- DL manuals

- Suzuki

- Offroad Vehicle

- LT-A750XP/Z

- Supplementary Service Manual

Suzuki LT-A750XP/Z Supplementary Service Manual

Summary of LT-A750XP/Z

Page 1

Lt-a750xp/z use this manual with: lt-a750x/z service manual (99500-47021-01e) 9 9 5 0 1 - 4 7 0 5 0 - 0 1 e.

Page 2: Foreword

Foreword this supplementary service manual is a supplement to suzuki lt-a750x/z service manual. It has been prepared exclusively for the following applicable model. Applicable model: lt-a750xk9 this supplementary service manual describes only service information which differ from that of the main ma...

Page 3: Table of Contents

00 0 1 2 3 4 5 6 9 precautions............................................................... 00-i precautions ............................................................ 00-1 general information ................................................... 0-i general information ..............................

Page 5: Section 00

Table of contents 00- i 00 section 00 contents precautions precautions ...............................................00-1 precautions........................................................... 00-1 warning / caution / note......................................00-* general precautions .................

Page 6: Precautions

00-1 precautions: precautions precautions precautions precautions for eps (lt-a750xp/zk9) b931g30000004 eps wiring • the eps parts are connected to various lead wires. The coupler and lead wire connections, as well as the lead wire and wire harness routings must be done correctly. Make sure that the...

Page 7: Section 0

Table of contents 0- i 0 section 0 contents general information general information ................................ 0a-1 general description .............................................0a-1 symbols ...............................................................0a-* abbreviations .....................

Page 8: General Information

0a-1 general information: general information general information general description abbreviations (lt-a750xp/zk9) b931g30101012 note please refer to the lt-a750xk9 (’09-model) service manual for other abbreviations which are not given in this manual. E: eps: electronic power steering vehicle side ...

Page 9

General information: 0a-2 warning, caution and information labels location (lt-a750xp/zk9) b931g30101015 5 14 17, 18 11 9 6 3 7 8 10 12, 13 15, 16 4 1, 20, 21 22, 23 24 19 25 2, 26, 27 [a] i931h1010010-03 1. Certification plate (english) for p-24, 33 15. Front carrier warning label (english) for p-2...

Page 10

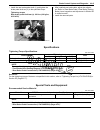

0a-3 general information: specifications specifications (lt-a750xp/zk9) b931g30107003 note these specifications are subject to change without notice. Dimensions and curb mass engine drive train item specification remark overall length 2 115 mm (83.3 in) p-28, 33 2 165 mm (85.2 in) p-17, 24 overall w...

Page 11

General information: 0a-4 chassis electrical capacities item specification remark front suspension independent, double wishbone, coil spring, oil damped rear suspension independent, double wishbone, coil spring, oil damped front wheel travel 170.5 mm (6.7 in) rear wheel travel 195 mm (7.7 in) caster...

Page 12

0a-5 general information: special tools and equipment special tool b931g30108002 09900–06107 snap ring remover (open type) 09900–20102 vernier calipers (200 mm) 09900–25008 multi circuit tester set 09900–25009 needle-point probe set 09904–41010 suzuki diagnostic system set 09924–84521 bearing instal...

Page 13: Maintenance and Lubrication

Maintenance and lubrication: 0b-1 general information maintenance and lubrication repair instructions air cleaner element inspection and cleaning (lt-a750xp/zk9) b931g30206033 clean element every 1 000 km (600 miles, 3 months) if the air cleaner is clogged with dust, intake resistance will be increa...

Page 14

0b-2 maintenance and lubrication: 5) measure the distances (“a” and “b”) between the front wheels. Subtract the measurement of “a” from that of “b” to find the toe-out. If the toe-out is not within specification, adjust the tie-rod to the right or left until the toe-out is within the specified range...

Page 15

Maintenance and lubrication: 0b-3 chassis bolt and nut inspection (lt-a750xp/ zk9) b931g30206032 tighten chassis bolt and nut initially at 200 km (100 miles, 1 month) and every 1 000 km (600 miles, 3 months) thereafter check that all chassis bolts and nuts are tightened to their specified torque. 1 ...

Page 16

0b-4 maintenance and lubrication: specifications tightening torque specifications b931g30207001 note the specified tightening torque is described in the following. “chassis bolt and nut inspection (lt-a750xp/zk9) (page 0b-3)” reference: for the tightening torque of fastener not specified in this sec...

Page 17: Service Data

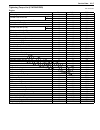

Service data: 0c-1 general information service data specifications service data (lt-a750xp/zk9) b931g30307003 valve + valve guide unit: mm (in) camshaft + cylinder head unit: mm (in) item standard limit valve diam. In. 36.0 (1.42) — ex. 33.0 (1.30) — tappet clearance (when cold) in. 0.10 – 0.20 (0.0...

Page 18

0c-2 service data: cylinder + piston + piston ring unit: mm (in) conrod + crankshaft unit: mm (in) oil pump clutch unit: mm (in) item standard limit compression pressure (automatic-decomp. Actuated) approx. 1 000 kpa (10.0 kgf/cm 2 , 142 psi) — piston-to-cylinder clearance 0.030 – 0.040 (0.0012 – 0....

