- DL manuals

- Suzuki

- Offroad Vehicle

- LT-Z400

- Service Manual

Suzuki LT-Z400 Service Manual

Summary of LT-Z400

Page 2: Group Index

Group index general information 1 periodic maintenance 2 engine 3 fuel system 4 cooling and lubrication system 5 chassis 6 electrical system 7 servicing information 8 foreword this manual contains an introductory description on the suzuki lt-z400 and procedures for its inspec- tion, service, and ove...

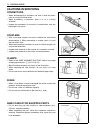

Page 3: General Information

1 general information 1-1 contents general information warning/caution/note .............................................................. 1- 2 general precautions ................................................................ 1- 2 suzuki lt-z400k3 (2003-model) .......................................

Page 4: Warning/caution/note

1-2 general information warning/caution/note please read this manual and follow its instructions carefully. To emphasize special information, the symbol and the words warning, caution and note have special meanings. Pay special attention to the mes- sages highlighted by these signal words. ! Indicat...

Page 5

General information 1-3 " * if parts replacement is necessary, replace the parts with suzuki genuine parts or their equiv- alent. * when removing parts that are to be reused, keep them arranged in an orderly manner so that they may be reinstalled in the proper order. * be sure to use special tools w...

Page 6: Serial Number Location

1-4 general information suzuki lt-z400k3 (2003-model) * difference between photographs and actual vehicles depends on the markets. Serial number location the frame serial number or v.I.N. (vehicle identification number) 1 is stamped on the left side of the frame pipe. The engine serial number 2 is l...

Page 7

General information 1-5 fuel (for the other countries) use unleaded gasoline that is graded 91 octane or higher by the research method. Engine oil (for usa) suzuki recommends the use of suzuki performance 4 motor oil or oils that meet api service classifications sf or sg and that have a viscosity ra...

Page 8: Break-Ln Procedures

1-6 general information break-ln procedures during manufacturing only the best possible materials are used and all machined parts are finished to a very high standard. It is still necessary to allow the moving parts to “break-ln” before subjecting the engine to maximum stresses. The future performan...

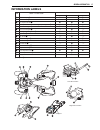

Page 9: Information Labels

General information 1-7 information labels label or plate name no applied specification e-03 e-28 e-33 1 certification plate e ¡ — ¡ 2 information label e — — ¡ 3 tire air pressure label e ¡ ¡ ¡ 4 tire air pressure label and warning no-passenger label f — ¡ — 5 general warning label e ¡ ¡ ¡ 6 genera...

Page 10: Specifications

1-8 general information specifications dimensions and dry mass overall length....................................................... 1 830 mm (72.0 in) overall width ........................................................ 1 165 mm (45.9 in) overall height...............................................

Page 11

General information 1-9 chassis front suspension................................................. Independent, double wishbone, coil spring, oil damped rear suspension ................................................. Swingarm type, coil spring, oil damped front wheel travel............................

Page 12: Country And Area Codes

1-10 general information country and area codes the following codes stand for the applicable countries and areas. Code country or area e-03 e-28 e-33 usa canada california (usa).

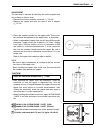

Page 13: How To Use This Manual

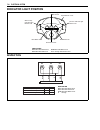

How to use this manual to locate what you are looking for: 1. The text of this manual is divided into sections. 2. The section titles are listed in the group index. 3. Holding the manual as shown at the right will allow you to find the first page of the section easily. 4. The contents are listed on ...

Page 14

Symbol listed in the table below are the symbols indicating instructions and other information necessary for servic- ing. The meaning of each symbol is also included in the table. Symbol definition symbol definition torque control required. Data beside it indicates specified torque. Apply thread loc...

Page 15: Periodic Maintenance

2 6 periodic maintenance 2-1 contents periodic maintenance periodic maintenance schedule ............................................2- 2 periodic maintenance chart ...........................................2- 2 maintenance and tune-up procedures ...............................2- 3 air cleaner .......

Page 16

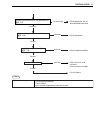

2-2 periodic maintenance periodic maintenance schedule the chart below lists the recommended intervals for all the required periodic service work necessary to keep the vehicle operating at peak performance and economy. Maintenance intervals are expressed in terms of kilometers, miles and months, and...

Page 17

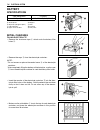

Periodic maintenance 2-3 maintenance and tune-up procedures this section describes the servicing procedures for each item mentioned in the periodic maintenance chart. Air cleaner if the air cleaner is clogged with dust, intake resistance will be increased, with a resultant decrease in power output a...

Page 18

2-4 periodic maintenance ! • remove the drain cap 1 of the air cleaner box to allow any water to drain out. Exhaust pipe nuts and muffler bolts • tighten the exhaust pipe nuts 1, muffler connection bolt 2, and muffler mounting bolt 3 to the specified torque. " exhaust pipe nut: 23 n·m (2.3 kgf-m, 16...

Page 19

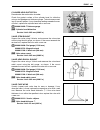

Periodic maintenance 2-5 valve clearance excessive valve clearance results in valve noise and insufficient valve clearance results in valve damage and reduced power. Check the intake and exhaust valve clearances at the distances indicated above and adjust the valve clearances to specification, if ne...

Page 20

2-6 periodic maintenance • remove the valve timing inspection plug 1 and generator cover cap 2. Note: * the piston must be at top dead center (tdc) on the compres- sion stroke in order to check or adjust the tappet clearance. * the tappet clearance should only be checked when the engine is cold. • r...

Page 21

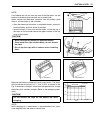

Periodic maintenance 2-7 adjustment the clearance is adjusted by replacing the existing tappet shim with a thicker or thinner shim. • remove the intake or exhaust camshafts. ( #3-10) • remove the tappet and shim by hand or with a magnet. ( #3-19) • check the numbers printed on the tappet shim. These...

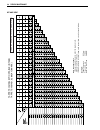

Page 22

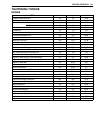

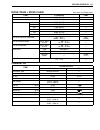

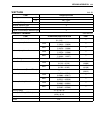

2-8 periodic maintenance intake side t appet shim selection t able (int ake) t appet shim no . (12892-41c00-xxx) t appet shim set no .(12800-41810) ho w to use this c har t: i. Measure tappet clear ance when the engine is cold. Ii. Measure present shim siz e . Iii. Match clear ance in v e rtical col...

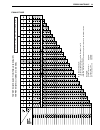

Page 23

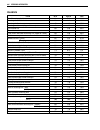

Periodic maintenance 2-9 exhaust side ho w to use this c har t: i. Measure tappet clear ance when the engine is cold. Ii. Measure present shim siz e . Iii. Match clear ance in v e rtical column with present shim siz e in hor iz ontal column. Example: t appet clear ance is 0.38 mm present shim siz e ...

Page 24

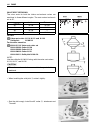

2-10 periodic maintenance spark plug • disconnect the spark plug cap 1 and remove the spark plug. Carbon deposits check to see if there are carbon deposits on the spark plug. If carbon is deposited, remove it using a spark plug cleaner machine or carefully use a tool with a pointed end. Spark plug g...

Page 25

Periodic maintenance 2-11 spark plug installation ! • insert the spark plug and finger tighten it to the cylinder head and then tighten it to the specified torque. " spark plug: 11 n·m (1.1 kgf-m, 8.0 lb-ft) fuel hose inspect the fuel hose for damage and fuel leakage. If any dam- ages are found, rep...

Page 26

2-12 periodic maintenance • connect the electric tachometer or the multi circuit tester to the high-tension cord. • start the engine and set the engine idle speed between 1 400 and 1 600 r/min by turning the throttle stop screw 1. % engine idle speed: 1 500 ± 100 r/min $ 09900-26006: tachometer, or ...

Page 27

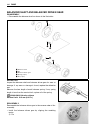

Periodic maintenance 2-13 oil filter replacement • drain the engine oil as described in the engine oil replace- ment procedure. • remove the oil filter cap 1 and oil filter 2. • replace the oil filter with a new one. • install the new o-ring 3. • install the spring 4 and new o-ring 5. ! • replace th...

Page 28

2-14 periodic maintenance engine coolant engine coolant level check • check the engine coolant level by observing the upper a and lower b lines on the engine coolant reservoir. • if the level is below the lower line, add engine coolant until the level reaches the upper line. Engine coolant replaceme...

Page 29

Periodic maintenance 2-15 • install the radiator cap securely. • after warming up and cooling down the engine, add engine coolant until the level is between the upper and lower lines on the engine coolant reservoir. ! % engine coolant capacity (including reserve): 1 200 ml (1.3 us qt, 1.1 lmp qt) ra...

Page 30

2-16 periodic maintenance clutch • loosen the locknut 1. • turn the adjuster 2 in or out to obtain the correct play. • tighten the locknut 1. % clutch lever play a: 10 – 15 mm (0.4 – 0.6 in) brakes brake pads • remove the front and rear wheels. ( #6-10) the extent of brake pad wear can be checked by...

Page 31

Periodic maintenance 2-17 • adjust the brake switch so the brake light comes on when the brake pedal is depressed 7 – 10 mm (0.3 – 0.4 in). Parking brake parking brake adjustment may be required if the parking brake does not work properly. Every time the brake pads are replaced, adjust the parking b...

