- DL manuals

- Suzuki

- Scooter

- UF50

- Service Manual

Suzuki UF50 Service Manual

Summary of UF50

Page 1

9 9 5 0 0 - 1 0 4 9 1 - 0 1 e uf50

Page 2: Foreword

Foreword this manual contains an introductory description on the suzuki uf50/uf50z and procedures for its in- spection, service, and overhaul of its main components. Other information considered as generally known is not included. Read the general information section to famil- iarize yourself with t...

Page 3: How To Use This Manual

How to use this manual to locate what you are looking for: 1. The text of this manual is divided into sections. 2. The section titles are listed in the group index. 3. Holding the manual as shown at the right will allow you to find the first page of the section easily. 4. The contents are listed on ...

Page 4

Symbol listed in the table below are the symbols indicating instructions and other information necessary for servic- ing. The meaning of each symbol is also included in the table. Symbol definition torque control required. Data beside it indicates specified torque. Indicates service data. Apply oil....

Page 5: General Information

General information 1-1 general information contents warning/caution/note............................................................................ 1- 2 general precautions ............................................................................ 1- 2 suzuki uf50y/uf50zy (2000-model) .............

Page 6: Warning/caution/note

1-2 general information warning/caution/note please read this manual and follow its instructions carefully. To emphasize special information, the symbol and the words warning, caution and note have special meanings. Pay special attention to the mes- sages highlighted by these signal words. Indicates...

Page 7

General information 1-3 if parts replacement is necessary, replace the parts with suzuki genuine parts or their equiva- lent. When removing parts that are to be reused, keep them arranged in an orderly manner so that they may be reinstalled in the proper order. Be sure to use special tools when inst...

Page 8: Fuel and Oil Recommendations

1-4 general information suzuki uf50y/uf50zy (2000-model) fuel and oil recommendations be sure to use the specified fuel and oils. Fuel and oil specifica- tions are listed below. Fuel use unleaded gasoline that is graded 91 octane or higher rated by the research method. 3 fuel tank cap engine oil use...

Page 9

General information 1-5 final gear oil use a good quality sae 10w-40 multigrade motor oil. Brake fluid specification and classification: dot 4 this motorcycle uses a glycol-based brake fluid. Do not use or mix other types of brake fluid such as silicone-based and petroleum-based fluids for refilling...

Page 10: Information Labels

1-6 general information information labels battery caution label engine starting label tire information label loading cap label general warning label.

Page 11: Specifications

General information 1-7 specifications dimensions and dry mass overall length ................................................... 1 840 mm overall width .................................................... 650 mm overall height ................................................... 1 095 mm wheelbase ....

Page 12

1-8 general information chassis front suspension ............................................. Inverted telescopic, coil spring rear suspension .............................................. Swingarm type, coil spring, oil damped steering angle ................................................. 45° (...

Page 13: Periodic Maintenance

Periodic maintenance 2-1 periodic maintenance contents periodic maintenance schedule ....................................................... 2- 2 periodic maintenance chart .......................................................... 2- 2 maintenance and tune-up procedure ................................

Page 14

2-2 periodic maintenance periodic maintenance schedule the chart below lists the recommended intervals for all the required periodic service work necessary to keep the motorcycle operating at peak performance and economy. Maintenance intervals are expressed in terms of kilometers and months, and are...

Page 15: Maintenance And Tune-Up

Periodic maintenance 2-3 maintenance and tune-up procedure this section describes the servicing procedures for each item mentioned in the periodic maintenance chart on the previous page. Battery inspect every 3 000 km (6 months). Remove the battery holder cover. ( 6-30) first, disconnect the - batte...

Page 16

2-4 periodic maintenance air cleaner clean every 3 000 km (6 months). If the air cleaner is clogged with dust, intake resistance will be increased, with a resultant decrease in engine output and an increase in fuel consumption. Check and clean the air cleaner elements in the following manner. Remove...

Page 17

Periodic maintenance 2-5 cylinder head and cylinder remove carbon every 3 000 km (6 months). ( 3-13) spark plug clean every 3 000 km (6 months). Replace every 6 000 km (12 months). Remove the left side leg shield. ( 5-3) disconnect the spark plug cap and remove the spark plug. Ngk denso standard bpr...

Page 18

2-6 periodic maintenance spark plug gap measure the spark plug gap using a thickness gauge. If the spark plug gap is out of specification, adjust the gap. Spark plug gap standard: 0.6 – 0.7 mm 09900-20804: thickness gauge electrodes check the condition of the electrodes. If the electrode is extremel...

