- DL manuals

- Suzuki

- Motorcycle

- RM-Z450

- Owner's Service Manual

Suzuki RM-Z450 Owner's Service Manual

Summary of RM-Z450

Page 1

Part no. 99011-35g52-01a july, 2006 en tk rm-z450 owner’s service manual.

Page 2

This manual should be considered a permanent part of the motorcycle and should remain with the motorcycle when resold or otherwise transferred to a new owner or operator. The manual contains important safety information and instructions which should be read carefully before operating the motorcycle..

Page 3: Foreword

Foreword this manual is presented as a means whereby you can maintain your rm-z450 in top working condi- tion at all times. Your riding skill and the mainte- nance steps outlined in this manual will assure you of top performance from your machine under any type of competition. We sincerely wish you ...

Page 4: General Considerations

General considerations • wear a helmet and goggles a helmet is the most important piece of gear to wear. Helmets do not reduce essential vision or hearing. Generally, helmets do not cause or intensify injury if you crash. Helmets simply help your skull protect your intelligence, your memory, your pe...

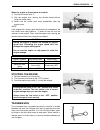

Page 5: Serial Number Location

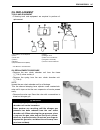

Serial number location the frame number 1 is stamped on the steering head as shown in the photograph. The engine serial num- ber 2 is stamped on the right side of the crankcase assembly. Write down the serial numbers here for your future reference. Frame no. Engine no..

Page 6: Warnings For Servicing

Warnings for servicing ! Warning never run the engine indoors or in a garage. Exhaust gas contains carbon mon- oxide, a gas that is colorless and odorless and can cause death or severe injury. Only run the engine outdoors where there is fresh air. ! Warning hot engine and muffler can burn you. Wait ...

Page 7: Precautions For

Precautions for servicing • replace gaskets, snap rings, circlips, o-rings and cotter pins with new ones. • take care not to expand the end gap larger than required to slip the circlip over the shaft when installing a circlip. • use special tools where specified. • use genuine suzuki parts and recom...

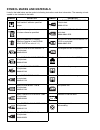

Page 8: Symbol Marks And Materials

Symbol marks and materials listed in the table below are the symbols indicating instructions and other information. The meaning of each symbol is also included in the table. Symbol definition symbol definition torque control required. Data beside it indicates specified torque. Apply thread lock supe...

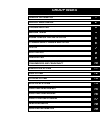

Page 9: Group Index

Group index general information 1 periodic maintenance 2 troubleshooting 3 machine tuning 4 engine removal and installation 5 cylinder head, cylinder and piston 6 clutch 7 kick starter 8 gearshifting 9 transmission and crankshaft 10 lubrication system 11 fuel system 12 cooling system 13 electrical s...

Page 10: General Information

1 general information 1-1 contents general information country and area codes the following codes stand for the applicable country(-ies) and area(-s). Code country or area effective frame no. 000 e-03 e-19 e-28 japan u. S. A. E.U. Canada js1rl 41a000 500156 – js1rl 41c 72 100001 – js1rl 41a000 50015...

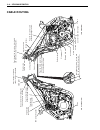

Page 11: Location Of Parts

1-2 general information location of parts 1 clutch lever 2 hot starter lever 3 engine stop switch 4 front brake lever 5 throttle grip 6 fuel tank cap 7 carburetor starter knob 8 gearshift lever 9 front suspension compression damp- ing adjuster 0 front suspension rebound damping adjuster a kick start...

Page 12: Accessory

General information 1-3 accessory side stand this motorcycle is not equipped with a side stand. To support the motorcycle for a short period of time, use the accessory side stand that comes supplied with the motorcycle. When servicing the motorcycle, use a service stand and support the underneath of...

Page 13: Operating Instructions

1-4 general information operating instructions starting the engine inspect the engine oil level, coolant level and air cleaner condi- tion before starting the engine. When the engine is cold: 1) turn the fuel valve lever to the “on” position. 2) shift the transmission into neutral. Note: do not repe...

Page 14

General information 1-5 when the engine is already warm or restarts: 1) pull the hot starter lever 1. 2) kick the engine over, leaving the throttle closed without using the starter knob. 3) return the hot starter lever back immediately after the engine starts. Note: if the engine fails starting, ope...

Page 15: Break-In (Running-In)

1-6 general information break-in (running-in) when the motorcycle is new 1) warm up the engine before starting off. 2) ride for 60 minutes using less than 1/2 throttle opening. 3) ride for 60 minutes using less than 3/4 throttle opening. Note: * the break-in (running-in) period is the period of grea...

Page 16: Exterior Parts

General information 1-7 exterior parts 5 n·m (0.5 kgf-m, 3.5 lb-ft) 5 n·m (0.5 kgf-m, 3.5 lb-ft).

Page 17

– memo –.

Page 18: Periodic Maintenance

2 periodic maintenance 2-1 contents periodic maintenance periodic maintenance ........................................................................ 2- 3 inspection before practice ...................................................... 2- 3 inspection before race (all items of inspection before pr...

Page 19: Periodic Maintenance

2-2 periodic maintenance contents periodic maintenance exhaust silencer ................................................................................ 2-26 silencer inspection and replacement ................................ 2-26 silencer reassembly ...................................................

Page 20: Periodic Maintenance

Periodic maintenance 2-3 periodic maintenance inspection before practice what to check check for spark plug • heat range, fouled electrode, tightness • loose high-tension cord air cleaner element • dust • lubrication engine oil oil level coolant coolant level cooling system • radiator hose damage • ...

Page 21

2-4 periodic maintenance inspection before race (all items of inspection before practice on previous page plus) what to check check for clutch clutch disc plates wear and distortion brake pads wear sprockets wear cleanliness fuel tank leakage fuel hose • damage • hoses are connected fuel filter fuel...

Page 22

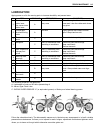

Periodic maintenance 2-5 periodic maintenance chart it is very important to inspect and maintain the machine regularly. Follow the guideline in the chart. The life of parts varies depending on the riding conditions. Perform more often than shown in the chart if you use the motorcycle under severe co...

Page 23

2-6 periodic maintenance note: r = replace, c = clean, t = tighten, i = inspect and clean, adjust lubricate or replace if necessary, l = lubricate interval races every race every 3 races every 6 races remarks service item hours every 2 hours every 6 hours every 12 hours tire i — — spoke nipple i — —...

Page 24: Spark Plug

Periodic maintenance 2-7 spark plug • remove the seat. ( !5-2) • remove the radiator covers and fuel tank. ( !5-2) • disconnect the spark plug cap. • remove the spark plug. " 09816-00141: spark plug wrench note: remove the dirt around the spark plug before removing the spark plug to prevent dirt fro...

Page 25: Air Cleaner

2-8 periodic maintenance air cleaner air cleaner element removal • remove the left frame cover. • remove the wing nut 1. • remove the element 2 from the element holder. Washing • fill a washing pan large enough to hold the element with a non-flammable cleaning solvent a. Immerse the element in the s...

Page 26: Engine Oil And Oil Filter

Periodic maintenance 2-9 note: follow the instructions below to keep the air cleaner element dry when cleaning the motorcycle. • cover the element with vinyl bag. • install the left frame cover. • cover the inlet hole on the frame cover in order to prevent water from coming into the air cleaner box....

Page 27

2-10 periodic maintenance inspection before engine oil level check • before starting the engine, check that there is sufficient oil for operating the engine. Note: the oil level measurement may become inaccurate unless the motorcycle is held upright as the motorcycle inclination affects the oil leve...

Page 28

Periodic maintenance 2-11 engine oil level inspection • during inspection, hold the motorcycle in an upright position on a level surface. Note: the oil level measurement may become inaccurate unless the motorcycle is held upright as the motorcycle inclination affects the oil level. • start and run t...

Page 29

2-12 periodic maintenance engine oil filter change • drain the engine oil as described in the engine oil replace- ment procedure. • remove the oil filter cap 1 and spring 2 with oil filter 3. • apply engine oil lightly to the gasket of the new oil filter before installation. • install the new oil fi...

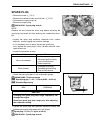

Page 30: Oil Strainers

Periodic maintenance 2-13 oil strainers oil strainer (no.1) removal • drain engine oil. ( !2-11) • remove the engine oil strainer cap. • pull out the oil strainer. Note: we recommend that inspect feed pump side oil strainer every race. Oil strainer (no.2) removal ( !10-4) inspection • check the oil ...

Page 31: Engine Coolant

2-14 periodic maintenance engine coolant engine coolant level check • remove the radiator cap 1. • check that the engine coolant level is at the bottom of the inlet hole. If not, replenish the radiator with specified engine cool- ant. • tighten the radiator cap securely. Note: * this motorcycle does...

Page 32

Periodic maintenance 2-15 engine coolant replenishment • use an anti-freeze and summer engine coolant which is com- patible with aluminum radiator, mixed with distilled water at the ratio of 50:50. Note: the radiator, cylinder and cylinder head are made of aluminum alloy. Using non-recommended engin...

Page 33: Clutch Cable

2-16 periodic maintenance clutch cable adjust the clutch cable play as follows: major adjustment • loosen the lock-nut 1. • turn adjuster 2 so the clutch lever has 10 – 15 mm (0.4 – 0.6 in) play at the clutch lever end before pressure is felt. • tighten the lock-nut 1. # clutch lever play a: 10 – 15...