Page 32

2-18 periodic maintenance • turn the parking brake adjuster 2 clockwise until it stops. • then turn the adjuster 2 ( – ) back. • tighten the adjuster locknut 1 while holding the adjuster 2 in position with a screw driver. " parking brake adjuster locknut: 18 n·m (1.8 kgf-m, 13.0 lb-ft) ! Brake fluid...

Page 33

Periodic maintenance 2-19 air bleeding the brake fluid circuit air trapped in the brake fluid circuit acts like a cushion absorb a large proportion of the pressure developed by the master cylin- der and thus interferes with the full braking performance of the brake caliper. The presence of air is in...

Page 34

2-20 periodic maintenance brake hoses • check the brake hoses for leakage, cracks, wear and dam- age. If any damages are found, replace the brake hoses with new ones. Tires tire tread condition operating the vehicle with excessively worn tires will decrease riding stability and consequently invite a...

Page 35

Periodic maintenance 2-21 ! ! Steering steering system should be adjusted properly for smooth manip- ulation of the handlebars and safe running. Toe-in • place the vehicle on level ground. • make sure the tire pressure for right and left tires is the same and set to the proper specification. • set t...

Page 36

2-22 periodic maintenance drive chain visually check the drive chain for the possible defects listed below. (support the motorcycle by a jack and a wooden block, turn the rear wheel slowly by hand with the transmission shifted to neutral.) * loose pins * excessive wear * damaged rollers * improper c...

Page 37

Periodic maintenance 2-23 • count out 21 pins (20 pitches) on the chain and measure the distance between the two points. If the distance exceeds the service limit, the chain must be replaced. % drive chain 20-pitch length service limit: 319.4 mm (12.57 in) adjusting • loosen or tighten both chain ad...

Page 38

2-24 periodic maintenance cleaning and lubricating • clean the drive chain with kerosine. If the drive chain tends to rust quickly, the intervals must be shortened. ! • after washing and drying the chain, oil it with a heavyweight motor oil. ! Suspensions • support the vehicle with a jack or wooden ...

Page 39

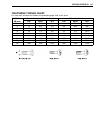

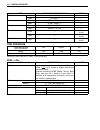

Periodic maintenance 2-25 chassis bolts and nuts check that all chassis nuts and bolts are tightened to their specified torque. (refer to page 2-26 and 2-27 for the locations of the following nuts and bolts.) tighten initially at 1 month and every 3 months there- after. Item n·m kgf-m lb-ft 1 handle...

Page 40

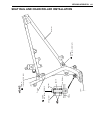

2-26 periodic maintenance.

Page 41

Periodic maintenance 2-27.

Page 42

2-28 periodic maintenance general lubrication proper lubrication is important for smooth operation and long life of each working part of the vehicle. Major lubrication points are indicated below. 1brake lever holder 5brake cam grease 2throttle lever 6drive shaft joint spline motor oil 3steering shaf...

Page 43: Compression Pressure Check

Periodic maintenance 2-29 compression pressure check the compression pressure reading of a cylinder is a good indicator of its internal condition. The decision to overhaul the cylinder is often based on the results of a compression test. Periodic mainte- nance records kept at your dealership should ...

Page 44: Oil Pressure Check

2-30 periodic maintenance oil pressure check check the engine oil pressure periodically. This will give a good indication of the condition of the moving parts. % oil pressure: above 20 kpa (0.2 kgf/cm², 2.8 psi) below 60 kpa (0.6 kgf/cm², 8.5 psi) low or high oil pressure can indicate any of the fol...

Page 45: Engine

3 6 engine 3-1 contents engine engine components removable with engine in place ...3- 2 engine left side .....................................................................3- 2 engine right side ..................................................................3- 2 engine center .....................

Page 46

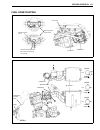

3-2 engine engine components removable with engine in place the parts listed below can be removed and installed without removing the engine from the frame. Refer to the page listed in each section for removal and installation instructions. Engine left side engine right side engine center parts remov...

Page 47

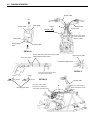

Engine 3-3 engine removal and remounting engine removal before taking the engine out of the frame, wash the engine using a steam cleaner. Engine removal is sequentially explained in the following steps. • drain engine coolant. ( !2-14) • remove the engine under cover 1. • drain engine oil. ( !2-12) ...

Page 48

3-4 engine • remove the fuel tank. ( !4-3) • disconnect the spark plug cap 1 oil tank overflow hose 2 and breather hose 3. • remove the engine coolant inlet hose 4 and disconnect the outlet hose 5. • disconnect the breather hose 6 and remove the oil return tank 7 with hose 8. • remove the carburetor...

Page 49

Engine 3-5 • remove the engine sprocket cover. • remove the clutch cable bracket 1. • disconnect the clutch inner cable 2 from the cam lever. • disconnect the generator lead wire couplers 3 and neutral switch lead wire coupler 4. • remove the reverse gear cable bracket 5. • disconnect the reverse ge...

Page 50

3-6 engine • loosen the muffler clamp bolt 1. • remove the muffler 2. • remove the radiator lower mounting bolt 3 and push lower of the radiator forward. • remove the thermostat cover 4 and thermostat. • remove the exhaust pipe 5. • remove the engine mounting bolts and nut. • remove the engine mount...

Page 51

Engine 3-7 engine remounting remount the engine in the reverse order of engine removal. Pay attention to the following points: note: * the engine mounting nuts are self-locking. * once the nut has been removed, it is no longer of any use. Be sure to use new nuts, and then tighten them to the specifi...

Page 52

3-8 engine • install the engine sprocket with drive chain after loosening the chain adjuster bolts. Note: the letter a on the engine sprocket should face to the outside. • apply thread lock super “1303” to the sprocket bolts. $ 99000-32030: thread lock super “1303” • tighten the engine sprocket bolt...

Page 53: Engine Disassembly

Engine 3-9 engine disassembly • remove the clutch release arm 1. • remove the starter motor 2. • remove the spark plug. & 09930-10121: spark plug wrench set • remove the spring holder bolt 3 of the can chain tension adjuster with spring. • remove the cam chain tension adjuster 4. • remove the cylind...

Page 54

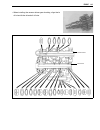

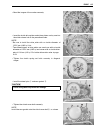

3-10 engine • remove the valve timing inspection plug 1 and generator cover cap 2. • turn the generator rotor until the “t” line on the generator rotor is aligned with the center of the hole in the generator cover. Note: before removing the camshaft journal holders, the piston must be at tdc of the ...

Page 55

Engine 3-11 • remove the cylinder head bolts, and then remove the cylinder head. Note: if the cylinder head does not come off easily, lightly tap it using a plastic mallet. • remove the cylinder head gasket 1 and dowel pins 2. • remove the cam chain guide 3. • remove the cylinder base nuts 4, and th...

Page 56

3-12 engine • remove the starter drive gear cover and starter drive gear 1. • remove the generator rotor cover. • remove the starter driven gear 2, dowel pins 3, and gasket 4. • remove the clutch cover. A: bolt with washer • remove the dowel pins 5 and gasket 6..

Page 57

Engine 3-13 • hold the generator rotor using a 27-mm offset wrench. • loosen the clutch spring set bolts working in diagonal stages. • remove the bolts and springs. • remove the clutch pressure plate, clutch drive plates, and clutch driven plates. • remove the clutch push piece 1, push rod 2. • flat...

Page 58

3-14 engine • remove the primary driven gear assembly 1 and washer 2. • remove the coller 3. • remove the cam chain tensioner 4 and cam chain 5. • remove the oil pipe 6. • remove the oil pump idle gear 7 and oil pump driven gear 8. • remove the pin 9 and oil pump assembly. " do not remove the snap r...

Page 59

Engine 3-15 • remove the gearshift shaft 1 by removing the snap ring 2. • remove the gearshift pawl lifter 3 and gearshift cam driven gear 4. • remove the gearshift cam stopper arm 5. • remove the gearshift cam driven gear bolt. • hold the generator rotor using a 27-mm offset wrench, and then remove...

Page 60

3-16 engine • remove the key 1, balancer drive gear 2 and pin. • hold the generator rotor using a 27-mm offset wrench, and then remove the generator rotor nut. • remove the generator rotor using the special tool. & 09930-31921: rotor remover note: temporarily install the generator rotor nut to the c...

Page 61

Engine 3-17 • remove the neutral switch 1. • remove the o-ring 2, switch contacts 3 and springs 4. • remove the left crankcase securing bolts. • remove the right crankcase securing bolts. • separate the crankcase using the special tool. & 09920-13120: crankcase separating tool note: fit the crankcas...

Page 62

3-18 engine • remove the reverse idle gear with its shaft. • remove the countershaft assembly 1 and driveshaft assem- bly 2. • remove the balancer shaft. • remove the crankshaft from the crankcase using the special tool. & 09920-13120: crankcase separating tool.

Page 63

Engine 3-19 engine components inspection and service cylinder head disassembly " • remove the intake pipe. • remove the engine coolant hose housing 1 and thermostat 2. • remove the tappets 3 and shims 4 by hand or by using a magnet. Identify the position of each removed part. Organize the parts in t...

Page 64

3-20 engine • compress the valve springs, and then remove the valve cot- ters 1 from the valve stem using the special tools. & 09916-14510: valve spring compressor 09916-14910: attachment 09916-84511: tweezers • remove the valve spring retainer 2 and valve spring 3. • remove the valve 4 from the oth...