Page 19

Periodic maintenance 2-7 carburetor inspect initially at 1 000 km (2 months) and every 3 000 km (6 months) thereafter. Engine idle speed adjust the throttle cable play. Remove the left side leg shield. ( 5-3) warm up the engine. Note: make this adjustment when the engine is hot. Connect the multi ci...

Page 20

2-8 periodic maintenance final gear oil inspect initially at 1 000 km (2 months) and every 6 000 km (12 months) thereafter. Remove the final gear oil level bolt 1 and inspect the oil level. If the oil level is below the brim of the final gear oil level hole, add oil until it runs out from the level ...

Page 21

Periodic maintenance 2-9 brake hose inspect every 3 000 km (6 months). Replace every four years. Check the brake hose for leakage, cracks, wear, and damages. If any damages are found, replace the brake hose with a new one. Brake fluid inspect every 3 000 km (6 months). Replace fluid every two years....

Page 22

2-10 periodic maintenance air bleeding the brake fluid circuit air trapped in the brake fluid circuit acts like a cushion to absorb a large proportion of the pressure developed by the master cyl- inder, thus interferes with the full braking performance of the brake caliper. The presence of air is in...

Page 23

Periodic maintenance 2-11 steering inspect initially at 1 000 km (2 months) and every 3 000 km (6 months) thereafter. The steering should be adjusted properly for smooth turning of the handlebar and safe operation. Overtight steering prevents smooth turning of the handlebar and too loose steering wi...

Page 24

2-12 periodic maintenance tires inspect initially at 1 000 km (2 months) and every 3 000 km (6 months) thereafter. Tire tread condition operating the motorcycle with excessively worn tires will de- crease riding stability and consequently invite a dangerous situ- ation. It is highly recommended to r...

Page 25

Periodic maintenance 2-13 cylinder head nuts and exhaust pipe nut and bolt tighten initially at 1 000 km (2 months) and every 3 000 km (6 months) thereafter. Cylinder head nuts, when they are not tightened to the specified torque, may result in leakage of the compressed mixture and reduce output. Ti...

Page 26

2-14 periodic maintenance 1 2 3 4 5 6 7 8 6 9 0 a b c.

Page 27

Periodic maintenance 2-15 general lubrication proper lubrication is important for smooth operation and long life of each working part of the motorcycle. Major lubrication points are indicated below. 1 rear brake lever holder 2 center stand pivot and spring hook 3 front brake lever holder 4 speedomet...

Page 28: Automatic Clutch Inspection

2-16 periodic maintenance automatic clutch inspection the uf50/uf50z is equipped with a centrifugal type automatic clutch and a variable ratio belt drive transmission. To insure proper performance and longevity of the clutch as- sembly it is essential that the clutch assembly engages smoothly and gr...

Page 29

Periodic maintenance 2-17 clutch lock-up perform this inspection to determine if the clutch is engaging fully and not slipping. Remove the trunk. ( 5-4) connect the multi circuit tester to the high-tension cord. Start the engine. Apply the rear brake as firm as possible. Fully open the throttle for ...

Page 30: Engine

Engine 3-1 engine 3 contents engine components removable with the engine in place .......................................................................................... 3- 2 engine removal and remounting ...................................................... 3- 3 engine removal ....................

Page 31

3-2 engine engine components removable with the engine in place the parts listed below can be removed and reinstalled without removing the engine from the frame. Refer to the page listed in each section for removal reinstallation instructions. Engine left side parts removal installation air cleaner ...

Page 32: Engine Removal and

Engine 3-3 engine removal and remounting engine removal before taking the engine out of the frame, wash the engine with a steam cleaner. Engine removal is sequentially explained in the following steps. Remove the side leg shields and frame covers. ( 5-3 to 5-5) disconnect the - battery lead wire. ( ...

Page 33

3-4 engine remove the rear brake cable holders 1 and adjusting nut 2. Disconnect the air cleaner intake boot. Remove the rear shock absorber lower mounting bolt. Remove the engine mounting nut, shaft, and engine. 1 1 1 2.

Page 34

Engine 3-5 engine remounting remount the engine in the reverse order of removal. Pay atten- tion to the following points: install the crankcase bracket 1 to the frame and insert the crankcase bracket mounting shaft. Push down on the rear part of the crankcase bracket and have the damper 2 touch the ...

Page 35: Engine Disassembly

3-6 engine engine disassembly remove the air cleaner. Remove the exhaust pipe/muffler assembly. Disconnect the oil hoses and remove the oil pump..

Page 36

Engine 3-7 remove the oil pump gear 1, intake pipe and carburetor. A: twist-off bolt remove the reed valve and gaskets. Remove the cylinder/cylinder head cover 2 and cooling fan cover 3. Remove the cooling fan. Remove the cooling fan case. 1 a 2 3.

