- DL manuals

- Suzuki

- Offroad Vehicle

- LT-A400

- Service Manual

Suzuki LT-A400 Service Manual

Summary of LT-A400

Page 1

Printed in japan k8 9 9 5 0 0 - 4 3 0 7 0 - 0 1 e k8.

Page 2

Foreword this manual contains an introductory description on the suzuki lt-a400/f, lt-f400/f and procedures for its inspection/service and overhaul of its main components. Other information considered as generally known is not included. Read the general information section to familiarize yourself wi...

Page 3

00 0 1 2 3 4 5 6 7 8 9 10 11 precautions............................................................... 00-i precautions ............................................................ 00-1 general information ................................................... 0-i general information ....................

Page 5

Table of contents 00- i 00 section 00 contents precautions precautions ...............................................00-1 precautions........................................................... 00-1 warning / caution / note..................................... 00-1 general precautions .................

Page 6

00-1 precautions: precautions precautions precautions warning / caution / note b827h10000001 please read this manual and follow its instructions carefully. To emphasize special information, the symbol and the words warning, caution and note have special meanings. Pay special attention to the message...

Page 7

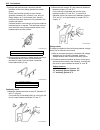

Precautions: 00-2 • never reuse a circlip. When installing a new circlip, take care not to expand the end gap larger than required to slip the circlip over the shaft. After installing a circlip, always ensure that it is completely seated in its groove and securely fitted. • use a torque wrench to ti...

Page 8

00-3 precautions: • check the male connector for bend and female connector for excessive opening. Also check the coupler for locking (looseness), corrosion, dust, etc. Clamp • clamp the wire harness at such positions as indicated in “wiring harness routing diagram in section 9a (page 9a-8)”. • bend ...

Page 9

Precautions: 00-4 battery • battery connection in reverse polarity is strictly prohibited. Such a wrong connection will damage the components of the fi systems instantly when reverse power is applied. • removing any battery terminal of a running engine is strictly prohibited. The moment such removal...

Page 10

00-5 precautions: 3) using a test male terminal, check the female terminals of the circuit being checked for contact tension. Check each terminal visually for poor contact (possibly caused by dirt, corrosion, rust, entry of foreign object, etc.). At the same time, check to make sure that each termin...

Page 11

Precautions: 00-6 3) also, if measured values are as listed following, a resistance (abnormality) exists which causes the voltage drop in the circuit between terminals “a” and “b”. Voltage between “a” and body ground: approx. 5 v “b” and body ground: approx. 5 v – 2 v voltage drop “c” and body groun...

Page 12

00-7 precautions: using the multi-circuit testers • use the suzuki multi-circuit tester set. • use well-charged batteries in the tester. • be sure to set the tester to the correct testing range. Special tool (a): 09900–25008 (multi-circuit tester set) using the testers • incorrectly connecting the (...

Page 13

Table of contents 0- i 0 section 0 contents general information general information ................................ 0a-1 general description .............................................0a-1 symbols .............................................................. 0a-1 abbreviations .....................

Page 14

0a-1 general information: general information general information general description symbols b827h10101001 listed in the table below are the symbols indicating instructions and other information necessary for servicing. The meaning of each symbol is also included in the table. Abbreviations b827h10...

Page 15

General information: 0a-2 m: max: maximum mil: malfunction indicator lamp (led) min: minimum n: nox: nitrogen oxides o: ohc: over head camshaft p: pcv: positive crankcase ventilation (crankcase breather) r: rh: right hand rom: read only memory s: sae: society of automotive engineers vehicle side vie...

Page 16

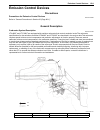

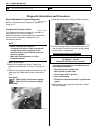

0a-3 general information: vehicle identification number b827h10101005 the frame serial number or v.I.N. (vehicle identification number) “a” is stamped on the left side of the rear frame pipe. The engine serial number “b” is located on the left side of the crankcase. These numbers are required especi...

Page 17

General information: 0a-4 break-in procedures b827h10101008 during manufacture only the best possible materials are used and all machined parts are finished to a very high standard but it is still necessary to allow the moving parts to “break-in” before subjecting the engine to maximum stresses. The...

Page 18

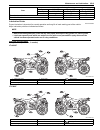

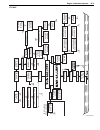

0a-5 general information: warning, caution and information labels location b827h10101011 2 23 1 24 26 21 22 8 9 16 15 7 3 17 18 6 10 20 19 5 4 25 12 13 14 11 [a] [b] [d] [c] i827h1010011-02 1. Certification plate (english) for p-24, 33 16. Gearshift label (french) for p-28 2. Information label (engl...

Page 19

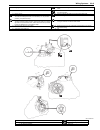

General information: 0a-6 component location electrical components location b827h10103001 lt-a400/f 1 3 5 6 7 8 11 10 12 13 14 15 4 2 9 i827h1010007-01 1. Battery 6. Ignition switch 11. Starter motor 2. Main fuse 7. Output terminal 12. Brake light switch 3. Starter relay 8. Handlebar switch (lh) 13....

Page 20

0a-7 general information: 16 17 18 19 21 22 23 20 i827h1010008-02 16. Ignition coil 19. Regulator/rectifier 22. Reverse diode 17. Cooling fan 20. Cdi unit 23. Generator 18. Ignition/starter control relay 21. Neutral switch diode.

Page 21

General information: 0a-8 lt-f400/f 1 3 5 6 8 10 11 12 13 14 4 2 7 9 i827h1010009-02 1. Battery 6. Handlebar switch (lh) 11. Brake light switch 2. Main fuse 7. Parking brake switch 12. Starter motor 3. Starter relay 8. Burke light switch 13. Cooling fan thermo-switch 4. Neutral relay 9. Ignition swi...

Page 22

0a-9 general information: 23 15 16 17 18 21 22 19 20 i827h1010010-04 15. Ignition coil 18. Regulator/rectifier 21. Neutral diode 16. Cooling fan 19. Cdi unit 22. Generator 17. Ignition/starter control relay 20. Reverse switch 23. Neutral switch.

Page 23

General information: 0a-10 specifications specifications b827h10107001 note these specifications are subject to change without notice. Lt-a400/f dimensions and dry mass engine drive train item specification remark overall length 2 160 mm (85.0 in) p-17, 24 2 060 mm (81.1 in) p-28, 33 overall width 1...

Page 24

0a-11 general information: chassis electrical capacities item specification remark front suspension independent, double wishbone, coil spring, oil damped rear suspension swingarm type, coil spring, oil damped front wheel travel 170 mm (6.7 in) rear wheel travel 170 mm (6.7 in) caster 3 ° trail 14 mm...

Page 25

General information: 0a-12 lt-f400/f dimensions and dry mass engine drive train item specification remark overall length 2 160 mm (85.0 in) p-17, 24 2 060 mm (81.1 in) p-28,33 overall width 1 200 mm (47.2 in) p-17, 24 1 145 mm (45.1 in) p-28,33 overall height 1 220 mm (48.0 in) wheelbase 1 270 mm (5...

Page 26

0a-13 general information: chassis electrical capacities item specification remark front suspension independent, double wishbone, coil spring, oil damped rear suspension swingarm type, coil spring, oil damped front wheel travel 170 mm (6.7 in) rear wheel travel 170 mm (6.7 in) caster 3 ° trail 14 mm...

Page 27

General information: 0a-14 special tools and equipment special tool b827h10108007 09900–06107 snap ring pliers 09900–06108 snap ring pliers 09900–20101 vernier calipers (1/15 mm, 150 mm) 09900–20102 vernier calipers (1/20 mm, 200 mm) 09900–20202 micrometer (1/100 mm, 25 – 50 mm) 09900–20205 micromet...

Page 28

0a-15 general information: 09915–64512 compression gauge 09915–74511 oil pressure gauge set 09916–10911 valve lapper set 09916–14510 valve spring compressor 09916–14910 valve spring compressor attachment 09916–34542 reamer handle 09916–34570 valve guide reamer (5.0 mm) 09916–34580 valve guide reamer...

Page 29

General information: 0a-16 09924–64510 final driving gear coupling holder 09924–84521 bearing installer set 09930–10121 spark plug wrench set 09930–30104 rotor remover slide shaft 09930–30141 attachment a 09930–30721 rotor remover 09930–31921 rotor remover 09930–40113 rotor holder 09930–44541 rotor ...

Page 30

0b-1 maintenance and lubrication: general information maintenance and lubrication precautions precautions for maintenance b827h10200001 the “periodic maintenance schedule chart” lists the recommended intervals for all the required periodic service work necessary to keep the vehicle operating at peak...

Page 31

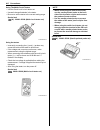

Maintenance and lubrication: 0b-2 lubrication points b827h10205002 proper lubrication is important for smooth operation and long life of each working part of the vehicle. Major lubrication points are indicated as follows. Note • before lubricating each part, clean off any rusty spots and wipe off an...

Page 32

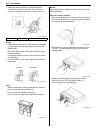

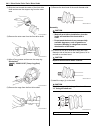

0b-3 maintenance and lubrication: repair instructions air cleaner element inspection and cleaning b827h10206001 clean element every 1 000 km (600 miles, 3 months) if the air cleaner is clogged with dust, intake resistance will be increased, with a resultant decrease in power output and an increase i...

Page 33

Maintenance and lubrication: 0b-4 exhaust pipe bolt and muffler bolt inspection b827h10206002 tighten exhaust pipe bolts, muffler bolt and nut initially at 200 km (100 miles, 1 month) and every 1 000 km (600 miles, 3 months) thereafter check the exhaust pipe bolts, muffler bolts and nuts to the spec...

