- DL manuals

- Suzuki

- Engine

- K9K

- Service Manual

Suzuki K9K Service Manual

IMPORTANT

WARNING/CAUTION/NOTE

Please read this manual and follow its instructions carefully. To emphasize special information, the words

,

and

NOTE

have special meanings. Pay special attention to the messages high-

lighted by these signal words.

The circle with a slash in this manual means “Don’t do this” or “Don’t let this happen”.

WARNING

!

CAUTION

!

Indicates a potential hazard that could result in death or injury.

WARNING

!

Indicates a potential hazard that could result in vehicle damage.

CAUTION

!

NOTE:

Indicates special information to make maintenance easier or instructions clearer.

This service manual is intended for authorized Suzuki dealers and qualified service technicians only.

Inexperienced technicians or technicians without the proper tools and equipment may not be able to

properly perform the services described in this manual.

Improper repair may result in injury to the technician and may render the vehicle unsafe for the driver

and passengers.

WARNING

!

For vehicles equipped with a Supplemental Restraint (Air Bag) System:

• Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

• If the air bag system and another vehicle system both need repair, Suzuki recommends that the air

bag system be repaired first, to help avoid unintended air bag system activation.

• Do not modify the steering wheel, instrument panel or any other air bag system component on or

around air bag system components or wiring. Modifications can adversely affect air bag system

performance and lead to injury.

• If the vehicle will be exposed to temperatures over 93 °C (200 °F), for example, during a paint baking

process, remove the air bag system components, that is air bag (inflator) modules, SDM and/or seat

belt with pretensioner, beforehand to avoid component damage or unintended activation.

WARNING

!

Summary of K9K

Page 1

Important warning/caution/note please read this manual and follow its instructions carefully. To emphasize special information, the words , and note have special meanings. Pay special attention to the messages high- lighted by these signal words. The circle with a slash in this manual means “don’t d...

Page 2

Recommendaton of genuine suzuki parts and accessories use suzuki strongly recommends the use of genuine suzuki parts* and accessories. Genuine suzuki parts and accessories are built to the highest standards of quality and performance, and are designed to fit the vehicle's exact specifications. A wid...

Page 3

Table of contents general information engine and emission control system (m13 engine) 6e 0a 6e general information 0a 0b 6e2 maintenance and lubrication 0b engine and emission control system (k9k engine) 6e2 6f heating and air conditioning 1a 6g heater and ventilation 1a ignition system (electronic ...

Page 4

Engine mechanical (k9k engine) 6a2-5 4) install special tools (oil pressure gauge) to vacated threaded hole. Special tool (a): 09915-77311 (b): 09915-77420 (c): 09915-77430 5) start engine and warm it up to normal operating tempera- ture. 6) after warming up, measure oil pressure. Oil pressure speci...

Page 5

6a2-6 engine mechanical (k9k engine) valve lash (clearance) measurement of valve lash (clearance) 1) disconnect negative (–) cable at battery. 2) remove cylinder head cover referring to “cylinder head cover removal and installation” in this section. 3) turn crankshaft pulley clockwise until cam lobe...

Page 6

Engine mechanical (k9k engine) 6a2-7 example of intake side: when thickness of removed tappet is 7.8875 mm (0.310531 in.), and measured valve lash (clearance) is 0.200 mm (0.00787 in.). A = 7.8875 mm (0.310531 in.) + 0.200 mm (0.00787 in.) – 0.1875 mm (0.007382 in.) = 7.900 mm (0.31102 in.) calculat...

Page 7

6a2-8 engine mechanical (k9k engine) repair instructions air cleaner filter removal and installation removal 1) open air cleaner case (2) unhooking its clamps (1). 2) remove air cleaner filter from case. Installation reverse removal procedure for installation. Air cleaner filter inspection and clean...

Page 8

Engine mechanical (k9k engine) 6a2-9 installation reverse removal procedure for installation noting the following. • tighten air cleaner outlet hose clamp (1) to specified torque. Tightening torque air cleaner outlet hose clamp (a): 2.5 n·m (0.25 kg-m, 2.0 lb-ft) intercooler components 1, (a) 1. Int...

Page 9

6a2-10 engine mechanical (k9k engine) intercooler removal and installation removal 1) remove front bumper. 2) remove intercooler inlet hose (1) and outlet hose (2) from intercooler. 3) remove intercooler (3) and its bracket (4). Installation reverse removal procedure for installation noting the foll...

