- DL manuals

- Suzuki

- Motorcycle

- GSF1250

- Service Manual

Suzuki GSF1250 Service Manual

Summary of GSF1250

Page 1

9 9 5 0 0 - 3 9 3 0 0 - 0 1 e printed in japan k7 gsf1250/s/a/sa no.7761 gsf1250/s/a/sa 99500-39300-01e cover14 for ps printing (30 mm) 2006.12.29 top bottom dic216 k7 gsf1250/s/a/sa.

Page 2: Foreword

Foreword this manual contains an introductory description on the suzuki gsf1250/s/a/sa and procedures for its inspec- tion/service and overhaul of its main components. Other information considered as generally known is not included. Read the general information section to familiarize yourself with t...

Page 3: Table of Contents

00 0 1 2 3 4 5 6 9 precautions............................................................... 00-i precautions ............................................................ 00-1 general information ................................................... 0-i general information ..............................

Page 5: Section 00

Table of contents 00- i 00 section 00 contents precautions precautions ...............................................00-1 precautions........................................................... 00-1 warning / caution / note..................................... 00-1 general precautions .................

Page 6: Precautions

00-1 precautions: precautions precautions precautions warning / caution / note b718h10000001 please read this manual and follow its instructions carefully. To emphasize special information, the symbol and the words warning, caution and note have special meanings. Pay special attention to the message...

Page 7

Precautions: 00-2 • use a torque wrench to tighten fasteners to the specified torque. Wipe off grease and oil if a thread is smeared with them. • after reassembling, check parts for tightness and proper operation. • to protect the environment, do not unlawfully dispose of used motor oil, engine cool...

Page 8

00-3 precautions: • check the male connector for bend and female connector for excessive opening. Also check the coupler for locking (looseness), corrosion, dust, etc. Clamp • clamp the wire harness at such positions as indicated in “wiring harness routing diagram in section 9a (page 9a-8)”. • bend ...

Page 9

Precautions: 00-4 • be careful not to touch the electrical terminals of the electronic parts (ecm, abs control unit/hu, etc.). The static electricity from your body may damage them. • when disconnecting and connecting the coupler, make sure to turn off the ignition switch, or electronic parts may ge...

Page 10

00-5 precautions: • before measuring voltage at each terminal, check to make sure that battery voltage is 11 v or higher. Terminal voltage check with a low battery voltage will lead to erroneous diagnosis. • never connect any tester (voltmeter, ohmmeter, or whatever) to the electronic unit when its ...

Page 11

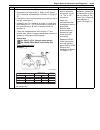

Precautions: 00-6 continuity check 1) measure resistance across coupler “b” (between “a” and “c” in figure). If no continuity is indicated (infinity or over limit), the circuit is open between terminals “a” and “c”. 2) disconnect the coupler “b” and measure resistance between couplers “a” and “b-1”....

Page 12

00-7 precautions: 3) measure resistance between terminal at one end of circuit (“a” terminal in figure) and body ground. If continuity is indicated, there is a short circuit to ground between terminals “a” and “c”. 4) disconnect the connector/coupler included in circuit (coupler “b”) and measure res...

Page 13

Precautions: 00-8 • after using the tester, turn the power off. Special tool : 09900–25008 (multi-circuit tester set) note • when connecting the multi-circuit tester, use the needle pointed probe to the back side of the lead wire coupler and connect the probes of tester to them. • use the needle poi...

Page 14

00-9 precautions:.

Page 15: Section 0

Table of contents 0- i 0 section 0 contents general information general information ................................ 0a-1 general description .............................................0a-1 symbols .............................................................. 0a-1 abbreviations .....................

Page 16: General Information

0a-1 general information: general information general information general description symbols b718h10101001 listed in the table below are the symbols indicating instructions and other information necessary for servicing. The meaning of each symbol is also included in the table. Abbreviations b718h10...

Page 17

General information: 0a-2 fp relay: fuel pump relay g: gen: generator gnd: ground gp switch: gear position switch h: hc: hydrocarbons ho2 sensor: heated oxygen sensor (ho2s) i: iap sensor: intake air pressure sensor (iaps) iat sensor: intake air temperature sensor (iats) ig: ignition isc valve: idle...

Page 18

0a-3 general information: read only memory (rom): rom s: secondary air injection (air): — secondary throttle control system (stcs): stc system (stcs) secondary throttle valve (stv): st valve (stv) secondary throttle valve actuator (stva): stv actuator (stva) t: throttle body (tb): throttle body (tb)...

Page 19

General information: 0a-4 left side suzuki gsf1250sa (2007-model) right side left side vehicle identification number b718h10101004 the frame serial number or v.I.N. (vehicle identification number) “a” is stamped on the right side of the steering head pipe. The engine serial number “b” is located on ...

Page 20

0a-5 general information: engine oil (for other countries) oil quality is a major contributor to your engine’s performance and life. Always select good quality engine oil. Use of sf/sg or sh/sj in api with ma in jaso. Suzuki recommends the use of sae 10w-40 engine oil. If sae 10w-40 engine oil is no...

Page 21

General information: 0a-6 country and area codes b718h10101008 the following codes stand for the applicable country(-ies) and area(-s). Wire color symbols b718h10101009 code country or area effective frame no. Gsf1250 k7 (e-02) u.K. Js1ch122200100001 – gsf1250 k7 (e-19) e.U. Js1ch122100100001 – gsf1...

Page 22

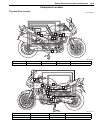

0a-7 general information: warning, caution and information labels location b718h10101010 7 6 12, 13 9 1 2 8 4 10 3 5 [c] [a] 11 [d] [b] i718h1010016-02 gsf1250/a gsf1250s/sa 1. Noise label — for e-03, 24, 33 2. Information label — for e-03, 28, 33 3. Vacuum hose routing label — for e-33 4. Fuel caut...

Page 23

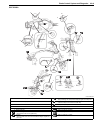

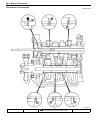

General information: 0a-8 component location electrical components location b718h10103001 7 7 8 5 6 11 12 13 14 4 1 2 3 10 9 i718h1010014-03 1. Fuel pump relay 6. Fuel level gauge 11. Mode selection switch coupler 2. Starter relay/main fuse 7. Ignition coil/plug cap 12. Isc valve 3. Cooling fan rela...

Page 24

0a-9 general information: 20 21 17 18 19 15 16 16 22 23 24 25 27 26 28 29 30 31 i718h1010015-04 15. Iap sensor (no.1) 21. Turn signal/side-stand relay 27. Gp switch 16. Fuel injector 22. Horn 28. Starter motor 17. Iap/tp/iat sensor 23. Cooling fan 29. Speed sensor 18. Stp sensor 24. Ckp sensor 30. H...

Page 25

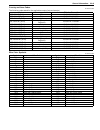

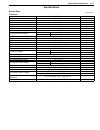

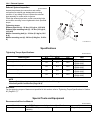

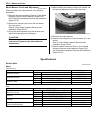

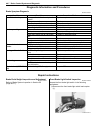

General information: 0a-10 specifications specifications (gsf1250/s) b718h10107001 note these specifications are subject to change without notice. Dimensions and dry mass engine drive train item specification remark overall length 2 130 mm (83.9 in) overall width 790 mm (31.1 in) overall height 1 09...

Page 26

0a-11 general information: chassis electrical capacities item specification remark front suspension telescopic, coil spring, oil damped rear suspension link type, coil spring, oil damped front suspension stroke 130 mm (5.1 in) rear wheel travel 136 mm (5.4 in) steering angle 35 ° (right & left) cast...

Page 27

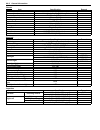

General information: 0a-12 specifications (gsf1250a/sa) b718h10107002 note these specifications are subject to change without notice. Dimensions and dry mass engine drive train item specification remark overall length 2 130 mm (83.9 in) overall width 790 mm (31.1 in) overall height 1 095 mm (43.1 in...

Page 28

0a-13 general information: chassis electrical capacities item specification remark front suspension telescopic, coil spring, oil damped rear suspension link type, coil spring, oil damped front suspension stroke 130 mm (5.1 in) rear wheel travel 136 mm (5.4 in) steering angle 35 ° (right & left) cast...

Page 29

General information: 0a-14 special tools and equipment special tool b718h10108002 09900–06107 snap ring pliers 09900–06108 snap ring pliers 09900–18740 hexagon socket (24 mm) 09900–20102 vernier calipers (1/20 mm, 200 mm) 09900–20202 micrometer (1/100 mm, 25 – 50 mm) 09900–20204 micrometer (75 – 100...

Page 30

0a-15 general information: 09915–40610 oil filter wrench 09915–40611 oil filter wrench 09915–63311 compression gauge attachment 09915–64512 compression gauge 09915–74521 oil pressure gauge hose 09915–74540 oil pressure gauge attachment 09915–77331 meter (for high pressure) 09916–10911 valve lapper s...

Page 31

General information: 0a-16 09923–74511 bearing remover 09924–84510 bearing installer set 09924–84521 bearing installer set 09930–10121 spark plug wrench set 09930–11920 torx bit (jt40h) 09930–11940 bit holder 09930–11950 torx wrench 09930–30104 rotor remover slide shaft 09930–34970 rotor remover set...

Page 32: Maintenance and Lubrication

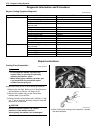

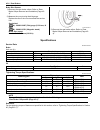

0b-1 maintenance and lubrication: general information maintenance and lubrication precautions precautions for maintenance b718h10200001 the “periodic maintenance schedule chart” lists the recommended intervals for all the required periodic service work necessary to keep the motorcycle operating at p...