Page 34

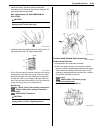

0b-5 maintenance and lubrication: 5) turn the crankshaft until the piston reaches tdc on the compression stroke by slowly pulling the recoil starter rope. Pull the recoil starter rope until the line (4) on the generator rotor is aligned with the mark (5) on the crankcase. 6) remove the valve timing ...

Page 35

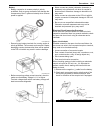

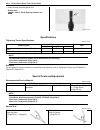

Maintenance and lubrication: 0b-6 spark plug inspection and cleaning b827h10206005 inspect spark plug every 2 000 km (1 200 miles, 6 months) heat range 1) remove the spark plug. Refer to “spark plug removal and installation in section 1h (page 1h- 3)”. 2) check spark plug heat range by observing ele...

Page 36

0b-7 maintenance and lubrication: spark arrester cleaning b827h10206006 clean spark arrester every 2 000 km (1 200 miles, 6 months) clean the spark arrester in the following procedures: 1) remove the spark arrester (1) from the muffler. 2) clean the spark arrester with a brush. Warning ! Only clean ...

Page 37

Maintenance and lubrication: 0b-8 4) check the oil level on the dipstick. If the level is below low level line “a”, add oil to full level line “b”. If the level is above full level line “b”, drain oil to full level line “b”. Note when inspecting the oil level, the oil filler cap threads are not run ...

Page 38

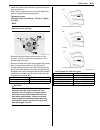

0b-9 maintenance and lubrication: 7) install the new oil filter. Turn it by hand until you feel that the oil filter o-ring contacts the oil filter mounting surface. Then, tighten the oil filter two full turns (or to the specified torque) using the special tool. Note to properly tighten the oil filte...

Page 39

Maintenance and lubrication: 0b-10 front differential gear oil replacement (lt- a400f, lt-f400f) b827h10206010 replace front differential gear oil every 2 years replace the oil filter differential gear oil in the following procedures: 1) place the vehicle on level ground. 2) remove the front under c...

Page 40

0b-11 maintenance and lubrication: 8) install the front under cover. Refer to “exterior parts removal and installation in section 9d (page 9d- 3)”. Final gear oil inspection b827h10206011 inspect final gear oil every 2 000 km (1 200 miles, 6 months) inspect the final gear oil level in the following ...

Page 41

Maintenance and lubrication: 0b-12 3) remove the oil filler plug (2) and oil level plug (3). 4) drain final gear oil by removing the drain plug (4). 5) tighten the oil drain plug (4) to the specified torque. Caution ! Replace the gasket with a new one. Tightening torque final gear oil drain plug (a)...

Page 42

0b-13 maintenance and lubrication: throttle cable play inspection and adjustment b827h10206013 inspect throttle cable play initially at 200 km (100 miles, 1 month) and every 1 000 km (600 miles, 3 months) thereafter inspect and adjust the throttle cable play “a” as follows. Throttle cable play “a” 3...

Page 43

Maintenance and lubrication: 0b-14 clutch inspection (lt-f400/f) b827h10206031 inspect clutch system every 2 000 km (1200 miles, 6 months) the lt-f400/f is equipped with a centrifugal type automatic clutch. To insure proper performance and longevity of the clutch assemblies it is essential that the ...

Page 44

0b-15 maintenance and lubrication: front brake system inspection b827h10206018 inspect brake system initially at 200 km (100 miles, 1 month) and every 1 000 km (600 miles, 3 months) thereafter warning ! • the front brake system of this vehicle is filled with a glycol-based brake fluid. Do not use or...

Page 45

Maintenance and lubrication: 0b-16 rear brake pedal / rear brake (parking brake) lever inspection and adjustment b827h10206019 note adjust the rear brake by adjusting the brake pedal first and then adjust the brake lever. Brake pedal free travel 1) inspect the brake pedal free travel “a”. Adjust the...

Page 46

0b-17 maintenance and lubrication: rear brake lining wear limit this vehicle has brake lining wear limit indicator on the rear brake. Inspect the wear of brake lining in the following procedures: 1) make sure that the rear brake is properly adjusted. 2) while fully applying the rear brake, check tha...

Page 47

Maintenance and lubrication: 0b-18 steering system inspection b827h10206022 inspect steering system initially at 200 km (100 miles, 1 month) and every 1 000 km (600 miles, 3 months) thereafter steering should be adjusted properly for smooth turning of handlebars and safe running. 1) place the vehicl...

Page 48

0b-19 maintenance and lubrication: 5) after adjustment has been made, tighten the four lock-nuts to the specified torque. Tightening torque tie-rod lock-nut (a): 29 n·m (2.9 kgf-m, 21.0 lb-ft) suspension inspection b827h10206024 inspect suspension every 2 000 km (1 200 miles, 6 months) inspect suspe...

Page 49

Maintenance and lubrication: 0b-20 7 steering knuckle pinch bolt (upper and lower) 50 n ⋅m 5.0 kgf-m, 36.0 lb-ft) 10 tie-rod end nut 29 n ⋅m (2.9 kgf-m, 21.0 lb-ft) 11 tie-rod lock nut 29 n ⋅m (2.9 kgf-m, 21.0 lb-ft) 8 front shock absorber mounting bolt (upper) 55 n ⋅m (5.5 kgf-m, 40.0 lb-ft) 9 fron...

Page 50

0b-21 maintenance and lubrication: compression pressure check b827h10206026 refer to “compression pressure check in section 1d (page 1d-2)”. Oil pressure check b827h10206027 refer to “oil pressure check in section 1e (page 1e- 4)”. Automatic clutch inspection (lt-a400/f) b827h10206029 this vehicle i...

Page 51

Maintenance and lubrication: 0b-22 specifications tightening torque specifications b827h10207002 note the specified tightening torque is also described in the following. “chassis bolt and nut inspection (page 0b-19)” reference: for the tightening torque of fastener not specified in this section, ref...

Page 52

0b-23 maintenance and lubrication: 09900–25008 09900–26006 multi-circuit tester set engine tachometer (solar cell type) ) (page 0b-13) / ) (page 0b-14) / ) (page 0b-21) ) (page 0b-13) / ) (page 0b-14) / ) (page 0b-21) 09915–40610 09917–14910 oil filter wrench valve adjuster driver ) (page 0b-8) / )(...

Page 53

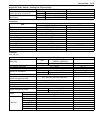

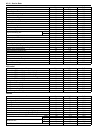

Service data: 0c-1 general information service data specifications service data (lt-a400/f) b827h10307001 valve + valve guide unit: mm (in) camshaft + cylinder head unit: mm (in) cylinder + piston + piston ring unit: mm (in) item standard limit valve diam. In. 30.6 (1.20) — ex. 27.0 (1.06) — valve c...

Page 54

0c-2 service data: conrod + crankshaft unit: mm (in) oil pump clutch unit: mm (in) drive train unit: mm (in) except ratio piston ring to groove clearance 1st — 0.180 (0.0071) 2nd — 0.150 (0.0059) piston ring groove width 1st 1.01 – 1.03 (0.0398 – 0.0406) — 2nd 1.01 – 1.03 (0.0398 – 0.0406) — oil 2.0...

Page 55

Service data: 0c-3 engine oil temp. Switch + cooling fan thermo-switch carburetor electrical unit: mm (in) item standard/specification limit engine oil temp. Indicator light switch operating temperature off → on approx. 160 °c (320 °f) — on → off approx. 140 °c (284 °f) — cooling fan thermo-switch o...

Page 56

0c-4 service data: wattage unit: w brake + wheel unit: mm (in) tire fuel + oil item specification p-17 others headlight hi 35 x 2 ← lo 35 x 2 ← brake light/taillight 21/5 ← speedometer light 1.7 ← reverse indicator light 3.4 ← neutral indicator light 3.4 ← engine oil temp. Indicator light 3.4 ← high...

Page 57

Service data: 0c-5 service data (lt-f400/f) b827h10307003 valve + valve guide unit: mm (in) camshaft + cylinder head unit: mm (in) cylinder + piston + piston ring unit: mm (in) fuel tank capacity including reserve 16.0 l (4.2/3.5 us/lmp gal) reserve 2.9 l (0.8/0.6 us/lmp gal) engine oil type sae 10 ...

Page 58

0c-6 service data: conrod + crankshaft unit: mm (in) oil pump clutch unit: mm (in) drive train unit: mm (in) except ratio piston diam. 81.930 – 81.945 (3.2256 – 3.2262) measure at 15 mm (0.6 in) from the skirt end. 81.880 (3.2236) cylinder distortion — 0.05 (0.002) piston ring free end gap 1st r app...

Page 59

Service data: 0c-7 engine oil temp. Switch + cooling fan thermo-switch carburetor electrical unit: mm (in) transmission gear ratio low 3.083 (37/12) — 2nd 1.933 (29/15) — 3rd 1.388 (25/18) — 4th 1.095 (23/21) — top 0.913 (21/13) — reverse 2.833 (34/12) — transmission shift fork to groove clearance 0...

Page 60

0c-8 service data: wattage unit: w brake + wheel unit: mm (in) generator coil resistance 0.3 – 1.5 Ω b – b generator no-load voltage (when the engine is cold) 65 v (ac) and more at 5 000 r/min generator max. Output approx. 225 w at 5 000 r/min regulated voltage 13.5 – 15.0 v at 5 000 r/min ignition ...

Page 61

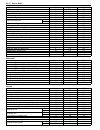

Service data: 0c-9 tire fuel + oil tightening torque list (lt-a400/f) b827h10307002 engine item standard note cold inflation tire pressure front 32.5 kpa (0.325 kgf/cm 2 , 4.7 psi) load capacity up to 172 kg (380 lbs) rear 30 kpa (0.30 kgf/cm 2 , 4.4 psi) tire size front at25 x 8-12 , tubeless rea...

