- DL manuals

- Suzuki

- Motorcycle

- GZ250 Marauder

- Service Manual

Suzuki GZ250 Marauder Service Manual

Summary of GZ250 Marauder

Page 2: Foreword

Foreword this manual contains an introductory description on the suzuki gz250 and procedures for its inspec- tion/service and overhaul of its main components. Other information considered as generally known is not included. Read the general information section to fa- miliarize yourself with the moto...

Page 3: How To Use This Manual

How to use this manual to locate what you are looking for: 1. The text of this manual is divided into sections. 2. The section titles are listed in the group index. 3. Holding the manual as shown at the right will allow you to find the first page of the section easily. 4. The contents are listed on ...

Page 4

Symbol listed in the table below are the symbols indicating instructions and other information necessary for servicing. The meaning of each symbol is also included in the table. Symbol definition symbo l definition torque cont rol required. Data beside it indicates specified torque. Apply threa d lo...

Page 5: General Information

General information --------------------------------------------contents ------------------------------------------------- 1 warning/caution/note ....................................................................... 1- 1 general precautions.............................................................

Page 6: Warning/caution/note

1-1 general information warning/caution/note please read this manual and follow its instructions carefully. To emphasize special information, the symbol and the words warning, caution and note have special meanings. Pay special attention to the messages highlighted by these signal words. Warning ind...

Page 7

General information 1-2 caution * if parts replacement is necessary, replace the parts with suzuki genuine parts or their equivalent. * when removing parts that are to be reused, keep them arranged in an orderly manner so that they may be reinstalled in the proper order. * be sure to use special too...

Page 8

* to protect the environment, do not unlawfully dispose of used motor oil and all other fluids, batteries, and tires. * to protect the earth's natural resouces, properly dispose of used motorcycles and parts..

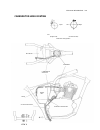

Page 9: Suzuki Gz250X ('99-Model)

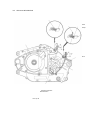

1-3 general information suzuki gz250x ('99-model) serial number location the frame serial number or v.I.N. (vehicle identification number) is stamped on the right side of the steering head pipe. The engine serial number is located on the left side of the crankcase. These numbers are required especia...

Page 10

General information 1-4 engine oil use only oils which are rated sf or sg under the api clas- sification. The recommended viscosity is sae 10w/40. If sae 10w/40 engine oil is not available, select an alterna- tive according to the chart. Brake fluid specification and classification: dot 4 warning th...

Page 12: Specifications

General information 1-6 specifications dimensions and dry mass overall length ......................................... Overall width ............................................ Overall height .......................................... Wheelbase ................................................ Grou...

Page 13

1-7 general information electrical ignition type ......................................................... Electronic ignition (transistorized) ignition timing .................................................... 10° b. T.D.C. At 1 300 r/min spark plug ..................................................

Page 14: Country And Area Codes

General information 1- 8 country and area codes the following codes stand for the applicable country(-ies) and area(-s). Code country or area e-01 general e-02 uk e-03 u.S.A. (except for california) e-04 franc e e-17 sweden, finland (e-15), norway (e-16), denmark (e -26) e-22 germany e-24 australia ...

Page 15: Periodic Maintenance

Periodic maintenance --------------------------------------------contents --------------------------------------------- periodic maintenance schedule .................................................. 2- 1 periodic maintenance chart ...................................................... 2- 1 lubrica...

Page 16

2-1 periodic maintenance periodic maintenance schedule the chart below lists the recommended intervals for all the required periodic service work necessary to keep the motorcycle operating at peak performance and economy. Maintenance intervals are ex- pressed in terms of kilometers and months, and a...

Page 17

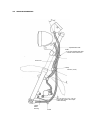

Periodic maintenance 2-2 lubrication points proper lubrication is important for smooth operation and long life of each working part of the motor- cycle. Major lubrication points are indicated below. Side-stand pivot drive chain and spring hook brake pedal pivot note: * before lubricating each part, ...

Page 18

2-3 periodic maintenance maintenance and tune-up procedures this section describes the servicing procedures for each item in the periodic maintenance chart. Exhaust pipe bolts and muffler mounting bolts tighten every 5 000 km (3 000 miles, 15 months). • tighten the exhaust pipe bolts and muffler mou...

Page 19

Periodic maintenance 2-4 • carefully use compressed air to clean the air cleaner element. Caution _________________________________ always apply compressed air to the outside of the air cleaner element. If compressed air is applied to the inside, dirt will be forced into the pores of the air cleaner...

Page 20

2-5 periodic maintenance remove the valve inspection caps the valve clearance specification is different for intake and exhaust valves. Valve clearance adjustment must be checked and adjusted, 1) at the time of periodic inspection, 2) when the valve mechanism is serviced, and 3) when the camshaft is...

Page 21

Periodic maintena nce 2-6 adjustment the clearance is adjusted using the special tool and offset wrench. • loosen the locknuts • insert a thickness gauge between the valve stem end and the adjusting screw on the rocker arm. • adjust the valve clearance by turning the adjusting screw using the specia...

Page 22

2-7 periodic maintenance check the spark plug for burns. If any abnormalities are found, replace the spark plug as indicated below. Ngk denso remarks dr7ea x22esr-u if the standard spark plug is apt to get wet, replace wit h this plug. Dr8ea x24esr-u standard dr9ea x27esr-u if the standard spark plu...

Page 23

Periodic maintenance 2-8 • start the engine, turn the throttle stop screw and set the engine idle speed as follows. Engine idle speed: 1 300 ± 50 r/min .... For e-03, -28, -33 1 300 ±100 r/min ..... For the others 09900-26006: tachometer throttle cable play inspect initially at 1 000 km (600 miles, ...

Page 24

2-9 periodic maintenance starter plunger cable play starter plunger cable play should be 0.5-1.0 mm (0.02-0.04 in) as shown. If the play is incorrect, adjust it as follows: • loosen the lock nut and turn the adjuster in or out until the specified play is obtained. • tighten the lock nut while holdin...

Page 25

Periodic maintenance 2-10 • start up the engine and allow it to run for a few minutes at idling speed. • turn off the engine and wait about one minute, then check the oil level through the inspection window . If the level is below the "f" mark, add oil to the proper level. Oil filter replacement • d...

Page 26

Replacement..

Page 27

2-11 periodic maintenance checking and adjusting • remove the rear axle cotter pin. (for e-28 model) • loosen the rear axle nut • tense the drive chain fully by turning chain adjuster nuts • count out 21 pins (20-pitch) on the chain measure the distance between the two points. If the distance exceed...

Page 28

Periodic maintenance 2-12 • after cleaning and drying the chain, oil it with a heavy- weight engine oil. Caution do not use any oil sold commercially as "drive chain oil", this type of oil can such oil can damage the "0"-rings (or seals). Brakes (brake) inspect initially at 1 000 km (600 miles, 3 mo...

Page 29

2-13 periodic maintenance front brake pads the extent of brake pad wear can be checked by observing the limit line on the pad. When the wear exceeds the limit line, replace the pads with new ones. (see p. 5-8.) a caution replace the brake pad as a set, otherwise braking performance will be adversely...

Page 30

Periodic maintena nce 2-14 rear brake pedal height • loosen the lock nut • adjust the brake pedal height by turning the adjuster to locate the pedal 50 mm (2.0 in) above the top face of the footrest. Rear brake adjusting • adjust the free travel to 20-30 mm (0.8-1.2 in) by turning the adjusting nut ...

Page 31

2-15 periodic maintenance tire inspect every 5 000 km (3 000 miles, 15 months). Tire tread condition operating the motorcycle with excessively worn tires will decrease riding stability and consequently invite a danger- ous situation. It is highly recommended to replace a tire when the remaining dept...

