- DL manuals

- Suzuki

- Motorcycle

- RV125

- Service Manual

Suzuki RV125 Service Manual

Summary of RV125

Page 1

9 9 5 0 1 - 3 1 1 5 0 - 0 1 e 背厚 4 mm printed in japan k7 use this manual with: rv125 service manual (99500-31233-01e) r v 1 2 5 dic120 no.3900 rv125k7_01e supply 99500-31150-01e 2006.8.28 cover_14 ps printing (4 mm) 2/1 k 7.

Page 2: Rv125K7 (’07-Model)

Rv125k7 (’07-model) 1 contents rv125k7 (’07-model) © copyright suzuki motor corporation 2006 this manual describes service data, service specifications, troubleshooting for fi system and servicing procedures which differ from those of the k6 (’06-model). Note: • any differences between the k6 (’06-m...

Page 3: Rv125K7 (’07-Model)

2 rv125k7 (’07-model) rv125k7 (’07-model) contents fuel system .................................................................................................. 83 fuel tank .............................................................................................. 83 fuel level indicator check ...

Page 4: Abbreviations Used In This

Rv125k7 (’07-model) 3 abbreviations used in this manual a abdc : after bottom dead center ac : alternating current acl : air cleaner, air cleaner box api : american petroleum institute atdc : after top dead center a/f : air fuel mixture b bbdc : before bottom dead center btdc : before top dead cente...

Page 5: Specifications (Rv125K7)

4 rv125k7 (’07-model) specifications (rv125k7) dimensions and dry mass overall length....................................................... 2 140 mm overall width ........................................................ 860 mm overall height....................................................... 1 ...

Page 6

Rv125k7 (’07-model) 5 chassis front suspension................................................. Telescopic, coil spring, oil damped rear suspension ................................................. Swingarm type, coil spring, oil damped front suspension stroke...................................... 1...

Page 7

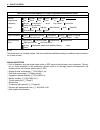

6 rv125k7 (’07-model) periodic maintenance schedule the chart below lists the recommended intervals for all the required periodic service work necessary to keep the motorcycle operating at peak performance and economy. Mileages are expressed in terms of kilometers and time for your convenience. Note...

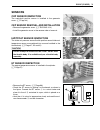

Page 8: Maintenance and Tune-Up

Rv125k7 (’07-model) 7 maintenance and tune-up procedures this section describes the servicing procedures for each peri- odic maintenance item which differ from those of the rv125k6 (’06-model). For details other than the following items, refer to the rv125 service manual. Throttle cable play adjust ...

Page 9

8 rv125k7 (’07-model) fuel line inspect the fuel hoses for damage and fuel leakage. If any defects are found, replace the fuel hose with a new one. Inspect initially at 1 000 km (5 months) and every 4 000 km (20 months) thereafter. Replace every 4 years..

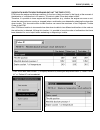

Page 10: Sds Check

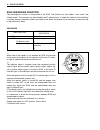

Rv125k7 (’07-model) 9 sds check using sds, sample the data at the time of new and periodic vehicle inspections. After saving the sampled data in the computer, file them by model and by user. The periodically filed data help improve the accuracy of troubleshooting since they can indicate the conditio...

Page 11

10 rv125k7 (’07-model) data at 3 000 r/min under no load data at the time of racing.

Page 12

Rv125k7 (’07-model) 11 data of intake negative pressure during idling (90 °c) data of manifold absolute pressure operation at the time of starting.

Page 13

12 rv125k7 (’07-model) example of trouble three data; value 1 (current data 1), value 2 (past data 2) and value 3 (past data 3); can be made in compar- ison by showing them in the graph. Read the change of value by comparing the current data to the past data that have been saved under the same condi...

Page 14: Fi System Diagnosis

Rv125k7 (’07-model) 13 fi system diagnosis precautions in servicing when handling the component parts or servicing the fi system, observe the following points for the safety of the system. Electrical parts connector/coupler • when connecting a connector, be sure to push it in until a click is felt. ...

Page 15

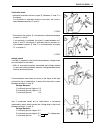

14 rv125k7 (’07-model) • when connecting meter probe from the terminal side of the coupler (where connection from harness side not being possi- ble), use extra care not to force and cause the male terminal to bend or the female terminal to open. Connect the probe as shown to avoid opening of female ...

