- DL manuals

- Suzuki

- Offroad Vehicle

- LT-A50

- Service Manual

Suzuki LT-A50 Service Manual

Summary of LT-A50

Page 1

9 9 5 0 0 - 2 0 2 1 2 - 0 1 e lt-a50

Page 2: Group Index

Group index 1 foreword this manual contains an introductory description on the suzuki lt-a50 and procedures for its inspec- tion/service and overhaul of its main components. Other information considered as generally known is not included. Read the general information section to fa- miliarize yoursel...

Page 3: How To Use This Manual

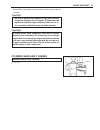

How to use this manual to locate what you are looking for: 1. The text of this manual is divided into sections. 2. The section titles are listed in the group index. 3. Holding the manual as shown at the right will allow you to find the first page of the section easily. 4. The contents are listed on ...

Page 4

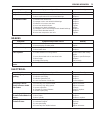

Symbol (for usa) listed in the table below are the symbols indicating instructions and other information necessary for servic- ing. The meaning of each symbol is also included in the table. Torque control required. Data beside it indicates specified torque. Apply oil. Use engine oil unless otherwise...

Page 5

Symbol (for the other countries) listed in the table below are the symbols indicating instructions and other information necessary for servic- ing. The meaning of each symbol is also included in the table. Torque control required. Data beside it indicates specified torque. Apply oil. Use engine oil ...

Page 6: General Information

General information 1-1 1 general information warning/caution/note ............................................................. 1- 2 general precautions .............................................................. 1- 2 suzuki lt-a50k2 (2002-model) ....................................................

Page 7: Warning/caution/note

1-2 general information warning/caution/note please read this manual and follow its instructions carefully. To emphasize special information, the symbol and the words warning, caution and note have special meanings. Pay special attention to the mes- sages highlighted by these signal words. ! Indicat...

Page 8

General information 1-3 " * if parts replacement is necessary, replace the parts with suzuki genuine parts or their equiva- lent. * when removing parts that are to be reused, keep them arranged in an orderly manner so that they may be reinstalled in the proper order. * be sure to use special tools w...

Page 9: Serial Number Location

1-4 general information suzuki lt-a50k2 (2002-model) * difference between photographs and the actual vehicles depends on the markets. Serial number location the frame serial number or v.I.N. (vehicle identification number) 1 is stamped on the left side of the frame pipe. The engine serial number 2 i...

Page 10: Break-In Procedures

General information 1-5 fuel (for the other countries) gasoline used should be graded 91 octane or higher. An unleaded gasoline is recommended. Engine oil (for usa) use suzuki cci super 2-cycle motor lubricant or an equivalent good quality synthetic based 2-stroke engine oil rated fc under the jaso ...

Page 11: Information Labels

1-6 general information information labels no label or plate name applied specification p02 p03 p28 1 certification plate 2 compliance label 3 manual notice label 4 parking brake label e 5 parking brake label f 6 tire pressure label e 7 tire pressure label f 8 general warning label e 9 general warni...

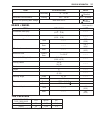

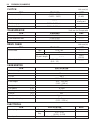

Page 12: Specifications

General information 1-7 specifications dimensions and dry mass overall length ................................................................... 1 260 mm (49.6 in) overall width .................................................................... 760 mm (29.9 in) overall height .......................

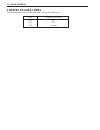

Page 13: Country Or Area Codes

1-8 general information country or area codes the following codes stand for the applicable country(-ies) and area(-s). Code country or area p-02 uk p-03 usa p-28 canada.

Page 14: Periodic Maintenance

Periodic maintenance 2-1 2 periodic maintenance contents periodic maintenance schedule ......................................... 2- 2 periodic maintenance chart ............................................. 2- 2 lubrication points ................................................................ 2- 3...

Page 15

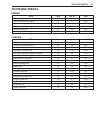

2-2 periodic maintenance interval initial every every item 1 month 3 months 6 months air cleaner – c – cylinder head, cylinder and muffler – c c spark plug – c r throttle cable i i i idle speed i i i fuel line i i i replace every 4 years transmission oil r – r drive chain clean, lubricate and inspec...

Page 16

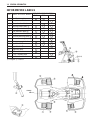

Periodic maintenance 2-3 drive chain brake cable steering shaft holder trottle cable trottle lever lubrication points proper lubrication is important for smooth operation and long life of each working part of the vehicle. Major lubrication points are indicated below. Note: * before lubricating each ...

Page 17

2-4 periodic maintenance maintenance and tune-up procedures this section describes the servicing procedures for each item in the periodic maintenance chart. • fill a container with a non-flammable cleaning solvent. • immerse the air cleaner element in the cleaning solvent and wash it. • squeeze the ...

Page 18

Periodic maintenance 2-5 • reinstall the cleaned air cleaner element in the reverse order of removal. ! * be sure to position the element snugly and correctly, so that no incoming air will by-pass it. Remember, the rapid wear of piston rings and the cylinder bore is of- ten caused by a defective or ...

Page 19

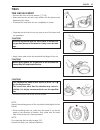

2-6 periodic maintenance 0.5 – 0.6 mm (0.020 – 0.024 in) spark plug clean every 3 months. Replace every 6 months. Neglecting the spark plug maintenance will eventually leads to difficult starting and poor engine performance. If the spark plug is used for a long period, the electrode gradually burns ...

Page 20

Periodic maintenance 2-7 engine idle speed inspect initially at 1 month and every 3 months thereaf- ter. • adjust the throttle cable play. (see above.) • warm up the engine. Note: make this adjustment when the engine is hot. • start the engine, turn the throttle stop screw 1 and set the en- gine idl...