Page 32

Periodic maintena nce 2-16 front fork inspect every 10 000 km (6 000 miles, 30 months). Inspect the front forks for oil leakage, scoring or scratches on the outer surface of the inner tubes. Replace any defec- tive parts, if necessary. Rear suspension inspect every 10 000 km (6 000 miles, 30 months)...

Page 33

2-17 periodic maintenance.

Page 34

Periodic maintenance 2-18 compression pressure check the compression pressure reading of the cylinder is a good indicator of its internal condition. The decision to overhaul the cylinder is often based on the results of a compression test. Periodic maintenance records kept at your dealership should ...

Page 35

2-19 periodic maintenance oil pressure check check the oil pressure periodically. This will give a good indication of the condition of the moving parts. Oil pressure specifica tion above 30 kpa (0.3 kg/cm 2 , 4.3 psi) below 70 kpa (0.7 kg/cm 2 , 10.0 psi) at 3 000 r/min., oil temp, at 60°c (140°f) i...

Page 36: Engine

Engine i ----------------------------------------------- contents -------------------------------- engine components removable with the engine in place ....................................................................................................... .... 3- 1 engine removal and reinstallation ...

Page 37: Place

3-1 engine engine components removable with the engine in place the parts listed below can be removed and reinstalled without removing the engine from the frame. Refer to the pages listed in each section for removal and reinstallation instructions. Engine center see page exhaust pipe and muffler ......

Page 38

Engine 3-2 engine removal and reinstallation engine removal • remove the front seat. (see p. 5-1.) • remove the fuel tank. (see p. 4-1.) • remove the right frame cover. (see p. 5-1.) • disconnect the battery lead wire. • drain the engine oil. (see p. 2-9.) • remove the right footrest bracket. • remo...

Page 39

3-3 engine • remove the engine sprocket cover. • flatten the lock washer. • remove the engine sprocket nut and washer. Note: when loosening the engine sprocket nut, temporarily install the right footrest bracket and depress the brake pedal. • remove the engine sprocket. Note: if it is difficult to r...

Page 40

Engine 3-4 • remove the starter plunger . • loosen the carburetor clamp screws. • remove the carburetor. ¿warning gasoline is very explosive. Extreme care must be taken. • disconnect the engine ground wire. • disconnect the crankcase breather hose • disconnect the starter motor lead wire. • disconne...

Page 41

3-5 engine • support the motorcycle with a jack or wooden block. • remove the engine mounting bolts and nuts • remove the frame down tube mounting bolts and nuts • remove the lower engine mounting bolt and nut • remove the upper engine mounting bolt and nut note: when removing the upper mounting bol...

Page 42

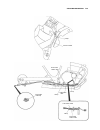

Engine 3-6 engine reinstallation reinstall the engine in the reverse order of engine removal. • install the engine mounting bolts and nuts as shown in the following illustration. • tighten the engine mounting nuts to the specified torque. Note: the engine mounting nuts are self-locking. Once the nut...

Page 43

3-7 engine • tighten the engine ground wire and the clamp by crank- case bolt as shown. • clamp the neutral switch lead wire and side-stand switch lead wire • position the carburetor clamps as shown in the illustra- tion. • install the clutch release arm as shown in the illustration. Note: align the...

Page 44

Engine 3-8 • tighten the exhaust pipe bolts and muffler mounting bolt to the specified torque. Exhaust pipe bolt: 14 n-m (1.4 kg-m, 10.0 ib-ft) muffler mounting bolt: 29 n-m (2.9 kg-m, 21.0 ib-ft) caution check the wire, cable and hose routing. (see pp. 7-11 to -18.) • install the right footrest and...

Page 45: Engine Disassembly

3-9 engine engine disassembly the procedure for engine disassembly is sequentially ex- plained in the following steps. • remove the valve inspection caps • remove the spark plug. • remove the valve timing inspection plug and generator cover cap. • rotate the crankshaft and align the "t" line on the ...

Page 46

Engine 3-10 • remove the camshaft and camshaft sprocket . Caution do not drop the cam chain into the crankcase. • remove the c-ring caution do not drop the c-ring into the crankcase. • remove the cylinder head nuts diagonally. • remove the cylinder head by removing the cylinder head nuts note: if th...

Page 47

3-11 engine • remove the cylinder gasket and dowel pins. • place a clean rag over the cylinder base to prevent the piston pin circlip from dropping into the crankcase. Then, remove the piston pin circlip with a long-nose pliers. • remove the piston pin using the special tool. 09910-34510: piston pin...

Page 48

Engine 3-12 • remove the generator cover. • remove the gasket and dowel pins. • remove the clutch cover. • remove the gasket and dowel pins. • while holding the generator rotor using the special tool, remove the clutch spring mounting bolts in a crisscross pattern, and remove the clutch springs and ...

Page 49

3-13 engine • remove the washer , bearing , clutch push piece and clutch push rod • remove the clutch drive and driven plates. • remove the spring washer and washer seat • flatten the lock washer of the clutch sleeve hub nut. • remove the clutch sleeve hub nut using the special tool. 09920-53740: cl...

Page 50

Engine 3-14 • remove the thrust washer and primary driven gear assembly • remove the spacer and thrust washer • remove the círclíp and oil pump driven gear • remove the pin and washer . • remove the oil pump a caution do not attempt to disassemble the oil pump as- sembly. • remove the gearshift shaf...

Page 51

3-15 engine • while holding the generator rotor using the special tool, remove the balancer shaft bolt 09930-44913: rotor holder • remove the cam chain • remove the primary drive gear nut using the special tool. 09930-44913: rotor holder a caution the primary drive gear nut has left-hand threads. • ...

Page 52

Engine 3-16 • remove the shaft and starter idle gear • remove the generator rotor nut using the special tool. 09930-44913: rotor holder • remove the generator rotor using the special tool. 09930-34960: rotor remover • remove the generator rotor key • remove the starter driven gear • remove the beari...

Page 53

3-17 engine • remove the gearshift cam stopper. • remove the crankcase bolts. • separate the left and right crankcases using the special tool. 09920-13120: crankcase separator note: * fit the crankcase separator, so that the tool arms are in parallel with the side of crankcase. * the crankshaft and ...

Page 54

Engine 3-18 • remove the gearshift cam stopper spring • remove the gearshift fork shafts and gearshift forks • remove the gearshift cam • remove the transmission. • remove the balancer shaft • remove the balancer shaft drive gear • remove the crankshaft using the special tool. 09920-13120: crankcase...

Page 55: Engine Components

3-19 engine engine components inspection and service crankcase bearings bearing inspection while the bearing is in the crankcase, rotate its inner race and check to see that it turns smoothly. If it does not turn quietly and smoothly, or if there are signs of any abnormali- ties, the bearing is defe...

Page 56

Engine 3-20 • remove the oil seal using the special tool. 09913-75510: bearing remover/installer a caution the removed oil seal should be replaced with a new one. Bearing installation • install the bearings using the special tools. 09913-75510: bearing remover/installer (for ) 09913-75520: bearing r...

Page 57

3-21 engine • install the left crankcase bearing using the special tool and suitable attachment (used beanng e.G.). 09913-75510: bearing remover/installer • install the washer • install the left drlveshaft bearing with the bearing retainer • install the bearing retainers note: apply a small quantity...

Page 58

Engine 3-22 clutch release camshaft removal • remove the oil seal retainer and clutch cable guide • remove the oil seal • remove the clutch release cam shaft reassembly • apply engine oil to the clutch release camshaft as shown in the illustration. • install the clutch release camshaft , washer and ...

Page 59

3-23 engine cylinder head cover caution identify the position of each removed part. Organize the parts in their re spective groups (i.E., intake or exhaust) so that they can be installed in their original locations. Disassembly • remove the rocker arm shaft bolts • remove the rocker arm shafts • rem...