Page 65

Engine 3-21 cylinder head distortion decarbonize the combustion chamber. Check the gasket surface of the cylinder head for distortion using a straightedge and thickness gauge. Take clearance read- ings at several places. If any clearance reading exceeds the ser- vice limit, replace the cylinder head...

Page 66

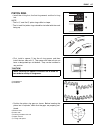

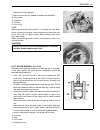

3-22 engine valve stem deflection lift the valve about 10 mm (0.39 in) from the valve seat. Mea- sure the valve stem deflection in two directions, “x” and “y”, per- pendicular to each other. Position the dial gauge as shown. If the deflection exceeds the service limit, determine whether the valve or...

Page 67

Engine 3-23 • oil the stem hole of each valve guide and drive the guide into the guide hole using the valve guide installer and attachment. & 09916-44310: valve guide remover/installer 09916-53360: valve guide installer attachment " • after fitting the valve guides, refinish their guiding bores with...

Page 68

3-24 engine valve seat servicing the valve seats for both the intake and exhaust valves are machined to three different angles. The seat contact surface is cut at 45°. For usa & valve seat cutter: n-114, n-121 and n-128 solid pilot: n-100-5.0 for the other countries & 09916-21110: valve seat cutter ...

Page 69

Engine 3-25 initial seat cut • descale and clean up the seat using the 45° cutter. Rotate the cutter one or two turns. • measure the valve seat width w after every cut. • if the valve seat is pitted or burned, use the 45° cutter to con- dition the seat some more. Note: cut only the minimum amount ne...

Page 70

3-26 engine final seat cut • if the contact area is too low or too narrow, use the 60° cutter to raise and widen the contact area. If the contact area is too high or too wide, use the 15° or 30° cutter to lower and narrow it to the correct width. • after the desired seat position and width is achiev...

Page 71

Engine 3-27 valve spring the force of the coil spring keeps the valve seat tight. A weak- ened spring results in reduced engine power output and accounts for the chattering noise coming from the valve mecha- nism. Check the valve springs for proper strength by measuring their free length and also by...

Page 72

3-28 engine • install the valve spring retainer by pressing down the spring using the valve lifter. Fit the cotter halves to the stem end and release the lifter to allow the cotter 1 to wedge between the retainer and the valve stem. Make sure that the rounded lip 2 of the cotter fits snugly into the...

Page 73

Engine 3-29 camshaft journal wear measure the oil clearance, with the camshaft installed, using the plastigauge. & 09900-22301: plastigauge 09900-22302: plastigauge % camshaft journal oil clearance (in & ex) service limit: 0.150 mm (0.0059 in) • tighten the camshaft journal holder bolts evenly and i...

Page 74

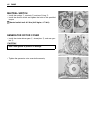

3-30 engine cam chain tension adjuster and ten- sioner check that the push rod slides smoothly when unlocking the ratchet mechanism 1. If push rod does not slide smoothly, replace the cam chain ten- sion adjuster with a new one. Check the contacting surface of the cam chain tensioner and cam chain g...

Page 75

Engine 3-31 piston and piston ring piston diameter measure the piston diameter using the micrometer at 15 mm (0.6 in) from the skirt end. If the piston diameter is less than the service limit, replace the piston with a new one. & 09900-20204: micrometer (75 – 100 mm) % piston diameter service limit:...

Page 76

3-32 engine piston ring free end gap and piston ring end gap measure the piston ring free end gap using the vernier calipers, first, and then fit the piston ring squarely into the cylinder and measure the piston ring end gap using the thickness gauge. If any measurement exceeds the service limit, re...

Page 77

Engine 3-33 conrod conrod small end i.D. Measure the conrod small end inside diameter using the small bore gauge. If the conrod small end inside diameter exceeds the service limit, replace the conrod with a new one. & 09900-20605: dial calipers % conrod small end i.D. Service limit: 20.040 mm (0.789...

Page 78

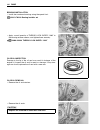

3-34 engine balancer shaft and balancer driven gear disassembly • disassemble the balancer shaft as shown in the illustration. Inspection inspect the balancer shaft and balancer driven gear for wear or damage. If any wear or damage is found, replace the defective part. Measure the free length of eac...

Page 79

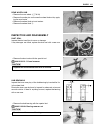

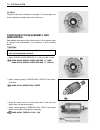

Engine 3-35 starter clutch • hold the rotor using a 27-mm offset wrench and remove the bolts. • install the starter clutch in the proper direction as shown. Note: when installing the starter clutch onto the rotor, make sure that the flange side a in the bearing faces to the rotor. • apply engine oil...

Page 80

3-36 engine starter torque limiter " check the slip torque of the starter torque limiter using the spe- cial tools and vise as shown, if the slip torque is not within the specified torque, replace the starter torque limiter with a new one. & 09930-73170: starter torque limiter holder 09930-73180: st...

Page 81

Engine 3-37 • when installing the outer rotor, face the punched mark 1 on the outer rotor to the outside. Clutch clutch drive plates measure the thickness of the clutch drive plates using vernier calipers. If a clutch drive plate is not within the service limit, replace the clutch plates as a set. &...

Page 82

3-38 engine gearshift fork and gear gearshift-fork-to-gearshift-fork groove clearance clearance for each gearshift fork plays an important role in the smoothness and positiveness of the shifting process. Measure the gearshift fork clearance in the groove of its respec- tive gear using the thickness ...

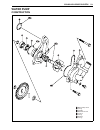

Page 83

Engine 3-39 transmission disassembly disassemble the transmission gears as shown. 1 countershaft 2 5th drive gear 3 3rd drive gear 4 4th drive gear 5 2nd drive gear 6 driveshaft 7 2nd driven gear 8 4th driven gear 9 3rd driven gear 0 5th driven gear a reverse driven gear b 1st/reverse dog c 1st driv...

Page 84

3-40 engine reassembly reassemble the transmission in the reverse order of disassem- bly. Pay special attention to the following points: note: before installing the gears, apply engine oil to the inner surface of each gear and bushing. " note: when reassembling the transmission, attention must be gi...

Page 85

Engine 3-41 • when installing the reverse driven gear bushing, align the its oil hole with the driveshaft oil hole. Countershaft driveshaft.

Page 86

3-42 engine crankcase oil sump filter • remove the oil sump filter. • clean the oil sump filter using compressed air. • align the oil passage holes when installing the oil sump filter. Oil jet • remove the oil jet. • fit the new o-ring and apply engine oil to it. • install the oil jet as shown..

Page 87

Engine 3-43 oil pump idle gear shaft and gearshift arm stopper • remove the oil pump idle gear shaft 1. • apply thread lock “1342” to the gearshift arm stopper. • tightening the gearshift arm stopper 2 to the specified torque. ( 99000-32050: thread lock “1342” # gearshift arm stopper: 19 n·m (1.9 kg...

Page 88

3-44 engine bearing installation • install the crankcase bearings using the special tool. & 09913-70210: bearing installer set • apply a small quantity of thread lock super “1303” to the bearing retainer screws, and tighten them securely. $ 99000-32030: thread lock super “1303” oil seal inspection d...

Page 89

Engine 3-45 oil seal installation • install the oil seals into the crankcase. Pay attention to the fol- lowing points: • apply suzuki super grease “a” to the lip of the oil seals. ) 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (others) • install the new oil seals u...

Page 90

3-46 engine clutch cover oil filter !2-13 water pump !5-13 oil check valve • remove the bushing 1, oil check valve ball 2 and spring 3. • install the spring 3, oil check valve ball 2 and bushing 1 to the clutch cover 4 as shown. " the rubber part of bushing 1 must face to the out- side..

Page 91: Engine Reassembly

Engine 3-47 engine reassembly reassemble the engine in the reverse order of disassembly. Pay special attention to the following points: note: apply engine oil to each running and sliding part before reas- sembling the engine. Crankshaft • determine the width between the webs referring to the figure ...

Page 92

3-48 engine gearshift cam, fork and reverse lock shaft • install the gearshift forks into the gearshifting grooves in the correct position and direction. 1 gearshift fork no.1 2 gearshift fork no.2 3 gearshift fork no.3 • install the gearshift cam 4. • install the gearshift fork shaft 5 and reverse ...

Page 93

Engine 3-49 crankcase • thoroughly remove the sealant material and oil stains on the mating surface of the right and left crankcases. • install the dowel pins 1 to the left crankcase. • apply engine oil to the conrod big end and to the transmission gears. • apply suzuki bond “1207b” or “1215” to the...

Page 94

3-50 engine • after the crankcase bolts have been tightened, check if the crankshaft, countershaft, and driveshaft rotate smoothly. If a large resistance is felt to rotation, try to free the shafts by tap- ping them with a plastic mallet. Starter clutch and generator rotor • remove the grease from t...

Page 95

Engine 3-51 primary drive gear and balancer gear • install the pins 1. • install the balancer drive gear 2. • install the key 3 and cam chain drive sprocket 4. • apply engine oil to the thread and inside surface of the nut. • hold the generator rotor using a 27-mm offset wrench, and then tighten the...

Page 96

3-52 engine gearshift cam driven gear • tighten the gearshift cam driven gear bolt to the specified torque. # gearshift cam driven gear bolt: 24 n·m (2.4 kgf-m, 17.5 lb-ft) • install each pawl lifter into the gearshift cam driven gear. The large shoulder a must face to the outside. • apply a small q...

