- DL manuals

- Suzuki

- Motorcycle

- RM85

- Owner's Service Manual

Suzuki RM85 Owner's Service Manual

Summary of RM85

Page 1

Part no. 99011-02b82-01a april, 2006 en tk rm85/l owner’s service manual.

Page 2

This manual should be considered a permanent part of the motorcycle and should remain with the motorcycle when resold or otherwise transferred to a new owner or operator. The manual contains important safety information and instructions which should be read carefully before operating the motorcycle..

Page 3: Foreword

Foreword this manual is presented as a means whereby you can maintain your rm85 in top working condition at all times. Your riding skill and the maintenance steps outlined in this manual will assure you of top performance from your machine under any type of competition. We sincerely wish you and you...

Page 4: General Considerations

General considerations • wear a helmet and goggles a helmet is the most important piece of gear to wear. Helmets do not reduce essential vision or hearing. Generally, helmets do not cause or intensify injury if you crash. Helmets simply help your skull protect your intelligence, your memory, your pe...

Page 5: Serial Number Location

Serial number location the frame number 1 is stamped on the steering head. The engine serial number 2 is stamped on the right side of the crankcase assembly. Write down the serial numbers here for your future reference. Frame no. Engine no..

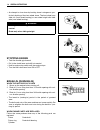

Page 6: Warnings For Servicing

Warnings for servicing warning never run the engine indoors or in a garage. Exhaust gas contains carbon mon- oxide, a gas that is colorless and odorless and can cause death or severe injury. Only run the engine outdoors where there is fresh air. warning hot engine and muffler can burn you. Wait ...

Page 7: Precautions For

Precautions for servicing • replace gaskets, circlips, o-rings and cotter pins with new ones. • take care not to expand the end gap larger than required to slip the circlip over the shaft when installing a circlip. • use special tools where specified. • use genuine suzuki parts and recommended oil. ...

Page 8: Symbol Marks And Materials

Symbol marks and materials symbol mark materials apply suzuki super grease “a” 99000-25010 apply suzuki silicone grease 99000-25100 apply thread lock super “1303” 99000-32030 apply thread lock super “1322” 99000-32110 apply suzuki bond “1207b” 99000-31140 use or apply dot 4 brake fluid..

Page 9

Symbol mark materials use suzuki fork oil ss-05 99000-99001-ss5 use suzuki rear suspension oil ss-25 99000-99001-s25 use engine coolant. Suzuki coolant 99000-99032-11x apply engine oil or transmission oil. Tighten a nut or bolt to the specified torque. Replace a part with a new one when reassembling...

Page 10

– memo –.

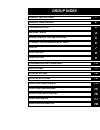

Page 11: Group Index

Group index general instructions 1 periodic maintenance 2 troubleshooting 3 machine tuning 4 engine removal and installation 5 cylinder, piston and exhaust valve 6 clutch 7 kick starter 8 gearshifting 9 transmission and crankshaft 10 fuel system 11 cooling system 12 electrical system 13 front and re...

Page 12: General Instructions

1 general instructions 1-1 contents general instructions location of parts ............................................................................... 1- 2 fuel and oil recommendation ........................................................ 1- 3 intructing young rider ..............................

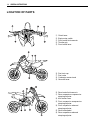

Page 13: Location Of Parts

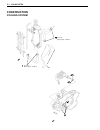

1-2 general instructions location of parts 1 clutch lever 2 engine stop switch 3 front brake fluid reservoir 4 throttle grip 5 front brake lever 6 fuel tank cap 7 fuel valve 8 carburetor starter knob 9 gearshift lever 0 rear brake fluid reservoir a rear suspension compression damping adjuster b kick...

Page 14

General instructions 1-3 fuel and oil recommendation this motorcycle is of the two-stroke design, which requires a premixture of gasoline and oil. Gasoline: use only unleaded gasoline of at least 90 pump octane (r/2 + m/2 method). ..... For canada use only unleaded gasoline of at least 95 octane. (r...

Page 15: Intructing Young Rider

1-4 general instructions intructing young rider this is important advice to a parent children are important; the sight of a new motorcycle excites their imagination; and the expectation is often so great as to make them forget the importance of safty precautions. Please go through this manual with a...

Page 16

General instructions 1-5 note: for practice, choose a level ground free of traffic and spacious enough to permit driving several yards with the engine powered. In short, break-in the young rider gradually. Clothing rule 4. Wear simple clothes loose fitting clothes are unsafe for riding. Loose belts ...

Page 17

1-6 general instructions • pull the starter knob out. • close the throttle. Kick the kick starter lever to start the engine. If the engine fails to fire up, kick again. If third or fourth attempt fails, then push back starter knob to original position, and open the throttle wider by turning the thro...

Page 18

General instructions 1-7 starting off • pull in the clutch lever fully and push the gearshift lever down to change the gear from neutral to low position. • release the clutch lever gently while twisting the throttle grip slowly. • pick up speed just a little on low. Twist throttle grip forward and p...

Page 19

1-8 general instructions • an attempt to slow down by braking alone is dangerous, par- ticularly braking of the front wheel alone. The front wheel may slide out (front wheel braking) or rear wheel might skid side- wise (rear wheel braking). Stopping engine • twist the throttle grip forward. • pull i...

Page 20: Periodic Maintenance

2 periodic maintenance 2-1 contents periodic maintenance periodic maintenance ........................................................................ 2- 2 spark plug .............................................................................................. 2- 4 air cleaner ........................

Page 21: Periodic Maintenance

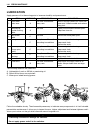

2-2 periodic maintenance periodic maintenance inspection before practice inspection before race what to check check for spark plug • heat range, fouled electrode, tightness • loose high-tension cord air cleaner element lubrication transmission oil oil level engine coolant engine coolant level coolin...

Page 22

Periodic maintenance 2-3 periodic maintenance chart it is very important to inspect and maintain the machine regularly. Follow the guideline in the chart. The life of parts varies depending on the riding conditions. Perform more often than shown in the chart if you use the motorcycle under severe co...

Page 23: Spark Plug

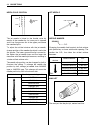

2-4 periodic maintenance spark plug • inspect the spark plug condition, electrode color, carbon deposits, spark plug gap, and washer damage, after removing the spark plug. Note: remove the dirt around the spark plug before removing the spark plug to prevent dirt from entering the combustion cham- be...

Page 24: Air Cleaner

Periodic maintenance 2-5 air cleaner air cleaner element removal • remove the seat. • remove the air cleaner cap 1. • remove the wing nut 2. • remove the element from the element holder. Washing • fill a washing pan large enough to hold the element with a non-flammable cleaning solvent a. Immerse th...

Page 25: Transmission Oil

2-6 periodic maintenance • install the element in the air cleaner box. • install the air cleaner cap. Note: running the engine without the air cleaner cap can vary the car- buretion. Do not run the engine without the air cleaner cap. Note: follow the instructions below to keep the air cleaner elemen...

Page 26

Periodic maintenance 2-7 transmission oil level inspection and replenishment • run the engine for a few minutes and stop it. Wait 5 minutes. • place the motorcycle on level ground and hold the motorcycle vertically. • remove the oil level screw 1. Check that oil comes out of the hole. • if oil does ...

Page 27: Engine Coolant

2-8 periodic maintenance engine coolant engine coolant level check • remove the radiator cap 1. • check that the engine coolant level is at the bottom of the inlet hole. If not, replenish the radiator with specified engine cool- ant. • tighten the radiator cap securely. Note: * this motorcycle does ...