Page 34: Throttle Cable

Periodic maintenance 2-17 throttle cable adjust the throttle cable play a as follows: throttle cable adjustment • loosen the lock-nut 1. • turn adjuster 2 so the throttle grip has 2 – 4 mm (0.08 – 0.16 in) play in circumference. • tighten the lock-nut 1. # throttle cable play a: 2 – 4 mm (0.08 – 0.1...

Page 35: Hot Starter

2-18 periodic maintenance hot starter adjust the hot starter cable play as follows: • loosen the lock-nut 1. • turn adjuster 2 so the hot starter lever clearance a mea- sured at the lever holder obtains 2 –3 mm (0.08 – 0.12 in) when squeezing the lever until pressure is felt. • tighten the lock-nut ...

Page 36: Engine Idle Speed

Periodic maintenance 2-19 engine idle speed • adjust the throttle cable play. ( !2-16) • warm up the engine. Note: make this adjustment when the engine is hot. • connect the multi-circuit tester to the high-tension cord. • start the engine, turn the throttle stop screw 1 and set the engine idle spee...

Page 37: Fuel Hose

2-20 periodic maintenance fuel hose • inspect the fuel hose for damage and fuel leakage. If any defects are found, the fuel hose must be replaced. • replace the fuel hose every four years. Fuel filter • drain the fuel. • turn the fuel valve to the off position. • disconnect the fuel hose 1 and remov...

Page 38: Valve Clearance

Periodic maintenance 2-21 valve clearance • remove the seat. ( !5-2) • remove the radiator covers and fuel tank. ( !5-2) • disconnect the spark plug cap. ( !2-7) • remove the spark plug. ( !2-7) • remove the cylinder head cover and its cylinder head cover gasket. The valve clearance specification is...

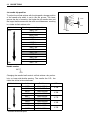

Page 39

2-22 periodic maintenance valve clearance adjustment the clearance is adjusted by replacing the existing tappet shim by a thicker or thinner shim. • remove the intake or exhaust camshafts. ( !6-4) • remove the tappet 1 and shim 2 by fingers or magnetic hand. • check the figures printed on the shim. ...

Page 40

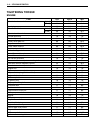

Periodic maintenance 2-23 (intake side) 242 2.425 245 2.450 248 2.475 250 2.500 252 2.525 255 2.550 258 2.575 260 2.600 262 2.625 265 2.650 268 2.675 270 2.700 272 2.725 240 2.400 275 2.750 278 2.775 280 2.800 282 2.825 285 2.850 295 2.950 298 2.975 300 3.000 238 2.375 235 2.350 232 2.325 230 2.300 ...

Page 41

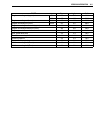

2-24 periodic maintenance (exhaust side) 242 245 248 250 2 52 255 258 2 60 262 265 268 2 70 272 275 2 78 280 2 82 285 295 298 3 00 238 235 232 230 228 225 222 220 218 215 212 210 208 205 155 152 150 2.425 2.450 2.475 2.500 2.525 2.550 2.575 2.600 2.625 2.650 2.675 2.700 2.725 2.750 2 .775 2.800 2.82...

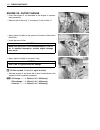

Page 42: Cylinder Head, Cylinder and

Periodic maintenance 2-25 cylinder head, cylinder and piston cylinder head inspection • remove the cylinder head. ( !6-4) • decarbonize the combustion chambers. • inspect for pinholes, cracks and other damage. • if any defects are found, replace the cylinder head with a new one. Cylinder inspection ...

Page 43: Exhaust Silencer

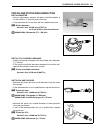

2-26 periodic maintenance exhaust silencer silencer inspection and replacement • remove the baffle mounting bolts. • remove the baffle 1 and inner plate 2. • inspect the glass wool 3 for clogging with carbon deposit or tar. • replace the glass wool 3 with a new one if necessary..

Page 44: Drive Chain and Sprockets

Periodic maintenance 2-27 silencer reassembly • install the baffle and diffuser. • tighten four bolts. Note: apply suzuki bond to the circumference of the silencer pipe and diffuser. ( 99000-31140: suzuki bond “1207b” or equivalent • the baffle mounting bolt is of flanged type which tightens the bod...

Page 45

2-28 periodic maintenance drive chain adjustment • loosen the axle nut 1. • loosen the lock-nuts 2 and adjust the drive chain slack to the specification by turning the adjusters 3. Make sure that the right and left adjuster plates 4 are at the same position on scales 5. • with the adjusters 3 held i...

Page 46

Periodic maintenance 2-29 drive chain lubrication • remove the chain clip and joint from the drive chain and remove the drive chain. • clean the drive chain with kerosine. • after washing and drying the chain, oil it with a heavyweight motor oil. Note: the standard drive chain is did520mxv. • reasse...

Page 47: Tensioner Roller

2-30 periodic maintenance drive chain guide, buffer and tensioner roller drive chain guide inspection • inspect the drive chain guide 1 for bends and damage. Note: the drive chain can hit a bent guide causing noise and drive chain wear. • inspect the chain guide defense 2 for wear. • replace the def...

Page 48: Brakes

Periodic maintenance 2-31 brakes brake fluid level • inspect the brake fluid level in both front and rear reservoirs. If the brake fluid level is lower than lower mark a, replenish the reservoir with the specified brake fluid to the upper line. ( !16-14) inspect brake pad wear and brake fluid leakag...

Page 49

2-32 periodic maintenance brake pad • inspect the brake pads for wear. If the brake pads are worn, replace them with new ones. ( !16-5) note: * pump the brake lever and pedal several times to restore the brake pads after replacing the brake pads. * replace both right and left pads together when repl...

Page 50: Front Fork

Periodic maintenance 2-33 front fork • move the front fork up and down several times and inspect for smooth movement. • inspect for damage and oil leaks. • inspect the bolts and nuts for tightness. • if any defects are found, replace the front fork with a new one. • place a stand under the chassis t...

Page 51: Steering

2-34 periodic maintenance spoke nipple and rim lock inspection • inspect the spokes for tension by squeezing the spoke nip- ples. • retighten the spoke nipples with a spoke nipple wrench so as all spokes have same tension. $ spoke nipple: 6 n·m (0.6 kgf-m, 4.5 lb-ft) • inspect the rim lock 1 for tig...

Page 52: Lubrication

Periodic maintenance 2-35 lubrication apply grease or oil to the moving parts to increase durability and prevent wear. The following materials are necessary: a. Lightweight oil such as wd-40 or penetrating oil b. Aerosol type chain lube c. Suzuki super grease “a” (or equivalent grease) or water-proo...

Page 53: Compression Pressure Check

2-36 periodic maintenance compression pressure check the compression pressure reading of a cylinder is a good indicator of its internal condition. The decision to replace the cylinder is often based on the results of a compression test. Compression pressure specification (automatic decomp. Actuated)...

Page 54: Oil Pressure Check

Periodic maintenance 2-37 oil pressure check check the oil pressure periodically. This will give a good indication of the condition of the moving parts. # oil pressure: low or high oil pressure can indicate any of the following conditions: low oil pressure * clogged oil filter * oil leakage from the...

Page 55

– memo –.

Page 56: Troubleshooting

3 18 troubleshooting 3-1 contents troubleshooting engine ........................................................................................................ 3- 2 carburetor ............................................................................................ 3- 6 radiator (cooling system...

Page 57: Engine

3-2 troubleshooting engine complaint symptom and possible causes remedy engine will not start or is hard to start. Compression too low • valve clearance out of adjustment • worn valve guides or poor seating of valves • mistiming valves • excessively worn piston ring • worn-down cylinder bore • poor ...

Page 58

Troubleshooting 3-3 complaint symptom and possible causes remedy noisy engine excessive valve chatter • too large valve clearance • weakened or broken valve springs • worn tappet or cam surface • worn and burnt camshaft journal noise seems to come from piston • worn down piston or cylinder • combust...

Page 59

3-4 troubleshooting complaint symptom and possible causes remedy engine lacks power. Defective engine internal parts • loss of tappet clearance • weakened valve springs • valve timing out of adjustment • worn piston ring or cylinder • poor seating of valves • fouled spark plug • incorrect spark plug...

Page 60

Troubleshooting 3-5 complaint symptom and possible causes remedy slipping clutch • weakened clutch springs • worn or distorted pressure plate • worn or distorted clutch plates • insufficient throttle cable play replace replace replace adjust dragging clutch • some clutch spring weakened while others...

Page 61: Carburetor

3-6 troubleshooting carburetor radiator (cooling system) complaint symptom and possible causes remedy starting difficulty. • improperly working starter knob • improperly working hot starter lever • clogged starter jet passage • maladjusted pilot screw • maladjusted throttle stop screw • clogged slow...

Page 62: Chassis

Troubleshooting 3-7 chassis complaint symptom and possible causes remedy heavy steering • overtightened steering stem nut • broken bearing in steering stem • distorted steering stem • not enough pressure in tires adjust replace replace adjust wobbly handlebars • loss of balance between right and lef...

Page 63: Brakes

3-8 troubleshooting brakes complaint symptom and possible causes remedy insufficient brake power • leakage of brake fluid from hydraulic system • worn pads • oil adhesion of engaging surface of pads • worn disc • air in hydraulic system • not enough brake fluid in the reservoir repair or replace rep...

