-26 remove the cam lever nut and bolt. Pull off the brake cam, washer, o-ring and cam lever. Inspect the wheel bearings for play by hand, rotate the inner race by hand to inspect whether abnormal noise occurs and it rotates smoothly. Replace the bearing if there are any defects. Inspe...

Page 105

C h a s s i s 5-27 axle shaft using the special tools, check the axle shaft for runout and replace it if the runout exceeds the limit. Inspect the sprocket teeth for wear. If they are worn as illustrated, replace the sprocket and drive chain. Measure the brake drum i d to determine the extent of wea...

Page 106

C h a s s i s 5-28 reassembly reassemble and remount the rear wheel and rear brake in the reverse order of disassembly and removal, and also carry out the following steps. The bearing apply grease to the bearings before installing. Install the bearings by using the special tool. Insert the bearing b...

Page 107

C h a s s i s 5-29 brake cam apply grease to the brake cam . 99000-25010: super grease “a” be careful not to apply too much grease to the brake cam. If the grease gets on the lining, the brake slippage will result. Warning brake cam lever install the brake cam lever and tighten the cam lever nut wit...

Page 108

C h a s s i s 5-30 construction 1 2 3 4 5 6 7 8 9 rear swingarm pivot shaft dust seal thrust washer oil seal spacer spacer washer rear torque link rear swing arm lock washer bolt chain buffer rear swing arm pivot nut rear torque link nut item n m kgf m a b 50-80 5.0-8.0 10-15 1.0-1.5 10 11 12 a b a ...

Page 109

C h a s s i s 5-31 removal and disassembly remove the rear wheel (refer to page 5-24) remove the rear absorber mounting nuts, take off the rear absorber, right and left.. Remove the chain case mounting screws, take off the chain case. Remove the swing arm pivot nut and draw out the shaft remove the ...

Page 110

C h a s s i s 5-32 inspect the bushing for wear and damage. Using a dial gauge check the pivot shaft for runout and replace it if the runout exceeds the limit. , inspection bushing swing arm pivot shaft 09900-20606: dial gauge (1/100) 09900-20701: magnetic stand 09900-21304: v block - pivot shaft ru...

Page 111: E L E C T R I C A L

E l e c t r i c a l contents starter system ignition system charging system dashboard lights switches battery 6-1 6-5 6-7 6-11 6-12 6-12 6-15 6 6.

Page 112: Starter

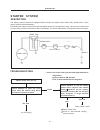

E l e c t r i c a l 6-1 starter system description the starter system is shown in the diagram below: namely, the starter motor, starter relay, starter button, clutch switch, ignition switch and battery. Depressing the starter switch(on the right handlebar switch box) energizes the relay, causing the...

Page 113

E l e c t r i c a l 6-2 starter motor disassembly remove the starter motor. (refer to page 3-7) disassemble the starter motor as shown. 1 2 3 4 5 6 o-ring housing end(outside) starter motor body amature shaft carbon brush housing end(inside) measure the starter relay voltage at the starter relay con...

Page 114

E l e c t r i c a l 6-3 starter motor inspection carbon brush commutator armature coil starter motor reassembly inspect the commutator for discoloration abnormal wear. If the commutator is abnormally worn replace the armature if the commutator surface is discolored polish it with 400 sandpaper and w...

Page 115

E l e c t r i c a l 6-4 measure the relay coil resistance between the terminals using the multi circuit tester. If the resistance is not within the specified value, replace the starter relay with a new one. 09900-25008: pocker tester starter relay resistance: 3-6 Ω tester knob indication: resistance...

Page 116: Ignition System

E l e c t r i c a l 6-5 ignition system t r i g g e r c o i l i g n i t i o n s w i t c h spark plug b a t t e r y i g n i t i o n c o i l generator r o/y o/y b/w w g fuse description in the capacitor discharged ignition system, the electrical energy generated by the magneto charges the capacitor. T...

Page 117

E l e c t r i c a l 6-6 ignition coil kΩ Ω tap tap spark plug (refer to page 2-7) remove the spark plug cap . Inspect the resistence of ignition coil with the pocket tester. 09900-25008: pocket tester primary: 3 4-4.6 ) secondary: 11.05-14.95 k tap plug cap) . Ω (tap-tap Ω ( - tester knob indication...

Page 118: Charging System

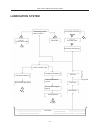

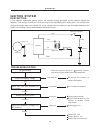

E l e c t r i c a l 6-7 charging system description troubleshooting battery runs down quickly check accessories which excessively waste electric power remove accessories faulty generator coils or disconnected lead wires. Installed not installed no leak correct short circuit of wiring harness. Loose ...

