- DL manuals

- Suzuki

- Motorcycle

- SVF650K9

- Setup Manual

Suzuki SVF650K9 Setup Manual

K9

December ’08 Printed in Japan (TK) 19

99505-01149-01E

FOREWORD

This motorcycle has been designed and produced utilizing Suzuki’s most modern

technology. The finest product, however, cannot perform properly unless it is cor-

rectly assembled and serviced. This set-up manual has been produced to aid you in

properly assembling and servicing this motorcycle.

Please review this set-up manual carefully before performing any work. Take special

care to properly perform the required assembly and servicing marked by either a

Warning or a Caution. Failure to follow the directions in either of these two (2) cate-

gories could lead to serious problems.

and areas are

denoted to emphasize certain areas and carry the following meanings:

Indicates a potential hazard that could result in death or injury.

Indicates a potential hazard that could result in motorcycle damage.

This set-up manual is based on a motorcycle of standard specification. Some minor

differences from this manual may be found in other specifications.

Summary of SVF650K9

Page 1

K9 december ’08 printed in japan (tk) 19 99505-01149-01e foreword this motorcycle has been designed and produced utilizing suzuki’s most modern technology. The finest product, however, cannot perform properly unless it is cor- rectly assembled and serviced. This set-up manual has been produced to ai...

Page 2: Preparation

1 preparation workshop a: packed motorcycle b: working space self protection uncrating the motorcycle remove the carton. A: crate the workshop where the machine is assembled should be clean, spacious, and have a level floor. The technician should wear protective clothing such as leather gloves, a lo...

Page 3

2 remove the bolts of the bracket. A: bolt remove the bolts from the crate. A: bolt lift the steel frame to separate it from the base of the crate. Carefully remove the various component parts pack- aged around the motorcycle. A: steel frame b: crate base handling crates requires two operators. Be c...

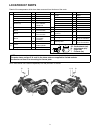

Page 4: Location of Parts

3 location of parts check all the components which have been removed from the base of the crate. Parts listed above are installed respectively into the positions as follows. Item part name q’ty remarks a handlebars assembly 1 clamp 2 allen bolt 4 8 × 25 mm burring washer 4 od:13.0 id:8.5 plastic cap...

Page 5

4 the photograph shown indicates the parts dismounted from the motorcycle in addition to the items shown in the preceding page. A: front brake master cylinder b: throttle assembly c: left switch d: clutch cable h h ii f f g g e e c c b b d d a a.

Page 6: Assembly

5 before assembling the motorcycle, thoroughly understand the “safety check out” described on page 32. After completion of assembly, carefully check the motorcycle referring to the “safety check out”, then deliver the motorcycle to the customer. Assembly removing the bracket remove the bolt to take ...

Page 7

6 handlebars loosen the throttle housing retaining screws. Insert the throttle assembly onto the handlebars. A: throttle assembly b: handlebars install the handlebars assembly with the two clamps, four allen bolts and washers. A: clamp b: 8 × 25 mm allen bolt c: burring washer od:13.0 mm id:8.5 mm d...

Page 8

7 a: front brake hose b: throttle cables c: right switch wiring harness d: clutch cable e: left switch wiring harness throttle insert the boss of throttle housing into the hole on the handlebars. Install the throttle assembly with two screws. A: boss b: hole c: 5 × 30 mm screw front brake master cyl...

Page 9

8 a: bolt b: holder c: front brake master cylinder d: handlebars connect the lead wires coupler to the front brake light switch. A: front brake light switch b: lead wire coupler left switch insert the boss of left switch housing into the hole on the handlebars. Install the left switch assembly with ...

Page 10

9 connect the lead wire coupler to the clutch lever posi- tion switch. A: clutch lever position switch b: lead wire coupler clutch cable pass the clutch cable through the lever cover. A: clutch cable b: lever cover turn the clutch cable adjuster and lock nut in as far as possible and align the slots...

Page 11

10 right clamp clamp the right switch wiring harness and front brake hose union with strap. A: strap l:140 mm b: front brake hose union c: right switch wiring harness left clamp the left switch wiring harness and clutch cable with strap. A: strap l:140 mm b: clutch cable c: left switch wiring harnes...

Page 12

11 attach a hoist band. Pass the hoist band through the handlebar clamps as shown in the photograph. A: hoist band 1. Lift the front of motorcycle by using a hoist. 2. Raise the rear of motorcycle. 3. Pull the crate base forward, then balance the motorcycle. Place the motorcycle on the side-stand, t...

Page 13

12 rear view mirror install the rear view mirror and tighten lock nuts securely after positioning them properly. Place the rubber boot. A: rear view mirror b: lock nut c: rubber boot removing the wrap film remove the wrap film from the muffler. A: muffler b: wrap film front rear brake disc to preven...

Page 14

13 warning label (for e-19 cc and e-19 cd selection) select the appropriate language label for your country. Stick the label selected for your country. A: for e-19 cc selection b: for e-19 cd selection c: warning label d: fuel tank license plate (except for e-28) a: washer od:20.0 mm id:6.5 mm b: re...

Page 15

14 owner’s manual remove the seat by using the key. A: key b: seat store the owner’s manual in place. A: owner’s manual reinstall the seat. Insert the seat hook into the seat hook retainer. Push the seat down to lock it. A: seat assembly b: seat hook c: seat hook retainer.