Page 62

0c-10 service data: differential chassis oil pump drive gear bolt 80 8.0 58.0 exhaust pipe nut 18 1.8 13.0 exhaust pipe mounting bolt 23 2.3 16.5 muffler mounting bolt 23 2.3 16.5 muffler connecting bolt 23 2.3 16.5 engine oil drain plug 23 2.3 16.5 cooling fan thermo-switch 20 2.0 14.5 engine oil t...

Page 63

Service data: 0c-11 tightening torque list (lt-f400/f) b827h10307004 engine brake disc bolt 23 2.3 16.5 brake caliper mounting bolt 26 2.6 19.0 footrest mounting bolt m8 25 2.5 18.0 m10 55 5.5 40.0 rear brake cam lever nut 11 1.1 8.0 rear axle housing mounting bolt (final gear case) 55 5.5 40.0 rear...

Page 64

0c-12 service data: differential chassis muffler mounting bolt 23 2.3 16.5 muffler connecting bolt 23 2.3 16.5 engine oil drain plug 23 2.3 16.5 drive bevel gear nut 100 10.0 72.5 driven bevel gear nut 100 10.0 72.5 engine mounting nut m8 40 4.0 29.0 m10 55 5.5 40.0 engine mounting bracket bolt 28 2...

Page 65

Service data: 0c-13 tightening torque chart for other bolts and nuts not listed in the preceding page, refer to this chart: rear brake cam lever nut 11 1.1 8.0 rear axle housing mounting bolt (final gear case) 55 5.5 40.0 rear axle housing mounting bolt (swingarm) 60 6.0 43.5 rear shock absorber mou...

Page 66

0c-14 service data:.

Page 67

Table of contents 1- i 1 section 1 contents engine precautions .................................................1-1 precautions............................................................. 1-1 precautions for engine.......................................... 1-1 engine general information and diagnos...

Page 68

1-ii table of contents cooling fan components .................................1e-12 cooling fan inspection .....................................1e-12 cooling fan removal and installation ..............1e-13 cooling fan thermo-switch removal and installation.............................................

Page 69

Table of contents 1-iii recoil starter assembly removal and installation........................................................ 1i-13 recoil starter disassembly and assembly ........ 1i-13 recoil starter inspection .................................... 1i-15 specifications..............................

Page 70

1-1 precautions: engine precautions precautions precautions for engine b827h11000001 refer to “general precautions in section 00 (page 00-1)” and “precautions for electrical circuit service in section 00 (page 00-2)”..

Page 71

Engine general information and diagnosis: 1a-1 engine engine general information and diagnosis diagnostic information and procedures engine symptom diagnosis b827h11104001 condition possible cause correction / reference item engine will not start or is hard to start (compression too low) worn cylind...

Page 72

1a-2 engine general information and diagnosis: engine idles poorly valve clearance out of adjustment. Adjust. Poor seating of valves. Replace. Defective valve guides. Replace. Worn rocker arm or arm shaft. Replace. Defective generator. Replace. Defective cdi unit. Replace. Spark plug gap too wide. A...

Page 73

Emission control devices: 1b-1 engine emission control devices precautions precautions for emission control devices b827h11200001 refer to “general precautions in section 00 (page 00-1)”. General description carburetor system description b827h11201001 lt-a400/f and lt-f400/f are equipped with precis...

Page 74

1b-2 emission control devices: repair instructions crankcase breather (pcv) hose inspection b827h11206001 inspect the pcv hose in the following procedures: 1) remove the right side cover. Refer to “exterior parts removal and installation in section 9d (page 9d- 3)”. 2) inspect the pcv hose (1) for w...

Page 75

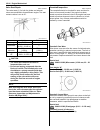

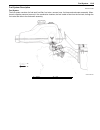

Engine mechanical: 1d-1 engine engine mechanical schematic and routing diagram throttle cable routing diagram b827h11402001 “e” “d” 4 5 6 6 “f” “c” “ a ” 12 2 “a” 1 “b” 2 3 up “ b ” 7 11 1 2 “g” 10 9 8 inside “h” i827h1140304-02 1. Clamp : bind the front brake switch lead wire and throttle cable wit...

Page 76

1d-2 engine mechanical: diagnostic information and procedures engine mechanical symptom diagnosis b827h11404001 refer to “engine symptom diagnosis in section 1a (page 1a-1)”. Compression pressure check b827h11404002 the compression pressure reading of a cylinder is a good indicator of its internal c...

Page 77

Engine mechanical: 1d-3 repair instructions engine components removable with the engine in place b827h11406001 engine components which can be removed while the engine is installed on the frame are as follows. For the installing and removing procedures, refer to respective paragraphs describing each ...

Page 78

1d-4 engine mechanical: engine left side movable driven face assembly (lt-a400/f) refer to “v-belt type continuously variable automatic transmission removal and installation in section 5a (page 5a-7)”. Refer to “movable / fixed driven face parts inspection in section 5a (page 5a-16)”. Refer to “v-be...

Page 79

Engine mechanical: 1d-5 air cleaner element removal and installation b827h11406002 removal 1) remove the seat. Refer to “exterior parts removal and installation in section 9d (page 9d-3)”. 2) remove the air cleaner box cover (1). 3) remove the air cleaner element bolt. 4) remove the air cleaner elem...

Page 80

1d-6 engine mechanical: engine assembly removal b827h11406013 before taking the engine out of the frame, wash the engine using a steam cleaner. Engine removal is sequentially explained in the following steps: 1) drain engine oil. Refer to “engine oil and filter replacement in section 0b (page 0b-7)”...

Page 81

Engine mechanical: 1d-7 10) remove the transfer gearshift arm (7). 11) disconnect the gear position switch lead wire coupler (8), ckp sensor lead wire coupler (9) and generator lead wire coupler (10). 12) disconnect the spark plug cap (11). 13) disconnect the pcv (breather) hose (12). 14) disconnect...

Page 82

1d-8 engine mechanical: 18) remove the muffler and exhaust pipe. 19) remove the front differential mounting bolts and slide the front differential assembly (19) forward. Refer to “front drive (differential) assembly removal and installation (lt-a400f, lt-f400f) in section 3b (page 3b-4)”. 20) remove...

Page 83

Engine mechanical: 1d-9 engine assembly installation b827h11406014 reinstall the engine in the reverse order of removal. Pay attention to the following points: note the engine mounting nuts are self-locking. Once the nut has been removed, it is no longer any use. Be sure to use new nuts, and then ti...

Page 84

1d-10 engine mechanical: • after finishing the engine installation, check the following items: – throttle cable play refer to “throttle cable play inspection and adjustment in section 0b (page 0b-13)”. – rear brake cable play refer to “rear brake pedal / rear brake (parking brake) lever inspection a...

Page 85

Engine mechanical: 1d-11 cylinder head cover 1) remove the valve timing inspection caps (1). 2) remove the cylinder head cover. 3) remove the dowel pins and camshaft end cap (2). Cam shaft 1) flatten the lock washer. 2) remove the cam chain sprocket bolts and lock washer. 3) remove the cam chain ten...

Page 86

1d-12 engine mechanical: cylinder head 1) remove the cylinder head nuts. 2) remove the cylinder head bolts. Note the cylinder head bolts must be loosened diagonally and evenly. 3) remove the cylinder head (1). Cylinder 1) remove the dowel pins and gasket (1). 2) remove the cam chain guide (2). 3) re...

Page 87

Engine mechanical: 1d-13 engine top side assembly b827h11406016 assemble the engine top side in the reverse order of disassembly. Pay attention to the following points: caution ! When turning the crankshaft, pull the cam chain upward, or the chain will be caught between the crankcase and the cam dri...

Page 88

1d-14 engine mechanical: • hold each piston ring with properly position, insert the piston into the cylinder. • tighten the cylinder base nuts temporarily. Caution ! When installing the cylinder and cylinder head, pull the cam chain upward, or the chain will be caught between the crankcase and cam d...

Page 89

Engine mechanical: 1d-15 • tighten the cylinder head nuts to the specified torque. Tightening torque cylinder head nut (8 mm) (initial): 10 n·m (1.0 kgf- m, 7.0 lb-ft) cylinder head nut (8 mm) (final): 25 n·m (2.5 kgf- m, 18.0 lb-ft) • tighten the cylinder base nuts to the specified torque. Tighteni...

Page 90

1d-16 engine mechanical: • install the lock washer so that it is covering the locating pin. • tighten the camshaft sprocket bolts (4). Tightening torque camshaft sprocket bolt (b): 15 n·m (1.5 kgf-m, 11.0 lb-ft) • bend up the washer tongue positively to lock the bolts. • apply engine oil to the cam ...

Page 91

Engine mechanical: 1d-17 • apply bond to the mating surface of the cylinder head cover. : sealant 99000–31140 (suzuki bond no.1207b or equivalent) i827h1140034-01.

Page 92

1d-18 engine mechanical: • lightly tighten the cylinder head cover bolts diagonally, and then tighten them to the specified torque. Tightening torque cylinder head cover bolt: 10 n·m (1.0 kgf-m, 7.0 lb-ft) caution ! • when tightening the cylinder head cover bolts, the piston must be at top dead cent...

Page 93

Engine mechanical: 1d-19 • fit a new gasket (2). Caution ! Use new gasket to prevent oil leakage. • tighten the cam chain tension adjuster bolts (3) to the specified torque. Tightening torque cam chain tension adjuster bolt (a): 10 n·m (1.0 kgf-m, 7.0 lb-ft) • install o-ring, spring and spring holde...