Page 33

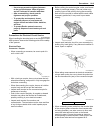

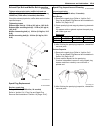

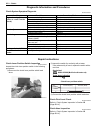

Maintenance and lubrication: 0b-2 lubrication points b718h10205002 proper lubrication is important for smooth operation and long life of each working part of the motorcycle. Major lubrication points are indicated as follows. Note • before lubricating each part, clean off any rusty spots and wipe off...

Page 34

0b-3 maintenance and lubrication: repair instructions air cleaner element replacement b718h10206001 replace air cleaner element every 18 000 km (11 000 miles, 36 months) refer to “air cleaner element removal and installation in section 1d (page 1d-6)”. Air cleaner element inspection and cleaning b71...

Page 35

Maintenance and lubrication: 0b-4 exhaust pipe bolt and muffler bolt inspection b718h10206005 tighten exhaust pipe bolts, muffler bolt and nut initially at 1 000 km (600 miles, 2 months) and every 12 000 km (7 500 miles, 24 months) thereafter. Check the exhaust pipe bolts, muffler bolts and nut to t...

Page 36

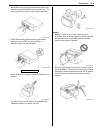

0b-5 maintenance and lubrication: spark plug gap 1) remove the spark plugs. Refer to “ignition coil / plug cap and spark plug removal and installation in section 1h (page 1h-4)”. 2) measure the spark plug gap using a thickness gauge. Adjust the spark plug gap if necessary. Spark plug gap 0.7 – 0.8 m...

Page 37

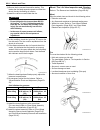

Maintenance and lubrication: 0b-6 note • the cam must be at positions, “a” or “b”, when checking or adjusting the valve clearance. Clearance readings should not be taken with the cam in any other position than these two positions. • the valve clearance should be taken when each cylinder is at top de...

Page 38

0b-7 maintenance and lubrication: 11) turn the crankshaft clockwise 360 ° (one full rotation) and align the match mark on the crankshaft with the mating surfaces of crankcases. Also, position the notches “e” on the right end of each camshaft as shown. Then, measure the following valve clearances “g”...

Page 39

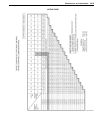

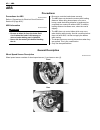

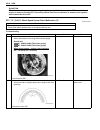

Maintenance and lubrication: 0b-8 (intake side) i718h1020003-02.

Page 40

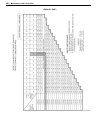

0b-9 maintenance and lubrication: (exhaust side) i718h1020004-02.

Page 41

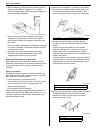

Maintenance and lubrication: 0b-10 6) install the camshafts and cam chain tension adjuster. Refer to “engine top side assembly in section 1d (page 1d-28)”. 7) rotate the engine so that the tappet is depressed fully. This will squeeze out oil trapped between the shim and the tappet that could cause a...

Page 42

0b-11 maintenance and lubrication: 3) tighten the oil drain plug (1) to the specified torque. Caution ! Replace the gasket washer with a new one. Tightening torque oil drain plug (a): 23 n·m (2.3 kgf-m, 16.5 lb-ft) 4) pour new oil through the oil filler. When performing an oil change (without oil fi...

Page 43

Maintenance and lubrication: 0b-12 4) install a new oil filter. Turn it by hand until you feel that the oil filter o-ring contacts the oil filter mounting surface. Then, tighten the oil filter two full turns (or to specified torque) using the special tool. Note to properly tighten the oil filter, us...

Page 44

0b-13 maintenance and lubrication: 3) check the engine coolant level by observing the full and lower lines on the engine coolant reservoir tank. If the level is below the lower line, add engine coolant to the full line from the engine coolant reservoir tank filler. 4) reinstall the seat. Engine cool...

Page 45

Maintenance and lubrication: 0b-14 5) slowly swing the motorcycle, right and left, to bleed the air trapped in the cooling circuit. 6) add engine coolant up to the thermostat connector inlet. 7) start up the engine and bleed air from the thermostat connector inlet completely. 8) add engine coolant u...

Page 46

0b-15 maintenance and lubrication: 3) inspect the clutch hose for crack, damage or clutch fluid leakage. If it is damaged, replace the clutch hose with a new one. 4) after finishing the clutch hose inspection, reinstall the removed parts. Clutch hose replacement b718h10206014 replace clutch hose eve...

Page 47

Maintenance and lubrication: 0b-16 4) count out 21 pins (20 pitches) on the chain and measure the distance between the two points. If the distance exceeds the service limit, the chain must be replaced. Drive chain 20-pitch length service limit: 319.4 mm (12.57 in) 5) after finishing the drive chain ...

Page 48

0b-17 maintenance and lubrication: brake system inspection b718h10206019 inspect brake system initially at 1 000 km (600 miles, 2 months) and every 6 000 km (4 000 miles, 12 months) thereafter. Inspect brake hose and brake fluid every 6 000 km (4 000 miles, 12 months) warning ! • the brake system of...

Page 49

Maintenance and lubrication: 0b-18 front and rear brake hose inspection 1) remove the seat, right frame cover and fuel tank. (gsf1250a/sa) refer to “exterior parts construction in section 9d (page 9d-2)” and “fuel tank removal and installation in section 1g (page 1g-9)”. 2) inspect the brake hoses a...

Page 50

0b-19 maintenance and lubrication: air bleeding from brake fluid circuit refer to “air bleeding from brake fluid circuit in section 4a (page 4a-8)”. Rear brake light switch adjustment refer to “rear brake light switch inspection and adjustment in section 4a (page 4a-8)”. Tire inspection b718h1020602...

Page 51

Maintenance and lubrication: 0b-20 steering system inspection b718h10206025 inspect steering system initially at 1 000 km (600 miles, 2 months) and every 12 000 km (7 500 miles, 24 months) thereafter. Steering should be adjusted properly for smooth turning of handlebars and safe running. Overtighten...

Page 52

0b-21 maintenance and lubrication: chassis bolt and nut inspection b718h10206028 tighten chassis bolt and nut initially at 1 000 km (600 miles, 2 months) and every 6 000 km (4 000 miles, 12 months) thereafter. Check that all chassis bolts and nuts are tightened to their specified torque. 1. Frame do...

Page 53

Maintenance and lubrication: 0b-22 compression pressure check b718h10206029 refer to “compression pressure check in section 1d (page 1d-3)”. Oil pressure check b718h10206030 refer to “oil pressure check in section 1e (page 1e- 3)”. Sds check b718h10206033 refer to “sds check in section 1a (page 1a-1...

Page 54

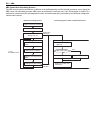

0b-23 maintenance and lubrication: specifications tightening torque specifications b718h10207001 note the specified tightening torque is also described in the following. “chassis bolt and nut inspection (page 0b-21)” reference: for the tightening torque of fastener not specified in this section, ref...

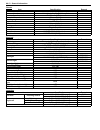

Page 55: Service Data

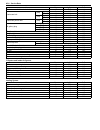

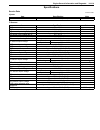

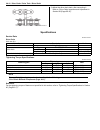

Service data: 0c-1 general information service data specifications service data b718h10307001 valve + guide unit: mm (in) camshaft + cylinder head unit: mm (in) item standard limit valve diam. In. 31 (1.22) — ex. 27 (1.06) — valve clearance (when cold) in. 0.10 – 0.20 (0.004 – 0.008) — ex. 0.20 – 0....

Page 56

0c-2 service data: cylinder + piston + piston ring unit: mm (in) conrod + crankshaft unit: mm (in) item standard limit compression pressure 1 300 – 1 700 kpa (13 – 17 kgf/cm 2 , 185 – 242 psi) 1 000 kpa (10 kgf/cm 2 , 142 psi) compression pressure difference — 200 kpa (2 kgf/cm 2 , 28 psi) piston-to...

Page 57

Service data: 0c-3 oil pump clutch unit: mm (in) transmission + drive chain unit: mm (in) except ratio thermostat + radiator + fan + coolant item standard limit oil pressure (at 60 °c, 140 °f) 100 – 400 kpa (1.0 – 4.0 kgf/cm 2 , 14 – 57 psi) at 3 000 r/min — item standard limit clutch drive plate th...

Page 58

0c-4 service data: injector + fuel pump + fuel pressure regulator fi sensors + secondary throttle valve actuator throttle body item specification note injector resistance 11 – 13 Ω at 20 °c (68 °f) fuel pump discharge amount 166 ml (5.6/5.8 us/lmp oz) and more/10 sec. Fuel pressure regulator operati...

Page 59

Service data: 0c-5 electrical unit: mm wattage unit: w item specification note firing order 1 ⋅ 2 ⋅ 4 ⋅ 3 spark plug type ngk: cr7e denso: u22esr-n gap 0.7 – 0.8 (0.028 – 0.031) spark performance over 8 (0.3) at 1 atm. Ckp sensor resistance 90 – 150 Ω ckp sensor peak voltage 2.0 v and more when cran...

Page 60

0c-6 service data: brake + wheel unit: mm (in) tire suspension unit: mm (in) item standard limit rear brake pedal height 50 – 60 (2.0 – 2.4) — brake disc thickness front 4.8 – 5.2 (0.189 – 0.205) 4.5 (0.18) rear 4.8 – 5.2 (0.189 – 0.205) 4.5 (0.18) brake disc runout — 0.30 (0.012) master cylinder bo...

Page 61

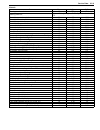

Service data: 0c-7 fuel + oil tightening torque specifications b718h10307002 engine item specification note fuel type use only unleaded gasoline of at least 87 pump octane (r/2 + m/2) or 91 octane or higher rated by the research method. Gasoline containing mtbe (methyl tertiary butyl ether), less th...