Page 28: Clutch Cable

Periodic maintenance 2-9 engine coolant replenishment • drain engine coolant. ( 12-3) • pour engine coolant. ( 12-3) • use an anti-freeze and summer engine coolant which is com- patible with aluminum radiator, mixed with distilled water at the ratio of 50 : 50. Note: the radiator, cylinder and cyl...

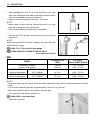

Page 29: Throttle Cable

2-10 periodic maintenance minor adjustment • loosen lock-nut 3. • turn adjuster 4 so the clutch lever has 10 – 15 mm (0.4 – 0.6 in) play at the clutch lever end before pressure is felt. • tighten lock-nut 3. clutch lever play: 10 – 15 mm (0.4 – 0.6 in) throttle cable adjust the throttle cable play...

Page 30: Fuel Valve

Periodic maintenance 2-11 fuel valve • drain the fuel. • disconnect the fuel hose 1 and remove the fuel valve 2. • clean the fuel filter with compressed air. Note: if the fuel filter is dirty with sediment, fuel will not flow smoothly. warning gasoline is highly flammable and explosive. Keep heat,...

Page 31: Piston

2-12 periodic maintenance cylinder head, cylinder and piston cylinder head • remove the cylinder head. ( 6-3) • remove carbon deposits from the combustion chamber sur- face. • inspect for pinholes, cracks and other damage. Cylinder • remove the cylinder. ( 6-3) • remove carbon deposits from the ex...

Page 32: Exhaust Silencer

Periodic maintenance 2-13 exhaust silencer silencer inspection and replacement • remove the seat and the right frame cover. • loosen the silencer mounting bolts and remove the silencer. • remove three bolts and extract the black frontal pipe from the aluminum case. • inspect the glass wool 1 for clo...

Page 33

2-14 periodic maintenance drive chain adjustment • loosen the axle nut 1. • loosen the lock-nut 2. • adjust the drive chain slack to the specification by turning the adjusters 3. • check that both right and left alignment marks 4 are at the same position. • tighten the axle nut 1 and lock-nut 2. a...

Page 34

Periodic maintenance 2-15 sprocket inspection • inspect the engine sprocket and rear sprocket for wear and cracks. Replace the sprockets if necessary. Note: when replacing a worn sprocket, it is likely that the drive chain will need to be replaced as well. Drive chain guide, buffer, tensioner roller...

Page 35: Brakes

2-16 periodic maintenance brakes brake fluid level • inspect the brake fluid level in both front and rear reservoirs. If the brake fluid level is lower than lower (lwr) mark, replenish the reservoir with the specified brake fluid to the upper level. Inspect brake pad wear and brake fluid leakage if ...

Page 36: Front Fork

Periodic maintenance 2-17 note: * pump the brake lever/pedal several times to restore the brake pads after replacing the brake pads. * replace both right and left pads together when replacing the brake pads. Front brake lever adjustment adjust the brake lever play as follows: • loosen lock-nut 1. • ...

Page 37: Rear Suspension

2-18 periodic maintenance rear suspension • move the rear suspension up and down several times and inspect for smooth movement. • inspect for damage and oil leaks. • inspect the bolts and nuts for tightness. Wheels and tires wheel rim • inspect the wheel bearing for rattles. Replace the bearings if ...

Page 38: Steering

Periodic maintenance 2-19 steering • inspect the steering by moving the front forward and back- ward, and right and left. If the steering has play or binds, inspect steering stem head nut tightness and steering bear- ings. ( 16-13).

Page 39: Lubrication

2-20 periodic maintenance lubrication apply grease or oil to the moving parts to increase durability and prevent wear. The following materials are necessary: a. Lightweight oil such as wd-40 or penetrating oil. B. Suzuki chain lube or an equivalent c. Water-proof wheel bearing grease. Follow the sch...

Page 40: Tightening Torque

Periodic maintenance 2-21 tightening torque part n·m kgf-m lb-ft cylinder head nut 28 2.8 20.5 magneto rotor nut 35 3.5 25.5 cylinder nut 25 2.5 18.0 crankcase bolt 10 1.0 7.3 clutch sleeve hub nut 70 7.0 50.5 primary drive gear nut 70 7.0 50.5 spark plug 28 2.8 20.5 transmission oil drain plug 23 2...

Page 41

2-22 periodic maintenance for other bolts and nuts not listed in the table, refer to this chart. Bolt diameter (mm) conventional or “4” marked bolt “7” marked or crown headed bolt n·m kgf-m lb-ft n·m kgf-m lb-ft 4 2.0 0.2 1.5 2.0 0.2 1.5 5 3.0 0.3 2.0 5.0 0.5 3.5 6 6.0 0.6 4.5 10.0 1.0 7.0 8 13.0 1....

Page 42: Troubleshooting

3 troubleshooting 3-1 contents troubleshooting troubleshooting ................................................................................. 3- 2 engine ................................................................................................. 3- 2 chassis ...................................

Page 43: Troubleshooting

3-2 troubleshooting troubleshooting engine complaint possible cause remedy engine does not start or hard to start fuel deterioration no fuel flow to the carburetor • fuel valve clogged • fuel hose clogged • fuel tank cap breather hose clogged • carburetor float valve malfunction carburetor overflow ...

Page 44

Troubleshooting 3-3 complaint possible cause remedy engine runs poorly in low speed range wide spark plug gap carburetor air screw maladjustment incorrect carburetor fuel level improper jet needle size incorrect ignition timing cdi unit malfunction ignition coil damage magneto malfunction magneto sh...

Page 45

3-4 troubleshooting complaint possible cause remedy overheating low engine coolant level engine coolant leak too lean air/fuel mixture incorrect ignition timing water pump malfunction cylinder head carbon deposits cylinder head o-ring damage exhaust pipe carbon deposits improper spark plug heat rang...

Page 46

Troubleshooting 3-5 chassis * optional stiffer and softer springs are available. Complaint possible cause remedy heavy handling steering stem nut overtightened steering head bearings damaged or rusted steering stem distortion adjust replace replace front wheel wobbling loose spoke nipples wheel dist...

Page 47

– memo –.

Page 48: Machine Tuning

4 machine tuning 4-1 contents machine tuning carburetor tuning ............................................................................. 4- 2 principles of carburetor tuning .......................................... 4- 2 carburetor tuning in practice ...............................................

Page 49: Carburetor Tuning

4-2 machine tuning carburetor tuning the carburetion of your motorcycle was carefully selected after extensive testing. You will find that the carburetion will function smoothly under many varied operating conditions. For best results we rec- ommend that the adjustments and carburetion jet- ting be ...

Page 50

Machine tuning 4-3 as shown below, each tuning parts is located between the air/fuel passage and has its own air/fuel mixture adjustable range in terms of the throttle valve opening. The chart indicates that the carburetor can supply correct air/fuel mixture to the engine in any range because of the...

Page 51

4-4 machine tuning needle clip position the jet needle is linked to the throttle valve by means of the needle clip. Its lower part is tapered and it has five grooves cut in the upper part where the needle clip fits. To adjust the air/fuel mixture with the jet needle, change position of the needle cl...

Page 52

Machine tuning 4-5 carburetor tuning in practice in the previous section, basic principles of carburetor tuning have been discussed. Described in this section are the bases for carburetor tuning required when coping with variations in air (oxygen) concentration. Variation in air (oxygen) concentrati...