Page 60

Engine 3-24 reassembly reassemble the cylinder head cover in the reverse order of disassembly. Pay attention to the following points: • apply engine oil to the rocker arm shafts. • install the rocker arms , wave washers and shafts [ a caution] use the new o-rings to prevent oil leakage. • tighten th...

Page 61

3-25 engine • compress the valve spring using the special tools. 09916-14510: valve lifter 09916-14910: valve lifter attachment • remove the valve cotters from the valve stem. 09916-84511: tweezers • remove the valve spring retainer and valve spring • remove the valve from the combustion chamber sid...

Page 62

Engine 3-26 cylinder head distortion decarbon the combustion chamber. Check the gasket surfac e of the cylinder head for distortion using a straightedge and thickness gauge. Take clearance readings at several places. If readings exceed the service limit, replace the cylinder head. 09900-20803: thick...

Page 63

3-27 engine valve stem wear measure the valve stem o.D. Using the micrometer. If it is out of s pecification, replac e the valve with a new one. If the valve stem o.D. Is within specification but the valve stem deflection is not, replace the valve guide. A fter replacing the valve or valve guide, re...

Page 64

Engine 3-28 • after installing the valve guides, re-finish their guiding bores using the special tools. Be sure to clean and oil the guides after reaming. 09916-34550: valve guide reamer (5.5 mm) 09916-34542: handle valve seat width • coat the valve seat uniformly with prussian blue. Install the val...

Page 65

3-29 engine • when installing the solid pilot , rotate it slightly. Seat the pilot snugly. Install the 45° cutter, attachment and t-handle. • using the 45° cutter, descale and clean up the seat. Ro- tate the cutter one or two turns. • measure the valve seat width after every cut. If the valve seat i...

Page 66

Contact area too low and too narrow on face of valve.

Page 67

Engine 3-30 valve springs check the valve springs for proper strength by measuring their free length and also the force required to compress them. If the spring length is less than the service limit or if the force required to compress the spring does not fall with- in the specified range, replace t...

Page 68

3-31 engine • apply molybdenum oil solution to the valve stems. Caution when inserting each valve, take care not to dam- age the lip of the stem seal. • install the valve springs with the smaller pitch facing the cylinder head. • install the valve spring retainer , press down the spring using the va...

Page 69

Engine 3-32 note: make sure that the "up" mark comes upward. Cam chain guide and cam chain tensioner check the cam chain guide and cam chain tensioner for wear and damage. If it is found to be damaged, replace it with a new one. Camshaft camshaft inspection if the engine produces abnormal noises, vi...

Page 70

3-33 engine note: install the cylinder head cover to its original position. Tighten the cylinder head cover bolts evenly and diagonally to the specified torque. Cylinder head cover bolt: 10 n ■ m (1.0 kg-m, 7.0 ib-ft) note: do not rotate the camshaft with the plastigauge in place. Remove the cylinde...

Page 71

Engine 3-34 cam chain tension adjuster the cam chain tension adjuster is maintained at the proper tension by an automatically adjusted tensioner. Insert a flat- head screwdriver into the slotted end of the cam chain ten- sion adjuster and turn it clockwise to release the tension. Remove the screwdri...

Page 72

3-35 engine piston ring-groove clearance measure the side clearance of the 1st and 2nd rings using the thickness gauge if any of the clearances exceed the limit, replace both the piston and piston rings. 09900-20803: thickness gauge 09900- 20205: micrometer (0-25 mm) service limit piston ring-groove...

Page 73

Engine 3-36 oversize rings oversize piston ring the following oversize piston ring is used. It bears the fol- lowing identification number. Piston ring 1st and 2nd 0.5 mm: 50 1.0 mm: 100 oversize oil ring the following oversize oil ring is used. It bears the follow- ing identification mark. Oil ring...

Page 74

3-37 engine crankshaft and conrod crankshaft, rh conrod bearing crank pin crankshaft, lh conrod small end i.D. Measure the conrod small end inside diameter using the dial calipers. If the conrod small end inside diameter ex- ceeds the service limit, replace the conrod. 09900-20605: dial calipers ser...

Page 75

Engine 3-38 conrod deflection and conrod big end side clearance wear on the big end of the conrod can be estimated by checking the movement of the small end of the rod. This method can also check the extent of wear on the parts of the conrod's big end. 09900-20701: magnetic stand 09900-20606: dial g...

Page 76

3-39 engine balancer shaft and balancer shaft driven gear disassembly • disassemble the balancer shaft as shown in the illustration. Balancer shaft key balancer shaft driven gear spring (6 pcs.) pin (3 pcs.) inspection inspect the balancer shaft and balancer shaft driven gear for wear or damage. If ...

Page 77

Engine 3-40 starter clutch and starter driven gear bearing 1 starter driven gear 2 starter clutch 3 roller 4 push piece 5 spring starter clutch install the starter driven gear onto the starter clutch and turn the starter driven gear by hand (the gear turns in only one direction). The starter driven ...

Page 78

3-41 engine • hold the generator rotor with the rotor holder and re- move the starter clutch bolts. 09930-44913: rotor holder reassembly • locate the shim to the proper position. • apply a small quantity of thread lock super "1303" to the starter clutch bolts and tighten them to the specified torque...

Page 79

Engine 3-42 transmission disassembly • disassemble the transmission gears as shown in the illustration. Reassembly assemble the countershaft and driveshaft in the reverse order of disassembly. Pay attention to the following points. Note: before installing the gears, apply engine oil to the bearing a...

Page 80

3-43 engine when installing a new circlip, pay attention to the direc- tion of the circlip. Fit the circlip to the side where the thrust is as shown in the illustration. The rounded side should be against the gear surface. Thrust sharp edge washers and circlips thickness 1.2 mm (0.05 in) 1.0 mm (0.0...

Page 81

Engine 3-44 gearshift forks measure the gearshift fork clearance in the groove of its respective gear using the thickness gauge. The clearance for each of the two gears hift forks plays an import ant role in the smoothness and positiveness of the shifting action. Each fork has its prongs fitted into...

Page 82

3-45 engine clutch clutch drive plates measure the thickness and claw width of the clutch drive plates using vernier calipers. If a clutch drive plate is not within the service limit, replace the clutch plates as a set. 09900-20101: vernier calipers service limit thickness (no.1): 2.62 mm (0.103 in)...

Page 83

Engine 3-46 clutch cover • remove the oil seal retainer • remove the oil seal using the special tool. 09913-50121: oil seal remover • install the new oil seal using a suitable socket • install the oil seal retainer. Note: apply a small quantity of thread lock "1342" to the oil seal retainer screws. ...

Page 84

3-47 engine oil sump filter • remove the oil sump filter cap • remove the oil sump filter inspection check the oil sump filter for any damage or clogs. Cleaning clean the oil sump filter with a compressed air..

Page 85: Crankshaft

Engine 3-48 engine reassembly reassemble the engine in the reverse order of disassembly. The following steps require special atten- tion or precautionary measures should be taken. Note: apply engine oil to each running and sliding part before reassembling. Crankshaft • when installing the crankshaft...

Page 86: Forks

3-49 engine • install the washer , balancer shaft driven gear washer and shim onto the balancer shaft. Note: make sure that the key is aligned with the keyway. • align the punch mark on the balancer shaft driven gear with the punch mark on the balancer shaft drive gear gearshift cam and gearshift fo...

Page 87

Engine 3-50 • install the gearshift fork shafts note: position the gearshift cam as shown in fig. So that the gearshift fork shafts can be installed easily. • install the the gearshift cam stopper spring crankcase • wipe both crankcase mating surfaces with a cleaning solvent. • apply suzuki bond "12...

Page 88

3-51 engine • install the dowel pins into the left half of the crankcase. • install the o-ring a caution use a new o-ring • apply engine oil to the conrod big end and transmission gears. • tighten the crankcase bolts to the specified torque. Crankcase bolt: 11 n-m (1.1 kg-m, 8,0 ib-ft) note: install...