Page 16: Servicing

15 servicing battery the battery is located under the seat. Remove the seat by using the key. Remove the prop stay. A: prop stay remove the screw. Unhook the hook. A: battery holder b: screw c: hook unhook the hook and remove the battery holder. Remove the battery from the motorcycle. A: battery hol...

Page 17

16 remove the caps from the electrolyte container. A: caps b: sealed area with just enough force to break the nozzle seal of elec- trolyte container, push each nozzle of the electrolyte container into the battery’s electrolyte filler ports and hold the container firmly so that it does not fall. Take...

Page 18

17 after confirming that the electrolyte has entered the battery completely, remove the electrolyte containers from the battery. Wait for around 20 minutes. Insert the caps into the filler holes, pressing in firmly so that the top of the each caps does not protrude above the upper surface of the bat...

Page 19

18 1. Reinstall the battery in the battery box. 2. First connect the + lead to the + positive terminal of the battery. 3. Cover + terminal with rubber boot. 4. Connect the - lead to the - negative terminal of the battery. 5. Reinstall the battery holder. 6. Reinstall the prop stay. 7. Reinstall the ...

Page 20

19 front brake air bleeding any air which may have been trapped in the brake fluid circuit must be bled completely. If the brake lever or brake pedal feels spongy or weak, then most likely there is air in the brake fluid circuit. If air bleed is necessary, carry out the following proce- dure. 1. Con...

Page 21

20 front brake lever make sure the front brake lever position is correct. The standard setting for this motorcycle is as indicated in the table below. A: adjuster throttle cable this motorcycle has a twin throttle cable system. Cable a is for pulling cable and cable b is for return- ing. Check the t...

Page 22

21 clutch cable check the clutch lever play at the clutch lever end when squeezing the lever until pressure is felt. Clutch lever play: 10–15 mm if adjustment is necessary, carry out the following pro- cedure. 1. Shift the lever cover e. 2. Loosen the clutch lever adjuster lock nut c and turn in the...

Page 23

22 drive chain check the drive chain slack. Drive chain slack: 20–30 mm if adjustment is necessary, carry out the following pro- cedure. 1. Loosen the axle nut. 2. Adjust the slack in the drive chain by turning the right and left chain adjuster bolts. 3. Proper chain slack is obtained when the drive...

Page 24

23 rear suspension checking spring setting make sure the spring setting of the rear suspension is correct. The standard setting of this motorcycle is as indicated in the table below. A: adjuster tire pressure using an accurate air gauge, check the air pressure of the front and rear tires. The pressu...

Page 25

24 engine coolant the engine coolant level should be kept between the “f” (full) and “l” (low) level. Inspect the level with the motorcycle held vertically on level ground. A: engine coolant reservoir if the level is lower than the “l” (low) level, add the properly mixed engine coolant as follows. R...

Page 26

25 3. Remove the reservoir tank cap and add 50 : 50 mix- ture of engine coolant and distilled water to the “f” (full) level from the engine coolant filler hole. 4. Reinstall the reservoir tank cap. 5. Reinstall the fuel tank. 6. Reinstall the frame covers. 7. Reinstall the prop stay. 8. Reinstall th...

Page 27

26 engine oil oil quality is a major contributor to your engine’s per- formance and life. Always select good quality engine oil. Use oil with an api (american petroleum institute) classification of sf/sg or sh/sj, or with a jaso clas- sification of ma. Sae engine oil viscosity suzuki recommends the ...

Page 28

27 energy conserving suzuki does not recommend the use of “energy conserving” oils. Some engine oils which have an api classification of sh or higher have an “energy conserving” indi- cation in the api classification doughnut mark. These oils can affect engine life and clutch perform- ance. Idle spe...

Page 29: Tightening Torque

28 tightening torque for other bolts and nuts not listed, refer to this chart. Item part name n·m kgf-m front fork a handlebar clamp bolt 23 2.3 b steering stem head nut 90 9.0 c front fork upper bracket bolt 23 2.3 d front fork lower bracket bolt 23 2.3 e front axle clamp bolt 23 2.3 brake f front ...

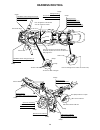

Page 30: Harness Routing

29 harness routing clamp clamp clamp clamp clamp clamp clamp clamp clamp pass the ignition coil lead wire over the regulator/rectifier. Front brake hose clutch cable clutch cable clutch cable clamp clamp clamp clamp clamp clamp throttle cable to the horn and cooling fan. Pass the wiring harness unde...

Page 31

30 guide guide wiring harness clamp pass the wiring harness under the fuel hose. Fuel hose pass the throttle position sensor lead wire between the high tension cord and cylinder head. Clamp clamp clamp clamp clamp clamp clamp battery - lead wire battery - lead wire wiring harness wiring harness wiri...

Page 32: Cable Routing

31 cable routing throttle cable (pulling) throttle cable (returning) pass the throttle cables inside of the throttle cable guide and behind the headlight housing brace. Clutch cable pass the clutch cable left side of the frame head pipe. Pass the throttle cables right side of the frame head pipe. Pa...

Page 33: Safety Check Out

32 safety check out engine and transmission chassis sp= spring cold inflation tire pressure electricals road test inspection after completion of the setting-up the motorcy- cle all the following items should be double- checked to confirm that the operation and func- tion of the motorcycle are satisf...