Page 53

4-6 machine tuning judging air/fuel mixture for proper carburetor tuning, it is necessary to know how to judge the air/fuel mixture made in the carburetor; whether too rich, too lean or properly mixed. Given below are the symptoms observed when the engine is not supplied with the proper air/fuel mix...

Page 54

Machine tuning 4-7 1 adjustment of slow system 1) set the air screw as specified. 2) see if the selected slow jet is correct or not by judging the air/fuel mixture. If air/fuel mixture is rich, replace it with smaller one. If air/fuel mix- ture is lean, replace it with larger one. 2 adjustment of ma...

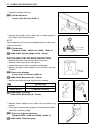

Page 55: Front Fork Tuning

4-8 machine tuning front fork tuning front fork the front fork compression and rebound damping force, and oil quantity are adjustable for rider’s preference, rider’s weight and course condition. Note: * break-in new front forks before attempting adjustment. * be sure to adjust both right and left fr...

Page 56

Machine tuning 4-9 front fork spring replacement and oil level adjustment • remove the front forks, left and right. ( 16-3) • thoroughly clean the fork before disassembly. • drain fork oil. ( 16-4) • place the front fork vertically without spring. • compress it fully. • pour specified front fork o...

Page 57

4-10 machine tuning • refill specified front fork oil up to the top level of the outer tube again. Move the outer tube up and down several strokes until no more bubbles come out from the oil. • keep the front fork vertically and wait 5 – 6 minutes. Note: * always keep oil level over the cartridge to...

Page 58

Machine tuning 4-11 • adjust the height h of the inner rod threads by turning the lock-nut 1. H: 14 mm • set the rebound damping adjuster 1.5 mm (0.06 in) as shown before assembling the front fork cap. • slowly turn the fork cap bolt 2 to seat at the lock-nut 3 by hand tightening. • hold the fork ca...

Page 59

4-12 machine tuning front fork tuning procedure test ride the motorcycle and find out how the front suspension reacts on various types of surface. According to the symptom noticed, adjust the front fork to the best setting for rider and race track conditions. To adjust, attempt changing fork oil cap...

Page 60: Rear Suspension Tuning

Machine tuning 4-13 rear suspension tuning rear suspension the rear suspension compression and rebound damping force, and spring pre-load are adjustable for rider’s preference, rider’s weight and course condition. Note: break-in the rear suspension when riding with a new rear cush- ion unit. Compres...

Page 61

4-14 machine tuning rear suspension tuning procedure • adjust the rear suspension according to the rider’s weight and preference by referring to the table below. (spring replacement 17-4) • measure the distance l1 from the seat bolt to the chain adjuster lock-nut with the motorcycle on the stand an...

Page 62

Machine tuning 4-15 note: when adjusting the damping setting, attempt turning the adjuster 1/4 to 1/2 turn at a time for each adjust- ment. Symptom section adjustment procedure bottoms • jump • large bump 1. Adjust the compression damping to a harder (h) setting. (see note below.) 2. Adjust the sag ...

Page 63: Suspension Balance

4-16 machine tuning suspension balance balancing the front to rear suspension properly is the most critical adjustment for suspension performance. If the front forks are adjusted harder than the rear suspension, such as changing to heavier front fork oil, stiffer compression and rebound setting, air...

Page 64

5 engine removal and installation 5-1 contents engine removal and installation engine removal and installation ................................................. 5- 2 removal ............................................................................................. 5- 2 installation .................

Page 65

5-2 engine removal and installation engine removal and installation removal • remove the frame covers 1 (left & right) and seat 2. • remove the clamps 3. • turn the fuel valve lever to the “off” position and disconnect the fuel hose. • remove the radiator cover 4. • remove the fuel tank mounting bol...

Page 66

Engine removal and installation 5-3 • remove the muffler mounting bolts. • remove the exhaust pipe and muffler. • remove the exhaust pipe and gasket. • disconnect the radiator hose 1. • disconnect the radiator hose 2. • remove the spark plug cap 3 and spark plug 4. • disconnect the magneto lead wire...

Page 67

5-4 engine removal and installation • loosen the carburetor clamp screws and remove the carbure- tor. • remove the magneto cover. • remove the drive chain. • remove the clutch release arm 1 and disconnect the clutch cable. • remove the engine mounting bolts..

Page 68

Engine removal and installation 5-5 • loosen the swingarm pivot nut. • extract three quarters of the swingarm pivot shaft so as to keep the swingarm in position. Note: the swingarm will come off when the swingarm pivot shaft is completely removed. • remove the engine from the frame. Installation • f...

Page 69

5-6 engine removal and installation • fit the projection of the carburetor to the depression on intake pipe. • apply a small quantity of engine oil to the exhaust pipe o-ring. • install the exhaust gasket and exhaust pipe. After mounting the engine, inspect the following items. • transmission oil le...

Page 70

6 cylinder, piston and exhaust valve 6-1 contents cylinder, piston and exhaust valve construction ........................................................................................ 6- 2 cylinder, piston and exhaust valve ..................................... 6- 2 engine top end ..................

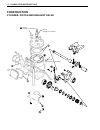

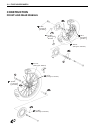

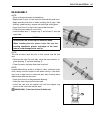

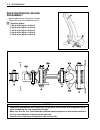

Page 71: Construction

6-2 cylinder, piston and exhaust valve construction cylinder, piston and exhaust valve 28 n.M (2.8 kgf-m, 20.5 lb-ft) 28 n.M (2.8 kgf-m, 21.0 lb-ft) 25 n.M (2.5 kgf-m, 18.0 lb-ft).

Page 72: Engine Top End

Cylinder, piston and exhaust valve 6-3 engine top end cylinder head removal • remove the frame covers and seat. ( 5-2) • remove the radiator covers and fuel tank. ( 5-2) • remove the muffler. ( 5-2) • drain engine coolant. ( 12-3) • loosen the clamp and disconnect the radiator hose 1. • remove t...

Page 73

6-4 cylinder, piston and exhaust valve • loosen the four cylinder nuts 1. • remove the cylinder 2. Note: loosen the cylinder nuts diagonally. • remove the gasket 3 and dowel pins 4. Piston removal • remove the cylinder head and cylinder. ( 6-3) • remove the piston pin circlip 1. Note: place cloth o...

Page 74

Cylinder, piston and exhaust valve 6-5 • remove the exhaust valve shaft stop retainer 2. • loosen the bolt 3. Draw out the shaft. • remove the spacers 4, springs 5 and valve shaft arm 6. • remove the exhaust valve assembly 7. Cylinder head inspection • remove carbon deposits from the cylinder head. ...

Page 75

6-6 cylinder, piston and exhaust valve • inspect for cylinder distortion. cylinder distortion service limit: 0.05 mm (0.002 in) • measure the cylinder bore for wear with a cylinder gauge 15 mm (0.59 in) from the top surface. Note: the cylinder bore must be measured perpendicular to the crank- shaf...

Page 76

Cylinder, piston and exhaust valve 6-7 • fit the piston ring into the cylinder and measure the piston ring end gap with a thickness gauge. piston ring end gap service limit: 0.80 mm (0.031 in) • measure the piston ring free end gap. piston ring free end gap service limit: 3.2 mm (0.13 in) exhaus...

Page 77

6-8 cylinder, piston and exhaust valve conrod inspection • measure the conrod small end bore. conrod small end bore service limit: 18.040 mm (0.7102 in) 09900-20605: dial gauge • fit the piston pin and bearing into the conrod small end and check the play. Piston ring and piston reassembly • appl...