Page 19

Service data: 0c-3 drive train unit: mm (in) except ratio thermostat + radiator + fan + coolant item standard limit automatic transmission ratio variable change (2.763 – 0.780) — secondary reduction ratio 2.158 (40/21 x 17/15) — final reduction ratio front 3.600 (36/10) — rear 3.600 (36/10) — transf...

Page 20

0c-4 service data: injector + fuel pump + fuel pressure regulator fi sensors + secondary throttle valve actuator throttle body item specification note injector resistance 11 – 13 Ω at 20 °c (68 °f) fuel pump discharge amount 55.5 ml (1.88/1.95 us/lmp qt) and more/10 sec. Fuel pressure regulator oper...

Page 21

Service data: 0c-5 electrical unit: mm (in) wattage unit: w item specification note spark plug type ngk: cr6e denso: u20esr-n gap 0.7 – 0.8 (0.028 – 0.031) spark performance over 8 (0.3) at 1 atm. Ckp sensor resistance 150 – 250 Ω ckp sensor peak voltage 5.0 v and more ignition coil resistance prima...

Page 22

0c-6 service data: brake + wheel unit: mm (in) tire unit: mm (in) suspension unit: mm (in) fuel + oil item standard/specification limit rear brake pedal height 12.5 – 22.5 (0.5 – 0.9) — rear brake pedal free travel 20 – 30 (0.8 – 1.2) — front brake disc thickness — 3.0 (0.20) front brake disc runout...

Page 23

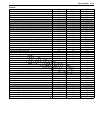

Service data: 0c-7 tightening torque list (lt-a750xp/zk9) b931g30307004 engine item n ⋅m kgf-m lbf-ft spark plug 11 1.1 8.0 cylinder head cover bolt initial 10 1.0 7.0 final 14 1.4 10.5 cam drive idle gear/sprocket shaft 41 4.1 29.5 intake pipe bolt 9 0.9 6.5 cylinder head bolt (m6) 10 1.0 7.0 cylin...

Page 24

0c-8 service data: drive train fi system, intake air system and fuel system cooling system item n ⋅m kgf-m lbf-ft 4wd/diff-lock actuator mounting bolt 22 2.2 16.0 front drive (differential) gear case bolt 22 2.2 16.0 front drive (differential) gear case mounting nut 50 5.0 36.0 front drive (differen...

Page 25

Service data: 0c-9 chassis item n ⋅m kgf-m lbf-ft handlebar clamp bolt 26 2.6 19.0 handlebar holder nut 60 6.0 43.5 rear brake lever holder clamp bolt 10 1.0 7.0 throttle lever case bolt 2 0.2 1.5 steering shaft upper nut 120 12.0 87.0 steering shaft bolt 26 2.6 19.0 eps control unit mounting nut 12...

Page 26

0c-10 service data: tightening torque chart for other bolts and nuts not listed in the preceding page, refer to this chart: bolt diameter “a” (mm) conventional or “4” marked bolt “7” marked bolt n ⋅m kgf-m lbf-ft n ⋅m kgf-m lbf-ft 4 1.5 0.15 1.0 2.3 0.23 1.5 5 3 0.3 2.0 4.5 0.45 3.0 6 5.5 0.55 4.0 1...

Page 27: Section 1

Table of contents 1- i 1 section 1 contents engine precautions ................................................. 1-* precautions.............................................................. 1-* precautions for engine........................................... 1-* engine general information and diag...

Page 28

1-ii table of contents specifications....................................................... 1c-* service data........................................................ 1c-* tightening torque specifications........................ 1c-* special tools and equipment ............................. 1c-* rec...

Page 29

Table of contents 1-iii water pump removal and installation.................1f-* water pump disassembly and assembly ............1f-* water pump related parts inspection.................1f-* specifications........................................................1f-* service data ........................

Page 30

1-iv table of contents starter motor related parts inspection (lt- a750xp/zk9) ..................................................... 1i-3 specifications........................................................ 1i-5 service data..........................................................1i-* service dat...

Page 31: Starting System

Starting system: 1i-1 engine starting system repair instructions starter motor components (lt-a750xp/zk9) b931g31906022 1 2 5 6 3 4 5 7 (a) (b) (c) (d) fwd fw d i931g3190012-03 1. O-ring 6. Starter motor case : 5 n ⋅m (0.5 kgf-m, 3.5 lbf-ft) 2. Housing end (inside) 7. Housing end (outside) : apply g...

Page 32

1i-2 starting system: starter motor removal and installation (lt- a750xp/zk9) b931g31906023 removal 1) turn the ignition switch off and disconnect the battery (–) lead wire. Refer to “battery removal and installation (lt-a750xp/zk9) in section 1j (page 1j-2)”. 2) remove the right side cover. Refer t...

Page 33

Starting system: 1i-3 • apply a small quantity of moly paste to the armature shaft. : moly paste 99000–25140 (suzuki moly paste or equivalent) • align the match mark on the starter motor case with the match mark on the housing end. • tighten the starter motor housing bolts (2) to the specified torqu...

