- DL manuals

- Suzuki

- Motorcycle

- Intruder VL800

- Service Manual

Suzuki Intruder VL800 Service Manual

Summary of Intruder VL800

Page 1

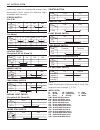

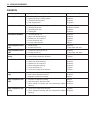

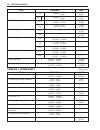

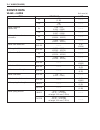

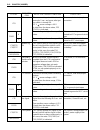

Group index general information 1 periodic maintenance 2 engine 3 shaft drive 4 fuel and lubrication system 5 cooling system 6 chassis 7 electrical system 8 servicing information 9 emission control information 10 revised 09/07.

Page 3: Supplements

17 16 vl800/tk6 ('06- model) 15 vl800tk5 ('05- model) 14 vl800k5 ('05- model) 13 vl800k4 ('04- model) 12 vl800k3 ('03- model) 11 vl800k2 ('02- model) supplements vl800/c/tk9 (”09 model) 18 vl800/tk7 & tk8 ('07&’08- model) wiring diagram 19.

Page 4: How To Use This Manual

How to use this manual to locate what you are looking for: 1. The text of this manual is divided into sections. 2. The section titles are listed in the group index. 3. Holding the manual as shown at the right will allow you to find the first page of the section easily. 4. The contents are listed on ...

Page 5

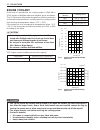

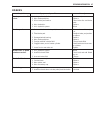

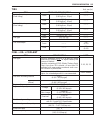

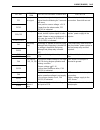

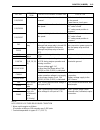

Symbol (for usa) listed in the table below are the symbols indicating instructions and other information necessary for servicing. The meaning of each symbol is also included in the table. Torque control required. Data beside it indicates specified torque. Apply oil. Use engine oil unless otherwise s...

Page 6

Symbol (for the other countries) listed in the table below are the symbols indicating instructions and other information necessary for servicing. The meaning of each symbol is also included in the table. Torque control required. Data beside it indicates specified torque. Apply oil. Use engine oil un...

Page 7: General Information

General information 1-1 contents general information 1.

Page 8: Warning/caution/note

1-2 general information warning/caution/note please read this manual and follow its instructions carefully. To emphasize special information, the symbol and the words warning, caution and note have special meanings. Pay special attention to the mes- sages highlighted by these signal words. ! Indicat...

Page 9

General information 1-3 " * if parts replacement is necessary, replace the parts with suzuki genuine parts or their equiva- lent. * when removing parts that are to be reused, keep them arranged in an orderly manner so that they may be reinstalled in the proper order. * be sure to use special tools w...

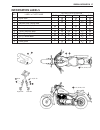

Page 10: Serial Number Location

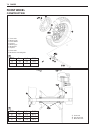

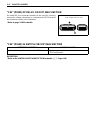

1-4 general information serial number location the frame serial number or v.I.N. (vehicle identification number) 1 is stamped on the right side of the steering head pipe. The engine serial number 2 is located on the right s de of the crankcase. These numbers are required especially for registering t...

Page 11

General information 1-5 engine oil (for usa) suzuki recommends the use of suzuki performance 4 motor oil or an oil which is rated sf or sg under the api (american petroleum institute) service classification. The recom- mended viscosity is sae 10w/40. If an sae 10w/40 oil is not available, select an ...

Page 12: Break-In Procedures

1-6 general information break-in procedures during manufacturing only the best possible materials are used and all machined parts are finished to a very high standard. It is still necessary to allow the moving parts to “break-in” before subjecting the engine to maximum stresses. The future performan...

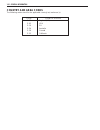

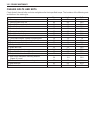

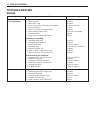

Page 13: Information Labels

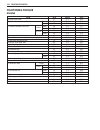

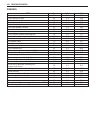

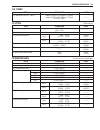

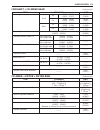

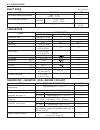

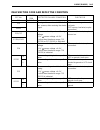

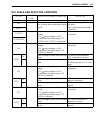

General information 1-7 information labels no. Label or plate name applied specification e-02 e-03 e-19 e-24 e-28 e-33 1 noise label – – – 2 information label – – – 3 vacuum hose routing label – – – – – 4 fuel caution label – – – – 5 manual notice label – – – – 6 tire air pressure label 7 warning sa...

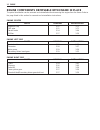

Page 14: Specifications

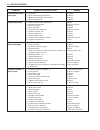

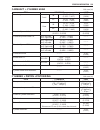

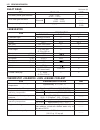

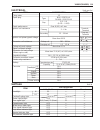

1-8 general information specifications dimensions and dry mass overall length ................................................................ 2 510 mm (98.818 in) overall width ................................................................. 985 mm (38.779 in) overall height .........................

Page 15

General information 1-9 chassis front suspension .......................................................... Telescopic, coil spring, oil damped rear suspension ........................................................... Link type, coil spring, oil damped, spring pre-load 7-way adjustable steering an...

Page 16: Country and Area Codes

1-10 general information country and area codes the following codes stand for the applicable country(-ies) and area(-s). Code country or area e-02 england (uk) e-03 usa e-19 eu e-24 australia e-28 canada e-33 california.

Page 17: Periodic Maintenance

Periodic maintenance 2-1 contents periodic maintenance 2.

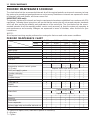

Page 18

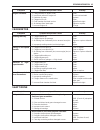

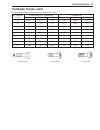

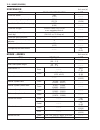

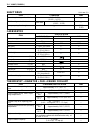

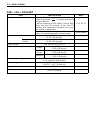

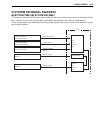

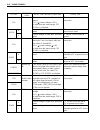

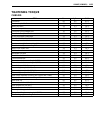

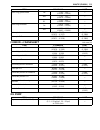

2-2 periodic maintenance periodic maintenance schedule the chart below lists the recommended intervals for all the required periodic service work necessary to keep the motorcycle operating at peak performance and economy. Maintenance intervals are expressed in terms of kilometer, miles and months, w...

Page 19

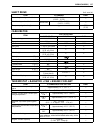

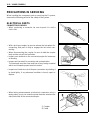

Periodic maintenance 2-3 clutch lever holder gearshift link pivot side-stand pivot and spring hook throttle cable brake lever holder brake pedal pivot and brake rod link lubrication points proper lubrication is important for smooth operation and long life of each working part of the motorcycle. Majo...

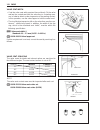

Page 20: Maintenance And Tune-Up

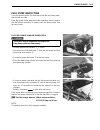

2-4 periodic maintenance maintenance and tune-up procedures this section describes the servicing procedures for each item mentioned in the periodic maintenance chart. Air cleaner • remove the screws and air cleaner case cover. • remove the air cleaner element. • carefully use air hose to blow the du...

Page 21

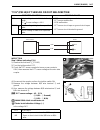

Periodic maintenance 2-5 • remove the spark plug caps. • remove the spark plugs with a spark plug wrench. Heat range • check spark plug heat range by observing electrode color. If the electrode of the spark plug is wet appearing or dark color, replace the spark plug with hotter type one. If it is wh...

Page 22

2-6 periodic maintenance spark plug and ignition coil/plug cap installation • install the spark plugs to the cylinder head with fingers, and then tighten them to the specified torque with a wrench. % spark plug: 11 n.M (1.1 kgf.M, 8.0 ib-ft) $ do not crossthread or over tighten the spark plug, or th...

Page 23

Periodic maintenance 2-7 • remove all the inspection caps. • remove all the spark plugs. • remove the generator cover plug 3 and the timing inspection plug 4. • rotate the generator rotor to set the no.1 engine’s piston at tdc of the compression stroke. (rotate the rotor until the “r i t” line on th...

Page 24

2-8 periodic maintenance front no. 2 engine no. 1 engine engine oil and oil filter engine oil replacement • keep the motorcycle upright. • place an oil pan below the engine, and drain oil by removing the oil drain plug 1 and filler cap 2. • start up the engine and allow it to run for several minutes...

Page 25

Periodic maintenance 2-9 oil filter replacement • drain the engine oil as described in the engine oil replacement procedure. • remove the oil filter with the special tool. # 09915-40610: oil filter wrench • apply engine oil lightly to the gasket of the new oil filter before installation. • install t...

Page 26

2-10 periodic maintenance fuel hose inspect the fuel hose 1 for damage and fuel leakage. If any de- fects are found, replace the fuel hose. Engine idle speed note: warm up the engine before adjusting the engine idle speed. • start the engine, turn the throttle stop screw and set the engine idle spee...

Page 27

Periodic maintenance 2-11 throttle cable play adjust the throttle cable play a as follows. Minor adjustment 1st step: • loosen the lock nut 1 of the throttle returning cable 2 and fully turn in the adjuster 3. 2nd step: • loosen the lock nut 4 of the throttle pulling cable 5. • turn the adjuster 6 i...

Page 28

2-12 periodic maintenance major adjustment • remove the fuel tank. ( !5-3) • loosen the lock nuts 1 of the throttle returning cable 2. • turn the returning cable adjuster 3 to obtain proper cable play. • loosen the lock nuts 4 of the throttle pulling cable 5. • turn the pulling cable adjuster 6 in o...

Page 29

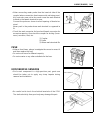

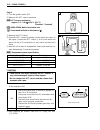

Periodic maintenance 2-13 cooling system engine coolant level check • keep the motorcycle upright. • check the engine coolant level by observing the full and lower lines on the engine coolant reservoir. A full line b lower line • if the level is below the lower line, add engine coolant to the full l...