Page 97

Engine 3-53 oil pump • before mounting the oil pump, apply engine oil to the sliding surfaces of the oil pump case, outer rotor, inner rotor, and crankcase. • apply a small quantity of thread lock “1342” or thread lock super “1322” to the oil pump mounting screws, and then tighten them securely. ( 9...

Page 98

3-54 engine clutch • hold the clutch sleeve hub using the special tool, and then tighten the clutch sleeve hub nut to the specified torque. & 09920-53740: clutch sleeve hub holder # clutch sleeve hub nut: 70 n·m (7.0 kgf-m, 50.5 lb-ft) 1 clutch release camshaft 2 bolt 3 spring retainer 4 spring 5 pr...

Page 99

Engine 3-55 • bend the tongue of the washer securely. • insert the clutch drive plates and driven plates one by one into the clutch sleeve hub in the prescribed order. Note: * be sure to install the drive plate with an inside diameter of 122.5 mm (4.82 in), first. * two different types of drive plat...

Page 100

3-56 engine neutral switch • install the springs 1, contacts 2 and new o-ring 3. • install the neutral switch and tighten the bolts to the specified torque. # neutral switch bolt: 6.5 n·m (0.65 kgf-m, 4.7 lb-ft) generator rotor cover • install the starter driven gear 1, dowel pins 2, and new gas- ke...

Page 101

Engine 3-57 piston ring • install the oil ring first, the 2nd ring second, and the 1st ring last. Note: * the 1st 1 and 2nd 2 piston rings differ in shape. * the 1st and 2nd piston rings should be installed with the mark facing up. • first, install a spacer 3 into the oil ring groove, and then insta...

Page 102

3-58 engine piston and cylinder • apply molybdenum oil solution onto the piston pin and small end of the conrod. Note: install the piston with the punch mark 1 on the piston head fac- ing toward the exhaust side. • place a clean rag over the cylinder base to prevent the piston pin circlip from dropp...

Page 103

Engine 3-59 • install the cam chain guide 1. Note: make sure that the guide 1 is inserted properly or binding of the cam chain and guide may result. • install the dowel pins 2 and new gasket 3. " cylinder head • with the head snugly seated on the cylinder, secure it by tightening the bolts in diagon...

Page 104

3-60 engine camshaft/automatic decompression assembly • turn the generator rotor until the “t” line on the generator rotor is aligned with the center of the hole in the generator cover. " note: just before installing the camshaft into the cylinder head, apply molybdenum oil solution to the camshaft ...

Page 105

Engine 3-61 • with the “t” line aligned with the center of the hole, hold the camshaft steady and lightly pull up the cam chain to remove any slack between the cam chain drive sprocket and exhaust camshaft sprocket. • the exhaust camshaft sprocket has an arrow marked “1” 1. Turn the exhaust camshaft...

Page 106

3-62 engine • install the dowel pins 1. • place each camshaft journal holders and cam chain guide into the correct position. Note: camshaft journal holders marked “ex” are for the exhaust side and those marked “in” are for the intake side. • tighten the camshaft journal holder bolts to the specified...

Page 107

Engine 3-63 cam chain tension adjuster • apply engine oil to the push rod. • unlock the ratchet mechanism 1 and push the push rod 2 all the way. • install the new gasket and cam chain tension adjuster to the cylinder. • tighten the cam chain tension adjuster mounting bolts to the specified torque. #...

Page 108: Fuel System

2 4 6 fuel system 4-1 contents fuel system fuel tank ..........................................................................................4- 2 construction .........................................................................4- 2 fuel line inspection ...........................................

Page 109: Fuel Tank

4-2 fuel system fuel tank construction insert the breather hose no. 2 into the steering stem shaft. Fit the cutaway on the cushion to the frame bracket. 1 steering stem head cover 2 breather hose no.1 3 breather hose no.2 4 fuel tank cap 5 fuel tank 6 fuel valve 7 fuel hose 8 duct cover 9 air cleane...

Page 110

Fuel system 4-3 fuel line inspection inspect the fuel lines, fuel tank 1, fuel tank breather hoses 2 and fuel tank cap 3 for damage, clogging and leakage of fuel. If any damages are found, replace the defective parts with the new ones. Removal • remove the seat, fuel tank side covers. ( !6-4) • turn...

Page 111: Fuel Valve

4-4 fuel system fuel valve removal and inspection • remove the fuel tank. ( !4-3) • drain fuel completely. • remove the fuel valve. " fuel strainer if the fuel strainer is dirty with sediment or rust, fuel will not flow smoothly and loss in engine power may result. Clean the fuel strainer with compr...

Page 112: Carburetor

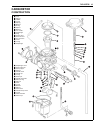

Fuel system 4-5 carburetor construction 1 cap 2 spring 3 holder 4 o-ring 5 spring 6 washer 7 e-ring 8 spacer 9 washer 0 jet needle a diaphragm b ring c piston valve d vacuum hose e air vent hose f cover g o-ring h diaphragm i diaphragm cover j starter plunger k pilot jet pipe l pilot jet m needle va...

Page 113

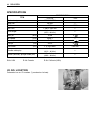

4-6 fuel system specifications e-03: usa e-28: canada e-33: california (usa) i.D. No. Location carburetor has an i.D. Number 1 punched on its body. Item specification e-03, 28 e-33 carburetor type mikuni bsr36 ← bore size 36 mm ← i.D. No. 07g0 07g1 idle r/min 1 500 ± 100 r/min ← float height 13.0 ± ...

Page 114

Fuel system 4-7 removal • remove the fuel tank left side cover. ( !6-4) • disconnect the fuel hose 1 and vacuum hose 2. • loosen the carburetor clamp screw. • loosen the carburetor clamp screw. • disconnect the air vent hose 3. • disconnect the starter cable 4. • remove the carburetor side cap 5..

Page 115

4-8 fuel system • disconnect the throttle cable 6. • remove the o-ring 7. Disassembly • remove the fuel hose a, over flow hose b and vacuum hose c. • remove the throttle stop screw d. • remove the carburetor top cap. # • remove the spring 1, o-ring 2 and diaphragm assembly 3. Do not use compressed a...

Page 116

Fuel system 4-9 • remove the jet needle holder 4, o-ring 5, spring 6, washer 7, jet needle 8 and washer 9. • remove the diaphragm cover 0. • remove the diaphragm a. • remove the float chamber..

Page 117

4-10 fuel system • remove the o-ring b. # • remove the float pin c, float d and needle valve e. • remove the valve seat f. Replace the removed o-ring with a new one to prevent leakage of fuel..

Page 118

Fuel system 4-11 • remove the following parts. G main jet, main jet ring, needle jet holder and needle jet h pilot screw i starter jet j pilot jet k pilot air jet note: before removing the pilot screw h, its setting must be deter- mined. Slowly turn the pilot screw clockwise and count the num- ber o...

Page 119

4-12 fuel system cleaning " • clean all jets with a spray-type carburetor cleaner and dry them using compressed air. • clean all circuits of the carburetor thoroughly – not just the perceived problem area. Clean the circuits in the carburetor body with a spray-type cleaner. If necessary, soak each c...

Page 120

Fuel system 4-13 needle valve inspection if foreign matter is caught between the valve seat and the nee- dle valve, the gasoline will continue flowing and overflow. If the valve seat and needle valve are worn beyond the permissible limits, similar trouble will occur. Conversely, if the needle valve ...

Page 121

4-14 fuel system valve seat • install the valve seat 1 into the carburetor body, and then tighten the screw 2. Note: make sure that the collar of the screw 2 holds the step of the valve seat 1 securely. Diaphragm • install the diaphragm assembly and o-ring 1. Note: when installing the diaphragm, mak...

Page 122

5 cooling and lubrication system 5-1 contents cooling and lubrication system cooling system ..............................................................................5- 2 description .............................................................................5- 2 engine coolant ...................

Page 123: Cooling System

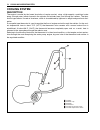

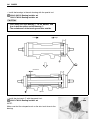

5-2 cooling and lubrication system cooling system description the engine is cooled by the forced circulation of engine coolant, using a high-capacity, centrifugal water pump, through water jackets formed in the cylinder and cylinder head, and through the radiator. The tube- and-fin type radiator is ...

Page 124: Engine Coolant

Cooling and lubrication system 5-3 engine coolant at the time of manufacture, the cooling system is filled with a 50:50 mixture of distilled water and ethylene glycol anti-freeze. This 50:50 mixture will provide the optimum corrosion protection and excellent heat protection, and will protect the coo...

Page 125: Radiator And Hoses

5-4 cooling and lubrication system radiator and hoses cooling circuit inspection before removing the radiator and draining the engine coolant, check the following. Check the cooling system for leaks with a radiator tester 1. Remove the radiator cap and connect the radiator tester to the filler. Pres...

Page 126

Cooling and lubrication system 5-5 radiator hose inspection • remove the front fender. ( %6-4) any radiator hose found in a cracked condition or flattened must be replaced. Any leakage from the connecting section should be corrected by proper tightening. Radiator removal • remove the front fender. (...

Page 127

5-6 cooling and lubrication system • disconnect the engine coolant temperature switch lead wire coupler 1 and cooling fan motor lead wire coupler 2. • disconnect the upper and lower radiator hoses. • remove the three mounting bolts and radiator assembly. Radiator remounting • install the radiator an...

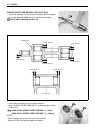

Page 128: Cooling Fan

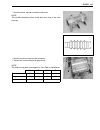

Cooling and lubrication system 5-7 cooling fan inspection • remove the front fender. ( %6-4) • disconnect the cooling fan lead wire coupler. Test the cooling fan motor for load current with an ammeter con- nected as shown in the illustration. The voltmeter is for making sure that the battery applies...