Page 34

1i-4 starting system: armature coil measure for continuity between each segment. Measure for continuity between each segment and the armature shaft. If there is no continuity between the segments or there is continuity between the segments and shaft, replace the armature with a new one. Special tool...

Page 35

Starting system: 1i-5 specifications service data (lt-a750xp/zk9) b931g31907003 unit: mm (in) tightening torque specifications b931g31907004 note the specified tightening torque is described in the following. “starter motor components (lt-a750xp/zk9) (page 1i-1)” reference: for the tightening torque...

Page 36: Charging System

1j-1 charging system: engine charging system repair instructions generator removal and installation (lt- a750xp/zk9) b931g31a06010 removal 1) disconnect the (–) battery lead wire. Refer to “battery removal and installation (lt-a750xp/zk9) (page 1j-2)”. 2) drain engine oil. Refer to “engine oil and f...

Page 37

Charging system: 1j-2 • tighten the crankshaft spacer nut (2) to the specified torque with the special tool. Special tool (a): 09930–44530 (rotor holder) tightening torque left crankshaft spacer nut (a): 38 n·m (3.8 kgf-m, 27.5 lbf-ft) battery removal and installation (lt-a750xp/ zk9) b931g31a06011 ...

Page 38

1j-3 charging system: specifications tightening torque specifications b931g31a07002 reference: for the tightening torque of fastener not specified in this section, refer to “tightening torque list (lt-a750xp/zk9) in section 0c (page 0c-7)”. Special tools and equipment recommended service material b9...

Page 39: Section 3

Table of contents 3- i 3 section 3 contents driveline / axle precautions ................................................. 3-* precautions.............................................................. 3-* precautions for driveline / axle .............................. 3-* drive chain / drive train /...

Page 40

3-ii table of contents transfer related parts inspection....................... 3c-* transfer related bearing inspection................... 3c-* gear position (gp) switch inspection................. 3c-* gear position (gp) switch removal and installation.................................................

Page 41

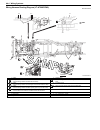

Drive chain / drive train / drive shaft: 3a-1 driveline / axle drive chain / drive train / drive shaft repair instructions front drive shaft components (lt-a750xp/zk9) b931g33106009 fwd fw d 1 2 3 7 6 5 4 8 9 10 i931h1310012-03 1. Circlip 6. Inner boot band (small) : apply grease. 2. Snap ring 7. Dr...

Page 42

3a-2 drive chain / drive train / drive shaft: front drive shaft disassembly and assembly (lt-a750xp/zk9) b931g33106011 refer to “front drive shaft assembly removal and installation in related manual”. Disassembly caution ! Do not disassemble the wheel side joint. If any damages are found, replace it...

Page 43

Drive chain / drive train / drive shaft: 3a-3 assembly caution ! • wash all parts before installation, clean the inside and outside of the boots with a cloth. • do not wash the boots in any commercially available degreaser, such as gasoline or kerosene. Washing in a degreaser causes deterioration of...

Page 44

3a-4 drive chain / drive train / drive shaft: 5) insert the cage into the outer race and install the new stopper ring to the groove of the outer race. Caution ! • replace the stopper ring with a new one. • position the opening of stopper ring “c” so that it will not be lined up with a ball. 6) after...

Page 45

Drive chain / drive train / drive shaft: 3a-5 rear drive shaft components (lt-a750xp/zk9) b931g33106013 rear drive shaft disassembly and assembly (lt-a750xp/zk9) b931g33106015 refer to “rear drive shaft assembly removal and installation in related manual”. Rear drive shaft disassembly and assembly a...

Page 46

3a-6 drive chain / drive train / drive shaft: special tools and equipment recommended service material b931g33108001 note required service material is also described in the following. “front drive shaft components (lt-a750xp/zk9) (page 3a-1)” “rear drive shaft components (lt-a750xp/zk9) (page 3a-5)”...

Page 47: Section 4

Table of contents 4- i 4 section 4 contents brake precautions ................................................. 4-* precautions.............................................................. 4-* precautions for brake system ............................... 4-* brake fluid information.....................

Page 48

4-ii table of contents parking / rear brake cable routing diagram .... 4d-* repair instructions .............................................. 4d-* parking / rear brake inspection and adjustment ........................................................ 4d-* parking / rear brake cable removal and inst...

Page 49

Brake control system and diagnosis: 4a-1 brake brake control system and diagnosis schematic and routing diagram front brake hose routing diagram (lt-a750xp/zk9) b931g34102003 1 “b” 2 “c” 3 4 5 5 7 4 (a) 8 9 4 (a) 8 9 10 11 11 12 (a) 8 11 “e” 6 “f” (b) “d” (b) “a” “d” “d” i931h1410043-05 1. Master cy...

Page 50

4a-2 brake control system and diagnosis: repair instructions front brake hose removal and installation (lt- a750xp/zk9) b931g34106019 removal caution ! Make sure that the vehicle is supported securely. 1) remove the front fender. Refer to “front side exterior parts removal and installation in sectio...

Page 51

Brake control system and diagnosis: 4a-3 rear brake pedal construction (lt-a750xp/zk9) b931g34106020 rear brake pedal removal and installation (lt- a750xp/zk9) b931g34106021 removal 1) remove the right inner fender. Refer to “front side exterior parts removal and installation in section 9d in relate...