Page 30

2-14 periodic maintenance air bleeding the cooling circuit • add engine coolant up to the radiator inlet. • support the motorcycle upright. • slowly swing the motorcycle, right and left, to bleed the air trapped in the cooling circuit. • add engine coolant up to the radiator inlet. • start up the en...

Page 31

Periodic maintenance 2-15 final gear oil • keep the motorcycle upright. • place an oil pan under the final gear case. Remove the filler cap 1 and drain plug 2 to drain oil. • refit the drain plug 2. Pour the specified oil (sae 90 hypoid gear oil with gl-5 under api classification) through the filler...

Page 32

2-16 periodic maintenance brake light switch • adjust the rear brake light switch so that the brake light will come on just before pressure is felt when the brake pedal is depressed. Rear brake pedal height • loosen the lock nut 1. • adjust the brake pedal height a by turning the adjuster 2. " rear ...

Page 33

Periodic maintenance 2-17 air bleeding the brake fluid circuit air trapped in the brake fluid circuit acts like a cushion to absorb a large proportion of the pressure developed by the master cylin- der and thus interferes with the full braking performance of the brake caliper. The presence of air is...

Page 34

2-18 periodic maintenance tire pressure if the tire pressure is too high or too low, steering will be ad- versely affected and tire wear will increase. Therefore, maintain the correct tire pressure for good roadability and a longer tire life. Cold inflation tire pressure is as follows. " cold inflat...

Page 35

Periodic maintenance 2-19 steering the steering should be adjusted properly for smooth turning of the handlebars and safe operation. Overtight steering prevents smooth turning of the handlebars and too loose steering will cause poor stability. Check that there is no play in the front fork. Support t...

Page 36

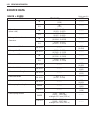

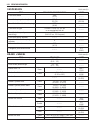

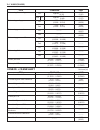

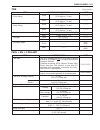

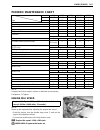

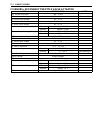

2-20 periodic maintenance chassis bolts and nuts check that all chassis bolts and nuts are tightened to their specified torque. The locations of the following nuts and bolts on the motorcycle. Item n.M kgf.M ib-ft 1 steering stem head nut 90 9.0 65.0 2 steering stem lock nut 80 8.0 58.0 3 front fork...

Page 37

Periodic maintenance 2-21.

Page 38: Compression Pressure Check

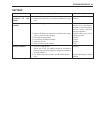

2-22 periodic maintenance overhaul the engine in the following cases: * compression pressure in one of the cylinders is less than 900 kpa (9 kgf/cm 2 , 128 psi). * the difference in compression pressure between any two cyl inders is more than 200 kpa (2 kgf/cm 2 , 28 psi). * all compression pressure...

Page 39: Oil Pressure Check

Periodic maintenance 2-23 oil pressure check check the engine oil pressure periodically. This will give a good indication of the condition of the moving parts. Oil pressure specification 350 – 650 kpa (3.5 – 6.5 kgf/cm 2 , 50 – 92 psi) at 3 000 r/min., oil temp. At 60°c (140°f) if the oil pressure i...

Page 40: Engine

Engine 3-1 contents engine 3.

Page 41

3-2 engine engine components removable with engine in place the parts listed below can be removed and reinstalled without removing the engine from the frame. Refer to the page listed in this section for removal and reinstallation instructions. Engine center parts removal installation inspection cap ...

Page 42

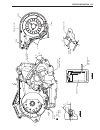

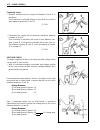

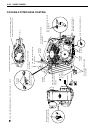

Engine 3-3 engine removal and installation engine removal before taking the engine out of the frame, wash the engine using a steam cleaner. Engine removal is sequentially explained in the following steps. Reinstall the engine by reversing the removal pro- cedure. • drain engine oil. ( !2-8) • drain ...

Page 43

3-4 engine • disconnect the neutral switch lead wire coupler 1. • disconnect the generator lead wire coupler 2 and the signal generator lead wire coupler 3. • disconnect the side-stand switch lead wire coupler 4. • remove the clutch release mechanism. • remove the push rod. • remove the left footres...

Page 44

Engine 3-5 • remove the air cleaner box bracket. • disconnect the negative pressure hose 1. • remove the carburetor. Caburetor removal !5-15 • remove the spark plug caps. • remove the right frame cover. • remove the no. 1 muffler..

Page 45

3-6 engine • remove the no.2 exhaust pipe. • remove the rear clutch cover. • remove the cooling fan mounting bolts. • remove the engine mounting bolt 1. • remove the no. 1 exhaust pipe and the no. 2 muffler..

Page 46

Engine 3-7 • remove the frame down tube. • support the engine with an engine jack. • remove the engine mounting bolts and nuts. • gradually lower the engine..

Page 47

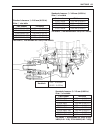

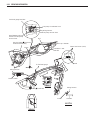

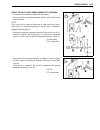

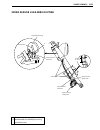

3-8 engine engine installation install the engine in the reverse order of engine removal. Pay attention to the following points: • install the universal joint. Note: be sure to face the short portion a backward when installing it. • install the boot. Note: make sure that the “up” mark b faces up. • ...

Page 48

Engine 3-9 79 n.M (7.9 kgf.M, 57.0 lb-ft) 79 n.M (7.9 kgf.M, 57.0 lb-ft) 50 n.M (5.0 kgf.M, 36.0 lb-f ) 50 n.M (5.0 kgf.M, 36.0 lb-ft) 23 n.M (2.3 kgf.M, 16.5 lb-ft) 25 n.M (2.5 kgf.M, 18.0 lb-ft) note: * the engine mounting nuts are self-locking. Once the nut has been removed, they are no longer of...

Page 49

3-10 engine • install the gearshift lever and the footrest in the correct posi- tion. " gearshift lever height a standard: 90 mm (3.5 in) • apply grease to the push rod and install it. # 99000-25030: suzuki super grease “a” (for usa) 99000-25010: suzuki super grease “a” (for the others) • apply grea...

Page 50: Engine Disassembly

Engine 3-11 engine disassembly • remove the pair pipes. • remove the spark plugs. % 09930-10121: spark plug wrench set • remove the valve timing inspection plug 1 and the generator cover cap 2. • position “rit” mark on the generator with the center of the valve timing inspection hole. Cylinder head ...

Page 51

3-12 engine cylinder head/cylinder • loosen the water hose clamp screws. • remove the cylinder head bolts. (front cylinder) • remove the cylinder head and cylinder. (front cylinder) • after unlocking the ratchet, push the cam chain tension ad- juster rod fully. • insert the special tool between the ...

Page 52

Engine 3-13 • remove the cylinder head bolt and nut. (rear cylinder) • push the cam chain tension adjuster rod and insert the special tool. % 09918-53810: chain tensioner lock tool • remove the cylinder head by removing the cylinder head bolts. • remove the water hose and pipe. • remove the cylinder...

Page 53

3-14 engine starter motor • remove the starter motor cover. • remove the starter motor. Clutch • remove the clutch cover. • remove the clutch spring mounting bolts and springs diago- nally. • remove the pressure plate 1..

Page 54

Engine 3-15 • remove the thrust washer 1, bearing 2, push piece 3 and push rod. • remove the clutch drive and driven plates. • remove the spring washer 4 and spring washer seat 5. • remove the clutch sleeve hub nut with the special tool. % 09920-53740: clutch sleeve hub holder • remove the washer 6 ...

Page 55

3-16 engine • remove the primary driven gear assembly and the oil pump drive chain. • remove the thrust washer 1 and spacer 2. Oil pump • remove the oil pump by removing the circlip. % 09900-06107: snap ring pliers • remove the pin 1 and washer 2. Gearshift • draw out the gearshift shaft 1. • remove...

Page 56

Engine 3-17 • remove the gearshift cam plate 1. • remove the gearshift cam stopper 2. Primary drive gear remove the primary drive gear by removing the primary drive gear bolt with the special tool. % 09930-40113: rotor holder & this bolt has left-hand thread. Turning it counter-clockwise may cause d...

Page 57

3-18 engine neutral switch • remove the neutral switch assembly. • remove the oil pressure switch lead wire. Generator • remove the generator cover. • remove the starter motor driven gear and the idle gear. • loosen the generator rotor bolt. Note: when loosen the rotor bolt, do not remove it. The ro...

Page 58

Engine 3-19 • remove the cam chain tensioner and the chain. Water pump • remove the water pump cover. • remove the water pump assembly. Secondary driven gear • remove the secondary driven gear housing bolts. • remove the secondary driven gear case..

Page 59

3-20 engine • remove the secondary driven gear assembly. • remove the bearing 1. • remove the oil jet 2. Oil jet • remove the oil jets. Crankcase • remove the crankcase bolts. • separate the crankcase into two parts with the special tool. % 09920-13120: crankcase separator.

Page 60

Engine 3-21 • remove the crankshaft. • remove the gearshift fork shafts and gearshift forks. • remove the transmission. Secondary drive bevel gear • remove the over driving gear 1 and bush 2. • remove the secondary drive bevel gear assembly..

Page 61: Engine Components Inspection

3-22 engine engine components inspection and servicing cylinder head cover disassembly & be sure to identify each removed part as to its location, and lay the parts out in groups designated as “no.1 cyl- inder”, “no.2 cylinder”, “exhaust”, “intake”, so that each will be restored to the original loca...

Page 62

Engine 3-23 "r" "f" camshaft the camshafts should be checked for wear and also for runout of cams and journals if the engine has been noted to produce ab- normal noise or vibration or to lack output power. Any of these malconditions could be caused by a worn camshafts. The camshaft can be distinguis...