Page 129

5-8 cooling and lubrication system • remove the cooling fan. • remove the cooling fan motor. Remounting remount the cooling fan in the reverse order of removal..

Page 130: Cooling Fan Thermo-Switch

Cooling and lubrication system 5-9 cooling fan thermo-switch the cooling fan is secured behind the radiator by three bolts and is automatically controlled by the thermo- switch. The thermo-switch remains open when the temperature of the engine coolant is low, but closes when the temperature reaches ...

Page 131

5-10 cooling and lubrication system inspection • check the thermo-switch closing or opening temperatures by testing it at the bench as shown in the figure. Connect the thermo-switch 1 to a circuit tester and place it in the oil con- tained in a pan, which is placed on a stove. • heat the oil to rais...

Page 132

Cooling and lubrication system 5-11 engine coolant temperature switch removal • remove the front fender. ( %6-4) • drain a small amount of engine coolant. ( %2-14) • disconnect the engine coolant temperature switch lead wire coupler 1. • remove the engine coolant temperature switch 2. Inspection • c...

Page 133: Thermostat

5-12 cooling and lubrication system thermostat removal • drain a small amount of engine coolant. ( %2-14) • place a rag under the thermostat case. • remove the thermostat case. • remove the thermostat. Inspection inspect the thermostat pellet for signs of cracking. Test the thermostat at the bench f...

Page 134: Water Pump

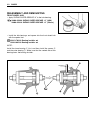

Cooling and lubrication system 5-13 water pump construction 1 water pump cover 2 o-ring 3 impeller 4 mechanical seal 5 oil seal 6 o-ring 7 bearing 8 o-ring.

Page 135

5-14 cooling and lubrication system removal and disassembly • drain engine coolant. ( %2-14) • drain engine oil. ( %2-12) " • disconnect the radiator hose. • disconnect the rear brake switch spring and brake pedal spring as to lower side. • remove the master cylinder mounting bolts. • remove the clu...

Page 136

Cooling and lubrication system 5-15 • remove the water pump cover. • remove the snap ring 1, water pump driven gear 2, pin 3 and washer 4. • remove the e-ring 5, impeller 6, and water pump body 7. • remove the bearing using the special tool. & 09921-20240: bearing remover set note: if there is no ab...

Page 137

5-16 cooling and lubrication system • place a rag over the water pump. • remove the oil seal using a suitable bar. Note: if there is no abnormal condition, the oil seal removal is not nec- essary. ! • remove the mechanical seal ring 1 and the rubber seal 2 from the impeller. Inspection bearing • ins...

Page 138

Cooling and lubrication system 5-17 bearing case/mechanical case • visually inspect the bearing case and mechanical case for damage. • replace the water pump body if necessary. Impeller • visually inspect the impeller and its shaft for damage. Reassembly and installation • install the oil seal using...

Page 139

5-18 cooling and lubrication system • install the new mechanical seal using a suitable size socket wrench. Note: on the new mechanical seal, the seealer a has been applied. • install the new bearing using the special tool. & 09913-70210: bearing installer set • install the rubber seal 1 into the imp...

Page 140

Cooling and lubrication system 5-19 • install the new o-rings 1 and 2. • apply grease to the o-rings. * 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (others) • install the water pump body with the impeller to the clutch cover. • install the e-ring to the impeller s...

Page 141

5-20 cooling and lubrication system • install the new o-ring to the water pump cover. ! • apply engine coolant to the o-ring. • install the water pump cover to the clutch cover. • install the clutch cover. ( %3-55) • install the master cylinder mounting bolts. ) master cylinder mounting bolt: 10 n·m...

Page 142: Oil Tank and Hoses

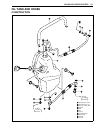

Cooling and lubrication system 5-21 oil tank and hoses construction 1 oil tank hose, rh 2 oil tank hose, lh 3 oil hose union bolt 4 gasket 5 bolt 6 pin 7 o-ring 8 overflow hose 9 drain plug 0 gasket a oil tank 12 n.M 1.2 kgf-m 8.5 lb-ft 23 n.M 2.3 kgf-m 16.5 lb-ft.

Page 143

5-22 cooling and lubrication system removal • remove the front fender. ( %6-4) • drain engine coolant. ( %2-14) • remove the radiator. ( %5-5) • drain engine oil. ( %2-12) • remove the oil tank protector 1. • remove the engine protector 1. • remove the oil hoses..

Page 144

Cooling and lubrication system 5-23 • remove the oil tank. Remounting remount the oil tank and hoses in the reverse order of removal. Pay attention to the following points. • when connecting the oil tank right hose, place the base of oil pipe against the stopper on engine. • tighten the oil hose uni...

Page 145: Lubrication System

5-24 cooling and lubrication system lubrication system oil pressure %2-30 oil filter %2-13 oil sump filter %3-42 oil pump %3-36.

Page 146

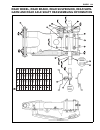

Cooling and lubrication system 5-25 engine lubrication system chart primary gears oil jet piston orifice oil tank oil pump oil pump (for return) oil sump filter oil hose oil hose idle gear drive gear right crankcase left crankcase countershaft oil pipe by-pass oil filter clutch cover oil check valve...

Page 147: Chassis

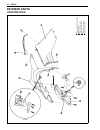

Contents chassis exterior parts ......................................................................................... 6- 2 construction ................................................................................... 6- 2 removal ..................................................................

Page 148

6 chassis 6-1 front wheel, front brake, front suspension and steering reassembling information ......................................6-48 rear brake .................................................................................................6-49 construction .......................................

Page 149: Exterior Parts

6-2 chassis exterior parts construction 1 re v erse loc k release knob 2 f ront f ender 3 fuel tank top co v e r 4 fuel tank side co v e r 5 headlight assemb ly 6 center front f ender.

Page 150

Chassis 6-3 rear fender shield battery plate rear fender bracket cushion right mud guard reinforcement left mud guard reinforcement right mud guard left mud guard foot rest 55 n.M (5.5 kgf-m, 40.0 lb-ft) / before adhering the shield, degrease the front fender. 2 mm (0.08 in) 1 2 3 4 5 6 7 8 9 0

Page 151

6-4 chassis removal seat • remove the seat by pulling the lock release lever 1 which is located behind the rear fender. Front fender • remove the seat. ( !Above) • remove the fuel tank cap 1. • remove the fuel tank top cover 2. • remove the fuel tank side covers 3..

Page 152

Chassis 6-5 • remove the reverse lock release knob 4. • remove the front fender mounting bolts. • disconnect the headlight coupler 5. • remove the front fender. • remove the headlight assembly 6..

Page 153

6-6 chassis footrest mud guard • remove the mud guards 1. Footrest • remove the footrest mud guards. ( !Above) • remove the footrests..

Page 154

Chassis 6-7 rear fender • remove the seat. ( !6-4) • remove the fasteners. • remove the battery plate 1. • remove the battery 2. • disconnect the battery lead wire clamp 3. • remove the starter relay 4. • remove the rear fender mounting bolts. • remove the rear fender..

Page 155

6-8 chassis remounting remount the exterior parts in the reverse order of removal. Pay attention to the following points: footrest • apply thread lock “1342” to the bolts 1 and tighten bolts to the specified torque. " 99000-32050: thread lock “1342” # footrest mounting bolt: 55 n·m (5.5 kgf-m, 40.0 ...

Page 156: Front And Rear Wheels

Chassis 6-9 front and rear wheels construction 1 disc cover 2 front disc 3 spacer 4 dust seal 5 hub bearing 6 bearing spacer 7 front wheel hub 8 hub bearing 9 dust seal 0 spacer a washer b cotter pin c tire valve d front tire e front wheel rim f sprocket flange g sprocket h washer i rear wheel hub j...

Page 157

6-10 chassis removal front and rear wheels • place the vehicle on level ground. • support the vehicle with a jack or wooden block. • remove the wheel. • remove the front hub plate 1. Front wheel hub • remove the front wheel. ( !See above) • remove the cotter pin, then loosen the wheel hub nut. • rem...

Page 158

Chassis 6-11 rear wheel hub • remove the rear wheel. ( !6-10) • remove the cotter pin and loosen the wheel hub nut by apply- ing the rear brake. • remove the wheel hub nut and washer. • remove the wheel hub 1. Inspection and disassembly dust seal inspect the dust seal lips for wear or damege. If any...

Page 159

6-12 chassis reassembly and remounting front wheel hub • apply suzuki super grease “a” to the hub bearing. ' 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (others) • install the hub bearings and spacer into the front wheel hub with the special tool. & 09913-70210: b...

Page 160

Chassis 6-13 • install the dust seals 4 into the front wheel hub with fabric portion facing to outside. • apply suzuki super grease “a” to the dust seal’s lip. ' 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (others) • install the spacers 5 to the wheel hub. • insta...

Page 161

6-14 chassis rear wheel hub • apply small amount of suzuki super grease “a” to the wheel hub’s spline. ' 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (others) • install the rear wheel hub 1, washer and nut. • tighten the rear wheel hub nut to the specified torque. ...

Page 162: Tires

Chassis 6-15 tires tire replacement • remove the front and rear wheels. ( !6-10) • after removing the air valve cap, release the tire pressure by depressing the valve. • dismount the bead from the rim completely as shown. • separate the tire from the rim by using a set of tire levers and rim protect...