Page 21

2-8 periodic maintenance transmission oil change initially at 1 month and every 6 months thereaf- ter. After a long period of use, the transmission oil will deteriorate and quicken the wear of sliding and interlocking surfaces. Replace the transmission oil periodically. Refer to the following proced...

Page 22

Periodic maintenance 2-9 • count out 21 pins (20-pitch) on the chain measure the distance between the two points. If the distance exceeds the service limit, the chain must be replaced. $ drive chain 20-pitch length: 259.0 mm (10.20 in) note: when replacing the drive chain, replace the drive chain an...

Page 23

2-10 periodic maintenance brakes inspect initially at 1 month and every 3 months thereaf- ter. Front brake lever play • turn the adjusting nuts 1 so that the brake lever play a is within specification. $ front brake lever play a : 3 – 7 mm (0.12 – 0.28 in) rear brake lever play • turn the adjusting ...

Page 24

Periodic maintenance 2-11 tires inspect every months. Tire pressure if the tire pressure is too high or too low, steering will be adversely affected and tire wear increased. Therefore, maintain the correct tire pressure for good roadability and a longer tire life. Cold infla- tion tire pressure is a...

Page 25

2-12 periodic maintenance suspension inspect every 6 months thereafter. Inspect the front and rear shock absorbers for oil leakage and wear. Replace the defective part if necessary. Tire tread condition operating the vehicle with excessively worn tires will decrease riding stability and consequently...

Page 26

Periodic maintenance 2-13 spark arrester clean every 6 months. • put the range lever into neutral and set the parking brake. • remove the drain bolts 1 . • start the engine and fully open the throttle several times to blow out the accumulated carbon particles. • stop the engine, and replace the drai...

Page 27

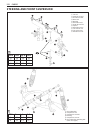

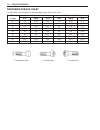

2-14 periodic maintenance chassis bolts and nuts tighten initially at 1 month and every 3 months thereafter. Check that all chassis bolts and nuts are tightened to their specified torque. (refer to page 2-15 for the locations of the following bolts and nuts on the motorcycle.) item n.M kgf.M lb-ft 1...

Page 28

Periodic maintenance 2-15 ,,.

Page 29: Lock-Up Inspection

2-16 periodic maintenance initial engagement and clutch lock-up inspection the lt-a50 is equipped with a centrifugal type automatic clutch. To insure proper performance and longevity of the clutch assem- blies it is essential that the clutches engage smoothly and gradu- ally. Before checking the ini...

Page 30

Periodic maintenance 2-17 clutch lock-up inspection perform this inspection to determine if the clutch is engaging fully and not slipping. • connect a tachometer onto the spark plug lead. • start the engine. • apply the front and rear brakes as firmly as possible. • fully open the throttle for a bri...

Page 31: Engine

Engine 3-1 3 engine contents engine components removable with the engine in place .............................................................................................. 3- 2 engine removal and remounting ............................................ 3- 3 engine removal ..........................

Page 32

3-2 engine engine components removable with the engine in place the parts listed below can be removed and reinstalled without removing the engine from the frame. Refer to the pages listed in each section for removal and reinstallation instructions. Engine left side engine sprocket .....................

Page 33

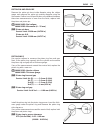

Engine 3-3 engine removal and remounting engine removal before taking the engine out of the frame, wash the engine using a steam cleaner. Engine removal is sequentially explained in the following steps. • drain the transmission oil. ( ! 2-8) • remove the seat. ( ! 5-2) • remove the frame cover. ( ! ...

Page 34

3-4 engine • remove the clamp. • remove the recoil starter bolt. • loosen the screw. • remove the carburetor assembly. • remove the oil tank 1 . • disconnect the generator lead wire and remove the spark plug cap 2 ..

Page 35

Engine 3-5 • remove the engine sprcket cover 1 . • remove the drive chain 2 . • remove the engine mounting bolts..

Page 36

3-6 engine engine remounting remount the engine in the reverse order of engine removal. • apply a small quantity of thread lock “1342” to the threasds of engine mounting nut b and c. " " " " " 99000-32050: thread lock “1342” • tighten the engine mounting nuts to the specified torque. # engine mounti...

Page 37

Engine 3-7 • install the drive chain. $ the drive chain joint clip should attached in the way that the slit end will face opposite the direction of travel. • pour the specified amount of transmission oil in to the crank- case. ( ! 2-8) % oil change : 500 ml (0.53/0.44 us/imp qt) overhaul : 550 ml (0...

Page 38

3-8 engine power reduction plate the power reduction plate 1 has been attached inside the exhaust flange as shown in the illustrations. & do not remove the power reduction plate until the rider develops sufficient skills to operate lt-a50 safety at the maximum speed with the power reduction system i...

Page 39: Engine Disassembly

Engine 3-9 engine disassembly • remove the rear brake cable guide 1 . • remove the cylinder head and cylinder. • place a clean rag over the cylinder base to prevent the piston pin circlip from dropping into the crankcase. • remove the piston pin circlip 2 . • remove the piston pin and piston. • remo...

Page 40

3-10 engine • remove the clutch cover. • hold the generator rotor using the special tool. • remove the clutch sleeve nut. ' 09930-40113: rotor holder • remove the thrust washer 1 , wave washer 2 and clutch guide plate 3 . • remove the washer 4 and clutch shoe assembly, clutch drum. • remove the circ...

Page 41

Engine 3-11 • remove the oil guide bearing retainer plate. • remove the spacer 1 and washer 2 . • hold the generator rotor using the special tool. • remove the generator rotor nut. ' 09930-40113: rotor holder • remove the generator rotor using the special tools. ' 09930-30104: sliding shaft 09930-30...