Page 16

Rv125k7 (’07-model) 15 • when disconnecting and connecting the ecm, make sure to turn off the ignition switch 1, or electronic parts may get damaged. • battery connection in reverse polarity is strictly prohibited. Such a wrong connection will damage the components of the fi system instantly when re...

Page 17

16 rv125k7 (’07-model) electrical circuit inspection procedure while there are various methods for electrical circuit inspection, described here is a general method to check for open and short circuit using an ohmmeter and a voltmeter. Open circuit check possible causes for the open circuits are as ...

Page 18

Rv125k7 (’07-model) 17 continuity check • measure resistance across coupler b (between a and c in the figure). If no continuity is indicated (infinity or over limit), the circuit is open between terminals a and c. 1 ecm • disconnect the coupler b and measure resistance between couplers a and b. If n...

Page 19

18 rv125k7 (’07-model) short circuit check (wire harness to ground) • disconnect the negative cable from the battery. • disconnect the connectors/couplers at both ends of the circuit to be checked. Note: if the circuit to be checked branches to other parts as shown, disconnect all connectors/coupler...

Page 20

Rv125k7 (’07-model) 19 using the multi-circuit tester • use the suzuki multi-circuit tester set (09900-25008). • use well-charged batteries in the tester. • be sure to set the tester to the correct testing range. Using the tester • incorrectly connecting the + and - probes may cause the inside of th...

Page 21

20 rv125k7 (’07-model) fi system technical features injection time (injection volume) the factors to determine the injection time include the basic fuel injection time, which is calculated on the basis of intake air pressure, engine speed and throttle opening angle, and various compensations. These ...

Page 22

Rv125k7 (’07-model) 21 compensation of injection time (volume) the following different signals are output from the respective sensors for compensation of the fuel injection time (volume). Injection stop control signal description engine temperature sensor signal when engine temperature is low, injec...

Page 23

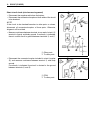

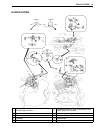

22 rv125k7 (’07-model) fi system parts location a ecm d ignition coil (ig coil) b tip-over sensor (tos) e speedometer c heated oxygen sensor (ho2s).

Page 24

Rv125k7 (’07-model) 23 a ecm h engine temperature sensor (ets) f fuel injector i crankshaft position sensor (ckps) g isc valve j intake air pressure sensor/throttle position sensor/intake air temperature sensor (iaps/tps/iats).

Page 25

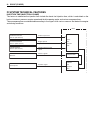

24 rv125k7 (’07-model) fi system wiring diagram cr ankshaft position sensor (ckps) throttle position sensor (tps) intak e air pressure sensor (iaps) intak e air temper ature sensor (ia ts) tip-o v er sensor (t os) ho2 sensor (ho2s) neutr al s witch engine temper ature sensor fuel injector ho2 sensor...

Page 26

Rv125k7 (’07-model) 25 fuel injector the system employs fuel injector (discharge pump; dcp) that causes injection fuel to be pressurized within the pump. The fuel injector pressurizes gravity fed fuel with its plunger and injects the pressurized fuel into the intake pipe. With the pressure plunger c...

Page 27

26 rv125k7 (’07-model) fuel circulation from the fuel tank, fuel enters into the fuel injector through the fuel filter. Vapor generated here returns to the fuel tank. Ecm ecm (engine control module) consists of cpu (central pro- cessing unit), memory (rom/ram) and in/out section. Sig- nals from vari...

Page 28

Rv125k7 (’07-model) 27 to sensor to (tip-over) sensor detects the vehicle inclination. When the vehicle tips to more than 65°, a signal is sent to ecm. When this signal continues for more than 4 seconds, ecm interrupts cur- rent to fuel injector and ignition coil. To restart the engine, turn the ign...

Page 29

28 rv125k7 (’07-model) ckp sensor ckp (crank position) sensor generates the reference ignition signal and sends it to ecm. Ecm calculates and determines the injection and ignition tim- ings on the basis of this signal. Ho2 sensor ho2 (heated oxygen) sensor is made of zirconia element (plat- inum pla...

Page 30

Rv125k7 (’07-model) 29 ecm terminal terminal no. Circuit terminal no. Circuit 1 power ground (e0) d ignition coil 2 isc valve e fi indicator light 3 control ground (e1) f fuel injector - 4 sensor ground (e2) g mode select switch 5 power source (+b) h fuel injector + 6 ho2 sensor heater i — 7 — j neu...