Page 10

Engine mechanical (k9k engine) 6a2-11 cylinder head cover components cylinder head cover removal and installa- tion removal 1) disconnect negative (–) cable at battery. 2) remove drive belt referring to “generator drive belt removal and installation” in section 6h2. 3) remove injector cover (1), gen...

Page 11

6a2-12 engine mechanical (k9k engine) 5) loosen cylinder head cover bolts in such order (“1” to “8”) as shown in the figure and remove them. 6) remove cylinder head cover (1). Installation 1) remove oil, old sealant and dust from sealing surfaces. After cleaning, apply sealant “a” to cylinder head s...

Page 12

Engine mechanical (k9k engine) 6a2-13 oil pressure switch removal and installation removal 1) disconnect negative (–) cable at battery. 2) detach degassing tank from its bracket. 3) disconnect oil pressure switch connector (1). 4) remove oil pressure switch (2). Installation 1) install oil pressure ...

Page 13

6a2-14 engine mechanical (k9k engine) 8) remove compressor bracket (1). 9) install lifting device (1). 10) remove oil filter unit bracket (1). 11) disconnect heat exchanger hose (4). 12) remove engine left mounting bracket (2), and then remove heat exchanger (3). Installation 1) install heat exchang...

Page 14

Engine mechanical (k9k engine) 6a2-15 4) install oil filter unit bracket (1) as shown in figure. Tightening torque oil filter unit bracket bolt (a): 45 n·m (4.5 kg-m, 32.5 lb-ft) 5) install generator and compressor bracket (1) referring to “generator drive belt tensioner components” in section 6h2. ...

Page 15

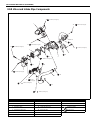

6a2-16 engine mechanical (k9k engine) egr valve and intake pipe components 1. Egr pipe 9. Egr pipe clamp 17. Egr valve body bolt 2. Egr cooler pipe 10. Gasket 18. Intake pipe no.1 3. Egr cooler 11. Egr cooler pipe bolt 19. Intake no.1 nut 4. Intake pipe no.2 12. Egr cooler bolt 20. O-ring 5. Egr val...

Page 16

Engine mechanical (k9k engine) 6a2-17 egr valve and intake pipe removal and installation removal 1) disconnect negative (–) cable at battery. 2) disconnect egr valve connector (1) and boost pressure sensor connector (2). 3) disconnect hose (3) from oil vapor recirculation valve (4), and then remove ...

Page 17

6a2-18 engine mechanical (k9k engine) 7) remove egr valve body (1) with egr pipe (2). Installation 1) install egr valve body assembly (1) with new gasket and egr pipe bolt. Tightening torque egr pipe bolt (a): 42 n·m (4.2 kg-m, 30.5 lb-ft) egr cooler pipe bolt (b): 21 n·m (2.1 kg-m, 15.5 lb-ft) egr ...

Page 18

Engine mechanical (k9k engine) 6a2-19 3) install intake pipe no.1 with new gasket. Tightening torque intake pipe no.1 nut: 11 n·m (1.1 kg-m, 8.0 lb-ft) 4) apply engine oil to new o-ring, and install intake pipe no.2 (2) with new o-ring. Tightening torque intake pipe no.2 bolt (a): 10 n·m (1.0 kg-m, ...

Page 19

6a2-20 engine mechanical (k9k engine) reassembly 1) hold egr valve body with soft jawed vise (1), and install egr cooler (3) with new gasket. 2) install egr cooler pipe (2) with new gasket. Tightening torque egr cooler bolt (a): 12 n·m (1.2 kg-m, 9.0 lb-ft) egr cooler pipe bolt (b): 12 n·m (1.2 kg-m...

Page 20

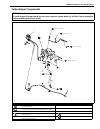

Engine mechanical (k9k engine) 6a2-21 turbocharger components warning: to avoid danger of being burned, do not service exhaust system while it is still hot. Service should be performed after system cools down. 1. Turbocharger oil return pipe 8. Turbocharger nut 2. Turbocharger do not disassemble. 9....

Page 21

6a2-22 engine mechanical (k9k engine) turbocharger removal and installation removal 1) disconnect negative (–) cable at battery. 2) remove air cleaner assembly referring to “air cleaner assembly removal and installation” in this section. 3) remove egr valve body referring to “egr valve and intake pi...