Page 42

3-12 engine • separate the crankcase using the special tool. ' 09920-13120: crankcase separator • remove the countershaft and driveshaft. • remove the crankshaft using the special tool. ' 09920-13120: crankcase separator.

Page 43: Engine Components Inspection

Engine 3-13 engine components inspection and service cylinder head remove carbon from the combustion chamber and clean the cyl- inder head. Check the gasket surface of the cylinder head for distortion. Use a straightedge and thickness gauge. Take clearance readings at several places. ' 09900-20803: ...

Page 44

3-14 engine piston piston diameter measure the piston diameter with a micrometer at 23 mm (0.9 in) from the skirt end. If the piston diameter is less than the service limit, replace the piston. ' 09900-20202: micrometer (25 – 50 mm) % piston diameter service limit: 40.880 mm (1.6094 in) piston-cylin...

Page 45

Engine 3-15 piston pin and pin bore measure the piston pin bore inside diameter using the caliper gauge and measure the piston pin outside diameter using the micrometer. If either is out of specification or the different between these two measurements is more than the limits, replace both the piston...

Page 46

3-16 engine crankshaft crankshaft runout support the crankshaft using the v-blocks as shown. Position the dial gauge, as shown, and rotate the crankshaft slowly to read the runout. If the runout exceeds the service limit, correct the runout or re- place the crankshaft assembly with a new one. ' 0990...

Page 47

Engine 3-17 conrod small end i.D. Measure the conrod small end inside diameter using the dial cali- pers. If the conrod small end inside diameter exceeds the service limit, replace the conrod. % conrod small end i.D. Service limit: 16.040 mm (0.6315 in) ' 09900-20605: dial calipers • when rebuilding...

Page 48

3-18 engine oil seals and bearings inspection damage to the lip of the oil seal may result in leakage of the fuel- air mixture or transmission oil. Inspect the oil seal and if it is dam- aged, replace it with a new one. Wash the bearing with a cleaning solvent and lubricate it with motor oil before ...

Page 49

Engine 3-19 reassembly • apply grease to the lip of the oil seals. For u.S.A. ( 99000-25030: suzuki super grease “a” for the others ( 99000-25010: suzuki super grease “a” • install the oil seals using the special tool. ' 09913-70210: bearing installer set • install the bearings using the special too...

Page 50: Engine Reassembly

3-20 engine crankcase • install the countershaft and driveshaft. • install the dowel pins 1 . • before assembling the crankcase, apply the engine oil to each gear and bearing. Engine reassembly reassemble the engine in the reverse order of disassembly. The following steps require special attention o...

Page 51

Engine 3-21 • after the crankcase screws have been tightened, make sure that the crankshaft, countershaft and driveshaft rotate smoothly. • if their shafts do not rotate smoothly, try to free it by tapping with plastic hammer. Generator rotor • install the generator stator 1 . Note: apply a small qu...

Page 52

3-22 engine clutch • install the primary driven gear 1 and a new circlip 2 . Note: fit the circlip into groove securely. • install the washer 4 and spacer 3 . 1 oil seal 2 thrust washer 3 wave washer 4 wave washer 5 wave washer guide plate 6 clutch shoe 7 trust washer 8 key 9 clutch drum/primary dri...

Page 53

Engine 3-23 • install the clutch drum 1 , washer 2 and key 3 . • install the key into the key groove and mount the clutch shoe on the key. • install the wave washer. • install the guide plate, wave washer and thrust washer. • hold the generator rotor using special tool. • tighten the clutch shoe nut...

Page 54

3-24 engine • install the new gasket and clutch cover. Note: * screw a holds a clamp for carburetor overflow pipe. Piston ring and piston • install the piston rings onto the piston. 1st ring : keystone ring 2nd ring : keystone ring and expander ring note: the piston rings should be installed with th...

Page 55

Engine 3-25 recoil starter cylinder head • install the new cylinder head gasket 1 . • install the cylinder head and tighten the cylinder head nuts di- agonally to the specified torque. # cylinder head nut: 9 n.M (0.9 kgf.M, 6.5 lb-ft) cylinder • install the new cylinder base gasket 1 . • apply suzuk...

Page 56

3-26 engine removal and disassembly • loosen the lock nut 1 and turn the adjuster 2 clockwise as far as going in. • unhook the cable end piece 3 from the lever assembly. • remove the circlip 4 and washer. • remove the lever assembly 5 from the cover. • pull out the reel. & when removing and installi...

Page 57

Engine 3-27 • install the lever assembly to the cover. • apply thread lock “1342” to the nut 1 . " 99000-32050: thread lock “1342” • install the reel in the cover. • install the return spring to the cover so that the rachet is pushed inward. • apply suzuki super grease “a” to the return spring 2 . F...

Page 58

3-28 engine • tie a knot at the end of rope. • pull the rope and check that the rachet is pushed out. • after remounting the recoil starter, the following adjustment or necessary. *rear brake lever play ........................... ! 2-10 *recoil starter adjustment ..................... ! 2-11.

Page 59: Fuel and Lubrication System

Fuel and lubrication system 4-1 4 fuel and lubrication system contents fuel tank and fuel valve ............................................................ 4- 2 removal......................................................................................... 4- 2 fuel filter inspection and cleaning ...

Page 60: Fuel Tank and Fuel Valve

4-2 fuel and lubrication system fuel tank and fuel valve removal ! Gasoline is very explosive. Extrem care must be taken. • turn the fuel valve “off” position. • remove the frame cover. ( " 5-2) • replace the fuel tank cap. 1 breather hose 2 fuel tank cap 3 fuel tank 4 fuel valve.