Page 78

Cylinder, piston and exhaust valve 6-9 • install the spacers 1, springs 2, valve shaft arm 4 and shaft. • tighten the bolt 3. • tighten the stopper bolt 5. • install the gasket and cover..

Page 79

6-10 cylinder, piston and exhaust valve cylinder reassembly • install the new gasket. Install the dowel pins 1. • apply engine oil to the cylinder bore. • hold the piston and piston ring, and insert the piston into the cylinder. • tighten the cylinder nuts to the specified torque according to the sp...

Page 80

Cylinder, piston and exhaust valve 6-11 • install the new o-rings onto the cylinder. • install the cylinder head. • tighten the cylinder head nuts to the specified torque accord- ing to the specified tightening order as shown. cylinder head nut: 28 n·m (2.8 kgf-m, 20.5 lb-ft) • reassemble the exha...

Page 81

6-12 cylinder, piston and exhaust valve exhaust valve governor removal and disassembly • drain transmission oil. ( 2-7) • drain engine coolant. ( 12-3) • remove the exhaust pipe. ( 5-2) • remove the rear brake pedal. ( 15-14) • remove the clutch cover. ( 7-3) • remove the exhaust valve bolt. ( ...

Page 82

Cylinder, piston and exhaust valve 6-13 • remove the spring 5, retainer 6 and bearing 7. • remove the washers 8, spacer 9 bearing 0 and stator a. • remove the balls b. Exhaust valve governor inspection • inspect the bearing for wear. • replace the bearing if there is anything unusual..

Page 83

6-14 cylinder, piston and exhaust valve • inspect the balls and their grooves of governor and actuator for wear or damage. • if they are worn or damaged, replace them with the new ones. Exhaust valve governor reassembly and installation installation is in the reverse order of removal and disassembly...

Page 84: Clutch

7 clutch 7-1 contents clutch construction ........................................................................................ 7- 2 clutch ................................................................................................ 7- 2 clutch ...................................................

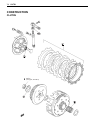

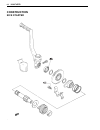

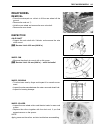

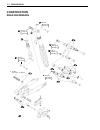

Page 85: Construction

7-2 clutch construction clutch 70 n.M (7.0 kgf-m, 50.5 lb-ft).

Page 86: Clutch

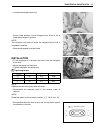

Clutch 7-3 clutch clutch plate removal • drain transmission oil. ( 2-7) • drain the engine coolant. ( 12-3) • remove the rear brake pedal. ( 15-14) • remove the clutch release arm 1. • remove the kick starter lever 2. • remove the clutch cover. • loosen the bolts diagonally and remove them. • rem...

Page 87

7-4 clutch clutch spring inspection • measure the clutch spring free length. clutch spring free length service limit: 39.4 mm (1.55 in) note: replace five clutch springs together even if only one spring is exceed the service limit. Clutch rack and pinion inspection • inspect the clutch release rac...

Page 88

Clutch 7-5 • replace the gasket with a new one. • install the dowel pins. • align the clutch release rack teeth with the pinion gear. • align the water pump empeller to the crankshaft end. • install the clutch cover. • tighten the bolts diagonally. • reassemble the rear brake pedal. ( 15-14) • inst...

Page 89

7-6 clutch • remove the washer 1, primary driven gear ass’y 2. • remove the needle bearing 3 and washer 4. • remove the snap ring 5 and kick idle gear 6. Clutch sleeve hub inspection • inspect the clutch sleeve hub and primary driven gear ass’y for wear and cracks. • inspect the kick idle gear and n...

Page 90

Clutch 7-7 • install the primary driven gear ass’y and washer. • install the clutch sleeve hub, lock washer 1 and clutch sleeve hub nut 2. • tighten the clutch sleeve hub nut with the special tool to the specified torque. 09920-53740: clutch sleeve hub holder clutch sleeve hub nut: 70 n·m (7.0 k...

Page 91

7-8 clutch • reassemble the clutch plates and pressure plate. ( 7-4) • install the dowel pins. • replace the gasket with a new one. • install the clutch cover and bolts. Tighten the clutch cover bolts diagonally. ( 7-5) • connect the radiator hose. • install the clutch release arm and kick starter...

Page 92: Kick Starter

8 kick starter 8-1 contents kick starter construction ........................................................................................ 8- 2 kick starter .................................................................................... 8- 2 kick starter .......................................

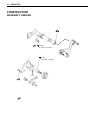

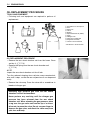

Page 93: Construction

8-2 kick starter construction kick starter.

Page 94: Kick Starter

Kick starter 8-3 kick starter removal • drain transmission oil. ( 2-7) • drain engine coolant. • remove the kick starter lever. • remove the clutch assembly. ( 7-5) • remove the snap ring 1. • remove the kick idle gear 2. • remove the kick starter drive gear 3. • install the kick starter lever tem...

Page 95

8-4 kick starter inspection • inspect the oil seal 1 for oil leakage and oil seal lip damage. • inspect the return spring 2 for damage. • inspect the kick shaft 3 and drive gear for contact surface wear. • inspect the kick drive gear teeth for damage. • inspect the kick drive gear ratchet part for w...

Page 96

Kick starter 8-5 • install the kick shaft assembly to the crankcase. • hook the return spring to the crankcase’s hole. • install the kick starter to the kick shaft. Note: be sure to align the punch marks on the kick starter and kick starter shaft when installing the kick starter. • reassemble the ki...

Page 97

– memo –.

Page 98: Gearshifting

9 gearshifting 9-1 contents gearshifting construction ........................................................................................ 9- 2 gearshift linkage ......................................................................... 9- 2 gearshift linkage ........................................

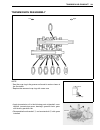

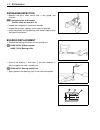

Page 99: Construction

9-2 gearshifting construction gearshift linkage 19 n.M (1.9 kgf-m, 13.5 lb-ft) 23 n.M (2.3 kgf-m, 16.5 lb-ft).

Page 100: Gearshift Linkage

Gearshifting 9-3 gearshift linkage removal • drain transmission oil. ( 2-7) • drain engine coolant. ( 12-3) • remove the kick starter lever and clutch assembly. ( 7-5) • remove the gearshift lever. • remove the gearshift shaft 2. • remove the two screws. Remove the pawl lifter 3. • remove the gea...

Page 101

9-4 gearshifting • remove the gearshift cam stopper 1. • remove the spring 2. Inspection • inspect the gearshift shaft 1 for bends and damage. • inspect the return spring 2 for damage. • inspect the pawls 3, springs 4 and pins 5 for damage. • inspect the gearshift cam stopper. Reassembly • reassembl...

Page 102

Gearshifting 9-5 • align the pin groove a with the pin b when installing the stopper plate 1. • tighten the gear shift cam bolt 2. gearshift cam bolt: 23 n·m (2.3 kgf-m, 16.5 lb-ft) • install the springs, pins and pawls to the shifter. Wider side a of pawl should be positioned outside. • with the ...

Page 103

9-6 gearshifting • reassemble the gearshift cam shifter and pawl lifter. • apply thread lock super “1322” to the screws. • tighten the screws. 99000-32110: thread lock super “1322” • reassemble the gearshift return spring 1 to the gearshift shaft properly. • align the center teeth on the gearshift...

Page 104: Transmission and Crankshaft

10 transmission and crankshaft 10-1 contents transmission and crankshaft construction ...................................................................................... 10- 2 transmission and crankshaft ............................................... 10- 2 engine bottom side .......................