Page 63

3-24 engine if the camshaft journal oil clearance measured exceeds the limit, measure the outside diameter of camshaft. Replace either the cylinder head set or the camshaft if the clear- ance is incorrect. " camshaft journal o.D. (sprocket side) : 24.959 – 24.980 mm (0.9826 – 0.9835 in) (other side)...

Page 64

Engine 3-25 cylinder head valve and valve spring disassembly • using special tools, compress the valve springs and remove the two cotter halves 1 from valve stem. % 09916-14510: valve spring compressor 09916-14910: valve spring compressor attachment 09916-84511: tweezers • remove the valve spring re...

Page 65

3-26 engine valve stem runout support the valve with “v” blocks, as shown, and check its runout with a dial gauge. The valve must be replaced if the runout exceeds the limit. " valve stem runout service limit: 0.05 mm (0.002 in) % 09900-20701: magnetic stand 09900-20606: dial gauge (1/100 mm) 09900-...

Page 66

Engine 3-27 valve guide servicing • using the valve guide remover, drive the valve guide out to- ward the intake or exhaust rocker arm side. % 09916-44910: valve guide remover/installer note: * discard the removed valve guide subassemblies. * only oversized valve guides are available as replacement ...

Page 67

3-28 engine 45˚ 15˚ valve seat exhaust valve seat width • coat the valve seat with prussian blue uniformly. Fit the valve and tap the coated seat with the valve face in a rotating man- ner, in order to obtain a clear impression of the seating contact. In this operation, use the valve lapper to hold ...

Page 68

Engine 3-29 • insert the solid pilot 1 (09916-24450: n-100-5.52) with a slight rotation. Seat the pilot snugly. Install the 45° cutter, attachment and t-handle. Initial seat cut • using the 45° cutter, descale and clean up the seat. Rotate the cutter one or two turns. • measure the valve seat width ...

Page 69

3-30 engine bottom narrowing cut • if the contact area w is too wide or too low, use the 60° (intake side only) to narrow and raise the contact area. Final seat cut • if the contact area w is too low or too narrow, use the 45° cutter to raise and widen the contact area. Note: after cutting the 15°, ...

Page 70

Engine 3-31 6.51 – 7.49 kgf (14.35 – 16.51 lbs) 32.5 mm (1.28 in) valve stem end condition inspect the valve stem end face for pitting and wear. If pitting or wear of the stem end face are present, the valve stem end may be resurfaced, providing that the length 1 will not be reduced to less than the...

Page 71

3-32 engine • insert the valves, with their stems coated with high quality mo- lybdenum disulfide lubricant (suzuki moly paste) all around and along the full stem length without any break. ' 99000-25140: suzuki moly paste & when inserting each valve, take care not to damage the lip of the stem seal....

Page 72

Engine 3-33 15 mm (0.6 in) cylinder bore measure the cylinder bore diameter at six places. If any one of the measurements exceeds the limit, overhaul the cylinder and replace the piston with an oversize, or replace the cylinder. Once the reboring is done on any one cylinder which measurements is bey...

Page 73

3-34 engine piston-to-cylinder clearance as a result of the aforesaid measurement, if the piston to cylinder clearance exceeds the following limit, overhaul the cylinder and use an oversize piston, or replace both cylinder and piston. " piston to cylinder clearance service limit: 0.12 mm (0.0047 in)...

Page 74

Engine 3-35 0.5 mm o.S. 1.0 mm o.S. Paint oil ring spacer oversize piston ring the following two types of oversize piston rings are used. They bear the following identification numbers. Size 1st 2nd 0.5 mm o.S. 50 50 1.0 mm o.S. 100 100 oversize oil ring the following two types of oversize oil rings...

Page 75

3-36 engine 2nd ring 1st ring piston ring reassembly • install the piston rings in the order of oil ring, 2nd ring and 1st ring. • the first member to go into the oil ring groove is a spacer 1. After placing the spacer, fit the two side rails 2. Note: side designations, top and bottom, are not appli...

Page 76

Engine 3-37 conrod/crankshaft conrod small end i.D. Using a small bore gauge, measure the conrod small end inside diameter. ! Conrod small end i.D. Service limit: 20.040 mm (0.7890 in) " 09900-20602: dial gauge (1/1000 mm, 1 mm) 09900-22403: small bore gauge (18 – 35 mm) if the conrod small end insi...

Page 77

3-38 engine • place plastigauge axially on the crank pin avoiding the oil hole, at tdc or bdc side as shown. • tighten the bearing cap with two-step torque values. Note: when fitting the bearing cap to crank pin, be sure to discriminate between its two ends, i.D. Code side and the other. I.D. Code a...

Page 78

Engine 3-39 conrod i.D. Specification code 1 i.D. Specification 1 44.000 – 44.006 mm (1.7323 – 1.7325 in) 2 44.006 – 44.012 mm (1.7325 – 1.7328 in) 3 44.012 – 44.018 mm (1.7328 – 1.7330 in) crank pin o.D. Specification code 2 o.D. Specification 1 40.994 – 41.000 mm (1.6139 – 1.6142 in) 2 40.988 – 40...

Page 79

3-40 engine conrod/crank pin bearing assembly • when fitting the bearing to the bearing cap and conrod, be sure to fix the stopper part 1 first and press in the other end. • apply molybdenum oil solution to the crank pin and bearing surface. % 99000-25140: suzuki moly paste • when mounting the conro...

Page 80

Engine 3-41 • measure the crankshaft journal bearing i.D. 1 by using the special tool. ! Crankshaft journal bearing i.D. 1 standard: 48.000 – 48.015 mm (1.8898 – 1.8904 in) " 09900-20508: cylinder gauge set if each crankshaft journal bearing i.D. Is not within the standard range, replace them with n...

Page 81

3-42 engine crankshaft thrust clearance install the crankshaft in the right crankcase half after installing the thrust shim on the crankshaft. Note: the oil grooved face a of thrust shim 1 is faced to crankshaft web side. • place the thrust washer, camshaft drive sprocket and primary drive gear on t...

Page 82

Engine 3-43 clutch clutch drive and driven plates note: wipe off the engine oil from the drive and driven plates with a clean rag. Measure the thickness of drive plates with a vernier calipers. If each drive plate is not within the standard range, replace it with a new one. ! Clutch drive plate thic...

Page 83

3-44 engine generator/signal generator/ starter clutch generator stator and signal generator stator inspection &8-8, 19, 20 generator stator and signal generator stator servicing when replacing the generator stator or signal generator stator, route the wire properly. Starter clutch inspection instal...

Page 84

Engine 3-45 starter clutch servicing • hold the rotor with off-set wrench and remove the starter clutch securing bolts. • when fitting the one way clutch to the guide 1, position flange side a of one way clutch to the rotor side. • apply thread lock super “1303” to the securing bolts and tighten the...

Page 85

3-46 engine fwd transmission disassembly • disassemble the transmission gears as shown in the illustration. 1 driveshaft bolt 2 over driving gear 3 1st driven gear 4 4th driven gear 5 3rd driven gear 6 driveshaft 7 5th driven gear 8 2nd driven gear 9 counter haft/1st drive gear 0 4th drive gear a 3r...

Page 86

Engine 3-47 reassembly assemble the countershaft and driveshaft in the reverse order of disassembly. Pay attention to following points: note: always use new circlips. Note: before installing the gears, coat lightly moly paste or engine oil to the driveshaft and countershaft. % 99000-25140: suzuki mo...

Page 87

3-48 engine $ when installing the 1st and 3rd driven gear bushings, align the bushing oil hole with the driveshaft oil hole. Transmission gears and related parts.

Page 88

Engine 3-49 gearshift fork gearshift fork to groove clearance using a thickness gauge, check the shifting fork clearance in the groove of its gear. The clearance for each of the three shifting forks plays an impor- tant role in the smoothness and positiveness of shifting action. If the clearance che...

Page 89

3-50 engine crankcase oil sump filter • remove the oil sump filter cover. • remove the oil sump filter. • clean the oil sump filter using compressed air. • when installing the o-ring, apply grease to it. ( 99000-25030: suzuki super grease “a” (for usa) 99000-25010: suzuki super grease “a” (for the o...

Page 90

Engine 3-51 • when installing the oil pipe, use the new o-rings. • apply a small quantity of the thread lock “1342” to the oil pipe retainer bolts and tighten them securely. ) 99000-32050: thread lock “1342” oil pressure regulator • remove the oil pressure regulator. Check the operation of the oil p...

Page 91

3-52 engine • remove the bearing with the special tool. " 09921-20220: bearing remover set note: if abnormal noise does not occur, it is not necessary to remove the bearing. Bearing reassembly • install the bearing into the crankcase with the special tool. " 09913-70210: bearing installer set oil pr...

Page 92: Engine Reassembly

Engine 3-53 engine reassembly reassemble the engine in the reverse order of disassembly. The following steps require special attention or precautionary mea- sures should be taken. Note: apply engine oil to each running and sliding part before reas- sembling. Secondary drive bevel gear • install the ...

Page 93

3-54 engine crankshaft • install the thrust shim 1 on the crankshaft. Note: * the grooved face a of thrust shim 1 faces to crankshaft web side. * the thrust shim is selected by the crankshaft thrust clearance. ( &3-42) • install the crankshaft into the left crankcase half. Note: coat lightly moly pa...

Page 94

Engine 3-55 • fit the gasket to the bolt a. • when securing the right and left crankcase halves, tighten each bolt a little at a time to equalize the pressure. Tighten all the securing bolts to the specified torque values. # crankcase 8mm bolt:(initial) 15 n.M (1.5 kgf.M, 11.0 lb-ft) (final) 22 n.M ...

Page 95

3-56 engine • tighten the secondary gear case bolts to the specified torque. # secondary gear case bolt (initial): 15 n.M (1.5 kgf.M, 11.0 lb-ft) (final) : 22 n.M (2.2 kgf.M, 16.0 lb-ft) note: fit the washer to the bolt a. • tighten the secondary driven bevel gear bolt to the specified torque. Note:...

