- DL manuals

- Suzuki

- Automobile

- Swift

- User Manual

Suzuki Swift User Manual

IMPORTANT

WARNING/CAUTION /NOTE

Please read this manual and follow its instructions

carefully. To emphasize special information, the

words WARNING, CAUTION and NOTE have spe-

cial meanings. Pay special attention to the messages

highlighted by these signal words.

NOTE:

Indicates special information to make mainte-

nance easier or instructions clearer.

WARNING:

Indicates a potential hazard that could result

in death or injury.

CAUTION:

Indicates a potential hazard that could result

in vehicle damage.

WARNING:

This service manual is intended for authorized

SUZUKI dealers and qualified service me-

chanics only. Inexperienced mechanics or

mechanics without the proper tools and

equipment may not be able to properly per-

form the services described in this manual.

Improper repair may result in injury to the me-

chanic and may render the vehicle unsafe for

the driver and passengers.

Summary of Swift

Page 1

Important warning/caution /note please read this manual and follow its instructions carefully. To emphasize special information, the words warning, caution and note have spe- cial meanings. Pay special attention to the messages highlighted by these signal words. Note: indicates special information t...

Page 2: Foreword

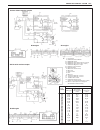

() x () x () x () x () x () x () x () x () x () x () x () x () x () x () x () x () x () x foreword this supplementary service manual is a supplement to sf series service manu- als mentioned in next page and has been prepared exclusively for the following applicable mod- el. Applicable model: sf310/s...

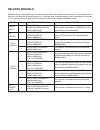

Page 3: Related Manuals

Related manuals related manuals listed below are in the chronological order with the latest one at the top. For the efficient use of manuals, start with one at the top of the list (i.E., the latest one). If desired section, item or description is not found in it, try next one in the list and do the ...

Page 4

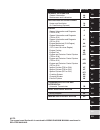

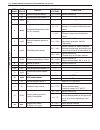

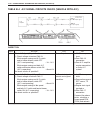

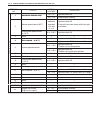

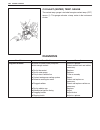

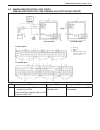

6 6 6-1 6a 6a1 6b 6c 6e1 6e1 6e2 6f 6f 6f1 6g 6h 6k general information general information maintenance and lubrication 1a 1b table of contents section 0a 0b 7b 8 8a 8g heating and air conditioning heater and ventilation air conditioning (oprional) engine general information and diagnosis (tbi for g...

Page 5: Section 0A

General information 0a-1 0a section 0a general information contents how to use this manual 0a- 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Precautions 0a- 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 6: How To Use This Manual

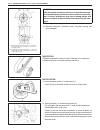

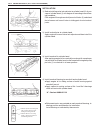

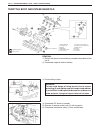

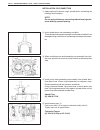

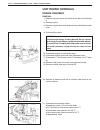

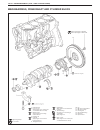

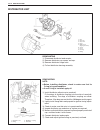

1. Flywheel bolts or drive plate bolts for a / t vehicle 6) install oil pump. Refer to “oil pump”. 7) install flywheel (for m / t vehicle) or drive plate (for a / t vehicle). Using special tool, lock flywheel or drive plate, and tighten flywheel or drive plate bolts to specified torque. Special tool...

Page 7: Precautions

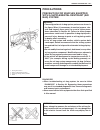

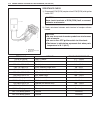

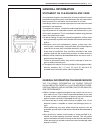

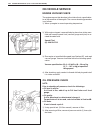

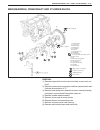

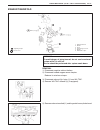

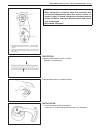

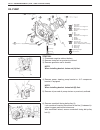

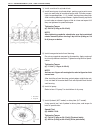

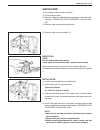

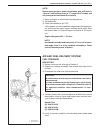

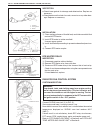

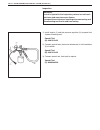

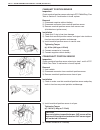

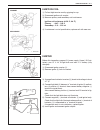

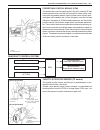

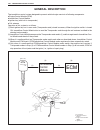

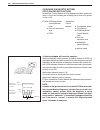

1. Air bag wire harness 2. Driver air bag (inflator) module 3. Passenger air bag (inflator) module 4. Sdm general information 0a-3 precautions precaution for vehicles equipped with a supplemental restraint (air bag) system warning: d the configuration of air bag system parts are as shown in the figu...

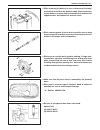

Page 8

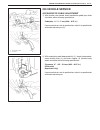

1. Slit on workbench 2. Workbench vise 3. Lower mounting bracket always carry air bag (inflator) module with trim cover (air bag opening) away from body. Always place air bag (inflator) module on workbench with trim cover (air bag opening) up, away from loose objects. 0a-4 general information handli...

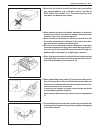

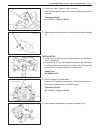

Page 9

General information 0a-5 caution: d even when the accident was light enough not to cause air bags to deploy, be sure to inspect system parts and other related parts according to instructions under “repair and inspection required after an accident” in section 9j. D when servicing parts other than air...

Page 10

0a-6 general information general precautions the warning and caution below describe some general precautions that you should observe when servicing a vehicle. These general precautions apply to many of the service procedures described in this manual, and they will not necessarily be repeated with ea...

Page 11

General information 0a-7 d when removing the battery, be sure to disconnect the nega- tive cable first and then the positive cable. When reconnect- ing the battery, connect the positive cable first and then the negative cable, and replace the terminal cover. D when removing parts that are to be reus...

Page 12

0a-8 general information d when disconnecting vacuum hoses, attach a tag describing the correct installation positions so that the hoses can be re- installed correctly. D after servicing fuel, oil, coolant, vacuum, exhaust or brake systems, check all lines related to the system for leaks. D for vehi...

Page 13

General information 0a-9 d always be careful not to handle electrical parts (computer, relay, etc.) in a rough manner or drop them. Precautions for catalytic converter for vehicles equipped with a catalytic converter, use only un- leaded gasoline and be careful not to let a large amount of un- burne...

Page 14

0a-10 general information d when disconnecting connectors, never pull the wiring har- ness. Unlock the connector lock first and then pull them apart by holding connectors themselves. D when connecting connectors, also hold connectors and put them together until they lock securely (a click is heard)....

Page 15

General information 0a-11 d be careful not to touch the electrical terminals of parts which use microcomputers (e.G. Electronic control unit like as ecm, pcm, p / s controller, etc.). The static electricity from your body can damage these parts. D never connect any tester (voltmeter, ohmmeter, or wh...

Page 16

1. Check for loose connection sensor ecm 0a-12 general information d when checking connection of terminals, check its male half for bend and female half for excessive opening and both for locking (looseness), corrosion, dust, etc. D before measuring voltage to check for electrical system, check to m...

Page 17

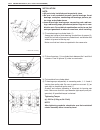

1. Looseness of crimping 2. Open 3. Thin wire (single strand of wire) check contact tension by inserting and removing just for once general information 0a-13 3) using a test male terminal, check both terminals of the circuit be- ing checked for contact tension of its female terminal. Check each term...

Page 18

1. Other parts 1. To other parts 2 v voltage drop 0a-14 general information if measurements were taken as shown in the figure at the left and results were as listed below, it means that the circuit is open be- tween terminals b-1 and a-1. Voltage between: c-1 and body ground: approx. 5 v b-1 and bod...

Page 19

1. Check contact tension by inserting and removing just once 2. Check each terminal for bend and proper alignment general information 0a-15 intermittent and poor connection most intermittent are caused by faulty electrical connections or wir- ing, although a sticking relay or solenoid can occasional...

Page 20

0a-16 general information precaution for installing mobile communication equipment when installing mobile communication equipment such as cb (citi- zens-band)-radio or cellular-telephone, be sure to observe the fol- lowing precautions. Failure to follow cautions may adversely affect electronic contr...

Page 21

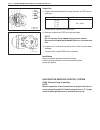

1. Transfer lock bolt 2. Shift fork shaft testing following items d speedometer d chassis dynamo d brake d wheel balance (on car type) towing vehicle with front or rear wheels lifted up driving front wheels which are jacked up 4wd 2wd general information 0a-17 precaution in servicing full-time 4wd v...

Page 22: Identification Information

M / t a / t g10 g13 [a] [a] [b] [b] 0a-18 general information identification information vehicle identification number the number is punched on the front dash panel in the engine room. Identification whether vehicle equipped with wu-twc or not it can be identified by the shape of exhaust manifold (1...

Page 23

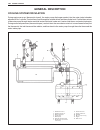

Note: air bag caution / warning labels are attached on the vehicle equipped with air bag system only. Air bag caution label tire information placard child lock caution label fuel limitation emission control information label (if equipped) a / c warning label (if equipped with a / c) engine cooling f...

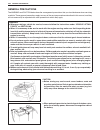

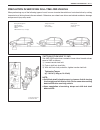

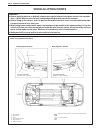

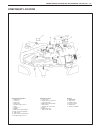

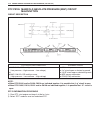

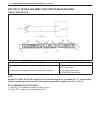

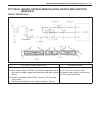

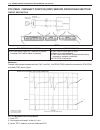

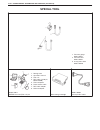

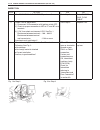

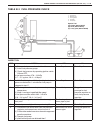

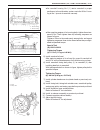

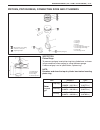

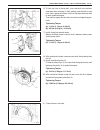

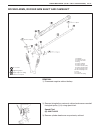

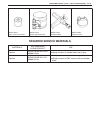

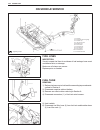

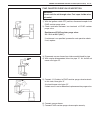

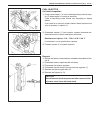

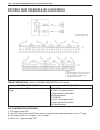

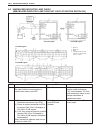

Page 24: Vehicle Lifting Points

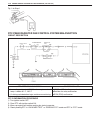

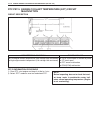

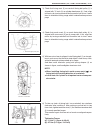

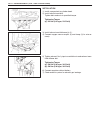

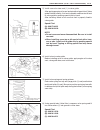

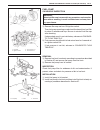

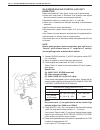

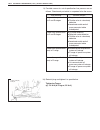

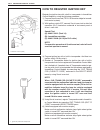

1. Front left tire 2. Rear left tire 3. Front 4. Front fender left panel 5. Rear left panel 6. Embossed-mark when using frame contact hoist: front support location rear support location 110 mm (4.3 in.) support location forward of embossed-mark 120 mm (4.7 in.) support location rearward of embossed-...