Page 89

Generator rotor • remove any grease from the tapered portion of the gen- erator rotor and crankshaft. • install the washer so that the convex side of it faces the crankcase bearing. • install the bearing • install the starter driven gear • install the generator rotor key onto the crankshaft. • insta...

Page 90

3-53 engine • install the primary drive gear , wave washer and primary drive gear nut note: this nut has left hand threads. 09930-44913: rotor holder primary drive gear nut : 100 n-m (10.0 kg-m, 72.5 ib-ft) balancer shaft bolt • apply a small quantity of thread lock "1342" to the balancer shaft bolt...

Page 91

Engine 3-54 • install the gearshift cam driven gear assembly. • install the pawl lifter and cam guide note: apply a small quantity of thread lock "1342" to the threads of the screws. • install the return spring to the gearshift shaft as shown. • install the gearshift shaft. Note: align the center te...

Page 92

3-55 engine clutch • install the washer and spacer onto the counter- shaft. Note: apply engine oil to the inside and outside surfaces of the spacer. • install the primary driven gear assembly and thrust washer onto the countershaft. Note: when engaging the primary drive and driven gears, turn the pr...

Page 93

Engine 3-56 • install the clutch sleeve hub and lock washer. • install the clutch sleeve hub nut, and tighten it to the specified torque using the special tool. 09920-53740: clutch sleeve hub holder clutch sleeve hub nut: 50 n-m (5.0 kg-m, 36.0 ib-ft) • bend the lock washer securely. • install the w...

Page 94

3-57 engine clutch cover • install the two dowel pins and new gasket • tighten the clutch cover bolts securely. A caution install the new gasket washer to the bolt . Starter idle gear • install the starter idle gear a caution apply engine oil to the starter idle gear generator cover • install the do...

Page 95: Engine Sprocket Spacer

Neutral switch • install the spring and neutral switch contact and new o-ring • install the neutral switch. Engine sprocket spacer • apply suzuki super grease "a" to the o-ring of the engine sprocket spacer and the oil seal lip. 99000-25010: suzuki super grease "a" a caution use a new o-ring * insta...

Page 96

3-59 engine piston and piston ring • first, install a spacer into the oil ring groove and then install the two side rails . The spacer and side rails do not have a specific top or bottom when they are new. When reassembling used parts, install them in their original place and direction. A caution wh...

Page 97

Engine 3-60 the following are reminders for piston installation: • before installing the piston pin, apply molybdenum oil solution onto its surface. • apply engine oil to the big and small ends of the conrod. • place a clean rag over the cylinder base to prevent the piston pin circlip from dropping ...

Page 98

3-61 engine cylinder head • install the dowel pins into the cylinder and then install the cylinder head gasket onto the cylinder. A caution use a new gasket to prevent gas leakage. • place the cylinder head onto the cylinder. • cylinder head nuts and washers must be installed cor- rectly as shown. C...

Page 99

Engine 3-62 camshaft • turn the crankshaft counterclockwise, and align the t line on the generator rotor with the mark on the generator cover while keeping the cam chain tight. I a caution] if the crankshaft is turned without drawing the cam chain upward, the cam chain will catch be- tween crankcase...

Page 100

3-63 engine • bend the lock washer securely. Camshaft pin bolt lock washer camshaft sprocket • install the camshaft end cap. Cam chain tension adjuster note: * before installing the cam chain tension adjuster, lock the tension spring with a flat-head screwdriver. * before installing the cam chain te...

Page 101

Engine 3-64 cylinder head cover • pour motor oil in the oil pocket in the cylinder head. Note: turn the crankshaft and check that all the moving parts (e.G., cam follower, camshaft) work properly. • clean the mating surfaces of the cylinder head and head cover. • install the dowel pins. • apply suzu...

Page 102

Fuel and lubrication system -------------------------------------------- contents --------------------------------------------- fuel tank and fuel valve ................................................................ 4- 1 removal ........................................................................

Page 103: Fuel Tank And Fuel Valve

4-1 fuel and lubrication system fuel tank and fuel valve removal a warning gasoline is very explosive. Extreme care must be taken. • remove the front seat. (see p. 5-1.) • remove the fuel tank mounting bolts. • turn the fuel valve to "on" or "res" position. • disconnect the fuel hose and vacuum hose...

Page 104: Carburetor

Fuel and lubrication system 4-2 carburetor specifications item specification e-01, 02, 04, 25, 34 e-17, 22, 24 carburetor type mikuni bsr32ss bore size 32 mm i.D. No 13f0 13f2 idle r/min. 1 300 ± 100 r/min. Float height 13.0 ±0. 5 mm main jet (m.J.) #115 jet needle (j.N.) 5c60-3rd needle jet (n.J.) ...

Page 105

4-3 fuel and lubrication system construction top cap spring jet needle holder washer spacer jet needle piston valve/diaphragm diaphragm starter plunger pilot jet jet holder main jet pilot screw starter jet throttle stop screw float gasket needle valve seat needle valve float chamber.

Page 106

Fuel and lubrication system 4-4 removal • remove the fuel tank. (see p. 4-1.) • remove the starter plunger • loosen the lock nuts and disconnect the throttle cables • remove the overflow hose and air vent hose • loosen the clamp screws. • remove the carburetor. Disassembly • remove the fuel hose and...

Page 107

4-5 fuel and lubrication system remove the diaphragm cover ©. Remove the diaphragm • remove the carburetor top cap. • remove the spring and piston valve along with diaphragm • remove the jet needle holder ..

Page 108

Fuel and lubrication system 4-6 • remove the jet needle holder spring washer spacer the o-ring should be replaced with a new one. • remove the float chamber body . • remove the screw • remove the float pin • remove the float assembly along with the needle valve . A caution do not use a wire to clean...

Page 109

4-7 fuel and lubrication system • remove the pilot air jet no.1 and no.2 • remove the needle jet pilot screw removal (for e-03, -28, -33) because harsh cleaning solvents can damage the o-rlng seals in the pilot system, the pilot system components should be removed before cleaning. • use a 1/8" size ...

Page 110

Fuel and lubrication system 4- 8 cleaning awarning some carburetor cleaning chemicals, especially dip-type soaking solutions, are very corrosive and must be handled carefully. Always follow the chemical manufacturer's instructions on proper use, handling and storage. Clean all jets with a spray-type...

Page 111

4-9 fuel and lubrication system float height adjustment to check the float height, turn the carburetor upside down. Measure the float height while the float arm is just con- tacting the needle valve using vernier calipers. Bend the tongue as necessary to bring the float height to the specified value...

Page 112

Lubrication system oil pressure see p. 2-19. Oil filter see pp. 2-9 and -10. Oil sump filter when replacing the engine oil, make sure that the oil sump filter has no tears or damage. Also, be sure to clean the oil sump filter periodically. (see pp. 3-16, -47 and -51.) fuel and lubrication system 4-1...

Page 113

4-11 fuel and lubrication system engine lubrication system chart.

Page 114: Chassis

Chassis --------------------------------------------contents ---------------------------------------------- exterior parts ...................................................................................... 5- 1 removal ................................................................................

Page 115: Exterior Parts

5-1 chassis exterior parts removal front seat • remove the seat with the ignition key. Right frame cover • remove the screw. • remove the right frame cover. Left frame cover • remove the screw. • remove the left frame cover. • remove the seat lock. Hooked part hooked part rear seat • remove the rear...

Page 116

Chassis 5-2 front wheel construction item n-m kg-m ib-ft 65 6.5 47.0 23 2.3 16.5 23 2.3 16.5 dust cover spacer bearing front w heel spacer bearing brake disc speedometer gearbox front axle axle pinch bolt brake disc bolt.