Page 37

3-8 engine remove the rear fender. Loosen the cylinder head nuts diagonally, as shown, and then remove them. Remove the cylinder head and gasket. Remove the cylinder and gasket. Place a clean rag over the cylinder base to prevent the piston pin circlip from dropping into the crankcase. Then, remove ...

Page 38

Engine 3-9 remove the kick starter lever 1, clutch cover 2, gaskets, and dowel pins. Hold the generator rotor using the special tool and then re- move the kick starter nut. 09930-40113: rotor holder remove the kick starter 3, fixed drive face 4, movable drive face 5, spacers, and washers. Hold the c...

Page 39

3-10 engine remove the starter pinion gear cap 1, starter pinion gear assembly 2, and dowel pins. Drain the final gear oil. Hold the generator rotor using the special tool and then re- move the generator rotor nut. 09930-40113: rotor holder remove the generator rotor using the special tool. 09920-13...

Page 40

Engine 3-11 remove the rear wheel. Remove the brake shoes. Remove the brake cam lever 1, return spring 2, brake lining wear limit indicator 3, and brake camshaft 4. Remove the gearbox cover. Remove the final driven gear with the rear axle shaft 5, idle shaft/gear 6, and dowel pins 7. 3 4 2 1 7 5 6 7.

Page 41

3-12 engine remove the driveshaft using the special tool. 09920-13120: crankcase separating tool remove the center stand spring 1. Remove the cotter pin 2 and center stand shaft 3. Remove the center stand 4. Remove the crankcase bolts. Separate the left and right crankcases using the special tool. 0...

Page 42: Engine Components Inspection

Engine 3-13 engine components inspection and service cylinder head distortion decarbonize the combustion chamber. Check the gasket surface of the cylinder head for distortion. Use a straightedge and thickness gauge. Take clearance readings at several places. If readings exceed the service limit, rep...

Page 43

3-14 engine piston piston diameter measure the piston diameter using a micrometer at 15 mm from the skirt end. If the piston diameter is less than the service limit, replace the piston with a new one. 09900-20202: micrometer (25 – 50 mm) piston diameter service limit: 40.885 mm piston-to-cylinder cl...

Page 44

Engine 3-15 piston pin and pin bore measure the piston pin bore inside diameter using the dial cali- pers and the piston pin outside diameter using the micrometer. If either is out of specification or the difference between the mea- surements is more than their limits, replace the piston and pis- to...

Page 45

3-16 engine crankshaft and conrod 1 oil seal (r) 2 bearing (r) 3 crankshaft (r) 4 crank pin 5 crank pin bearing 6 conrod 7 crankshaft (l) 8 spacer 9 piston pin bearing 0 bearing (l) a oil seal (l) b oil seal crankshaft runout support the crankshaft using v-blocks as shown. Position the dial gauge, a...

Page 46

Engine 3-17 conrod deflection wear on the big end of the conrod can be estimated by checking the movement of the small end of the rod. This method can also check the extent of wear on the parts of the big end of the conrod. 09900-20701: magnetic stand 09900-20606: dial gauge (1/100 mm) 09900-21304: ...

Page 47

3-18 engine clutch shoe/movable driven face 1 fixed driven face 2 bearing 3 circlip 4 needle roller bearing 5 movable driven face 6 oil seal 7 pin 8 o-ring 9 movable driven face spring guide item n·m kgf-m a 50 5.0 b 50 5.0 0 oil seal a spring b clutch shoe assembly c clutch housing d washer a clutc...

Page 48

Engine 3-19 remove the clutch shoe assembly 1 and driven face spring 2. Use a thin-blade screwdriver to pry up the movable driven face spring guide. Remove the pins 3, movable driven face 4, and fixed driven face 5. Remove the bearing using the special tools. 09923-73210: bearing remover 09930-30102...

Page 49

3-20 engine remove the bearing using the special tool. 09941-50111: bearing remover replace the removed bearing with a new one. Remove the oil seals 1 and o-rings 2. Replace the removed oil seals and o-rings with new ones. Clutch shoe inspect the clutch shoe for chips, cracks, uneven wear and burn- ...

Page 50

Engine 3-21 driven face spring measure the free length of the driven face spring. If the length is shorter than the service limit, replace the spring with a new one. Driven face spring length service limit: 104.5 mm driven face pins and oil seals rotate the driven faces and make sure that they turn ...

Page 51

3-22 engine install the needle roller bearing using the special tool. 09924-84521: bearing installer note: face the stamped side of the needle roller bearing out. Apply suzuki super grease “a” between the sliding sur- face of the fixed driven face and movable driven face. 99000-25010: suzuki super g...