Page 31

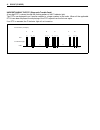

30 rv125k7 (’07-model) self-diagnosis function the self-diagnosis function is incorporated in the ecm. The function has two modes, “user mode” and “dealer mode”. The user can only be notified by the fi indicator light. To check the function of the individual fi system devices, the dealer mode is pro...

Page 32

Rv125k7 (’07-model) 31 dealer mode the defective function is memorized in the ecm. Use the special tool’s coupler to connect to the dealer mode coupler. The memorized malfunction code is displayed by the flashing pattern of fi indicator light. Malfunction means that the ecm does not receive normal s...

Page 33

32 rv125k7 (’07-model) fail-safe function fi system is provided with fail-safe function to allow the engine to start and the motorcycle to run in a mini- mum performance necessary even under malfunction condition. The engine can start and can run even if the above signal is not received from each se...

Page 34

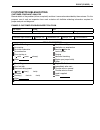

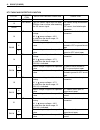

Rv125k7 (’07-model) 33 fi system troubleshooting customer complaint analysis record details of the problem (failure, complaint) and how it occurred as described by the customer. For this purpose, use of such an inspection form such as below will facilitate collecting information required for proper ...

Page 35

34 rv125k7 (’07-model) note: the above form is a standard sample. The form should be modified according to conditions and characteris- tics of each market. Visual inspection • prior to diagnosis using the mode select switch or sds, perform the following visual inspections. The rea- son for visual in...

Page 36

Rv125k7 (’07-model) 35 self-diagnostic procedures note: * do not disconnect the coupler from ecm, battery cable from battery, ecm ground wire from engine or main fuse before confirming the dtc (diagnostic trouble code) stored in mem- ory. Such disconnection will erase the memorized information in ec...

Page 37

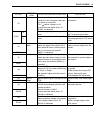

36 rv125k7 (’07-model) understanding the dtc (diagnostic trouble code) a two-digit dtc is shown through the flashing pattern of the fi indicator light. The dtcs are displayed from a smaller number to a larger number in that order. When all the applicable dtcs have been displayed, the displaying of t...

Page 38

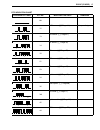

Rv125k7 (’07-model) 37 dtc indication chart flashing pattern dtc no. Malfunction part remarks 00 none 12 ckp sensor ( page 44) pick up coil signal 13 iap sensor ( page 47) 14 tp sensor ( page 52) 15 et sensor ( page 57) 21 iat sensor ( page 61) 23 to sensor ( page 65) 24 ignition coil ( page ...

Page 39

38 rv125k7 (’07-model) *40 c40 code has no first digit display. For this reason, the interval a between the displays as shown below is longer than the others. Self-diagnosis reset procedure • after repairing the trouble, turn off the ignition switch and turn on again. • if the fi indicator light tur...

Page 40

Rv125k7 (’07-model) 39 use of sds diagnostic procedures note: * do not disconnect the coupler from ecm, battery cable from battery, ecm ground wire from engine or main fuse before confirming the dtc (diagnostic trouble code) stored in mem- ory. Such disconnection will erase the memorized information...

Page 41

40 rv125k7 (’07-model) use of sds diagnosis reset procedure • after repairing the trouble, turn off the ignition switch and turn on again. • click the dtc inspection button 1. • check the dtc. • the previous malfunction history code (past dtc) still remains stored in the ecm. Therefore, erase the hi...

Page 42

Rv125k7 (’07-model) 41 show data when trouble displaing data at the time of dtc) ecm stores the engine and driving conditions (in the form of data as shown in the figure) at the moment of the detection of a malfunction in its memory. This data is called “show data when trouble”. Therefore, it is pos...

Page 43

42 rv125k7 (’07-model) dtc table and defective condition dtc no. Detected item detected failure condition check for 00 no fault ––––––––––– ––––––––––– 12 ckp sensor the ckp sensor signal does not reach ecm for 4 sec. Or more, after receiving the iap sensor signal. Ckp sensor wiring and mechan- ical...

Page 44

Rv125k7 (’07-model) 43 dtc no. Detected item detected failure condition check for 23 to sensor the sensor voltage should be the fol- lowing for 2 sec. And more, after igni- tion switch is turned on. 0.2 v sensor voltage in other than the above value, 23 (p1651) is indicated. To sensor, lead wire/cou...