Page 94

1d-20 engine mechanical: spark plug • install the spark plug. Special tool : 09930–10121 (spark plug wrench set) tightening torque spark plug: 11 n·m (1.1 kgf-m, 8.0 lb-ft) cylinder head cover disassembly and assembly b827h11406040 disassembly caution ! Be sure to identify each removed part as to it...

Page 95

Engine mechanical: 1d-21 cylinder head cover relate parts inspection b827h11406041 refer to “engine top side disassembly (page 1d-10)”. Refer to “engine top side assembly (page 1d-13)” refer to “cylinder head cover disassembly and assembly (page 1d-20)”. Cylinder head cover distortion 1) remove the ...

Page 96

1d-22 engine mechanical: cylinder head disassembly and assembly b827h11406042 disassembly caution ! Be sure to identify each removed part as to its location, and lay the parts out in groups designated as “exhaust”, “intake”, so that each will be restored to the original location during assembly. 1) ...

Page 97

Engine mechanical: 1d-23 • insert the valves, with their stems coated with molybdenum oil solution all around and along the full stem length without any break. M/o: molybdenum oil (molybdenum oil solution) caution ! When inserting each valve, take care not to damage the lip of the stem seal. • insta...

Page 98

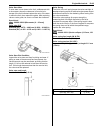

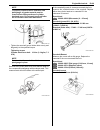

1d-24 engine mechanical: valve stem runout support the valve with v-blocks as shown, and check its runout with the dial gauge. The valve must be replaced if the runout exceeds the limit. Special tool : 09900–20607 (dial gauge (1/100 mm, 10 mm)) : 09900–20701 (magnetic stand) : 09900–21304 (v-block (...

Page 99

Engine mechanical: 1d-25 valve stem wear if valve stem is worn down to the limit, as measured with a micrometer. Where the clearance is found to be in excess of the limit indicated replace the valve, if the stem is within the limit, then replace the guide. After replacing valve or valve guide, be su...

Page 100

1d-26 engine mechanical: valve seat width 1) visually check for valve seat width on each valve face. If the valve face has worn abnormally, replace the valve. 2) coat the valve seat with a red lead (prussian blue)and set the valve in place. 3) rotate the valve with light pressure. Special tool (a): ...

Page 101

Engine mechanical: 1d-27 4) re-finish the valve guide holes in the cylinder head with the reamer and handle. Special tool : 09916–34580 (valve guide reamer (10.8 mm)) : 09916–34542 (reamer handle) 5) install a ring onto each valve guide. Be sure to use new rings. 6) cool down the new valve guides in...

Page 102

1d-28 engine mechanical: valve seat repair b827h11406027 the valve seats (1) for both the intake and exhaust valves are machined to three different angles. The seat contact surface is cut at 45 °. Caution ! • the valve seat contact area must be inspected after each cut. • do not use lapping compound...

Page 103

Engine mechanical: 1d-29 note to properly measure the oil clearance with plastigauge, all gasket material must be removed from fitting surfaces of cylinder head and cover. Do not apply bond until after the oil clearance has been determined. • tighten the camshaft journal holder bolts evenly and diag...

Page 104

1d-30 engine mechanical: cam chain tension adjuster inspection b827h11406020 the cam chain tension adjuster is maintained at the proper tension automatically. 1) remove the cam chain tension adjuster. Refer to “engine top side disassembly (page 1d-10)”. 2) check that the push rod slides smoothly whe...

Page 105

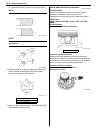

Engine mechanical: 1d-31 cylinder bore inspect the cylinder wall for any scratches, nicks or other damage.Measure the cylinder bore diameter at six places. Special tool : 09900–20530 (cylinder gauge set) cylinder bore service limit: 82.070 mm (3.2311 in) piston ring removal and installation b827h114...

Page 106

1d-32 engine mechanical: b) install the 2nd ring (3) and 1st ring (4) to piston. Note 1st ring (4) and 2nd ring (3) differ in shape. Note face the stamped mark “c” upward when assembling. 2) position the gaps of the three rings and side rails as shown. Before inserting piston into the cylinder, chec...

Page 107

Engine mechanical: 1d-33 piston ring-to-groove clearance using the thickness gauge, measure the side clearances of the 1st and 2nd piston rings. If any of the clearances exceeds the limit, replace both piston and piston rings. Special tool : 09900–20803 (thickness gauge) : 09900–20205 (micrometer (0...

Page 108

1d-34 engine mechanical: piston pin and pin bore using a small bore gauge, measure the piston pin bore inside diameter, using the micrometer, measure the piston pin outside diameter. If the reading exceeds following limit, replace both piston and piston pin. Special tool : 09900–20602 (dial gauge (1...

Page 109

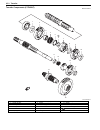

Engine mechanical: 1d-35 generator remove the generator component parts (1). Refer to “generator removal and installation in section 1j (page 1j-5)”. Starter system remove the starter idle gear no.1, no.2, and starter driven gear. Refer to “starter clutch removal and installation in section 1i (page...

Page 110

1d-36 engine mechanical: automatic transmission remove the automatic transmission component parts (1). Refer to “v-belt type continuously variable automatic transmission removal and installation in section 5a (page 5a-7)”. And “clutch shoe removal and installation in section 5a (page 5a-16)”. Gear p...

Page 111

Engine mechanical: 1d-37 crankcase 1) remove the crankcase bolts. 2) separate the crankcase with the special tool. Note • the crankcase separator plate is parallel with the end face of the crankcase. • the crankshaft must remain in the left crankcase half. Special tool (a): 09920–13120 (crankcase se...

Page 112

1d-38 engine mechanical: balancer 1) remove the balancershaft driven gear (1). 2) remove the key (2). 3) remove the balancershaft with the special tools. Special tool (a): 09930–30104 (rotor remover slide shaft) (b): 09930–30141 (attachment a) crankshaft 1) remove the crankshaft with the special too...

Page 113

Engine mechanical: 1d-39 speedometer gearbox remove the speedometer gearbox (1) and gasket (2). Transfer shift cam stopper remove the bolt, spring and transfer shift cam stopper (1) before removing the generator cover. Generator cover 1) remove the generator cover (1). 2) remove the dowel pins and g...

Page 114

1d-40 engine mechanical: gearshift system 1) remove the gearshift cam plate guide (1). 2) remove the gearshift shaft (2) and gearshift cam plate (3). Cam chain remove the cam chain (1). Oil filter remove the oil filter with the special tool. Special tool (a): 09915–40610 (oil filter wrench) oil pump...

Page 115

Engine mechanical: 1d-41 6) remove the pin (6) and washer (7). 7) remove the oil pump (8). 8) remove the dowel pins. Generator rotor 1) remove the generator rotor bolt with the special tool. Special tool (a): 09930–44541 (rotor holder) 2) install the special tool (attachment) to the crankshaft end. ...

Page 116

1d-42 engine mechanical: 2) remove the crankcase bolts. 3) separator the crankcase with the special tool. Note • the crankcase separator plate is parallel with the end face of the crankcase. • the crankcase must remain in the crankcase half. Special tool (a): 09920–13120 (crankcase separating tool) ...

Page 117

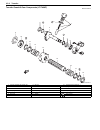

Engine mechanical: 1d-43 3) remove the front output shaft (4) and rear output shaft (5). (lt-f400f) 4) remove the rear output shaft (5). (lt-f400) balancer 1) remove the balancershaft driven gear (1). 2) remove the key (2). 3) remove the balancershaft with the special tools. Special tool (a): 09930–...

Page 118

1d-44 engine mechanical: crankshaft • when installing the crankshaft in the crankcase, it is necessary to pull its left end into the crankcase with the special tools. Special tool (a): 09910–32812 (crankshaft installer) (b): 09940–52861 (front fork oil seal installer) caution ! Never fit the cranksh...

Page 119

Engine mechanical: 1d-45 • install the washers (4), bearing (5) and gearshift shaft (6). • install the washer (7). • install the gearshift forks (8) (9) and transfer output shaft assembly (10). Note each gearshift fork has own embossed letters. • install the transfer input shaft assembly (11). • ins...

Page 120

1d-46 engine mechanical: • apply bond to the mating surface of the left crankcase. • assemble the crankcase within few minutes. • tighten the crankcase bolts to the specified torque. Note • tighten the larger diameter crankcase bolts first and then smaller ones diagonally and evenly. • fit the cramp...

Page 121

Engine mechanical: 1d-47 • install the oil pump driven gear (4) as shown in the figure. • install new snap ring. Caution ! Never reuse the removed snap ring. Special tool : 09900–06107 (snap ring pliers) • install the pin (5). • install the oil pump drive gear (6) and washer (7). • apply thread lock...

Page 122

1d-48 engine mechanical: • apply a bond lightly to the groove of the lead wire grommet. : sealant 99000–31140 (suzuki bond no.1207b or equivalent) automatic transmission • install the automatic transmission component parts (1). Refer to “v-belt type continuously variable automatic transmission remov...

Page 123

Engine mechanical: 1d-49 starter system • install the starter driven gear, starter idle gear no.1 and no.2. Refer to “starter clutch removal and installation in section 1i (page 1i-9)”. Generator • install the generator component parts (1). Refer to “generator removal and installation in section 1j ...

Page 124

1d-50 engine mechanical: starter motor • install the starter motor (1). Refer to “starter motor removal and installation in section 1i (page 1i-3)”. Lt-f400/f crankshaft • when mounting the crankshaft in the crankcase, it is necessary to pull its left end into the crankcase with the special tools. S...

Page 125

Engine mechanical: 1d-51 • install the c-ring (3). Note be sure to fit the pin “a” on the bearings into the groove of the crankcase. • install the driveshaft assembly (4), and countershaft assembly(5). • install the reverse idle gear shaft (6). • install the snap ring (7), washer (8) and spacer (9)....