Page 61

Fuel and lubrication system 4-3 • disconnect the fuel hose 1 , and vacuum hose 2 . • remove the fuel tank. • remove the fuel valve assembly. Fuel filter inspection and creaning if the fuel filter is dirty with sediment or rust, fuel will not flow smoothly and loss in engine power may result. Clean t...

Page 62: Carburetor

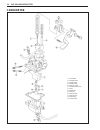

4-4 fuel and lubrication system carburetor 1 jet needle 2 throttle valve 3 starter valve 4 needle valve 5 pilot air screw 6 throttle stop screw 7 float 8 needle jet 9 main jet 0 pilot jet no.1 a pilot jet no.2 b drain plug c starter lever.

Page 63

Fuel and lubrication system 4-5 specifications item specification carburetor type mikuni vm12sc bore size 12 mm i.D. No 43f0 idle r/min. 1 800 ± 100 r/min. Float height 24.5 – 25.0 mm (0.96 – 0.98 in) main jet (m.J.) # 55 jet needle (j.N.) 3e3-4th needle jet (n.J.) e-6 pilot jet (p.J.) # 15 air scre...

Page 64

4-6 fuel and lubrication system removal • remove the right frame cover. ( " 5-2) • remove the clamp. • turn the fuel valve to “off” position. • disconnect the fuel hose 1 . • lossen the carburetor clamp bolt 2 . • remove the screws 3 with throttle valve. • remove the carburetor assebly. • remove the...

Page 65

Fuel and lubrication system 4-7 disassembly • disconnect the throttle cable and remove the throttle valve 1 and spring 2 . • remove the jet needle 3 . • remove the screws and float chamber. • remove the main jet 4 , needle jet 5 , pilot jet no.1 6 and pilot jet no.2 7 . • remove the needle valve 8 ....

Page 66

4-8 fuel and lubrication system • clean all jets with a spray-type carburetor cleaner and dry them using compressed air. • clean all circuits of the carburetor thoroughly - not just the per- ceived problem area. Clean the circuits in the carburetor body with a spray-type cleaner and allow each circu...

Page 67

Fuel and lubrication system 4-9 reassembly and remounting reassemble and remount the carburetor in the reverse order of disassembly and removal. Pay attention to the following points: • align the projection a on the carburetor body with the slit b of the throttle valve 2 . Float height adjustment to...

Page 68

4-10 fuel and lubrication system carburetion proper carburetion is determined by several interrelated factors (i.E. Engine power, fuel consumption, fuel cooling ability, jet settings etc.). Therefore, the jet size and the positions of any adjustable parts should not be changed from the original sett...

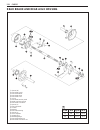

Page 69: Oil Pump

Fuel and lubrication system 4-11 oil pump inspection and disassembly • remove the stopper screw 1 and from the clutch cover. 1 stopper screw 2 gasket 3 oil hose 4 oil pump cam 5 plunger 6 plunger spring 7 oil pump valve 8 oil pump driven gear 9 oil seal 0 air bleeder screw a o-ring b check valve a u...

Page 70

4-12 fuel and lubrication system oil seal oil pump cam oil pump driven gear oil pump valve plunger check valve sopper screw washer union bolt gasket • remove the oil pump cam. Note: when removing the oil pump cam, the plunger and its spring will pop out. Do not miss there two parts. Inspect the oil ...

Page 71

Fuel and lubrication system 4-13 checking oil pump use the cci oil gauge to check the oil pump discharge rate. Mea- sure the amount of oil that the oil pump draws during the proce- dure. • remove the frame cover. ( " 5-2) • remove the drive chain and engine sprocket from the drive shaft. ( " 3-5) • ...

Page 72: Chassis

Chassis 5-1 5 chassis contents exterior parts ................................................................................ 5- 1 removal.........................................................................................5- 2 remounting ...........................................................

Page 73: Exterior Parts

5-2 chassis exterior parts removal seat • remove the seat. Steering cover • remove the screws. • disconnect the ignition switch lead wires, and than remove the steering cover. Frame cover • remove the frame cover. Note: replace the fuel tank cap 1 after removing the frame cover. • remove the screws ...

Page 74

Chassis 5-3 note: to remove the fastener, dapress the head a of fastener core and pull out the fastener. Remounting remount the exterior parts in the reverse order of removal. Pay attention following point: frame cover • install the frame cover using the fastner. • push the botton a of fastener core...

Page 75: Front and Rear Wheels

5-4 chassis front and rear wheels removal • place the vehicle on level ground. • remove the wheel set nuts. • support the vehicle with a jack or wooden block and remove the front and rear wheels. Remounting • remount the wheels in the reverse order of removal. Pay atten- tion to the following point....

Page 76: Tires

Chassis 5-5 tires tire replacement • remove the front and rear wheels. ( " 5-4) • after removing the air valve cap, release the tire pressure by depressing the valve. • dismount the bead from the rim completely as shown. • separate the tire from the rim by using a set of tire levers and rim protecto...

Page 77

5-6 chassis • inflate the tire to seat the tire bead. $ maximum tire bead seat pressure front : 250 kpa (2.5 kgf/cm 2 , 36 psi) rear : 250 kpa (2.5 kgf/cm 2 , 36 psi) # place the tire under a protective tire cage or similar pro- tective covering device before inflating the tire. To mini- mize the po...

Page 78: Front Brake

Chassis 5-7 front brake removal and disassembly • remove the front wheel. ( " 5-4) • remove the wheel center cap. • remove the cotter pin and axle nut 1 . • remove the front wheel hub 2 . • remove the front brake shoe assembly 3 . 1 front brake shoe 2 spring 3 front brake cam shaft 4 o-ring 5 dust s...