Page 52

4a-4 brake control system and diagnosis: 5) remove the rear brake pedal shaft (3). 6) remove the rear brake pedal (4) and rear brake pedal spring (5). 7) remove the dust seals (6) if necessary. Caution ! If there are wear or damage, replace the dust seals (6) with new ones. 8) remove the washers (7)...

Page 53

Brake control system and diagnosis: 4a-5 • install the rear brake pedal shaft (1) and tighten the brake pedal shaft nut (2) to the specified torque. Tightening torque rear brake pedal shaft nut (a): 60 n·m (6.0 kgf-m, 43.5 lbf-ft) • after installed rear brake cable, adjust the adjuster nut. Refer to...

Page 54

4a-6 brake control system and diagnosis:.

Page 55: Section 6

Table of contents 6- i 6 section 6 contents steering precautions .................................................6-1 precautions............................................................. 6-1 precautions for steering ........................................ 6-* precautions for steering (lt-a750xp...

Page 56

6-ii table of contents dtc “c1153” eps control unit supply voltage circuit malfunction (lt-a750xp/ zk9) ................................................................6c-46 dtc “c1152”, “c1154”, “c1155” eps control unit malfunction (lt-a750xp/zk9).................6c-47 repair instructions ............

Page 57: Precautions

Precautions: 6-1 steering precautions precautions precautions for steering (lt-a750xp/zk9) b931g36000002 refer to “general precautions in section 00 in related manual” and “precautions for eps (lt-a750xp/zk9) in section 00 (page 00-1)”..

Page 58: Steering General Diagnosis

6a-1 steering general diagnosis: steering steering general diagnosis diagnostic information and procedures steering symptom diagnosis (lt-a750xp/zk9) b931g36104002 condition possible cause correction / reference item heavy steering distorted steering shaft. Replace. Improper front wheel alignment. A...

Page 59: Steering / Handlebar

Steering / handlebar: 6b-1 steering steering / handlebar repair instructions steering / handlebars components (lt-a750xp/zk9) b931g36206008 1 2 3 4 5 7 12 13 14 15 16 17 18 12 “a” “a” “a” 12 20 20 19 “a” (a) 10 11 9 fwd fw d 8 6 i931g3620028-02 1. Handlebars 10. Lower dust seal 19. Handlebar left sw...

Page 60

6b-2 steering / handlebar: steering / handlebars assembly construction (lt-a750xp/zk9) b931g36206009 (a) (a) (f) (e) 6 (d) 3 (c) 4 (c) 2 (d) 3 (c) 2 (a) “b” view a a 5 (a) (b) 1 i931h1620037-06 1. Handlebar holder nut : 60 n ⋅m (6.0 kgf-m, 43.5 lbf-ft) 2. Tie-rod end nut : 29 n ⋅m (2.9 kgf-m, 21.0 l...

Page 61

Steering / handlebar: 6b-3 handlebars removal and installation (lt- a750xp/zk9) b931g36206010 removal 1) remove the auxiliary headlight cover. Refer to “auxiliary headlight removal and installation in section 9b in related manual” 2) remove the combination meter. Refer to “combination meter removal ...

Page 62

6b-4 steering / handlebar: 9) remove the handlebar upper clamps (7) and handlebars (8). 10) remove the left brake lever from the handlebars (left side). Installation install the handlebars in the reverse order of removal. Pay attention to the following points: • install the left brake lever (1) to t...

Page 63

Steering / handlebar: 6b-5 • apply adhesive agent to the handlebar right and left end and right and left grip inner wall. : handle grip bond (handle grip bond (commercially available)) • insert the projection “d” of the left handlebar switch assembly into the hole of the handlebars. • tighten the le...

Page 64

6b-6 steering / handlebar: steering shaft removal and installation (lt- a750xp/zk9) b931g36206012 removal 1) remove the eps control unit. Refer to “eps control unit removal and installation (lt-a750xp/zk9) in section 6c (page 6c-48)”. 2) remove the eps body assembly. Refer to “eps body assembly remo...

Page 65

Steering / handlebar: 6b-7 installation install the steering shaft in the reverse order of removal. Pay attention to the following points: • install the steering shaft bushing (1) along with dust seal (2) with the special tool. Special tool (a): 09924–84521 (bearing installer set) • apply grease to ...

Page 66

6b-8 steering / handlebar: • install the cotter pin (8). Caution ! The removed cotter pin (8) must be replaced with a new one. • install eps body assembly. Refer to “eps body assembly removal and installation (lt-a750xp/zk9) in section 6c (page 6c-50)”. • install the eps control unit. Refer to “eps ...

Page 67

Steering / handlebar: 6b-9 4) remove the other tie-rod end in the same manner as described previously. 5) separate the tie-rod ends (2), nuts (3), (4) and tie- rods (5). Caution ! The lock-nuts (3) have left-hand threads. Installation install the tie-rod in the reverse order of removal. Pay attentio...