Page 126

1d-52 engine mechanical: • install the gearshift forks (1), (2), (3), (4), gearshift cam (5) and reverse cam assembly (6). Note • each fork has own embossed letters. • face the letter upward (to the right side). Crankcase • wipe the crankcase mating surfaces (both surfaces) with a cleaning solvent. ...

Page 127

Engine mechanical: 1d-53 • assemble the crankcase within few minutes. • tighten the crankcase bolts to the specified torque. Note tighten the larger diameter crankcase bolts first and then smaller ones diagonally and evenly. Tightening torque crankcase bolt (m6): 11 n·m (1.1 kgf-m, 8.0 lb-ft) crankc...

Page 128

1d-54 engine mechanical: oil pump • install the dowel pins. • install the oil pump (1). • install the washer (2) and pin (3). • install the oil pump driven gear (4) as shown in the figure. Note install the oil pump driven gear as shown in the figure. • install new snap ring. Caution ! Never reuse th...

Page 129

Engine mechanical: 1d-55 oil filter • install the oil filter with the special tool. Refer to “engine oil and filter replacement in section 0b (page 0b-7)”. Special tool (a): 09915–40610 (oil filter wrench) cam chain install the cam chain (1). Gearshift • install the gearshift cam plate (1). • instal...

Page 130

1d-56 engine mechanical: gear position switch • install the springs and switch contacts. • install the gear position switch (1). • apply a bond lightly to the groove of the lead wire grommet. : sealant 99000–31140 (suzuki bond no.1207b or equivalent) transfer gearshift system install the transfer re...

Page 131

Engine mechanical: 1d-57 transfer gearshift cam stopper • install the transfer gearshift cam stopper (1) and spring into the bolt (2). • tighten the bolt (2) to the specified torque. Tightening torque transfer gearshift cam stopper bolt (a): 22 n·m ( 2.2 kgf-m, 16.0 lb-ft) speedometer gearbox • appl...

Page 132

1d-58 engine mechanical: conrod and crankshaft inspection b827h11406035 refer to “engine bottom side disassembly (page 1d- 34)”. Conrod small end i.D. Measure the conrod small end inside diameter with the dial calipers. If conrod small end inside diameter exceeds the service limit, replace the conro...

Page 133

Engine mechanical: 1d-59 width between crankshaft webs b827h11406036 measure the width between crankshaft webs “a”. Width between crankshaft webs “a” standard: 59.9 – 60.1 mm (2.36 – 2.37 in) crankshaft oil seal inspection b827h11406037 check the oil seals for damage. If any damage is found, replace...

Page 134

1d-60 engine mechanical: lt-f400/f generator cover bearing removal and installation b827h11406039 removal lt-a400/f left crankcase 1) remove the retainers. 2) remove the oil seal (1) with the special tool. Special tool (a): 09913–50121 (oil seal remover) 3) remove the transfer input shaft bearing an...

Page 135

Engine mechanical: 1d-61 2) remove the other bearings with the special tool. Special tool (c): 09913–70210 (bearing installer set) lt-f400/f left crankcase 1) remove the retainers. 2) remove the balancer shaft bearing with the special tool. Special tool (a): 09921–20240 (bearing remover set) 3) remo...

Page 136

1d-62 engine mechanical: 3) remove other bearings with the special tool. Special tool (a): 09913–70210 (bearing installer set) lt-a400/f generator cover 1) remove the magnet stator. Refer to “generator removal and installation in section 1j (page 1j-5)”. 2) remove the oil seal retainer. 3) remove th...

Page 137

Engine mechanical: 1d-63 lt-f400/f generator cover 1) remove the magnet stator. Refer to “generator removal and installation in section 1j (page 1j-5)”. 2) remove the oil seal retainer. 3) remove the oil seal (1) with the special tool. Special tool (a): 09913–50121 (oil seal remover) 4) remove the s...

Page 138

1d-64 engine mechanical: lt-a400/f left crankcase 1) install the bearings with the special tool. Caution ! Use the suitable size attachment for each bearing. Special tool (a): 09913–70210 (bearing installer set) 2) install the oil seal with the special tool. Special tool (a): 09913–70210 (bearing in...

Page 139

Engine mechanical: 1d-65 lt-f400/f left crankcase 1) install the bearings with the special tool. Caution ! Use the suitable size attachment for each bearing. Special tool (a): 09913–70210 (bearing installer set) 2) apply thread lock to the screws, and tighten them. : thread lock cement 99000–32110 (...

Page 140

1d-66 engine mechanical: • apply grease to bearing, o-ring and oil seal lip. • install the oil seal with the special tool. Special tool (a): 09913–70210 (bearing installer set) note when installing the oil seals, the stamped mark on the oil seal faces outside. : grease 99000–25010 (suzuki super grea...

Page 141

Engine mechanical: 1d-67 • apply grease to bearing, o-ring and oil seal lip. • install the oil seal with the special tool. Special tool (a): 09913–70210 (bearing installer set) note when installing the oil seals, the stamped mark on the oil seal faces outside. : grease 99000–25010 (suzuki super grea...

Page 142

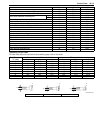

1d-68 engine mechanical: camshaft + cylinder head unit: mm (in) cylinder + piston + piston ring unit: mm (in) conrod + crankshaft unit: mm (in) item standard limit cam height in. & ex. 33.130 – 33.170 (1.3043 – 1.3059) 32.830 (1.2925) camshaft journal oil clearance φ 22 0.032 – 0.066 (0.0013 – 0.002...

Page 143

Engine mechanical: 1d-69 tightening torque specifications b827h11407002 note the specified tightening torque is also described in the following. “engine assembly installation (page 1d-9)” reference: for the tightening torque of fastener not specified in this section, refer to “tightening torque list...

Page 144

1d-70 engine mechanical: special tool b827h11408002 sealant suzuki bond no.1207b or equivalent p/no.: 99000–31140 ) (page 1d-13) / ) (page 1d-16) / ) (page 1d-17) / ) (page 1d-48) / ) (page 1d-52) / ) (page 1d-56) thread lock cement thread lock cement super 1303 or equivalent p/no.: 99000–32030 ) (p...

Page 145

Engine mechanical: 1d-71 09900–20607 09900–20701 dial gauge (1/100 mm, 10 mm) magnetic stand ) (page 1d-24) / ) (page 1d-24) / ) (page 1d-24) / ) (page 1d-29) / ) (page 1d-58) / ) (page 1d-58) ) (page 1d-24) / ) (page 1d-24) / ) (page 1d-24) / ) (page 1d-29) / ) (page 1d-58) / ) (page 1d-58) 09900–2...

Page 146

1d-72 engine mechanical: 09915–63311 09915–64512 compression gauge attachment compression gauge ) (page 1d-2) ) (page 1d-2) 09916–10911 09916–14510 valve lapper set valve spring compressor ) (page 1d-26) ) (page 1d-22) / ) (page 1d-23) 09916–14910 09916–34542 valve spring compressor attachment reame...

Page 147

Engine mechanical: 1d-73 09930–31921 09930–40113 rotor remover rotor holder ) (page 1d-41) / ) (page 1d-43) ) (page 1d-36) / ) (page 1d-40) / ) (page 1d-47) / ) (page 1d-54) 09930–44541 09940–52861 rotor holder front fork oil seal installer ) (page 1d-41) / ) (page 1d-53) ) (page 1d-44).

Page 148

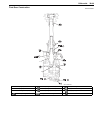

1e-1 engine lubrication system: engine engine lubrication system precautions precautions for engine oil b827h11500001 refer to “fuel and oil recommendation in section 0a (page 0a-3)”. Schematic and routing diagram engine lubrication system chart diagram b827h11502001 lt-a400/f oil sump filter orific...

Page 149

Engine lubrication system: 1e-2 lt-f400/f oil sump fil ter oil jet orifice oil fil ter oil cooler oil pump cylinder camshaft journal (center) st ar ter idle gear shaft primar y driven gear bushing clutch pla tes transfer input shaft bushing/gears countershaft bushing/gears genera t o r cover conrod ...

Page 150

1e-3 engine lubrication system: cylinder head cooling system chart diagram b827h11502002 oil sump filter orifice oil filter oil cooler oil pump cylinder head (ex) cylinder head cooling i827h1150003-01.

Page 151

Engine lubrication system: 1e-4 diagnostic information and procedures engine lubrication symptom diagnosis b827h11504001 oil pressure check b827h11504002 check the engine oil pressure periodically. This will give a good indication of the condition of the moving parts. Note before checking the oil pr...

Page 152

1e-5 engine lubrication system: 7) stop the engine and remove the oil pressure gauge and attachment. 8) reinstall the main oil gallery plug (1) and tighten it to the specified torque. Caution ! Use a new gasket to prevent oil leakage. Tightening torque main oil gallery plug (a): 23 n·m (2.3 kgf-m, 1...

Page 153

Engine lubrication system: 1e-6 oil sump filter inspection and cleaning b827h11506004 inspect the oil sump filter in the following procedures: 1) remove the oil sump filter. Refer to “oil sump filter removal and installation (page 1e-5)”. 2) if the oil sump filter is clogged with sediment or rust, c...

Page 154

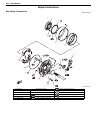

1e-7 engine lubrication system: 3) remove the oil pump drive gear (1) with holding the oil pump driven gear (2) using the special tool. Special tool (a): 09930–40113 (rotor holder) 4) remove the pin (3). 5) remove the snap ring (4) and oil pump driven gear. Special tool : 09900–06107 (snap ring plie...

Page 155

Engine lubrication system: 1e-8 • install the oil pump drive gear (3) so that its flange side faces side faces the crankcase side. • apply thread lock to the oil pump drive gear bolt. : thread lock cement 99000–32030 (thread lock cement super 1303 or equivalent) • tighten the oil pump drive gear bol...