Page 45

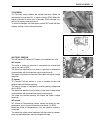

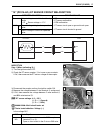

44 rv125k7 (’07-model) “12” (p0335) ckp sensor circuit malfunction inspection step 1 1) turn the ignition switch off. 2) remove the seat. ( rv125k3 5-3) 3) check the ckp sensor coupler 1 for loose or poor contacts. If ok, then measure the ckp sensor resistance. 4) disconnect the ckp sensor coupler ...

Page 46

Rv125k7 (’07-model) 45 5) if ok, then check the continuity between each terminal and ground. ckp sensor continuity: ∞Ω (infinity) (g – ground) (bl – ground) 09900-25008: multi-circuit tester set tester knob indication: resistance (Ω) are the resistance and continuity ok? 6) after repairing the...

Page 47

46 rv125k7 (’07-model) . Is the voltage ok? 3) after repairing the trouble, clear the dtc using sds tool. ( page 40) yes • bl or b/br wire open or shorted to ground. • loose or poor contacts on the ckp sensor cou- pler or ecm coupler (terminal p or 4). • if wire and connection are ok, intermittent ...

Page 48

Rv125k7 (’07-model) 47 “13” (p0105-h/l) iap sensor circuit malfunction note: iap sensor is incorporated in the tp sensor/iat sensor. Inspection step 1 (when indicating 13:) 1) turn the ignition switch off. 2) check the iap sensor coupler 1 for loose or poor contacts. If ok, then measure the iap sens...

Page 49

48 rv125k7 (’07-model) 3) disconnect the iap sensor coupler. 4) turn the ignition switch on. 5) measure the voltage at the r wire and ground. 6) if ok, then measure the voltage at the r wire and b/br wire. iap sensor input voltage: 4.5 – 5.5 v (+ r – - ground) (+ r – - b/br) 09900-25008: multi-c...

Page 50

Rv125k7 (’07-model) 49 5) disconnect the ecm coupler. 6) check the continuity between g/b wire c and terminal n. 7) if ok, then check the continuity between b/br wire b and ter- minal 4. iap sensor lead wire continuity: continuity () 09900-25008: multi-circuit tester set 09900-25009: needle poi...

Page 51

50 rv125k7 (’07-model) 6) disconnect the ecm coupler. 7) check the continuity between r wire a and terminal 9. 8) also, check the continuity between g/b wire c and terminal n. iap sensor lead wire continuity: continuity () 09900-25008: multi-circuit tester set 09900-25009: needle pointed probe ...

Page 52

Rv125k7 (’07-model) 51 step 2 1) connect the iap sensor coupler and ecm coupler. 2) insert the needle pointed probes to the lead wire coupler. 3) start the engine at idle speed and measure the iap sensor output voltage (between g/b and b/br wires). iap sensor output voltage: 2.0 – 3.5 v at idle sp...

Page 53

52 rv125k7 (’07-model) “14” (p0120-h/l) tp sensor circuit malfunction note: tp sensor is incorporated in the iap sensor/iat sensor. Inspection step 1 (when indicating 14:) 1) turn the ignition switch to off. 2) check the tp sensor coupler 1 for loose or poor contacts. If ok, then measure the tp sens...

Page 54

Rv125k7 (’07-model) 53 3) disconnect the tp sensor coupler. 4) turn the ignition switch on. 5) measure the voltage at the r wire and ground. 6) if ok, then measure the voltage at the r wire and b/br wire. tp sensor input voltage: 4.5 – 5.5 v (+ r – - ground) (+ r – - b/br) 09900-25008: multi-cir...

Page 55

54 rv125k7 (’07-model) 5) disconnect the ecm coupler. 6) check the continuity between p wire a and terminal m. 7) also, check the continuity between b/br wire c and terminal 4. tp sensor lead wire continuity: continuity () 09900-25008: multi-circuit tester set 09900-25009: needle pointed probe ...

Page 56

Rv125k7 (’07-model) 55 6) disconnect the ecm coupler. 7) check the continuity between p wire a and terminal m. 8) also, check the continuity between r wire b and terminal 9. tp sensor lead wire continuity: continuity () 09900-25008: multi-circuit tester set 09900-25009: needle pointed probe set...

Page 57

56 rv125k7 (’07-model) step 2 1) connect the tp sensor coupler. 2) turn the ignition switch on. 3) measure the tp sensor output voltage (between + p and - b/br) by turning the throttle grip. tp sensor output voltage throttle valve is closed: approx. 0.7 v throttle valve is opened: approx. 3.9 v ...