Page 64: Electrical

Troubleshooting 3-9 electrical complaint symptom and possible causes remedy no sparking or poor sparking • defective ignition coil • defective spark plug • defective cdi unit • defective magneto • open-circuited wiring connections replace replace replace replace check and repair spark plug soon beco...

Page 65

– memo –.

Page 66: Machine Tuning

4 machine tuning 4-1 contents machine tuning carburetor tuning ............................................................................. 4- 2 principles of carburetor tuning .......................................... 4- 2 slow system .................................................................

Page 67: Carburetor Tuning

4-2 machine tuning carburetor tuning the carburetion of your motorcycle is carefully selected after extensive testing. You will find that the carbu- retion will function smoothly under many varied operating conditions. For best results we recommend that the adjustments and carburetion jetting be lef...

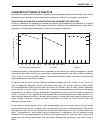

Page 68

Machine tuning 4-3 as shown below, each of the asterisk (*) marked parts is located between the air/fuel passage and has its own air/fuel mixture adjustable range in terms of the throttle valve opening. The chart indicates that the car- buretor can supply correct air/fuel mixture to the engine in an...

Page 69

4-4 machine tuning pilot screw (p.S.) the pilot screw controls volume of the air/fuel mixture in slow range. Pilot screw specifications indicate the number of turns out from the lightly seated position. Throttle stop screw the throttle stop screw determines the full closed position of the throttle v...

Page 70

Machine tuning 4-5 main system main jet (m.J.) the main jet, like the slow jet, meters fuel flow. Each jet size is indicated by a number. Larger number means a larger bore diameter and fitting a larger number main jet enriches the air/fuel mixture. * included alternated parts intermediate system jet...

Page 71

4-6 machine tuning jet needle clip position to adjust the air/fuel mixture with the jet needle, change position of the needle clip which is set in the 5th groove. The lower groove the clip is moved to, the higher the jet needle rises and the larger the clearance with the main nozzle becomes, resulti...

Page 72

Machine tuning 4-7 carburetor tuning in practice in the previous section, basic principles of carburetor tuning have been discussed. Described in this section are the bases for carburetor tuning required when coping with variations in air (oxygen) concentration. Variation in air (oxygen) concentrati...

Page 73

4-8 machine tuning judging air/fuel mixture for proper carburetor tuning, it is necessary to know how to judge the air/fuel mixture made in the carburetor; whether too rich, too lean or properly mixed. Given below are the symptoms observed when the engine is not supplied with the proper air/fuel mix...

Page 74

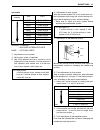

Machine tuning 4-9 jet needle shaded: standard * : included alternate parts none : optional parts 1 adjustment of slow system 1) set the pilot screw as specified. 2) see if the selected slow jet is correct or not by judging the air/fuel mixture. If air/fuel mixture is rich, replace it with smaller o...

Page 75: Front Fork Tuning

4-10 machine tuning front fork tuning the front fork compression and rebound damping force, and oil level are adjustable for rider’s preference, rider’s weight and course condition. Note: * break-in new front forks before attempting adjustment. * be sure to adjust both right and left front forks equ...

Page 76

Machine tuning 4-11 oil quantity minor adjustment adding the fork oil • remove the air bleed screw 1. • add the fork oil with a injector from the air bleed hole. Reducing the fork oil • remove the front forks. ( "17-4) • remove the air bleed screw. • leaning the front fork, reduce the fork oil from ...

Page 77

4-12 machine tuning oil change (only for outer tube oil chamber) • remove the front forks. ( "17-4) • thoroughly clean the fork before disassembly. • clamp the outer tube with a vise. Protect the outer tube with a rag when using a vise. ( "17-5) • loosen and remove the fork cap bolt (sub-tank) from ...

Page 78

Machine tuning 4-13 • slide down the outer tube. • pour the specified amount of fork oil into the outer tube. # 99000-99001-ss5: suzuki fork oil ss-05 or equivalent note: be sure to adjust the fork oil quantity within the above-men- tioned range. • raise the outer tube and temporarily tighten the fo...

Page 79

4-14 machine tuning spring change • remove the front forks. ( "17-4) • thoroughly clean the fork before disassembly. • remove the fork cap bolt and drain fork oil. ( "17-5) • loosen the center bolt completely. ( "17-6) • compress the outer tube by hands and install the conrod holder (special tool) b...

Page 80

Machine tuning 4-15 • make sure approx. 10 mm (0.39 in) of inner rod thread is exposed on the end. ( "17-14) • install the damper rod assembly. ( "17-14) • insert the push rod into the inner rod. • insert the shaped projection of center bolt into the push rod. ( "17-15) • check or adjust the clearan...

Page 81

4-16 machine tuning front fork tuning procedure test ride the motorcycle and find out how the front suspension reacts on various types of surface. According to the symptom noticed, adjust the front fork to the best setting for rider and race track conditions. To adjust, attempt changing fork oil cap...

Page 82: Rear Suspension Tuning

Machine tuning 4-17 rear suspension tuning the rear suspension compression and rebound damping force, and spring pre-load are adjustable for rider’s preference, rider’s weight and course condition. Note: * break-in the rear suspension when riding with a new rear cushion unit. ( "1-6) * inspect the f...

Page 83

4-18 machine tuning rebound damping force adjustment note: to set the adjuster, you must gently turn the adjust screw clock- wise until it stops, then back it out the recommended number of turns. Do not force the adjust screw past the stopped position, or you may damage the adjuster. • turn the adju...

Page 84

Machine tuning 4-19 rear suspension tuning procedure • adjust the rear suspension according to the rider’s weight and preference by referring to the table below. • measure the distance l1 from the seat bolt to the chain adjuster lock-nut with the motorcycle on the stand and the rear wheel lifted off...

Page 85

4-20 machine tuning after the sag measurement has been set 104 mm (4.09 in), test ride the motorcycle and adjust the suspen- sion for the rider and track conditions referring to the guide below. Note: when adjusting the damping force setting, attempt turning the adjuster 1 to 2 click stops at a time...

Page 86: Suspension Balance

Machine tuning 4-21 suspension balance balancing the front to rear suspension properly is the most critical adjustment for suspension performance. If the front forks are adjusted harder than the rear suspension, such as changing to heavier front fork oil, stiffer compression and rebound setting, air...

Page 87

– memo –.

Page 88

5 engine removal and installation 5-1 contents engine removal and installation engine removal and installation ................................................. 5- 2 removal ............................................................................................. 5- 2 installation .................

Page 89

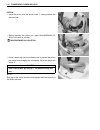

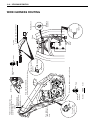

5-2 engine removal and installation engine removal and installation removal • drain engine oil. ( !2-11) • drain engine coolant. ( !13-3) • remove the seat 1. • remove the radiator covers 2, left and right. • remove the right frame cover 3. • place the jack under the frame to support the motorcycle....

Page 90

Engine removal and installation 5-3 • remove the exhaust pipe 5 and exhaust pipe gasket 6. • remove the muffler 7. • remove the front protectors, left and right. • remove the radiator mounting bolts, left and right. • disconnect the radiator hose 8, 9. • remove the radiator hose 0..

Page 91

5-4 engine removal and installation • disconnect the magneto lead wire coupler a and clamp. • disconnect the clutch cable b. • remove the carburetor. ( !12-5) • disconnect the spark plug cap. • remove the cotter pin c, washer d and clip e. • remove the brake pedal spring f, master cylinder rod pin g...

Page 92

Engine removal and installation 5-5 • remove the drive chain clip m and release the drive chain. • remove the circlip n and engine sprocket o. # 09900-06107: snap ring pliers • remove the front engine brackets p, left and right. • remove the upper engine brackets q, left and right. • remove the engi...

Page 93

5-6 engine removal and installation installation install the engine in the reverse order of removal. Pay attention to the following points: • fit the swingarm in its position and hold it with the swingarm pivot shaft. • mount the engine on the frame. • tighten the engine mounting bolts, nuts and swi...

Page 94

Engine removal and installation 5-7 • connect both ends of the drive chain with the joint pin a inserted from the wheel side a as installed on the motorcycle. B o-ring seal … 4 pcs. C joint plate note: when installing the joint plate c, its stamp mark must face the outside. • reassemble the drive ch...

Page 95

5-8 engine removal and installation • install the clip d, washer e and cotter pin f. • install the kick starter lever in the correct position. ( !8-7) $ kick starter lever bolt: 23 n·m (2.3 kgf-m, 16.5 lb-ft) • fit the projection of the carburetor to the depression of intake pipe. • temporarily tigh...

Page 96

Engine removal and installation 5-9 • tighten the connector clamp bolt k temporarily. Note: when install the connector clamp, fit the convex part of the con- nector clamp onto the concave part of muffler. • check the clearance between exhaust pipe and radiator hose. • be sure to tighten the bolts an...

Page 97

– memo –.

Page 98

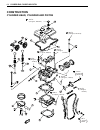

6 cylinder head, cylinder and piston 6-1 contents cylinder head, cylinder and piston construction ........................................................................................ 6- 2 cylinder head, cylinder and piston ...................................... 6- 2 engine top side ................