Page 156

1e-9 engine lubrication system: oil cooler and oil hose components b827h11506009 oil cooler / oil cooler hose inspection and cleaning b827h11506010 oil cooler hose inspection inspect the oil cooler hoses in the following procedures: 1) remove the left inner fender. Refer to “exterior parts removal a...

Page 157

Engine lubrication system: 1e-10 oil cooler inspection inspect the oil cooler for oil leakage. If any defects are found, replace the oil cooler with a new one. If the fins are bent or dented, repair them by carefully straightening them with the blade of a small screwdriver. Refer to “oil cooler / oi...

Page 158

1e-11 engine lubrication system: • pass the oil hoses between the transfer cable and front brake pipe. • apply thread lock to the oil cooler hose bolts (engine side) (1) and tighten them to the specified torque. • clamp the oil hose (inlet) and speedometer cable. : thread lock cement 99000–32130 (th...

Page 159

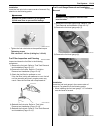

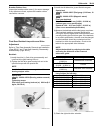

Engine lubrication system: 1e-12 cooling fan components b827h11506012 cooling fan inspection b827h11506013 inspect the cooling fan in the following procedures: 1) remove the left inner fender. Refer to “exterior parts removal and installation in section 9d (page 9d- 3)”. 2) disconnect the cooling fa...

Page 160

1e-13 engine lubrication system: cooling fan removal and installation b827h11506014 removal 1) remove the left inner fenders. Refer to “exterior parts removal and installation in section 9d (page 9d-3)”. 2) disconnect the cooling fan motor lead wire coupler (1). 3) remove the cooling fan bracket bol...

Page 161

Engine lubrication system: 1e-14 cooling fan thermo-switch inspection b827h11506016 inspect the cooling fan thermo-switch in the following procedures: 1) remove the cooling fan thermo-switch. Refer to “cooling fan thermo-switch removal and installation (page 1e-13)”. 2) check the thermo-switch closi...

Page 162

1e-15 engine lubrication system: engine oil temperature switch inspection b827h11506018 inspect the engine oil temperature switch in the following procedures: 1) remove the engine oil temperature switch. Refer to “engine oil temperature switch removal and installation (page 1e-14)”. 2) check the swi...

Page 163

Engine lubrication system: 1e-16 oil pressure regulator inspection b827h11506020 refer to “oil pressure regulator removal and installation (page 1e-15)”. Inspect the operation of the oil pressure regulator by pushing the piston with a proper bar. If the piston does not operate, replace the oil press...

Page 164

1e-17 engine lubrication system: tightening torque specifications b827h11507002 note the specified tightening torque is also described in the following. “oil cooler and oil hose components (page 1e-9)” “cooling fan components (page 1e-12)” reference: for the tightening torque of fastener not specifi...

Page 165

Engine lubrication system: 1e-18 09930–40113 rotor holder ) (page 1e-7) / )(page 1e- 8).

Page 166

1g-1 fuel system: engine fuel system precautions precautions for fuel system b827h11700001 warning ! Gasoline is highly flammable and explosive. Extreme care must be taken. Keep heat, sparks and flames away from gasoline. General description i.D. No. Location b827h11701002 each carburetor has an i.D...

Page 167

Fuel system: 1g-2 fuel system description b827h11701001 fuel system the fuel system consists of a fuel tank, fuel filter, fuel valve, vacuum hose, fuel hose and carburetor assembly. When there is negative pressure (vacuum) in the combustion chamber, the fuel is able to flow from the fuel tank, throu...

Page 168

1g-3 fuel system: fuel valve when the engine is not operating, the fuel valve (1) is kept closed by the tension of the spring (2), which closes the fuel passageway and stops the flow of fuel to the carburetor. When the engine has started, negative pressure (vacuum) “a” is generated in the combustion...

Page 169

Fuel system: 1g-4 diaphragm and piston operation the carburetor is a variable-venturi type, whose venturi cross sectional area is increased or decreased automatically by the piston valve (1). The piston valve moves according to the negative pressure present on the downstream side of the venturi “a”....

Page 170

1g-5 fuel system: slow system this system supplies fuel during engine operation when the throttle valve (1) is closed or slightly opened. The fuel from the float chamber (2) is metered by the slow jet (3) where it mixes with air coming in through the slow air jet (4). This mixture, rich with fuel, t...

Page 171

Fuel system: 1g-6 main system as the throttle valve (1) is opened, engine speed rises and negative pressure in the venturi “a” increases. This causes the piston valve (2) to move upward. The fuel in the float chamber (3) is metered by the main jet (4). The metered fuel enters the needle jet (5), mix...

Page 172

1g-7 fuel system: starter (enricher) system pulling the starter (enricher) plunger causes fuel to be drawn into the starter circuit from the float chamber (1). The starter jet (2) meters this fuel. The fuel then flows into the fuel pipe (3) and mixes with the air coming from the float chamber (1). T...

Page 173

Fuel system: 1g-8 transient enrichment system the transient enrichment system is a device which keeps fuel/air mixture ratio constant in order not to generate unstable combustion when the throttle grip is returned suddenly during high speed driving. For normal operation, sum of the air (1) and (2) k...

Page 174

1g-9 fuel system: float system the float (1) and needle valve (2) work in conjunction with one another. As the float (1) moves up and down, so does the needle valve (2). When there is a high fuel level in the float chamber (3), the float (1) rises and the needle valve (2) pushes up against the valve...

Page 175

Fuel system: 1g-10 schematic and routing diagram carburetor hose routing diagram b827h11702001 lh rh [a] lh rh [b] 1 3 2 3 2 3 2 up “a” i827h1170040-02 1. Vacuum hose 3. Air vent hose [a]: intake pipe side 2. Fuel hose “a” clamp end should face downward. [b]: air cleaner side.

Page 176

1g-11 fuel system: diagnostic information and procedures carburetor symptom diagnosis b827h11704001 condition possible cause correction / reference item starting difficulty clogged starter jet. Clean. Clogged starter jet passage. Clean. Air leaking from joint between starter body and carburetor. Tig...

Page 177

Fuel system: 1g-12 repair instructions fuel tank construction b827h11706018 1 2 3 (a) “ a ” 4 3 3 4 i827h1170041-02 1. Fuel tank upper cover “a”: 29 mm (1.14 in) 2. Fuel tank : 4.6 n ⋅m (0.46 kg-f, 3.5 lb-ft) 3. Fuel tank cushion : do not reuse. 4. Frame.

Page 178

1g-13 fuel system: fuel tank removal and installation b827h11706009 removal warning ! • keep away from fire or spark. • spilled gasoline should be wiped off immediately. • work in a well-ventilated area. 1) remove the side covers. Refer to “exterior parts removal and installation in section 9d (page...

Page 179

Fuel system: 1g-14 installation install the fuel valve in the reverse order of removal. Pay attention to the following points: warning ! Replace the gasket washers (1) and gasket (2) with new ones to prevent fuel leakage. • tighten the fuel valve bolts to the specified torque. Tightening torque fuel...

Page 180

1g-15 fuel system: fuel level gauge inspection b827h11706007 inspect the fuel level gauge as follows: 1) inspect the float (1) of the fuel gauge assembly moves smoothly. 2) inspect that the needle moves correctly as the float of the fuel gauge assembly moves up and down as shown in the illustration....

Page 181

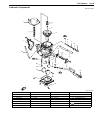

Fuel system: 1g-16 carburetor components b827h11706027 1 5 7 28 2 3 4 8 9 10 11 6 14 13 15 12 17 18 19 16 24 27 26 23 29 25 21 20 22 fwd fw d i827h1170042-02 1. Top cap 9. Spring 17. Needle jet 24. Float pin 2. Spring retainer 10. Holder 18. Needle jet holder 25. Pilot screw 3. Jet needle 11. Cap 19...

Page 182

1g-17 fuel system: carburetor assembly removal and installation b827h11706028 warning ! Gasoline is highly flammable and explosive. Keep heat, spark and flame away. Removal 1) turn the fuel valve on position. 2) remove the side cover. Refer to “exterior parts removal and installation in section 9d (...

Page 183

Fuel system: 1g-18 3) remove the carburetor top cap (8). Caution ! Do not use compressed air on the carburetor body before removing the diaphragm; this may damage the diaphragm. 4) remove the spring (9), spring retainer (10), spacer (11), jet needle (12) and diaphragm (13). 5) remove the float chamb...

Page 184

1g-19 fuel system: 9) remove the following parts. • main jet (20) • needle jet holder (21) • needle jet (22) • slow jet (23) • starter jet (24) • pilot screw (25) note before removing the pilot screw (25), its setting must be determined. Slowly turn the pilot screw clockwise and count the number of ...

Page 185

Fuel system: 1g-20 carburetor assembly b827h11706030 reassemble the carburetor in the reverse order of disassembly. Pay attention to the following points: • apply thin coat of the grease to new pilot screw o- ring. Caution ! Replace the o-ring with new one. : grease 99000–25010 (suzuki super grease ...

Page 186

1g-21 fuel system: float height inspection and adjustment b827h11706031 inspect and adjust the float height in the following procedures: 1) remove the carburetor assembly. Refer to “carburetor assembly removal and installation (page 1g-17)”. 2) remove the float chamber body. Refer to “carburetor dis...

Page 187

Fuel system: 1g-22 cleaning warning ! Some carburetor cleaning chemicals, especially dip-type soaking solutions, are very corrosive and must be handled carefully. Always follow the chemical manufacturer’s instructions on proper use, handling and storage. 1) clean all jets with a spray-type carbureto...