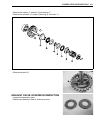

Page 105: Construction

10-2 transmission and crankshaft construction transmission and crankshaft 70 n.M (7.0 kgf-m, 50.5 lb-ft).

Page 106: Engine Bottom Side

Transmission and crankshaft 10-3 engine bottom side • dismount the engine. ( 5-2) note: the following parts must be removed before disassembling the engine bottom side (crankcase). • remove the engine sprocket cover and engine sprocket. • remove the gearshift lever. ( 9-3) • remove the cylinder he...

Page 107

10-4 transmission and crankshaft transmission removal • remove the gearshift fork shafts 1 and forks 2. • remove the gearshift cam 3. • remove the driveshaft ass’y 4 and countershaft ass’y 5. Crankshaft removal • remove the crankshaft with the special tool. 09920-13120: crankcase separating tool t...

Page 108

Transmission and crankshaft 10-5 • inspect the gearshift forks and shafts for wear and damage. • measure the gearshift fork thickness with a vernier calipers. gearshift fork thickness • measure the gearshift fork groove width with a vernier cali- pers. gearshift fork groove width • measure the g...

Page 109

10-6 transmission and crankshaft crankshaft inspection • measure the crankshaft runout with v-blocks and dial gauge. crankshaft runout service limit: 0.05 mm (0.002 in) 09900-20607: dial gauge (1/100 mm) 09900-20701: magnetic stand 09900-21304: v-block note: place the crankshaft onto the v-block...

Page 110

Transmission and crankshaft 10-7 • install each new oil seal with the special tools. • apply grease to each oil seal lip. 09913-70210: bearing installer set note: be sure to check the direction of the crankshaft bearing oil seals before fitting them. Bearing inspection, removal and installation • ...

Page 111

10-8 transmission and crankshaft • remove the bearing retainers 1, 2. • remove the bearings with the special tool. 09913-70210: bearing installer set • remove the bearing 3 with the special tool. 09921-20220: bearing remover set crankshaft installation • install the crankshaft into the left cran...

Page 112

Transmission and crankshaft 10-9 transmission reassembly note: * seat the snap ring in the groove and locate its end as shown in the illustration. * replace the removed snap ring with a new one. • apply transmission oil to the following parts: driveshaft, coun- tershaft, transmission gears, bearings...

Page 113

10-10 transmission and crankshaft • install the gear shift forks 1, 2, 3. • install the gear shift cam 3 and gearshift shafts 4, 5. Note: turn the gearshift cam to the neutral position and confirm that the driveshaft and countershaft turn without resistance. Crankcase reassembly • install the new ga...

Page 114

Transmission and crankshaft 10-11 primary driven gear reassembly • install the primary driven gear and washer onto the crank- shaft. • apply thread lock super “1322” to the primary driven gear nut and tighten it to the specified torque with the special tool. 99000-32110: thread lock super “1322” ...

Page 115

– memo –.

Page 116: Fuel System

11 fuel system 11-1 contents fuel system construction ...................................................................................... 11- 2 fuel system .................................................................................... 11- 2 carburetor ..........................................

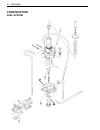

Page 117: Construction

11-2 fuel system construction fuel system.

Page 118: Carburetor

Fuel system 11-3 carburetor removal and disassembly • remove the seat and fuel tank. ( 5-2) • turn the fuel valve lever to “off”. • disconnect the fuel hose. • loosen the carburetor clamp screws and remove the carbure- tor. • remove the carburetor top cap and throttle valve. • compress the spring 2...

Page 119

11-4 fuel system • remove the air vent hoses 1, overflow hoses 2 fuel hose 3. • loosen the screws and remove the carburetor float chamber 5. • remove the float pin 6 and floats 7. • remove the jet holder 8. • remove the needle valve ass’y 9. • remove the main jet 0, and slow jet a. • remove the star...

Page 120: Reed Valve

Fuel system 11-5 inspection • inspect the following parts for damage: jet needle throttle valve float • inspect the following jets for clogging: main jet slow jet starter jet • inspect the needle valve for wear. • measure the float height with a vernier calipers. To measure the float height, tilt th...

Page 121

11-6 fuel system reassembly reverse the sequence of removal..

Page 122: Cooling System

12 cooling system 12-1 contents cooling system construction ...................................................................................... 12- 2 cooling system ............................................................................ 12- 2 engine coolant .....................................

Page 123: Construction

12-2 cooling system construction cooling system 2.5 n.M (0.25 kgf-m, 1.8 lb-ft) 2.5 n.M (0.25 kgf-m, 1.8 lb-ft).

Page 124: Engine Coolant

Cooling system 12-3 engine coolant engine coolant replacement • place the motorcycle on a block. • remove the radiator cap. • drain engine coolant by removing the drain plug 1 and dis- connecting the radiator hose 2. • tighten the drain plug 1 and connect the radiator hose 2. • pour engine coolant. ...

Page 125

12-4 cooling system radiator removal • remove the seat and fuel tank. ( 5-2) • drain engine coolant. ( 12-3) • disconnect all the radiator hoses. • remove the radiator by removing its mounting bolts. Cooling system inspection inspect the following items. • radiator coolant leakage • radiator hose ...

Page 126: Water Pump

Cooling system 12-5 water pump water pump removal and inspection • drain engine coolant and transmission oil. ( 12-3 and 2-7) • remove the water pump cover 1. • remove the clutch cover. ( 7-3) • remove the snap rings 2 with snap ring pliers. • remove the impeller. • inspect the impeller for damage...

Page 127

12-6 cooling system water pump reassembly • apply thread lock super “1322” to the outer surface of the oil seal. Install the oil seal with a proper tool. 99000-32110: thread lock super “1322” • apply grease to the machanical seal lip. • insert the water pump shaft. • install the bearing with the s...

Page 128: Electrical System

13 electrical system 13-1 contents electrical system construction ...................................................................................... 13- 2 electrical system ...................................................................... 13- 2 electrical circuit ..............................

Page 129: Construction

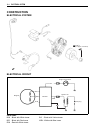

13-2 electrical system construction electrical system electrical circuit color code: b/w : black with white tracer b/y : black with yellow tracer b/r : black with red tracer w/bl : white with blue tracer r/w : red with white tracer 35 n.M (3.5 kgf-m, 25.5 lb-ft) magneto b/r r/w b/w cdi unit b/y engi...

Page 130: Ignition System

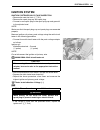

Electrical system 13-3 ignition system ignition system peak voltage inspection • remove the seat fuel tank. ( 5-2) • remove the spark plug cap and spark plug. • connect a new spark plug to the spark plug cap and ground it to the cylinder head. Note: make sure that the spark plug cap and spark plug ...

Page 131

13-4 electrical system ignition coil inspection • remove the seat and fuel tank. ( 5-2) • measure the ignition coil electrical resistance. 09900-25008: multi-circuit tester tester knob indication: resistance (w) cdi unit inspection • remove the seat. ( 5-2) • remove the cdi unit from the frame. ...

Page 132

Electrical system 13-5 stator coil inspection • remove the seat and fuel tank. ( 5-2) • disconnect the magneto lead wire coupler. • measure the stator coils electrical resistance. 09900-25008: multi-circuit tester tester knob indication: resistance ( Ω) magneto rotor and stator removal and reasse...