Page 62

0c-8 service data: fi system and intake air system cooling system oil pressure switch lead wire bolt 1.5 0.15 1.1 crankcase bolt [m6] (initial) 6 0.6 4.5 (final) 11 1.1 8.0 [m8] (initial) 15 1.5 11.0 (final) 26 2.6 19.0 crankshaft journal bolt [m9] (initial) 18 1.8 13.0 (final) 32 3.2 23.0 oil galle...

Page 63

Service data: 0c-9 chassis item n ⋅m kgf-m lb-ft steering stem head nut 65 6.5 47.0 steering stem nut tighten 45 n ⋅m (4.5 kgf-m, 32.5 ib-ft) then turn back 1/2 – 1/4. Front fork upper clamp bolt 23 2.3 16.5 front fork lower clamp bolt 23 2.3 16.5 front fork cap bolt 23 2.3 16.5 front fork damper ro...

Page 64

0c-10 service data: tightening torque chart for other bolts and nuts not listed in the preceding page, refer to this chart: bolt diameter “a” (mm) conventional or “4” marked bolt “7” marked bolt n ⋅m kgf-m lb-ft n ⋅m kgf-m lb-ft 4 1.5 0.15 1.0 2.3 0.23 1.5 5 3 0.3 2.0 4.5 0.45 3.0 6 5.5 0.55 4.0 10 ...

Page 65: Section 1

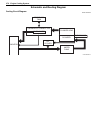

Table of contents 1- i 1 section 1 contents engine precautions .................................................1-1 precautions............................................................. 1-1 precautions for engine.......................................... 1-1 engine general information and diagnos...

Page 66

1-ii table of contents pair control solenoid valve removal and installation.........................................................1b-6 pair system inspection .....................................1b-6 crankcase breather (pcv) hose inspection.......1b-8 crankcase breather (pcv) hose / cover / separa...

Page 67

Table of contents 1-iii schematic and routing diagram........................ 1e-2 engine lubrication system chart diagram ......... 1e-2 diagnostic information and procedures............ 1e-3 engine lubrication symptom diagnosis ............. 1e-3 oil pressure check ...................................

Page 68

1-iv table of contents ckp sensor removal and installation ................1h-8 engine stop switch inspection............................1h-8 ignition switch inspection....................................1h-9 ignition switch removal and installation.............1h-9 specifications......................

Page 69: Precautions

Precautions: 1-1 engine precautions precautions precautions for engine b718h11000001 refer to “general precautions in section 00 (page 00-1)” and “precautions for electrical circuit service in section 00 (page 00-2)”..

Page 70

1a-1 engine general information and diagnosis: engine engine general information and diagnosis general description injection timing description b718h11101001 injection time (injection volume) the factors to determine the injection time include the basic fuel injection time, which is calculated on th...

Page 71

Engine general information and diagnosis: 1a-2 compensation of injection time (volume) the following different signals are output from the respective sensors for compensation of the fuel injection time (volume). Injection stop control self-diagnosis function b718h11101002 the self-diagnosis function...

Page 72

1a-3 engine general information and diagnosis: for example: the ignition switch is turned on, and the engine stop switch is turned off. In this case, the speedometer does not receive any signal from the ecm, and the panel indicates “chec”. If chec is indicated, the lcd does not indicate the trouble ...

Page 73

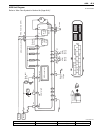

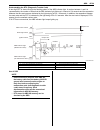

Engine general information and diagnosis: 1a-4 schematic and routing diagram fi system wiring diagram b718h11102001 ckps speedometer fi pa ir control solenoid v alv e fp fp rela y ig coil stv a isc v alv e star ter rela y star ter motor clp s witch m side-stand s witch engine stop s witch side-stand...

Page 74

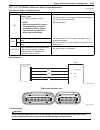

1a-5 engine general information and diagnosis: terminal alignment of ecm coupler b718h11102002 i718h1110004-02 terminal no. Circuit terminal no. Circuit 1 stva signal (stva, 2a) 31 ckp sensor signal (ckp-) 2 stva signal (stva, 1a) 32 serial data for self-diagnosis 3 evap page control valve [e-33 onl...

Page 75

Engine general information and diagnosis: 1a-6 component location fi system parts location b718h11103001 “a” “b” “c” “d” “e” “f” “h” “i” “j” “g” i718h1110146-04 “a”: ecm “c”: cooling fan relay “e”: isc valve “g”: cooling fan “i”: pair control solenoid valve “b”: to sensor “d”: stv actuator “f”: ho2 ...

Page 76

1a-7 engine general information and diagnosis: diagnostic information and procedures engine symptom diagnosis b718h11104001 condition possible cause correction / reference item engine will not start or is hard to start (compression too low) valve clearance out of adjustment. Adjust. Worn valve guide...

Page 77

Engine general information and diagnosis: 1a-8 engine stalls often (incorrect fuel/air mixture) defective iap sensor or circuit. Repair or replace. Clogged fuel filter. Clean or replace. Defective fuel pump. Replace. Defective fuel pressure regulator. Replace. Damaged or cracked vacuum hose. Replace...

Page 78

1a-9 engine general information and diagnosis: engine noisy (noise seems to come from water pump) worn or damaged impeller shaft. Replace. Worn or damaged mechanical seal. Replace. Contact between pump case and impeller. Replace. Too much play on pump shaft bearing. Replace. Engine runs poorly in hi...

Page 79

Engine general information and diagnosis: 1a-10 engine lacks power (defective control circuit or sensor) low fuel pressure. Repair or replace. Defective tp sensor. Replace. Defective iat sensor. Replace. Defective ckp sensor. Replace. Defective gp sensor. Replace. Defective iap sensor. Replace. Defe...

Page 80

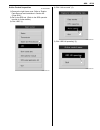

1a-11 engine general information and diagnosis: self-diagnostic procedures b718h11104005 use of mode select switch note • do not disconnect coupler from ecm, the battery cable from the battery, ecm ground wire harness from the engine or main fuse before confirming dtc (diagnostic trouble code) store...

Page 81

Engine general information and diagnosis: 1a-12 use of sds note • do not disconnect the coupler from ecm, the battery cable from the battery, ecm ground wire harness from the engine or main fuse before confirming dtc (diagnostic trouble code) stored in memory. Such disconnection will erase the memor...

Page 82

1a-13 engine general information and diagnosis: 4) start the engine or crank the engine for more than 4 seconds. 5) check the dtc to determine the malfunction part. Refer to “dtc table (page 1a-18)”. Note • read the dtc (diagnostic trouble code) and show data when trouble (displaying data at the tim...

Page 83

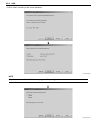

Engine general information and diagnosis: 1a-14 show data when trouble (displaying data at the time of dtc) b718h11104008 use of sds ecm stores the engine and driving conditions (in the form of data as shown in the figure) at the moment of the detection of a malfunction in its memory. This data is c...

Page 84

1a-15 engine general information and diagnosis: 2) click the drop down button (2), either “failure #1” or “failure #2” can be selected. Sds check b718h11104009 using sds, sample the data at the time of new and periodic vehicle inspections. After saving the sampled data in the computer, file them by ...

Page 85

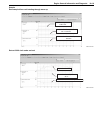

Engine general information and diagnosis: 1a-16 sample data sampled from cold starting through warm-up data at 3 000 r/min under no load check the engine r/min. 1 200 r/min. Check the water temperature. 50 ˚c and more check the manifold absolute pressure. Xxx kpa i718h1110149-01 check the manifold a...

Page 86

1a-17 engine general information and diagnosis: data at the time of racing data of intake negative pressure during idling (100 °c) throttle: quick wide open throttle: slowly open secondary throttle valve opens closes in according with the throttle valve opening pair control solenoid valve on off in ...

Page 87

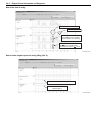

Engine general information and diagnosis: 1a-18 example of trouble three data; value 1 (current data 1), value 2 (past data 2) and value 3 (past data 3); can be made in comparison by showing them in the graph. Read the change of value by comparing the current data to the past data that have been sav...

Page 88

1a-19 engine general information and diagnosis: in the lcd (display) panel, the malfunction code is indicated from small code to large code. C26 (p0353) ) (page 1a-73) ignition signal #3 (ig coil #3) for #3 cylinder c27 (p0354) ) (page 1a-73) ignition signal #4 (ig coil #4) for #4 cylinder c28 (p165...

Page 89

Engine general information and diagnosis: 1a-20 fail-safe function table b718h11104003 fi system is provided with fail-safe function to allow the engine to start and the motorcycle to run in a minimum performance necessary even under malfunction condition. The engine can start and can run even if th...

Page 90

1a-21 engine general information and diagnosis: fi system troubleshooting b718h11104004 customer complaint analysis record details of the problem (failure, complaint) and how it occurred as described by the customer. For this purpose, use of such an inspection form such as following will facilitate ...

Page 91

Engine general information and diagnosis: 1a-22 visual inspection prior to diagnosis using the mode select switch or sds, perform the following visual inspections. The reason for visual inspection is that mechanical failures (such as oil leakage) cannot be displayed on the screen with the use of mod...

Page 92

1a-23 engine general information and diagnosis: c17 iap sensor (no.2) the sensor should produce following voltage. 0.5 v ≤ sensor voltage in other than the above range, c17 (p1750) is indicated. Iap sensor (no.2), lead wire/ coupler connection p1750 h sensor voltage is higher than specified value. I...

Page 93

Engine general information and diagnosis: 1a-24 c32/c33 c34/c35 fuel injector ckp sensor (pickup coil) signal is produced, but fuel injector signal is interrupted 4 times or more continuously. In this case, the code c32 (p0201), c33 (p0202), c34 (p0203) or c35 (p0204) is indicated. Primary fuel inje...