Page 117

Left right.

Page 118

5-3 chassis removal front wheel • loosen the axle pinch bolt • loosen the front axle • raise the front wheel off the ground with a jack or wood- en block. • remove the front wheel by removing the front axle • remove the dust cover and spacer • remove the brake disc. 09900-00410: hexagon wrench set i...

Page 119

Chassis 5-4 remove the wheel bearings as follows: • insert the adapter into the wheel bearing. • after inserting the wedge bar from the opposite side, lock the wedge bar into the slit of the adapt er. • drive out both bearings by striking the wedge bar. 09941-50111: bearing remover a caution the rem...

Page 120

5-5 chassis reassembly • apply suzuki super grease "a" to the bearings be- fore installing. 99000-25010: suzuki super grease "a" • install the wheel bearings using the special tools as de- scribed below. 09924-84510: bearing installer set 09924-84521: bearing installer set caution * first install th...

Page 121

Chassis 5-6 remounting remount the front wheel in the reverse order of removal. Pay attention to the following points: • apply suzuki super grease "a" to the speedometer gearbox. 99000-25010: suzuki sup er greas e "a" • align the lugs on the speedometer gearbox with the recesses on the front wheel. ...

Page 122: Front Brake

5-7 chassis front brake construction item n-m kg-m kg-m 23 2.3 16.5 10 1.0 7.0 39 3.9 28.0 18 1.8 13.0 7.5 0.75 5.5 ¿warning this brake system is filled with an ethylene glycol-based dot 4 brake fluid. Do not use or mix different types of fluid, such as silicone-based or petroleum-based brake fluids...

Page 123

Chassis 5-8 brake pad replacement • loosen the brake pad mounting bolt • remove the brake caliper mounting bolts • remove the brake pad mounting bolt • remove the brake pads a caution * do not operate the brake lever during or after brake pad removal. * replace the brake pads as a set, otherwise bra...

Page 124

5-9 chassis brake caliper removal and disassembly • disconnect the brake hose from the brake caliper by re- moving the brake hose union bolt and allow the brake fluid to drain into a suitable receptacle. • loosen the brake pad mounting bolt. • remove the brake caliper by removing the mounting bolts ...

Page 125

Chassis 5-10 brake caliper inspection brake caliper inspect the brake caliper cylinder wall for nicks, scratches or other damage. Brake caliper pistons inspect the brake caliper piston for any scratches or other damage. Brake caliper reassembly and remounting reassemble and remount the brake caliper...

Page 126

5-11 chassis • tighten the brake caliper mounting bolts and brake pad mounting bolt to the specified torque. • tighten the brake hose union bolt to the specified torque. Brake caliper mounting bolt 39 n-m (3.9 kg-m, 28.0 ib-ft) brake pad mounting bolt : 18 n-m (1.8 kg-m, 13.0 ib-ft) brake hose union...

Page 127

Chassis 5-12 • place a rag underneath the brake hose union bolt on the master cylinder to catch any spilt brake fluid. • remove the brake hose union bolt. A caution immediately wipe off any brake fluid contacting any part of the motorcycle. The brake fluid reacts chemically with paint, plastics and ...

Page 128

5-13 chassis • remove the piston/secondary cup and return spring master cylinder inspection inspect the master cylinder bore for any scratches or other damage. Inspect the piston surface for any scratches or other dam- age. Inspect the primary cup, secondary cup and dust seal for wear or damage. Mas...

Page 129

Chassis 5-14 • when remounting the master cylinder onto the handle- bars, align the master cylinder holder's mating surface with punch mark on the handlebars and tighten the upper clamp bolt first. Master cylinder bolt: 10 n-m (1.0 kg-m, 7.0 ib-ft) master cylinder clearance • install the brake hose ...

Page 130: Front Fork

5-15 chassis front fork construction item n-m kg-m ib-ft 23 2.3 16.5 20 2.0 14.5 removal and disassembly • remove the front wheel. (see p. 5-3.) • remove the brake caliper. (see p. 5-9.) a caution secure the brake caliper to the frame with a string etc., taking care not to bend the brake hose. • rem...

Page 131

Chassis 5-16 • remove the front fork after loosening the front fork upper and lower clamp bolts note: slightly loosen the front fork cap bolt to facilitate later disassembly. • remove the front fork cap bolt , spacer , washer and spring • invert the front fork and stroke it several times to drain ou...

Page 132

5-17 chassis • remove the damper rod and rebound spring from the inner tube. • separate the inner tube from the outer tube. • remove the following parts. Oil seal washer outer tube slide metal inner tube slide metal the removed oil seal and slide metals should be replaced with new ones. • remove the...

Page 133

Chassis 5-18 inner and outer tubes inspect the inner tube sliding surface and outer tube sliding surface for scuffing. Reassembly and remounting reassemble and remount the front fork in the reverse order of removal and disassembly. Pay attention to the following points: i a caution ! * wash each met...

Page 134

5-19 chassis • tighten the damper rod bolt to the specified torque. 09900-00410: hexagon wrench set front fork damper rod bolt: 20 n-m (2.0 kg-m, 14.5 ib-ft) caution use a new damper rod gasket to prevent oil leakage. • install the oil seal stopper ring and dust seal a caution make sure that the oil...

Page 135

Chassis 5-20 • pour the specified fork oil into the inner tube. Fork oil type: suzuki fork oil ss-08 (#10) 99000-99001-ss8: suzuki fork oil ss-08 specification front fork oil capacity (each leg): 369 ml (12.5/13.0 us/imp oz) • hold the front fork leg in a vertical position and adjust the fork oil le...

Page 136

5-21 chassis • tighten the front fork lower clamp bolts and front fork cap bolts to the specified torque. • tighten the front fork upper clamp bolts to the speci- fied torque. Front fork upper clamp bolt: 23 n-m (2.3 kg-m, 16.5 ib-ft) front fork lower clamp bolt: 33 n • m (3.3 kg-m, 24.0 ib-ft) fron...

Page 137: Steering

Chassis 5-22 steering construction item n-m kg-m ib-ft 65 6.5 47.0 16 1.6 11.5 45 4.5 32.5 23 2.3 16.5 33 3.3 24.0 steering stem upper bracket handlebar clamp handlebar holder steering stem nut dust seal bearing, upper bearing, low er steering stem steering stem low er cover handlebars handlebar bal...

Page 138

Removal and disassembly • remove the front wheel. (see p. 5-4.) • remove the front fork. (see p. 5-15.) • disconnect the front brake light switch lead wires. • remove the front brake master cylinder. • remove the right handlebar balancer . • remove the handlebar right switch • disconnect the throttl...

Page 139

5-23 chassis • remove the left handlebar balancer . • remove the handlebar left switch • disconnect the clutch lever position switch coupler • remove the rear view mirror • disconnect the clutch cable. • remove the handlebar clamp bolt caps. • remove the handlebars by removing the handlebar clamp bo...

Page 140

Chassis 5-24 • remove the steering stem lower cover • remove the front brake hose/speedometer cable guide • disconnect the speedometer cable • remove the speedometer . • remove the front turn signal light brackets. • remove the handlebar holders • remove the steering stem head bolt ^5© - tj«e.

Page 141

5-25 chassis • remove the steering stem nut using the special tool. 09940-14911: steering stem nut wrench • draw out the steering stem lower bracket. Note: hold the steering stem lower bracket to prevent it from fal- ling. • remove the dust seal , upper bearing inner race and upper bearing • remove ...

Page 142

Chassis 5-26 • drive out the steering stem upper and lower bearing races using the special tool. 09941-54911: bearing outer race remover 09941-74910: steering bearing installer reassembly and remounting reassemble and remount the steering stem in the reverse order of removal and disassembly. Pay att...