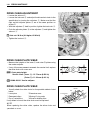

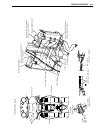

Page 99: Construction

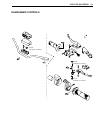

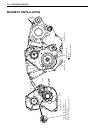

6-2 cylinder head, cylinder and piston construction cylinder head, cylinder and piston 10 n.M (1.0 kgf-m, 7.0 lb-ft) 11 n.M (1.1 kgf-m, 8.0 lb-ft) 46 n.M (4.6 kgf-m, 33.5 lb-ft) 14 n.M (1.4 kgf-m, 10.0 lb-ft) 10 n.M (1.0 kgf-m, 7.0 lb-ft) 10 n.M (1.0 kgf-m, 7.0 lb-ft) 23 n.M 2.3 kgf-m, 16.5 lb-ft 11...

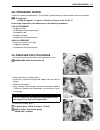

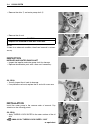

Page 100: Engine Top Side

Cylinder head, cylinder and piston 6-3 engine top side cylinder head cover removal • remove the seat. ( !5-2) • remove the radiator covers and fuel tank. ( !5-2) • disconnect the spark plug cap and remove the spark plug. ( !2-7) • remove the cylinder head cover 1 and cylinder head cover gasket. Cams...

Page 101

6-4 cylinder head, cylinder and piston • remove the cam chain tension adjuster cap bolt 3 and spring. • remove the cam chain tension adjuster 4 and its gasket. • remove the camshaft journal holders 5. Note: loosen the camshaftjournal holder bolts diagonally. • disengage the camshafts 7 from cam chai...

Page 102

Cylinder head, cylinder and piston 6-5 • remove the cylinder head base bolts 3. • loosen the cylinder base bolt 4. • remove the cylinder head bolts and washers. Note: when loosening the cylinder head bolts, loosen each bolt little by little diagonally. • remove the cylinder head 5. Note: if the cyli...

Page 103

6-6 cylinder head, cylinder and piston • remove the cylinder gasket 2 and dowel pins. Piston and piston ring removal • remove the cylinder. ( !6-5) • place a clean rag over the cylinder base to prevent the piston pin circlip 1 from dropping into the crankcase. • remove the piston pin circlip 1. • re...

Page 104

Cylinder head, cylinder and piston 6-7 cam chain, cam chain tensioner and cam chain guide removal • remove the cylinder head. ( !6-4) • remove the magneto cover and magnet rotor. ( !14-10 to -11) • remove the cam chain no.1 guide 1. • remove the cam chain 2. • remove the cam chain tensioner 3..

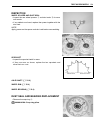

Page 105: Engine Top Components

6-8 cylinder head, cylinder and piston engine top components inspection and service automatic decomp. Inspection • check the decomp. Cam moves smoothly and shaft 1 rotates together. • if any abnormal condition are found, replace the camshaft assembly. Camshaft inspection cam sprocket • inspect the s...

Page 106

Cylinder head, cylinder and piston 6-9 cam wear • measure the cam height h using the micrometer. • replace a camshaft if the cams are worn to the service limit. " cam height h service limit in.: 33.27 mm (1.310 in) ex.: 33.39 mm (1.315 in) # 09900-20202: micrometer (25 – 50 mm) camshaft journal wear...

Page 107

6-10 cylinder head, cylinder and piston • if the camshaft journal oil clearance measured exceeds the limit, measure the inside diameter of the camshaft journal holder and outside diameter of the camshaft journal. • replace the camshaft or the cylinder head depending upon which one exceeds the specif...

Page 108

Cylinder head, cylinder and piston 6-11 cam chain no.1 guide, cam chain no.2 guide and cam chain tensioner inspection • inspect the contacting surface of the cam chain guides and cam chain tensioner. • if it is worn or damaged, replace it with a new one. Cylinder head and valve inspection valve disa...

Page 109

6-12 cylinder head, cylinder and piston • remove the valve spring retainer 4 and valve spring 5. • remove the valve 6 from the combustion chamber side. • remove the valve stem seal 7 and spring seat 8. • remove the other valves in the same manner as described previously. Cylinder head distortion • d...

Page 110

Cylinder head, cylinder and piston 6-13 valve stem runout • support the valve using v-blocks and check its runout using the dial gauge as shown. • if the runout exceeds the service limit, replace the valve. " valve stem runout (in & ex): service limit:0.05 mm (0.002 in) # 09900-20607: dial gauge (1/...

Page 111

6-14 cylinder head, cylinder and piston valve stem wear • if the valve stem is worn down to the limit, as measured with a micrometer, replace the valve. • if the stem is within the limit, then replace the guide. • after replacing valve or guide, be sure to recheck the deflec- tion. " valve stem o.D....

Page 112

Cylinder head, cylinder and piston 6-15 • cool down the new valve guides in a freezer for about one hour and heat the cylinder head to 100 – 150 °c (212 – 302 °f) with a hot plate. • apply engine oil to the valve guide hole. • drive the valve guide into the hole using the valve guide installer 1 and...

Page 113

6-16 cylinder head, cylinder and piston • if the seat width w measured exceeds the standard value or seat width is not uniform, refuse the seat using the seat cutter. " valve seat width w: standard: 0.9 – 1.1 mm (0.035 – 0.043 in) valve seat servicing the valve seats 1 for both the intake valve 2 an...

Page 114

Cylinder head, cylinder and piston 6-17 • clean and assemble the head and valve components. Fill the intake and exhaust ports with gasoline to check for leaks. • if any leaks occur, inspect the valve seat and face for burrs or other things that could prevent the valve from sealing. Valve spring • ch...

Page 115

6-18 cylinder head, cylinder and piston • install the valve spring with the small-pitch portion a facing cylinder head. A small-pitch portion b large-pitch portion c upward d paint • put on the valve spring retainer 2, and using the valve lifter, press down the spring, fit the valve cotter halves to...

Page 116

Cylinder head, cylinder and piston 6-19 oil seal inspection • remove the retainer 1 and plug 2. • inspect the oil seal lip for wear and damage. Oil seal removal • remove the retainer 1 and plug 2. • remove the oil seal 3. Oil seal installation • apply suzuki super grease “a” to the oil seal clip. ' ...

Page 117

6-20 cylinder head, cylinder and piston cylinder inspection cylinder distortion • check the gasketed surface of the cylinder for distortion with a straightedge and thickness gauge, taking a clearance read- ing at several places indicated. • if the largest reading at any position of the straightedge ...

Page 118

Cylinder head, cylinder and piston 6-21 piston and piston ring inspection piston diameter • using a micrometer, measure the piston outside diameter at 15 mm (0.59 in) a from the piston skirt end. • if the measurement is less than the limit, replace the piston. " piston diameter: service limit: 95.38...

Page 119

6-22 cylinder head, cylinder and piston piston ring-to-groove clearance • decarbonize the piston ring and piston ring groove. • measure the side clearances of the 1st piston ring using the thickness gauge. • if any of the clearances exceed the limit, replace both the pis- ton and piston ring. # 0990...

Page 120

Cylinder head, cylinder and piston 6-23 crankshaft and conrod inspection for inspection other than the following, refer to page 10-7. Conrod small end i.D. • using a small bore gauge, measure the inside diameter of the conrod small end. • if the inside diameter of the conrod small end exceeds the li...

Page 121

6-24 cylinder head, cylinder and piston cam chain, cam chain tensioner and cam chain guide installation install the cam chain and cam chain tensioner in the reverse order of removal. Pay attention to the following points: • install the cam chain tensioner 1. $ cam chain tensioner bolt: 11 n·m (1.1 k...

Page 122

Cylinder head, cylinder and piston 6-25 piston and piston ring installation install the piston and piston ring in the reverse order of removal. Pay attention to the following points: piston ring • install the piston rings in the order of oil ring and 1st ring. • the first member to go into the oil r...

Page 123

6-26 cylinder head, cylinder and piston piston • install the piston with the punch mark 1 facing towards the exhaust side. • before installing the piston pin, apply molybdenum oil solution onto its surface. % molybdenum oil solution • place a clean rag over the cylinder base to prevent the piston pi...

Page 124

Cylinder head, cylinder and piston 6-27 cylinder and cylinder head installation install the cylinder and cylinder head in the reverse order of removal. Pay attention to the following points: cylinder • thoroughly wipe off oil from the fitting surface of the crank- case. • apply suzuki bond “1215” to...

Page 125

6-28 cylinder head, cylinder and piston cylinder head • install the dowel pins into the cylinder and then install the cyl- inder head gasket 1 onto the cylinder. • place the cylinder head 2 on the cylinder. • install the seal washers to the cylinder head bolts as shown. • apply engine oil to the was...

Page 126

Cylinder head, cylinder and piston 6-29 camshaft (automatic decomp.) and cam chain tension adjuster installation install the camshaft and cam chain tension in the reverse order of removal. Pay attention to the following points: camshaft (automatic decomp.) • place a wrench over the crankshaft and tu...

Page 127

6-30 cylinder head, cylinder and piston • pull the exhaust side of the cam chain taut to install the camshaft sprocket (exhaust side). • turn the exhaust camshaft so that the timing mark c is aligned with the gasket surface of the cylinder head. Engage the cam chain with the exhaust camshaft sprocke...

Page 128

Cylinder head, cylinder and piston 6-31 cam chain tension adjuster • retract the push rod by pushing the stopper 1. • install a new gasket 2. • install the cam chain tension adjuster 3 with “up” mark faced upward. • tighten the cam chain tension adjuster mounting bolts to the specified torque. $ cam...