Page 119

E l e c t r i c a l 6-8 m a inspection battery leak current inspection remove the left side cover . Turn the ignition switch to the off position. Disconnect the battery lead wire. Measure voltage between the battery - terminal and the specified ground cable terminal if the reading exceeds the specif...

Page 120

E l e c t r i c a l 6-9 generator no-load performance inspection disconnect the generator coupler. (refer to page 6-4) start engine and keep it running at 5,000 rpm. Measure voltage between generator terminal and ground by using the pocket tester. If the reading is below standard values, replace wit...

Page 121: Fuel Level Gauge

E l e c t r i c a l 6-10 fuel level gauge removal b a resistence float position full empty a b 09900-25008: pocket tester tool Ω tester knob indication: x 1 range Ω 4-10Ω 90-100Ω inspection fuel level gauge remove the fuel lever gauge. (refer to page 4-3) check the resistance of each float position ...

Page 122: Dashboard

E l e c t r i c a l 6-11 remove the dashboard assembly. (refer to page 5-13) disassemble the dashboard assembly as follows. Using the pocket tester, check the continuity between lead wires. If the continuity measured is incorrect, replace the respective parts. Dashboard inspection when making this t...

Page 123: Lights

E l e c t r i c a l 6-12 headlight turn signal light lights tail light/brake light switches inspect each switch for continuity with the pocket tester if any abnormality is found, replace the respective switch assemblies with new ones. . 09900-25008: pocket tester test scale: continuity ignition swit...

Page 124

E l e c t r i c a l 6-13 starter switch front brake light switch ○ ○ off on ○ ○ off b b y/g o/w 2 engine stop switch o/b o/w dimmer switch turn signal light switch horn switch ○ ○ ○ ○ b/l b/w ○ ○ off ○ ○ ○ ○ y/w w y b sb lg 1 1 2 3 4 5 3.

Page 125

E l e c t r i c a l 6-14 rear break light switch o w/b ○ ○ off on gear position indication light switch ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ neutral low 2nd 3rd 4th top y/l br/r g/l w/y r/b l ground clutch switch b/y b/w ○ ○ pass switch y o ○ ○ free push push 10 9 7 8.

Page 126: Battery

Battery specifications type 12n7-4a capacity 7 ah standard electrolyte s.G. 1.28 ± 0.01 20 c o battery r breathe pipe e l e c t r i c a l 6-15 initial charging filling electrolyte remove the short sealed tube before filling electrolyte. Fill battery with electrolyte (dilute sulfuric acid solution wi...

Page 127

E l e c t r i c a l 6-16 check the electrolyte level and add distilled water, as necessary, to raise the electrolyte to each cell’s upper level. Check the battery for proper charge by taking an electrolyte s.G. Reading. If the reading is 1.22 or less, as corrected to 20 c, it means that the battery ...

Page 128: Servicing Information

Servicing information contents troubleshooting special tools tightening torque service data wire and cable routing wiring diagram 7-1 7-7 7-9 7-11 7-16 7-18 7.

Page 129: Troubleshooting

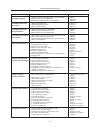

Servicing information 7-1 troubleshooting engine remedy symptom and possible causes complaint engine will not start or is hard to start. Engine stalls easily noisy engine slipping clutch. 1. Clutch control out of limit or loss of play. 2. Weakened clutch springs. 3. Worn or distorted pressure plate....

Page 130

Servicing information 7-2 remedy symptom and possible causes complaint dragging clutch. Transmission will not shift. Transmission will not shift back. Transmission jumps out of gear. Engine idles poorly. Engine runs poorly in high speed range. Dirty or heavy exhaust smoke. 1.Clutch control out of ad...

Page 131

7-3 s e rv i c e i n f o r m at i o n trouble with starting. Idle or low speed trouble. Medium or high- speed trouble. Overflow and fuel level fluctuations. Carburetor remedy symptom and possible causes complaint 1.Starting jet is clogged. 2.Starting pipe is clogged. 3. Air leakage from a joint betw...

Page 132

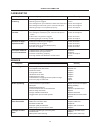

7-4 s e rv i c e i n f o r m at i o n chassis steering feels too heavy or stiff. Steering oscillation. Wobby front wheel. Front too soft. Absorbers front too stiff absorbers noisy front absorbers. Wobbly rear wheel. Rear too soft. Absorbers rear too stiff. Absorbers noisy rear absorbers. Complaint 1...

Page 133

7-5 s e rv i c e i n f o r m at i o n remedy symptom and possible causes complaint electrical no spark or poor spark. Spark plug soon become fouled with carbon. Spark plug become fouled too soon. Spark plug electrodes overheat or burn. Generator does not charge. Generator charge, but charging rate i...