Page 143

5-27 chassis • turn the steering stem lower bracket about fi ve or six times to the left and right. • loosen the steering stem nut of a turn note: this adjustment will vary from motorcycle to motorcycle. Mak e sure that the steering turns smoothly and easily in both directions. • install the steerin...

Page 144

Chassis 5-28 note: when installing the front turn signal lights, insert the projec- tion on the turn signal light bracket into the hole of steering stem upper bracket. • install the handlebar left switch. Note: insert the projection into the hole of the handlebars. * install the handlebar right swit...

Page 145

5-29 chassis rear wheel and rear brake construction spacer brake panel brake shoe spring bearing spacer brake camshaft rear w heel bearing damper drive chain guide rear sprocket mounting drum retainer bearing dust seal spacer rear sprocket rear axle rear axle nut rear brake cam lever nut rear sprock...

Page 146

Item n-m kg-m kg-m 78 7.8 56.5 10 1.0 7.0 50 5.0 36.0

Page 147

Chassis 5-30 removal • remove the clip and rear brake adjusting nut • remove the cotter pin, torque link nut and bolt. • remove the rear axle nut • raise the rear wheel off the ground with a jack or wood- en block. • loosen the drive chain adjusting nuts , left and right. • remove the rear axle. • d...

Page 148

5-31 chassis • remove the brake cam lever bolt and nut. • remove the brake cam lever • remove the washer , o-ring and brake camshaft inspection and disassembly wheel bearing ............................ See pp. 5-3 and -4. Wheel axle ................................................ See p. 5-4. Wheel...

Page 149

Chassis 5-32 • remove the retainer brake drum inspect the brake drum and measure the brake drum i.D. To determine the extent of wear. Replace the brake drum if the measurement exceeds the service limit. The value of this limit is indicated inside the brake drum. 09900-20101: vernier calipers service...

Page 150

5-33 chassis reassembly and remounting reassemble and remount the rear wheel and rear brake in the reverse order of removal and disassembly. Pay atten- tion to the following points: wheel bearing • apply suzuki super grease "a" to the bearing be fore installation. 99000-25010: suzuki super grease "a...

Page 151

Chassis 5-34 rear sprocket • tighten the rear sprocket nuts to the specified torque. Rear sprocket nut: 50 n-m (5.0 kg-m, 36.0 ib-ft) note: the stamped mark on the rear sprocket should face to the outside. Brake camshaft • when installing the brake camshaft, apply suzuki su- per grease "a" to the ca...

Page 152

5-35 chassis • apply suzuki super grease "a" to the brake cam and pin, and install the brake shoes. 99000-25010: suzuki super grease "a" a caution be careful not to apply too much grease to the cam and pin. If grease gets on the lining, brake slippage will result. Rear wheel • tighten the rear torqu...

Page 153

Chassis 5-36 rear suspension construction item n-m kg-m ib-ft 29 2.9 21.0 13 1.3 9.5 29 2.9 21.0 72 7.2 52.0 right side rear shock absorber rear torque link sw ingarm spacer dust seal dust seal spacer drive chain buffer sw ingarm pivot shaft rear shock absorber nut rear torque link nut rear shock ab...

Page 155

5-37 chassis removal • remove the rear wheel. (see p. 5-30.) • remove the drive chain case. • remove the rear brake cable holder • remove the rear brake cable from the swingarm. • remove the shock absorbers . • remove the swingarm pivot shaft end caps. • remove the swingarm pivot nut and washer. • r...

Page 156

Chassis 5-38 • remove the rear torque link from the swingarm. • remove the chain buffer from the swingarm. • remove the spacers inspection and disassembly swingarm pivot spacers and dust seals inspect the swingarm pivot spacers and dust seals for damage. If any defects are found, replace the spacer ...

Page 157

5-39 chassis • remove the swingarm needle bearings using the special tools. 09923-74510: bearing remover 09930-30102: sliding shaft a caution the removed needle bearings should be replaced with new ones. Swinga rm inspect the swingarm for damage. If any defects are found, replac e the swingarm with ...

Page 158

Chassis 5-40 reassembly and remounting reassemble and remount the swingarm and rear shock absorber in the reverse order of removal and disassembly. Pay attention to the following points: • press the needle bearings into the swingarm pivot using a suitable socket and the special tool. (see p. 5-36.) ...

Page 159

5-41 chassis • install the rear shock absorber and tighten the mounting bolts and nuts to the specified torque. Shock absorber mounting bolt/nut: 29 n-m (2.9kg-m,21.0lb-ft) note: install the rear shock absorbers with the spring tension ad- justing holes facing out. • install the rear wheel and rear ...

Page 160: Electrical System

Electrical system -------------------------------------------- contents --------------------------------------------- cautions in servicing ........................................................................ 6- 1 location of electrical components ..................................... 6-3 chargi...

Page 161

6-1 electrical system cautions in servicing connectors • when disconnecting a connector, be sure to hold the ter- minals; do not pull the lead wires. • when connecting a connector, push it in so it is firmly attached. • inspect the connector for corrosion, contamination and any breakage in the cover...

Page 162

Electrical system 6-2 battery • the mf battery used in this motorcycle does not require maintenance (e.G., electrolyte level inspection, distilled water replenishing). • during normal charging, no hydrogen gas is produced. However, if the battery is overcharged, hydrogen gas may be produced. Therefo...

Page 163

6-3 electrical system location of electrical components clutch lever position switch ignitor turn signal/side-stand relay fuse box ignition coil horn generator neutral switch side-stand switch regulator/rectifier.

Page 164

Electrical system 6-4 front brake light switch rear brake light switch starter motor starter relay main fuse battery.

Page 165

6-5 electrical system charging system description the circuit of the charging system is indicated in the figure, which is composed of an ac generator, regulator/rectifier unit and battery. The ac current generated from ac generator is converted by rectifier and is turned into dc current, then it cha...

Page 166

Electrical system 6-6 troubleshooting battery runs down quickly. Check accessories which use exces sive amounts of electricity. Accessories are installed • remove accessories. No accessories check the battery for current leaks. (see p. 6-7.) no current leaks measure the charging voltage between the ...

Page 167

Battery overcharges • faulty regulator/rectifier • faulty battery • poor contact of stator coil coupler.

Page 168

6-7 electrical system inspection battery leak current inspection • remove the front seat and right frame cover. (see p. 5-1.) • turn the ignition switch to the off position. • disconnect the battery lead wire. • connect the tester between the battery terminal and the battery lead wire. Note: leakage...

Page 169

Electrical system 6-8 stator coil resistance • remove the front seat. (see p. 5-1.) • remove the fuel tank. (see p. 4-1.) • disconnect the stator coil coupler. Measure the resistance between the three lead wires using a tester. Also check that the stator core is insulated. If the resistance is incor...

Page 170

6-9 electrical system regulator/rectifier • remove the front seat. (see p. 5-1.) • remove the fuel tank. (see p. 4-1.) • disconnect the regulator/rectifier couplers. Measure the voltage between the lead wires in the follow- ing table. 09900-25008: multi circuit tester set tester knob indication: dio...

Page 171

Electrical system 6-10 starter system and side-stand/ignition interlock system starter system description the start er system consists of the following components: the start er motor, starter relay, clutch lever position s witch, side-stand relay, side-stand s witch, neutral switch, starter button, ...

Page 172

6-11 electrical system troubleshooting starter motor will not run. The transmission is in neutral. Grasp the clutch lever. Turn on the ignition switch with the engine stop switch in "run" position. Listen for a click from the starter relay when the starter button is pushed. Clicks check if the start...

Page 173

• faulty starter clutch.

Page 174

Electrical system 6-12 starter motor removal and disassembly • disconnect the starter motor lead wire. • remove the starter motor. • disassemble the starter motor, as shown in the illustration. Starter motor inspection carbon brush inspect the brushes for abnormal wear, crack or smooth- ness in the ...