Page 163

6-16 chassis note: * for inspecting the tire, refer to page 2-20. * inspect the valve core, before installation. * when installing the front tire, make sure that the arrow a on the side wall of the front tire points in the direction of rotation. * when installing the rear tire, make sure that the in...

Page 164: Front Brake

Chassis 6-17 front brake construction ) % * this brake system is filled with an ethylene glycol-based dot 4 brake fluid. Do not use or mix different types of fluid, such as silicone-based or petroleum-based brake fluids. * do not use any brake fluid taken from old, used or unsealed containers. Never...

Page 165

6-18 chassis brake pad replacement • remove the front wheel. ( !6-10) • remove the brake caliper mounting bolts 1 and brake pad mounting pins 2. • remove the brake pads. % • install the new brake pads. Note: * before installing the new pads, inspect the pad mounting pins for wear. If excessive wear ...

Page 166

Chassis 6-19 brake fluid replacement • place the vehicle on a level surface and keep the handlebar straight. • remove the master cylinder reservoir cap and diaphragm. • suck up the old brake fluid as much as possible. • fill the reservoir with new brake fluid. * specification and classification: dot...

Page 167

6-20 chassis • remove the spring 1. • place a rag over the brake caliper piston to prevent the piston from popping out and then force out the piston using com- pressed air. % • remove the dust seal and piston seal. % • remove the cap 2 and loosen the brake caliper holder slide pin 3. • remove the br...

Page 168

Chassis 6-21 brake caliper inspection brake caliper inspect the brake caliper cylinder wall for nicks, scratches or other damage. If any damages are found, replace the brake cal- iper with a new one. Brake caliper piston inspect the brake caliper piston for any scratches or other dam- age. If any da...

Page 169

6-22 chassis brake caliper reassembly and remounting reassemble and remount the brake caliper in the reverse order of removal and disassembly. Pay attention to the following points: • wash the caliper bore and piston with the specified brake fluid. Thoroughly wash the dust seal grooves and piston se...

Page 170

Chassis 6-23 • apply suzuki silicone grease to the brake caliper holder slide pin. + 99000-25100: suzuki silicone grease • install the pin 1, washer 2 and caliper holder 3 to the cali- per. • apply thread lock super “1360” to the pin 1. , 99000-32130: thread lock super “1360” • tighten the pin 1 to ...

Page 171

6-24 chassis brake disc removal and disassembly • remove the front wheel. ( !6-10) • remove the front wheel hub. ( !6-10) • remove the brake disc. Brake disc inspection • remove the front wheel. ( !6-10) • remove the caliper. ( !6-19) inspect the brake disc for cracks or damage and measure the thick...

Page 172

Chassis 6-25 master cylinder removal and disassembly • place a rag underneath the brake hose union bolt on the mas- ter cylinder to catch any spilt brake fluid. Remove the brake hose union bolt and disconnect the brake hose. % • remove the master cylinder assembly. • disconnect the brake switch coup...

Page 173

6-26 chassis • remove the piston/secondary cup, primary cup and spring. 7 secondary cup 8 piston 9 primary cup 0 spring master cylinder inspection master cylinder inspect the master cylinder bore for any scratches or damage. If any damages are found, replace the master cylinder with a new one. Pisto...

Page 174

Chassis 6-27 • align the master cylinder holder’s mating surface a with the punch mark b on the handlebars and tighten the upper clamp bolt first. # master cylinder clamp bolt: 10 n·m (1.0 kgf-m, 7.0 lb-ft) c master cylinder d master cylinder upper clamp bolt e handlebar f clearance • tighten the br...

Page 175: Front Suspension

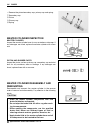

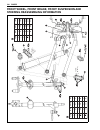

6-28 chassis front suspension construction 1 front shock absorber 2 upper wishbone arm 3 lower wishbone arm 4 coller 5 dust seal 6 bearing 7 dust cover 8 washer 9 dust seal 0 bearing a spacer b knuckle end c steering knuckle d tie rod end e tie rod item n·m kgf.M lb-ft a 60 6.0 43.5 b 65 6.5 47.0 c ...

Page 176

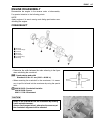

Chassis 6-29 removal • remove the front wheel. ( !6-10) • remove the front wheel hub. ( !6-10) • remove the brake caliper. ( !6-19) • remove the brake hose clamp 1. • disconnect the brake hose at the hose clamp. • remove the front disc cover 2. • remove the cotter pin and tie rod end nut. % • remove...

Page 177

6-30 chassis • remove the shock absorber 6. • remove the cotter pins and nuts. • remove the steering knuckle 7 with a commercially available ball bearing joint remover 8. Inspection and disassembly front shock absorber inspect the shock absorber for oil leakage or damage. If any damages are found, r...

Page 178

Chassis 6-31 • remove the spacer 1. Inspect the bushing and dust seal for wear or damage. If any damages are found, replace the shock absorber with a new one. • apply suzuki super grease “a” to the bushing and dust seals before remounting. ' 99000-25030: suzuki super grease “a” (usa) 99000-25010: su...

Page 179

6-32 chassis wishbone arm inspect the wishbone arm for wear or damage. If any damages are found, replace the wishbone arm with a new one. Wishbone arm pivot bearing • remove the spacer and dust seal. Inspect the dust seal lips and spacers for wear and damage. If any damages are found, replace them w...

Page 180

Chassis 6-33 • remove the needle bearing with the special tools. & 09923-73210: bearing puller 09930-30104: sliding hammer % brake disc cover inspect the brake disc cover for damage. If any damages are found, replace the brake disc cover with a new one. Reassembly and remounting reassemble and remou...

Page 181

6-34 chassis • install the bearings to the wishbone arm to the specified depth by using the special tool and a suitable spacer 1. & 09924-84510: bearing installer note: * position of the bearing is shown in the illustration. * when installing the sealed bearing that is used at the upper wishbone piv...

Page 182

Chassis 6-35 • install the wishbone arms to the steering knuckle and tighten the knuckle end nuts to the specified torque. # knuckle end nut: 43 n·m (4.3 kgf-m, 31.0 lb-ft) • install the cotter pins. % • tighten the wishbone arm pivot nuts to the specified torque. # wishbone arm pivot nut: 65 n·m (6...

Page 183

6-36 chassis • tighten the tie rod end nut to the specified torque. # tie rod end nut: 60 n·m (6.0 kgf-m, 43.5 lb-ft) • install the cotter pin. % note: when installing the tie rod end, install the washer 0 between the tie rod end a and steering knuckle b. Suspension setting spring pre-load adjustmen...

Page 184: Steering

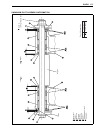

Chassis 6-37 steering construction item n·m kgf-m lb-ft a 23 2.3 16.5 b 23 2.3 16.5 c 49 4.9 35.5 d 60 6.0 43.5 e 29 2.9 21.0 @ 1 handlebar upper holder 2 handlebar lower holder 3 steering shaft 4 steering shaft holder 5 dust seal 6 bushing 7 dust seal 8 o-ring 9 dust seal 0 washer a tie rod b steer...

Page 185

6-38 chassis removal handlebars • remove the front fender. ( !6-4) • remove the master cylinder assembly 1 from the handle- bars. ( !6-25) • remove the throttle lever case 2. • disconnect the rear brake cable 3 and the clutch cable 4. • remove the clutch switch 5 with the detent a depressed. • remov...

Page 186

Chassis 6-39 • remove the oil hose cover by removing two fasteners. • disconnect the oil hoses 2 and breather hose 3. % • remove the oil tank 4. Do not reused the removed o-ring in order to prevent leakage of oil..

Page 187

6-40 chassis • remove the cotter pins and tie rod end nuts. % • remove the tie rods. • remove the cotter pin and steering shaft nut 5, washer 6 and dust seal 7. % • remove the o-ring 8. • remove the steering shaft holder bolts. • remove the cable/hose guide and the steering shaft holder half. Replac...

Page 188

Chassis 6-41 • remove the steering shaft 9. • remove the dust seals 0 from the steering shaft. • remove the steering shaft holder half a. • remove the dust seal b from the steering shaft. Inspection and disassembly inspect the removed parts for the following abnormalities. * handlebar distortion * h...

Page 189

6-42 chassis tie rod end inspect the tie rod ends for smooth movement. If there are any abnormalities, replace the tie rod end with a new one. Inspect the tie rod end boot for wear or damage. If any damages are found, replace the tie rod end with a new one. Steering shaft inspect the steering shaft ...

Page 190

Chassis 6-43 • install the steering shaft bushing 1 with the special tool. & 09924-84510: bearing installer set reassembly and remounting reassemble and remount the steering sfaft in the reverse order of removal and disassembly. Pay attention to the following points: steering shaft • apply suzuki su...

Page 191

6-44 chassis • apply suzuki super grease “a” to the dust seal lip and sliding surface of the steering shaft holders before remounting the steering shaft holders. ' 99000-25030: suzuki super grease “a” (usa) 99000-25010: suzuki super grease “a” (others) % • tighten the steering shaft holder bolts to ...

Page 192

Chassis 6-45 note: when installing the tie rod, make sure the narrow end 1 of the tie rod comes out. % oil tank and radiator • install the oil tank. ( !5-53) • reinstall the radiator assembly. ( !5-6) • pour engine oil. ( !2-12) • pour engine coolant and bleed air from the cooling circuit. ( !2-14) ...