Page 25

When using floor jack: general information 0a-21 in raising front or rear vehicle end off the floor by jacking, be sure to put the jack against the center portion of front cross member (1) or rear cross member (2). Warning: d never apply jack against suspension parts (i.E., stabilizer, etc.) or vehi...

Page 26

0a-22 general information a abs : anti-lock brake system atdc : after top dead center api : american petroleum institute atf : automatic transmission fluid alr : automatic locking retractor ac : alternating current a / t : automatic transmission a / c : air conditioning abdc : after bottom dead cent...

Page 27

General information 0a-23 l lh : left hand lspv : load sensing proportioning valve m maf sensor : mass air flow sensor (air flow sensor, afs, air flow meter, afm) map sensor : manifold absolute pressure sensor (pressure sensor, ps) max : maximum mfi : multiport fuel injection (multipoint fuel inject...

Page 28

G (base color) g (base color) y (stripe color) 0a-24 general information symbols symbol definition symbol definition tightening torque apply suzuki bond no. 1216 99000-31160 apply oil (engine, transmission, transfer, differential) apply silicone sealant 99000-31120 apply fluid (brake, power steering...

Page 29: Fasteners Information

General information 0a-25 metric bolts-identification class numbers or marks correspond to bolt strength-increasing numbers represent increasing strength. Nut strength identification fasteners information metric fasteners most of the fasteners used for this vehicle are metric fasteners. When replaci...

Page 30

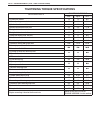

0a-26 general information self-lock nut standard tightening torque each fastener should be tightened to the torque specified in each section of this manual. If no description or specifi- cation is provided, refer to the following tightening torque chart for the applicable torque for each fastener. W...

Page 31: Section 0B

0b maintenance and lubrication 0b-1 section 0b maintenance and lubrication warning: for vehicles equipped with supplemental restraint (air bag) system: d service on and around the air bag system components or wiring must be performed only by an autho- rized suzuki dealer. Refer to “air bag system co...

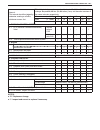

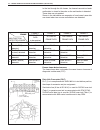

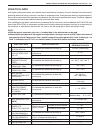

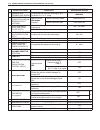

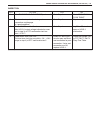

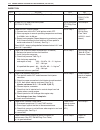

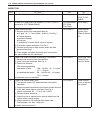

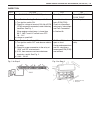

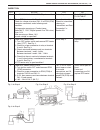

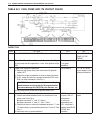

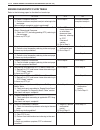

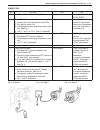

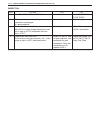

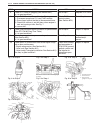

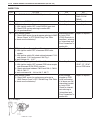

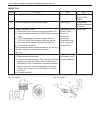

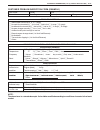

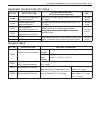

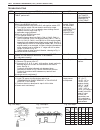

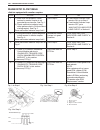

Page 32: Maintenance Schedule

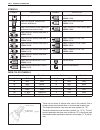

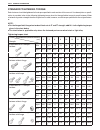

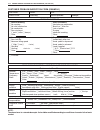

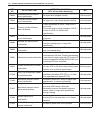

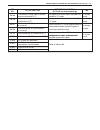

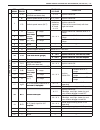

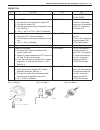

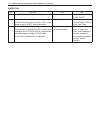

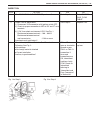

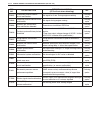

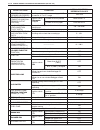

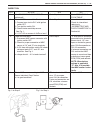

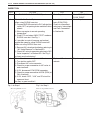

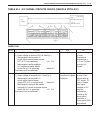

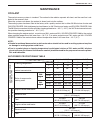

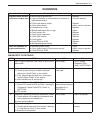

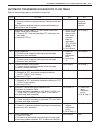

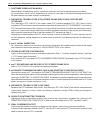

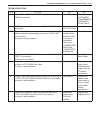

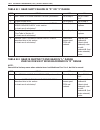

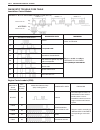

0b-2 maintenance and lubrication maintenance schedule normal condition schedule interval: this interval should be judged by this table includes services as scheduled up to 90,000 km (54,000 miles) mileage. Beyond 90,000 km (54,000 miles), carry out the same services at the same intervals respectivel...

Page 33

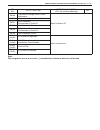

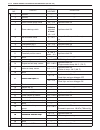

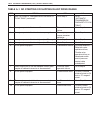

Maintenance and lubrication 0b-3 interval: this interval should be judged by this table includes services as scheduled up to 90,000 km (54,000 miles) mileage. Beyond 90,000 km (54,000 miles), carry out the same services at the same intervals respectively. This interval should be judged by odometer r...

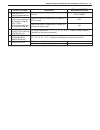

Page 34

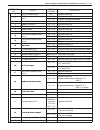

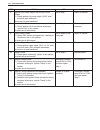

0b-4 maintenance and lubrication maintenance recommended under severe driving conditions if the vehicle is usually used under the conditions corresponding to any severe condition code given below, it is recommended that applicable maintenance operation be performed at the particular interval as give...

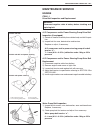

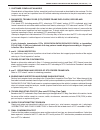

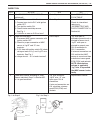

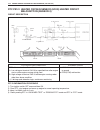

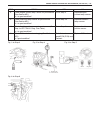

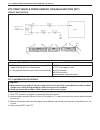

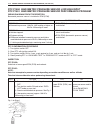

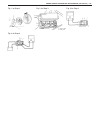

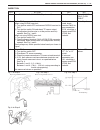

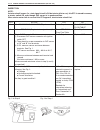

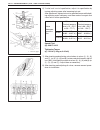

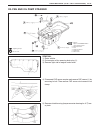

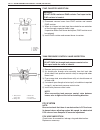

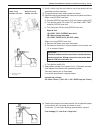

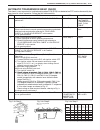

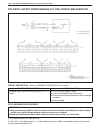

Page 35: Maintenance Service

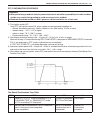

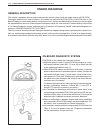

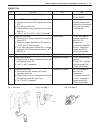

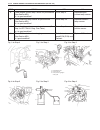

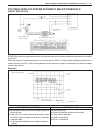

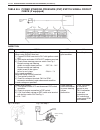

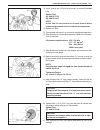

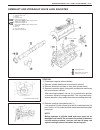

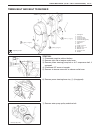

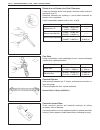

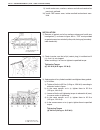

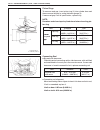

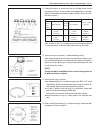

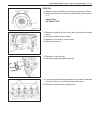

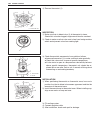

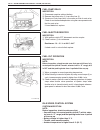

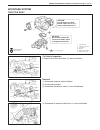

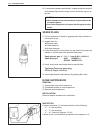

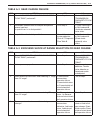

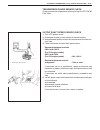

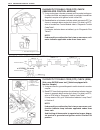

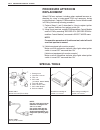

Vehicle with a/c vehicle with a/c and power steering vehicle with power steering 1. A/c compressor pulley 2. Power steering pump pulley 3. Tension pulley 4. Crankshaft pulley maintenance and lubrication 0b-5 maintenance service engine item 1-1 drive belt inspection and replacement warning: disconnec...

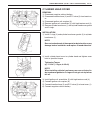

Page 36

1. Thickness gauge in ex 0b-6 maintenance and lubrication water pump belt replacement replace belt with a new one. Refer to section 6b for replacement procedure of pump belt. Note: when replacing belt with a new one, adjust belt tension to 5 – 7 mm (0.20 – 0.27 in.). Item 1-2 camshaft timing belt re...

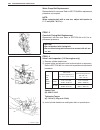

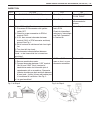

Page 37

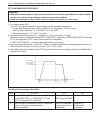

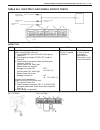

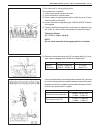

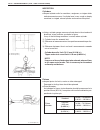

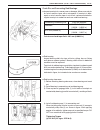

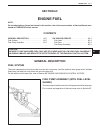

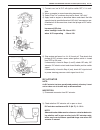

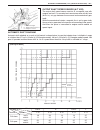

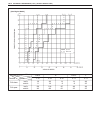

Maintenance and lubrication 0b-7 proper engine oil viscosity chart 1. Oil pan 2. Oil drain plug 1. Oil filter item 1-4 engine oil and filter change warning: new and used engine oil can be hazardous. Be sure to read “warning” in general precaution in sec- tion 0a and observe what in written there. Us...

Page 38

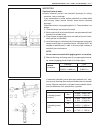

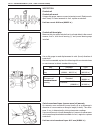

1. Full level mark (hole) 2. Low level mark (hole) oil pan capacity oil filter capacity others total 1.0 l and 1.3 l engine about 3.1 liters (6.5 / 5.5 us / lmp pt.) about 0.2 liter (0.4 / 0.3 us / lmp pt.) about 0.3 liter (0.6 / 0.5 us / lmp pt.) about 3.6 liters (7.5 / 6.3 us / lmp pt.) 0b-8 maint...

Page 39

For a / t for m / t maintenance and lubrication 0b-9 1) remove radiator cap when engine is cool. 2) loosen radiator drain plug (1) to drain coolant. 3) remove reservoir and drain. 4) tighten drain plug securely. Also install reservoir. 5) slowly pour specified amount of coolant to the base of radiat...

Page 40

0b-10 maintenance and lubrication ignition system item 2-1 spark plugs replacement replace spark plugs with new ones referring to section 6f or 6f1. Item 2-2 distributor cap and rotor inspection (if equipped) d check distributor cap and rubber caps for cracks. D clean dusty and stained parts using a...