Page 94

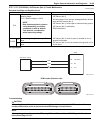

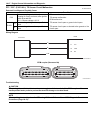

1a-25 engine general information and diagnosis: dtc “c12” (p0335): ckp sensor circuit malfunction b718h11104011 detected condition and possible cause wiring diagram ecm coupler (harness side) troubleshooting note after repairing the trouble, clear the dtc using sds tool. Refer to “use of sds diagnos...

Page 95

Engine general information and diagnosis: 1a-26 step action yes no 1 1) turn the ignition switch off. 2) check the ckp sensor coupler for loose or poor contacts. If ok, then measure the ckp sensor resistance. 3) disconnect the ckp sensor coupler and measure the resistance. Special tool (a): 09900–25...

Page 96

1a-27 engine general information and diagnosis: 2 1) crank the engine several seconds with the starter motor, and measure the ckp sensor peak voltage at the coupler. Special tool (a): 09900–25008 (multi-circuit tester set) tester knob indication voltage ( ) ckp sensor peak voltage 2.0 v and more ((+...

Page 97

Engine general information and diagnosis: 1a-28 dtc “c13” (p0105-h/l): iap sensor (no.1) circuit malfunction b718h11104012 detected condition and possible cause wiring diagram ecm coupler (harness side) troubleshooting caution ! When using the multi-circuit tester, do not strongly touch the terminal...

Page 98

1a-29 engine general information and diagnosis: c13 for iap sensor no.1 (use of mode select switch) step action yes no 1 1) turn the ignition switch off. 2) lift and support the fuel tank. Refer to “fuel tank removal and installation in section 1g (page 1g-9)”. 3) check the iap sensor coupler for lo...

Page 99

Engine general information and diagnosis: 1a-30 p0105-h for iap sensor (no.1) (use of sds) step action yes no 1 1) click the data monitor button (1). 2) check the manifold absolute pressure 1 data. Approx. 146 kpa (1.46 kgf/cm 3 , 21 psi) and more ok? Go to step 2. Go to step 4. 2 1) turn the igniti...

Page 100

1a-31 engine general information and diagnosis: 2 4) disconnect the iap sensor (no.1) coupler. 5) check the continuity between the b wire and w/bl wire. If the sound is not heard from the tester, the circuit condition is ok. Special tool (a): 09900–25008 (multi-circuit tester set) tester knob indica...

Page 101

Engine general information and diagnosis: 1a-32 p0105-l for iap sensor (no.1) (use of sds) step action yes no 1 1) click the data monitor button (1). 2) check the manifold absolute pressure 1 data. Approx. –20 kpa (–0.2 kgf/cm 3 , –2.8 psi) and less ok? Go to step 2. Go to step 4. 2 1) turn the igni...

Page 102

1a-33 engine general information and diagnosis: 2 4) disconnect the iap sensor (no.1) coupler. 5) check the continuity between the w/bl wire and ground. Also, check the continuity between the w/bl wire and b/ br wire. If the sound is not heard from the tester, the circuit condition is ok. Special to...

Page 103

Engine general information and diagnosis: 1a-34 3 1) connect the ecm coupler. 2) turn the ignition switch on. 3) measure the input voltage at the b wire and ground with the needle pointed probes. If ok, the measure the input voltage at the b wire and b/ br wire. Special tool (a): 09900–25008 (multi-...

Page 104

1a-35 engine general information and diagnosis: 4 1) turn the ignition switch off. 2) connect the ecm coupler and iap sensor (no.1) coupler. 3) insert the needle pointed probes to the lead wire coupler. 4) start the engine at idle speed and measure the iap sensor (no.1) output voltage at the wire si...

Page 105

Engine general information and diagnosis: 1a-36 5 1) turn the ignition switch off. 2) remove the iap sensor (no.1). Refer to “iap sensor (no.1) removal and installation in section 1c (page 1c- 2)”. 3) connect the vacuum pump gauge to the vacuum port of the iap sensor (no.1). 4) arrange 3 new 1.5 v b...

Page 106

1a-37 engine general information and diagnosis: dtc “c14” (p0120-h/l): tp sensor circuit malfunction b718h11104013 detected condition and possible cause wiring diagram ecm coupler (harness side) troubleshooting caution ! When using the multi-circuit tester, do not strongly touch the terminal of the ...

Page 107

Engine general information and diagnosis: 1a-38 c14 (use of mode select switch) step action yes no 1 1) turn the ignition switch off. 2) check the tp sensor coupler for loose or poor contacts. If ok, then measure the tp sensor input voltage. 3) disconnect the tp sensor coupler. 4) turn the ignition ...

Page 108

1a-39 engine general information and diagnosis: p0120-h (use of sds) step action yes no 1 1) click the data monitor button (1). 2) check the throttle position data. Throttle position approx. 125 ° and more ok? Go to step 2. Go to step 4. 2 1) turn the ignition switch off. 2) check the tp sensor coup...

Page 109

Engine general information and diagnosis: 1a-40 2 4) insert the needle pointed probes to the lead wire coupler. 5) check the continuity between the p/b wire and r wire. If the sound is not heard from the tester, the circuit condition is ok. Special tool (a): 09900–25008 (multi-circuit tester set) (b...

Page 110

1a-41 engine general information and diagnosis: p0120-l (use of sds) step action yes no 1 1) click the data monitor button (1). 2) check the throttle position data. Throttle position approx. 0 ° ok? Go to step 2. Go to step 4. 2 1) turn the ignition switch off. 2) check the tp sensor coupler for loo...

Page 111

Engine general information and diagnosis: 1a-42 2 5) check the continuity between the p/b wire and ground. Also, check the continuity between the p/b wire and b/br wire. If the sound is not heard from the tester, the circuit condition is ok. Special tool (a): 09900–25008 (multi-circuit tester set) (...

Page 112

1a-43 engine general information and diagnosis: 3 1) connect the ecm coupler. 2) turn the ignition switch on. 3) measure the input voltage at the r wire and ground. If ok, the measure the input voltage at the r and b/br wire. Special tool (a): 09900–25008 (multi-circuit tester set) tester knob indic...

Page 113

Engine general information and diagnosis: 1a-44 4 1) turn the ignition switch off. 2) connect the ecm coupler and tp sensor coupler. 3) insert the needle pointed probes to the lead wire coupler. 4) turn the ignition switch on. 5) measure the tp sensor output voltage at the p/b wire and b/br wire by ...

Page 114

1a-45 engine general information and diagnosis: dtc “c15” (p0115-h/l): ect sensor circuit malfunction b718h11104014 detected condition and possible cause wiring diagram ecm coupler (harness side) troubleshooting caution ! When using the multi-circuit tester, do not strongly touch the terminal of the...

Page 115

Engine general information and diagnosis: 1a-46 c15 (use of mode select switch) step action yes no 1 1) turn the ignition switch off. 2) check the ect sensor coupler for loose or poor contacts. If ok, then measure the ect sensor input voltage at the wire side coupler. 3) disconnect the coupler and t...

Page 116

1a-47 engine general information and diagnosis: p0115-h (use of sds) step action yes no 1 1) click the data monitor button (1). 2) check the engine coolant/oil temperature data. Approx. –30 ° c (–22 ° f) and less ok? Go to step 2. Go to step 3. 1 i718h1110251-01 i718h1110175-01.

Page 117

Engine general information and diagnosis: 1a-48 2 1) turn the ignition switch off. 2) check the ect sensor coupler for loose or poor contacts. If ok, then check the ect sensor lead wire continuity. 3) disconnect the ect coupler. 4) disconnect the ecm coupler. Refer to “ecm removal and installation i...

Page 118

1a-49 engine general information and diagnosis: p0115-l (use of sds) step action yes no 1 1) click the data monitor button (1). 2) check the engine coolant/oil temperature data. Approx. 120 ° c (248 ° f) and more ok? Go to step 2. Go to step 3. 2 1) turn the ignition switch off. 2) check the ect sen...

Page 119

Engine general information and diagnosis: 1a-50 2 4) check the continuity between the b/bl wire and ground. If the sound is not heard from the tester, the circuit condition is ok. Special tool (a): 09900–25008 (multi-circuit tester set) tester knob indication continuity test ( ) 5) connect the ect s...

Page 120

1a-51 engine general information and diagnosis: 3 1) turn the ignition switch off. 2) connect the ecm coupler. 3) remove the regulator/rectifier. Refer to “regulator / rectifier inspection in section 1j (page 1j-8)”. 4) disconnect the ect sensor coupler. 5) measure the ect sensor resistance. Special...

Page 121

Engine general information and diagnosis: 1a-52 dtc “c17” (p1750-h/l): iap sensor (no.2) circuit malfunction b718h11104030 detected condition and possible cause wiring diagram ecm coupler (harness side) troubleshooting caution ! When using the multi-circuit tester, do not strongly touch the terminal...

Page 122

1a-53 engine general information and diagnosis: note • after repairing the trouble, clear the dtc using sds tool. Refer to “use of sds diagnosis reset procedures (page 1a-13)”. • iap sensor (no.2) is incorporated in the tp sensor/iat sensor. C17 for iap sensor no.2 (use of mode select switch) step a...

Page 123

Engine general information and diagnosis: 1a-54 p1750-h for iap sensor no.2 (use of sds) step action yes no 1 1) click the data monitor button (1). 2) check the manifold absolute pressure 2 data. Approx. 126 kpa (1.26 kgf/cm 3 , 18 psi) and more ok? Go to step 2. Go to step 4. 2 1) turn the ignition...

Page 124

1a-55 engine general information and diagnosis: 2 6) check the continuity between the r and g/b wire. If the sound is not heard from the tester, the circuit condition is ok. Special tool (a): 09900–25008 (multi-circuit tester set) (b): 09900–25009 (needle pointed probe set) tester knob indication co...