Page 79

5-8 chassis • remove the spring 1 . • remove the front brake adjusting nut 2 . • remove the front brake cam lever nut and bolt. • remove the brake cam lever and front brake camshaft 3 . • remove the brake panel. • remove the inner dust seal using the special tool. % 09913-50121: oil seal remover • r...

Page 80

Chassis 5-9 inspection bearings inspect the play a of the wheel hub bearings by hand while they are in the wheel hub. Rotate the inner race by hand to inspect it for abnormal noise and smooth rotation. Replace the wheel hub bearings if there is anything unusual. Brake drum/wheel hub inspect the brak...

Page 81

5-10 chassis • install the new dust seal using the special tool. % 09924-84521: bearing installer set • when installing the brake camshaft, apply suzuki super grease “a” to the camshaft. For usa & 99000-25030: suzuki super grease “a” for the others & 99000-25010: suzuki super grease “a” • when insta...

Page 82

Chassis 5-11 • tighten the front hub nut 1 to the specified torque. ! Front hub nut: 65 n.M (6.5 kgf.M, 47.9 lb-ft) • install the new cotter pin. • install the front wheel. ( " 5-4) • after installing the front brake, adjust the following items. * front brake lever play. ( " 2-10).

Page 83

5-12 chassis steering and front suspension 1 shock absorber 2 suspension arm 3 suspension arm bolt 4 bushing a suspension arm nut b shock absorber mounting bolt (lower and upper) 1 tie-rod 2 inner tie-rod end 3 knuckle arm bolt 4 dust seal 5 bushing 6 knuckle arm (l) 7 outer tie-rod end 8 spacer 9 k...

Page 84

Chassis 5-13 1 clamp 2 handlebar 3 steering shaft 4 dust seal 5 steering shaft holder 6 steering shaft lower dust seal 7 bushing 8 o-ring a handleber clamp bolt b steering shaft holder bolt c steering shaft lower nut ! Item n.M kgf.M lb-ft a 13 1.3 9.5 b 23 2.3 16.5 c 29 2.9 21.

Page 85

5-14 chassis removal and disassembly front suspension • remove the front wheel. ( " 5-4) • remove the front brake. ( " 5-7) • remove the front brake cable 1 . • remove the cotter pin and remove the tie-rod end nut 2 . • remove the front suspensions arm nuts. • remove the front shock absorber upper b...

Page 86

Chassis 5-15 • remove the knuckle arm bushings using the special tools. % 09923-73210: bearing remover 09930-30104: sliding shaft steering • remove the front suspension. ( " 5-12) • remove the front and rear brake cable. • remove the throttle case cover screws. • remove the throttle cable. • remove ...

Page 87

5-16 chassis • remove the cotter pin and steering shaft lower nut 1 and tie- rod end nut 2 . • remove the tie-rods. • remove the handlebar clamp bolts. • remove the cotter pin. • remove the steering shaft holder bolts. • remove the steering shaft bushing..

Page 88

Chassis 5-17 • remove the dust seals 1 and 2 . • separate the tie rod ends 3 , nuts 4 , 5 and tie rods 6 . # the lock nuts 4 have left hand threads. Inspection inspect the removed parts for the following abnormallities. * handlebar distortion. * handlebar clamp wear. Dust seals inspect the dust seal...

Page 89

5-18 chassis front shock absorber • inspect the shock absorber for oil leakage or damage. If any damage are found, replace the front shock absorber with a new one. ! Do not attempt to disassemble the front shock absorber. It is unserviceable. Tie-rod/tie-rod end • inspect the tie-rod for distortion ...

Page 90

Chassis 5-19 reasembly and remounting reassemble and remount the steering stem and front suspen- sion in the reverse order of removal and disassembly. Pay atten- tion to the following points. Steering shaft • install the steering shaft bushing using the special tool. % 09924-84510: bearing installer...

Page 91

5-20 chassis • tighten the steering shaft nut to the specified torque and new cotter pin. ! Steering shaft lower nut: 29 n.M (2.9 kgf.M, 2.1 lb-ft) • tighten the steering shaft holder bolts to the specified torque and new cotter pins. ! Steering shaft holder bolt: 23 n.M (2.3 kgf.M, 16.5 lb-ft) tie-...

Page 92

Chassis 5-21 • secure the each handlebar clamp in such a way that the clear- ances a ahead and behind of the handlebars are equalized. • align the groove 1 on the handlebar with the lug 2 on the handlebar switch. Front suspension • install the knuckle arm bushing using the special tool. % 09924-8451...

Page 93

5-22 chassis • tighten the front suspension arm bolts to the specified torque. ! Front suspension arm bolt: 50 n.M (5.0 kgf.M, 36 lb-ft) • tighten the front shock absorber upper bolt to the specified torque. ! Front shock absorber upper bolt: 29 n.M (2.9 kgf.M, 21lb-ft) • tighten the tie-rod end nut...

Page 94

Chassis 5-23 right angle (90 deg.) right angle (90 deg.) forward toe-in adjustment adjust the toe-in as follows: • place the vehicle on level ground and set the handlebars straight. Make sure all the tires are inflated to the standard pressure. ( " 2-11) • place 30 kg (66 lbs) of weight on the seat....

Page 95

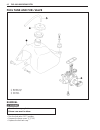

5-24 chassis rear brake and rear axle housing 1 spacer (r) 2 rear brake cover 3 rear brake drum 4 rear brake shoe 5 rear brake cam 6 o-ring 7 rear brake anchor panel 8 brake cam lever spring 9 rear brake cam lever 0 spacer (l) a rear axle shaft b oil seal c bearing d rear axle housing e spacer (l) f...