Page 52

Engine 3-23 movable drive face 1 movable drive face 2 roller 3 movable drive plate 4 damper 5 movable drive face cover 6 spacer 7 spacer 8 drive belt 9 fixed drive face 0 washer a kick starter b concave washer a kick starter nut disassembly remove the movable drive face cover 1 and movable drive pla...

Page 53

3-24 engine roller and sliding surface inspect each roller and its sliding surface for wear or damage. If any damages are found, replace the rollers as a set. Drive belt remove the drive belt and check for cracks, wear and separa- tion and measure the drive belt width with vernier calipers. If any d...

Page 54

Engine 3-25 kick starter 1 spacer 2 kick starter shaft 3 kick starter spring 4 clutch cover 5 dowel pin 6 gasket 7 gasket 8 kick starter lever 9 kick starter drive gear disassembly remove the kick starter driven gear 1, kick starter shaft spring 2, and kick starter shaft 3. Reassembly apply suzuki s...

Page 55

3-26 engine apply a light coat of suzuki super grease “a” onto the end of the kick starter shaft. 99000-25010: suzuki super grease “a” install the kick starter spring and hook its end 1 onto the clutch cover boss 2. Apply suzuki super grease “a” onto the shaft and gear of the kick starter drive gear...

Page 56

Engine 3-27 install the rear axle shaft bearing using the special tool. 09913-70210: bearing installer set right driveshaft bearing and idle shaft bearing remove the right driveshaft bearing and idle shaft bearing using the special tools. 09921-20210: bearing remover 09930-30102: sliding hammer repl...

Page 57

3-28 engine right crankshaft bearing remove the right crankshaft bearings using the special tools. 09923-73210: bearing remover 09930-30102: sliding hammer replace the removed bearing with a new one. Install the right crankshaft bearing using the special tool. 09913-70210: bearing installer set left...

Page 58

Engine 3-29 install the oil seals into the crankcase and gearbox cover, as shown below. Replace the removed oil seals with new ones. Apply suzuki super grease “a” to the lip of the oil seals. 99000-25010: suzuki super grease “a” rear axle shaft oil seal remove the rear axle shaft bearing. ( 3-26) re...

Page 59

3-30 engine install the drive shaft oil seal into the left crankcase, slowly, using the special tool. 09913-70210: bearing installer set crankshaft oil seals remove the crankshaft oil seals from the left and right crank- case, using the special tool. 09913-50121: oil seal remover replace the removed...

Page 60

Engine 3-31 engine mounting bushings inspect each engine mounting bushings 1 and 2 for damage. If any damage is found, replace the engine mounting bushing with a new one. Press out the engine mounting bushings in a vise using two steel tubes of the appropriate size, as shown. Replace the removed bus...

Page 61: Engine Reassembly

3-32 engine engine reassembly reassemble the engine in the reverse order of disassembly. The following steps require special attention or precautionary mea- sures should be taken. Note: apply engine oil to each running and sliding part before reas- sembling. Crankshaft mount the crankshaft into the ...

Page 62

Engine 3-33 install the left crankshaft inner oil seal 1 using the special tool. 09941-74910: bearing installer apply suzuki super grease “a” (approximately 10 g) to the oil pump drive gear (on the crankshaft surface side). 99000-25010: suzuki super grease “a” install the left crankshaft outer oil s...

Page 63

3-34 engine rear axle shaft and transmission 1 crankcase 2 gearbox cover 3 rear axle shaft/final driven gear 4 idle shaft/gear 5 washer 6 washer 7 drive shaft install the idle shaft/gear 1, with the thrust washer 2, into the gearbox. Install the rear axle shaft/final driven gear 3. Install the thrus...

Page 64

Engine 3-35 install the driveshaft 1 and dowel pins 2. Install the gearbox cover. Tighten the bolts, a little at a time, diagonally. Apply a light coat of suzuki super grease “a” onto the pivoting surface of the brake cam, and then install the brake cam into the crankcase. 99000-25010: suzuki super ...

Page 65

3-36 engine align the tang 1 on the brake lining wear indicator plate 2 with the cutaway 3 on the brake cam. Then, slide the brake lining wear indicator plate onto the brake cam. Install the return spring and brake cam lever onto the brake cam and tighten the brake cam lever nut to the specified tor...

Page 66

Engine 3-37 apply thread lock super “1322” to the generator rotor nut and then tighten it to the specified torque using the spe- cial tool. 99000-32110: thread lock super “1322” 09930-40113: rotor holder generator rotor nut: 40 n·m (4.0 kgf-m) starter pinion and starter gear tighten the final gear o...

Page 67

3-38 engine drive belt insert the drive belt, as low as possible, between the clutch shoe/movable driven face while pulling out the driven face to provide the maximum drive belt clearance. The drive belt contact surface of the driven face should be thoroughly cleaned. Thoroughly clean the clutch hou...