Page 125

Engine general information and diagnosis: 1a-56 p1750-l for iap sensor no.2 (use of sds) step action yes no 1 1) click the data monitor button (1). 2) check the manifold absolute pressure 2 data. Approx. 0 kpa (0 kgf/cm 3 , 0 psi) and less ok? Go to step 2. Go to step 4. 2 1) turn the ignition switc...

Page 126

1a-57 engine general information and diagnosis: 2 3) disconnect the iap sensor (no.2) coupler. 4) insert the needle pointed probes to the lead wire coupler. 5) check the continuity between the g/b wire and ground. Also, check the continuity between the g/b wire and b/ br wire. If the sound is not he...

Page 127

Engine general information and diagnosis: 1a-58 3 1) connect the ecm coupler. 2) turn the ignition switch on. 3) insert the needle pointed probes to the lead wire coupler. 4) measure the input voltage at the r wire and ground with the needle pointed probes. If ok, the measure the input voltage at th...

Page 128

1a-59 engine general information and diagnosis: p1750 for iap sensor no.2 (use of sds) 4 1) turn the ignition switch off. 2) connect the ecm coupler and iap sensor (no.2) coupler. 3) insert the needle pointed probes to the lead wire coupler. 4) starter the engine at idle speed and measure the iap se...

Page 129

Engine general information and diagnosis: 1a-60 dtc “c21” (p0110-h/l): iat sensor circuit malfunction b718h11104015 detected condition and possible cause wiring diagram ecm coupler (harness side) troubleshooting caution ! When using the multi-circuit tester, do not strongly touch the terminal of the...

Page 130

1a-61 engine general information and diagnosis: c21 (use of mode select switch) step action yes no 1 1) turn the ignition switch off. 2) check the iat sensor coupler for loose or poor contacts. If ok, then measure the iat sensor input voltage. 3) disconnect the iat sensor coupler and turn the igniti...

Page 131

Engine general information and diagnosis: 1a-62 p0110-h (use of sds) step action yes no 1 1) click the data monitor button (1). 2) check the intake air temperature data. Approx. –30 ° c (–22 ° f) and less ok? Go to step 2. Go to step 3. 1 i718h1110251-01 i718h1110184-02.

Page 132

1a-63 engine general information and diagnosis: 2 1) turn the ignition switch off. 2) check the iat sensor coupler for loose or poor contacts. If ok, then check the iat sensor lead wire continuity. 3) disconnect the iat sensor coupler. 4) disconnect the ecm coupler. Refer to “ecm removal and install...

Page 133

Engine general information and diagnosis: 1a-64 p0110-l (use of sds) step action yes no 1 1) click the data monitor button (1). 2) check the intake air temperature data. Approx. 125 ° c (257 ° f) and more ok? Go to step 2. Go to step 3. 2 1) turn the ignition switch off. 2) check the iat sensor coup...

Page 134

1a-65 engine general information and diagnosis: 2 4) insert the needle pointed probes to the lead wire coupler. 5) check the continuity between the dg wire and ground. If the sound is not heard from the tester, the circuit condition is ok. Special tool (a): 09900–25008 (multi-circuit tester set) (b)...

Page 135

Engine general information and diagnosis: 1a-66 3 1) turn the ignition switch off. 2) disconnect the iat sensor coupler. 3) measure the iat sensor resistance. Special tool (a): 09900–25008 (multi-circuit tester set) tester knob indication resistance ( Ω) iat sensor resistance approx. 2.56 k Ω at 20 ...

Page 136

1a-67 engine general information and diagnosis: dtc “c23” (p1651-h/l): to sensor circuit malfunction b718h11104016 detected condition and possible cause wiring diagram ecm coupler (harness side) troubleshooting caution ! When using the multi-circuit tester, do not strongly touch the terminal of the ...

Page 137

Engine general information and diagnosis: 1a-68 c23 (use of mode select switch) step action yes no 1 1) turn the ignition switch off. 2) remove the seat. Refer to “exterior parts removal and installation in section 9d (page 9d-6)”. 3) check the to sensor coupler for loose or poor contacts. If ok, th...

Page 138

1a-69 engine general information and diagnosis: p1651-h (use of sds) step action yes no 1 1) turn the ignition switch off. 2) remove the seat. Refer to “exterior parts removal and installation in section 9d (page 9d-6)”. 3) check the to sensor coupler for loose or poor contacts. If ok, then check th...

Page 139

Engine general information and diagnosis: 1a-70 p1651-l (use of sds) 1 8) check the continuity between the b wire “b” and terminal “22”. Also, check the continuity between b/br wire “c” and terminal “29”. Special tool (a): 09900–25008 (multi-circuit tester set) (b): 09900–25009 (needle pointed probe...

Page 140

1a-71 engine general information and diagnosis: 1 4) disconnect the to sensor coupler. 5) check the continuity between the b wire “b” and ground. Also, check the continuity between the b wire “b” and b/ br wire “c”. If the sound is not heard from the tester, the circuit condition is ok. Special tool...

Page 141

Engine general information and diagnosis: 1a-72 2 1) connect the ecm coupler and to sensor coupler. 2) dismount the to sensor from its bracket. Refer to “to sensor removal and installation in section 1c (page 1c-3)”. 3) insert the needle pointed probes to the lead wire coupler. 4) turn the ignition ...

Page 142

1a-73 engine general information and diagnosis: dtc “c24” (p0351), “c25” (p0352), “c26” (p0353) or “c27” (p0354): ignition system malfunction b718h11104017 note refer to “no spark or poor spark in section 1h (page 1h-3)” for details. Dtc “c28” (p1655): secondary throttle valve actuator (stva) malfun...

Page 143

Engine general information and diagnosis: 1a-74 step action yes no 1 1) remove the regulator/rectifier. Refer to “regulator / rectifier construction in section 1j (page 1j-8)”. 2) check the stva lead wire coupler for loose or poor contacts. 3) move the air cleaner backward. Refer to “air cleaner ele...

Page 144

1a-75 engine general information and diagnosis: 2 1) turn the ignition switch off. 2) move the throttle body right side. Refer to “throttle body removal and installation in section 1d (page 1d-9)”. 3) disconnect the stva lead wire coupler. 4) check the continuity between each terminal and ground. Sp...

Page 145

Engine general information and diagnosis: 1a-76 active control inspection 1) set up the sds tool. (refer to the sds operation manual for further details.) 2) turn the ignition switch on. 3) click “secondary throttle operating control” (1). 4) click each button (2). At this time, if an operation soun...

Page 146

1a-77 engine general information and diagnosis: dtc “c29” (p1654-h/l): secondary throttle position sensor (stps) circuit malfunction b718h11104019 detected condition and possible cause wiring diagram ecm coupler (harness side) troubleshooting caution ! When using the multi-circuit tester, do not str...

Page 147

Engine general information and diagnosis: 1a-78 c29 (use of mode select switch) step action yes no 1 1) turn the ignition switch off. 2) check the stp sensor coupler for loose or poor contacts. If ok, then measure the stp sensor input voltage. 3) disconnect the stp sensor coupler. 4) turn the igniti...

Page 148

1a-79 engine general information and diagnosis: p1654-h (use of sds) step action yes no 1 1) click the data monitor button (1). 2) check the secondary throttle actuator position sensor data. Secondary throttle position approx. 100% and more ok? Go to step 2. Go to step 4. 2 1) turn the ignition swit...

Page 149

Engine general information and diagnosis: 1a-80 2 3) disconnect the stp sensor coupler. 4) check the continuity between the y/w wire and r wire. If the sound is not heard from the tester, the circuit condition is ok. Special tool (a): 09900–25008 (multi-circuit tester set) tester knob indication con...

Page 150

1a-81 engine general information and diagnosis: p1654-l (use of sds) step action yes no 1 1) click the data monitor button (1). 2) check the secondary throttle actuator position sensor data. Secondary throttle position approx. 0% ok? Go to step 2. Go to step 4. 2 1) turn the ignition switch off. 2) ...

Page 151

Engine general information and diagnosis: 1a-82 2 4) check the continuity between the y/w wire and ground. Also, check the continuity between the y/w wire and b/ br wire. If the sound is not heard from the tester, the circuit condition is ok. Special tool (a): 09900–25008 (multi-circuit tester set) ...

Page 152

1a-83 engine general information and diagnosis: 3 1) connect the ecm coupler. 2) disconnect the stp sensor coupler. 3) turn the ignition switch on. 4) measure the input voltage at the r wire and ground. Also, measure the input voltage at the r wire and b/br wire. Special tool (a): 09900–25008 (multi...

Page 153

Engine general information and diagnosis: 1a-84 4 1) turn the ignition switch off. 2) connect the ecm coupler and stp sensor coupler. 3) move the air cleaner box backward. Refer to “throttle body removal and installation in section 1d (page 1d- 9)”. 4) disconnect the stva lead wire coupler. Refer to...

Page 154

1a-85 engine general information and diagnosis: dtc “c31” (p0705): gp switch circuit malfunction b718h11104020 detected condition and possible cause wiring diagram ecm coupler (harness side) troubleshooting caution ! When using the multi-circuit tester, do not strongly touch the terminal of the ecm ...

Page 155

Engine general information and diagnosis: 1a-86 step action yes no 1 1) turn the ignition switch off. 2) remove the left frame cover. Refer to “exterior parts removal and installation in section 9d (page 9d-6)”. 3) check the gp switch coupler for loose or poor contacts. If ok, then measure the gp sw...

Page 156

1a-87 engine general information and diagnosis: dtc “c32” (p0201), “c33” (p0202), “c34” (p0203) or “c35” (p0204): fuel injector circuit malfunction b718h11104021 detected condition and possible cause wiring diagram ecm coupler (harness side) troubleshooting caution ! When using the multi-circuit tes...