Page 22

Engine mechanical (k9k engine) 6a2-23 6) connect intercooler inlet hose. 7) install egr valve body referring to “egr valve and intake pipe removal and installation” in this section. 8) install air cleaner assembly referring to “air cleaner assem- bly removal and installation” in this section. 9) con...

Page 23

6a2-24 engine mechanical (k9k engine) exhaust manifold removal and installation removal 1) disconnect negative (–) cable at battery. 2) remove turbocharger assembly referring to “turbocharger removal and installation” in this section. 3) loosen exhaust manifold nuts in numerical order (“1” to “8”) e...

Page 24

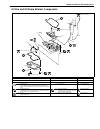

Engine mechanical (k9k engine) 6a2-25 oil pan and oil pump strainer components 1. Upper oil pan gasket 7. Oil pump strainer 13. Engine oil drain plug 2. Oil pan baffle plate bolt 8. Oil pump strainer bolt 14. Level gauge 3. Oil pan baffle plate 9. Lower oil pan gasket 15. Level gauge tube nut 4. Upp...

Page 25

6a2-26 engine mechanical (k9k engine) oil pan and oil pump strainer removal and installation removal 1) disconnect negative (–) cable at battery. 2) drain engine oil referring to “engine oil and filter change” in section 0b. 3) remove engine hood after disconnecting windshield washer hose. 4) remove...

Page 26

Engine mechanical (k9k engine) 6a2-27 10) loosen lower oil pan bolts in numerical order (“1” to “22”) as shown in figure, and remove them. 11) remove lower oil pan from upper oil pan. 12) remove oil pump strainer (1) from upper oil pan (2). 13) loosen upper oil pan bolts in numerical order (“1” to “...

Page 27

6a2-28 engine mechanical (k9k engine) installation 1) clean sealing surfaces on cylinder block, upper oil pan and lower oil pan. 2) clean inside of oil pan and oil pump strainer screen (1). 3) install oil pan baffle plate to upper oil pan. Tightening torque oil pan baffle plate bolt (a): 8 n·m (0.8 ...

Page 28

Engine mechanical (k9k engine) 6a2-29 5) install upper oil pan to cylinder block as follows. A) fit upper oil pan to cylinder block with new gasket. B) tighten upper oil pan bolts temporarily by hand. C) tighten upper oil pan bolts (“1” to “8”) to 6 n·m (0.6 kg-m, 4.5 lb-ft) according to numerical o...

Page 29

6a2-30 engine mechanical (k9k engine) 10) install engine to vehicle as follows. A) install engine left mounting (1). B) lower engine. C) tighten engine mounting nuts (2) to specified torque. Tightening torque engine mounting nut (a): 55 n·m (5.5 kg-m, 40.0 lb-ft) d) remove lifting device (3). 11) in...

Page 30

Engine mechanical (k9k engine) 6a2-31 8) remove fuel filter referring to “fuel filter removal and installation” in section 6c2. 9) disconnect discharge hose pipe from a/c compressor refer- ring to “major components and location” in section 1b. 10) remove transmission referring to “transmission dismo...

Page 31

6a2-32 engine mechanical (k9k engine) 16) install lifting device (1). 17) remove engine mounting nuts (2). 18) before lifting engine, check to ensure all hoses, electric wires and cables are disconnected from engine. 19) remove engine assembly from vehicle. 1 2 2.

Page 32

Engine mechanical (k9k engine) 6a2-33 installation reverse removal procedure for installation noting the following. • tighten engine mounting nuts (1) to specified torque. Tightening torque engine mounting nut (a): 55 n·m (5.5 kg-m, 40.0 lb-ft) • install transmission assembly referring to “transmiss...

Page 33

6a2-34 engine mechanical (k9k engine) timing belt and belt tensioner components 1. Timing belt upper cover 7. Timing belt pulley 13. Generator upper bracket support bolt 2. Generator upper bracket support 8. Timing belt tensioner bolt 14. Cmp sensor 3. Timing belt lower cover 9. Timing belt tensione...

Page 34

Engine mechanical (k9k engine) 6a2-35 timing belt and belt tensioner removal and installation removal 1) remove engine assembly from vehicle referring to “engine assembly removal and installation” in this section. 2) remove injector cover (1) and generator upper bracket (2). 3) remove timing belt up...