Page 68

Engine 3-39 install the dowel pins 1 and new gaskets 2. Install the clutch cover 3 and kick starter lever 4. Piston install the piston rings onto the piston. 1st: keystone ring 2nd: rectangular ring and expander ring note: the piston rings should be installed with the mark facing up. Position the pi...

Page 69

3-40 engine cylinder apply engine oil onto the piston and cylinder wall surfaces, and then install the cylinder over the piston carefully. Cylinder head tighten the cylinder head nuts diagonally, as shown, and to the specified torque. Cylinder head nut: 10 n·m (1.0 kgf-m) oil pump gear apply suzuki ...

Page 70: Fuel and Lubrication System

Fuel and lubrication system 4-1 fuel and lubrication system 4 contents fuel valve .................................................................................................... 4- 2 fuel tank and oil tank ........................................................................... 4- 3 removal ...

Page 71: Fuel Valve

4-2 fuel and lubrication system fuel valve when the engine has started, negative pressure (vacuum) is generated at the intake port. The negative pressure causes the fuel valve diaphragm to compress its spring, opening the fuel passageway and allow- ing the fuel to flow to the carburetor. When the en...

Page 72: Fuel Tank and Oil Tank

Fuel and lubrication system 4-3 fuel tank and oil tank removal gasoline is highly flammable and explosive. Keep heat, sparks, and flames away from gasoline. Remove the frame cover. ( 5-4 and 5-5) disconnect the turn signal light lead wires 1 and license plate light coupler 2. Disconnect the fuel lev...

Page 73

4-4 fuel and lubrication system remove the fuel tank cap 1 and fuel tank 2. Note: after removing the fuel tank, reinstall the fuel tank cap. Disconnect the oil hose 3, oil level indicator switch coupler 4, and remove the oil tank 5. Remounting remount the fuel tank and oil tank in the reverse order ...

Page 74

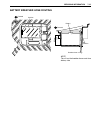

Fuel and lubrication system 4-5 fuel tank cushions 15 mm cushion 80 mm 105 mm 8 mm 13 mm 65 mm 40 mm 15 mm 25 mm 6 mm 20 mm 20 mm 15 mm 60 mm 75 mm b a view a view b 45˚ cushion.

Page 75: Carburetor

4-6 fuel and lubrication system carburetor construction 1 top cap 2 throttle valve spring 3 jet needle 4 throttle valve 5 thermoelement 6 carburetor body 7 pilot air screw 8 throttle stop screw 9 needle valve 0 float pin a float b needle jet c needle jet holder d slow jet e main jet f float chamber ...

Page 76

Fuel and lubrication system 4-7 specifications item specification carburetor type keihin pws14 bore size 14 mm i.D. No. 30f0 idle r/min 1 900 ± 200 r/min float height 5.1 ± 0.5 mm main jet (m.J.) # 65 jet needle (j.N.) n5gj-2nd slow jet (s.J.) # 42 air screw (a.S.) 2 turns back throttle cable play 2...

Page 77

4-8 fuel and lubrication system removal remove the trunk. ( 5-4) remove the clamps, disconnect the thermoelement coupler 1 and carburetor heater lead wire 2. Disconnect the vacuum hose 3 and fuel hose 4. Loosen the carburetor clamp screw and remove the carbure- tor mounting bolts. Remove the top cap...

Page 78

Fuel and lubrication system 4-9 separate the jet needle 1 and throttle valve 2. Remove the each carburetor hoses. Remove the float chamber 3. Remove the float 4 and needle valve 5 by removing the float pin 6. When removing the float pin, be careful not to damage the carburetor body and float. Remove...

Page 79

4-10 fuel and lubrication system remove the thermoelement cover 1 and remove the ther- moelement 2. Do not disassemble the thermoelement. It is not ser- viceable. Remove the carburetor heater. 1 2.

Page 80

Fuel and lubrication system 4-11 cleaning some carburetor cleaning chemicals, especially dip- type soaking solutions, are very corrosive and must be handled carefully. Always follow the chemical manufacturer’s instructions for proper use, handling and storage. Clean all jets with a spray-type carbur...

Page 81

4-12 fuel and lubrication system float height adjustment to check the float height, turn the carburetor upside down. Mea- sure the float height a while the float arm is just contacting the needle valve using vernier calipers. Bend the tongue as neces- sary to bring the float height a to the specifie...

Page 82: Oil Pump

Fuel and lubrication system 4-13 oil pump air bleeding whenever air leaks into the oil pipe from the oil tank or the oil pump is removed, the oil pump must be bled of any air. Hold the motorcycle in a stationary position. Loosen the screw 1 to bleed the air. After all of the air has been bled, tight...