Page 58

Rv125k7 (’07-model) 57 “15” (p0115-h/l) et sensor circuit malfunction inspection step 1 (when indicating 15:) 1) turn the ignition switch off. 2) check the et sensor coupler 1 for loose or poor contacts. If ok, then measure the et sensor voltage at the coupler. 3) disconnect the coupler and turn the...

Page 59

58 rv125k7 (’07-model) step 1 (when indicating p0115-h:) 1) turn the ignition switch off. 2) check the et sensor coupler 1 for loose or poor contacts. If ok, then check the et sensor lead wire continuity. 3) disconnect the et sensor coupler and ecm coupler. 4) check the continuity between o wire a a...

Page 60

Rv125k7 (’07-model) 59 step 1 (when indicating p0115-l:) 1) turn the ignition switch off. 2) check the et sensor coupler 1 for loose or poor contacts. If ok, then measure the output voltage. 3) disconnect the et sensor coupler. 4) check the continuity between o wire a and ground. If the sound is not...

Page 61

60 rv125k7 (’07-model) step 2 1) turn the ignition switch off. 2) disconnect the et sensor coupler. 3) measure the et sensor resistance between b wires. et sensor resistance: approx. 5 – 13 kΩ at 20 – 40 °c (b – b) 09900-25008: multi-circuit tester set tester knob indication: resistance (Ω) re...

Page 62

Rv125k7 (’07-model) 61 “21” (p0110-h/l) iat sensor circuit malfunction note: iat sensor is incorporated in the iap sensor/tp sensor. Inspection step 1 (when indicating 21:) 1) turn the ignition switch off. 2) check the iat sensor coupler 1 for loose or poor contacts. If ok, then measure the iat sens...

Page 63

62 rv125k7 (’07-model) 4) measure the voltage between dg wire terminal and ground. 5) also, measure the voltage between dg wire terminal and b/br wire terminal. iat sensor input voltage: 4.5 – 5.5 v (+ r – - ground) (+ r – - b/br) 09900-25008: multi-circuit tester set 09900-25009: needle pointed...

Page 64

Rv125k7 (’07-model) 63 step 1 (when indicating p0110-l:) 1) turn the ignition switch off. 2) check the iat sensor coupler for loose or poor contacts. If ok, then check the iat sensor lead wire continuity. 3) disconnect the iat sensor coupler. 4) check the continuity between dg wire and ground. If th...

Page 65

64 rv125k7 (’07-model) step 2 1) turn the ignition switch off. 2) measure the iat sensor resistance. iat sensor resistance: approx. 2.56 kΩ at 20 °c approx. 1.20 k Ω at 40 °c (terminal – terminal) 09900-25008: multi-circuit tester set tester knob indication: resistance (Ω) is the resistance ok...

Page 66

Rv125k7 (’07-model) 65 “23” (p1651-h/l) to sensor circuit malfunction inspection step 1 (when indicating 23:) 1) turn the ignition switch off. 2) remove the right frame cover. ( rv125k3 5-3) 3) check the to sensor coupler 1 for loose or poor contacts. If ok, then measure the to sensor resistance. 4...

Page 67

66 rv125k7 (’07-model) step 1 (when indicating p1651-h:) 1) turn the ignition switch off. 2) remove the right frame cover. 3) check the to sensor coupler 1 for loose or poor contacts. If ok, then check the to sensor lead wire continuity. 4) disconnect the to sensor coupler. 5) check the continuity b...

Page 68

Rv125k7 (’07-model) 67 step 1 (when indicating p1651-l:) 1) turn the ignition switch off. 2) remove the right frame cover. 3) check the to sensor coupler 1 for loose or poor contacts. If ok, then check the to sensor lead wire continuity. 4) disconnect the to sensor coupler. 5) check the continuity b...

Page 69

68 rv125k7 (’07-model) step 2 1) connect the to sensor coupler and ecm coupler. 2) insert the needle pointed probes to the lead wire coupler. 3) turn the ignition switch on. 4) measure the voltage between br/w and b/br wires. to sensor voltage (normal): 0.4 – 1.4 v (+ br/w – - b/br) also, measure ...