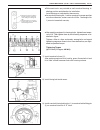

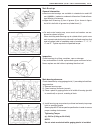

Page 41

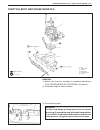

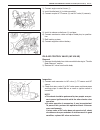

1.0 liter engine 1.3 liter engine maintenance and lubrication 0b-11 2) visually check that air cleaner filter is not excessively dirty, dam- aged or oily. 3) clean filter with compressed air from air outlet side of filter. 4) install air cleaner filter into case. 5) clamp case cap securely and insta...

Page 42

0b-12 maintenance and lubrication emission control system item 4-1 pcv (positive crankcase ventilation) valve inspection check crankcase ventilation hoses and pcv hoses for leaks, cracks or clog, and pcv valve (1) for stick or clog. Refer to on-ve- hicle service of section 6e1 or 6e2 for pcv valve c...

Page 43

Maintenance and lubrication 0b-13 item 5-2 brake hoses and pipes inspection perform this inspection where there is enough light and use a mirror as necessary. D check brake hoses and pipes for proper hook-up, leaks, cracks, chafing, wear, corrosion, bends, twists and other damage. Replace any of the...

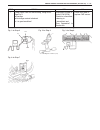

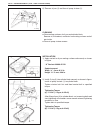

Page 44

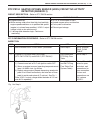

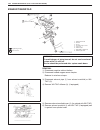

“a”: parking brake lever stroke: 4 – 9 notches (with 20 kg or 44 lbs of pull pressure) 1. Wear indicator 1. Clutch pedal “a”: free travel 0b-14 maintenance and lubrication item 5-4 brake lever and cable inspection parking brake lever d check tooth tip of each notch for damage or wear. If any damage ...

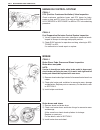

Page 45

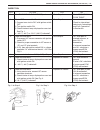

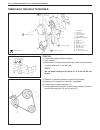

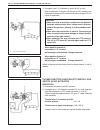

1. Drive shaft 2. Boot maintenance and lubrication 0b-15 [wheel disc inspection] inspect each wheel disc for dents, distortion and cracks. A disc in badly damaged condition must be replaced. [tire rotation] rotate tires referring to section 3f. Wheel bearing inspection 1) check front wheel bearing f...

Page 46

1. Ball joint stud dust seal (boot) 2. Suspension arm 1. Tie-rod end boot 2. Steering gear case boot 3. Universal joint 0b-16 maintenance and lubrication d check front and rear suspension systems for damaged, loose or missing parts; also for parts showing signs of wear or lack of lu- brication. Repa...

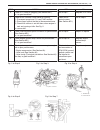

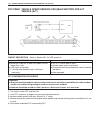

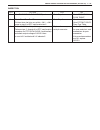

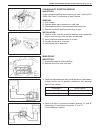

Page 47

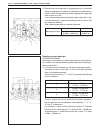

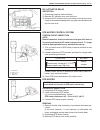

2wd 4wd 1. Oil filler / level plug 2. Oil drain plug maintenance and lubrication 0b-17 item 6-7 manual transmission oil inspection and change [inspection] 1) inspect transmission case for evidence of oil leakage. Repair leaky point if any. 2) make sure that vehicle is placed level for oil level chec...

Page 48

1. Oil level gauge 2. Full hot mark 3. Low hot mark 4. Full cold mark 5. Low cold mark 1. Drain plug 0b-18 maintenance and lubrication item 6-9 automatic transmission [fluid level inspection] 1) inspect transmission case for evidence of fluid leakage. Repair leaky point, if any. 2) make sure that ve...

Page 49

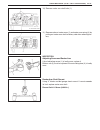

“a”: oil point 1. Upper hinge 2. Lower hinge 3. Door 4. Body maintenance and lubrication 0b-19 item 6-10 all latches, hinges and locks inspection doors check that each door of front, rear and back doors opens and closes smoothly and locks securely when closed. If any malfunction is found, lubricate ...

Page 50

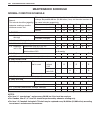

0b-20 maintenance and lubrication final inspection seats check that seat slides smoothly and locks securely at any position. Also check that reclining mechanism of front seat back allows it to be locked at any angle. Seat belt inspect belt system including webbing, buckles, latch plates, retractors ...

Page 51

Maintenance and lubrication 0b-21 [parking brake] check that lever has proper travel. Check to ensure that parking brake is fully effective when the vehicle is stopped on the safe slope and brake lever is pulled all the way. Steering d check to ensure that steering wheel is free from in- stability, ...

Page 52: Section 6

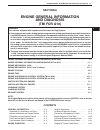

6 engine general information and diagnosis (tbi for g10) 6-1 general information 6- 3 . . . . . . . . . . . . . . Statement on cleanliness and care 6- 3 . . . . . General information on engine service 6- 3 . . Precaution on fuel system service 6- 4 . . . . . Fuel pressure relief procedure 6- 5 . . ....

Page 53

Diagnostic trouble code clearance 6-14 . . . . . Diagnostic trouble code table 6-15 . . . . . . . . . Fail-safe table 6-18 . . . . . . . . . . . . . . . . . . . . . . . Visual inspection 6-19 . . . . . . . . . . . . . . . . . . . . . Engine basic inspection 6-20 . . . . . . . . . . . . . . . Engine ...

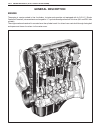

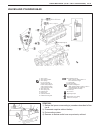

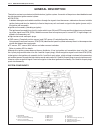

Page 54: General Information

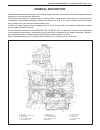

1. No.1 cylinder 2. No.2 cylinder 3. No.3 cylinder 1 2 3 engine general information and diagnosis (tbi for g10) 6-3 general information statement on cleanliness and care an automobile engine is a combination of many machined, honed, polished and lapped surfaces with tolerances that are measured in t...

Page 55

Hose connection clamp securely at a position 3 to 7mm (0.12–0.27 in.) from hose end. With short pipe, fit hose as far as it reaches pipe joint as shown. Hose pipe clamp clamps securely at a position 3 to 7 mm (0.12–0.27 in.) from hose end. With following type pipe, fit hose as far as its peripheral ...

Page 56

Engine general information and diagnosis (tbi for g10) 6-5 fuel pressure relief procedure caution: this work must not be done when engine is hot. If done so, it may cause adverse effect to catalyst. After making sure that engine is cold, release fuel pressure as fol- lows. 1) place transmission gear...

Page 57: Engine Diagnosis

6-6 engine general information and diagnosis (tbi for g10) engine diagnosis general description this vehicle is equipped with an engine and emission control system which are under control of ecm (pcm). The engine and emission control system in this vehicle are controlled by ecm (pcm). Ecm (pcm) has ...

Page 58

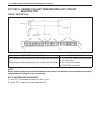

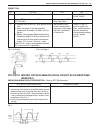

An example of freeze frame data 1. Trouble code p0102 (1st) 2. Engine speed 782 rpm 3. Eng cool tmp. 80 _c 4. Vehicle spd. 0 km/h 5. Map sensor 39 kpa 6. St. Term ft1 – 0.8% lean 7. Lg. Term ft1 – 1.6% lean 8. Fuel 1 stat. Closed loop 9. Fuel 2 stat. Not used 10. Load value 25.5% 1st, 2nd or 3rd in ...

Page 59

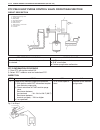

Body ground ecm (pcm) ground serial data line (k line of iso 9141) suzuki serial data line 6-8 engine general information and diagnosis (tbi for g10) in the 2nd through the 4th frames, the freeze frame data of each malfunction is stored in the order as the malfunction is detected. These data are not...

Page 60

Engine general information and diagnosis (tbi for g10) 6-9 precaution in diagnosing trouble d don’t disconnect couplers from ecm (pcm), battery cable from battery, ecm (pcm) ground wire harness from engine or main fuse before confirming diagnostic information (dtc, freeze frame data, etc.) stored in...

Page 61

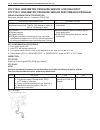

6-10 engine general information and diagnosis (tbi for g10) engine diagnostic flow table refer to the following pages for the details of each step. Step action yes no 1 customer complaint analysis 1) perform customer complaint analysis referring to the next page. Was customer complaint analysis perf...

Page 62

Engine general information and diagnosis (tbi for g10) 6-11 1. Customer complaint analysis record details of the problem (failure, complaint) and how it occurred as described by the customer. For this purpose, use of such an inspection form will facilitate collecting information to the point require...

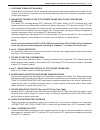

Page 63

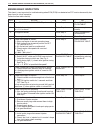

6-12 engine general information and diagnosis (tbi for g10) customer problem inspection form (example) user name: model: vin: date of issue: date reg. Date of problem: mileage: problem symptoms j difficult starting j no cranking j no initial combustion j no combustion j poor starting at ( jcold jwar...

Page 64

Engine general information and diagnosis (tbi for g10) 6-13 malfunction indicator lamp (mil) check 1) turn on ignition switch (but the engine at stop) and check that mil lights. If mil does not light up (or mil dims), go to “diagnostic flow table a-1” for troubleshooting. 2) start engine and check t...

Page 65

6-14 engine general information and diagnosis (tbi for g10) diagnostic trouble code (dtc) clearance 1) connect suzuki scan tool (tech-1) or generic scan tool to data link connector in the same manner as when making this connec- tion for dtc check. 2) turn ignition switch on. 3) erase dtc and pending...

Page 66

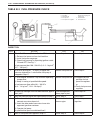

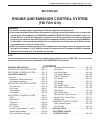

Engine general information and diagnosis (tbi for g10) 6-15 diagnostic trouble code (dtc) table dtc no. Detecting item detecting condition (dtc will set when detecting:) mil p0105 manifold absolute pressure circuit malfunction low pressure-high vacuum-low voltage (or map sensor circuit shorted to gr...

Page 67

6-16 engine general information and diagnosis (tbi for g10) dtc no. Detecting item detecting condition (dtc will set when detecting:) mil p0335 crankshaft position sensor circuit malfunction no signal during engine running 1 driving cycle p0340 camshaft position sensor circuit malfunction no signal ...

Page 68

Engine general information and diagnosis (tbi for g10) 6-17 dtc no. Detecting item detecting condition (dtc will set when detecting:) mil p0705 transmission range sensor (switch) circuit malfunction (a / t) no signal or multiple signals inputted with shifted in “d” range 1 driving cycle p0720 output...

Page 69

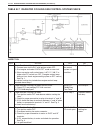

6-18 engine general information and diagnosis (tbi for g10) fail-safe table when any of the following dtcs is detected, ecm (pcm) enters fail-safe mode as long as malfunction continues to exist but that mode is canceled when ecm (pcm) detects normal condition after that. Dtc no. Detected item fail-s...

Page 70

Engine general information and diagnosis (tbi for g10) 6-19 operation visual inspection visually check following parts and systems. Inspection item referring section d engine oil – – – – – level, leakage d engine coolant – – – – – level, leakage d fuel – – – – – level, leakage d a/t fluid – – – – – ...