Page 35

6a2-36 engine mechanical (k9k engine) 7) remove tdc pin cap (1). 8) turn crankshaft pulley clockwise, and stop it just before aligning slit (1) of camshaft pulley hub (2) matches with hole (3) of cylinder head. 9) insert special tool (a) into tdc pin hole as shown in figure. Special tool (a): 09919-...

Page 36

Engine mechanical (k9k engine) 6a2-37 12) loosen crankshaft pulley bolt as follows. A) lock flywheel using special tool (c). Special tool (c): 09916-98110 b) remove special tools (a) and (b). C) loosen crankshaft pulley bolt, and remove crank shaft pul- ley. D) remove special tool (c). E) insert spe...

Page 37

6a2-38 engine mechanical (k9k engine) 3) install timing belt inner cover (1), timing belt pulley (2) and timing belt tensioner (3), if necessary. 4) remove one camshaft pulley bolt (1), and loosen the other two bolts (2) by one turn. 5) install timing belt (1) with aligning its matching lines (2) wi...

Page 38

Engine mechanical (k9k engine) 6a2-39 7) check that camshaft pulley bolts (1) do not touch long slot- ted end (2). 8) install removed camshaft pulley bolt, and tighten all cam- shaft pulley bolts to specified torque. Tightening torque camshaft pulley bolt (a): 14 n·m (1.4 kg-m, 10.5 lb-ft) 9) remove...

Page 39

6a2-40 engine mechanical (k9k engine) 14) check that special tool (b) inserts holes of camshaft belt pul- ley hub and cylinder head smoothly. If not, loosen camshaft pulley bolts (1) by one turn, and turn camshaft pulley hub (2) to just aligning slit (3) of camshaft pulley hub with hole (4) of cylin...

Page 40

Engine mechanical (k9k engine) 6a2-41 18) turn crankshaft two revolutions clockwise, and stop it just before aligning slit (1) of camshaft pulley (2) with hole (3) of cylinder head. 19) insert special tool (a) into tdc pin hole as shown in figure. Special tool (a): 09919-58110 20) turn crankshaft pu...

Page 41

6a2-42 engine mechanical (k9k engine) 23) apply sealant “a” to thread of tdc pin cap (1), and tighten tdc pin cap as specified torque. Tightening torque tdc pin cap (a): 20 n·m (2.0 kg-m, 14.5 lb-ft) “a”: rhodorseal 5661® 24) install generator upper bracket support (1). Tightening torque generator u...

Page 42

Engine mechanical (k9k engine) 6a2-43 timing belt and belt tensioner inspection • inspect timing belt for wear or crack. Replace it as necessary. • inspect timing belt tensioner and roller for smooth rotation. Replace it as necessary..

Page 43

6a2-44 engine mechanical (k9k engine) oil pump and oil pump chain components oil pump and oil pump chain removal and installation removal 1) remove engine assembly from vehicle referring to “engine assembly removal and installation” in this section. 2) remove upper oil pan referring to “oil pan and ...

Page 44

Engine mechanical (k9k engine) 6a2-45 3) remove oil pump (1) from cylinder block. 4) remove timing belt referring to “timing belt and belt ten- sioner removal and installation” in this section. 5) remove gasket holder plate (1). 6) remove gasket holder plate oil seal (2). 7) remove oil pump chain (1...

Page 45

6a2-46 engine mechanical (k9k engine) 2) install gasket holder plate (1) to cylinder block with new gas- ket, and tighten gasket holder plate bolts as follows. A) tighten gasket holder plate bolts (“1” and “6”) to 11 n·m (1.1 kg-m, 8.0 lb-ft). B) tighten gasket holder plate bolts (“2”, “3”, “4” and ...

Page 46

Engine mechanical (k9k engine) 6a2-47 a) install bolt (3) and spacer (4) of special tool to crankshaft. B) install protector (2) together with new oil seal (1) to spacer (4). C) install oil seal installer (5) to bolt (3). D) tighten nut (6) of special tool until oil seal installer (5) comes into con...

Page 47

6a2-48 engine mechanical (k9k engine) • check oil pump chain for wear or damage. If any malcondition is found, replace oil pump chain. Camshaft and tappet components 1. Camshaft housing bolt : tighten 10 n·m (1.0 kg-m, 7.5 lb-ft) by the specified procedure. 6. Camshaft pulley 11. Vacuum pump oil hos...