Page 96

Chassis 5-25 removal and disassembly • remove the cotter pin 1 . • remove the rear axle nut by applying the rear brake. • remove the rear wheels. • remove the spacer, 2 , 3 . • remove the rear brake drum cover. • remove the rear axle, rear brake drum and rear sprocket. • remove the rear brake shoes ...

Page 97

5-26 chassis • disconnect the rear brake cables. • remove the rear brake panel. • remove the rear brake cam lever bolt and cam lever. • remove the rear brake cam 1 , brake lining indicator plate 2 , spring 3 , and o-rings 4 . • remove the rear axle housing. • remove the dust seals using the special ...

Page 98

Chassis 5-27 • remove the rear axle bearings using the special tool. % 09921-20240: bearing remover set • remove the spacer 1 . Inspection dust seal inspect the dust seals for wear or damage. If any damages are found, replace the tie rod with a new one. Bearing wash the bearing with a cleaning solve...

Page 99

5-28 chassis brake shoe • inspect the brake shoes for wear or damage. If any wear or damages are found, replace the brake shoes as a set. # replace the brake shoes as a set. Otherwise braking performence will be adversely affected. Rear axle support the rear axle using v-blocks and measure the rear ...

Page 100

Chassis 5-29 • install the rear axle bearing using the special tool. • install the dust seals using the special tool. % 09924-84510: bearing installer set note: install the right side bearing 1 first, the spacer 2 and left side bearing 3 . Make sure the sealed side of the bearing face out- ward. • t...

Page 101

5-30 chassis rear brake cam indicator plate • install the rear brake indicator plate 1 , spring 2 , and rear brake cam lever 3 . • when installing the brake cam lever on the camshaft, align the punch mark 4 of the cam lever with the slit 5 of the camshaft. Note: a line the groove a on the cam shaft ...

Page 102

Chassis 5-31 • install the brake drum 1 , and circrip 2 . • install the rear sprocket and rear axle. • install the chain cover. • install the rear brake drum cover. • install the spacer right 3 and left 4 ..

Page 103

5-32 chassis • tighten the rear hub nut to the specified torque. ! Rear hub nut: 75 n.M (7.5 kgf.M, 55 lb-ft) • install the new cotter pin. • after installing the rear brake and drive chain, adjust the follow- ing items. * rear brake lever play ......................................... " 2-10 * driv...

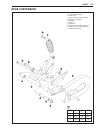

Page 104: Rear Suspension

Chassis 5-33 rear suspension ! Item n.M kgf.M lb-ft a 29 2.9 21 b 29 2.9 21 c 102 10.2 74 1 rear shock absorber 2 chain case 3 rear shock absorber lower bolt 4 swingarm pivot bolt 5 bushing 6 spacer 7 swingarm a rear shock absorber upper bolt b rear shock absorber lower nut c swingarm pivot nut.

Page 105

5-34 chassis removal and disassembly • remove the rear brake and rear axle housing. ( " 5-23) • remove the rear shock absorber upper bolt 1 . • remove the swingarm pivot nut 2 . • remove the swingarm 3 . • remove the rear shock absorber lower bolt 4 . Inspection rear shock absorber • inspect the rea...

Page 106

Chassis 5-35 bushing • inspect the bushing for wear or damage. If any dameges found, replace the bushing with a new one. Reassembly and remounting • reasembl and remount the rear suspension in the reverse or- der of removal and disassembly. Pay attention to the following points: • tighten the rear s...

Page 107

5-36 chassis • install the rear axle housing and rear brake. ( " 5-27) • after installing the rear suspension adjust the following items. * rear brake lever play ........................................... " 2-10 * drive chain slack .................................................. " 2-8.

Page 108: Electrical System

Electrical system 6-1 6 electrical system contents cautions in servicing ................................................................... 6- 2 ignition system ............................................................................... 6- 3 description ............................................

Page 109: Cautions In Servicing

6-2 electrical system cautions in servicing connectors • when disconnecting a connector, be sure to hold the termi- nals; do not pull the lead wires. • when connecting a connector, push it in so it is firmly attached. • inspect the connector for corrosion, contamination and any breakage in the cover...

Page 110: Ignition System

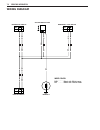

Electrical system 6-3 ignition system description the ignition system is shown in the diagram below: namely the generator, cdi/ignition coil unit and spark plug. Generator cdi/ignition coil unit spark plug troubleshooting.

Page 111

6-4 electrical system inspection ignition coil primary peak voltage • remove the seat. ( ! 5-2) • remove the frame cover. ( ! 5-2) • remove the spark plug cap. • connect a new spark plug to the spark plug cap on the cylinder head. Note: make sure that the spark plug cap and spark plug are connected....

Page 112: Switch

Electrical system 6-5 b/y switch measure the engine stop switch and emergency switch for conti- nuity using a tester. If any abnormality is found, replace the switch assembly with a new one. Engine stop switch wire color b/r: black with red tracer b/y: black with yellow tracer b/w: black with white ...

Page 113: Servicing Information

Servicing information 7-1 7 servicing information contents troubleshooting ..........................................................................7- 2 wiring diagram ............................................................................... 7- 6 wire and cable routing ..........................

Page 114: Troubleshooting

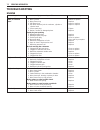

7-2 servicing information troubleshooting engine complaint symptom and possible causes remedy engine will not compression too low start, or is hard to 1. Worn cylinder. Rebore or replace. Start. 2. Worn piston ring. Replace. 3. Stiff piston ring. Repair or replace. 4. Gas leaks from the joint in cra...