Page 70

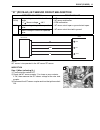

Rv125k7 (’07-model) 69 “32” (p0201) fuel injector circuit malfunction note: when the ignition switch is turned to on position, the fuel injec- tor starts to operate approx. 2 sec. As purge operation (initial operation) inspection step 1 1) turn the ignition switch off. 2) check the fuel injector cou...

Page 71

70 rv125k7 (’07-model) 5) if ok, then check the continuity between each terminal and ground. fuel injector continuity: ∞Ω (infinity) (terminal – ground) 09900-25008: multi-circuit tester set tester knob indication: resistance (Ω) are the resistance and continuity ok? 6) after repairing the tro...

Page 72

Rv125k7 (’07-model) 71 “40” (p0505) isc valve circuit malfunction inspection step 1 1) turn the ignition switch off. 2) check the isc valve coupler 1 for loose or poor contacts. If ok, then check the isc valve resistance. 3) disconnect the isc valve coupler. 4) measure the isc valve resistance. is...

Page 73

72 rv125k7 (’07-model) 5) if ok, then check the continuity between each terminal and ground. isc valve continuity: ∞Ω (infinity) (terminal – ground) 09900-25008: multi-circuit tester set tester knob indication: resistance (Ω) are the resistance and continuity ok? 6) after repairing the trouble...

Page 74

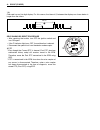

Rv125k7 (’07-model) 73 active control inspection (isc rpm control) check 1 1) set up the sds tool. (refer to the sds operation manual for further details.) 2) check that the engine is running. 3) make sure that the engine temperature on data monitor is indicated 80 °c or more. 4) click the “active c...

Page 75

74 rv125k7 (’07-model) check 3 1) click the button 1 and increase the “spec” 2 to 1 300 rpm slowly. 2) check that the “desired idle speed” 3 is nearly equal to the “spec” 2. Also, check that the air volume 4 of the isc duty increases . Check 4 1) increase the “spec” 1 to 1 900 rpm. 2) check that the...

Page 76

Rv125k7 (’07-model) 75 “44” (p0130/p0135) ho2 sensor (ho2s) circuit malfunction inspection step 1 (when indicating 44/p0130:) 1) turn the ignition switch off. 2) remove the seat. 3) check the ho2 sensor coupler 1 for loose or poor contacts. If ok, then check the ho2 sensor lead wire continuity. 4) d...

Page 77

76 rv125k7 (’07-model) 7) disconnect the ecm coupler. 8) check the continuity between w/g wire a and terminal c. 9) also, check the continuity between b/br wire b and terminal 4. ho2 sensor lead wire continuity: continuity () 09900-25008: multi-circuit tester set 09900-25009: needle pointed pro...

Page 78

Rv125k7 (’07-model) 77 is the voltage ok? 5) after repairing the trouble, clear the dtc using sds tool. ( page 40) step 1 (when indicating 44/p0135:) 1) turn the ignition switch off. 2) remove the seat. 3) check the ho2 sensor 1 for loose or poor contacts. If ok, then measure the ho2 sensor resista...

Page 79

78 rv125k7 (’07-model) step 2 (when indicating 44/p0135:) 1) connect the ho2 sensor coupler. 2) insert the needle pointed probes to the ho2 sensor coupler. 3) turn the ignition switch on and measure the heater voltage between w wire (harness side) and ground. 4) if the tester voltage indicates the b...

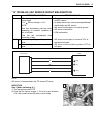

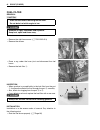

Page 80: Sensors

Rv125k7 (’07-model) 79 sensors ckp sensor inspection the crankshaft position sensor is installed in the generator cover. ( page 44) ckp sensor removal and installation • remove the generator cover. ( rv125k3 3-14) • install the generator cover in the reverse order of removal. Iap/tp/iat sensor ins...

Page 81

80 rv125k7 (’07-model) • if the et sensor ohmic value does not change in the propor- tion indicated, replace it with a new one. engine temperature sensor specification et sensor removal and installation • remove the clamp 1. • disconnect the coupler 2. • remove the et sensor 3. • install the et se...

Page 82

Rv125k7 (’07-model) 81 to sensor removal and installation • remove the right frame cover. ( rv125k3 5-3) • remove the rear fender bolts. • remove the to sensor. • install the to sensor in the reverse order of removal. Note: when installing the to sensor, the arrow mark a must be pointed upward. Ho2...