Page 188

1g-23 fuel system: fuel tightening torque specifications b827h11707002 note the specified tightening torque is also described in the following. “fuel tank construction (page 1g-12)” reference: for the tightening torque of fastener not specified in this section, refer to “tightening torque list (lt-a...

Page 189

Ignition system: 1h-1 engine ignition system schematic and routing diagram ignition system diagram b827h11802001 refer to “wire color symbols in section 0a (page 0a-4)”. Ignition system components location b827h11802002 refer to “electrical components location in section 0a (page 0a-6)”. Diagnostic ...

Page 190

1h-2 ignition system: no spark or poor spark b827h11804002 troubleshooting note check that the transfer is in neutral and the engine stop switch is in the “run” position. Check that the fuse is not blown and the battery is fully-charged before diagnosing. Spark plug quickly becomes fouled with oil o...

Page 191

Ignition system: 1h-3 repair instructions spark plug removal and installation b827h11806001 removal warning ! The hot engine can burn you. Wait until the engine is cool enough to touch. 1) turn the ignition switch off. 2) remove the left side cover. Refer to “exterior parts removal and installation ...

Page 192

1h-4 ignition system: 4) connect the multi-circuit tester with the peak voltage adaptor as follows: caution ! Before using the multi-circuit tester and peak voltage adaptor, refer to the appropriate instruction manual. Note do not disconnect the ignition coil lead wires. Special tool : 09900–25008 (...

Page 193

Ignition system: 1h-5 ignition coil removal and installation b827h11806010 remove 1) remove the fuel tank. Refer to “fuel tank removal and installation in section 1g (page 1g-13)”. 2) disconnect the spark plug cap. 3) disconnect the lead wires (1) and remove the ignition coil (2). Installation insta...

Page 194

1h-6 ignition system: ckp sensor resistance 1) remove the left side cover and left footrest mudguard. Refer to “exterior parts removal and installation in section 9d (page 9d-3)”. 2) disconnect the ckp sensor coupler (1). 3) measure the resistance between the lead wires and ground. If the resistance...

Page 195

Ignition system: 1h-7 3) disconnect the ignition switch coupler (1) (green). Installation install the ignition switch in the reverse order of removal. Pay attention to the following point: • route the wiring harness properly. Refer to “wiring harness routing diagram in section 9a (page 9a-8)”. Speci...

Page 196

1i-1 starting system: engine starting system schematic and routing diagram starting system diagram b827h11902001 refer to “wire color symbols in section 0a (page 0a-4)”. Component location starting system components location b827h11903001 refer to “electrical components location in section 0a (page ...

Page 197

Starting system: 1i-2 starter motor will not run b827h11904002 note make sure the fuses are not blown and the battery is fully-charged before diagnosing. Troubleshooting starter motor runs but does not crank the engine b827h11904003 the starter motor runs when the transfer is in neutral, but does no...

Page 198

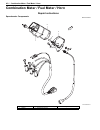

1i-3 starting system: repair instructions starter motor components b827h11906001 starter motor removal and installation b827h11906002 removal 1) turn the ignition switch off and disconnect the battery (–) lead wire. Refer to “battery removal and installation in section 1j (page 1j-13)”. 2) remove th...

Page 199

Starting system: 1i-4 • tighten the starter motor mounting bolts (1) with the engine ground lead wire (2) and starter motor lead wire mounting nut (3) to the specified torque. Refer to “wiring harness routing diagram in section 9a (page 9a-8)”. Tightening torque starter motor mounting bolt (a): 10 n...

Page 200

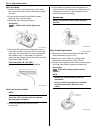

1i-5 starting system: carbon brush inspect the carbon brushes for abnormal wear, cracks or smoothness in the brush holder. If either carbon brush is defective, replace the brush holder set with a new one. Measure the length “a” of the carbon brushes using a vernier calipers. If the measurement is le...

Page 201

Starting system: 1i-6 6) disconnect the starter motor lead wire (4) and battery (+) lead wire (5). 7) remove the starter relay. Installation install the starter relay in the reverse order of removal. Starter relay inspection b827h11906006 inspect the starter relay in the following procedures: 1) rem...

Page 202

1i-7 starting system: 3) remove the neutral relay (1). Installation install the neutral relay in the reverse order of removal. Neutral relay inspection b827h11906008 inspect the neutral relay in the following procedures: 1) remove the neutral relay. Refer to “neutral relay removal and installation (...

Page 203

Starting system: 1i-8 4) connect the neutral switch diode. 5) install the left inner fender. Refer to “exterior parts removal and installation in section 9d (page 9d- 3)”. Ignition / starter control relay removal and installation b827h11906010 removal 1) remove the rear fender. Refer to “exterior pa...

Page 204

1i-9 starting system: 2) disconnect the gear position switch coupler (1). 3) inspect the gear position switch for continuity with the tester. If any abnormality is found, replace the gear position switch with a new one. Refer to “gear position (gp) switch removal and installation (lt- a400/f) in sec...

Page 205

Starting system: 1i-10 6) hold the generator rotor with the special tool and remove the starter clutch bolts. Special tool (a): 09930–44541 (rotor holder) 7) remove the one way clutch (6) from the guide (7). Installation install the starter clutch in the reverse order of removal. Pay attention to th...

Page 206

1i-11 starting system: starter driven gear bearing removal and installation b827h11906015 removal 1) remove the starter driven gear. Refer to “starter clutch removal and installation (page 1i-9)”. 2) remove the bearing with the special tool. Special tool (a): 09913–70210 (bearing installer set) inst...

Page 207

Starting system: 1i-12 starter idle gear inspect the starter idle gear no.1 (1) and no.2 (2) for wear or damage. If any damage is found, replace it with a new one. Starter button inspection b827h11906017 inspect the starter button in the following procedures: 1) remove the left inner fender. Refer t...

Page 208

1i-13 starting system: recoil starter assembly removal and installation b827h11906019 removal 1) remove the left side cover and left footrest mudguard. Refer to “exterior parts removal and installation in section 9d (page 9d-3)”. 2) remove the recoil starter assembly (1). Installation install the re...

Page 209

Starting system: 1i-14 4) disengage the rope (9) from the handle (10). 5) hook the rope to groove “a” of the reel (11). 6) turn the rope on the reel (11) properly. 7) remove the reel (11). 8) remove the spiral spring (12). Assembly assemble the recoil starter in the reverse order of disassembly. Pay...

Page 210

1i-15 starting system: • connect the handle (1) to the rope (2). • install the ratchet related parts. • apply grease to the shaft and ratchet guide. : grease 99000–25010 (suzuki super grease a or equivalent) • tighten the nut to the specified torque. Tightening torque recoil starter center nut (a): ...

Page 211

Starting system: 1i-16 reel inspect the reel for wear or damage. If any defects are found, replace the reel with a new one. Rope inspect the rope for damage. If any defects are found, replace the rope with a new one. Specifications service data (lt-a400/f, lt-f400/f) b827h11907001 unit: mm (in) tigh...

Page 212

1i-17 starting system: note required service material is also described in the following. “starter motor components (page 1i-3)” “recoil starter components (page 1i-12)” special tool b827h11908002 09900–20102 09900–25008 vernier calipers (1/20 mm, 200 mm) multi-circuit tester set ) (page 1i-5) ) (pa...

Page 213

Charging system: 1j-1 engine charging system schematic and routing diagram charging system diagram b827h11a02001 component location charging system components location b827h11a03001 refer to “electrical components location in section 0a (page 0a-6)”. Diagnostic information and procedures charging sy...

Page 214

1j-2 charging system: battery runs down quickly b827h11a04002 troubleshooting unstable charging lead wire insulation frayed due to vibration, resulting in intermittent short- circuiting. Repair or replace. Internally short-circuited generator. Replace. Defective regulator/rectifier. Replace. Battery...

Page 215

Charging system: 1j-3 repair instructions battery current leakage inspection b827h11a06001 inspect the battery current leakage in the following procedures: 1) turn the ignition switch off. 2) remove the seat. Refer to “exterior parts removal and installation in section 9d (page 9d-3)”. 3) disconnect...

Page 216

1j-4 charging system: generator inspection b827h11a06003 generator coil resistance 1) remove the left side cover and left footrest mudguard. Refer to “exterior parts removal and installation in section 9d (page 9d-3)”. 2) connect the tachometer to the spark plug high tension cord. 3) disconnect the ...

Page 217

Charging system: 1j-5 generator removal and installation b827h11a06004 removal 1) disconnect the (–) battery lead wire. Refer to “battery removal and installation (page 1j-13)”. 2) drain engine oil. Refer to “engine oil and filter replacement in section 0b (page 0b-7)”. 3) remove the left side cover...

Page 218

1j-6 charging system: 12) remove the generator cover (10). 13) remove the gasket (11) and dowel pins. 14) hold the generator rotor with the special tool and remove the generator rotor nut. Special tool (a): 09930–44541 (rotor holder) 15) install the special tool (attachment) to the crankshaft end. S...

Page 219

Charging system: 1j-7 18) remove the generator stator (15) along with the ckp sensor (16). Installation install the generator in the reverse order of removal. Pay attention to the following points: • tighten the generator stator set bolts and ckp sensor mounting bolts to the specified torque. Note b...

Page 220

1j-8 charging system: • install the dowel pins and new gasket (3). Caution ! Use a new gasket to prevent oil leakage. • install the generator cover and tighten the generator cover bolts. Caution ! Fit the clamp to the bolt “c”. Refer to “wiring harness routing diagram in section 9a (page 9a-8)”. • f...

Page 221

Charging system: 1j-9 • when installing the transfer gearshift arm, align the wide spline teeth of the arm and shaft. • install the gearshift link arm in the following angle. (lt- f400/f). • connect the oil hose. Refer to “oil cooler / oil cooler hose removal and installation in section 1e (page 1e-...