Page 83: Chassis

Chassis 5-1 chassis 5 contents exterior parts ...................................................................................................... 5- 2 construction .................................................................................................... 5- 2 removal ......................

Page 84: Exterior Parts

5-2 chassis exterior parts construction 1 f rame cov er (r) 2 f rame cov er (l) 3 t runk 4 side leg shield (r) 5 side leg shield (l) 6 l o w er leg shield 7 leg shield 8 co v e r 9 batter y holder cov e r 0 f ootboard a f ront leg shield.

Page 85

Chassis 5-3 removal leg shield remove the battery. ( 6-30) remove the side leg shields 1. Remove the frame cover. Remove the footboard 2. Remove the cover 3. Remove the front leg shield mounting screws. Disconnect the headlight lead wires 4 and remove the front leg shield 5. 1 2 3 4 5.

Page 86

5-4 chassis remove the lower leg shield 1. Remove the ignition switch cap 2. Remove the leg shield 3. Seat remove the seat 1. Frame cover remove the seat. Remove the side leg shield. ( 5-3) remove the trunk 1 and fuel tank cap 2. 1 2 3 1 2 1.

Page 87

Chassis 5-5 remove the upper fuel tank cover 1. After removing the upper fuel tank cover, reinstall the fuel tank cap. Remove the passenger grab handle 2. Remove the frame cover mounting screw. Disconnect the seat lock cable 3, brake light/taillight lead wires 4, and remove the frame cover 5. Remoun...

Page 88: Front Wheel

5-6 chassis front wheel construction 1 front axle 2 spacer 3 brake disc 4 bearing 5 front wheel 6 spacer 7 speedometer gearbox a front axle nut b brake disc bolt item n·m kgf-m a 42 4.2 b 23 2.3 removal disconnect the speedometer cable 1. Remove the front axle nut 2. Raise the front wheel off the gr...

Page 89

Chassis 5-7 remove the brake disc. Inspection and disassembly speedometer gearbox dust seal inspect the speedometer gearbox dust seal for damage. If any damage is found, replace the speedometer gearbox with a new one. Wheel bearings inspect the play of the wheel bearings by hand while they are in th...

Page 90

5-8 chassis front wheel make sure that the wheel runout (axial and radial) does not ex- ceed the service limit when checked as shown. An excessive amount of runout is usually due to worn or loose wheel bearings and can be corrected by replacing the bearings. If bearing re- placement fails to reduce ...

Page 91

Chassis 5-9 brake disc make sure that the brake disc is clean and free of any grease. Apply thread lock super “1360” to the brake disc mount- ing bolts and tighten them to the specified torque. 99000-32130: thread lock super “1360” brake disc mounting bolt: 23 n·m (2.3 kgf-m) speedometer gearbox app...

Page 92: Front Brake

5-10 chassis front brake construction 1 cap 2 diaphragm 3 master cylinder 4 piston set 5 push rod 6 dust boot 7 brake hose 8 caliper 9 piston 0 piston and dust seal a shim b pad set c pad mounting pin d o-ring a master cylinder mounting bolt b brake hose union bolt c air bleeder valve d brake calipe...

Page 93

Chassis 5-11 brake pads replacement remove the brake caliper mounting bolts 1. Remove the brake pad mounting pins 2 and brake pads. Do not operate the brake lever during or after brake pad removal. Measure the thickness a of the brake pads. If the brake pad thickness is below the service limit, repl...

Page 94

5-12 chassis brake fluid replacement place the motorcycle on a level surface and keep the handle- bar straight. Remove the master cylinder reservoir cap and diaphragm. Suck up the old brake fluid as much as possible. Fill the reservoir with fresh brake fluid. Specification and classification: dot 4 ...

Page 95

Chassis 5-13 remove the brake pads. ( 5-11) remove the brake caliper housing bolts. Separate the brake caliper. Remove the o-ring. Do not reuse the o-ring to prevent fluid leakage. Place a rag over the brake caliper pistons to prevent them from popping out, and then force out the piston using com- p...

Page 96

5-14 chassis brake caliper reassembly and remounting reassemble and remount the brake caliper in the reverse order of removal and disassembly. Pay attention to the following points: wash the caliper bores and brake caliper pistons with the specified brake fluid. Thoroughly wash the dust seal grooves...

Page 97

Chassis 5-15 brake disc inspection remove the front wheel. ( 5-6) check the brake disc for cracks or damage and measure the thickness using the micrometer. If the thickness is less than the service limit or if any damages are found, replace the brake disc with a new one. 09900-20205: micrometer (0 –...