Page 134

7-6 s e rv i c e i n f o r m at i o n remedy symptom and possible causes complaint 1. Not enough electrolyte. 2.Battery case is cracked. 3. 4.Battery has been left in a run-down condition for a long time. 5.Contaminated electrolyte (foreign matter has enters the battery and become mixed with the ele...

Page 135: Special Tools

S e rv i c i n g i n f o r m at i o n special tools 09900-20803 thickness gauge 09900-20205 micrometer (1/100mm,0~25mm) 09910-32812 crankshaft installer - 09921 20240 bearing remover tool 09900-20606 dial meter (1/100mm,10mm) 09900-20202 micrometer (1/100mm, 25~50mm) 09913-50121 oil seal remover 099...

Page 136

S e rv i c i n g i n f o r m at i o n 09941-54911 bearing outer race remover 11f14-010 front absorber tools 09941-74910 bearing installer 11f14-018 valve spring tools 11f14-001 rotor holder 11f14-017 valve adjust spring 09941-34513 bearing installer 11f14-019 ”t” valve adjust wrench 11f14-023 pressu...

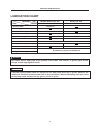

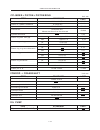

Page 137: Tightening Torque

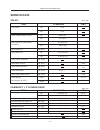

Engine tightening torque n•m kg•m item cylinder head cover bolt cylinder head nut camshaft sprocket bolt crankcase side bolt oil drain plug primary drive gear nut cltuch sleeve hub nut oil inspection plug engine sprocket nut muffler clamp bolt tensioner bolt camshaft sprocket bolt generator rotor nu...

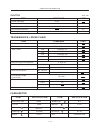

Page 138

S e rv i c i n g i n f o r m at i o n 7-10 n m • kg m • item chassis handlebars clamp bolt front absorber upper clamp bolt steering stem head bolt front absorber lower clamp bolt front axle nut front brake disc bolt air bleeder valve front brake caliper bolt brake hose union bolt master cylinder mou...

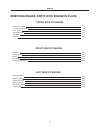

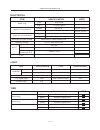

Page 139: Service Data

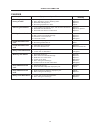

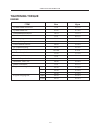

S e rv i c i n g i n f o r m at i o n 7-11 service data valve in. In. In. Ex . Ex . Ex . In & ex . . In & ex . . In & ex . . In & ex . . In & ex . . Inner outer item valve diam. Valve clearance (when cold) valve stem o.D. Valve stem deflection valve stem runout valve head thickness valve seat width ...

Page 140

S e rv i c i n g i n f o r m at i o n 7-12 cylinder + piston + piston ring item compression pressure piston to cylinder clearance cylinder bore piston diam. Cylinder distortion piston ring free end gap piston ring end gap piston ring to groove clearance piston ring groove width piston ring thickness...

Page 141

S e rv i c i n g i n f o r m at i o n 7-13 carburetor clutch item clutch cable play drive plate thickness drive plate claw width driven plate distortion clutch spring free length transmission + drive chain item primary reduction ratio final reduction ratio gear ratios shift fork to groove clearance ...

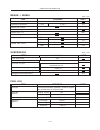

Page 142

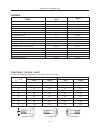

S e rv i c i n g i n f o r m at i o n electrical specification note y-y bl-g terminal - ground or terminal - terminal plug cap - terminal or plug cap - plug cap specification item 35 w 35 w 5/21 w 10 w 5 w dashboard light high beam indicator light turn signal indicator light gear indication light sp...

Page 143

S e rv i c i n g i n f o r m at i o n 7-15 unit mm : unit mm : suspension item front fork stroke front fork spring free length fork fork oil type front fork oil capacity(each leg) rear suspension spring adjustment swing arm pivot shaft runout brake + wheel item rear brake pedal height brake disc thi...

Page 144: Wire Routing

Wire routing s e rv i c i n g i n f o r m at i o n 7-16.

Page 145

S e rv i c i n g i n f o r m at i o n 7-17.

Page 146

S e rv i c i n g i n f o r m at i o n wiring d iagram 7-18 m dashbaord right handlebar switch engine st op switch t ail light/brake light 15a 12v 7ah ba tter y st ar ter mot or genera to r gear position switch n sp il ta fuel 1 2 34 5 on off on off b l n 1 2 3 4 5 push + lo hi push + + l push push r...

Page 147

Jiang men dachangjiang group co., ltd customer service department 1st ed. Dec, 2014 printed in china.

Page 148

Suzuki motor corporation jiangmen dachangjiang group co., ltd..