Page 68

6b-10 steering / handlebar: tie-rod end inspect the tie-rod ends for smooth movement. If there are any abnormalities, replace the tie-rod ends with new ones. Inspect the tie-rod end boots for wear or damage. If any defects are found, replace the tie-rod ends with new ones. Steering shaft inspect the...

Page 69

Steering / handlebar: 6b-11 tightening torque specifications b931g36207004 note the specified tightening torque is described in the following. “steering / handlebars components (lt-a750xp/zk9) (page 6b-1)” “steering / handlebars assembly construction (lt-a750xp/zk9) (page 6b-2)” reference: for the t...

Page 70

6c-1 power assisted steering system: steering power assisted steering system precautions precautions for eps (lt-a750xp/zk9) b931g36300001 refer to “general precautions in section 00 in related manual” and “precautions for eps (lt-a750xp/zk9) in section 00 (page 00-1)”. Note when repairing eps syste...

Page 71

Power assisted steering system: 6c-2 general description p/s system description (lt-a750xp/zk9) b931g36301001 this electronic power steering (eps) system consists of a eps control unit (2), a torque sensor (3), a eps motor (4). In this system, the eps control unit determines the level and direction ...

Page 72

6c-3 power assisted steering system: detecting principle the column shaft is connected to the input shaft by means of serration. The output shaft and input shaft are connected via torsion bar. When torque is inputted from the column shaft, a relative angular displacement occurs between the input sha...

Page 73

Power assisted steering system: 6c-4 control system in the eps control unit, the steering assist control determines the basic power assist force and the convergence control improves the steering operation feeling. The controller determines the target motor current by the calculation of these control...

Page 74

6c-5 power assisted steering system: eps diagnosis general description (lt-a750xp/zk9) b931g36301002 the p/s system in this vehicle is controlled by the eps control unit. The eps control unit has an self diagnostic system which detects a malfunction in this system. When diagnosing troubles, be sure ...

Page 75

Power assisted steering system: 6c-6 schematic and routing diagram eps wiring diagram (lt-a750xp/zk9) b931g36302001 refer to “wire color symbols in section 0a in related manual”. On2 on1 off 12 3 45 6 1 ignition switch fuse box 1. Head hi 2. Head lo 3. Fuel 4. Ignition 5. F an 6. Power source 10 a 1...

Page 76

6c-7 power assisted steering system: eps control unit diagram (lt-a750xp/zk9) b931g36302002 refer to “wire color symbols in section 0a in related manual”. Eps control unit coupler (eps control unit harness end) 30 a 40 a ignition switch eps main fail-safe relay eps motor speed sensor (vehicle speed)...

Page 77

Power assisted steering system: 6c-8 eps system wiring harness routing diagram (lt-a750xp/zk9) b931g36302003 refer to “wiring harness routing diagram (lt-a750xp/zk9) in section 9a (page 9a-4)”. Component location eps components location (lt-a750xp/zk9) b931g36303001 1 2 3 4 i931g3630002-02 1. Eps co...

Page 78

6c-9 power assisted steering system: diagnostic information and procedures eps troubleshooting (lt-a750xp/zk9) b931g36304001 the eps is equipped with a self-diagnosis function. The detected malfunction is stored as a diagnostic trouble code which causes the eps indicator light to light up or flash i...

Page 79

Power assisted steering system: 6c-10 information gathering to properly diagnose a malfunction, one must not make guesses or assumptions about the circumstances that caused it. Proper diagnosis and repair require duplicating the situation in which the malfunction occurred. If a diagnosis is made wit...

Page 80

6c-11 power assisted steering system: steering related parts refer to “steering parts inspection in section 6b in related manual”. Battery battery voltage inspection 1) turn the ignition switch off. 2) remove the seat. Refer to “seat removal and installation in section 9d in related manual”. 3) meas...

Page 81

Power assisted steering system: 6c-12 eps system check (lt-a750xp/zk9) b931g36304003 warning ! Carry out test drive in light traffic area to prevent an accident. Step action yes no 1 1) perform “customer complaint analysis”. Was customer complaint analysis performed according to instruction? Go to s...

Page 82

6c-13 power assisted steering system: 4 (the eps indicator light does not light up) 1) turn the ignition switch off. 2) disconnect the eps control unit coupler (1) and (2). 3) turn the ignition switch on with the eps control unit coupler disconnected, measure the voltage between terminal “a” and ter...

Page 83

Power assisted steering system: 6c-14 5 1) turn the ignition switch on with the eps control unit coupler disconnected, measure the voltage between terminal “a” and terminal “b” at the coupler. Special tool (a): 09900–25008 (multi circuit tester set) tester knob indication voltage ( ) normal value (“...

Page 84

6c-15 power assisted steering system: 7 (the eps indicator light does not go off) 1) remove the seat. Refer to “seat removal and installation in section 9d in related manual”. 2) open the fuse box and inspect the ignition fuse (1). Caution ! If a fuse is blown, find the cause of the problem and corr...

Page 85

Power assisted steering system: 6c-16 8 1) turn the ignition switch off. 2) disconnect the eps control unit coupler (1) and (2). 3) turn the ignition switch on with the eps control unit coupler disconnected, measure the voltage between terminal “a” and terminal “b” at the coupler. Special tool (a): ...