Page 115

Servicing information 7-3 complaint symptom and possible causes remedy engine idles poorly. 1. Worn cylinder. Replace. 2. Worn piston rings. Replace. 3. Stiff piston ring. Replace. 4. Gas leaks from crankshaft oil seal. Replace. 5. Excessive spark plug gap. Adjust or replace. 6. Defective cdi/igniti...

Page 116

7-4 servicing information carburetor complaint symptom and possible causes remedy starting difficulty. 1. Clogged fuel pipe. Clean. 2. Air leaking from joint between starter body and tighten, adjust or replace carburetor. Gasket. 3. Air leaking from carburetor joint. Tighten or replace defective par...

Page 117

Servicing information 7-5 complaint symptom and possible causes remedy suspension too stiff. 1. Worn suspension arms and related bushings. Replace. Suspension too noisy. 1. Loose suspension system bolts. Tighten. 2. Worn suspension arms and related bushings. Replace. Rear wheels wobble. 1. Distorted...

Page 118: Wiring Diagram

7-6 servicing information wiring diagram off run pull free off on b/r b/w b/y b/w b/w b/w b/y b/y b/y b/y b/y b/w b/y b/w b/y b/w b/y b/w ignition switch magneto engine stop switch cdi unit/ignition coil emergency stop switch b/w b/y wire color . . . . . . . . . . . . Black with white tracer black w...

Page 119: Wire and Cable Routing

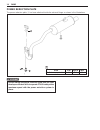

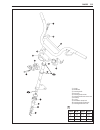

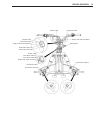

Servicing information 7-7 wire and cable routing wire routing engine stop switch lead wire clamp ignition lead wire clamp clamp clamp emergency switch lead wire generator lead wire clamp to engine stop switch ignition lead wire wiring harness clamp cdi/ignition coil generator lead wire clamp.

Page 120

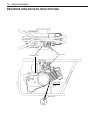

7-8 servicing information rear brake cable rear brake cable fit claw of bracket rear brake cable throttle cable engine stop switch lead wire throttle cable rear brake cable front brake cable (r) front brake cable (l) cable guide cable routing.

Page 121

Servicing information 7-9 front brake cable (l) front brake cable (l) rear brake cable rear brake cable rear brake cable cable guide front brake cable (r) front brake cable (r) front brake cable (l) front brake cable (r) engine stop switch lead wire engine stop switch lead wire throttle cable thrott...

Page 122

7-10 servicing information drain hose drain hose clamp breather hose air vent hose breather and air vent hose routing.

Page 123: Special Tools

Servicing information 7-11 special tools 09930-40113 rotor holder 09930-30161 attachment “c” 09900-00410 hexagon wrench set 09900-06107 snap ring pliers 09900-06108 snap ring pliers 09900-09004 impact driver set 09900-20101 vernier calipers (150 mm) 09900-20202 micrometer (25 – 50 mm) 09900-20205 mi...

Page 124

7-12 servicing information note: when ordering a special tool, please confirm whether it is available or not. 09941-50111 bearing remover.

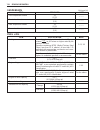

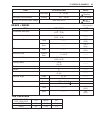

Page 125: Tightening Torque

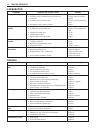

Servicing information 7-13 tightening torque engine item n.M kgf.M lb-ft exhaust pipe clamp nut 10 1.0 7.0 engine mounting bolt (lower) 31 3.1 22.5 engine mounting bolt 41 4.1 29.5 cylinder head nut 9 0.9 6.5 generator rotor nut 50 5.0 36.0 clutch shoe nut 85 8.5 61.5 chassis item n.M kgf.M lb-ft ha...

Page 126

7-14 servicing information tightening torque chart for other bolts and nuts listed in the preceding page, refer to this chart: bolt diameter conventional or “4” marked bolt “7” marked bolt a (mm) n.M kgf.M lb-ft n.M kgf.M lb-ft 4 1.5 0.15 1.0 2.3 0.23 1.5 5 3 0.3 2.0 4.5 0.45 3.0 6 5.5 0.55 4.0 10 1...

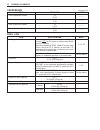

Page 127: Service Data

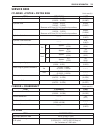

Servicing information 7-15 service data cylinder + piston + piston ring unit: mm (in) item standard limit piston to cylinder clearance 0.065 – 0.075 0.120 (0.0026 – 0.0030) (0.0047) cylinder bore 41.000 – 41.015 41.065 (1.6142 – 1.6148) (1.6167) measure at 20 mm (0.8 in) from the top surface. Piston...

Page 128

7-16 servicing information clutch unit: mm (in) item standard limit clutch wheel i.D. 87.00 – 87.15 87.50 (3.425 – 3.431) (3.445) clutch shoe thickness ——— no groove at any part clutch engagement 2 200 – 2 600 r/min. ——— clutch lock-up 2 500 – 2 900 r/min. ——— transmission unit: mm (in) except ratio...

Page 129

Servicing information 7-17 item specification note ignition coil resistance secondary 13 – 20 k Ω plug cap – terminal generator coil resistance primary 100 – 160 Ω b/y – ground ignition coil primary peak voltage more than 100 v : b/y : ground brake + wheel unit: mm (in) item standard limit front bra...

Page 130

7-18 servicing information suspension unit: mm (in) item standard limit front suspension stroke 31 ——— (1.22) front wheel travel 52 ——— (2.0) rear suspension stroke 31 ——— (1.22) rear wheel travel 51 ——— (2.0) fuel + oil item specification note fuel type p-03, 28 for the others fuel tank 2.6 l (0.7/...