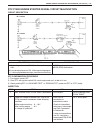

Page 71

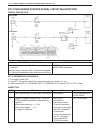

6-20 engine general information and diagnosis (tbi for g10) engine basic inspection this check is very important for troubleshooting when ecm (pcm) has detected no dtc and no abnormality has been found in visual inspection. Follow the flow table carefully. Step action yes no 1 was “engine diag. Flow...

Page 72

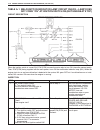

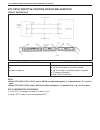

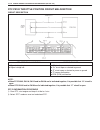

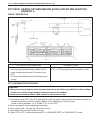

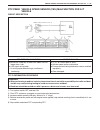

Select “data list” mode select menu f4: misc test engine general information and diagnosis (tbi for g10) 6-21 fig. 1 for step 5 fig. 2 for step 6 fig. 3 for step 6 fig. 4 for step 8 fig. 5 for step 11.

Page 73

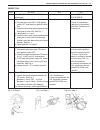

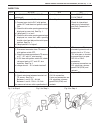

6-22 engine general information and diagnosis (tbi for g10) engine diagnosis table perform troubleshooting referring to following table when ecm (pcm) has detected no dtc and no abnormality has been found in visual inspection and engine basic inspection previously. Condition possible cause referring...

Page 74

Engine general information and diagnosis (tbi for g10) 6-23 condition possible cause referring item low oil pressure d improper oil viscosity d malfunctioning oil pressure switch d clogged oil strainer d functional deterioration of oil pump d worn oil pump relief valve d excessive clearance in vario...

Page 75

6-24 engine general information and diagnosis (tbi for g10) condition possible cause referring item overheating d inoperative thermostat d poor water pump performance d clogged or leaky radiator d improper engine oil grade d clogged oil filter or oil strainer d poor oil pump performance d faulty rad...

Page 76

Engine general information and diagnosis (tbi for g10) 6-25 condition possible cause referring item engine hesitates (momentary lack of response as accelerator is depressed. Can occur at all vehicle speeds. Usually most severe when first trying to make vehicle move, as from a stop sign.) ignition sy...

Page 77

6-26 engine general information and diagnosis (tbi for g10) condition possible cause referring item engine has no power ignition system out of order d faulty spark plug d faulty ignition coil with ignitor d leaks, loose connection or disconnection of high-tension cord engine overheating fuel system ...

Page 78

Engine general information and diagnosis (tbi for g10) 6-27 condition possible cause referring item improper engine idling or engine fails to idle ignition system out of order d faulty spark plug d leaky or disconnected high-tension cord d faulty ignition coil with ignitor fuel system out of order d...

Page 79

6-28 engine general information and diagnosis (tbi for g10) condition possible cause referring item excessive hydrocarbon (hc) emission or carbon monoxide (co) ignition system out of order d faulty spark plug d leaky or disconnected high-tension cord d faulty ignition coil with ignitor low compressi...

Page 80

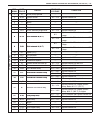

Engine general information and diagnosis (tbi for g10) 6-29 ambient temp. Scan tool data as the data values given below are standard values estimated on the basis of values obtained from the normally operating vehicles by using a scan tool, use them as reference values. Even when the vehicle is in g...

Page 81

6-30 engine general information and diagnosis (tbi for g10) scan tool data condition normal condition / reference values desired idle at idling with no load after warming up, m / t 850 r / min (desired idle speed) g g , at neutral, a / t at “p” range 850 r / min tp sensor volt (throttle position ign...

Page 82

Engine general information and diagnosis (tbi for g10) 6-31 scan tool data condition normal condition / reference values vss (for 4-a / t) (vehicle speed sensor) at stop. 0 km / h 0 mph shift sol1 con (command signal) mon (monitor signal) ignition switch on, selector lever is shifted at p, r or n ra...

Page 83

6-32 engine general information and diagnosis (tbi for g10) scan tool data definitions fuel system (fuel system status) air / fuel ratio feedback loop status displayed as either open or closed loop. Open indicates that ecm (pcm) ignores feedback from the exhaust oxygen sensor. Closed indicates final...

Page 84

Engine general information and diagnosis (tbi for g10) 6-33 canist purge duty (evap canister purge flow duty, %) this parameter indicates valve on (valve open) time rate within a certain set cycle of evap purge solenoid valve which controls the amount of evap purge. 0% means that the purge valve is ...

Page 85

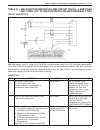

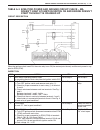

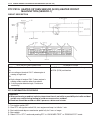

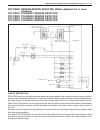

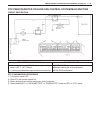

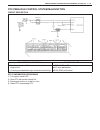

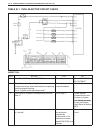

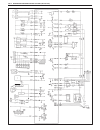

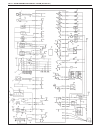

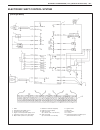

6-34 engine general information and diagnosis (tbi for g10) 1. Ecm (pcm) 2. Ecm (pcm) couplers (viewed from harness side) 1. Ecm (pcm) 2. Couplers 3. Body ground 4. Service wire 16 c03 c02 c01 1 2 1 2 3 4 5 6 7 8 9 10 11 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 9 10 11 12 13 12 13 14 15 16 17 18 19 20 21 22 ...

Page 86

Engine general information and diagnosis (tbi for g10) 6-35 connect or “c02 ” ter- minal wire color circuit standard voltage condition 1 b ecm (pcm) ground – – 2 w / bl power source 10 – 14 v ignition switch on 3 — blank — — 4 — blank — — 5 — blank — — 6 — blank — — 7 r / g evap canister purge valve...

Page 87

6-36 engine general information and diagnosis (tbi for g10) connect or “c01 ” ter- minal wire color circuit standard voltage condition 1 lg power source for sensor 4.75 – 5.25 v ignition switch on 2 or camshaft position sensor (+) — — 3 w / b crankshaft position sensor (+) — — 4 gr / g closed thrott...

Page 88

Engine general information and diagnosis (tbi for g10) 6-37 connect or “c03 ” ter- minal wire color circuit standard voltage condition 1 v / w data link connector (suzuki serial data line) 4 – 6 v ignition switch on bl vehicle speed sensor (+) (a / t) 0.4 – 0.8 v ignition switch on 2 y / g vehicle s...

Page 89

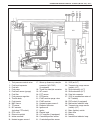

6-38 engine general information and diagnosis (tbi for g10) 1 2 1. Ecm (pcm) coupler disconnected 2. Ohmmeter resistance check 1) disconnect ecm (pcm) couplers from ecm (pcm) with ignition switch off. Caution: never touch terminals of ecm (pcm) itself or connect voltmeter or ohmmeter. 2) check resis...

Page 90

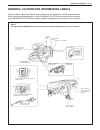

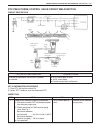

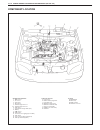

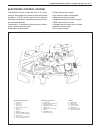

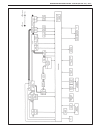

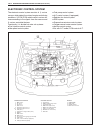

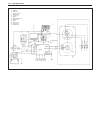

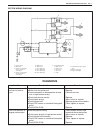

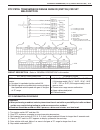

Engine general information and diagnosis (tbi for g10) 6-39 information sensors - 1. Map sensor - 2. Tp sensor - 3. Iat sensor - 4. Ect sensor - 5. Heated oxygen sensor-1 - 6. Vss - 7. Ignition coil - 8. Battery - 9. Cmp sensor (in distributor) - 10. A/c contoller (if equipped) - 11. Ckp sensor - 12...

Page 91

6-40 engine general information and diagnosis (tbi for g10) “ig coil meter” main relay ignition switch in fuse malfunction indicator lamp in combination meter table a-1 malfunction indicator lamp circuit check – lamp does not come “on” at ignition switch on (but engine at stop) circuit description w...

Page 92

Engine general information and diagnosis (tbi for g10) 6-41 table a-2 malfunction indicator lamp circuit check – lamp remains “on” after engine starts wiring diagram / circuit description – refer to table a-1. Inspection step action yes no 1 diagnostic trouble code (dtc) check 1) check dtc referring...

Page 93

Main fuse ignition switch main fuse malfunction indicator lamp in combination meter relay box “ig coil meter” 6-42 engine general information and diagnosis (tbi for g10) table a-3 ecm (pcm) power and ground circuit check – mil doesn’t light at ignition switch on and engine doesn’t start though it is...

Page 94

Engine general information and diagnosis (tbi for g10) 6-43 fig. 1 for step 2 fig. 2 for step 2 fig. 3 for step 2 1. Main relay 2. Relay box step action yes no 5 ecm (pcm) power circuit check 1) using service wire, ground terminal c02-22 and measure voltage between terminal c02-2 and ground at ignit...

Page 95

Map sensor to tp sensor to other sensors 6-44 engine general information and diagnosis (tbi for g10) dtc p0105 manifold absolute pressure (map) circuit malfunction circuit description dtc detecting condition possible cause d map: 5 kpa, 37.5 mmhg or less (low pressure – high vacuums – low voltage) o...

Page 96

Engine general information and diagnosis (tbi for g10) 6-45 fig. 1 for step 2 fig. 2 for step 3 scan tool dlc inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check map sensor and its circuit. 1) connect scan tool to dlc with i...

Page 97

To other sensors iat sensor 6-46 engine general information and diagnosis (tbi for g10) dtc p0110 intake air temp. (iat) circuit malfunction circuit description dtc detecting condition possible cause d low intake air temperature (high voltage-high resistance) or d high intake air temperature (low vo...

Page 98

Engine general information and diagnosis (tbi for g10) 6-47 fig. 1 for step 2 fig. 2 for step 3 fig. 3 for step 4 scan tool dlc inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check iat sensor and its circuit. 1) connect scan ...

Page 99

Ect sensor to combination (ect) meter to other sensors 6-48 engine general information and diagnosis (tbi for g10) dtc p0115 engine coolant temperature (ect) circuit malfunction circuit description dtc detecting condition possible cause d low engine coolant temperature (high voltage-high resistance)...

Page 100

Engine general information and diagnosis (tbi for g10) 6-49 fig. 1 for step 2 fig. 2 for step 3 fig. 3 for step 4 scan tool dlc inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check ect sensor and its circuit. 1) connect scan ...

Page 101

To other sensors throttle position sensor to other sensors 6-50 engine general information and diagnosis (tbi for g10) dtc p0120 throttle position circuit malfunction circuit description dtc detecting condition possible cause d signal voltage high or d signal voltage low d “g” circuit open d “lg/w” ...