Page 157

Engine general information and diagnosis: 1a-88 step action yes no 1 1) turn the ignition switch off. 2) lift and support the fuel tank. Refer to “fuel tank removal and installation in section 1g (page 1g-9)”. 3) check the injector coupler for loose or poor contacts. If ok, then measure the injector...

Page 158

1a-89 engine general information and diagnosis: 1 5) if ok, then check the continuity between each terminal and ground. Special tool (a): 09900–25008 (multi-circuit tester set) injector continuity ∞Ω (infinity) are the resistance and continuity ok? Go to step 2. Replace the injector with a new one. ...

Page 159

Engine general information and diagnosis: 1a-90 2 1) turn the ignition switch on. 2) measure the injector voltage between the y/r wire and ground. Special tool (a): 09900–25008 (multi-circuit tester set) tester knob indication voltage ( ) injector voltage battery voltage ((+) terminal: y/r – (–) ter...

Page 160

1a-91 engine general information and diagnosis: dtc “c40” (p0505 / p0506 / p0507): isc valve circuit malfunction b718h11104022 detected condition and possible cause wiring diagram ecm coupler (harness side) troubleshooting caution ! • be careful not to disconnect the isc valve coupler at least 5 sec...

Page 161

Engine general information and diagnosis: 1a-92 step action yes no 1 1) turn the ignition switch off. 2) check the isc valve coupler for loose or poor contacts. If ok, then check the isc valve lead wire continuity. 3) disconnect the isc valve coupler and ecm coupler. Refer to “ecm removal and instal...

Page 162

1a-93 engine general information and diagnosis: 2 1) move the throttle body right side. Refer to “throttle body removal and installation in section 1d (page 1d-9)”. 2) disconnect the isc valve coupler. 3) check the continuity between each terminal and ground. Special tool (a): 09900–25008 (multi-cir...

Page 163

Engine general information and diagnosis: 1a-94 active control inspection (isc rpm control) check 1 1) set up the sds tool. (refer to the sds operation manual for further details.) 2) check that the engine is running. 3) click the “active control”. 4) click the “isc rpm control” (1). 5) check that t...

Page 164

1a-95 engine general information and diagnosis: check 2 1) click the button (4) and decrease the “spec” (2) to 1 100 rpm slowly. 2) check that the “desired idle speed” (3) is nearly equal to the “spec” (2). At the same time, check that the number of steps (5) in the isc valve position decreases. 3) ...

Page 165

Engine general information and diagnosis: 1a-96 check 4 1) click the button (6) and increase the “spec” (2) to 1 400 rpm. 2) check that the “desired idle speed” (3) is approx. 1 400 rpm. 3) check that the “engine speed” (7) is close to 1 400 rpm. Note be careful not to increase the “spec” to 1 700 r...

Page 166

1a-97 engine general information and diagnosis: dtc “c41” (p0230-h/l): fp relay circuit malfunction b718h11104023 detected condition and possible cause wiring diagram ecm coupler (harness side) troubleshooting caution ! When using the multi-circuit tester, do not strongly touch the terminal of the e...

Page 167

Engine general information and diagnosis: 1a-98 c41 (use of mode select switch) p0230-h (use of sds) step action yes no 1 1) turn the ignition switch off. 2) remove the seat. Refer to “exterior parts removal and installation in section 9d (page 9d-6)”. 3) check the fp relay coupler for loose or poor...

Page 168

1a-99 engine general information and diagnosis: p0230-l (use of sds) step action yes no 1 1) turn the ignition switch off. 2) remove the seat. Refer to “exterior parts removal and installation in section 9d (page 9d-6)”. 3) check the fp relay coupler for loose or poor contacts. If ok, then check the...

Page 169

Engine general information and diagnosis: 1a-100 dtc “c41” (p2505): ecm power input signal malfunction b718h11104031 detected condition and possible cause wiring diagram ecm coupler (harness side) troubleshooting caution ! When using the multi-circuit tester, do not strongly touch the terminal of th...

Page 170

1a-101 engine general information and diagnosis: step action yes no 1 1) turn the ignition switch off. 2) remove the seat. Refer to “exterior parts removal and installation in section 9d (page 9d-6)”. 3) check the ecm coupler for loose or poor contacts. If ok, then measure the ecm input voltage. 4) ...

Page 171

Engine general information and diagnosis: 1a-102 dtc “c42” (p1650): ig switch circuit malfunction b718h11104024 detected condition and possible cause troubleshooting note • refer to “ignition switch inspection in section 9c (page 9c-10)” for details. • after repairing the trouble, clear the dtc usin...

Page 172

1a-103 engine general information and diagnosis: troubleshooting (when indicating c44/p0130:) caution ! When using the multi-circuit tester, do not strongly touch the terminal of the ecm coupler with a needle pointed tester probe to prevent the terminal damage or terminal bend. Note after repairing ...

Page 173

Engine general information and diagnosis: 1a-104 1 6) disconnect the ecm coupler. Refer to “ecm removal and installation in section 1c (page 1c-1)”. 7) check the continuity between the w/g wire “a” and terminal “12”. Also, check the continuity between the b/ br wire “b” and terminal “29”. Special to...

Page 174

1a-105 engine general information and diagnosis: 2 1) connect the ecm coupler and ho2 sensor coupler. 2) warm up the engine enough. 3) insert the needle pointed probes to the lead wire coupler. 4) measure the ho2 sensor output voltage between the w/ g wire and b/br wire, when idling condition. Speci...

Page 175

Engine general information and diagnosis: 1a-106 troubleshooting (when indicating c44/p0135:) note after repairing the trouble, clear the dtc using sds tool. Refer to “use of sds diagnosis reset procedures (page 1a-13)”. Step action yes no 1 1) turn the ignition switch off. 2) remove the left frame ...

Page 176

1a-107 engine general information and diagnosis: 2 1) connect the ho2 sensor coupler. 2) insert the needle pointed probes to the lead wire coupler. 3) turn the ignition switch on and measure the heater voltage between the w/b wire and ground. If the tester voltage indicates the battery voltage, it i...

Page 177

Engine general information and diagnosis: 1a-108 dtc “c49” (p1656): pair control solenoid valve circuit malfunction b718h11104028 detected condition and possible cause wiring diagram ecm coupler (harness side) troubleshooting caution ! When using the multi-circuit tester, do not strongly touch the t...

Page 178

1a-109 engine general information and diagnosis: step action yes no 1 1) turn the ignition switch off. 2) remove the fuel tank. Refer to “fuel tank removal and installation in section 1g (page 1g-9)”. 3) check the pair control solenoid valve coupler for loose or poor contacts. If ok, then measure th...

Page 179

Engine general information and diagnosis: 1a-110 active control inspection 1) set up the sds tool. (refer to sds operation manual for further details.) 2) turn the ignition switch on. 3) click “pair sol operating control” (1). 2 1) turn the ignition switch on. 2) measure the voltage between the o/w ...

Page 180

1a-111 engine general information and diagnosis: 4) click each button (2). At this time, if an operating sound is heard from the pair control solenoid valve, the function is normal. Dtc “c60” (p0480): cooling fan relay circuit malfunction b718h11104029 detected condition and possible cause wiring di...

Page 181

Engine general information and diagnosis: 1a-112 troubleshooting caution ! When using the multi-circuit tester, do not strongly touch the terminal of the ecm coupler with a needle pointed tester probe to prevent the terminal damage or terminal bend. Note after repairing the trouble, clear the dtc us...

Page 182

1a-113 engine general information and diagnosis: active control inspection note cooling fan relay and cooling fan motor operation can be checked until the engine coolant temperature is less than 100 °c (212 °f) after starting the engine. 1) set up the sds tool. (refer to sds operation manual for fur...

Page 183

Engine general information and diagnosis: 1a-114 specifications service data b718h11107001 injector fi sensors item specification note injector resistance 11 – 13 Ω at 20 °c (68 f°) — item specification note ckp sensor resistance 90 – 150 Ω ckp sensor peak voltage 2.0 v and more when cranking iap se...

Page 184

1a-115 engine general information and diagnosis: special tools and equipment special tool b718h11108001 09900–25008 ) (page 1a-66) / ) (page 1a-68) / ) (page 1a-69) / ) (page 1a-70) / ) (page 1a-71) / ) (page 1a-71) / ) (page 1a-72) / ) (page 1a-75) / ) (page 1a-78) / ) (page 1a-80) / ) (page 1a-80)...

Page 185: Emission Control Devices

Emission control devices: 1b-1 engine emission control devices precautions precautions for emission control devices b718h11200001 refer to “general precautions in section 00 (page 00-1)”. General description fuel injection system description b718h11201001 gsf1250 motorcycles are equipped with a fuel...

Page 186

1b-2 emission control devices: crankcase emission control system description b718h11201002 the engine is equipped with a pcv system to prevent discharging crankcase emissions into the atmosphere. Blow-by gas in the engine is constantly drawn into the crankcase, which is returned to the combustion ch...

Page 187

Emission control devices: 1b-3 exhaust emission control system description b718h11201003 the exhaust emission control system is composed of the pair system, ho2 sensor, catalyst system and isc system. The fresh air is drawn into the exhaust port through the pair control solenoid valve and pair reed ...

Page 188

1b-4 emission control devices: schematic and routing diagram pair system hose routing diagram b718h11202001 1 1 2 “a” “a” “a” “b” “b” “b” “c” “c” “ a ” “ a ” “ a ” “ a ” “ a ” i718h1120043-01 1. Pair control solenoid valve “a”: marking (yellow) “c”: to air cleaner box 2. Pair reed valve “b”: marking...

Page 189

Emission control devices: 1b-5 repair instructions heated oxygen sensor (ho2s) removal and installation b718h11206005 removal warning ! Do not remove the ho2 sensor while it is hot. Caution ! • be careful not to expose the ho2 sensor to excessive shock. • do not use an impact wrench when removing or...