Page 222

1j-10 charging system: regulator / rectifier inspection b827h11a06005 inspect the regulator/rectifier in the following procedures: 1) turn the ignition switch off. 2) remove the rear fender. Refer to “exterior parts removal and installation in section 9d (page 9d-3)”. 3) disconnect the coupler and r...

Page 223

Charging system: 1j-11 battery components b827h11a06006 battery charging b827h11a06007 initial charging filling electrolyte note when filling electrolyte, the battery must be removed from the vehicle and must be put on the level ground. 1) remove the aluminum tape (1) which seals the battery filler ...

Page 224

1j-12 charging system: 5) make sure that air bubbles (4) rise to the top of each electrolyte container, and leave in this position for about more than 20 minutes. Note if no air bubbles come out from a filler port, tap the bottom of the electrolyte container two or three times. Never remove the cont...

Page 225

Charging system: 1j-13 battery recharging caution ! Do not remove the caps on the battery top while recharging. Note when the vehicle is not used for a long period, check the battery every 1 month to prevent the battery discharge. 1) remove the battery from the vehicle. Refer to “battery removal and...

Page 226

1j-14 charging system: specifications service data (lt-a400/f, lt-f400/f) b827h11a07001 battery caution ! Never use anything except the specified battery. Generator tightening torque specifications b827h11a07002 reference: for the tightening torque of fastener not specified in this section, refer to...

Page 227

Charging system: 1j-15 09930–31921 09930–44541 rotor remover rotor holder ) (page 1j-6) ) (page 1j-6) / )(page 1j- 7).

Page 228

1k-1 exhaust system: engine exhaust system precautions precautions for exhaust system b827h11b00001 warning ! To avoid the risk of being burned, do not touch the exhaust system when the system is hot. Any service on the exhaust system should be performed when the system is cool. Caution ! Make sure ...

Page 229

Exhaust system: 1k-2 muffler / exhaust pipe removal and installation b827h11b06002 removal 1) remove the right inner fender. Refer to “exterior parts removal and installation in section 9d (page 9d-3)”. 2) remove the rear fender. Refer to “exterior parts removal and installation in section 9d (page ...

Page 230

1k-3 exhaust system: • tighten the exhaust pipe nuts (3) and exhaust pipe mounting bolt (4) to the specified torque. Tightening torque exhaust pipe nut (a): 18 n·m (1.8 kgf-m, 13.0 lb-ft) exhaust pipe mounting bolt (b): 23 n·m (2.3 kgf- m, 16.5 lb-ft) • install the muffler. • tighten the muffler mou...

Page 231

Exhaust system: 1k-4 specifications tightening torque specifications b827h11b07001 note the specified tightening torque is also described in the following. “exhaust system components (page 1k-1)” reference: for the tightening torque of fastener not specified in this section, refer to “tightening tor...

Page 232

1k-5 exhaust system:.

Page 233

Table of contents 2- i 2 section 2 contents suspension precautions .................................................2-1 precautions............................................................. 2-1 precautions for suspension .................................. 2-1 suspension general diagnosis............

Page 234

2-1 precautions: suspension precautions precautions precautions for suspension b827h12000001 refer to “general precautions in section 00 (page 00-1)”. Warning ! All suspensions, bolts and nuts are an important part in that it could affect the performance of vital parts. They must be tightened to the...

Page 235

Suspension general diagnosis: 2a-1 suspension suspension general diagnosis diagnostic information and procedures suspension and wheel symptom diagnosis b827h12104001 condition possible cause correction / reference item wobbly front wheel distorted wheel rim. Replace. Worn hub bearings. Replace. Defe...

Page 236

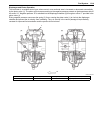

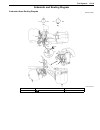

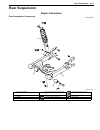

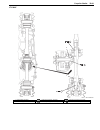

2b-1 front suspension: suspension front suspension repair instructions front suspension components b827h12206001 1 2 3 (a) 13 (c) 15 9 10 4 6 7 8 7 5 11 12 12 (e) 17 11 fwd fw d fwd fw d (c) 15 (b) 14 (b) 16 i827h1220045-05 1. Front shock absorber 10. Bushing : 60 n ⋅m (6.0 kgf-m, 43.5 lb-ft) 2. Upp...

Page 237

Front suspension: 2b-2 front suspension assembly construction b827h12206002 8. Outer dust seal 17. Tie rod end nut 9. Lower suspension arm : 55 n ⋅m (5.5 kgf-m, 40.0 lb-ft) (a) 1 (g) 7 (b) 2 (c) 3 (j) 10 11 (i) 9 (k) 12 (h) 8 (e) 5 (g) 7 (e) 5 (d) 4 (f) 6 i827h1220001-04 1. Front shock absorber moun...

Page 238

2b-3 front suspension: front suspension inspection b827h12206004 refer to “suspension inspection in section 0b (page 0b-19)”. Front shock absorber inspection b827h12206005 inspect the front shock absorber for damage and oil leakage, and absorber bushing for wear or damage. If any defects are found, ...

Page 239

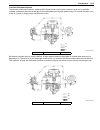

Front suspension: 2b-4 5) remove the front disc cover (6). 6) remove the cotter pin, tie-rod end nut and washer. 7) disengage the tie-rod end with the special tool. Warning ! When using the tie-rod end remover, keep clear of the tie-rod end because it may come loose with some force and could strike ...

Page 240

2b-5 front suspension: • connect the tie-rod end to the steering knuckle and tighten the tie-rod end nut to the specified torque. Tightening torque tie-rod end nut (b): 29 n·m (2.9 kgf-m, 21.0 lb-ft) • install new cotter pin (1). Caution ! The removed cotter pin (1) must be replaced with a new one. ...

Page 241

Front suspension: 2b-6 • tighten the front hub nut to the specified torque. Tightening torque front hub nut (d): 110 n·m (11.0 kgf-m, 79.5 lb-ft) • install the cotter pin (3). Caution ! The removed cotter pin (3) must be replaced with a new one. Front wheel hub / steering knuckle related parts inspe...

Page 242

2b-7 front suspension: 2) remove the wheel hub bearings with the special tools. Special tool (a): 09923–74511 (bearing remover) (b): 09930–30104 (rotor remover slide shaft) installation install the wheel hub bearings and steering knuckle dust seals in the reverse order of removal. Pay attention to t...

Page 243

Front suspension: 2b-8 • install the steering knuckle dust seals using the special tool. Caution ! Removed oil seal must be replaced with a new one. Special tool (a): 09913–70210 (bearing installer set) front suspension upper / lower arm removal and installation b827h12206010 removal 1) remove the f...

Page 244

2b-9 front suspension: installation 1) apply thread lock to the suspension arm pivot bolts (lower). : thread lock cement 99000–32030 (thread lock cement super 1303 or equivalent) 2) temporarily tighten the suspension arm pivot nuts (lower) (1). 3) install the steering knuckle (2) and suspension uppe...

Page 245

Front suspension: 2b-10 suspension arm inspect the suspension arm for wear or damage. If any damages are found, replace the suspension arm with a new one. Bushing inspect the rubber bushing (suspension arm) for wear or other damage. If any damages are found, replace the bushing with a new one. Refer...

Page 246

2b-11 front suspension: installation 1) install the knuckle end with the special tool. Special tool (a): 09913–70210 (bearing installer set) 2) install the snap ring (1) with the special tool. Caution ! Replace the snap ring (1) with a new one. Special tool : 09900–06107 (snap ring pliers) 3) instal...

Page 247

Front suspension: 2b-12 specifications tightening torque specifications b827h12207001 note the specified tightening torque is also described in the following. “front suspension components (page 2b-1)” “front suspension assembly construction (page 2b-2)” reference: for the tightening torque of fasten...

Page 248

2b-13 front suspension: special tool b827h12208002 09900–06107 09913–50121 snap ring pliers oil seal remover ) (page 2b-10) / ) (page 2b-11) ) (page 2b-6) 09913–70210 09923–74511 bearing installer set bearing remover ) (page 2b-7) / )(page 2b- 8) / )(page 2b-11) ) (page 2b-7) 09930–30104 09942–72410...

Page 249

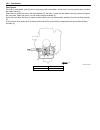

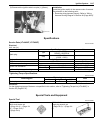

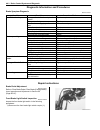

Rear suspension: 2c-1 suspension rear suspension repair instructions rear suspension components b827h12306001 1 (a) 4 2 3 3 (b) 5 (c) 6 i827h1230011-01 1. Rear shock absorber 5. Rear shock absorber mounting lower nut : 102 n ⋅m (10.2 kgf-m, 74.0 lb-ft) 2. Swingarm 6. Swingarm pivot nut : apply threa...

Page 250

2c-2 rear suspension: rear shock absorber removal and installation b827h12306003 removal 1) place the vehicle on level ground and support the vehicle with a jack. Caution ! Make sure that the vehicle is supported securely. 2) remove the rear shock absorber (1). Installation install the rear shock ab...

Page 251

Rear suspension: 2c-3 6) remove the rear shock absorber lower mounting bolts (2). 7) remove the swingarm (3). Installation install the swingarm in the reverse order of removal. Pay attention to the following points: • apply thread lock to the swingarm pivot bolts. : thread lock cement 99000–32030 (t...

Page 252

2c-4 rear suspension: swingarm bushing removal and installation b827h12306019 refer to “swingarm removal and installation (page 2c- 2)”. Removal remove the swingarm bushings using a hydraulic press and suitable tools. Installation install the swingarm bushings using a hydraulic press and suitable to...

Page 253