Page 96

Engine 3-57 • install the new o-ring. • install the water pump cover. Note: fit the clamp to the bolt a. Cam chain/cam chain tensioner • install the cam chain tensioner and cam chain. # cam chain tensioner bolt: 10 n.M (1.0 kgf.M, 7.0 lb-ft) 1 for front cylinder 2 for rear cylinder note: the no. 2 c...

Page 97

3-58 engine • install the starter driven gear and the idle gear. • install the new gasket and dowel pins. • install the generator cover. Note: fit the new gaskets to the bolts a. Neutral switch • install the springs and switch contacts. • install the neutral switch. • install the oil pressure switch...

Page 98

Engine 3-59 oil filter • apply engine oil lightly to the gasket of the oil filter before in- stallation. • install the oil filter turning it by hand until feeling that the filter gasket contacts the mounting surface. Then tighten it 2 turns using the oil filter wrench. " 09915-40610: oil filter wren...

Page 99

3-60 engine • install the cam driven gear 1 after installing the springs, pins and gearshift pawls. • install the cam guide and the pawl lifter. • apply a small quantity of thread lock “1342” to the nuts. ) 99000-32050: thread lock “1342” • install the gearshift return spring properly. • install the...

Page 100

Engine 3-61 • install the oil pump driven gear and the circlip. " 09900-06107: snap ring pliers clutch • install the spacer 1 and the thrust washer 2. • engage the chain with the oil pump drive gear. • install the primary driven gear assembly and engage the chain with the oil pump driven gear. • app...

Page 101

3-62 engine • install the washer 1 and the clutch sleeve hub nut 2. Note: the convex side of the washer faces outside. • tighten the clutch sleeve hub nut to the specified torque with the special tool. # clutch sleeve hub nut: 60 n.M (6.0 kgf.M, 43.5 lb-ft) " 09920-53740: clutch sleeve hub holder 95...

Page 102

Engine 3-63 • install the wave washer seat 1 and the wave washer 2. • install the clutch drive plate no.2 a first. • install the drive and driven plate one by one into the clutch sleeve hub. • install the push rod. • install the clutch push piece 3, bearing 4 and thrust washer 5. • apply engine oil ...

Page 103

3-64 engine • install the clutch cover and tighten the bolts. Note: fit the new gasket to the bolt a. Starter motor • install the starter motor. Note: apply grease to the new o-ring. ( 99000-25030: suzuki super grease “a” (for usa) 99000-25010: suzuki super grease “a” (for the others) • install the ...

Page 104

Engine 3-65 • place a cloth beneath the piston, and install the circlip 1. $ when turning the crankshaft, pull the cam chains up- ward, or the chains will be caught between the crank- case and the cam drive sprocket. Cylinder • install the cam chain tension adjuster to the cylinder. • after unlockin...

Page 105

3-66 engine cylinder head • install the cam chain guide. 1 for front cylinder 2 for rear cylinder • fit the dowel pins and the new cylinder head gasket. $ use a new gasket to prevent gas leakage. • install the cylinder head and tighten the cylinder head bolts diagonally to the specified torque. (rea...

Page 106

Engine 3-67 front cylinder • assemble the front cylinder and the cylinder head. • tighten the cylinder head bolts and nut. # cylinder head bolt and nut (m8): 25 n.M (2.5 kgf.M, 18.0 lb-ft) • install the front cylinder assembly to the crankcase. • connect the water hoses. • tighten the cylinder head ...

Page 107

3-68 engine camshaft pin bend up bolt washer sprocket • align the arrow marks on the front and rear camshafts so it is parallel with the surface of the cylinder heads. Note: arrow marks are located to forward. • engage the chains on the cam sprockets with the locating pin holes a as shown in the pho...

Page 108

Engine 3-69 1 6 1216 fwd front rear • apply suzuki bond “1216b” to the mating surface of the cyl- inder head cover. • fit the camshaft end caps 1. • apply grease to the o-ring 2 and install it. (front cylinder only) 1216 99000-31230: suzuki bond “1216b” ( 99000-25030: suzuki super grease “a” (for us...

Page 109

3-70 engine front rear fwd 1216 1216 • remove the tensioner lock tools. Note: click sound is heard when the cam chain tension adjuster is re- leased. Location of cylinder head cover bolt note: * before installing the bolt 1, apply suzuki bond “1207b” to the thread of the bolt. * allen bolt: 2 * stai...

Page 110

Engine 3-71 • install the intake pipe. • apply grease to the new o-ring and install the water outlet union. ( 99000-25030: suzuki super grease “a” (for usa) 99000-25010: suzuki super grease “a” (for the others) • install the gasket and the breather cover. • apply grease to the new o-rings and instal...

Page 111

3-72 engine • install the pair pipes. • install the head cover caps 1. • install the spark plugs. " 09930-10121: spark plug wrench set.

Page 112: Shaft Drive

Shaft drive 4-1 contents shaft drive 4.

Page 113: Secondary Bevel Gears

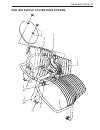

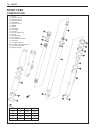

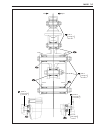

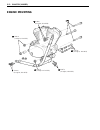

4-2 shaft drive *a secondary bevel gears construction 1 bush 2 overdriving driven gear 3 circlip 4 output cam dog 5 damper spring 6 secondary bevel gear set 7 shims (5 kinds) 8 driven bevel gear bearing 9 o-ring 0 shims (5 kinds) a o-ring b oil seal housing c oil seal d bearing stopper e universal j...

Page 114

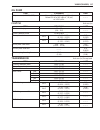

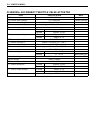

Shaft drive 4-3 backlash 0.05 – 0.32 mm (0.002 – 0.013 in) adjust backlash by selecting shims. (use two pieces of shims.) shim 1 size table part number thickness 24945-05a-0a0 0.30 mm (0.012 in) 24945-05a-0b0 0.35 mm (0.014 in) 24945-05a-0c0 0.40 mm (0.016 in) 24945-05a-0d0 0.50 mm (0.020 in) 24945-...

Page 115

4-4 shaft drive removal secondary drive bevel gear the crankcase must be separated to service the secondary drive bevel gear. The secondary drive bevel gear service requires en- gine removal and disassembly. Refer to the engine removal and the engine disassembly sections for secondary drive bevel ge...

Page 116

Shaft drive 4-5 secondary driven bevel gear • remove the bearing stopper with the special tool. # 09921-21820: bearing retainer wrench inspection inspect the removed parts for the following abnormalities. * drive and driven bevel gears damage or wear * improper tooth contact * abnormal noise of bear...

Page 117

4-6 shaft drive secondary gear shims adjustment backlash note: * hollow portion a of the secondary driven bevel gear assembly faces inside. * it is not necessary to apply suzuki bond “1207b” to the matching surface at this stage. • install the secondary drive bevel gear assembly with the re- moved s...

Page 118

Shaft drive 4-7 • adjust the dial gauge so that it touches the secondary drive bevel gear cam dog; hold the driven bevel gear securely, and turn the drive bevel gear in each direction, reading the total backlash on the dial gauge. % secondary bevel gear backlash standard: 0.05 – 0.32 mm (0.002 – 0.0...

Page 119

4-8 shaft drive 1 incorrect (contact at tooth top) 2 correct 3 incorrect (contact at tooth root) tooth contact after bringing the backlash within specification by changing the secondary driven bevel gear shims, it will be necessary to check tooth contact. • remove the drive bevel gear assembly from ...

Page 120

Shaft drive 4-9 reassembly secondary driven bevel gear • apply grease to the lip of oil seal. & 99000-25030: suzuki super grease “a” (for usa) 99000-25010: suzuki super grease “a” (for the others) • tighten the bearing stopper to the specified torque with the special tool. ! Bearing stopper: 105 n.M...

Page 121: Final Bevel Gears

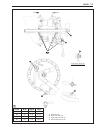

4-10 shaft drive final bevel gears construction 1 oil seal 2 final gear bearing case 3 o-ring 4 plate 5 final driven gear bearing 6 shims (4 kinds) 7 final driven bevel gear 8 shims (8 kinds) 9 bearing retainer 0 final driven gear bearing a oil seal b final gear case c shims (5 kinds) d stopper plat...

Page 122

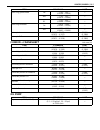

Shaft drive 4-11 standard clearance a: 1.00 mm (0.039 in) shim 1 size table part number thickness 27445-38a00-030 0.30 mm (0.012 in) 27445-38a00-035 0.35 mm (0.014 in) 27445-38a00-040 0.40 mm (0.016 in) 27445-38a00-050 0.50 mm (0.020 in) 27445-38a00-060 0.60 mm (0.024 in) the shims 1 are available a...

Page 123

4-12 shaft drive final gear case removal after draining final gear oil, the following components must be removed in the described order before removing the final gear case. Note: refer to the following pages for the details of each step. • drain final gear oil. ( "2-15) • remove the rear wheel. ( "7...

Page 124

Shaft drive 4-13 1 spring 2 propeller shaft 3 circlip • using a chisel, unlock the nut. • remove the final drive bevel gear coupling nut with the special tool. # 09924-62430: 22 mm long socket 09924-64510: final drive gear coupling holder • remove the washer and the final drive coupling. • remove th...

Page 125

4-14 shaft drive • remove the bearing from the final drive bevel gear with the bearing puller. $ the removed bearing must be replaced with a new one. Note: if no abnormal noise, the bearing removal is not necessary. • remove the final gear bearing case bolts. • remove the final gear bearing case fro...

Page 126

Shaft drive 4-15 • remove the bearing retainer screws, using an impact driver set. # 09900-09004: impact driver set • remove the final driven gear bearing and oil seal with the spe- cial tools. # 09941-64511: bearing remover 09930-30102: sliding shaft $ the removed bearing and oil seal must be repla...