Page 86

6c-17 power assisted steering system: 9 1) turn the ignition switch on with the eps control unit coupler disconnected, measure the voltage between terminal “a” and terminal “b” at the coupler. Special tool (a): 09900–25008 (multi circuit tester set) tester knob indication voltage ( ) normal value (“...

Page 87

Power assisted steering system: 6c-18 10 1) turn the ignition switch off. 2) short the mode select coupler terminals using the special tool. Special tool (a): 09930–82710 (mode select switch) 3) check for continuity between terminal “a” and terminal “b” at the coupler. Special tool (a): 09900–25008 ...

Page 88

6c-19 power assisted steering system: dtc (diagnostic trouble code) output (lt- a750xp/zk9) b931g36304004 note • even through the eps is operating correctly, a dtc is memorized in any of the following conditions. – previous malfunctions were repaired, but the dtcs were not deleted. • after carrying ...

Page 89

Power assisted steering system: 6c-20 understanding the dtc (diagnostic trouble code) a four-digit dtc is shown through the flashing pattern of the eps indicator light. A number between 1 and 9 is represented by the number of times that the eps indicator light lights up in interval of 0.3 seconds an...

Page 90

6c-21 power assisted steering system: 3) read the dtc (diagnostic trouble code) and show data when trouble (displaying data at the time of dtc) according to instructions displayed on sds. Note • not only is sds used for detecting diagnostic trouble codes but also for reproducing and checking on scre...

Page 91

Power assisted steering system: 6c-22 3) while the dtcs are being output, set the special tool to off. Caution ! The dtc deletion mode starts 11.5 seconds after the switch is set to off. 4) in the dtc deletion mode, switch the mode coupler switch off to on five times or more within 10 seconds, each ...

Page 92

6c-23 power assisted steering system: 5) click the “eps” button (1). 6) click the “dtc inspection” button (2). 7) check the dtc. Note the previous malfunction history code (past dtc) still remains stored in the eps control unit. Therefore, erase the history code memorized in the eps control unit usi...

Page 93

Power assisted steering system: 6c-24 sds check (lt-a750xp/zk9) b931g36304006 using sds, take the sample of data from the new vehicle and at the time of periodic maintenance at your dealer. Save the data in the computer or by printing and filing the hard copies. The saved or filed data are useful fo...

Page 94

6c-25 power assisted steering system: scroll the screen dtc table (lt-a750xp/zk9) b931g36304007 * 1 : it goes off after running the engine. I931g3630066-01 dtc malfunction cause indicator status reference none normal on * 1 — c1111 torque sensor (main) circuit voltage failure on refer to “dtc “c1111...

Page 95

Power assisted steering system: 6c-26 dtc “c1111”: torque sensor (main) circuit malfunction (lt-a750xp/zk9) b931g36304008 troubleshooting caution ! Never remove the torque sensor to prevent accident and damage. Note • after repairing the trouble, clear the dtc using a sds tool or mode coupler switch...

Page 96

6c-27 power assisted steering system: step action yes no 1 1) turn the ignition switch off. 2) check the torque sensor coupler for loose or poor contact. If ok, measure the torque sensor input voltage. 3) disconnect the torque sensor coupler. 4) turn the ignition switch on. 5) measure the input volt...

Page 97

Power assisted steering system: 6c-28 2 1) turn the ignition switch off. 2) connect the torque sensor coupler. 3) insert the needle-point probes to lead wire coupler. 4) turn the ignition switch on. 5) measure the voltage between g wire “a” and b wire “b” by turning the handlebars left and right. Sp...

Page 98

6c-29 power assisted steering system: dtc “c1113”: torque sensor (main / sub) circuit correlation malfunction (lt-a750xp/zk9) b931g36304009 troubleshooting caution ! Never remove the torque sensor to prevent accident and damage. Note • after repairing the trouble, clear the dtc using a sds tool or m...

Page 99

Power assisted steering system: 6c-30 step action yes no 1 1) turn the ignition switch off. 2) check the torque sensor coupler for loose or poor contact. If ok, measure the torque sensor input voltage. 3) disconnect the torque sensor coupler. 4) turn the ignition switch on. 5) measure the input volt...

Page 100

6c-31 power assisted steering system: 1 6) next, measure the voltage between g wire “c” and ground, g wire “c” and b wire “b”, w wire “d” and ground and w wire “d” and b wire “b”. If the voltage of each measurement is 0 v ok. Special tool (a): 09900–25008 (multi circuit tester set) tester knob indic...

Page 101

Power assisted steering system: 6c-32 2 1) turn the ignition switch off. 2) connect the torque sensor coupler. 3) insert the needle-point probes to lead wire coupler. 4) measure the torque sensor (main) voltage between g wire “a” and b wire “b”. Also, measure the torque sensor (sub) voltage between ...

Page 102

6c-33 power assisted steering system: dtc “c1114”: torque sensor power supply circuit malfunction (lt-a750xp/zk9) b931g36304010 troubleshooting caution ! Never remove the torque sensor to prevent accident and damage. Note after repairing the trouble, clear the dtc using a sds tool or mode coupler sw...