Page 48

Engine mechanical (k9k engine) 6a2-49 camshaft and tappet removal and installa- tion removal 1) remove engine assembly from vehicle referring to “engine assembly removal and installation” in this section. 2) remove timing belt referring to “timing belt and tensioner removal and installation” in this...

Page 49

6a2-50 engine mechanical (k9k engine) 10) remove tappet (1) from cylinder head. Installation 1) apply engine oil around tappet (1), and then install it to cylin- der head. 2) remove oil, old sealant and dust from sealing surfaces. After cleaning, apply sealant “a” to cylinder head (1) sealing sur- f...

Page 50

Engine mechanical (k9k engine) 6a2-51 b) install camshaft pulley (1) to camshaft with aligning key (3) of camshaft pulley to key groove (4) of camshaft (2), and then tighten camshaft pulley nut to temporary. C) apply engine oil to sliding surface of each camshaft and camshaft journal. D) fit camshaf...

Page 51

6a2-52 engine mechanical (k9k engine) 8) install new oil seal (1) together with protector (2) using spe- cial tool and plastic hammer until special tool comes into contact with cylinder head. Special tool (a): 09911-98120 9) install cylinder head cover referring to “cylinder head cover removal and i...

Page 52

Engine mechanical (k9k engine) 6a2-53 camshaft and tappet inspection camshaft • check teeth of sprocket for wear or damage. • check journals and cam faces for wear or damage. If any malcondition is found, replace camshaft. • using a micrometer, measure cam height “a”. If measured height is out of sp...

Page 53

6a2-54 engine mechanical (k9k engine) e) install camshaft housing to cylinder head as follows. I) fit camshaft housing to cylinder head. Ii) tighten camshaft housing bolts temporarily by hand. Iii) tighten camshaft housing bolts in numerical order as indi- cated in figure a little at a time till the...

Page 54

8-10 body electrical system power door lock system with keyless entry system (if equipped) power door lock system with keyless entry system component location [a]: m13 engine model 3. Lock position 7. Transmitter [b]: k9k engine model 4. Unlock position 8. Door switch 1. Power door lock controller 5...

Page 55

Body electrical system 8-11 system description only for m13 engine model the keyless entry system has the following signal modes in order to feed back the signal when the controller received lock and unlock signals from transmitter. Change of signal mode only for m13 engine model 1) confirm that all...

Page 56

8-12 body electrical system 5) check the following operation: a) when pushing “lock” button (1) on transmitter (2), check all doors lock and hazard warning lights flash once. B) when pushing “unlock” button (3) on transmitter (2), check all doors unlock and hazard warning lights flash twice and inte...

Page 57

Body electrical system 8-13 keyless entry system circuit check m13 engine model terminal circuit specification condition 2 key remainder circuit 10 – 14 v ignition key is in ignition switch. 0 – 1 v ignition key is not in ignition switch. 4 door switch & interior light circuit 0 – 1 v driver side, p...

Page 58

8-14 body electrical system k9k engine model terminal circuit specification condition 7 hazard waning signal circuit (right side) figure “a” push “lock” button on transmitter once. Figure “b” push “unlock” button on transmitter once. 8 hazard waning signal circuit (left side) figure “a” push “lock” ...

Page 59

Body electrical system 8-15 transmitter replacement of transmitter battery if transmitter becomes unreliable, replace transmitter battery as follows. M13 engine model 1) remove screw (1) and transmitter cover (2). 2) remove transmitter (3) from transmitter holder (4). 3) put edge of coin or flat bla...

Page 60

8-16 body electrical system code registration procedure if transmitter or door lock controller is replaced with new one or additional transmitter(s) is necessary, register key code(s) as fol- lows. M13 engine model 1) confirm that the vehicle is the following conditions. • all doors are closed. • ig...

Page 61

Body electrical system 8-17 power door mirror control system (if equipped) door mirror actuator inspection 1) remove front door inner garnish from front door. 2) disconnect door mirror coupler. 3) check that door mirror operates properly when battery volt- age is applied to coupler terminals. Connec...

Page 62

8-18 body electrical system door mirror heater (if equipped) mirror heater (if equipped) inspection 1) remove door inner garnish from front door. 2) disconnect door mirror coupler (1). 3) check for continuity between terminals “a” and “b”. If not continuity, replace outside mirror..