Page 83

82 rv125k7 (’07-model) • remove the ho2 sensor 2. • installation is in the reverse order of removal. • tighten the ho2 sensor to the specified torque. ho2 sensor: 25 n·m (2.5 kgf-m) do not remove the ho2 sensor while it is hot. * be careful not to expose the ho2 sensor to exces- sive shock. * do n...

Page 84: Fuel System

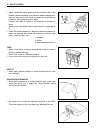

Rv125k7 (’07-model) 83 fuel system fuel tank removal • remove the seat. ( rv125k3 5-3) • place a rag under the hose joint and disconnect the fuel hose 1. • disconnect the fuel level switch lead wire coupler 2. • remove the fuel tank bolts. • disconnect the fuel hose 3. • remove the fuel tank. * dra...

Page 85

84 rv125k7 (’07-model) • remove the inlet tube filter 4. • remove the fuel level switch 5. Inspection inlet tube filter • inspect the inlet tube filter for clogging or any damage. • if necessary, clean the inlet tube filter using compressed air. Fuel level switch • connect a 12 v battery and bulb (1...

Page 86

Rv125k7 (’07-model) 85 installation installation is in the reverse order of removal. Pay attention to the following point: fuel level indicator check relay removal and installation fuel level indicator check relay is located behind the ecm. • remove the right frame cover. ( rv125k3 5-3) • remove th...

Page 87

86 rv125k7 (’07-model) fuel filter removal • remove the right frame cover. ( rv125k3 5-3) • remove the screws. • place a rag under the hose joint and disconnect the fuel hoses. • remove the fuel filter 1. Inspection • when gosoline is poured lightly to the fuel filter from the port 1, the gasoline ...

Page 88

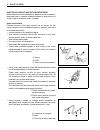

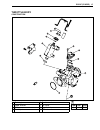

Rv125k7 (’07-model) 87 throttle body construction 1 return pipe 5 cushion seal 2 upper cushion 6 isc valve item n·m kgf-m 3 o-ring 7 throttle body a 2 0.2 4 fuel injector a isc valve screw.

Page 89

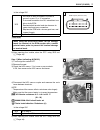

88 rv125k7 (’07-model) removal and disassembly • remove the seat. ( rv125k3 5-3) • remove the frame covers. ( rv125k3 5-3) • disconnect the isc valve coupler 1, fuel injector coupler 2 and iap/tp/iat sensor coupler 3. • place a rag under the hose joint and disconnect the fuel hose 4. • disconnect ...

Page 90

Rv125k7 (’07-model) 89 • loosen the air cleaner outlet tube clamp screw. • remove the intake pipe nuts. • move the air cleaner box backward and remove the throttle body. • remove the insulator 7. • remove the o-rings 8 and 9. • remove the fuel injector 0. Do not snap the throttle valve from full ope...

Page 91

90 rv125k7 (’07-model) • remove the return pipe a, bracket b and upper cushion c. • remove the o-ring d and cushion seal e. • remove the isc valve f. Never remove the iap/tp/iat sensor g from the throt- tle body. * never remove the throttle valve h from the throttle body. * never use carburetor clea...

Page 92

Rv125k7 (’07-model) 91 inspection check following items for any damage or clogging. * o-ring * throttle valve * injector cushion seal isc valve • remove the o-ring. • visually inspect the isc valve for wear, damage or carbon deposit, replace it with a new one if necessary. Note: the isc valve can be...

Page 93

92 rv125k7 (’07-model) • install the injector as shown. • install the o-rings 2 and 3. • install the insulator. Note: set the insulator so the o-ring faces to the engine side and tab a upward. • install the throttle body. • connect the throttle pulling cable 4 and throttle returning cable 5 to the t...

Page 94: Wiring Diagram

Rv125k7 (’07-model) 93 wiring diagram handleb ar switch (r) speedometer diode fuel ga uge check rela y engine st op switch st ar ter b utt on fr ont brake switch 1 free hi lo off on l push r push push on off on off free push c on lock p off ru n off battery starter motor generator neutral switch sta...

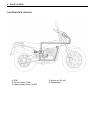

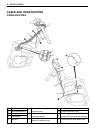

Page 95: Cable and Hose Routing

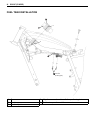

94 rv125k7 (’07-model) cable and hose routing cable routing 1 throttle cable no.1 *1 pass the throttle cables in front of the brake hose. *4 set the clamp as shown. 2 throttle cable no.2 *5 clamp the harness only. 3 wiring harness *2 pass the throttle cables above the wiring harness. *6 set the uppe...