Page 127

4-16 shaft drive • adjust the dial gauge so that it touches the backlash measur- ing tool arm at the mark; hold the final driven bevel gear se- curely, and turn the final drive bevel gear coupling slightly in each direction, reading the total backlash on the dial gauge. % final bevel gear backlash s...

Page 128

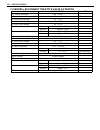

Shaft drive 4-17 shims 1 specifications part no shim thickness 27326 34201 1.05 mm (0.041 in) 27326-34211 1.10 mm (0.043 in) 27326 34221 1.20 mm (0.047 in) 27326-34231 1.25 mm (0.049 in) 27326-34241 1.35 mm (0.053 in) 27326-34201-140 1.40 mm (0.055 in) 27326-34201-145 1.45 mm (0.057 in) 27326-34201-...

Page 129

4-18 shaft drive tooth contact after backlash adjustment is carried out, the tooth contact must be checked. • remove the bolts from the final gear bearing case, and remove the case with the two 5 mm screws. ( "4-14) do not mis- place the shims. Remove the final driven bevel gear. • clean and de-grea...

Page 130

Shaft drive 4-19 final gear case reassembly reassemble the final gear case in the reverse order of disassem- bly. Pay attention to the following points. • install a new oil seal 1 and o-ring 2 to the bearing stopper. $ use new o-ring and oil seat to prevent oil leakage. • install the bearing to the ...

Page 131

4-20 shaft drive • install the needle roller bearing for the final driven bevel gear into the final gear case with the special tool. # 09913-76010: bearing installer note: the stamped ward on the bearing end should face to the driven bevel gear side. • install the bearing retainer. Apply a small qua...

Page 132

Shaft drive 4-21 • apply suzuki bond “1207b” to the mating surface of the final gear case and final gear bearing case. $ do not block the breather passage when applying suzuki bond “1207b”. ( 99000-31140: suzuki bond “1207b” • apply thread lock “1342” to the final gear case bolts and tighten them to...

Page 133

4-22 shaft drive • apply a small quantity of the thread lock “1303” to the final drive bevel gear coupling nut. ' 99000-32030: thread lock ‘‘1303’’ • tighten the nut to the specified torque with the special tool. ! Final drive bevel gear coupling nut: 100 n.M (10.0 kgf.M, 72.5 lb-ft) # 09924-62430: ...

Page 134

Shaft drive 4-23 • install the stopper plate. $ when installing the plate, fit the protrusion a of plate to the one of the bearing stopper grooves. Note: two kinds of plates are available to lock the stopper at the proper position. Final gear case installation installation is in the reverse order of...

Page 135: Fuel and Lubrication System

Fuel and lubrication system 5-1 fuel and lubrication system 5.

Page 136: Fuel System

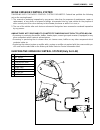

5-2 fuel and lubrication system fuel system the fuel pump is operated by a vacuum force which is supplied from the carburetor intake pipe. The fuel sent under pressure by the fuel pump flows into the float chamber when the float of the carburetor has dropped and the needle valve is open. When the ne...

Page 137: Fuel Tank/fuel Valve

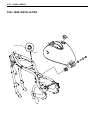

Fuel and lubrication system 5-3 fuel tank/fuel valve removal ! Gasoline is highly flammable and explosive. Keep heat, sparks, and flames away from gasoline. • remove the front seat. ( "7-2) • remove the speedometer. • disconnect the speedometer coupler. # be careful not to scratch the fuel tank. • r...

Page 138

5-4 fuel and lubrication system • remove the fuel valve. • disconnect the fuel hose 1 and vacuum hose 2. • remove the throttle stop screw. • remove the fuel tank. • remove the fuel level gauge mounting bolts. • remove the fuel level gauge 3. • remove the o-ring 4..

Page 139

Fuel and lubrication system 5-5 fuel tank fuel valve 4.4 n.M (0.44 kgf.M, 3.2 lb-ft) cushion cushion cushion inspection fuel valve if the fuel filter is dirty with sediment or rust, fuel will not flow smoothly and loss in engine power may result. Clean the fuel filter with compressed air. Also check...

Page 140: Fuel Pump

5-6 fuel and lubrication system 10 n.M (1 0 kgf m, 7.0 lb-ft) fuel tank fuel pump removal • remove the battery 1. • disconnect the lead wire coupler 2. • remove the ignitor 3. • disconnect the fuse case coupler 4. • remove the starter lead wire 5. • remove the battery case. • remove the fuel pump mo...

Page 141

Fuel and lubrication system 5-7 inspection ! Gasoline is highly flammable and explosive. Keep heat, sparks, and flames away from gasoline. • disconnect the fuel hose 1, connect the suitable hose and insert the free end of the hose into a receptacle. Check the fuel flow when cranking the engine for f...

Page 142: Carburetor

5-8 fuel and lubrication system carburetor construction a throttle stop screw b pilot screw c float d pilot jet e main jet holder f main jet g needle valve h coasting valve i throttle position sensor 1 top cap 2 spring 3 jet needle stopper 4 o-ring 5 e-ring 6 jet needle 7 diaphragm/piston valve 8 fu...

Page 143

Fuel and lubrication system 5-9 specifications location of carburetor i d. No. The carburetor i.D. Is stamped on the location 1 on the carbure- tor as shown in the right pho o. Item specification e-02, 19, 24 e-03, 28 e-33 carburetor type mikuni bdsr34 ← ← bore size 34 mm ← ← i.D. No. 41f1 41f2 41f3...

Page 144

5-10 fuel and lubrication system diaphragm and piston operation the carburetor is a variable-venturi type, whose venturi cross sectional area is increased or decreased automatically by the piston valve 1. The piston valve moves according to the negative pressure present on the downstream side of the...

Page 145

Fuel and lubrication system 5-11 air mixture fuel slow system this system supplies fuel to the engine during engine operation with throttle valve 1 closed or slight opened. The fuel from the float chamber 2 is first passage and metered by the pilot jet 3 where it mixes with air coming in through #1 ...

Page 146

5-12 fuel and lubrication system main system as the throttle valve 1 is opened, engine speed rises and negative pressure in the venturi a increases. This causes the piston valve 2 moves upward. The fuel in the float chamber 3 is metered by the main jet 4. The metered fuel passes around main air blee...

Page 147

Fuel and lubrication system 5-13 air mixture fuel starter (enricher) system pulling the starter (enricher) plunger 1 causes fuel to be drawn into the starter circuit from the float chamber 2. The starter jet 3 meters this fuel. The fuel then flows into the fuel pipe 4 and mixes with the air coming f...

Page 148

5-14 fuel and lubrication system fuel accelerator pump system this system works only when the rider opens throttle grip quickly as pump send the necessary amount of fuel to the carburetor bore for correcting fuel/air mixture ratio. When the rider open the throttle grip quickly, the intaken air volum...

Page 149

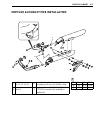

Fuel and lubrication system 5-15 removal • remove the fuel tank. ( "5-3) • loosen the air intake pipe clamp screws. • disconnect the breather hose. • move the air inlet pipe to forward. • remove the throttle cables 1. • disconnect the throttle position sensor coupler 2. • disconnect the air vent hos...

Page 150

5-16 fuel and lubrication system • loosen the clamp screw and remove the carburetor. • remove the starter plunger. Disassembly • remove the carburetor top cap 1. • remove the spring 2 and piston valve 3 along with diaphragm 4. • pull out the jet needle holder 5..

Page 151

Fuel and lubrication system 5-17 • remove the spring 1, washers 2, 3, retainer 4 and jet needle 5. • remove the float chamber 6. $ 09900-09004: impact driver set • remove the accelerator pump plunger 7. • remove the o-ring 8. # use a new o-ring to prevent fuel leakage. • remove the float 9 and needl...

Page 152

5-18 fuel and lubrication system drill-stop pilot screw plug carburetor body • use a %” size drill bit with a drill-stop to remove the pilot screw plug. Set the drill-stop 6 mm from the end of the bit to prevent drilling into the pilot screw. Carefully drill through the plug. Thread a self-tapping s...

Page 153

Fuel and lubrication system 5-19 • remove the casting valve cover. • remove the casting valve 1 and the spring 2..

Page 154

5-20 fuel and lubrication system correct incorrect carburetor cleaning ! Some carburetor cleaning chemicals, especially diptype soaking solutions, are very corrosive and must be handled carefully. Always follow the chemical manufacturer’s instructions on proper use, handling and storage. • clean all...

Page 155

Fuel and lubrication system 5-21 carburetor heater inspection (for e02, e19) • disconnect the carburetor heater terminal lead wires. • connect the positive + terminal of a 12v battery to the termi- nal of the carburetor heater and the battery negative - termi- nal to the terminal. • check that the h...

Page 156

5-22 fuel and lubrication system 45˚ float height adjustment • measure the float height a by using a calipers with the carbu- retor slanting at an angle of 45° (as shown in the right illustra- tion) and the float arm just contacting the needle valve. • bend the tongue b of the float arm as necessary...

Page 157

Fuel and lubrication system 5-23 reassembly and reinstallation carburetor reassembly can be performed in the reverse order of disassembly. When reassembling, carefully observe the follow- ing instructions. # * assemble the parts taking consideration of their func- tion. * replace o-rings and seals w...

Page 158

5-24 fuel and lubrication system coasting valve • when installing the coasting valve to the body, align the hole a of the diagram and air hole b of the cover. Funnel • apply a small quantity of thread lock “1342” to the funnel stopper screws and tighten them. ( 99000-3250: thread lock “1342” pilot s...

Page 159

Fuel and lubrication system 5-25 throttle position sensor positioning • install the throttle position sensor with the flats on the throttle shaft end securely engaged with the slot on the throttle posi- tion sensor. • measure the resistance between the throttle position sensor terminals as shown in ...