Page 193

6-46 chassis • install the handle switch box with the lug c on the switch half inserted into the hole d on the handlebars. Note: when installing the handlebars, make sure that the cable, wiring harness and brake hose routing are proper. ( !8-11 to 8-20) • install the clutch lever assembly to the han...

Page 194

Chassis 6-47 toe-in adjustment adjust the toe-in as follows: • place the vehicle on level ground and set the handlebars straight. Make sure all the tires are inflated to the standard pressure. ( !2-20) • place 75 kg (165 lbs) of weight on the seat. • loosen the locknuts ( 1, 2) on each tie rod. % • ...

Page 195

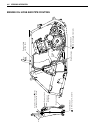

6-48 chassis front wheel, front brake, front suspension and steering reassembling information item n ·m kgf-m lb-ft 1 23 2.3 16.5 2 23 2.3 16.5 3 60 6.0 43.5 4 49 4.9 35.5 5 29 2.9 21.0 6 60 6.0 43.5 @ @ item n ·m kgf-m lb-ft 7 60 6.0 43.5 8 65 6.5 47.0 9 43 4.3 31.0 0 50 5.0 36.0 a 65 6.5 47.0 b 23...

Page 196: Rear Brake

Chassis 6-49 rear brake construction ) % * this brake system is filled with an ethylene glycol-based dot 4 brake fluid. Do not use or mix different types of fluid such as silicone-based or petroleum-based. * do not use any brake fluid taken from old, used or unsealed containers. Never reuse brake fl...

Page 197

6-50 chassis brake pad replacement • flatten the lock washer 1, and then slightly loosen the pad mounting pins 2. • loosen the locknut 3 and turn out the parking brake adjuster 4 several turns. • remove the caliper. • remove the brake pads by removing the pad mounting pins. % • install the new brake...

Page 198

Chassis 6-51 • tighten the caliper mounting bolts to the specified torque. # brake caliper mounting bolt: 26 n·m (2.6 kgf-m, 19.0 lb-ft) • adjust the parking brake. ( !2-17) brake fluid replacement • place the vehicle on a level surface. • remove the seat. ( !6-4) • remove the fuel tank right side c...

Page 199

6-52 chassis brake caliper removal and disassembly • disconnect the parking brake cable by removing the locknut 1 and lever 2. • disconnet the brake hose 3 and allow the brake fluid to drain into a suitable receptacle. • remove the parking brake housing 4. ) • remove the brake caliper by removing th...

Page 200

Chassis 6-53 • loosen the caliper holder slide pin 7, and then remove the caliper holder 8. • remove the caliper holder slide pin 9. • place a rag over the brake caliper piston to prevent the piston from popping out. • force out the piston by pushing the piston pin b. • remove the dust seal 0, pisto...

Page 201

6-54 chassis brake caliper inspection brake caliper inspect the brake caliper cylinder wall for nicks, scratches or other damage. If any damages are found, replace the brake cal- iper with a new one. Brake caliper piston inspect the brake caliper piston for any scratches or other dam- age. If any da...

Page 202

Chassis 6-55 brake caliper reassembly and remounting reassemble and remount the brake caliper in the reverse order of removal and disassembly. Pay attention to the following points: • wash the caliper bore and piston with the specified brake fluid. Thoroughly wash the dust seal grooves and piston se...

Page 203

6-56 chassis • apply suzuki silicone grease to the caliper holder slide pin. • install the slide pin into the caliper. + 99000-25100: suzuki silicone grease • install the pin 3, washer 4 and caliper holder 5 to the cali- per. • apply thread lock super “1303” to the pin 3. - 99000-32030: thread lock ...

Page 204

Chassis 6-57 • when replacing the boot with a new one, apply suzuki sili- cone grease to the groove of parking brake axle. + 99000-25100: suzuki silicone grease • loosen the locknut a and turn the adjuster b in completely, so that the cable play is maximum. • set the parking brake shaft 9 in neutral...

Page 205

6-58 chassis brake disc removal and remounting • remove the rear wheel. ( !6-10) • remove the rear axle. ( !6-80) • remove the brake disc. • install the brake disc to the rear axle with the punch mark a showed up. Note: make sure that the disc is free of any greasey matter. • apply thread lock super...

Page 206

Chassis 6-59 master cylinder removal and disassembly • drain the brake fluid. ( !6-51) • place a rag underneath the brake hose union bolt on the mas- tercylinder to catch any split brake fluid. Remove the brake hose union bolt 1 and disconnect the brake hose 2. % • loosen the locknut 3. • remove the...

Page 207

6-60 chassis • remove the connector 7 and o-ring 8 by removing the snap ring 9. • remove the dust boot 0. • remove the snap ring a. • remove the push rod b, piston/primary cup c and spring d. Master cylinder inspection master cylinder inspect the master cylinder bore for any scratches or damage. If ...

Page 208

Chassis 6-61 master cylinder reassembly and remounting reassemble and remount the master cylinder in the reverse order of removal and disassembly. Pay attention to the follwing point: % * specification and classification: dot 4 • apply suzuki moly paste to the master cylinder rod. . 99000-25140: suz...

Page 209: Rear Shock Absorber

6-62 chassis rear shock absorber construction removal • raise the rear wheel off the ground and support the vehicle with jack or wooden block. • remove the cushion lever cover 1. • remove the swingarm under cover 2. 1 rear shock absorber a rear shock absorber upper mounting nut b rear shock absorber...

Page 210

Chassis 6-63 • remove the cushion rod lower bolt/nut. • remove the rear shock absorber mounting bolts/nuts. • remove the rear shock absorber by lifting up the swingarm..

Page 211

6-64 chassis inspection inspect the shock absorber body and rubber bushing for dam- age and leakage of oil. If any defects are found, replace the shock absorber with a new one. % rear shock absorber disposal ) gas pressure release • remove the valve cap. • press the valve with a screwdriver to bleed...

Page 212

Chassis 6-65 remounting remounting the rear shock absorber in the reverse order of removal. Pay attention to the following points: • tigten each bolt/nut to the specified torque. # rear shock absorber nut (upper) 1: 60 n·m (6.0 kgf-m, 43.5 lb-ft) rear shock absorber nut (lower) 2: 55 n·m (5.5 kgf-m,...

Page 213

6-66 chassis damping force adjustment the rebound and compression damping force are adjustable for rider’s preference, rider’s weight and field condition. Note: do not turn the adjuster screws more than given position, or the adjuster may be damaged. Rebound damping force adjustment fully turn the d...

Page 214: Rear Suspension

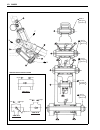

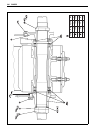

Chassis 6-67 rear suspension construction 1 swingarm 2 chain adjuster plate 3 chain buffer 4 dust cover 5 washer 6 dust seal 7 bearing 8 bushing 9 dust seal 0 collar a swingarm under cover b chain buffer c rear shock absorber d cushion rod e cushion lever f bearing g cushion lever cover h grease nip...

Page 215

6-68 chassis removal cushion lever and cushion rod • place the vehicle on the level ground and support the vehicle with a jack or wooden block. • remove the swingarm under cover 1. • remove the cushion lever cover 2. • remove the cushion rod 3. • remove the cushion lever 4. Rear swingarm • remove th...

Page 216

Chassis 6-69 • remove the parking cable guide 2. • loosen the swingarm pivot nut and remove the swingarm pivot shaft. • remove the swingarm assembly. • remove the chain buffer 3..

Page 217

6-70 chassis inspection and disassembly spacer • remove the dust covers 1, washers 2 and spacers 3 from the swingarm. • remove the spacers from the cushion lever and cushion rod. • inspect the spacers for any flaws or other damage. If any defects are found, replace the spacers with new ones. Dust se...

Page 218

Chassis 6-71 swingarm bearing and bushing insert the spacer 1 into the bearing 2, bushing 3 and then check the play when moving the spacer up and down. If excessive play is noted, replace the bearing and bushing with a new one. • remove the dust seals. • remove the pivot bearings with special tools....

Page 219

6-72 chassis cushion lever bearing and cushion rod bearing insert the spacer into the bearing, and then check the play when moving the spacer up and down. If excessive play is noted, replace the bearing with a new one. • remove the dust seals. % • remove the cushion lever bearings by using the speci...

Page 220

Chassis 6-73 swingarm pivot shaft using a dial gauge, check the pivot shaft runout. If the runout exceeds service limit, replace the pivot shaft with a new one. & 09900-20607: dial gauge (1/100 mm, 10 mm) 09900-20701: magnetic stand 09900-21304: v-block (100 mm) ( swingarm pivot shaft runout: servic...

Page 221

6-74 chassis reassembly reassemble the cushion lever, cushion rod and swingarm in the reverse order of disassembly and removal. Pay attention to the following points: swingarm bearing and dust seal • press the bearing into the swingarm pivot with special tool to the depth of 5 mm (0.2 in). ( !6-75) ...

Page 222

Chassis 6-75 swingarm pivot assembly information left right 1 dust co v e r 2 w asher 3 dust seal 4 bear ing 5 bushing 6 dust seal 7 spacer 8 swingar m piv ot shaft 9 swingar m a 5 mm (0.2 in) b 12 mm (0.47 in) press-fitting position engine f rame 84 n . M (8.4 kgf-m, 61.0 lb-ft).