Page 133

13-6 electrical system magneto rotor and stator reassembly • install the key onto the crankshaft. • install the magneto rotor. • hold the conrod with the special tool. • apply thread lock super “1322” to the nut and tighten the nut to the specified torque. 09910-20116: conrod holder 99000-32110:...

Page 134: Front and Rear Wheels

14 front and rear wheels 14-1 contents front and rear wheels construction ...................................................................................... 14- 2 front and rear wheels ............................................................ 14- 2 front wheel ...................................

Page 135: Construction

14-2 front and rear wheels construction front and rear wheels ( ) ( ) ( ) 8.5 n.M (0.85 kgf-m, 6.0 lb-ft) 8.5 n.M (0.85 kgf-m, 6.0 lb-ft) 44 n.M 4.4 kgf-m 32.0 lb-ft ( ) 8.5 n.M 0.85 kgf-m 6.0 lb-ft 65 n.M 6.5 kgf-m 47.0 lb-ft 40 n.M (4.0 kgf-m, 29.0 lb-ft) fwd 4 n.M 0.4 kgf-m 3.0 lb-ft 4 n.M (0.4 k...

Page 136: Front Wheel

Front and rear wheels 14-3 front wheel removal • place the motorcycle on a block to lift front wheel off the ground. • remove the cotter pin. • loosen the axle nut 1. • remove the axle. • remove the front wheel and collars. Inspection axle shaft • support the axle shaft with v-blocks and measure the...

Page 137

14-4 front and rear wheels front wheel bearing removal • fit the bearing remover into the wheel bearing. 09921-20220: bearing remover set • remove the bearings and spacer. Front wheel bearing reassembly • apply grease to the bearings. • reassemble the spacer and bearings with the special tool. 0...

Page 138: Rear Wheel

Front and rear wheels 14-5 rear wheel removal • place the motorcycle on a block to lift the rear wheel off the ground. • remove the axle nut 1. • hold the rear wheel and remove the rear axle shaft. • remove the rear wheel. Inspection axle shaft • support the axle shaft with v-blocks and measure the ...

Page 139

14-6 front and rear wheels rear wheel bearing removal • remove the dust seals and snap ring from the wheel hub. • fit the bearing remover into the wheel bearing. 09921-20220: bearing remover set • remove the bearings and spacer. Rear wheel bearing reassembly • apply grease to the bearings. • reass...

Page 140: Disc Plate Replacement

Front and rear wheels 14-7 disc plate replacement • remove the front and rear wheels. ( 14-3 and -5) • replace the disc. • apply thread lock super “1322” to the screws. 99000-32110: thread lock super “1322” • tighten the screws and nuts 1 (front only) to the specified torque. brake disc screw :...

Page 141

– memo –.

Page 142: Front and Rear Brakes

15 front and rear brakes 15-1 contents front and rear brakes construction ...................................................................................... 15- 2 front and rear brakes ............................................................ 15- 2 brake fluid ...................................

Page 143: Construction

15-2 front and rear brakes construction front and rear brakes ( ) ( ) ( ) ( ) 10 n.M (1.0 kgf-m, 7.3 lb-ft) ( ) 23 n.M 2.3 kgf-m 16.5 lb-ft ( ) 23 n.M 2.3 kgf-m 16.5 lb-ft 10 n.M 1.0 kgf-m 7.3 lb-ft 10 n.M (1.0 kgf-m, 7.3 lb-ft) 23 n.M 2.3 kgf-m 16.5 lb-ft 18 n.M 1.8 kgf-m 13 .0 lb-ft ( ) 7.5 n.M 0....

Page 144: Brake Fluid

Front and rear brakes 15-3 brake fluid brake fluid air bleeding • remove the reservoir cap. • connect a transparent tube to the bleeder valve and set the other end into a receptacle. • pour brake fluid up to the upper line. • pump the brake lever/pedal until air bubbles stop coming out from the rese...

Page 145

15-4 front and rear brakes • tighten the air bleeder valve. brake caliper air bleeder valve: 7.5 n·m (0.75 kgf-m, 5.5 lb-ft) • pour brake fluid up to the upper line. • reassemble the reservoir cap. Brake fluid replacement • remove the reservoir cap. • connect a transparent tube to the bleeder valv...

Page 146: Brake Disc

Front and rear brakes 15-5 • remove the clamp 1. Remove the pad mounting pin 2. Note: replace the two pads as a set. • install the new brake pads to the caliper. Note: make sure that the tip a of the spring is fitted to the inner pad 3. • tighten the caliper mounting bolts. caliper mounting bolt: ...

Page 147: Brake Caliper

15-6 front and rear brakes brake caliper front caliper removal and disassembly • drain brake fluid. ( 15-4) • place a drain pan under the caliper and remove the union bolt 1. • remove the caliper mounting bolts 2. • remove the brake pads and spring 3 from the caliper. • remove the caliper bracket 4...

Page 148

Front and rear brakes 15-7 • apply low-pressure air into the caliper through the hole to remove the piston. • remove the piston seal 1 and dust seal 2. Rear caliper removal and disassembly • drain brake fluid. ( 15-4) • place a rag under the brake hose union bolt to catch spilled brake fluid. • rem...

Page 149

15-8 front and rear brakes • remove the brake pads and spring 3 from the caliper. • remove the caliper bracket 4. • wrap the caliper with a rag to prevent brake fluid scatter and piston pop-out. • apply low-pressure air into the caliper through the hole to remove the piston. • remove the piston seal...

Page 150

Front and rear brakes 15-9 caliper cleaning • flush the caliper ports with pressurized air. • wash the caliper piston and cylinder with fresh brake fluid. Note: do not use gasoline or other cleaning solvents to wash the cali- per parts. brake fluid: dot 4 front caliper reassembly • apply brake flu...

Page 151: Master Cylinder

15-10 front and rear brakes master cylinder front master cylinder removal and disassembly • drain brake fluid. ( 15-4) • loosen the brake hose adaptor and disconnect the brake hose. • remove the master cylinder holder bolts. Note: hold the brake hose with a wrench to prevent the brake from twisting...

Page 152

Front and rear brakes 15-11 • remove the bolt 1 and brake lever 2. • remove the dust boot 1. • remove the snap ring 2 with snap ring pliers. • remove the washer 3, piston/cup set 4 and spring 5. Rear master cylinder removal and disassembly • drain brake fluid. ( 15-4) • remove the rear brake pedal....

Page 153

15-12 front and rear brakes master cylinder inspection • inspect the cylinder bore and piston for scuffing. • inspect the piston rod and spring for damage. If any abnormal condition is noted, replace the master cylinder. • inspect the dust boot, if any damages are found, replace it with a new one. M...

Page 154

Front and rear brakes 15-13 • tighten the brake hose adaptor 1 to the specified torque. brake hose adaptor: 18 n·m (1.8 kgf-m, 13.0 lb-ft) note: hold the brake hose with a wrench to prevent the brake hose from twisting when tightening the adaptor. • refill brake fluid and bleed air from the brake ...

Page 155: Brake Pedal

15-14 front and rear brakes brake pedal brake pedal removal and reassembly removal • remove the nut from the brake pedal pivot. • remove the cotter pin and pin from the push rod end. • remove the return spring. Reassembly • reassemble the pin, washer and cotter pin to the push rod end. • install the...

Page 156: Front Fork and Steering

16 front fork and steering 16-1 contents front fork and steering construction ...................................................................................... 16- 2 front fork and steering ......................................................... 16- 2 front fork .................................