Page 98

5-16 chassis remove the brake lever and brake light switch. Remove the dust boot and push rod. Remove the circlip. Remove the piston/secondary cup 1 and return spring 2. Remove the master cylinder reservoir cap 3 and diaphragm 4. Drain the brake fluid. Master cylinder inspection master cylinder insp...

Page 99

Chassis 5-17 piston inspect the piston surface for any scratches or other damage. If any damages are found, replace the piston with a new one. Rubber parts inspect the primary cup, secondary cup and dust seal for wear or damage. If any damages are found, replace the piston/sec- ondary cup, and dust ...

Page 100: Front Suspension

5-18 chassis front suspension construction 1 damper 2 upper spring 3 inner tube 4 lower spring 5 upper circlip 6 bushing 7 lower circlip 8 dust seal 9 brake caliper bracket a brake caliper bracket mounting bolt item n·m kgf-m a 20 2.0 removal and disassembly remove the front wheel. ( 5-6) remove the...

Page 101

Chassis 5-19 remove the lower circlip 1. Replace the removed lower circlip with a new one. Remove the lower bushing 2. Note: when removing the lower bushing 2, pull the inner tube 3 down. Remove the upper circlip 4, lower spring 5, and inner tube 6. Replace the removed upper circlip with a new one. ...

Page 102

5-20 chassis inspection fork spring measure the fork spring free length. If the fork spring free length is shorter than the service limit, replace the fork spring with a new one. Front fork spring free length service limit: 122 mm inner tube inspect the inner tube sliding surface for any scuffing or...

Page 103

Chassis 5-21 upper circlip install the circlip 1 into the groove 2. Replace the upper circlip with a new one. The rounded side on the circlip must face upward. After installing the upper circlip, make sure that it is properly seated in the groove. Bushing install the lower bushing 3 using the specia...

Page 104

5-22 chassis handlebar covers and speedometer assembly construction 1 front handlebar cover 2 rear handlebar cover.

Page 105

Chassis 5-23 removal remove the rear view mirrors 1. Remove the front handlebar cover 2. Disconnect the front turn signal light lead wires. Disconnect the speedometer cable 3 and speedometer cou- plers 4. Remove the speedometer assembly 5. Disconnect the handlebar switch couplers. 1 2 4 3 5.

Page 106

5-24 chassis remove the rear handlebar cover 1. Remounting remount the handlebar covers and the speedometer assembly in the reverse order of removal. 94p50730 1.

Page 107: Steering Stem

Chassis 5-25 steering stem construction 1 handlebar 2 washer 3 steering stem nut 4 inner upper race 5 inner lower race 6 steel ball 7 outer lower race 8 steering stem a handlebar clamp nut b handlebar set bolt c steering stem locknut item n·m kgf-m a 50 5.0 b 25 2.5 c 30 3.0 removal and disassembly ...

Page 108

5-26 chassis remove the rear brake cable 5. Disconnect the rear brake light switch lead wires 6. Remove the handlebar. Remove the steering stem locknut using the special tool. 09910-60611: universal clamp wrench remove the throttle cable 1 and throttle grip 2. Remove the brake hose 3 and speedometer...

Page 109

Chassis 5-27 remove the upper and lower steel balls. Steel balls upper : 25 pcs lower : 30 pcs inspection inspect the removed parts for the following abnormalities. If any damages are found, replace the respective part with a new one. Steering race wear and brinelling worn and damaged steel balls di...

Page 110

5-28 chassis steel balls apply suzuki super grease “a” to the steering races when installing the upper and lower steel balls. 99000-25010: suzuki super grease “a” steel balls upper : 25 pcs lower : 30 pcs steering stem tighten the steering stem nut 1, and then loosen it 1/8 – 1/4 of a turn. Note: th...

Page 111

Chassis 5-29 finger tighten the handlebar set bolt 1 and handlebar clamp nut 2, and then tighten them to the specified torque. Handlebar set bolt: 25 n·m (2.5 kgf-m) handlebar clamp nut: 50 n·m (5.0 kgf-m) note: hold the front fork legs, move them back and forth and make sure that the steering is no...

Page 112

5-30 chassis rear wheel, rear brake, and rear shock absorber construction a rear axle nut b rear brake cam lever nut c rear shock absorber upper mounting bolt d rear shock absorber lower mounting nut item n·m kgf-m a 120 12.0 b 10 1.0 c 29 2.9 d 35 3.5 1 rear wheel 2 brake shoe 3 brake cam 4 return ...

Page 113

Chassis 5-31 rear shock absorber remove the frame cover. ( 5-4 and 5-5) remove the rear shock absorber. Inspection brake drum inspect the brake drum and measure the brake drum i.D. To de- termine the extent of wear. If the measurement exceeds the ser- vice limit, replace the brake drum with a new on...