Page 102

Engine general information and diagnosis (tbi for g10) 6-51 fig. 1 for step 2 fig. 2 for step 3 fig. 3 for step 4 scan tool “lg” “lg/w” “3” “4” “1” inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check tp sensor and its circui...

Page 103

To other sensors throttle position sensor to other sensors 6-52 engine general information and diagnosis (tbi for g10) dtc p0121 throttle position circuit range/performance problem circuit description dtc detecting condition possible cause d after engine warmed up. D while vehicle running at specifi...

Page 104

Engine general information and diagnosis (tbi for g10) 6-53 fig. 1 for step 2 fig. 2 for step 2 fig. 3 for step 3 closed (condition “a”) fully open throttle opening condition “a” clearance between throttle lever and throttle stop screw is less than 0.35 mm (0.014 in.). Clearance “1” “3” “4” inspecti...

Page 105

To generator to other sensor main fuse ignition switch heater 6-54 engine general information and diagnosis (tbi for g10) dtc p0130 heated oxygen sensor (ho2s) circuit malfunction (sensor-1) circuit description dtc detecting condition possible cause d when running at idle speed after engine warmed u...

Page 106

Engine general information and diagnosis (tbi for g10) 6-55 fig. 1 for step 3 fig. 2 for step 3 normal fig. 1 ho2s-1 output voltage 1 cycle time response time inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 is there dtc(s) oth...

Page 107

6-56 engine general information and diagnosis (tbi for g10) dtc confirmation procedure – refer to dtc p0130 section. Inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 is there dtc(s) other than ho2s-1 (dtc p0133)? Go to applicab...

Page 108

To generator to other sensor heater ignition switch main fuse “ig coil meter” engine general information and diagnosis (tbi for g10) 6-57 dtc p0135 heated oxygen sensor (ho2s) heater circuit malfunction (sensor-1) circuit description dtc detecting condition possible cause dtc will set when a or b co...

Page 109

6-58 engine general information and diagnosis (tbi for g10) fig. 1 for step 2 fig. 2 for step 3 c01-8 inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check heater for operation. 1) check voltage at terminal c01-8. See fig. 1. ...

Page 110

To other sensor heater ignition switch main fuse “ig coil meter” to ignition coil to other sensor engine general information and diagnosis (tbi for g10) 6-59 dtc p0136 heated oxygen sensor (ho2s) circuit malfunction (sensor-2) circuit description dtc detecting condition possible cause dtc will set w...

Page 111

6-60 engine general information and diagnosis (tbi for g10) lusual driving: driving at 30 – 40 mph, 50 – 60 km/h including short stop according to traffic signal. (under driving condition other than high-load, high-engine speed, rapid accelerating and decelerating) 1) 2) 3) 4) 5) 6) 7) 8) 9) 10) 11)...

Page 112

Engine general information and diagnosis (tbi for g10) 6-61 inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check exhaust system for leakage, loose connection and damage. Is it good condition? Go to step 3. Repair or replace. ...

Page 113

6-62 engine general information and diagnosis (tbi for g10) to other sensor heater ignition switch main fuse “ig coil meter” to ignition coil to other sensor dtc p0141 heated oxygen sensor (ho2s) heater circuit malfunction (sensor-2) circuit description dtc detecting condition possible cause dtc wil...

Page 114

Engine general information and diagnosis (tbi for g10) 6-63 fig. 1 for step 2 inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check ho2s-2 heater and its circuit. 1) warm up engine to normal operating temperature. 2) stop engi...

Page 115

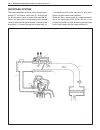

6-64 engine general information and diagnosis (tbi for g10) sensed information exhaust gas fuel injector a / f mixture signal to decrease amount of fuel injection signal to increase amount of fuel injection high voltage low voltage injector heated oxygen sensor-1 a / f mixture becomes richer oxygen ...

Page 116

Engine general information and diagnosis (tbi for g10) 6-65 dtc confirmation procedure warning: d when performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident. D road test should be ca...

Page 117

6-66 engine general information and diagnosis (tbi for g10) inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 is there dtc(s) other than fuel system (dtc p0171 / p0172)? Go to applicable dtc diag. Flow table. Go to step 3. 3 che...

Page 118

Engine general information and diagnosis (tbi for g10) 6-67 fig. 1 for step 3 fig. 2 for step 4 fig. 3 for step 5 fig. 4 for step 6 1. Throttle body 2. Fuel feed hose good no good step action yes no 8 check engine coolant temp. Sensor for performance (see section 6e1). Is it in good condition? Go to...

Page 119

Ignition coil igniter ignition switch main fuse injector resistor fuel injector crankshaft position sensor camshaft position sensor ground at engine “i / g coil meter” main relay 6-68 engine general information and diagnosis (tbi for g10) dtc p0300 random misfire detected (misfire detected at 2 or m...

Page 120

Engine general information and diagnosis (tbi for g10) 6-69 below specified value dtc detecting condition possible cause d engine under other than high revolution condition d not on rough road d engine speed changing rate d manifold absolute pressure changing rate d throttle opening changing rate d ...

Page 121

6-70 engine general information and diagnosis (tbi for g10) inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table“. 2 is there dtc other than fuel system (dtc p0171 / p0172) and misfire (dtc p0300-p0303)? Go to applicable dtc diag. Flow...

Page 122

Engine general information and diagnosis (tbi for g10) 6-71 1. Throttle body 2. Fuel feed hose good no good 1. Injector connector step action yes no 6 check pcv valve for clogging (see section 6e1). Is it in good condition? Go to step 7. Replace pcv valve. 7 check evap canister purge valve for closi...

Page 123

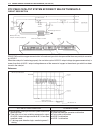

Oscilloscope waveforms crankshaft timing belt pulley ckp sensor 2v/div. 5ms/div. Waveforms at specified idle speed 6-72 engine general information and diagnosis (tbi for g10) dtc p0335 crankshaft position (ckp) sensor circuit malfunction circuit description dtc detecting condition possible cause d n...

Page 124

Engine general information and diagnosis (tbi for g10) 6-73 inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check ckp sensor for resistance. 1) disconnect ckp sensor connector with ignition switch off. 2) then check for proper...

Page 125

Display of fuel injection signal using oscilloscope 1. Cmp sensor signal 2. Fuel injector signal 3. Fuel injection time 2v/div. 20v/div. 1 2 10ms/div waveforms at specified idle speed 3 sensor rotor in distributor camshaft position sensor 6-74 engine general information and diagnosis (tbi for g10) d...

Page 126

Engine general information and diagnosis (tbi for g10) 6-75 fig. 1 for step 3 fig. 2 for step 5 “a”: air gap inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 is dtc p1500 (engine starter signal circuit malfunction) detected? Go...

Page 127

6-76 engine general information and diagnosis (tbi for g10) oscilloscope waveforms engine running at closed loop condition fuel cut idle after fuel cut 0.5 v / div 2 sec. / div heated oxygen sensor-1 warm up three way catalytic converter (if equipped) three way catalytic converter to other sensor to...

Page 128

Engine general information and diagnosis (tbi for g10) 6-77 1) 2) 3) 4) 35 – 45 mph (55 – 65 km / h) 30 – 40 mph (50 – 60 km / h) dtc confirmation procedure warning: d when performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful durin...

Page 129

6-78 engine general information and diagnosis (tbi for g10) inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check short term fuel trim. Did short term fuel trim vary within – 20% – +20% range in step 3) of dtc confirmation tes...

Page 130

Engine general information and diagnosis (tbi for g10) 6-79 main fuse main relay to other valves evap canister purge valve evap canister purge valve surge tank tank pressure control valve fuel vapor separator fuel filter cap fuel level sensor fuel tank evap canister dtc p0443 purge control valve cir...

Page 131

6-80 engine general information and diagnosis (tbi for g10) fig. 1 for step 1 main fuse ignition switch “ig coil meter” radiator fan relay radiator fan motor dtc p0480 radiator fan control system malfunction circuit description dtc detecting condition possible cause d low voltage at terminal c02-20 ...

Page 132

Engine general information and diagnosis (tbi for g10) 6-81 fig. 1 for step 2 fig. 2 for step 3 1. Radiator fan relay 2. Relay box inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check radiator cooling fan relay and its circui...

Page 133

6-82 engine general information and diagnosis (tbi for g10) vehicle speed sensor in combination meter c03-2 c03-2 dtc p0500 vehicle speed sensor (vss) malfunction (m/t) circuit description dtc detecting condition possible cause d vss signal not inputted while vehicle running in “d” range or during f...

Page 134

Engine general information and diagnosis (tbi for g10) 6-83 fig. 1 for step 3 fig. 2 for step 4 c03-2 inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 does speedometer indicate vehicle speed? Go to step 3. Speedometer cable dis...

Page 135

6-84 engine general information and diagnosis (tbi for g10) vehicle speed sensor (on a / t) counter shaft gear pcm c03-2 c03-13 bl p c03-2 c03-13 dtc p0500 vehicle speed sensor (vss) malfunction for a/t vehicle (a/t) circuit description – refer to section 6e1 for vss operation. Dtc detecting conditi...

Page 136

Engine general information and diagnosis (tbi for g10) 6-85 fig. 1 for step 2 fig. 2 for step 3 inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check vss for resistance. 1) disconnect vss connection with ignition switch off. 2...

Page 137

Main fuse main relay idle speed control relay to tp sensor idle speed control actuator 6-86 engine general information and diagnosis (tbi for g10) dtc p0505 idle control system malfunction circuit description dtc detecting condition possible cause dtc will set when a, b or c condition is met. A: thr...

Page 138

Engine general information and diagnosis (tbi for g10) 6-87 fig. 1 for step 3 fig. 2 for step 3 fig. 3 for step 3 1. Isca relay 2. Relay box dtc p0505 inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check idle control system. ...

Page 139

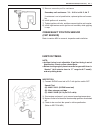

6-88 engine general information and diagnosis (tbi for g10) fig. 1 for step 2 fig. 2 for step 3 lever is apart from plunger lever contacts with plunger condition “a”: throttle lever is in contact with isc actuator plunger condition “b”: throttle lever is apart from plunger dtc p0510 closed throttle ...

Page 140

Engine general information and diagnosis (tbi for g10) 6-89 dtc p0601 internal control module memory check sum error dtc detecting condition possible cause dtc p0601: data write error (or check sum error) when written into ecm (pcm) : 2 driving cycle detection logic, continuous monitoring. Ecm (pcm)...

Page 141

Main fuse main relay efe heater efe heater relay 6-90 engine general information and diagnosis (tbi for g10) dtc p1250 early fuel evaporation (efe) heater circuit malfunction circuit description dtc detecting condition possible cause d voltage low at terminal c01-12 during engine warming up or d vol...