Page 190

1b-6 emission control devices: pair reed valve removal and installation b718h11206008 removal 1) remove the fuel tank. Refer to “fuel tank removal and installation in section 1g (page 1g-9)”. 2) drain engine coolant and remove the thermostat connector. Refer to “thermostat connector / thermostat rem...

Page 191

Emission control devices: 1b-7 2) inspect the hoses for wear or damage. If it is worn or damaged, replace the pair hose with a new one. Refer to “pair system hose routing diagram (page 1b-4)”. 3) reinstall the fuel tank. Refer to “fuel tank removal and installation in section 1g (page 1g-9)”. Pair r...

Page 192

1b-8 emission control devices: 4) check the resistance between the terminals of the pair control solenoid valve. Special tool : 09900–25008 (multi-circuit tester set) tester knob indication resistance ( Ω) pair control solenoid valve resistance 18 – 22 Ω at 20 – 30 °c (68 – 86 °f) 5) reinstall the p...

Page 193

Emission control devices: 1b-9 installation installation is in the reverse order of removal. Pay attention to the following points: • apply bond to the mating surface of the breather cover. : sealant 99000–31110 (suzuki bond no.1215 or equivalent) note • make surfaces free from moisture, oil, dust a...

Page 194

1b-10 emission control devices: specifications service data b718h11207001 fi sensors tightening torque specifications b718h11207002 reference: for the tightening torque of fastener not specified in this section, refer to “tightening torque specifications in section 0c (page 0c-7)”. Special tools and...

Page 195: Engine Electrical Devices

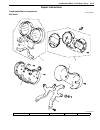

Engine electrical devices: 1c-1 engine engine electrical devices precautions precautions for engine electrical device b718h11300001 refer to “general precautions in section 00 (page 00-1)” and “precautions for electrical circuit service in section 00 (page 00-2)”. Component location engine electrica...

Page 196

1c-2 engine electrical devices: iap sensor (no.1) removal and installation b718h11306035 removal 1) remove the fuel tank. Refer to “fuel tank removal and installation in section 1g (page 1g-9)”. 2) disconnect the iap sensor (no.1) coupler (1) and vacuum hose (2). 3) remove the iap sensor (no.1) (3)....

Page 197

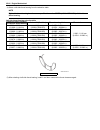

Engine electrical devices: 1c-3 ect sensor inspection b718h11306010 refer to “dtc “c15” (p0115-h/l): ect sensor circuit malfunction in section 1a (page 1a-45)”. Inspect the ect sensor in the following procedures: 1) remove the ect sensor. Refer to “ect sensor removal and installation (page 1c-2)”. 2...

Page 198

1c-4 engine electrical devices: stp sensor adjustment b718h11306025 adjust the stp sensor in the following procedures: 1) remove the air cleaner cover and air cleaner element. Refer to “air cleaner element removal and installation in section 1d (page 1d-6)”. 2) disconnect the stva lead wire coupler ...

Page 199

Engine electrical devices: 1c-5 installation 1) remove the air cleaner cover and air cleaner element. Refer to “air cleaner element removal and installation in section 1d (page 1d-6)”. 2) close the secondary throttle valve by finger. 3) with the stv fully closed, install the stp sensor (1) and tight...

Page 200

1c-6 engine electrical devices: isc valve preset and opening initialization b718h11306036 when removing or replacing the isc valve, set the isc valve to the following procedures: 1) turn the ignition switch on. 2) set up the sds tool. (refer to the sds operation manual for further details.) 3) click...

Page 201

Engine electrical devices: 1c-7 specifications service data b718h11307001 fi sensors item specification note ckp sensor resistance 90 – 150 Ω ckp sensor peak voltage 2.0 v and more when cranking iap sensor input voltage (no.1) 4.5 – 5.5 v iap sensor output voltage (no.1) approx. 2.7 v at idle speed ...

Page 202

1c-8 engine electrical devices: tightening torque specifications b718h11307002 reference: for the tightening torque of fastener not specified in this section, refer to “tightening torque specifications in section 0c (page 0c-7)”. Special tools and equipment recommended service material b718h11308001...

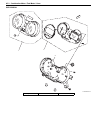

Page 203: Engine Mechanical

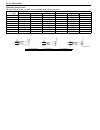

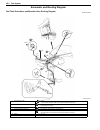

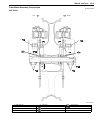

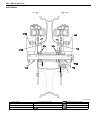

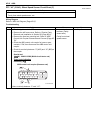

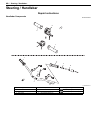

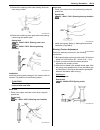

Engine mechanical: 1d-1 engine engine mechanical schematic and routing diagram camshaft and sprocket assembly diagram b718h11402001 i718h1140393-01.

Page 204

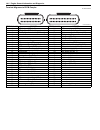

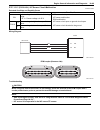

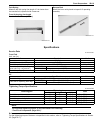

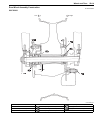

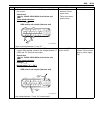

1d-2 engine mechanical: throttle cable routing diagram b718h11402002 1 2 “a” 4 3 2 1 3 4 5 6 7 “ a ” “ a ” i718h1140308-03 1. Wiring harness 4. Throttle cable no.2 7. Ignition switch lead wire 2. Cable guide (gsf1250s/sa only) 5. Handlebar switch lead wire (l) “a”: 0 mm (0 in) 3. Throttle cable no.1...

Page 205

Engine mechanical: 1d-3 diagnostic information and procedures engine mechanical symptom diagnosis b718h11404002 refer to “engine symptom diagnosis in section 1a (page 1a-7)”. Compression pressure check b718h11404001 the compression pressure reading of a cylinder is a good indicator of its internal c...

Page 206

1d-4 engine mechanical: repair instructions engine components removable with the engine in place b718h11406001 engine components which can be removed while the engine is installed on the frame are as follows. For the installing and removing procedures, refer to respective paragraphs describing each ...

Page 207

Engine mechanical: 1d-5 engine right side engine left side item removal inspection installation clutch cover refer to “clutch removal in section 5c (page 5c-13)”. — refer to “clutch installation in section 5c (page 5c-14)”. Clutch plates refer to “clutch removal in section 5c (page 5c-13)”. Refer to...

Page 208

1d-6 engine mechanical: air cleaner element removal and installation b718h11406034 removal 1) remove the fuel tank. Refer to “fuel tank removal and installation in section 1g (page 1g-9)”. 2) remove the air cleaner cover screws. 3) remove the air cleaner cover (1). 4) remove the air cleaner element ...

Page 209

Engine mechanical: 1d-7 installation install the throttle cables in the reverse order of removal. Pay attention to the following points: • install the throttle cables as shown in the cable routing diagram. Refer to “throttle cable routing diagram (page 1d-2)”. • check the throttle cable play and pro...

Page 210

1d-8 engine mechanical: throttle body construction b718h11406041 “b” 2 lh lh rh rh upper upper air cleaner side engine side 1 (a) (a) “a” i718h1140314-01 1. Clamp (air cleaner side) : after tighten the clamp band #2, 3 and tighten the clamp band #1, 4. “b”: clamp the drain hose at mark position. 2. ...

Page 211

Engine mechanical: 1d-9 throttle body removal and installation b718h11406042 removal 1) disconnect the battery (–) lead wire. Refer to “battery removal and installation in section 1j (page 1j-12)”. 2) remove the fuel tank. Refer to “fuel tank removal and installation in section 1g (page 1g-9)”. 3) r...

Page 212

1d-10 engine mechanical: installation install the throttle body in the reverse order of removal. Pay attention to the following points: • connect the throttle pulling cable (1) and throttle returning cable (2) to the throttle cable drum. • tighten the throttle body clamp screws. Refer to “throttle b...

Page 213

Engine mechanical: 1d-11 3) remove the fuel delivery pipe assembly (6). Caution ! Be careful not to twist the fuel delivery pipe’s t-joint (7), when disconnecting the fuel feed hose or removing the fuel delivery pipes, or joint part “a” of the fuel delivery pipe get damage. 4) remove the fuel inject...

Page 214

1d-12 engine mechanical: 9) remove the stp sensor (13). Note prior to disassembly, mark sensor’s original position with a paint or scribe for accurate reinstallation. Special tool : 09930–11950 (torx wrench) caution ! Never remove the iap/tp/iat sensor (14) from the throttle body. Caution ! Never se...

Page 215

Engine mechanical: 1d-13 assembly assemble the throttle body in the reverse order of disassembly. Pay attention to the following points: • apply a thin coat of engine oil to the o-ring. • with the stv fully closed, install the stp sensor (1) and tighten the stp sensor mounting screw to the specified...

Page 216

1d-14 engine mechanical: • apply a thin coat of engine oil to the new cushion seal (2) and the o-ring (3). Caution ! Replace the cushion seal and o-ring with the new ones. • apply a thin coat of engine oil to the new o-rings (4). Caution ! Replace the o-rings with the new ones. • assemble the fuel d...

Page 217

Engine mechanical: 1d-15 • tighten the fuel delivery pipe mounting screws to the specified torque. Tightening torque fuel delivery pipe mounting screw (a): 3.5 n·m ( 0.35 kgf-m, 2.45 lb-ft) throttle body inspection and cleaning b718h11406044 refer to “throttle body disassembly and assembly (page 1d-...

Page 218

1d-16 engine mechanical: 3) connect the respective vacuum tester hoses to each vacuum nipple on the throttle body. 4) start the engine. 5) set up the sds tool. (refer to the sds operation manual for further details.) 6) click “data monitor”. 7) warm up the engine (water temp. More than 80 ° (176 °f)...