Page 129

6-32 cylinder head, cylinder and piston • apply suzuki super grease “a” to the o-rings. ' 99000-25010: suzuki super grease “a” or equivalent • tighten each plug to the specified torque. $ tdc plug: 14 n·m (1.4 kgf-m, 10.0 lb-ft) crankshaft hole plug: 11 n·m (1.1 kgf-m, 8.0 lb-ft) cylinder head cover...

Page 130: Clutch

7 clutch 7-1 contents clutch construction ........................................................................................ 7- 2 clutch ................................................................................................ 7- 2 clutch plate .............................................

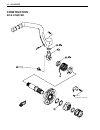

Page 131: Construction

7-2 clutch construction clutch 10 n.M (1.0 kgf-m, 7.0 lb-ft) 90 n.M 9.0 kgf-m, 65.0 lb-ft drive no. 1 plate (black paint) drive no. 2 plate (green paint) driven no. 1 plate (silver) driven no. 2 plate (gray).

Page 132: Clutch Plate

Clutch 7-3 clutch plate removal • drain engine oil. ( !2-11) • remove the brake pedal. ( !16-18) • remove the clutch cover 1 and its gasket. • hold the clutch housing with the special tool. " 09920-53740: clutch sleeve hub holder • remove the clutch spring set bolts and clutch springs. Note: loosen ...

Page 133

7-4 clutch • remove the clutch drive plates 4 and driven plates 5. Note: mark the paint mark a to the clutch driven no. 2 plate. A clutch driven no. 2 plate b clutch driven no. 1 plate c direction of outside • remove the spring washer 6 and spring washer seat 7. Mark the paint mark..

Page 134

Clutch 7-5 inspection drive plate • measure the drive plate thickness. # drive plate thickness service limit: 2.77 mm (0.109 in) " 09900-20101: vernier calipers • inspect the drive plates for wear, distortion and discoloration. • if the drive plate thickness is found to have reached the limit, repla...

Page 135

7-6 clutch push rod • inspect the push rod for wear and damage. • if any defects are found, replace the push rod with a new one. Release bearing • inspect the release bearing for play, discoloration, wear and seizure. • move the inner race by finger and inspect for smooth move- ment. • if it does no...

Page 136

Clutch 7-7 installation install the clutch plates in the reverse order of removal. Pay attention to the following points: • install the spring washer seat 1 and spring washer 2 onto the clutch sleeve hub correctly. • apply engine oil to the drive plates 3 and driven plates 4. • install the clutch dr...

Page 137

7-8 clutch • install the clutch springs and clutch spring set bolts. • hold the clutch housing with the special tool. " 09920-53740: clutch sleeve hub holder • tighten the clutch spring set bolts to the specified torque. Note: tighten the clutch spring set bolts diagonally. % clutch spring set bolt:...

Page 138

Clutch 7-9 primary driven gear and clutch sleeve hub removal • remove the clutch cover. ( !7-3) • remove the pressure plate and clutch plates. ( !7-3, -4) • flatten the lock washer 1. • hold the clutch sleeve hub with the special tool and loosen the nut 2. " 09920-53740: clutch sleeve hub holder • r...

Page 139

7-10 clutch inspection • inspect the clutch sleeve hub and primary driven gear for wear and cracks. • if necessary, replace the sleeve hub or driven gear. • inspect the needle bearings and spacer for damage and wear. • if any defects are found, replace the bearing or spacer. Installation install the...

Page 140

Clutch 7-11 • tighten the clutch sleeve hub nut with the special tool to the specified torque. " 09920-53740: clutch sleeve hub holder % clutch sleeve hub nut: 90 n·m (9.0 kgf-m, 65.0 lb-ft) • make sure the clutch sleeve hub for smooth movement. • bend the lock washer to secure the nut. • reassemble...

Page 141: Clutch Release Camshaft

7-12 clutch clutch release camshaft removal • disconnect the clutch cable 1. Note: loosen the clutch cable adjuster when disconnecting. • remove the clutch cover and its gasket. ( !7-3) • remove the pressure plate and push rod. ( !7-3) • pull the clutch release camshaft 2 out of crankcase. Inspectio...

Page 142

Clutch 7-13 installation install the clutch release camshaft in the reverse order of removal. Pay attention to the following points: • apply suzuki moly paste to the clutch release camshaft. & 99000-25140: suzuki moly paste or equivalent • apply suzuki super grease “a” to the oil seal lips. ' 99000-...

Page 143

– memo –.

Page 144: Kick Starter

8 kick starter 8-1 contents kick starter construction ........................................................................................ 8- 2 kick starter .................................................................................... 8- 2 kick starter .......................................

Page 145: Construction

8-2 kick starter construction kick starter 10 n·m (1.0 kgf-m, 7.0 lb-ft) 23 n·m (2.3 kgf-m, 16.5 lb-ft).

Page 146: Kick Starter

Kick starter 8-3 kick starter removal • drain engine oil. ( !2-11) • drain engine coolant. ( !13-3) • remove the brake pedal. ( !16-18) • disconnect the radiator hose 1. • remove the right front protector 2. • remove the kick starter lever 3. • remove the right crankcase cover 4, dowel pins and gask...

Page 147

8-4 kick starter • remove the following parts from the kick starter shaft 8: return spring 9 kick starter c spring guide 0 snap ring d shim a shim e spring b kick starter drive gear f " 09900-06107: snap ring pliers • remove the kick starter guide g. Inspection • inspect the oil seal lip for wear an...

Page 148

Kick starter 8-5 installation install the kick starter in the reverse order of removal. Pay atten- tion to the following points: • install the kick starter guide 1. # kick starter guide bolt: 10 n·m (1.0 kgf-m, 7.0 lb-ft) • install the kick starter drive gear 2 and shim 3 to the kick starter shaft. ...

Page 149

8-6 kick starter • install the shim 8 and spring 9 to the kick starter shaft. • install the kick starter shaft assembly to the crankcase. Note: securely engage the stopper portion c of the kick starter with the stopper guide d. • install the end of return spring to the crankcase. • install the kick ...

Page 150

Kick starter 8-7 • install the kick starter lever so that its punch mark f aligns with the truncated spline g. • tighten the kick starter lever bolt to the specified torque. # kick starter lever bolt: 23 n·m (2.3 kgf-m, 16.5 lb-ft) • install the brake pedal. ( !16-18) • install the radiator hose. ( ...

Page 151

– memo –.

Page 152: Gearshifting

9 gearshifting 9-1 contents gearshifting construction ........................................................................................ 9- 2 gearshift linkage ......................................................................... 9- 2 gearshift linkage ........................................

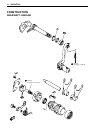

Page 153: Construction

9-2 gearshifting construction gearshift linkage 10 n.M (1.0 kgf-m, 7.0 lb-ft) 24 n.M (2.4 kgf-m, 17.5 lb-ft).

Page 154: Gearshift Linkage

Gearshifting 9-3 gearshift linkage removal • drain engine oil. ( !2-11) • drain engine coolant. ( !13-3) • remove the gearshift lever 1. Note: mark the gearshift shaft head at which the gearshift lever slit set for correct reinstallation. • remove the right crankcase cover and clutch assembly. ( !7-...

Page 155

9-4 gearshifting • remove the gearshift pawls 8, pins 9 and springs 0. • remove the gearshift cam driven gear pin a and gearshift cam stopper plate b. • remove the gearshift cam stopper c, spring d and washer e. Inspection • inspect the gearshift shaft 1 for bends and damage. • inspect the return sp...

Page 156

Gearshifting 9-5 installation install the gearshift in the reverse order of removal. Pay atten- tion to the following points: • install the washer 1, spring 2 and gearshift cam stopper 3. Note: install the spring 2 to the hole a. # shift cam stopper bolt: 10 n·m (1.0 kgf-m, 7.0 lb-ft) • align the pi...

Page 157

9-6 gearshifting • with the pawls held in pushed position, install the pawl lifter 0. • install the gearshift cam driven gear and pawl lifter. • apply thread lock super to the screws. • tighten the screws. $ 99000-32030: thread lock super “1303” or equivalent • install the gearshift return spring b,...

Page 158

Gearshifting 9-7 • align the mark on the gearshift shaft head with the gearshift lever matching surface. • tighten the gearshift lever bolt to specified torque. # gearshift lever bolt: 10 n·m (1.0 kgf-m, 7.0 lb-ft) inspection after installation • engine oil level and oil leakage ( !2-11) • engine co...

Page 159

– memo –.

Page 160: Transmission and Crankshaft

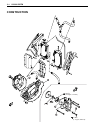

10 transmission and crankshaft 10-1 contents transmission and crankshaft construction ...................................................................................... 10- 2 transmission and crankshaft ............................................... 10- 2 engine bottom side .......................

Page 161: Construction

10-2 transmission and crankshaft construction transmission and crankshaft 90 n.M (9.0 kgf-m, 65.0 lb-ft).

Page 162: Engine Bottom Side

Transmission and crankshaft 10-3 engine bottom side • remove the engine. ( !5-2 to -5) note: the following parts must be removed before disassembling the engine bottom side (crankcase). • remove the cylinder head, cylinder and piston. ( !6-4 to -6) • remove the magneto cover. ( !14-10) • remove the ...