Page 175

6-13 electrical system commutator inspect the commutator for discoloration, abnormal wear or undercut if the commutator is abnormally worn, replace the arma- ture. If the commutator surface is discolored, polish it with #400 sandpaper and wipe it using a clean, dry cloth. If there is no undercut, sc...

Page 176

Electrical system 6-14 • apply a small quantity of suzuki moly paste to the armat ure shaft. 99000-25140: suzuki moly paste • apply suzuki super grease "a" to the o-rings. 99000-25010: suzuki sup er greas e "a" • apply a small quantity of thread lock "1342" to the starter motor housing bolts. Starte...

Page 177

6-15 electrical system measure the starter relay resistance between the terminals ( and ). Starter relay resistance: 3-6 side-stand/ignition interlock system part inspection if the interlock system does not operate properly, check each component. If any abnormality is found, replace the component wi...

Page 178

Electrical system 6-16 turn signal/side-stand relay the turn signal relay is corporated with the side-stand relay and diode to form the one component part which is called the turn signal/side-stand relay. It is located under the luggage box. • remove the front seat. (see p. 5-1.) • remove the luggag...

Page 179

6-17 electrical system diode inspection using multi circuit tester, measure the voltage between the terminals in the following table. Unit: v probe of tester to: p ro b e c te s te r to : , i 1.4-1.5 0.4-0.6 09900-25008: multi circuit te ster set tester knob indication: diode te st note: if the test...

Page 180

Electrical system 6- 18 ignition system (digital ignitor) description the fully transistorized ignition system consists of the following components: a generator, ignitor, igni- tion coil and spark plug. The ignition timing is programmed and stored in the ignitor. The pick-up coil is mounted in the g...

Page 181

6-19 electrical system troubleshooting check the ignition system couplers for poor connections. * check that the transmission is in neutral and the en gine stop switch is in the "run" position. Grasp the clutch lever. Check that the fuse is not blown and the battery is fully-charged before diagnosin...

Page 182

• open circuit in wiring harness • poor connection of ignition couplers.

Page 183

Electrical system 6-20 inspection ignition coil primary peak voltage • remove the front seat. (see p. 5-1.) • remove the fuel tank. (see p. 4-1.) • disconnect the spark plug cap. • connect new spark plug to the spark plug cap and ground it to the cylinder head. Note: make sure that the spark plug ca...

Page 184

6-21 electrical system ignition coil resistance measure the ignition coil resistance in both the primary and secondary windings. If the windings are in sound condition, their resistance should be close to the specified values. Ignition coil resistance primary: 3-5 ( terminal- terminal) secondary: 17...

Page 185

Electrical system 6-22 pick-up coil peak voltage • remove the front seat. (see p. 5-1.) • remove the luggage box. Note: be sure that all of the couplers are connected properly and the battery is fully-charged. • disconnect the ignitor coupler at the ¡gnitor. • measure the pick-up coil peak voltage b...

Page 186

6-23 electrical system • remove the front seat. (see p. 5-1.) • remove the fuel tank. (see p. 4-1.) • disconnect the pick-up coil coupler and connect the mul- ti circuit tester with the peak volt adaptor. Probe: green lead wire probe: blue lead wire • measure the pick-up coil peak voltage in the sam...

Page 187: Speedometer

Electrical system 6-24 speedometer removal and disassembly • remove the speedometer. • disassemble the speedometer as follows. Speedometer speedometer bracket speedometer cover socket assy..

Page 188

6-25 electrical system inspection check the continuity between lead wires. If there is no continuity, replace the respective parts. Note: when checking for continuity, it is not necessary to remove the speedometer. Wire color b : black b/w : black with white tracer gr : gray bl/b : blue with black t...

Page 189

Electrical system 6-26 lamps headlight and position light headlight: 12v 60/55w position light: 12v 4w ..... Except for e-03, -24, -28 and -33 models headlight bulb replacement • remove the headlight. • disconnect the socket • remove the rubber cap • remove the bulb by removing the bulb holder sprin...

Page 190

6-27 electrical system brake light/taillight brake light/taillight: 12v 21/5w brake light/taillight bulb replacement • remove the rubber cap behind the rear fender. • push in on the bulb socket , turn it counterclockwise, and pull it out. • remove the brake light/taillight bulb a caution if you touc...

Page 191

Electrical system 6-28 turn signal lights turn signal light/running light: 12v 21/5w ..... For e-03, -28 and -33 models turn signal light: 12v 21w ..... For the others turn signal light bulb replacement • remove the lens by removing the screws. • remove the bulb. Caution_____________________________...

Page 192

6-29 electrical system relays starter relay the starter relay is located behind the right frame cover. (see pp. 6-14 and -15.) turn signal/side-stand relay the turn signal relay is corporated with the side-stand relay and diode to form the one component part which is called the turn signal/side-stan...

Page 193: Switches

Electrical system 6-30 switches measure eac h switch for continuity using a tester. Switch assemblies with new ones. Ignition switch if any abnormality is found, replace the respective starter button for e-24 lighting switch (except for e-03, -24, -28, -33) horn button front brake light switch dimme...

Page 194

6-31 electrical system battery specifications type designation ftx7l-bs capacity 12v, 21.6 kc(6ah)/10hr standard electrolyte s.G. 1.320 at 20°c (68°f) stopper anode plates filter initial charging filling electrolyte • remove the aluminum tape which seals the battery filler holes * remove the caps fr...

Page 195

Electrical system 6-32 note: if air bubbles do not rise from any one of the filler ports, tap the bottom of the electrolyte container two or three times. Never remove the electrolyte container from the battery while there is still electrolyte in the container. • after the electrolyte container is co...

Page 196

6-33 electrical system recharging operation • measure the battery voltage using a tester. If the voltage reading is less than 12.0v (dc), recharge the battery with a battery charger. I a caution ! ________________________ when recharging the battery, remove the battery from the motorcycle. Note: whi...

Page 197: Servicing Information

Servicing information ------------------------------------------- contents -------------------------------------------- troubleshooting ................................................................................. 7- 1 wiring diagram .................................................................

Page 198: Troubleshooting

7-1 servicing information troubleshooting engine complaint symptom and possible causes remedy engine will not start, or is hard to start. S compression too low 1. Worn cylinder. 2. Worn piston ring. 3. Worn valve guide or improper valve seating. 4. Loose spark plug. 5. Broken, cracked or damaged pis...

Page 199

Servicing information 7-2 complaint symptom and possible causes remedy engine is noisy. Excessive valve chatter noisy engine. 1. Excessive valve clearance. Adjust. 2. Weak or broken valve spring. Replace. 3. Worn cam surface. Replace. 4. Worn or burnt camshaft journal. Noise seems to come from the p...

Page 200

7-3 servicing information complaint symptom and possible causes remedy transmission will not shift back. 1. Broken gearshift shaft return spring. 2. Rubbing or stuck gearshift shaft. 3. Worn or distorted gearshift fork. Replace. Repair or replace. Replace. Transmission jumps out of gear. 1. Worn gea...

Page 201

Servicing information 7-4 complaint symptom and possible causes remedy engine overheats. 1. Heavy carbon deposit on piston crown. Clean. 2. Not enough oil in the engine. Add oil. 3. Defective oil pump or clogged oil circuit. Replace or clean. 4. Too low in float chambers fuel level. Adjust. 5. Sucki...

Page 202

7-5 servicing information complaint symptom and possible causes remedy front wheel wobbles. 1. Distorted wheel rim. 2. Worn front wheel bearing. 3. Defective or incorrect tire. 4. Loose front axle. 5. Incorrect front fork oil level. 6. Loose wheel spoke. Replace. Replace. Replace. Tighten. Adjust. T...