Page 160: Lubrication System Chart

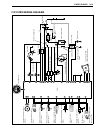

5-26 fuel and lubrication system lubrication system chart pressure regulator oil pan oil pump driven chain driveshaft gears driveshaft driveshaft left bearing clutch plates clutch sleeve hub countershaft gears countershaft countershaft left bearing oil jet secondary bevel gear and bearings secondary...

Page 161

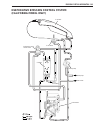

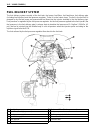

Pair (air supply) system 5-27 p air pipe mar king t o air cleaner p air air cleaner hose p air v alv e hose p air co v er p air pipe p air v acuum hose p air v alv e pair (air supply) system hose routing.

Page 162

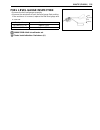

5-28 pair (air supply) system pair (air supply) system inspection hoses • inspect the hoses for wear or damage. • inspect that the hoses and pipes are securely connected. Pair control valve • inspect that air flows through the pair control valve air inlet port to the air outlet ports. • if air does ...

Page 163: Cooling System

Cooling system 6-1 contents cooling system 6.

Page 164: Engine Coolant

6-2 cooling system gauge pressure (kgf/cm 2 ) engine coolant at the time of manufacture, the cooling system is filled with a 50:50 mixture of distilled water and ethylene glycol anti-freeze. This 50:50 mixture will provide the optimum corrosion protection and excellent heat protection, and will prot...

Page 165: Radiator And Water Hose

Cooling system 6-3 radiator and water hose cooling circuit inspection before removing the radiator and draining the engine coolant, inspect the cooling circuit for tightness. • remove the fuel tank. ( #5-3) • remove the radiator cap 1 and connect the tester to the filler. " do not remove the radiato...

Page 166

6-4 cooling system radiator removal • remove the fuel tank. ( #5-3) • remove the frame head covers 1. • disconnect the water hoses. • drain engine coolant. • remove the radiator cover 2. • remove the radiator mounting bolts. • remove the radiator..

Page 167

Cooling system 6-5 radiator remounting the radiator is to be installed in the reverse order of the removal procedure. • install the radiator. • route the radiator hoses. ( #9-18) radiator cap inspection • fit the cap 1 to the radiator cap tester 2. • build up pressure slowly by operating the tester....

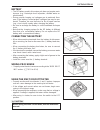

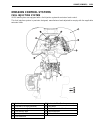

Page 168: Cooling Fan

6-6 cooling system • the voltmeter is for making sure that the battery applies 12 volts to the motor. With the motor with electric motor fan run- ning at full speed, the ammeter should be indicating not more than 5 amperes. • if the fan motor does not turn, replace the motor assembly with a new one....

Page 169: Cooling Fan Thermo-Switch

Cooling system 6-7 installation • put the cooling fan between the down tube and the engine. • tighten the down tube mounting bolts. ( #3-9) • tighten the cooling fan mounting bolts. • install the radiator. ( #6-5) cooling fan thermo-switch removal • remove the radiator. ( #6-4) • remove the cooling ...

Page 170: Engine Coolant Temperature

6-8 cooling system oil installation • install the o-ring 1. • tighten the cooling fan thermo-switch to the specified torque. ' cooling fan thermo-switch: 17 n.M (1.7 kgf.M, 12.5 lb-ft) • install the radiator. Engine coolant temperature switch removal • remove the radiator. ( #6-4) • remove the engin...

Page 171: Thermostat

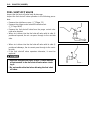

Cooling system 6-9 inspection inspect the thermostat pellet for signs of cracking. Test the thermostat at the bench for control action, in the follow- ing manner. • pass a string between flange, as shown in the illustration. • immerse the thermostat in the water contained in a beaker, as shown in th...

Page 172: Water Pump

6-10 cooling system valve lift • keep on heating the water to raise its temperature. • just when the water temperature reaches specified value, the thermostat valve should have lifted by at least 6.0 mm (0.24 in). $ thermostat valve lift standard: over 6.0 mm at 90°c (over 0.24 in at 194°f) • a ther...

Page 173

Cooling system 6-11 • remove the pin 1 and draw out the impeller shaft 2. • remove the mechanical seal ring 3 and rubber seal 4. • remove the bearing with the special tool. & 09921-20220: bearing remover set note: if no abnormal noise, bearing removal is not necessary. ! The removed bearing must be ...

Page 174

6-12 cooling system inspection bearing • inspect the play of the bearing by hand while it is in the water pump case. • rotate the inner race by hand to inspect for abnormal noise and smooth rotation. • replace the bearing if there is anything unusual. Mechanical seal • visually inspect the mechanica...

Page 175

Cooling system 6-13 • install the new mechanical seal with a suitable size socket wrench and the special tool. Note: the new mechanical seal has been applied the sealer a. & 09924-84521: bearing installer • install the new bearing with the special tool. & 09924-84521: bearing installer note: the sta...

Page 176

6-14 cooling system • apply grease to the o-ring. • set the water pump shaft end a to the oil pump shaft b. ( 99000-25030: suzuki super grease “a” (for usa) 99000-25010: suzuki super grease “a” (for the others) • install the water pump screws. • apply engine coolant to the o-ring and install the wat...

Page 177: Chassis

Chassis 7-1 contents chassis 7.

Page 178: Exterior Parts

7-2 chassis exterior parts removal seat • remove the rear seat by removing the bolts. ! Be careful not to scratch the rear fender. • remove the rear seat grip band by removing the bolts. • remove the seat. ! Be careful not to scratch the rear fender. Frame cover • remove the left frame cover 1 with ...

Page 179

Chassis 7-3 rear fender • remove the seat. ( "7-2) • disconnect the coupler 1. • remove the left or right side frame handle grip. • remove the rear fender 2. ! Be careful not to scratch the rear fenders. Note: when installing the frame handle grip bolts, apply a small quan- tity of thread lock “1303...

Page 180: Front Wheel

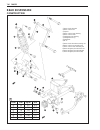

7-4 chassis left right front wheel construction a front axle b axle pinch bolt c brake disc bolt $ item n.M kgf.M lb-ft a 65 6.5 47.0 b 33 3.3 24.0 c 23 2.3 16.5 1 front axle 2 bearing (r) 3 front wheel 4 spacer 5 bearing (l) 6 brake disc 7 spacer a front axle b brake disc mounting bolt $ item n.M k...

Page 181

Chassis 7-5 removal and disassembly • loosen the front axle pinch bolt 1. • loosen the front axle 2 by using the special tool. % 09900-18710: hexagon socket (12 mm) • raise the front wheel off the ground with a jack or a wooden block. • remove the front axle 2, spacers 3 and front wheel. ! Do not op...

Page 182

7-6 chassis inspection wheel bearings inspect the play of the wheel bearings by finger while they are in the wheel. Rotate the inner race by finger to inspect for abnormal noise and smooth rotation. Replace the bearing in the following procedure if there is any- thing unusual. Wheel bearings removal...

Page 183

Chassis 7-7 reassembly and remounting reassemble and remount the front wheel in the reverse order of removal and disassembly. Pay special attention to the following points: wheel bearing • apply suzuki super grease “a” to the bearings before in- stalling. For usa ' 99000-25030: suzuki super grease “...

Page 184

7-8 chassis speed sensor • apply suzuki super grease “a” to the speed sensor dust seal. For usa ' 99000-25030: suzuki super grease “a” for the other countries ' 99000-25010: suzuki super grease “a” • align the grooves 1 on the speed sensor with the lugs 2 on the wheel hub. Front wheel • make sure th...

Page 185: Front Brake

Chassis 7-9 front brake construction ) * the brake system is illed with an glycol-based brake fluid, which is classified dot 4. Do not use or mix other types of brake fluid, such as silicone-based and petroleum-based brake fluids when refilling the brake system, otherwise serious damage to the brake...

Page 186

7-10 chassis brake pad replacement • remove the guide hook a. • remove the brake caliper by removing the brake caliper mount- ing bolts. • remove the pin 1. • remove the pad pin 2. • remove the brake pads 3. ! * do not operate the brake lever during or afte br ke pad removal. * replace the brake pad...

Page 187

Chassis 7-11 brake fluid replacement • place the motorcycle on a level surface and keep the handlebar straight. • remove the master cylinder reservoir cap and diaphragm. • remove as much old brake fluid as possible. • fill the reservoir with new brake fluid. * specification and classification: dot 4...

Page 188

7-12 chassis • remove the brake pads. ( "7-10) • remove the insulator. • remove the brake caliper holder. • remove the spring. • place a rag over the brake caliper pistons to prevent them from popping out, and then force out the pistons using compressed air. ! Do not use extremely high pressure to r...

Page 189

Chassis 7-13 rubber parts replace the removed rubber parts with new ones. Brake caliper reassembly and remounting reassemble and remount the brake caliper in the reverse order of removal and disassembly. Pay special attention to the following points: • wash the caliper bores and pistons with the spe...

Page 190

7-14 chassis • tighten the brake caliper mounting bolts 1, and brake hose union bolt 2 to the specified torque. $ brake caliper mounting bolt: 39 n.M (3.9 kgf.M, 28 lb-ft) brake hose union bolt: 23 n.M (2.3 kgf.M, 16.5 lb-ft) • for assembly procedure of brake hose: "9-18 • install the guide hook a. ...

Page 191

Chassis 7-15 master cylinder removal and disassembly • place a rag underneath the brake hose union bolt on the mas- ter cylinder to catch any spilt brake fluid. Remove the brake hose union bolt and disconnect the brake hose. ! Immediately wipe off any brake fluid contacting any part of the motorcycl...

Page 192

7-16 chassis • remove the piston assembly. Master cylinder inspection master cylinder inspect the master cylinder bore for any scratches or damage. If any damages are found, replace the master cylinder with a new one. Master cylinder reassembly and remounting reassemble and remount the master cy ind...