Page 142

Engine general information and diagnosis (tbi for g10) 6-91 1. Relay box 2. “ptc” inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check efe heater and its circuit. Check for voltage at terminal c01-12 of ecm (pcm) connector co...

Page 143

6-92 engine general information and diagnosis (tbi for g10) fig. 1 for step 1 dtc p1450 barometric pressure sensor low/high input dtc p1451 barometric pressure sensor performance problem wiring diagram / circuit description barometric pressure sensor is installed in ecm (pcm). Dtc detecting conditio...

Page 144

Main fuse m / t vehicle ignition switch (starter switch) starter a / t vehicle main fuse ignition switch (starter switch) transmission range sensor (switch) starter pcm engine general information and diagnosis (tbi for g10) 6-93 dtc p1500 engine starter signal circuit malfunction circuit description...

Page 145

To dlc “dome” main fuse 6-94 engine general information and diagnosis (tbi for g10) dtc p1510 ecm (pcm) back-up power supply malfunction circuit description battery voltage is supplied so that diagnostic trouble code memory, values for engine control learned by ecm (pcm), etc. Are kept in ecm (pcm) ...

Page 146: Blank

Engine general information and diagnosis (tbi for g10) 6-95 blank.

Page 147

“ig coil meter” main fuse ignition switch main relay to other circuits injector resistor fuel injector 6-96 engine general information and diagnosis (tbi for g10) table b-1 fuel injector circuit check inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engin...

Page 148

Engine general information and diagnosis (tbi for g10) 6-97 step action yes no 6 check injector resistor for resistance. 1) disconnect resistor connector with ignition switch off. 2) check for proper connection to resistor at each terminals. 3) if connection is ok, check resistance. Is resistance 1....

Page 149

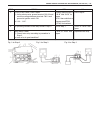

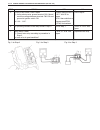

6-98 engine general information and diagnosis (tbi for g10) main fuse ignition switch to other circuits main relay fuel pump relay fuel pump caution: check to make sure that connection is made between correct terminals. Wrong connection can cause damage to ecm (pcm), wire harness, etc. Table b-2 fue...

Page 150

Engine general information and diagnosis (tbi for g10) 6-99 fig. 1 for step 2 fig. 2 for step 3 1. Service wire 2. Relay box fig. 3 for step 4 fig. 4 for step 4.

Page 151

1. Fuel pump 2. Fuel filter 3. Throttle body 4. Fuel injector 5. Fuel pressure regulator 6. Special tool (fuel pressure gauge & 3-way joint) 7. Fuel feed line 8. Fuel return line 6-100 engine general information and diagnosis (tbi for g10) table b-3 fuel pressure check inspection step action yes no ...

Page 152

Engine general information and diagnosis (tbi for g10) 6-101 fig. 1 for step 1 1. Fuel pressure gauge & 3way joint step action yes no 8 with fuel pump operated and fuel return hose blocked by pinching it, is fuel pressure applied? Faulty fuel pressure regulator. Shortage of fuel or fuel pump or its ...

Page 153

A / c amplifier (a / c on output signal) (a / c input signal) 6-102 engine general information and diagnosis (tbi for g10) table b-4 a/c signal circuits check (vehicle with a/c) inspection step action yes no 1 check a / c (input) signal circuit. 1) check voltage at terminal c03-19. While engine runn...

Page 154

Power steering pressure switch engine general information and diagnosis (tbi for g10) 6-103 table b-5 power steering pressure (psp) switch signal circuit check (if equipped) inspection step action yes no 1 check psp switch signal circuit. 1) connect suzuki scan tool to dlc with ignition switch off. ...

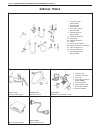

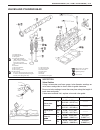

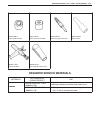

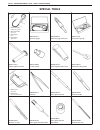

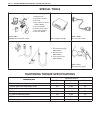

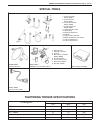

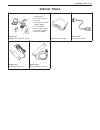

Page 155: Special Tool

6-104 engine general information and diagnosis (tbi for g10) 09931-76011 suzuki scan tool (tech 1 a) kit 1. Storage case 2. Operator’s manual 3. Tech 1 a 4. Dlc cable (14 / 26 pin, 09931-76040) 5. Test lead / probe 6. Power source cable 7. Dlc cable adaptor 8. Self-test adaptor - 1. Pressure gauge 0...

Page 156: Section 6

Engine general information and diagnosis (tbi for g13) 6-1 section 6 engine general information and diagnosis (tbi for g13) note: for the details of this section, refer to same section of the service manual mentioned in the foreword of this manual..

Page 157: Section 6-1

6-1 engine general information and diagnosis (sfi for g13) 6-1-1 general information 6-1- 3 . . . . . . . . . . . . . . Engine diagnosis 6-1- 6 . . . . . . . . . . . . . . . . . . . General description 6-1- 6 . . . . . . . . . . . . . . . . . . . On-board diagnostic system 6-1- 6 . . . . . . . . . ....

Page 158

6-1-2 engine general information and diagnosis (sfi for g13) dtc p0300 random misfire detected 6-1- 69 . . . . . . . . . . . . . . . . . . . . . . . . . . Dtc p0301 cylinder 1 misfire detected 6-1- 69 . . . . . . . . . . . . . . . . . . . . . . . . . . Dtc p0302 cylinder 2 misfire detected 6-1- 69 ....

Page 159: General Information

Engine general information and diagnosis (sfi for g13) 6-1-3 general information statement on cleanliness and care an automobile engine is a combination of many machined, honed, polished and lapped surfaces with tolerances that are measured in the thousands of an millimeter (ten thousands of an inch...

Page 160

Hose connection clamp securely at a position 3 to 7mm (0.12–0.27 in.) from hose end. With short pipe, fit hose as far as it reaches pipe joint as shown. Hose pipe clamp clamps securely at a position 3 to 7 mm (0.12–0.27 in.) from hose end. With following type pipe, fit hose as far as its peripheral ...

Page 161

Engine general information and diagnosis (sfi for g13) 6-1-5 fuel pressure relief procedure caution: this work must not be done when engine is hot. If done so, it may cause adverse effect to catalyst. After making sure that engine is cold, release fuel pressure as fol- lows. 1) place transmission ge...

Page 162: Engine Diagnosis

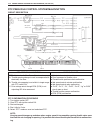

6-1-6 engine general information and diagnosis (sfi for g13) engine diagnosis general description this vehicle is equipped with an engine and emission control system which are under control of ecm (pcm). The engine and emission control system in this vehicle are controlled by ecm (pcm). Ecm (pcm) ha...

Page 163

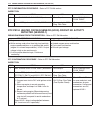

An example of freeze frame data 1. Trouble code p0102 (1st) 2. Engine speed 782 rpm 3. Eng cool tmp. 80 _c 4. Vehicle spd. 0 km/h 5. Map sensor 39 kpa 6. St. Term ft1 – 0.8% lean 7. Lg. Term ft1 – 1.6% lean 8. Fuel 1 stat. Closed loop 9. Fuel 2 stat. Not used 10. Load value 25.5% 1st, 2nd or 3rd in ...

Page 164

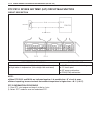

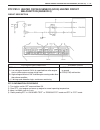

B+ body ground ecm (pcm) ground serial data line (k line of iso 9141) 6-1-8 engine general information and diagnosis (sfi for g13) in the 2nd through the 4th frames, the freeze frame data of each malfunction is stored in the order as the malfunction is detected. These data are not updated. Shown in ...

Page 165

Engine general information and diagnosis (sfi for g13) 6-1-9 precaution in diagnosing trouble d don’t disconnect couplers from ecm (pcm), battery cable from battery, ecm (pcm) ground wire harness from engine or main fuse before confirming diagnostic information (dtc, freeze frame data, etc.) stored ...

Page 166

6-1-10 engine general information and diagnosis (sfi for g13) engine diagnostic flow table refer to the following pages for the details of each step. Step action yes no 1 customer complaint analysis 1) perform customer complaint analysis referring to the next page. Was customer complaint analysis pe...

Page 167

Engine general information and diagnosis (sfi for g13) 6-1-11 1. Customer complaint analysis record details of the problem (failure, complaint) and how it occurred as described by the customer. For this purpose, use of such an inspection form will facilitate collecting information to the point requi...

Page 168

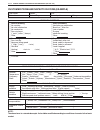

6-1-12 engine general information and diagnosis (sfi for g13) customer problem inspection form (example) user name: model: vin: date of issue: date of reg. Date of problem: mileage: problem symptoms j difficult starting j no cranking j no initial combustion j no combustion j poor starting at ( jcold...

Page 169

Engine general information and diagnosis (sfi for g13) 6-1-13 malfunction indicator lamp (mil) check 1) turn on ignition switch (but the engine at stop) and check that mil lights. If mil does not light up (or mil dims), go to “diagnostic flow table a-1” for troubleshooting. 2) start engine and check...

Page 170

6-1-14 engine general information and diagnosis (sfi for g13) diagnostic trouble code (dtc) clearance [using suzuki scan tool] 1) connect suzuki scan tool (tech-1) to data link connector in the same manner as when making this connection for dtc check. 2) turn ignition switch on. 3) erase dtc and pen...

Page 171

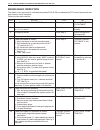

Engine general information and diagnosis (sfi for g13) 6-1-15 diagnostic trouble code (dtc) table note: 1 driving cycle: mil lights up when dtc is detected in the first driving cycle. 2 driving cycles: mil lights up when the same dtc is detected also in the next driving cycle after dtc is detected a...

Page 172

6-1-16 engine general information and diagnosis (sfi for g13) dtc no. Detecting item detecting condition (dtc will set when detecting:) mil p0335 crankshaft position sensor circuit malfunction no signal for 2 sec. During engine cranking 1 driving cycle p0340 camshaft position sensor circuit malfunct...

Page 173

Engine general information and diagnosis (sfi for g13) 6-1-17 dtc no. Detecting item detecting condition (dtc will set when detecting:) mil p0705 transmission range sensor circuit malfunction p0720 output speed sensor circuit malfunction p0751 shift solenoid a performance or stuck off refer to secti...

Page 174

6-1-18 engine general information and diagnosis (sfi for g13) fail-safe table when any of the following dtcs is detected, ecm (pcm) enters fail-safe mode as long as malfunction continues to exist but that mode is canceled when ecm (pcm) detects normal condition after that. Dtc no. Detected item fail...

Page 175

Engine general information and diagnosis (sfi for g13) 6-1-19 operation visual inspection visually check following parts and systems. Inspection item referring section d engine oil – – – – – level, leakage d engine coolant – – – – – level, leakage d fuel – – – – – level, leakage d a/t fluid – – – – ...