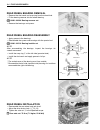

Page 157: Construction

16-2 front fork and steering construction front fork and steering 26 n.M (2.6 kgf-m, 19.0 lb-ft) 23 n.M (2.3 kgf-m, 16.5 lb-ft) 23 n.M (2.3 kgf-m, 16.5 lb-ft) 35 n.M (3.5 kgf-m, 25.5 lb-ft) 20 n.M (2.0 kgf-m, 14.5 lb-ft) 55 n.M (5.5 kgf-m, 40.0 lb-ft) 65 n.M (6.5 kgf-m, 47.0 lb-ft).

Page 158: Front Fork

Front fork and steering 16-3 front fork removal • place a block under the chassis tubes. • remove the fork covers, brake hose guide and brake hose cover. • remove the brake caliper. ( 15-6) • remove the front wheel. ( 14-3) • loosen the fork upper clamp bolts 1. • loosen the front fork cap bolt 2 ...

Page 159

16-4 front fork and steering • compress the front fork spring 3 and loosen the lock-nut 1. • remove the fork cap 2. • remove the fork spring 3. • remove the lock-nut 4 and the spring guide 5. • invert the front fork and stroke the inner rod several times to let out fork oil. • under the inverted con...

Page 160

Front fork and steering 16-5 • remove the dust seal 1 and the stopper ring 2. • pull out the inner tube from the outer tube. • remove the slide bushing 3 from the inner tube. • remove the following parts from the inner tube. Slide bushing 3 seal retainer 4 oil seal 5 stopper ring 6 dust seal 7 inspe...

Page 161

16-6 front fork and steering • inspect the inner tube for scratches. If it has scratches, replace it with a new one. • inspect the outer tube for dent. If it is dented all the way to the inner side, replace it with a new one. • inspect the damper rod assembly for scratches or bending. If it has scra...

Page 162

Front fork and steering 16-7 reassembly note: * clean all fork parts before reassembling. * replace the o-rings, oil seal and dust seal with the new ones. * apply specified front fork oil when installing the o-rings, slide bushing, guide bushing, damper unit and other sliding parts. • apply front fo...

Page 163

16-8 front fork and steering • attach the stopper ring 7 securely to the stopper ring groove of the outer tube. • attach the dust seal 8. Note: after attaching the dust seal, make sure that there are no cracks around the circumference of the seal. Cracks could allow water, mud and the like to enter ...

Page 164

Front fork and steering 16-9 fork oil • place the front fork vertically without spring. • compress it fully. • pour specified front fork oil up to the top level of the outer tube. • move the inner rod slowly with the special tool more than ten times until no more bubbles come out from the oil. 099...

Page 165

16-10 front fork and steering • pull up the inner rod with the special tool. 09940-52841: inner rod holder • install the fork spring. • adjust the height h of the inner rod threads by turning the lock-nut 1. H: 14 mm • set the rebound damping adjuster 1.5 mm (0.06 in) as shown before assembling th...

Page 166

Front fork and steering 16-11 reinstallation • reinstall the front forks. • set the aligning line t on the outer tube to the upper surface of the steering stem head. • check that the air valve a is positioned at the front. • tighten the fork lower clamp bolts 1 to the specified torque. fork lower ...

Page 167: Steering

16-12 front fork and steering steering removal • remove the front wheel. ( 14-3) • remove the brake caliper. ( 15-6) • remove the front number plate. • remove the handlebar holder bolts 1 and handlebars. • remove the brake hose guide. • remove the front fender. • loosen the steering stem head nut ...

Page 168

Front fork and steering 16-13 inspection • inspect the bearing races for wear. • inspect the needle bearings for wear. • inspect the steering stem for distortion. Bearing replacement note: replace the outer race and bearing as a set. • remove the upper and lower outer races with the special tools. ...

Page 169

16-14 front fork and steering reassembly • apply grease to the bearings and dust seals. • install the steering stem, upper bearing and steering stem nut. • tighten the steering stem nut with the special tool. 09940-14930: steering nut socket wrench steering stem nut: 45 n·m (4.5 kgf-m, 32.5 lb-f...

Page 170: Rear Suspension

17 rear suspension 17-1 contents rear suspension construction ........................................................................................ 17-2 rear suspension ............................................................................ 17-2 rear shock absorber .............................

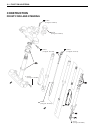

Page 171: Construction

17-2 rear suspension construction rear suspension 58 n.M (5.8 kgf-m, 42.0 lb-ft) 60 n.M 6.0 kgf-m 43.5 lb-ft 60 n.M 6.0 kgf-m 43.5 lb-ft 80 n.M 8.0 kgf-m 58.0 lb-ft 80 n.M 8.0 kgf-m 58.0 lb-ft 18 n.M 1.8 kgf-m 13.0 lb-ft 60 n.M 6.0 kgf-m 43.5 lb-ft fwd fwd.

Page 172: Rear Shock Absorber

Rear suspension 17-3 rear shock absorber rear shock absorber removal • place a block under chassis tubes. • remove the frame covers and seat. ( 5-2) • loosen the air cleaner clamp screw a. • remove the frame side tube 1. • loosen the bolts and screw 2. • remove the air cleaner box. • loosen the rea...

Page 173

17-4 rear suspension spring removal • remove the rear shock absorber unit from the frame. ( 17-3) • loosen the lock-nut 1 and turn the adjuster 2 with the spe- cial tool. • turn the lock-nut 1 and adjuster 2 fully to the end of the thread. 09910-60611: universal clamp wrench • remove the spring s...

Page 174

Rear suspension 17-5 spring installation • install the lock-nut, adjuster, spring, spring seat and spring retainers. Note: install the spring as small diameter side is seated to the adjuster. • adjust the spring set length and tighten the lock-nut. standard spring set length: 3.1 mm (0.12 in) comp...

Page 175

17-6 rear suspension oil replacement procedure tools and equipment • following tools and equipment are required to perform oil replacement. Oil replacement procedure • remove the rear shock absorber unit from the frame. Clean and dry it. ( 17-3) • remove the spring from the rear shock absorber unit...

Page 176

Rear suspension 17-7 • remove the compression adjuster assembly 1 with the spe- cial tool from the rear shock absorber. 09941-53650: rear shock absorber socket wrench • place a drain pan under the rear shock absorber unit. • move the rod and drain the oil completely. • push the valve core again to...

Page 177

17-8 rear suspension • reinstall the compression adjuster assembly 1 with the spe- cial tool. Note: replace the o-rings on the compression adjuster assembly with new ones. compression adjuster assembly: 18 n·m (1.8 kgf-m, 13.0 lb-ft) 09941-53650: rear shock absorber socket wrench • fill the rear...

Page 178

Rear suspension 17-9 rear shock absorber disassembly and inspection • remove the rear shock absorber unit from the frame. Clean and dry it. ( 17-3) • remove the spring from the rear shock absorber. ( 17-4) • turn the rebound damping force adjuster to the softest posi- tion. • press the valve with ...

Page 179

17-10 rear suspension rear shock absorber reassembly • apply the rear suspension oil to the o-rings and the “teflon coating metal”. • insert the damper rod assembly 1 and install the new circlip 2. • pull up the damper rod assembly 1 until it is stopped by the circlip 2. • install the stopper to the...

Page 180: Swingarm

Rear suspension 17-11 swingarm swingarm removal • remove the rear wheel. ( 14-5) • remove the chain guide 1. • remove the rear brake hose guide 2. • remove the rear brake caliper 3. • remove the drive chain. • remove the rear cushion rod bolt and nut 4. • remove the swingarm pivot nut 5. • remove t...