Page 163

10-4 transmission and crankshaft crankcase separation • remove the engine sprocket spacer 1 and two o-rings 2. • remove the oil strainer cap 3 and oil strainer (no.1). ( !2-13) • remove the crankcase bolts and engine oil drain plug 4. • separate the crankcase with the special tool. " 09920-13120: cr...

Page 164

Transmission and crankshaft 10-5 • remove the gearshift fork shaft 4. • remove the gearshift cam 5. • remove the gearshift forks 6. • remove the countershaft assembly 7 and driveshaft assem- bly 8. Crankshaft removal • remove the crankshaft with the special tool. " 09920-13120: crankcase separating ...

Page 165

10-6 transmission and crankshaft transmission inspection • inspect the gear teeth, dogs, and gearshift grooves for abnor- mal wear and damage. • inspect the bushings and splines for abnormal wear and dis- coloration. • if necessary, replace defective parts with a new one. • inspect the gearshift cam...

Page 166

Transmission and crankshaft 10-7 • measure the gearshift fork groove width with a vernier cali- pers. # gearshift fork groove width standard: 4.95 – 5.05 mm (0.195 – 0.199 in) " 09900-20101: vernier calipers conrod inspection • for conrod inspection other than the following, refer to page 6-??. • me...

Page 167

10-8 transmission and crankshaft oil seal inspection • inspect each oil seal lip for wear and damage. • if any defects are found, replace the oil seal with a new one. Oil seal removal and installation • remove the oil seals ( 1, 2, 3, 4) with the special tool. " 09913-50121: oil seal remover • fit e...

Page 168

Transmission and crankshaft 10-9 bearing inspection • inspect the bearings for play, discoloration, wear and seizure. • move the inner race by finger and inspect for smooth move- ment. • if it does not move smoothly, replace the bearing with a new one. Bearing removal and installation • remove the o...

Page 169

10-10 transmission and crankshaft • remove the bearings 2, 8. " 09921-20240: bearing remover set bearing 2, 8: remover 20 mm • remove the bearing 4. " 09941-64511: bearing/oil seal remover 09930-30104: sliding shaft • remove the bearing 9. " 09921-20200: bearing remover 09930-30104: sliding shaft • ...

Page 170

Transmission and crankshaft 10-11 installation • press the new bearings with the special tools. Bearing 1: $ 55 attachment bearing 2, 8: $ 42 attachment bearing 3, 6: $ 72 attachment bearing 4: $ 40 attachment bearing 5: $ 52 attachment bearing 7: $ 37 attachment bearing 9: $ 15 attachment " 09913-7...

Page 171

10-12 transmission and crankshaft crankshaft installation • fit the crankshaft into the left crankcase with the special tools. Note: use the attachment (inner driver attachment 3) for crankshaft bearing inside diameter. " 09910-32812: crankshaft installer 1 09911-11310: crankshaft installer attachme...

Page 172

Transmission and crankshaft 10-13 transmission installation note: install the snap ring in the groove and locate its end as shown in the illustration. • apply engine oil to the following parts: driveshaft, counter- shaft, transmission gears, bearings. • install the driveshaft 1 and countershaft 2 wi...

Page 173

10-14 transmission and crankshaft • install the gearshift forks 3, 4. • install the gearshift cam 5 and gearshift shaft 6. Note: turn the gearshift cam to the neutral position and confirm that the driveshaft and countershaft turn without resistance. • install the oil strainer (no.2) 7..

Page 174

Transmission and crankshaft 10-15 crankcase installation • fit the dowel pins and gasket 1. • fit the right crankcase on the left crankcase. • install the bracket a to the bolt. ( !19-24) • tighten the crankcase bolts and engine oil drain plug 2. ' crankcase bolt: 11 n·m (1.1 kgf-m, 8.0 lb-ft) engin...

Page 175

10-16 transmission and crankshaft • apply grease to oil seal lip and o-rings 5. % 99000-25010: suzuki super grease “a” or equivalent • fit the o-rings 5 and spacer 6 to the driveshaft. Primary drive gear installation • install the cam chain and cam chain tensioner. ( !6-24) • install the magneto rot...

Page 176

Transmission and crankshaft 10-17 • connect the crankcase breather hose 4. • install the oil pump no.1, no.2 and oil pump idle gear. ( !11-6) • install the gearshift linkage. ( !9-5) • install the kick idle gear and kick starter shaft. ( !8-5) • install the clutch assembly and right crankcase cover....

Page 177

– memo –.

Page 178: Lubrication System

11 lubrication system 11-1 contents lubrication system engine lubrication system ............................................................ 11- 2 engine lubrication system chart ........................................ 11- 2 engine oil level inspection ................................................

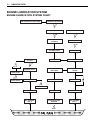

Page 179: Engine Lubrication System

11-2 lubrication system engine lubrication system engine lubrication system chart counter gears drive shaft drive gears oil filter by-pass oil strainer (no. 1) crankshaft right end right crankshaft crank pin conrod big end bearing cylinder head in & ex cam faces oil nozzle oil pump (no.1) oil strain...

Page 180

Lubrication system 11-3 engine oil level inspection ( !2-11) engine oil change ( !2-11) engine oil filter change ( !2-12) oil pressure check ( !2-37) oil strainer removal ( !2-13) oil strainer inspection ( !2-13) oil strainer installation ( !2-13) oil seal removal • remove the snap ring 1. " 09900-0...

Page 181

11-4 lubrication system oil seal installation • fit the new oil seal with the special tools. " 09913-70210: bearing installer set oil seal: # 22 attachment • apply suzuki super grease to the oil seal lip. $ 99000-25010: suzuki super grease “a” or equivalent • install the snap ring 1. " 09900-06108: ...

Page 182

Lubrication system 11-5 • remove the oil pump no.2 shaft 2, pin 3, inner rotor 4 and outer rotor 5. Oil pump no.1 and no.2 inspection • check the oil pump with each part for any defects or wear. • replace the defective parts with a new one..

Page 183

11-6 lubrication system oil pump no.1 and no.2 installation oil pump no.1 install the oil pump no.1 in the reverse order of removal. Pay attention to the following points: • install the oil pump no.1 cover 2, oil pump no.1 plate 3 and pin 4 to oil pump driven gear shaft 1. • fit the slot a of the in...

Page 184

Lubrication system 11-7 oil pump no.2 install the oil pump no.2 in the reverse order of removal. Pay attention to the following points: • install the pin 2 to oil pump no.2 shaft 1. • install the inner rotor 3 to oil pump no.2 shaft 1. Note: fit the slot a of the inner rotor to the pin 2. • apply en...

Page 185

– memo –.

Page 186: Fuel System

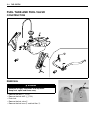

12 fuel system 12-1 contents fuel system fuel tank and fuel valve ............................................................... 12- 2 construction ................................................................................ 12- 2 removal ...........................................................

Page 187: Fuel Tank And Fuel Valve

12-2 fuel system fuel tank and fuel valve construction removal • remove the seat. ( !5-2) • remove the fuel tank. ( !5-2) • drain fuel. • remove the fuel valve 1. • remove the fuel hose 2 and fuel filter 3. " warning gasoline is highly flammable and explosive. Keep heat, spark and flame away. Fw d f...

Page 188

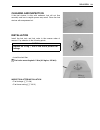

Fuel system 12-3 cleaning and inspection if the fuel strainer is dirty with sediment, fuel will not flow smoothly and loss in engine power may result. Clean the fuel strainer with compressed air. Installation install the fuel tank and fuel valve in the reverse order of removal. Pay attention to the ...

Page 189: Carburetor

12-4 fuel system carburetor construction 1 clip 2 jet needle 3 throttle valve 4 throttle position sensor 5 slow air jet 6 starter jet 7 pilot screw 8 slow jet 9 main jet 0 float valve a float b leak jet c throttle stop screw.

Page 190

Fuel system 12-5 removal • remove the seat and radiator covers. ( !5-2) • turn the fuel valve to the off position. • place a container beneath the drain hose, drain fuel from the float chamber by loosening the drain screw 1. • remove the radiator covers, left and right. • disconnect the fuel hose 2 ...

Page 191

12-6 fuel system • remove the throttle pulley cover 6. • loosen the lock-nuts 7. • remove the throttle cables from the pulley. Disassembly • remove the hot starter valve 1 and spring from the hot starter cable. • remove the drain hose, fuel hose and air vent hoses. Note: do not remove the throttle p...

Page 192

Fuel system 12-7 • remove the throttle valve assembly 5. • disassemble the throttle valve assembly. 6 throttle valve a spring 7 bearing b needle set screw 8 jet needle c floating valve 9 clip d seal 0 collar • remove the throttle shaft e with the link arm f, spring g, plastic washer h and steel wash...

Page 193

12-8 fuel system • remove the acceleration pump cover k. • remove the spring l, o-rings m and diaphragm n. • remove the float chamber o from the carburetor body. • remove the drain plug p and leak jet q. • remove the o-ring r and gasket s. • pull out the push rod t of acceleration pump. • remove the...

Page 194

Fuel system 12-9 • remove the following parts. Z main jet [ main nozzle \ buffer plate ] starter jet ^ slow jet • remove the slow air jet a..

Page 195

12-10 fuel system cleaning • clean all jets with a spray-type carburetor cleaner and dry them using compressed air. • clean all passageways of the carburetor thoroughly – not just the perceived problem area. Clean the passageways in the carburetor body with a spray-type cleaner. If necessary, soak c...