Page 103

Power assisted steering system: 6c-34 step action yes no 1 1) turn the ignition switch off. 2) check the eps control unit power source couplers for loose or poor contact. If ok, measure the torque sensor input voltage. 3) disconnect the torque sensor coupler. 4) turn the ignition switch on. 5) measu...

Page 104

6c-35 power assisted steering system: dtc “c1115”: torque sensor (sub) circuit malfunction (lt-a750xp/zk9) b931g36304011 troubleshooting caution ! Never remove the torque sensor to prevent accident and damage. Note after repairing the trouble, clear the dtc using a sds tool or mode coupler switch. R...

Page 105

Power assisted steering system: 6c-36 step action yes no 1 1) turn the ignition switch off. 2) check the torque sensor coupler for loose or poor contact. If ok, measure the torque sensor input voltage. 3) disconnect the torque sensor coupler. 4) turn the ignition switch on. 5) measure the input volt...

Page 106

6c-37 power assisted steering system: 2 1) turn the ignition switch off. 2) connect the torque sensor coupler. 3) insert the needle-point probes to lead wire coupler. 4) turn the ignition switch on. 5) measure the voltage between w wire “a” and b wire “b” by turning the handlebars left and right. Sp...

Page 107

Power assisted steering system: 6c-38 dtc “c1121”: vehicle speed signal circuit malfunction (lt-a750xp/zk9) b931g36304012 troubleshooting note after repairing the trouble, clear the dtc using a sds tool or mode coupler switch. Refer to “dtc (diagnostic trouble code) deleting (lt-a750xp/zk9) (page 6c...

Page 108

6c-39 power assisted steering system: 1 3) disconnect the eps control unit coupler [b], speed sensor coupler [c] and combination meter coupler [a]. Refer to “speed sensor removal and installation in section 9c in related manual” and “combination meter removal and installation in section 9c in relate...

Page 109

Power assisted steering system: 6c-40 2 1) connect the combination meter coupler and speed sensor coupler. 2) turn the ignition switch on. 3) measure the voltage between the bl/b wire “a” and ground. Special tool (a): 09900–25008 (multi circuit tester set) tester knob indication voltage ( ) vehicle ...

Page 110

6c-41 power assisted steering system: dtc “c1122”: engine speed signal circuit malfunction (lt-a750xp/zk9) b931g36304013 troubleshooting note start the engine after repairing the dtc and check that the indicator light is turned off. Refer to “precautions in diagnosing troubles (lt-a750xp/zk9) (page ...

Page 111

Power assisted steering system: 6c-42 2 1) turn the ignition switch off. 2) check the eps control unit coupler for loose or poor contact. If ok, then measure the engine speed signal lead wire continuity. 3) disconnect the eps control unit coupler and ecm coupler. 4) check the continuity between the ...

Page 112

6c-43 power assisted steering system: 3 1) connect the ecm coupler. 2) start the engine. 3) measure the voltage between w wire “a” and ground. Special tool (a): 09900–25008 (multi circuit tester set) tester knob indication voltage ( ) engine speed signal voltage it changes between 0 – 12 v is voltag...

Page 113

Power assisted steering system: 6c-44 dtc “c1141”, “c1142”, “c1143”, “c1145” eps motor circuit malfunction (lt-a750xp/zk9) b931g36304014 troubleshooting possible cause • faulty eps motor circuit. • faulty eps motor. • eps control unit malfunction. Step action yes no 1 1) turn the ignition switch off...

Page 114

6c-45 power assisted steering system: 2 1) turn the ignition switch off. 2) disconnect the eps motor coupler. 3) inspect the continuity of the eps motor. Refer to “eps motor inspection (lt-a750xp/zk9) (page 6c-53)”. Is continuity ok? Replace the eps control unit with a known good one, and inspect it...

Page 115

Power assisted steering system: 6c-46 dtc “c1153” eps control unit supply voltage circuit malfunction (lt-a750xp/zk9) b931g36304015 troubleshooting possible cause • faulty regulator/rectifier. • faulty eps control unit. • faulty wire harness, etc. Step action yes no 1 1) remove the seat. Refer to “s...

Page 116

6c-47 power assisted steering system: dtc “c1152”, “c1154”, “c1155” eps control unit malfunction (lt-a750xp/zk9) b931g36304016 troubleshooting • replace the eps control unit. Refer to “eps control unit removal and installation (lt-a750xp/zk9) (page 6c- 48)”. 3 1) turn the ignition switch off. 2) che...

Page 117

Power assisted steering system: 6c-48 repair instructions eps control unit construction (lt-a750xp/zk9) b931g36306001 eps control unit removal and installation (lt- a750xp/zk9) b931g36306002 removal 1) disconnect the battery (–) lead wire. Refer to “battery removal and installation (lt-a750xp/zk9) i...

Page 118

6c-49 power assisted steering system: 4) disconnect the torque sensor coupler (1). 5) remove the clamp (2) and release the eps motor lead wire (3). 6) release the clip part “a” of the eps control unit plate with the special tool. Special tool (a): 09942–83110 (clip remover) 7) remove the fastener (4...