Page 193

Chassis 7-17 • when installing the brake light switch, align the projection on the switch with the hole in the master cylinder. • when remounting the master cylinder onto the handlebars, align the master cylinder holder’s mating surface 1 with the punch mark 2 on the handlebars and tighten the upper...

Page 194: Front Fork

7-18 chassis front fork construction 1 o-ring 2 front fork spring 3 damper rod ring 4 rebound spring 5 damper rod 6 inner tube cover 7 rubber 8 washer 9 inner tube 0 slide metal a dust seal b oil seal stopper ring c oil seal d oil seal retainer e oil lock piece f inner tube cover guide g outer tube ...

Page 195

Chassis 7-19 removal and disassembly • remove the front wheel. ( "7-5) • remove the brake hose from the hose guide. • remove the guide hook a. • remove the front brake caliper by removing the bolts. • remove the front fender by removing its mounting bolts. ! Be careful not to scratch the front fende...

Page 196

7-20 chassis • remove the front fork inner tube cover 1, washer 2 and rub- ber 3. • remove the inner tube cover stopper 4 by loosening the bolt. • remove the inner tube cover guide 5. • remove the front fork spring stopper nut 6 and fork spring 7. % 09900-18720: hexagon socket (14 mm) • invert the f...

Page 197

Chassis 7-21 • remove the dust seal 1 and the oil seal stopper ring 2. • remove the oil seal by slowly pulling out the inner tube. Note: be careful not to damage the inner tube. ! The outer and inner tube’s slide metals must be replaced along with the oil seal and dust seal when assembling the front...

Page 198

7-22 chassis inspection inner and outer tubes inspect the inner tube sliding surface and outer tube sliding sur- face for scuffing. Fork spring measure the fork spring free length. If it is shorter than the ser- vice limit, replace it with a new one. & front fork spring free length service limit: 54...

Page 199

Chassis 7-23 note: when installing the oil lock piece, insert the tapered end a of oil lock piece into the inner tube. • insert the inner tube into the outer tube and install the oil seal 1 using the special tool. % 09940-52861: front fork oil seal installer • install the oil seal stopper ring 2. ! ...

Page 200

7-24 chassis fork oil • pour the specified fork oil into the inner tube. Fork oil type: suzuki fork oil ss-08 (#10) or equivalent fork oil , 99000-99001-ss8: suzuki fork oil ss-08 & front fork oil capacity (each leg): 412 ml (13.9/14.5 us/imp oz) • hold the front fork in a vertical position and adju...

Page 201

Chassis 7-25 • install the inner tube cover 1, rubber 2 and washer 3. • remount the front fork and tighten the front fork lower clamp bolts temporarily. Note: install the inner tube a until it seets to the flange part b of the steering stem upper bracket. • tighten the front fork spring stopper nut ...

Page 202: Steering

7-26 chassis steering construction removal and disassembly • remove the front wheel. ( "7-5) • remove the front fork. ( "7-19) • remove the rear view mirrors 1. 1 handlebars 2 handlebar balancer 3 handlebar set bolt cap 4 handlebar clamp/holder 5 steering stem upper bracket 6 steering stem nut 7 dus...

Page 203

Chassis 7-27 • disconnect the front brake light switch lead wires 1. • remove the front brake master cylinder 2. • remove the right handlebar balancer 3, the right handlebar switch 4 and the throttle grip 5. • disconnect the clutch lever position switch lead wires 6. • loosen the clutch lever holder...

Page 204

7-28 chassis • remove the steering stem head nut 1 and washer. • remove the steering stem upper bracket 2 and the front fork upper cover 3. Note: hold the front fork upper cover to prevent it from falling. • remove the cable guide 4. • remove the headlight. • remove the cooling air guide. • remove t...

Page 205

Chassis 7-29 • remove the front turn signal light bracket. • disconnect the front turn signal light lead-wire connector. • remove the brake hose guide. • remove the brake hose and speedo sensor lead-wire. ( "9- 21) • remove the head light housing. • remove the head light housing bracket. • remove th...

Page 206

7-30 chassis • remove the steering stem upper bearing 2. • remove the steering stem lower bearing 3. • remove the handlebar holders 4 from the steering stem up- per bracket. • remove the handlebar bushes by using the proper tool and special tools. % 09941-34513: steering outer race installer • remov...

Page 207

Chassis 7-31 inspection and disassembly inspect the removed parts for the following abnormalities. * handlebars distortion * race wear and brinelling * bearing wear or damage * abnormal bearing noise * distortion of the steering stem • remove the steering stem lower bearing inner race by using a chi...

Page 208

7-32 chassis • apply grease to the upper and lower bearings before remount- ing the steering stem. For usa # 99000-25030: suzuki super grease “a” for the other countries # 99000-25010: suzuki super grease “a” • install the bearings inner race and the dust seal. Steering stem nut • install the steeri...

Page 209

Chassis 7-33 handlebar holder • install the handlebar holders and related parts to the steering stem head. • tighten the handlebar holder nuts to the specified torque. $ handlebar holder nut: 70 n.M (7.0 kgf.M, 50.5 lb-ft) steering stem upper bracket • install the front fork upper cover, steering st...

Page 210

7-34 chassis forward punch mark clearance handlebars • when setting the handlebar clamp to the handlebar holder of the steering upper bracket, face the punched mark a on its clamp forward. • first, tighten the handlebar clamp bolts 1 to the half of speci- fied torque, and then tighten the handlebar ...

Page 211

Chassis 7-35 • install the clutch lever holder with the punch mark a aligned with the clutch lever holder clamp as shown. $ clutch lever holder clamp bolt: 10 n.M (1.0 kgf.M, 7.3 lb-ft) • install the front wheel. ( '7-5) • adjust the throttle cable play. ( '2-10) steering tension adjustment check th...

Page 212: Rear Wheel

7-36 chassis rear wheel construction 1 rear axle 2 spacer (lh) 3 lock washer 4 driven joint stopper 5 driven joint 6 damper 7 o-ring 8 bearing (lh) 9 spacer 0 bearing (rh) a wheel rim b brake shoe c brake camshaft d brake panel e brake cam lever a driven joint stopper bolt b rear axle nut c rear bra...

Page 213

Chassis 7-37 left right for e-03, e-28, e-33 $ item n.M kgf.M lb-ft a 65 6.5 47 b 10 1.0 0.73 c 35 3.5 25.5 d 25 2.5 18.0 a rear axle nut b brake cam lever nut c rear torque link nut (f) d rear torque link nut (r).

Page 214

7-38 chassis removal • remove the seat 1. ( '7-2) • remove the rear fender 2. ( '7-3) note: the rear fender removal is not necessary when the rear part of motorcycle can be lifted high enough to take the rear wheel out smoothly. • remove the exhaust pipes and mufflers assembly 3. ( '3-5) • remove th...

Page 215

Chassis 7-39 • remove the rear swingarm left cover. • remove the rear axle shaft. Disassembly • flatten the lock washers. • remove the fitting bolts, washers and plates. • pull off the driven joint 1. • remove the o-ring 1. • remove the dampers with a screw driver. ! The removed o-ring must be repla...

Page 216

7-40 chassis spacer left right left right clearance inspection and disassembly wheel bearing .................................................. '7-6 wheel axle ......................................................... '7-6 wheel rim ............................................................ '7-6 t...

Page 217

Chassis 7-41 wheel damper • install the dampers. Note: if soap water is applied around the damper, it makes the job easier. Driven joint • install the driven joint. Note: apply grease to the o-ring and the final gear spline before install- ing the driven joint. For usa # 99000-25030: suzuki super gr...

Page 218: Rear Brake

7-42 chassis rear brake removal and disassembly • remove the rear wheel. ( '7-38) • remove the rear brake panel. • remove the brake shoes. • remove the rear brake cam lever 1 and rear brake cam 2 by removing bolt. • remove the washer 3, o-ring 4 and spring 5..

Page 219

Chassis 7-43 inspection brake drum inspect the brake drum and measure the brake drum i.D. To deter- mine the extent of wear. Replace the brake drum if the measure- ment exceeds the service limit. The value of this limit is indicated inside the brake drum. " 09900-20102: vernier calipers ( brake drum...

Page 220: Rear Brake Rod

7-44 chassis • tighten the brake cam lever bolt to the specified torque. $ brake cam lever nut: 10 n.M (1.0 kgf.M, 7.0 lb-ft) • install the rear wheel. ( '7-41) • adjust the rear brake pedal free travel. ( '2-16) rear brake rod removal and disassembly • remove the exhaust pipes and mufflers assembly...

Page 221

Chassis 7-45 • remove the rear brake adjust nut, spring and washer. • remove the rear brake link. • remove the cotter pins. Reassembly remounting reassemble and remount the rear brake rod in the reverse order of removal and disassembly. Pay attention to the fo low ng points. • apply grease to the re...

Page 222: Rear Suspension

7-46 chassis rear suspension construction 1 rear shock absorber 2 rear cushion rod 3 spacer 4 rear cushion lever bearing 5 rear cushion lever 6 swingarm pivot bearing 7 swingarm bea ing 8 swingarm 9 b ot a rear shock absorber mounting nut b rear cushion rod mounting nut c rear cushion lever mounting...

Page 223

Chassis 7-47 left right ( ) 50 n m 5.0 kgf m 36 0 lb-f ( ) 78 n.M 7.8 kgf.M 56.5 lb-ft ( ) 100 n.M 10.0 kgf.M 72 5 lb-ft ( ) 100 n.M 10.0 kgf.M 72.5 lb-ft 1 mm 1 mm 1 mm 1 mm ( ) 9.5 n.M 0.95 kgf.M 7.0 lb-ft.

Page 224

7-48 chassis removal • remove the rear wheel. ( '7-41) • remove the final gear case with propeller shaft. • remove the secondary gear case cover 1. • remove the right frame lower cover 2, clutch rear cover 3. • remove the tool box. • remove the battery case. ( '5-6) : hooked part.