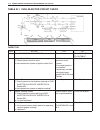

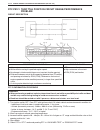

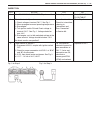

Page 176

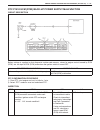

6-1-20 engine general information and diagnosis (sfi for g13) engine basic inspection this check is very important for troubleshooting when ecm (pcm) has detected no dtc and no abnormality has been found in visual inspection. Follow the flow table carefully. Step action yes no 1 was “engine diag. Fl...

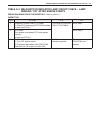

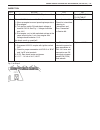

Page 177

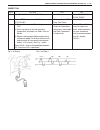

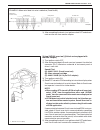

Select “data list” mode select menu f4: misc test when using suzuki scan tool engine general information and diagnosis (sfi for g13) 6-1-21 fig. 1 for step 5 fig. 2 for step 6 fig. 3 for step 6 fig. 4 for step 7 fig. 5 for step 10

Page 178

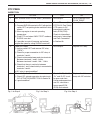

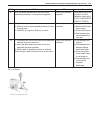

6-1-22 engine general information and diagnosis (sfi for g13) engine diagnosis table perform troubleshooting referring to following table when ecm (pcm) has detected no dtc and no abnormality has been found in visual inspection and engine basic inspection previously. Condition possible cause referri...

Page 179

Engine general information and diagnosis (sfi for g13) 6-1-23 condition possible cause] referring item low oil pressure d improper oil viscosity d malfunctioning oil pressure switch d clogged oil strainer d functional deterioration of oil pump d worn oil pump relief valve d excessive clearance in va...

Page 180

6-1-24 engine general information and diagnosis (sfi for g13) condition possible cause referring item overheating d inoperative thermostat d poor water pump performance d clogged or leaky radiator d improper engine oil grade d clogged oil filter or oil strainer d poor oil pump performance d faulty r...

Page 181

Engine general information and diagnosis (sfi for g13) 6-1-25 condition possible cause referring item engine hesitates (momentary lack of response as accelerator is depressed. Can occur at all vehicle speeds. Usually most severe when first trying to make vehicle move, as from a stop sign.) ignition ...

Page 182

6-1-26 engine general information and diagnosis (sfi for g13) condition possible cause referring item engine has no power ignition system out of order d faulty spark plug d faulty ignition coil with ignitor d leaks, loose connection or disconnection of high-tension cord engine overheating fuel syste...

Page 183

Engine general information and diagnosis (sfi for g13) 6-1-27 condition possible cause referring item improper engine idling or engine fails to idle ignition system out of order d faulty spark plug d leaky or disconnected high-tension cord d faulty ignition coil with ignitor fuel system out of order...

Page 184

6-1-28 engine general information and diagnosis (sfi for g13) condition possible cause referring item excessive hydrocarbon (hc) emission or carbon monoxide (co) ignition system out of order d faulty spark plug d leaky or disconnected high-tension cord d faulty ignition coil with ignitor low compres...

Page 185

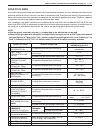

Engine general information and diagnosis (sfi for g13) 6-1-29 scan tool data as the data values given below are standard values estimated on the basis of values obtained from the normally operating vehicles by using a scan tool, use them as reference values. Even when the vehicle is in good conditio...

Page 186

6-1-30 engine general information and diagnosis (sfi for g13) scan tool data condition normal condition / reference values desired idle (desired idle speed) at idling with no load after warming up, m / t at neutral, a / t at “p” range 750 r / min tp sensor volt (throttle position ignition switch on ...

Page 187

Engine general information and diagnosis (sfi for g13) 6-1-31 scan tool data definitions fuel system (fuel system status) air / fuel ratio feedback loop status displayed as either open or closed loop. Open indicates that ecm (pcm) ignores feedback from the exhaust oxygen sensor. Closed indicates fin...

Page 188

6-1-32 engine general information and diagnosis (sfi for g13) canist purge duty (evap canister purge flow duty, %) this parameter indicates valve on (valve open) time rate within a certain set cycle of evap purge solenoid valve which controls the amount of evap purge. 0% means that the purge valve i...

Page 189

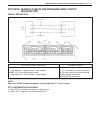

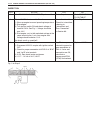

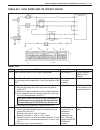

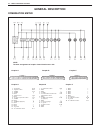

Engine general information and diagnosis (sfi for g13) 6-1-33 1. Ecm (pcm) 2. Ecm (pcm) couplers (viewed from harness side) inspection of ecm (pcm) and its circuits ecm (pcm) and its circuits can be checked at ecm (pcm) wiring couplers by measuring voltage and resistance. Caution: ecm (pcm) cannot b...

Page 190

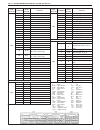

6-1-34 engine general information and diagnosis (sfi for g13) connect or “c01 ” terminal no. Circuit normal voltage condition 1 ground — — 2 ground — — 3 ground — — 4 evap canister purge valve 10 – 14 v ignition switch on indication deflection 5 power steering switch deflection repeated 0 v and igni...

Page 191

Engine general information and diagnosis (sfi for g13) 6-1-35 connect or “c02 ” terminal no. Circuit normal voltage condition 1 a / c on output signal 0 v ignition switch on 2 egr valve (stepper motor 10 – 14 v ignition switch on 2 coil 1) 0 – 1 v engine running at idle speed 3 data link connector 1...

Page 192

6-1-36 engine general information and diagnosis (sfi for g13) connect or “c03 ” terminal no. Circuit normal voltage condition 1 malfunction indicator lamp 0 – 1 v ignition switch on 1 malfunction indicator lamp 10 – 14 v when engine running 2 vehicle speed sensor (m / t) indicator deflection repeate...

Page 193

1 2 1. Ecm (pcm) coupler disconnected 2. Ohmmeter engine general information and diagnosis (sfi for g13) 6-1-37 resistance check 1) disconnect ecm (pcm) couplers from ecm (pcm) with ignition switch off. Caution: never touch terminals of ecm (pcm) itself or connect voltmeter or ohmmeter. 2) check res...

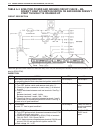

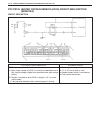

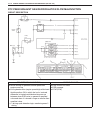

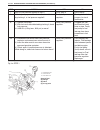

Page 194

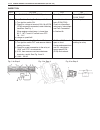

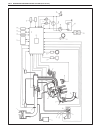

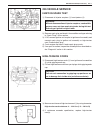

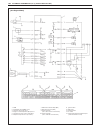

Information sensors - 1. Map sensor - 2. Tp sensor - 3. Iat sensor - 4. Ect sensor - 5. Heated oxygen sensor-1 5-1. Heated oxygen sensor-2 - 6. Vss (a / t) - 7. Transmission range switch (a / t) - 8. Battery - 9. Cmp sensor - 10. Ckp sensor - 11. Fuel level sensor (gauge) (in fuel tank) - 12. Psp sw...

Page 195

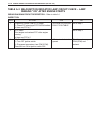

Main fuse ignition switch main relay malfunction indicator lamp in combination meter relay box fuse box c01-1 c01-2 c01-3 engine general information and diagnosis (sfi for g13) 6-1-39 table a-1 malfunction indicator lamp circuit check – lamp does not come “on” at ignition switch on (but engine at st...

Page 196

6-1-40 engine general information and diagnosis (sfi for g13) table a-2 malfunction indicator lamp circuit check – lamp remains “on” after engine starts wiring diagram / circuit description – refer to table a-1. Inspection step action yes no 1 diagnostic trouble code (dtc) check 1) check dtc referri...

Page 197

Main fuse ignition switch main relay malfunction indicator lamp in combination meter relay box fuse box engine general information and diagnosis (sfi for g13) 6-1-41 table a-3 ecm (pcm) power and ground circuit check – mil doesn’t light at ignition switch on and engine doesn’t start though it is cra...

Page 198

6-1-42 engine general information and diagnosis (sfi for g13) fig. 1 for step 2 fig. 2 for step 2 fig. 3 for step 2 step action yes no 5 ecm (pcm) power circuit check 1) using service wire, ground terminal c02-10 and measure voltage between terminal c02-5 / 6 and ground at ignition switch on. Is it ...

Page 199

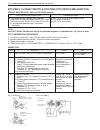

Map sensor to other sensors to tp sensor engine general information and diagnosis (sfi for g13) 6-1-43 dtc p0105 manifold absolute pressure (map) circuit malfunction circuit description dtc detecting condition possible cause d map: 4.9 kpa, 37 mmhg or less (low pressure – high vacuums – low voltage)...

Page 200

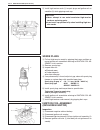

6-1-44 engine general information and diagnosis (sfi for g13) map sensor individual check 1) disconnect coupler from map sensor (1). 2) remove map sensor (1). 3) arrange 3 new 1.5 v batteries (2) in series (check that total volt- age is 4.5 – 5.0 v) and connect its positive terminal to “vin” termi- ...

Page 201

Engine general information and diagnosis (sfi for g13) 6-1-45 fig. 1 for step 2 fig. 2 for step 3 inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check map sensor and its circuit. 1) connect scan tool to dlc with ignition swit...

Page 202

6-1-46 engine general information and diagnosis (sfi for g13) iat sensor to other sensors dtc p0110 intake air temp. (iat) circuit malfunction circuit description dtc detecting condition possible cause d low intake air temperature (high voltage-high resistance) d high intake air temperature (low vol...

Page 203

Engine general information and diagnosis (sfi for g13) 6-1-47 fig. 1 for step 2 fig. 2 for step 3 fig. 3 for step 4 inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check iat sensor and its circuit. 1) connect scan tool to dlc ...

Page 204

6-1-48 engine general information and diagnosis (sfi for g13) to combination (ect) meter to other sensors note: before inspecting, be sure to check that cool- ant temp. Meter in combination meter indi- cates normal operating temperature (engine is not overheating). Dtc p0115 engine coolant temperatu...

Page 205

Engine general information and diagnosis (sfi for g13) 6-1-49 fig. 1 for step 2 fig. 2 for step 5 fig. 3 for step 6 inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check ect sensor and its circuit. 1) connect scan tool with ig...

Page 206

Throttle position sensor to map sensor to other sensors 6-1-50 engine general information and diagnosis (sfi for g13) dtc p0120 throttle position circuit malfunction circuit description dtc detecting condition possible cause d signal voltage high d signal voltage low d “g” circuit open d “gr” circui...

Page 207

Engine general information and diagnosis (sfi for g13) 6-1-51 fig. 1 for step 2 fig. 2 for step 3 fig. 3 for step 4 inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check tp sensor and its circuit. 1) connect scan tool to dlc w...