Page 131

Lt-a50k3/k4 (’03, 04-models) 8-1 8 lt-a50k3/k4 (’03, ’04-models) contents specifications ................................................................................. 8- 2 service data .....................................................................................8- 3.

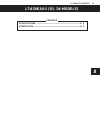

Page 132: Specifications

8-2 lt-a50k3/k4 (’03, 04-models) specifications dimensions and dry mass overall length ................................................................... 1 260 mm (49.6 in) overall width .................................................................... 760 mm (29.9 in) overall height ..............

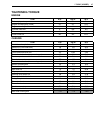

Page 133: Service Data

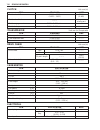

Lt-a50k3/k4 (’03, 04-models) 8-3 service data cylinder + piston + piston ring unit: mm (in) item standard limit piston to cylinder clearance 0.065 – 0.075 0.120 (0.0026 – 0.0030) (0.0047) cylinder bore 41.000 – 41.015 41.065 (1.6142 – 1.6148) (1.6167) measure at 20 mm (0.8 in) from the top surface. ...

Page 134

8-4 lt-a50k3/k4 (’03, 04-models) clutch unit: mm (in) item standard limit clutch wheel i.D. 87.00 – 87.15 87.50 (3.425 – 3.431) (3.445) clutch shoe thickness ——— no groove at any part clutch engagement 2 200 – 2 600 r/min. ——— clutch lock-up 2 500 – 2 900 r/min. ——— transmission unit: mm (in) except...

Page 135

Lt-a50k3/k4 (’03, 04-models) 8-5 item specification note ignition coil resistance secondary 13 – 20 k Ω plug cap – terminal generator coil resistance primary 100 – 160 Ω b/y – ground ignition coil primary peak voltage more than 100 v : b/y : ground brake + wheel unit: mm (in) item standard limit fro...

Page 136

8-6 lt-a50k3/k4 (’03, 04-models) suspension unit: mm (in) item standard limit front suspension stroke 31 ——— (1.22) front wheel travel 52 ——— (2.0) rear suspension stroke 31 ——— (1.22) rear wheel travel 51 ——— (2.0) fuel + oil item specification note fuel type p-03, 28 for the others fuel tank 2.6 l...

Page 137: Lt-A50K5 (’05-Model)

2 4 6 lt-a50k5 (’05-model) 9-1 contents lt-a50k5 (’05-model) 9 this chapter describes specifications, service data and servicing information which differ from those of the lt-a50k3/k4 (’03, ’04-models). Note: * any differences between the lt-a50k3/k4 (’03, ’04-models) and lt-a50k5 (’05-model) in spe...

Page 138: Specifications

9-2 lt-a50k5 (’05-model) specifications dimensions and dry mass overall length ...................................................................................... 1 260 mm (49.6 in) overall width ....................................................................................... 760 mm (29.9 ...

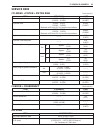

Page 139: Service Data

Lt-a50k5 (’05-model) 9-3 service data cylinder + piston + piston ring unit: mm (in) conrod + crankshaft unit: mm (in) item standard limit piston to cylinder clearance 0.065 – 0.075 (0.0026 – 0.0030) 0.120 (0.0047) cylinder bore 41.000 – 41.015 (1.6142 – 1.6148) measure at 20 mm (0.8 in) from the top...

Page 140

9-4 lt-a50k5 (’05-model) oil pump clutch unit: mm (in) transmission unit: mm (in) except ratio drive chain unit: mm (in) carburetor item specification oil pump reduction ratio 60.95 (53/20 × 23/1) oil pump discharge rate 0.6 – 0.8 ml (0.020/0.021 – 0.027/0.030 us/lmp oz) for 5 minutes at 2 000 r/min...

Page 141

Lt-a50k5 (’05-model) 9-5 electrical brake + wheel unit: mm (in) tire pressure vehicle load capacity: 38 kg (841 lbs) item specification note spark plug type ngk: bpr4h gap 0.50 – 0.60 (0.020 – 0.024) spark performance over 8 (0.3) at 1 atm. Ignition coil resistance secondary 13 – 20 k Ω plug cap – -...

Page 142

9-6 lt-a50k5 (’05-model) suspension unit: mm (in) fuel + oil item standard limit front suspension stroke 31 (1.22) — front wheel travel 52 (2.0) — rear suspension stroke 31 (1.22) — rear wheel travel 51 (2.0) — item specification note fuel type use only unleaded gasoline of at least 87 pump octane (...

Page 143: Tightening Torque

Lt-a50k5 (’05-model) 9-7 tightening torque engine chassis item n·m kgf-m lb-ft exhaust pipe clamp nut 10 1.0 7.0 engine mounting bolt (lower) 31 3.1 22.5 engine mounting bolt 41 4.1 29.5 cylinder head nut 9 0.9 6.5 generator rotor nut 50 5.0 36.0 clutch shoe nut 85 8.5 61.5 item n·m kgf-m lb-ft hand...

Page 144

9-8 lt-a50k5 (’05-model) rear brake and rear axle housing 1 spacer (r) 2 rear brake cover 3 rear brake drum 4 rear brake shoe 5 rear brake cam 6 o-ring 7 rear brake anchor panel 8 brake cam lever spring 9 rear brake cam lever 0 spacer (l) a rear axle shaft b oil seal c bearing d rear axle housing e ...

Page 145

Prepared by 3rd ed. March, 2004 1st ed. March, 2001 part no. 99500-20212-01e printed in japan 148.

Page 146

Printed in japan k2 k3 k4 k5.