Page 219

Engine mechanical: 1d-17 11) check for the synchronization of vacuum from #1 to #4 cylinders. 12) equalize the vacuum of the cylinders by turning each air screw and keep it running at idling speed. Note always set the engine rpm at idle rpm. 13) if the adjustment is not yet correct, remove each air ...

Page 220

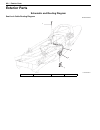

1d-18 engine mechanical: 4) remove the fuel tank. Refer to “fuel tank removal and installation in section 1g (page 1g-9)”. 5) drain engine coolant. Refer to “cooling system inspection in section 0b (page 0b-12)”. 6) disconnect the battery (–) lead wire. 7) disconnect the fuel feed hose (1). 8) remov...

Page 221

Engine mechanical: 1d-19 15) disengage the gearshift link arm by removing the bolt. Note mark the gearshift shaft head at which the gearshift link arm slit is set for correct reinstallation. 16) remove the engine sprocket inner cover by removing the bolts. 17) remove the speed sensor rotor (9) while...

Page 222

1d-20 engine mechanical: 23) disconnect the engine ground wire coupler (18) and oil pressure switch coupler (19). 24) disconnect the gp switch coupler (20) and starter motor lead wire (21). 25) support the engine with a proper jack. 26) remove the right engine mounting no.2 bracket (22). 27) remove ...

Page 223

Engine mechanical: 1d-21 engine assembly installation b718h11406003 reinstall the engine in the reverse order of engine removal. Pay attention to the following points: • insert the two mounting bolts from left side, and tighten their nuts. Note the engine mounting nuts are self-locking. Once the nut...

Page 224

1d-22 engine mechanical: • tighten all engine mounting bolts and nuts to the specified torque, as shown in the following illustration. • apply thread lock super to the driveshaft. : thread lock cement 99000–32030 (thread lock cement super 1303 or equivalent) • tighten the engine sprocket nut to the ...

Page 225

Engine mechanical: 1d-23 • tighten the speed sensor rotor bolt to the specified torque. Tightening torque speed sensor rotor bolt (h): 25 n·m (2.5 kgf-m, 18.0 lb-ft) • before installing the engine sprocket inner cover, apply a small quantity of suzuki super grease to the clutch push rod. : grease 99...

Page 226

1d-24 engine mechanical: engine top side disassembly b718h11406006 caution ! Identify the position of each removed part. Organize the parts in their respective groups (e.G., intake, exhaust) so that they can be reinstalled in their original positions. 1) remove the seat (1) and disconnect the batter...

Page 227

Engine mechanical: 1d-25 camshaft 1) remove the right crankshaft cover (1). 2) remove all of the spark plugs. Refer to “ignition coil / plug cap and spark plug removal and installation in section 1h (page 1h-4)”. Special tool : 09930–10121 (spark plug wrench set) 3) turn the crankshaft clockwise and...

Page 228

1d-26 engine mechanical: 8) remove the intake (7) and exhaust camshafts (8). 9) remove the dowel pins. Cylinder head 1) remove the radiator (1). Refer to “radiator / cooling fan motor removal and installation in section 1f (page 1f-5)”. 2) remove the exhaust pipe assembly (2) and muffler. Refer to “...

Page 229

Engine mechanical: 1d-27 cam chain no.1 guide remove the cam chain no.1 guide (1). Cylinder 1) disconnect the water hoses (1). 2) disconnect the ect sensor coupler (2). 3) remove the cylinder (3). Note if the cylinder does not come off easily, lightly tap it using a plastic hammer. 4) remove the cyl...

Page 230

1d-28 engine mechanical: 3) draw out each piston pin (2) and remove the pistons (3). Note scribe the cylinder number on the piston head. Engine top side assembly b718h11406007 assemble the engine top side in the reverse order of disassembly. Pay attention to the following points: piston • when insta...

Page 231

Engine mechanical: 1d-29 • position the piston ring gaps as shown. Before inserting each piston into its cylinder, check that the gaps are properly positioned. Cylinder • install the dowel pins and cylinder gasket (1). Caution ! Replace the cylinder gasket (1) with a new one. • apply molybdenum oil ...

Page 232

1d-30 engine mechanical: cam chain no.1 guide • pull the cam chain out of the cylinder and install the cam chain guide (1). Caution ! Be sure that the cam chain guide (1) is installed properly. Cylinder head • install the dowel pins, o-ring (1) and cylinder head gasket (2). Caution ! Replace the o-r...

Page 233

Engine mechanical: 1d-31 water hose • install the water hoses (1). Refer to “water hose routing diagram in section 1f (page 1f-3)”. Exhaust pipe / muffler • install the exhaust pipe assembly (1), muffler and radiator (2). Refer to “exhaust pipe / muffler removal and installation in section 1k (page ...

Page 234

1d-32 engine mechanical: • the other arrow marked “2” “d” should now be pointing straight up. Starting from the roller pin that is directly above the arrow marked “2” “d”, count out 16 roller pins (from the exhaust camshaft side going towards the intake camshaft side). • engage the 16th roller pin “...

Page 235

Engine mechanical: 1d-33 • install the oil pipe and tighten the mounting bolts to specified torque. Note fit the washer (1) to each oil pipe mounting bolt. Tightening torque oil pipe mounting bolt (a): 10 n·m (1.0 kgf-m, 7.0 lb-ft) cam chain tension adjuster • retract the push rod by pushing the sto...

Page 236

1d-34 engine mechanical: • after installing the cam chain tension adjuster, rotate the crankshaft (some turns), and recheck the positions of the camshafts. • be sure to check and adjust the valve clearance. Refer to “valve clearance inspection and adjustment in section 0b (page 0b-5)”. Throttle body...

Page 237

Engine mechanical: 1d-35 • apply suzuki bond to the cam end caps of the gasket as shown. : sealant 99000–31140 (suzuki bond 1207b or equivalent) • apply engine oil to both sides of the gaskets. Caution ! Use the gaskets with new ones to prevent oil leakage. • tighten the cylinder head cover bolts (4...

Page 238

1d-36 engine mechanical: valve clearance inspection and adjustment b718h11406008 refer to “valve clearance inspection and adjustment in section 0b (page 0b-5)”. Camshaft inspection b718h11406009 refer to “engine top side disassembly (page 1d-24)”. Refer to “engine top side assembly (page 1d-28)”. Ca...

Page 239

Engine mechanical: 1d-37 3) install each camshaft journal holder to its original position. Refer to “engine top side assembly (page 1d-28)”. 4) tighten the camshaft journal holder bolts in ascending order of numbers to the specified torque. Refer to “engine top side assembly (page 1d-28)”. Note do n...

Page 240

1d-38 engine mechanical: camshaft sprocket inspection b718h11406010 inspect the camshaft sprocket in the following procedures: 1) remove the intake and exhaust camshafts. Refer to “engine top side disassembly (page 1d-24)”. 2) inspect the teeth of each camshaft sprocket for wear or damage. If they a...

Page 241

Engine mechanical: 1d-39 cam chain tension adjuster inspection b718h11406012 the cam chain tension adjuster is maintained at the proper tension by an automatically adjusted. 1) remove the cam chain tension adjuster. Refer to “engine top side disassembly (page 1d-24)”. 2) check that the push rod slid...

Page 242

1d-40 engine mechanical: cam chain tensioner inspection b718h11406015 inspect the cam chain tensioner in the following procedures: 1) separate the crankcases, upper and lower. Refer to “engine bottom side disassembly (page 1d-53)”. 2) remove the crankshaft assembly from the upper crankcase. Refer to...

Page 243

Engine mechanical: 1d-41 3) remove the valve spring retainer (4) and valve spring (5). 4) pull out the valve (6) from the combustion chamber side. 5) remove the oil seal (7) and spring seat (8). 6) remove the other valves in the same manner as described previously. 7) remove the water outlet pipes (...

Page 244

1d-42 engine mechanical: note • when replacing the intake pipes, identify the different intake pipes according to each i.D. Code “a”. (1-18h0 for cylinder #1 and #4) (2-18h0 for cylinder #2 and #3) • make sure that the “1 up” mark faces up. (for cylinder #1) • make sure that the “4 up” mark faces up...

Page 245

Engine mechanical: 1d-43 • install the valve spring with the small-pitch portion “b” facing cylinder head. • put on the valve spring retainer (2), and using the special tools, press down the spring, fit the cotter halves to the stem end, and release the lifter to allow the cotter halves to wedge in ...

Page 246

1d-44 engine mechanical: cylinder head related parts inspection b718h11406017 refer to “cylinder head disassembly and assembly (page 1d-40)”. Cylinder head distortion 1) decarbonize the combustion chambers. 2) check the gasket surface of the cylinder head for distortion. Use a straightedge and thick...

Page 247

Engine mechanical: 1d-45 valve stem deflection lift the valve about 10 mm (0.39 in) “a” from the valve seat. Measure the valve stem deflection in two directions, “x” and “y”, perpendicular to each other. Position the dial gauge as shown. If the deflection exceeds the service limit, then determine wh...

Page 248

1d-46 engine mechanical: valve seat width 1) visually check for valve seat width on each valve face. If the valve face has worn abnormally, replace the valve. 2) coat the valve seat with a red lead (prussian blue) and set the valve in place. 3) rotate the valve with light pressure. Special tool (a):...

Page 249

Engine mechanical: 1d-47 valve guide replacement b718h11406018 1) remove the cylinder head. Refer to “engine top side disassembly (page 1d-24)”. 2) remove the valves. Refer to “cylinder head disassembly and assembly (page 1d-40)”. 3) using the valve guide remover, drive the valve guide out toward th...

Page 250

1d-48 engine mechanical: 8) after installing the valve guides, refinish their guiding bores using the reamer. Be sure to clean and oil the guides after reaming. Note • be sure to cool down the cylinder head to ambient air temperature. • insert the reamer from the combustion chamber and always turn t...

Page 251