Page 203

Servicing information 7-6 complaint symptom and possible causes remedy brake squeaks. 1. Carbon adhesion on brake pad surface. 2. Tilted brake pad. 3. Damaged wheel bearing. 4. Worn brake pad. 5. Foreign material in brake fluid. 6. Clogged return port of master cylinder. 7. Brake shoe surface glazed...

Page 204

7-7 servicing information complaint symptom and possible causes remedy generator charges but charging rate is below the specification. 1. Lead wires tend to get shorted or open-circuited or loosely connected at terminal. 2. Grounded or open-circuited stator coils or genera tor. 3. Defective regulato...

Page 205: Wiring Diagram

Wiring diagram for e-03, -28 and -33 servicing information 7-8.

Page 206

7-9 servicing information for e-24.

Page 207

For the others servicing information 7-10

Page 208

Clamp clamp wiring harness clamp pass through the w iring harness right side of the clutch cable, speedometer cable and brake hose. Clamp brake light/taillight rear turn signal light (l) wiring harness wiring harness starter motor clamp clamp starter motor lead w ire clamp rear fender turn signal/si...

Page 209

Clamp wiring harness clamp starter motor wiring harness high tension cord (ignition coil) handlebar switch (l&r) ________ clamp pass through the handlebar switch (r) lead wire under the brake hose. Clamp clamp clamp clamp battery terminal rear turn signal light (r) rear turn signal light (l) battery...

Page 210

7-13 servicing information generator lead w ire neutral sw itch pick-up coil clamp engine ground w ire side-stand sw itch lead w ire clamp generator rolor neutral switch lead wire side-stand sw itch lead w ire neutral sw itch lead w ire.

Page 211

Stator coil.

Page 212

Servicing information 7-14 cable routing clamp throttle cables throttle cable (pulling cable) throttle cable (returning cable) throttle cables brake hose clamp wiring harness starter cable clamp \ throttle cable (returning cable) throttle cable (pulling cable) clamp throttle cables starter cable pas...

Page 213

7-15 servicing information caliper rubber bushing guide speedometer cable guide pass the speedometer cable outside of the brake hose. Brake hose clamp 100 mm (4.0 in) ma x. 10 mm (0.4 in) 4 do not contact the guide to the caliper rubber bushing..

Page 214

Servicing information 7-16 clamp seat lock cable rear brake switch cable clamp rear brake cable rear brake cable clip clamp rear brake cable clamp rear brake switch cable.

Page 215: Front Brake Hose Routing

7-17 servicing information front brake hose routing clamp master cylinder master cylinder clamp / clamp the brake \ \ hose securely. / brake hose clamp speedometer cable clamp / clamp the brake \ \ hose securely. / brake caliper after touching the brake hose union to the stopper, tighten the union b...

Page 216

Servicing information 7-18 carburetor hose routing left right left right (engine side) (air cleaner side) carburetor clamp position view a air cleaner carburetor carburetor air vent hose battery case clamp air cleaner drain hose carburetor overflow hose.

Page 217: Frame Rear Cover Set-Up

7-19 servicing information frame rear cover set-up rear fender brace rear fender frame rear cover cushion nut frame spacer.

Page 218: Special Tools

Servicing information 7-20 special tools 09900-00401 "l" type hexagon w rench set 09900-00410 hexagon w rench set 09900-06107 snap ring pliers 09900-06108 snap ring pliers 09900-09004 impact driver set 09900-20101 vernier calipers (150 mm) 09900-20202 micrometer (25-50 mm) 09900-20203 micrometer (50...

Page 219

7-21 servicing information 09913-85210 bearing installer 09915-64510 compression gauge 09915-74510 oil pressure gauge 09916-14510 valve lifter 09916-14910 valve lifter attachment 09916-21111 valve seat cutter set see p. 3-28. 09916-24450 solid pilot (n- 100-5.52) 09916-34542 valve guide reamer handl...

Page 220

Servicing information 7-22 09941-50111 bearing remover 09941-54911 bearing outer race remover 09941-74910 steering bearing installer 09943-74111 front fork oil level gauge note: when ordering a special tool, please confirm whether it is available or not..

Page 221

Servicing information 7-24 chassis item n-m kg-m ib-ft handlebar clamp bolt 16 1.6 11.5 handlebar holder nut 45 4.5 32.5 steering stem head bolt 65 6.5 47.0 front fork upper clamp bolt 23 2.3 16.5 front fork lower clamp bolt 33 3.3 24.0 front fork cap bolt 23 2.3 16.5 front fork damper rod bolt 20 2...

Page 222

7-25 servicing information tightening torque chart for other bolts and nuts listed previously, refer to this chart: bolt diameter (mm) conventional or "4" marked bolt "7" marked bolt n-m kg-m ib-ft n-m kg-m ib-ft 4 1.5 0.15 1.0 2 0.2 1.5 5 3 0.3 2.0 5 0.5 3.5 6 6 0.6 4.5 10 1.0 7.0 8 13 1.3 9.5 23 2...

Page 223: Service Data

Servicing information 7-26 service data valve + guide unit: mm (in) item sta nda rd limit valve diam. In. 26 (1.0) e x. 22 (0.9) valve clearance (when cold) in. 0.03-0.08 (0.001 -0. 003) e x. 0.08-0.13 (0.003-0.005) valve guide to valve stem clearance in. 0.025-0.052 (0.0010-0.0020) e x. 0.040-0.067...

Page 224

7-27 servicing information camshaft + cylinder head unit: mm (in) item standard limit cam height in. 34.990-35.040 (1.3776-1.3795) 34.690 (1.3657) e x. 35.030-35.080 (1.3791-1.3811) 34.730 (1.3673) camshaft journal oil clearance 0.032-0.066 (0.0013-0.0026) 0.150 (0.0059) camshaft journal holder i.D....

Page 225

Servicing information 7-28 item standard limit piston ring groove width 1st 1.01-1.03 (0.040-0.041) 2nd 1.21-1.23 (0.047-0.048) oil 2.51-2.53 (0.099-0.100) piston ring thickness 1st 0.975-0.990 (0.0384-0.0390) 2nd 1.170-1.190 (0.0461 -0.0469) piston pin bore 18.002-18.008 (0.7087-0.7090) 18.030 (0.7...

Page 226

7-29 servicing information transmission + drive chain unit: mm (in) except ratio item standard limit primary reduction ratio 3.238(68/21) final reduction ratio 2.733(41/15) gear ratios low 2.636(29/11) 2nd 1.687(27/16) 3rd 1.263(24/19) 4th 1.000(20/20) top 0.818(18/22) shift fork to groove clearanc ...

Page 227

Servicing information 7-30 carburetor item specification e-03, 28 e-33 carburetor type mikuni bsr32ss bore size 32 mm i.D. No 13f3 13f4 idle r/min. 1 300 ± 50 r/min. Float height 13.0 ± 0. 5 mm main jet (m.J.) jet needle (j.N.) 5c65 needle jet (n.J.) pilot jet (p.J.) pilot air jet no. 1 (p.A.J.1) #8...

Page 228

7-31 servicing information wattage unit: w specification item e-01,02, 04, 17,22, 25,34 e-24 e-03, 28, 33 headlight hi 60 lo 55 position light 4 brake light/ taillight 21/5 turn signal light 21 (rear) front turn signal light/running light 21/5 speedometer light 1.7 neut ral indicator light 3.4 turn ...

Page 229

Servicing information 7-32 item standard limit tire tread depth front 1.6 (0.06) rear 2.0 (0.08) suspension unit: mm (in) item standard limit note front fork stroke 120 (4.7) front fork spring free length 301 (11-9) front fork oil level 105 (4.1) rear wheel travel 90 (3.5) swingarm pivot shaft runou...

Page 230

Prepared by suzuki motor corporation motorcycle service department june, 1998 part no. 99500-32100-01e printed in japan 224.