Page 225

Chassis 7-49 • remove the cushion lever mounting bolt and nut. • remove the shock absorber upper mounting bolt and nut. • remove the right side swingarm pivot bolt lock nut 1. • remove the left and right side swingarm pivot bolts 2. Note: slightly loosen the cushion rod mounting nuts and the shock a...

Page 226

7-50 chassis inspection and disassembly spacer • remove spacer from swingarm. • remove the spacers from the cushion lever. • inspect the spacers for any flaws or other damage. If any de- fects are found, replace the spacers with new ones. Swingarm bearing insert the spacer into swingarm cushion rod ...

Page 227

Chassis 7-51 cushion lever bearing insert the spacer into bearing and check the play to move the spacer up and down. If an excessive play is noted, replace the bearing with a new one. • remove the cushion rod lower side bearing 1 by using the special tools. " 09921-20220: bearing remover set (17 mm)...

Page 228

7-52 chassis reassembly reassemble the swingarm and shock absorber in the reverse order of disassembly and removal, and pay attention to the fol- lowing points: swingarm bearing • install the swingarm pivot bearing races by using the special tool. " 09913-70210: bearing installer set (40 mm) note: t...

Page 229

Chassis 7-53 remounting remount the swingarm and shock absorber in the reverse order of disassembly and removal, and pay attention to the following points. Swingarm • before installing the swingarm, install the boot and the univer- sal joint. Note: make sure that the “up” mark a on the boot faces up...

Page 230

7-54 chassis note: after tightening the swingarm pivot lock nut, be sure to check the swingarm operation. Shock absorber and cushion lever mounting nut • tighten the shock absorber upper mounting nut 1 to the speci- fied torque. $ shock absorber mounting nut: 50 n.M (5.0 kgf.M, 36.0 lb-ft) • tighten...

Page 231

Chassis 7-55 note: to install the final gear case easily, move the dust boot front and the universal joint back. Engage the universal joint to the propel- ler shaft first and then engage it to the secondary driven bevel gear shaft. • tighten the final gear case mounting nuts to the specified torque....

Page 233: Electrical System

Electrical system 8-1 contents electrical system 8.

Page 234: Cautions In Servicing

8-2 electrical system cautions in servicing connectors • when disconnecting a connector, be sure to hold the termi- nals; do not pull the lead wires. • when connecting a connector, push it in so it is firmly attached. • inspect the connector for corrosion, contamination and any breakage in the cover...

Page 235

Electrical system 8-3 battery • the mf battery used in this motorcycle does not require main- tenance (e.G., electrolyte level inspection, distilled water re- plenishment). • during normal charging, no hydrogen gas is produced. How- ever, if the battery is overcharged, hydrogen gas may be pro- duced...

Page 236

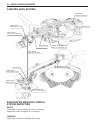

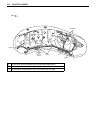

8-4 electrical system location of electrical components 1 ignition switch 2 ignition coil #2 3 fuel level gauge 4 rear brake switch 5 cooling fan 6 cooling fan thermo-switch 7 speedometer sensor.

Page 237

Electrical system 8-5 f oil pressure switch g generator h gear position switch i side-stand switch j fuse box k turn signal side-stand relay l regulator/rectifier 8 ignition coil #1 9 throttle position sensor 0 starter relay/main fuse a battery b ignitor c engine coolant temperature sensor d horn e ...

Page 238: Charging System

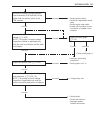

8-6 electrical system charging system troubleshooting battery runs down quickly. Check accessories which use excessive accessories • remove accessories. Amounts of electricity. Are installed no accessories check the battery for current current leaks • short circuit of wire harness leaks. ( ! 8-7) • ...

Page 239

Electrical system 8-7 measure the generator no-load voltage. ( ! 8-8) incorrect • faulty generator correct inspect the regulator/rectifier. Incorrect • faulty regulator/rectifier ( ! 8-9) correct inspect wirings. Incorrect • short circuit of wire harness poor contact of couplers correct • faulty bat...

Page 240

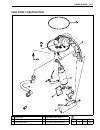

8-8 electrical system y y y y y y generator coil resistance • remove the secondary gear case cover. • disconnect the generator coupler. Measure the resistance between the three lead wires. If the resistance is not specified value, replace the stator with a new one. Also, check that the generator cor...

Page 241

Electrical system 8-9 regulator/rectifier • remove the secondary gear case cover. • disconnect the regulator/rectifier couplers. Measure the voltage between the lead wires using the multi cir- cuit tester as indicated in the table below. If the voltage is not within the specified valve, replace the ...

Page 242: System

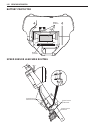

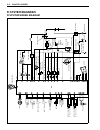

8-10 electrical system starter motor starter relay to ignition coils and ignitor o/w clutch lever position switch starter button engine stop switch o/b turn signal/ side-stand re ay g ignition switch r fuse(30a) gear position witch fuse (15a) batter y bl side-stand switch b/w y/b b/y y/g starter sys...

Page 243

Electrical system 8-11 check the starter relay. ( ! 8-13) incorrect • faulty starter relay correct • poor contact of the starter relay the starter motor runs when the transmission is in neutral, but does not run when the transmission is in any position other than neutral, with the side-stand up. Che...

Page 244

8-12 electrical system commutator inspect the commutator for discoloration, abnormal wear or un- dercut a. If abnormal wear is found, replace the armature with a new one. If the commutator surface is discolored, polish it with #400 sand paper and wipe it using a clean dry cloth. If there is no under...

Page 245

Electrical system 8-13 • apply a small quantity of suzuki moly paste to the arma- ture shaft. . 99000-25140: suzuki moly paste • align the tonque 1 on the brush holder with the groove 2 on the housing end. • align the threaded parts 3 on the housing end. • apply a small quantity of thread lock “1342...

Page 246

8-14 electrical system ! When disconnecting and connecting the gear position switch coupler, make sure to turn off the ignition switch, or electronic parts may get damaged. Measure the relay coil resistance between the terminals using the multi circuit tester. If the resistance is not within the spe...

Page 247

Electrical system 8-15 turn signal/side-stand relay the turn signal/side-stand relay is composed of the turn signal relay, and the side-stand relay and diode. • remove the secondary gear case cover. • remove the turn signal/side-stand relay. Side-stand relay inspection first check the insulation bet...

Page 248: Ignition System

8-16 electrical system generator pickup coil ignitor ignition coil #2 gnition coil #1 ignition switch main fuse battery fuse engine stop switch side stand relay throttle position sensor gear position switch g r y b/br bl r/b o/w g/bl b/w w b/y bl ¹ bl/w note: the ignition cut-off circuit is incorpor...

Page 249

Electrical system 8-17 measure the battery voltage between input lead wires (o/w and b/w) at the ignitor with the ignition switch in the incorrect • faulty ignition switch “on” position. • faulty turn signal/side-stand relay • faulty engine stop switch correct • broken wire harness or poor connectio...

Page 250

8-18 electrical system peak volt adaptor ignitor ig coil to engine stop switch inspection ignition coil primary peak voltage • remove the fuel tank. ( &5-3) • disconnect the two spark plug caps. • connect the new spark plugs to the each spark plug cap and ground them on the cylinder head. Note: make...

Page 251

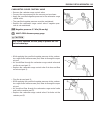

Electrical system 8-19 pickup coil peak voltage • remove the two seats. ( &7-2) • disconnect the wire harness coupler 1 at the ignitor. Note: make sure that all of the couplers are connected properly. Measure the pickup coil peak voltage in the following procedure. • connect the multi circuit tester...

Page 252

8-20 electrical system pickup coil pickup coil coupler pickup coil peak volt adaptor pickup coil coupler g bl pickup coil pickup coil coupler ignitor coupler peak volt adaptor g bl/w • shift the transmission into the neutral, and then turn the igni- tion switch to the “on” position. • pull the clutc...

Page 253: Speedometer

Electrical system 8-21 speedometer removal • remove the screws. • disconnect the cover and couple . ! When disconnecting and connecting the combination meter coupler, make sure to turn off the ignition switch, or electronic parts may get damaged. • remove the speedometer..

Page 254

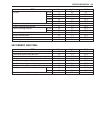

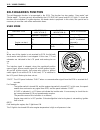

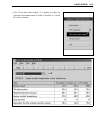

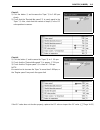

8-22 electrical system parts names 1 high beam indicator light 2 engine coolant temperature indicator light 3 turn signal indicator light 4 oil pressure indicator light 5 neutral indicator light 6 fuel level meter 7 speedometer/tripmeter/clock 8 select button 9 adjust button operating procedure init...

Page 255

Electrical system 8-23 0.5 second 3 seconds 3 seconds 3.5 seconds 3 seconds clock • displays the time (hours and minutes) on a 12-hour clock. • setting the time. Hold down the adjust button for two seconds while pressing the select button and then flashing the hour display. The setting that is flash...

Page 256

8-24 electrical system to oil pressure switch inspection engine coolant temperature indicator light engine coolant temperature sensor inspection: &6-8 • remove the fuel tank. ( &5-3) • disconnect the engine coolant temperature sensor coupler. • connect the jumper wire to the wire harness coupler. Ch...

Page 257

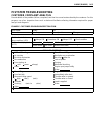

Electrical system 8-25 main wiring harness to fuel level gauge resistor fuel level meter • remove the fuel tank. ( &5-3) • connect the speedometer. • connect each resistor between the yellow/black and black/ white lead wire at the wire harness. • turn the ignition switch “on” position and wait for a...

Page 258

8-26 electrical system (top) (bottom) fuel level gauge inspection • remove the fuel tank. ( &5-3) • remove the fuel level gauge. Measure the resistance at each fuel level gauge float position. If the resistance is incorrect, replace the fuel level gauge with a new one. Float position resistance a “f...

Page 259