Page 96

Rv125k7 (’07-model) 95 hose routing 1 throttle body insulator *1 assemble the hoses, union and clamps in the proper direction as shown. 2 air cleaner outlet tube clamp *2 yellow marking 3 fuel hose 3-way union *3 white marking 4 fuel filter *4 red marking 5 fuel injector *5 fuel hose must be free fr...

Page 97

96 rv125k7 (’07-model) fuel tank installation 1 frame *1 align the recess of cushion with the positioning plate. 2 cushion *2 cut the clamp so the end 10 mm remains. 3 fuel tank joint 4.4 n.M (0.44 kgf-m) *2 *1.

Page 98: Special Tools

Rv125k7 (’07-model) 97 special tools note: when order the special tool, please confirm whether it is available or not. Tightening torque 09900-25008 multi-circuit tester set 09900-25009 needle pointed probe set 09904-41010 sds set tool 09930-82720 mode select switch 99565-01010-009 cd-rom ver. 9 ite...

Page 99: Service Data

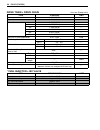

98 rv125k7 (’07-model) service data valve + guide unit: mm camshaft + cylinder head unit: mm item standard limit valve diam. In. 25.5 — ex. 22.5 — valve clearance (when cold) in. 0.03 – 0.08 — ex. 0.13 – 0.18 — valve guide to valve stem clearance in. 0.010 – 0.037 — ex. 0.030 – 0.057 — valve guide i...

Page 100

Rv125k7 (’07-model) 99 cylinder + piston + piston ring unit: mm conrod + crankshaft unit: mm oil pump clutch unit: mm item standard limit compression pressure 1 100 – 1 500 kpa (11 – 15 kgf/cm 2 ) 800 kpa (8.0 kgf/cm 2 ) piston-to-cylinder clearance 0.040 – 0.050 0.120 cylinder bore 57.000 – 57.015 ...

Page 101

100 rv125k7 (’07-model) drive train + drive chain unit: mm (except ratio) * fuel injector + isc valve item standard limit primary reduction ratio 3.470 (59/17) — final reduction ratio 3.500 (49/14) — gear ratios low 3.000 (33/11) — 2nd 1.857 (26/14) — 3rd 1.368 (26/19) — 4th 1.095 (23/21) — 5th 0.92...

Page 102

Rv125k7 (’07-model) 101 * fi sensors * throttle body item specification note ckp sensor resistance 172 – 288 Ω ckp sensor peak voltage 2.0 v (when cranking) and more + g – - bi iap sensor input voltage 4.5 – 5.5 v iap sensor output voltage approx. 2.0 – 3.5 v at idle speed + g/b – - b/br tp sensor i...

Page 103

102 rv125k7 (’07-model) electrical wattage unit: w item specification note spark plug type denso: u24esr-n ngk: cr8e gap 0.7 – 0.8 mm spark performance over 8 mm at 1 atm. Ignition coil resistance primary 1.6 – 2.7 Ω + tap – - tap secondary 18 – 26 k Ω plug cap – + tap generator coil resistance 0.4 ...

Page 104

Rv125k7 (’07-model) 103 brake + wheel unit: mm suspension unit: mm tire pressure item standard/specification limit rear brake pedal free travel 20 – 30 — rear brake pedal height 5 – 15 — brake drum i.D. Rear — 110.7 brake disc thickness front 4.0 ± 0.2 3.5 brake disc runout front — 0.30 master cylin...

Page 105

104 rv125k7 (’07-model) fuel + oil item specification note fuel type gasoline used should be graded 91 octane or higher. An unleaded gasoline type is recom- mended. Fuel tank capacity 6.5 l engine oil type sae 10w-40, api sf/sg or sh/sj with jaso ma engine oil capacity change 850 ml filter change 95...

Page 106

Prepared by september, 2006 part no. 99501-31150-01e printed in japan 104.

Page 107

9 9 5 0 1 - 3 1 1 5 0 - 0 1 e 背厚 4 mm printed in japan k7 use this manual with: rv125 service manual (99500-31233-01e) r v 1 2 5 dic120 no.3900 rv125k7_01e supply 99500-31150-01e 2006.8.28 cover_14 ps printing (4 mm) 2/1 k 7.