Page 223

6-76 chassis cushion rod/lever bearing and dust seal • install the bearings into the cushion rod/lever with the special tool to the specified depth shown in the illustration below. & 09924-84510: bearing installer set • install the dust seals into the cushion rod/lever. • apply suzuki super grease “...

Page 224

Chassis 6-77 remounting remount the cushion lever, cushion rod and swingarm in reverse order of removal. Pay attention to the following points: • install the swingarm and pivot shaft. • tighten the swingarm pivot nut to the specified torque. # swingarm pivot nut: 84 n·m (8.4 kgf-m, 61.0 lb-ft) • ins...

Page 225

6-78 chassis 60 n.M 6.0 kgf-m 43.5 lb-ft 78 n.M 7.8 kgf-m 56.5 lb-ft g f h 55 n.M 5.5 kgf-m 40.0 lb-ft 78 n.M 7.8 kgf-m 56.5 lb-ft 78 n.M 7.8 kgf-m 56.5 lb-ft right left left right left right grease nipple installation view of g view of f view of h approx.45.

Page 226: Rear Axle

Chassis 6-79 rear axle construction 1 rear wheel right hub 2 rear axle 3 rear brake disc 4 dust seal 5 bearing 6 rear axle housing 7 spacer 8 sprocket flange 9 sprocket 0 washer a rear wheel left hub a rear axle nut b disc bolt c rear axle housing bolt (m10) d rear axle housing bolt (m12) e sprocket...

Page 227

6-80 chassis removal • place the vehicle on the level ground and support the vehicle with a jack or wooden block. Sprocket • remove the left rear wheel. ( !6-10) • remove the left rear wheel hub. ( !6-11) • remove the rear caliper. • loosen the chain adjust nuts 1 and the rear axle housing bolts 2. ...

Page 228

Chassis 6-81 rear axle housing • remove the axle housing bolts 1. • remove the chain adjuster plate 2. • remove the axle housing from the swingarm. • remove the chain adjuster stud bolts 3 and boots 4. Inspection and disassembly sprocket inspect the sprocket teeth for wear. If they are worn as shown...

Page 229

6-82 chassis dust seal inspect the dust seals for wear or damage. If any defect are founds, replace the dust seal with a new one. Axle bearings inspect the play of the wheel bearings by finger while they are in the axle housing. Rotate the inner race by finger to inspect for abnormal noise and smoot...

Page 230

Chassis 6-83 reassembly and remounting reassemble the rear axle shaft and rear axle housing in the reverse order of removal and disassembly. Pay attention to the following points: rear sproket • install the rear sprocket 1 to the sprocket flange 2. • apply thread lock super “1303” or “1322” to the s...

Page 231

6-84 chassis • install the bearings to the axle housing with the special tool. & 09941-34513: bearing installer set 09913-70210: bearing installer set % • install the dust seals 3 with the special tool. & 09913-70210: bearing installer set note: make sure that the stamped mark on the dust seal faces...

Page 232

Chassis 6-85 • install the chain adjuster stud bolts and boots. Note: the smaller diameter portion of the boot must face to the axle housing. • install the axle housing into the swingarm. • tighten the axle housing bolts temporarily. Note: the axle housing bolts are unequal in size. Refer to table b...

Page 233

6-86 chassis rear axle shaft when the rear axle shaft is replaced with a new one, install the right axle nut onto the new axle shaft. • apply thread lock super “1303” or “1322” to the axle shaft. - 99000-32030: thread lock super “1303” (usa) $ 99000-32110: thread lock super “1322” (others) • tighten...

Page 234

Chassis 6-87 • install the sprocket flange 2 to the axle shaft. • apply suzuki bond “1207b” or “1215” to the axle shaft. / 99104-31140: suzuki bond “1207b” (usa) 0 99000-31110: suzuki bond “1215” (others) • apply thread lock super “1303” or “1322” to the thread portion of the rear axle shaft. - 9900...

Page 235

6-88 chassis • install the rear wheel hubs. ( !6-14) • install the rear wheels. ( !6-14) • adjust the chain slack. ( !2-22) • tighten the rear axle housing bolts to the specified torque in the described order. ( !2-23) # rear axle housing bolt (m10) 6: 73 n·m (7.3 kgf-m, 53.0 lb-ft) # rear axle hous...

Page 236

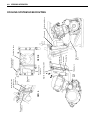

Chassis 6-89 rear wheel, rear brake, rear suspension, rear swin- garm and rear axle shaft reassembling information item n ·m kgf-m lb-ft 1 84 8.4 61.0 2 100 10.0 72.5 3 50 5.0 36.0 4 180 18.0 130.0 5 180 18.0 130.0 6 54 5.4 39.0 7 100 10.0 72.5 8 100 10.0 72.5 9 73 7.3 53.0 0 73 7.3 53.0 a 18 1.8 13...

Page 237

6-90 chassis item n ·m kgf-m lb-ft 1 54 5.4 39.0 2 180 18.0 130.0 3 180 18.0 130.0 4 23 2.3 16.5 5 180 18.0 130.0 @.

Page 238: Reverse Lock Release Cable

Chassis 6-91 reverse lock release cable removal • remove the reverse lock release knob 1 from the front fender. • remove the bracket. • remove the cap 2. • remove the screw 3 and washer 4. • remove the knob 5. • disconnect the cable by removing the rotor 6..

Page 239

6-92 chassis • remove the engine sprocket cover. ( !3-5) • disconnect the cable by removing the cable mounting bolt. Remounting remount the reverse lock release cable in the reverse order removal. Pay attention to the following points: • install the spring with the spring end a matched the groove b ...

Page 240

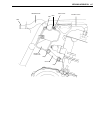

Chassis 6-93 cable play adjustment after installing the reverse lock release cable, adjust the cable play. The cable adjuster is located at inside of the fuel tank right side cover. • loosen the locknut 1. • turn the adjuster 2 in or out until the cable play a should be 1 – 2 mm (0.04 – 0.08 in) at ...

Page 241: Electrical System

7 7 electrical system 7-1 contents electrical system cautions in servicing ................................................................ 7- 2 connectors ............................................................................ 7- 2 couplers ........................................................

Page 242: Cautions In Servicing

7-2 electrical system cautions in servicing connectors • when disconnecting a connector, be sure to hold the termi- nals; do not pull the lead wires. • when connecting a connector, push it in so it is firmly attached. • inspect the connector for corrosion, contamination and any breakage in the cover...

Page 243

Electrical system 7-3 battery • the mf battery used in this vehicle does not require mainte- nance (e.G., electrolyte level inspection, distilled water replen- ishment). • during normal charging, no hydrogen gas is produced. How- ever, if the battery is overcharged, hydrogen gas may be pro- duced. T...

Page 244

7-4 electrical system location of electrical components handlebar switch ignition coil cdi unit regulator/rectifier.

Page 245

Electrical system 7-5 battery main fuse starter relay ignition switch engine coolant temp. Switch ( :5-10) cooling fan thermo-switch ( :5-9) starter motor.

Page 246: Charging System

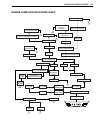

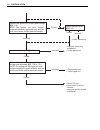

7-6 electrical system charging system troubleshooting generator regulator/rectifier ignition switch main fuse battery load no accessories no current leaks incorrect continued on next page • remove accessories • short circuit of wire harness • faulty electrical equipment • faulty battery • abnormal d...

Page 247

Electrical system 7-7 • faulty generator coil or disconnected lead wires • faulty generator • faulty regulator/rectifier measure the continuity of the generator coil. ( :7-9) measure the generator no-load voltage. ( :7-10) continuity correct inspect the regulator/rectifier. ( :7-10) correct inspect ...

Page 248

7-8 electrical system inspection battery current leakage • remove the seat. ( !6-4) • turn the ignition switch to the “off” position. • disconnect the - battery lead wire. Measure the current between - battery terminal and the - bat- tery lead wire using the multi circuit tester. If the reading exce...

Page 249

Electrical system 7-9 regulated voltage • remove the seat. ( !6-4) • start the engine, turn the ignition switch to light ( ') and the dimmer switch to hi and run the engine at 5 000 r/min. Measure the dc voltage between the + and - battery termi- nals using the multi circuit tester. If the voltage i...

Page 250

7-10 electrical system generator no-load performance • disconnect the generator lead wire coupler. • start the engine and run it at 5 000 r/min. Measure the ac voltage between the lead wires of the generator using the multi circuit tester. If the voltage is under the specified value, replace the ac ...

Page 251: Starter System

Electrical system 7-11 starter system troubleshooting clutch lever position switch starter button engine stop switch ignition switch batter y cdi fuse starter relay starter motor starter motor will not run. Check if the starter motor runs when its terminal is connected to the + battery terminal (do ...

Page 252

7-12 electrical system starter motor removal and disassembly • disconnect the starter motor lead wire 1 and engine ground lead wire 2. • remove the starter motor. • faulty starter relay correct • improper starter relay contact check the starter relay. ( :7-15) incorrect the starter motor runs when t...

Page 253

Electrical system 7-13 • disassembly the starter motor, as shown. Starter motor inspection carbon brushes inspect the carbon brushes for abnormal wear, cracks, or smoothness in the brush holder. If any damages are found, replace the brush assembly with a new one. Commutator inspect the commutator fo...

Page 254

7-14 electrical system oil seal check the seal lip for damage or leakage. If any damages are found, replace the starter motor with a new one. Starter motor reassembly and remounting reassemble and remount the starter motor in the reverse order of removal and disassembly. Pay attention to the followi...

Page 255