Page 196

Fuel system 12-11 fuel level • remove the drain hose and then install a proper cap 1 to the carburetor drain. • remove the drain screw and than connect the special tool. $ 09913-14541: fuel level gauge • hold the carburetor in the proper angle with a stand. • fill the float chamber with fuel. • remo...

Page 197

12-12 fuel system float height • tilt the carburetor until the float arm b just touches the float valve rod. • measure the float height a. % standard float height: 8.0 mm (0.315 in) $ 09900-20101: vernier calipers • if necessary, slightly bend the float arm b to change the float height. • recheck th...

Page 198

Fuel system 12-13 • fit the float chamber. • tighten the screws with the hose plates 6 and cable holder 7. • fit the spring 8. • install the diaphragm 9 so that the marks c face outside. • apply thin coat of the grease to the o-ring. & 09900-25010: suzuki super grease “a” or equivalent • install the...

Page 199

12-14 fuel system • apply suzuki silicone grease to the throttle shaft. ' 99000-25100: suzuki silicone grease or equivalent • hook the return spring onto the stopper of the throttle pulley. • insert the throttle shaft and install the steel washer a, plastic washer b and link arm c. • fit the end of ...

Page 200

Fuel system 12-15 • reassemble the hot start valve e to the hot start cable end. Acceleration pump timing if turn the stop screw of the acceleration pump, adjust the accel- eration pump timing after assemble the carburetor. • select a pin b of the same diameter as the throttle valve height a and ins...

Page 201

12-16 fuel system installation install the carburetor in the reverse order of removal. Pay atten- tion to the following points: • fit the projection on the carburetor body in the depression of the intake pipe. Inspection after installation • wire, cable and hose routing ( !19-18 to -22) • fuel leaka...

Page 202: Throttle Position Sensor

Fuel system 12-17 throttle position sensor inspection throttle position sensor input voltage • disconnect the throttle position sensor coupler 1. • shift the transmission into neutral. • start the engine. • measure the throttle position sensor input voltage using the multi circuit tester. % throttle...

Page 203

12-18 fuel system removal • remove the carburetor. ( !12-5) • remove the throttle position sensor using the special tool. $ 09930-11950: torx wrench, t25 installation • install the throttle valve with the throttle position sensor. Note: align the throttle shaft end a with the groove b of throttle po...

Page 204: Cooling System

13 cooling system 13-1 contents cooling system construction ...................................................................................... 13- 2 engine coolant ................................................................................... 13- 3 replacement .................................

Page 205: Construction

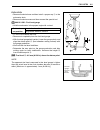

13-2 cooling system construction fw d fwd 11 n.M (1.1 kgf-m, 8.0 lb-ft) f w d fwd 10 n.M (1.0 kgf-m, 7.0 lb-ft).

Page 206: Engine Coolant

Cooling system 13-3 engine coolant replacement • open the radiator cap. • remove the drain bolt 1 and drain engine coolant. • replace the gasket washer with a new one and tighten the drain bolt 1. ! Engine coolant drain bolt: 11 n·m (1.1 kgf-m, 8.0 lb-ft) • pour specified engine coolant up to the bo...

Page 207: Cooling Circuit

13-4 cooling system cooling circuit inspection • remove the radiator cap. • connect the tester 1 to the filler. • give a pressure of about 120 kpa (1.2 kgf/cm 2 , 17.0 psi) and see if the system holds this pressure for 10 seconds. • if the pressure would fall during this 10-second interval, it means...

Page 208: Radiator

Cooling system 13-5 radiator inspection radiator • visually inspect the radiators and hose for damage. • fins bent down or dented can be repaired by straightening them with the blade of a small screwdriver. Radiator cap • fit the cap to the radiator cap tester. • build up pressure slowly by operatin...

Page 209

13-6 cooling system removal • remove the seat and fuel tank. ( "5-2) • drain engine coolant. ( "13-3) • remove the hoses. • remove the radiator covers 1, left and right. • remove the radiators, left and right. Installation install the radiator in the reverse order of removal. • rout the radiator hos...

Page 210: Water Pump

Cooling system 13-7 water pump removal water pump case • drain engine oil. ( "2-11) • remove the right front protector 1. • drain engine coolant by removing the drain bolt 2. • disconnect the radiator hose 3. • remove the water pump case 4. Note: use the pry points a to remove the case. Crankcase co...

Page 211

13-8 cooling system • remove the shim 3 and water pump shaft 4. • remove the oil seal. Note: if there is no abnormal condition, the oil seal removal is not nec- essary. Inspection impeller and water pump shaft • inspect the impeller and water pump shaft for damage. • replace the defective parts with...

Page 212

Cooling system 13-9 • press the oil seal with the suitable size socket wrench. • apply suzuki super grease to the oil seal lip. & 99000-25010: suzuki super grease “a” or equivalent impeller and water pump shaft • hold the water pump shaft with a wrench and tighten the impeller to the specified torqu...

Page 213

13-10 cooling system water pump case • install the dowel pins and oil filter 1. • install the spring 2 and a new gasket 3. • apply engine coolant to the gasket 3. • fit the water pump case. • tighten the water pump case bolts to the specified torque. ! Water pump case bolt: 11 n·m (1.1 kgf-m, 8.0 lb...

Page 214: Electrical System

14 electrical system 14-1 contents electrical system cautions in servicing ....................................................................... 14- 2 connector ...................................................................................... 14- 2 coupler .......................................

Page 215: Cautions In Servicing

14-2 electrical system cautions in servicing connector • when connecting a connector, be sure to push it in until a click is felt. • inspect the connector for corrosion, contamination and break- age in its cover. Coupler • with a lock type coupler, be sure to release the lock when dis- connecting, a...

Page 216

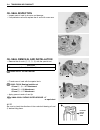

Electrical system 14-3 location of electrical components 1 engine stop switch 4 cdi unit 2 ignition coil 5 pick-up coil 3 throttle position sensor 6 magneto.

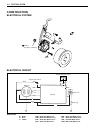

Page 217: Construction

14-4 electrical system construction electrical system electrical circuit wire color: g: green b/bl: black with blue tracer b/w: black with white tracer r: red b/br: black with brown tracer b/y: black with yellow tracer y: yellow b/g: black with green tracer r/w: red with white tracer b/r: black with...

Page 218

Electrical system 14-5 troubleshooting no spark or poor spark step 1 1) check the ignition system couplers for poor connections. Is there connection in the ignition system couplers? Step 2 1) measure the ignition coil primary peak voltage. ( "14-8) is the peak voltage ok? Step 3 1) inspect the spark...

Page 219

14-6 electrical system step 7 1) check the stator. Is the stator ok? Step 8 1) measure the engine stop switch resistance. ( "14-9) is the resistance ok? Yes go to step 8. No faulty stator yes • faulty cdi unit • open or short circuit in wire harness no faulty engine stop switch.

Page 220: Ignition System

Electrical system 14-7 ignition system ignition system peak voltage inspection • disconnect the magneto lead wire coupler 1. • connect the multi-circuit tester with peak volt adaptor as shown. • measure the highest peak voltage by depressing the kick starter pedal several times forcefully. # stator ...

Page 221

14-8 electrical system ignition system coil inspection • disconnect the magneto lead wire coupler 1. • measure the exciter, charge and pick-up coils resistance. # stator coil resistance # pick-up coil resistance ! 09900-25008: multi-circuit tester set & tester knob indication: resistance (Ω) if the ...

Page 222

Electrical system 14-9 ignition coil inspection • remove the seat and fuel tank. ( "5-2) • disconnect the ignition coil lead wire coupler 1 and spark plug cap 2. • measure the ignition coil resistance. # ignition coil resistance ! 09900-25008: multi-circuit tester set & tester knob indication: resis...

Page 223: Magneto Rotor

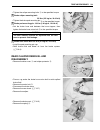

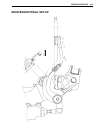

14-10 electrical system magneto rotor removal • drain engine oil. ( "2-11) • remove the seat and fuel tank. ( "5-2) • disconnect the magneto lead wire coupler and clamp. • remove the left front protector 1. • remove the gearshift lever 2. ( "9-3) • remove the magneto cover 3. • remove the gasket 4 a...

Page 224

Electrical system 14-11 • remove the magneto rotor nut with a special tool. ! 09930-44560: rotor holder • remove the magneto rotor with a special tool. ! 09930-35020: rotor remover • remove the magneto rotor key 5..

Page 225

14-12 electrical system installation • remove any grease from the tapered portion a of the mag- neto rotor and crankshaft b. • fit the magneto rotor key 1 into the crankshaft. • install the magneto rotor. • tighten the magneto rotor nut to the specified torque with a special tool. ' magneto rotor nu...

Page 226: Stator

Electrical system 14-13 stator removal • remove the magneto cover. ( "14-10) • remove the stator 1. • remove the clamp 2 and pick-up coil 3. • remove the grommet 4. Installation • apply thread lock to the stator set bolts and tighten them. ( 99000-32050: thread lock “1342” or equivalent • install th...

Page 227

– memo –.

Page 228: Front and Rear Wheels

15 front and rear wheels 15-1 contents front and rear wheels construction ...................................................................................... 15- 2 front wheel ......................................................................................... 15- 3 removal ....................