Page 181

17-12 rear suspension swingarm inspection • measure the pivot shaft runout with a dial gauge and v-blocks. swingarm pivot shaft runout service limit: 0.3 mm (0.01 in) • inspect the swingarm for cracks and damage. • inspect the bearings, spacers and oil seals for damage. • insert the spacers into t...

Page 182: Rear Suspension Linkage

Rear suspension 17-13 swingarm reassembly • reassemble the following parts into the swingarm. 1 spacer 2 dust seal 3 washer • apply grease to the dust seals, bearings and spacers. • install the swingarm to the frame. • tighten the swingarm pivot nut 4 to the specified torque. swingarm pivot nut: 5...

Page 183

17-14 rear suspension • remove the cushion rod 1 from the cushion lever 2. Rear suspension linkage inspection • inspect the cushion lever and cushion rod for damage. • inspect the dust seals and spacers for damage. • inspect the bearings for damage. • insert the spacers into the bearings and inspect...

Page 184

Rear suspension 17-15 • apply grease to the bearings. • install the bearings with the special tool and pipes, 24 mm (0.9 in) in diameter and 4 mm (0.2 in) in length. 09941-34513: bearing installer set note: position the bearings by refering to the illustration of page 17-16. • install the circlips...

Page 185

17-16 rear suspension rear suspension linkage reassembly • reassemble the rear suspension linkage. • tighten the nuts to the specified torque. tightening torque: a: 60 n·m (6.0 kgf-m, 43.5 lb-ft) b: 60 n·m (6.0 kgf-m, 43.5 lb-ft) c: 80 n·m (8.0 kgf-m, 58.0 lb-ft) d: 60 n·m (6.0 kgf-m, 43.5 lb-ft) ...

Page 186: Servicing Information

18 servicing information 18-1 contents servicing information service data ......................................................................................... 18- 2 special tools ...................................................................................... 18- 7 wire, cable and hose ro...

Page 187: Service Data

18-2 servicing information service data cylinder + piston + piston ring unit: mm (in) conrod + crankshaft unit: mm (in) clutch unit: mm (in) radiator item standard limit piston to cylinder clearance 0.040 – 0.050 (0.0016 – 0.0020) 0.120 (0.0047) cylinder bore 48.000 – 48.015 (1.8898 – 1.8904) measur...

Page 188

Servicing information 18-3 transmission unit: mm (in) except ratio drive chain unit: mm (in) carburetor item standard limit primary reduction ratio 3.444 (62/18) — final reduction ratio 3.357 (47/14) rm85 — 3.615 (47/13) rm85l — gear ratios low 2.545 (28/11) — 2nd 1.933 (29/15) — 3rd 1.571 (22/14) —...

Page 189

18-4 servicing information electrical unit: mm (in) brake + wheel unit: mm (in) item specification note spark plug type ngk: br10es gap 0.7 – 0.8 (0.028 – 0.031) spark performance over 8 (0.3) at 1 atm. Ignition coil resistance primary 0.2 – 1.0 Ω w/bl – ground secondary 12 – 20 k Ω plug cap – groun...

Page 190

Servicing information 18-5 suspension unit: mm (in) tire pressure item standard limit front fork stroke 275 (10.8) — front fork spring free length — 444 (17.48) front fork spring rate (each leg) 2.8 n/mm (0.28 kgf/mm) — front fork oil level 124 (4.88) — front fork damping force adjuster rebound 1 an...

Page 191

18-6 servicing information fuel + oil + coolant item specification note fuel type unleaded gasoline minumum 95 octane (ron) fuel tank capacity 5.0 l (1.3/1.1 us/imp gal) engine oil type motul 800 2t or equivalent two cycle racing lubricant air cleaner element oil type motul air filter oil or equival...

Page 192: Special Tools

Servicing information 18-7 special tools 09900-00401 hexagon wrench set 09900-06107 snap ring pliers 09900-06108 snap ring pliers 09900-09003 impact driver set 09900-20101 vernier calipers (150 mm) 09900-20202 micrometer (25 – 50 mm) 09900-20205 micrometer (0 – 25 mm) 09900-20508 cylinder gauge set ...

Page 193

18-8 servicing information 09924-84521 bearing installer 09930-30102 rotor remover slide shaft 09930-30141 flywheel rotor remover, attach- ment a 09930-30211 flywheel rotor remover, attach- ment g 09940-14930 steering nut socket wrench 09940-30250 front fork assem- bling 09940-52841 inner rod holder...

Page 194

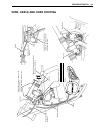

Servicing information 18-9 wire, cable and hose routing clamp clamp clamp cushion 90 30 cdi unit clamp engine stop s witch lead wire engine stop s witch lead wire should be passed under the steer ing stem head. Engine stop s w itch lead wire magnet lead wire cdi unit lead wire engine stop s witch le...

Page 195

18-10 servicing information radiator hose must be passed on right side of frame tube. Muffler cylinder breather hose face the clamp screw to up side. Exhaust breather hose frame radiator.

Page 196

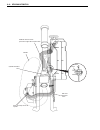

Servicing information 18-11 radiator o v erflo w hose magneto lead wire f ace the white mar k on the radiator hose to the left side . F ace the clamp scre w to bac k side . F ace the white mar k on the r adiator hose to bac k side . F ace the clamp scre w to bac k side . A chain roller f rame carb u...

Page 197

18-12 servicing information when loosening or tighten the adaptor, hold the front brake hose with a wrench to prevent the brake hose from twisting. Front brake master cylinder washer the front brake hose must be passed in front of the number plate. Front brake hose front brake hose guide front brake...

Page 198

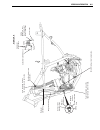

Servicing information 18-13 rear caliper brake hose guide top stopper clamp clamp no bent bolt rear master cylinder bracket no contact.

Page 199

18-14 servicing information view of b 90˚ b install the clutch le v er at an angle of 30˚ with hor iz on. Bef ore install the throttle g rip , apply g rease to the handlebars lightly . F ront br ak e master cylinder br ak e le v e r appro x. 30˚ a view of a.

Page 200

Servicing information 18-15 radiator hose throttle cable clamp clutch cable.

Page 201

18-16 servicing information throttle cable brake hose clutch cable cross the throttle cable and clutch cable above the number plate mounting boss.

Page 202: Specifications

Servicing information 18-17 specifications dimensions and dry mass overall length ...................................................... 1 805 mm (71.1 in) ......... Rm85 1 895 mm (74.6 in) ......... Rm85l overall width........................................................ 735 mm (28.9 in) overall...

Page 203

18-18 servicing information chassis front suspension ................................................. Telescopic, pneumatic/coil spring, oil damped rear suspension .................................................. Link type, oil damped front fork stroke ...............................................

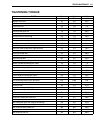

Page 204: Setting Data

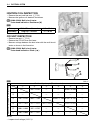

Servicing information 18-19 setting data *make copies. Date / / / / / / race/course / / / temp./humidity / / / whether course coudition main jet jet needle / / / slow jet pilot screw float level spark plug oil level mm mm mm comp. Adj. Position re-bound adj. Position spring spring spring set length ...

Page 205

– memo –.

Page 206

Rm85/l 99011 02b82 01a printed in taiwan 300 takatsuka, hamamatsu, japan k7 failure to follow these safety precautions may increase your risk of injury: ! Wear a helmet, eye protection, and bright protective clothing. ! Don’t ride after consuming alcohol or other drugs. ! This owner’s service manual...