Page 208

6-1-52 engine general information and diagnosis (sfi for g13) throttle position sensor to other sensors to other sensors dtc p0121 throttle position circuit range/performance problem circuit description dtc detecting condition possible cause d after engine warmed up. D while vehicle running at speci...

Page 209

Engine general information and diagnosis (sfi for g13) 6-1-53 fig. 1 for step 2 fig. 2 for step 2 fig. 3 for step 2 fig. 4 for step 3 closed (condition “a”) fully open throttle opening when using suzuki scan tool: when not using suzuki scan tool: inspection step action yes no 1 was “engine diag. Flo...

Page 210

6-1-54 engine general information and diagnosis (sfi for g13) ignition switch main fuse to ho2s-2 heater to other sensor heater fuse box dtc p0130 heated oxygen sensor (ho2s) circuit malfunction (sensor-1) circuit description dtc detecting condition possible cause d when running at idle speed after ...

Page 211

Engine general information and diagnosis (sfi for g13) 6-1-55 fig. 1 for step 3 fig. 2 for step 3 normal inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 is there dtc(s) other than ho2s-1 (dtc p0130)? Go to applicable dtc diag....

Page 212

6-1-56 engine general information and diagnosis (sfi for g13) fig. 1 ho2s-1 output voltage 1 cycle time response time dtc p0133 heated oxygen sensor (ho2s) circuit slow response (sensor-1) wiring diagram / circuit description – refer to dtc p0130 section. Dtc detecting condition possible cause d whe...

Page 213

Engine general information and diagnosis (sfi for g13) 6-1-57 fig. 1 for step 3 dtc p0134 heated oxygen sensor (ho2s) circuit no activity detected (sensor-1) circuit description – refer to dtc p0130 section. Dtc detecting condition possible cause d engine warmed up. D while running under other than ...

Page 214

Ignition switch main fuse to ho2s-2 heater to other sensor heater fuse box 6-1-58 engine general information and diagnosis (sfi for g13) dtc p0135 heated oxygen sensor (ho2s) heater circuit malfunction (sensor-1) circuit description dtc detecting condition possible cause dtc will set when a or b con...

Page 215

Engine general information and diagnosis (sfi for g13) 6-1-59 fig. 1 for step 2 fig. 2 for step 3 inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go t o“engine diag. Flow table”. 2 check heater for operation. 1) check voltage at terminal c01-7. See fig. 1. 2) w...

Page 216

6-1-60 engine general information and diagnosis (sfi for g13) to other sensor main fuse ignition switch heater to ho2s-1 heater dtc p0136 heated oxygen sensor (ho2s) circuit malfunction (sensor-2) circuit description dtc detecting condition possible cause dtc will set when a or b condition is detect...

Page 217

Engine general information and diagnosis (sfi for g13) 6-1-61 lusual driving: driving at 30 – 40 mph, 50 – 60 km/h including short stop according to traffic signal. (under driving condition other than high-load, high-engine speed, rapid accelerating and decelerating) 1) 2) 3) 4) 5) 6) 7) 8) 9) 10) 1...

Page 218

6-1-62 engine general information and diagnosis (sfi for g13) inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check exhaust system for leakage, loose connection and damage. Is it good condition? Go to step 3. Repair or replace...

Page 219

Engine general information and diagnosis (sfi for g13) 6-1-63 to other sensor main fuse ignition switch heater to ho2s-1 heater dtc p0141 heated oxygen sensor (ho2s) heater circuit malfunction (sensor-2) circuit description dtc detecting condition possible cause dtc will set when a or b condition it...

Page 220

6-1-64 engine general information and diagnosis (sfi for g13) fig. 1 for step 2 inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check ho2s-2 heater and its circuit. 1) warm up engine to normal operating temperature. 2) stop en...

Page 221

Engine general information and diagnosis (sfi for g13) 6-1-65 ignition switch main fuse main relay to ignition switch to other sensor relay box no.1 injector no.2 injector no.3 injector no.4 injector fuse box signal to decrease amount of fuel injection signal to increase amount of fuel injection hig...

Page 222

6-1-66 engine general information and diagnosis (sfi for g13) dtc confirmation procedure warning: d when performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident. D road test should be ...

Page 223

Engine general information and diagnosis (sfi for g13) 6-1-67 inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 is there dtc(s) other than fuel system (dtc p0171 / p0172)? Go to applicable dtc diag. Flow table. Go to step 3. 3 c...

Page 224

6-1-68 engine general information and diagnosis (sfi for g13) fig. 1 for step 3 fig. 2 for step 4 fig. 3 for step 5 fig. 4 for step 5 fig. 5 for step 5 fig. 6 for step 6 1. Fuel delivery pipe 2. Fuel feed hose 3. Fuel pressure gauge & 3 way joint step action yes no 8 check engine coolant temp. Senso...

Page 225

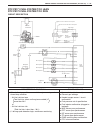

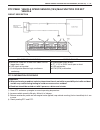

Engine general information and diagnosis (sfi for g13) 6-1-69 ignition coil assembly for no.1 & no.4 spark plugs ignition coil assembly for no.2 & no.3 spark plugs ignition switch main relay main fuse relay box to ignition switch ckp sensor cmp sensor no.1 injector no.2 injector no.3 injector no.4 i...

Page 226

Below specified value 6-1-70 engine general information and diagnosis (sfi for g13) 1. Ckp sensor signal 2. No.1 fuel injector signal 3. No.3 fuel injector signal 4. Fuel injection time display of fuel injection signal using oscilloscope waveforms at specified idle speed 5ms/div dtc detecting condit...

Page 227

Engine general information and diagnosis (sfi for g13) 6-1-71 inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table“. 2 is there dtc other than fuel system (dtc p0171 / p0172) and misfire (dtc p0300-p0304)? Go to applicable dtc diag. Fl...

Page 228

6-1-72 engine general information and diagnosis (sfi for g13) disconnect connectors when checking plugs for spark 1. Fuel delivery pipe 2. Fuel feed hose 3. Fuel pressure gauge & 3 way joint step action yes no 6 check pcv valve for clogging (see section 6e2). Is it in good condition? Go to step 7. R...

Page 229

Engine general information and diagnosis (sfi for g13) 6-1-73 crankshaft timing belt pulley ckp sensor oscilloscope waveforms waveforms at engine cranking (260 r/min) waveforms at specified idle speed 16 waives for 10 _ signals 13 waives for 10 _ signals 30 _ signal 30 _ signal 0.5 v / div. 10 ms / ...

Page 230

6-1-74 engine general information and diagnosis (sfi for g13) inspection note: if starter circuit is open (i.E., start signal circuit is ok but starter fails to run), this dtc is stored in memory at starter switch on, even though ckp sensor is in good condition. When starter motor fails to run and t...

Page 231

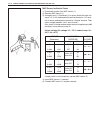

Engine general information and diagnosis (sfi for g13) 6-1-75 to ignition switch signal rotor on camshaft camshaft position sensor waveforms at specified idle speed oscilloscope waveforms 2 v / div. Crank angle 20 ms / div. 180 _ 720 _ dtc p0340 camshaft position (cmp) sensor circuit malfunction cir...

Page 232

6-1-76 engine general information and diagnosis (sfi for g13) inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check cmp sensor and connector for proper installation. Is cmp sensor installed properly and connector connected sec...

Page 233

Engine general information and diagnosis (sfi for g13) 6-1-77 gnd vout b+ magnetic substance (iron) mirror step action yes no 7 check signal rotor for the following, using mirror. See fig. 4. D damage d no foreign material attached is it in good condition? Intermittent trouble or faulty ecm (pcm). C...

Page 234

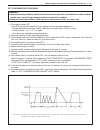

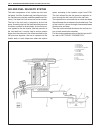

6-1-78 engine general information and diagnosis (sfi for g13) ignition switch main fuse relay box main relay egr valve 2 c13 dtc p0400 exhaust gas recirculation flow malfunction circuit description dtc detecting condition possible cause d while running at specified vehicle speed after engine warm-up...

Page 235

Engine general information and diagnosis (sfi for g13) 6-1-79 1) 2) 3) 4) 5) 6) 7) engine speed 4000 r/min 0 vehicle speed 0 50 – 55 mph 80 – 88 km/h (keep throttle valve opening constantly) dtc confirmation procedure warning: d when performing a road test, select a place where there is no traffic o...

Page 236

6-1-80 engine general information and diagnosis (sfi for g13) 1. Egr valve coupler inspection step action yes no 1 was engine diag. Flow table performed? Go to step 2. Go to engine diag. Flow table. 2 do you have suzuki scan tool? Go to step 3. Go to step 5. 3 egr valve operation check 1) with ignit...

Page 237

Engine general information and diagnosis (sfi for g13) 6-1-81 oscilloscope waveforms heated oxygen sensor-1 to other sensor heated oxygen sensor-2 warm up three way catalytic converter three way catalytic converter engine running at closed loop condition fuel cut idle after fuel cut 0.5 v / div 2 se...

Page 238

6-1-82 engine general information and diagnosis (sfi for g13) 1) 2) 3) 4) 41 – 46 mph (65 – 75 km / h) 28 – 34 mph (45 – 55 km / h) dtc confirmation procedure warning: d when performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful dur...

Page 239

Engine general information and diagnosis (sfi for g13) 6-1-83 inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check short term fuel trim. Did short term fuel trim vary within – 20% – +20% range in step 3) of dtc confirmation t...

Page 240

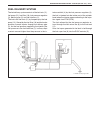

6-1-84 engine general information and diagnosis (sfi for g13) 1. Evap canister purge valve 2. To main relay 3. Ecm (pcm) 4. Sensed information 5. Intake manifold 6. Evap canister 7. Tank pressure control valve 8. Fuel vapor line 9. Fuel tank fig. 1 for step 1 dtc p0443 evap purge control valve circu...

Page 241

Radiator cooling fan relay to ecm main relay relay box “rdtr” (radiator fan) radiator cooling fan motor engine general information and diagnosis (sfi for g13) 6-1-85 dtc p0480 radiator cooling fan control system malfunction circuit description dtc detecting condition possible cause d low voltage at ...

Page 242

6-1-86 engine general information and diagnosis (sfi for g13) fig. 1 for step 2 fig. 2 for step 3 fig. 3 for step 3 inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 check radiator cooling fan relay and its circuit. 1) turn igni...

Page 243

Engine general information and diagnosis (sfi for g13) 6-1-87 vehicle speed sensor in combination meter dtc p0500 vehicle speed sensor (vss) malfunction for m/t vehicle circuit description dtc detecting condition possible cause d while fuel is kept cut at lower than 4000 r/min for longer than 4 sec....

Page 244

6-1-88 engine general information and diagnosis (sfi for g13) fig. 1 for step 3 fig. 2 for step 4 inspection step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table”. 2 does speedometer indicate vehicle speed? Go to step 3. Speedometer cable disconn...