Page 229: Construction

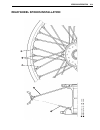

15-2 front and rear wheels construction 90 n.M (9.0 kgf-m, 65.0 lb-ft) 35 n.M (3.5 kgf-m, 25.5 lb-ft) 12 n.M (1.2 kgf-m, 8.5 lb-ft) 30 n.M (3.0 kgf-m, 21.5 lb-ft) 25 n.M (2.5 kgf-m, 18.0 lb-ft) fw d fwd.

Page 230: Front Wheel

Front and rear wheels 15-3 front wheel removal • remove the front axle nut 1. • loosen the left axle holder bolts 2. • place the motorcycle on a block to lift front wheel off the ground. • loosen the right axle holder bolts 3. • remove the front axle 4. • remove the front wheel. • remove the wheel s...

Page 231

15-4 front and rear wheels inspection spacer and dust seal • inspect the right and left dust seals 1 and wheel spacers 2 for wear and cracks. • if any defects are found, replace the spacer together with the dust seal. Note: apply grease to the spacer and dust seal before reassembling. Front axle • s...

Page 232

Front and rear wheels 15-5 wheel bearing • turn the inner race by finger and inspect it for smooth move- ment. • inspect for bearing damage. • if any defects are found, replace the bearing with a new one. Dust seal and bearing replacement • remove the dust seals with the special tool. " 09913-50121:...

Page 233

15-6 front and rear wheels • reassemble the bearings with the special tools, using the suitable spacer a match for the outside dimension of bear- ings. " 09924-84521: bearing installer set note: * install the left side (disc side) bearing first and then install the spacer and right side bearing. * a...

Page 234

Front and rear wheels 15-7 disc plate replacement • remove the disc plate. • apply thread lock super to the bolts. % 99000-32110: thread lock super “1322” or equivalent • tighten the bolts to the specified torque. & disc plate bolt: 12 n·m (1.2 kgf-m, 8.5 lb-ft) installation • hold the front axle sh...

Page 235: Rear Wheel

15-8 front and rear wheels rear wheel removal • loosen the rear axle nut 1. • place the motorcycle on a block to lift the rear wheel off the ground. • remove rear axle nut 1 and washer 2. • remove the rear axle shaft 3 and chain adjuster washers 4. • disengage the drive chain 5. • remove the rear wh...

Page 236

Front and rear wheels 15-9 inspection wheel spacer and dust seal • inspect the rear wheel spacers 1 and dust seals 2 for wear and cracks. • if any defects are found, replace the spacer together with the dust seal. Note: apply grease on the spacer and dust seal before reassembling. Sprocket • inspect...

Page 237

15-10 front and rear wheels • remove the dust seals with the special tool. " 09913-50121: oil seal remover • remove the bearings with the special tools. • remove the spacer 2 and bearing with the special tool. " 09921-20240: bearing remover set (remover 25 mm) • apply grease to the wheel bearings. $...

Page 238

Front and rear wheels 15-11 note: * install the left side (sprocket side) bearing first and then install the spacer and right side bearing. * after installing the bearings, inspect the bearings for smooth movement. • install the snap ring 1. " 09900-06108: snap ring pliers • fit the dust seals and a...

Page 239

15-12 front and rear wheels rear sprocket replacement • remove the rear sprocket. Note: install the rear sprocket as the letter on the sprocket surface faces outside. • tighten the nuts to the specified torque. & rear sprocket nut: 30 n·m (3.0 kgf-m, 21.5 lb-ft) installation • install the rear wheel...

Page 240: Front and Rear Brakes

16 front and rear brakes 16-1 contents front and rear brakes construction ...................................................................................... 16- 2 brake fluid air bleeding ................................................................ 16- 3 brake fluid replacement ................

Page 241: Construction

16-2 front and rear brakes construction fw d fwd fw d fwd 23 n·m (2.3 kgf-m, 16.5 lb-ft) 26 n·m (2.6 kgf-m, 19.0 lb-ft) 29 n·m (2.9 kgf-m, 21.0 lb-ft) 28 n·m (2.8 kgf-m, 20.0 lb-ft) 18 n·m (1.8 kgf-m, 13.0 lb-ft) 10 n·m (1.0 kgf-m, 7.0 lb-ft) 23 n·m (2.3 kgf-m, 16.5 lb-ft) 18 n·m (1.8 kgf-m, 13.0 lb...

Page 242: Brake Fluid Air Bleeding

Front and rear brakes 16-3 brake fluid air bleeding • remove the reservoir cap. • pour brake fluid up to the upper line. ! Specification and classification: dot 4 "#warning brake fluid can be hazardous to humans and pets. Brake fluid is harmful or fatal if swallowed, and harm- ful if it comes in con...

Page 243: Brake Fluid Replacement

16-4 front and rear brakes • connect a transparent tube to the bleeder valve and set the other end into a receptacle. • loosen the bleeder valve and pump the brake lever/pedal until air bubbles stop coming out from the reservoir. • hold the brake lever/pedal in the squeezed position. • open the blee...

Page 244: Brake Pads Replacement

Front and rear brakes 16-5 brake pads replacement front brake pads • remove the cap 1 and pad mounting pin 2. • remove the brake pads 3. Note: replace the two brake pads as a set. • fit the new brake pads into the caliper. • tighten the pad mounting pin to the specified torque. $ brake pad mounting ...

Page 245: Brake Disc Inspection

16-6 front and rear brakes brake disc inspection • inspect the brake disc for damage. • measure the front and rear brake disc thickness. & brake disc thickness service limit (front): 2.5 mm (0.10 in) (rear): 3.5 mm (0.14 in) • measure the front and rear brake disc runout. & brake disc runout service...

Page 246

Front and rear brakes 16-7 front caliper removal and disassembly • place a rag under the brake hose union bolt to catch spilled brake fluid. • remove the union bolt 1. • disconnect the brake hose. • remove the caliper mounting bolts 2. • remove the caliper. • remove the brake pads. ( %16-5) • remove...

Page 247

16-8 front and rear brakes • remove the dust seals 8 and piston seals 9. Caliper inspection • inspect the caliper cylinder for scuffing, wear and damage. • inspect the piston for scuffing, wear and damage. • replace the defective parts with a new one. Caliper cleaning • flush the caliper ports with ...

Page 248

Front and rear brakes 16-9 • tighten the caliper mounting bolts 1 to the specified torque. $ brake caliper mounting bolt: 25 n·m (2.5 kgf-m, 18.0 lb-ft) • tighten the brake pad mounting pin 2 to the specified torque. $ brake pad mounting pin: 18 n·m (1.8 kgf-m, 13.0 lb-ft) • set the brake hose end b...

Page 249

16-10 front and rear brakes • remove the caliper bracket 5 from the caliper. • remove the boots 6 and 7. • remove the spring 8. • wrap the caliper with a rag to prevent brake fluid scatter and piston pop-out. • apply low-pressure air into the caliper through the hole to remove the piston. • remove t...

Page 250

Front and rear brakes 16-11 • install the springs and boots. • apply suzuki silicone grease to the caliper axles. ' 99000-25100: suzuki silicone grease or equivalent • install the caliper bracket. • install the brake pads. • tighten the brake pad mounting pin temporarily. • install the rear wheel. (...

Page 251: Master Cylinder

16-12 front and rear brakes master cylinder front master cylinder removal and disassembly • drain brake fluid. ( %16-4) • place a rag under the brake hose union bolt 1 to catch spilled brake fluid. • remove the union bolt 1. • disconnect the brake hose. • remove the master cylinder holder bolts. • r...

Page 252

Front and rear brakes 16-13 • remove the dust boot 5. • remove the snap ring 6 with snap ring pliers. ( 09900-06108: snap ring pliers • remove the washer 7 and piston/cup set 8. Master cylinder inspection • inspect the cylinder bore and piston for scuffing, wear and damage. • inspect the piston rod ...

Page 253

16-14 front and rear brakes front master cylinder reassembly and installation reassemble and install the master cylinder in the reverse order of removal and disassembly. Pay attention to the following points: • apply grease to the brake lever pivot bolt and contact point between piston and brake lev...

Page 254

Front and rear brakes 16-15 rear master cylinder removal and disassembly • drain brake fluid. ( %16-4) • remove the cotter pin, washer and then master cylinder rod pin 1. • remove the master cylinder mounting bolts and master cylin- der 2. • place a rag under the brake hose union bolt 3 to catch spi...

Page 255

16-16 front and rear brakes master cylinder inspection • inspect the cylinder bore and piston for scuffing, wear and damage. • inspect the piston rod and spring for damage. Master cylinder cleaning. ( %16-13) rear master cylinder reassembly and installation reassemble and install the master cylinder...

Page 256: Brake Lever

Front and rear brakes 16-17 brake lever removal • remove the boot 1. • remove the bolt/nut and brake lever 2. • remove the brake lever adjuster return spring 3. ( 09930-11950: torx wrench, t25 installation install the brake lever in the reverse order of removal. Pay atten- tion to the following poin...

Page 257

16-18 front and rear brakes • remove the master cylinder rod pin 4. • remove the brake pedal pivot bolt 5 and return spring 6. Installation • apply suzuki super grease to the oil seal and brake pedal pivot bolt. ) 99000-25010: suzuki super grease “a” or equivalent • install the return spring 1 prope...

Page 258: Front Fork and Steering