Page 119

Power assisted steering system: 6c-50 • connect the eps motor coupler (3) and clamp (4). • connect the other eps control unit couplers. • install the front fender. Refer to “front side exterior parts removal and installation in section 9d in related manual”. Eps body assembly components (lt-a750xp/ ...

Page 120

6c-51 power assisted steering system: 9) remove the front brake hose union (7) and throttle cable (8) from the cable guide (9). 10) remove the steering shaft bolt (10). 11) remove the eps body assembly mounting nuts and bolts. 12) remove the cable guide (11). 13) remove the eps body assembly. Cautio...

Page 121

Power assisted steering system: 6c-52 • install the cable guide (1) and tighten the bolts (2) to the specified torque. Tightening torque eps body assembly mounting bolt (a): 26 n·m ( 2.6 kgf-m, 19.0 lbf-ft) • tighten the eps body assembly mounting nuts (3) to the specified torque. Tightening torque ...

Page 122

6c-53 power assisted steering system: • install the handlebar holder (8) and tighten the nuts to the specified torque. Tightening torque handlebar holder nut (e): 60 n·m (6.0 kgf-m, 43.5 lbf-ft) • install the center cover (9). • install the auxiliary headlight. Refer to “auxiliary headlight removal ...

Page 123

Power assisted steering system: 6c-54 specifications tightening torque specifications b931g36307001 note the specified tightening torque is described in the following. “eps control unit construction (lt-a750xp/zk9) (page 6c-48)” reference: for the tightening torque of fastener not specified in this ...

Page 124

6c-55 power assisted steering system: special tool b931g36308002 09900–25008 09900–25009 multi circuit tester set needle-point probe set ) (page 6c-11) / ) (page 6c-11) / ) (page 6c-13) / ) (page 6c-14) / ) (page 6c-14) / ) (page 6c-16) / ) (page 6c-17) / ) (page 6c-18) / ) (page 6c-27) / ) (page 6c...

Page 125: Section 9

Table of contents 9- i 9 section 9 contents body and accessories precautions ................................................. 9-* precautions.............................................................. 9-* precautions for electrical system .......................... 9-* component location ..........

Page 126

9-ii table of contents front carrier removal and installation ............... 9e-* rear carrier removal and installation ................ 9e-* front grip bar construction ................................ 9e-* front grip bar removal and installation ............. 9e-* trailer towing construction .......

Page 127: Wiring Systems

Wiring systems: 9a-1 body and accessories wiring systems schematic and routing diagram wiring diagram (lt-a750xp/zk9) b931g39102003 refer to “wire color symbols in section 0a in related manual”..

Page 128

9a-2 wiring systems: for p-17 on off horn headlight (l) speedometer brake lever switch (l) rear brake switch backup light ecm rear combina tion light on off push brake lever switch set secede emergency switch horn butt on auxiliar y headlight headlight (r) hi lo run off push dimmer switch engine st ...

Page 129

Wiring systems: 9a-3 for p-24, 28, 33 on off horn headlight (l) speedometer brake lever switch (l) rear brake switch ecm rear combina tion light option on off push brake lever switch horn butt on auxiliar y headlight headlight (r) hi lo run off push dimmer switch engine st op switch over ride switch...

Page 130

9a-4 wiring systems: wiring harness routing diagram (lt-a750xp/zk9) b931g39102004 “ b ” 2 3 3 “b” 2 1 4 7 6 5 view a “a” 1 “ a ” “ b ” 1 1 “ c ” “d” 8 9 “c” 7 fwd i931g3910905-02 1. Clamp 9. Throttle cable 2. Clamp : bind the wiring harness and hose with the clamp. “b”: pass the wiring harness and c...

Page 131

Wiring systems: 9a-5 “a” 1 (b) (a) 3 5 4 8 6 14 13 16 17 15 7 9 12 “c” 18 10 “e” “d” 2 11 11 “f” view f view a 19 “b” i931g3910903-02 1. Starter motor 14. Injector coupler 2. Starter motor terminal 15. Tp sensor coupler 3. Engine earth 16. Isc valve coupler 4. Clamp : bind the wiring harness and rea...

Page 132

9a-6 wiring systems: 3 “ a ” 5 7 8 9 10 11 12 “a” view 4 2 4 2 lh rh “c” 14 13 6 1 “a” “d” “b” i931h1910903-05 1. Clamp : bind the left handlebar switch lead wire, rear brake lever switch lead wire, horn lead wire (for p-17, 24) and emergency switch lead wire (for p-17) with the clamp. Cut the tip o...

Page 133

Wiring systems: 9a-7 specifications tightening torque specifications b931g3910s002 note the specified tightening torque is described in the following. “wiring harness routing diagram (lt-a750xp/zk9) (page 9a-4)” reference: for the tightening torque of fastener not specified in this section, refer to...

Page 134: Body Structure

9e-1 body structure: body and accessories body structure repair instructions body frame construction (lt-a750xp/zk9) b931g39506011 special tools and equipment recommended service material b931g39508001 note required service material is also described in the following. “body frame construction (lt-a7...

Page 135

Prepared by march, 2009 part no. 99501-47050-01e printed in japan 132.

Page 136

Printed in japan k9.