Page 114

5-32 chassis reassembly and remounting reassemble and remount the rear wheel, rear brake, and rear shock absorber in the reverse order of removal and disassem- bly. Pay attention to the following points: apply suzuki super grease “a” to the brake cam and pin, and then install the brake shoes. 99000-...

Page 115: Tires And Wheels

Chassis 5-33 tires and wheels tire removal the most critical factor of a tubeless tire is the seal between the wheel rim and the tire bead. Because of this, we recommended using a tire changer that can satisfy this sealing requirement and can make the operation efficient as well as functional. For o...

Page 116

5-34 chassis valve inspect the valve 1 for damage. If the seal rubber is peeling or damaged, replace the valve with a new one. Note: if the external appearance of the valve shows no abnormal con- dition, removing the valve is not necessary. Inspect the valve core seal 2 for deformation or damage. If...

Page 117

Chassis 5-35 tire apply a special tire lubricant to the tire bead. When installing the tire, make sure the arrow 1 faces the direction of wheel rotation and align the balancing. Replace the removed valve with a new one. The tire is designed to have specified rotational direction. Never apply oil, gr...

Page 118

5-36 chassis after the tire is properly seated to the wheel rim, inflate the tire to the recommended pressure. Correct the wheel balance if necessary. Do not inflate the tire to more than 400 kpa (4.0 kgf/ cm 2 ). The tire could burst with sufficient force to cause severe injury. Never stand directl...

Page 119: Electrical System

Electrical system 6-1 electrical system contents cautions in servicing ........................................................................................................................... 6- 2 connector .............................................................................................

Page 120: Cautions In Servicing

6-2 electrical system cautions in servicing connector when disconnecting a connector, be sure to hold the termi- nals; do not pull the lead wires. When connecting a connector, push it in so it is firmly attached. Inspect the connector for corrosion, contamination and any breakage in the cover. Coupl...

Page 121

Electrical system 6-3 connecting the battery when disconnecting terminals from the battery for disassem- bly or servicing, be sure to disconnect the - battery lead wire, first. When connecting the battery lead wires, be sure to connect the + battery lead wire, first. If the terminal is corroded, rem...

Page 122

6-4 electrical system location of electrical components 1 fuel level indicator switch 2 thermoswitch 3 oil level indicator switch 4 cdi unit 5 right handlebar switch 6 horn 7 turn signal relay 8 resistor 9 regulator/rectifier 0 generator a starter motor 2 1 3 4 5 6 9 7 8 0 a.

Page 123

Electrical system 6-5 b left handlebar switch c ignition switch d thermoelement e carburetor heater f battery g fuse h starter relay i ignition coil b c d e g h f i.

Page 124: Charging and Lighting System

6-6 electrical system charging and lighting system description the charging system for this motorcycle uses a generator, as shown below. The charging and lighting coils are mounted on the generator stator and generate ac current as the generator rotor turns. The ac current, which is generated in the...

Page 125

Electrical system 6-7 troubleshooting • remove accessories accessories are installed battery runs down quickly. Others no accessories • short circuit of the wire harness • loose or disconnected wires • faulty battery current leaks correct no continuity incorrect incorrect check the battery for curre...

Page 126

6-8 electrical system inspection battery current leakage turn the ignition switch to the “off” position. Remove the battery holder cover. ( 6-30) disconnect the - battery lead wire. Measure the battery current between the - battery terminal and the - battery lead wire using the multi circuit tester....

Page 127

Electrical system 6-9 stator coil resistance remove the trunk. ( 5-4) disconnect the generator coupler 1. Measure the resistance between the lead wires using the multi circuit tester. If the resistance is not within the specified value, replace the stator coil with a new one. 09900-25008: multi circ...

Page 128: Starter System

6-10 electrical system starter system description the starter system consists of the following components: the starter motor, starter relay, starter button, brake light switches (front and rear brakes), ignition switch, and battery. Pressing the starter button, while squeezing the front or rear brak...

Page 129

Electrical system 6-11 starter motor removal and disassembly disconnect the starter motor lead wire and remove the starter motor 1. Others engine does not turn though the starter motor runs. • faulty starter pinion gear assembly no voltage incorrect • faulty ignition switch • faulty starter button •...

Page 130

6-12 electrical system disassemble the starter motor, as shown. Starter motor inspection carbon brushes inspect the carbon brushes for abnormal wear, cracks, or smooth- ness in the brush holder. If any damages are found, replace the brush assembly with a new one. Commutator inspect the commutator fo...

Page 131

Electrical system 6-13 starter motor reassembly reassemble the starter motor in the reverse order of disassem- bly. Pay attention to the following point: apply a small quantity of suzuki moly paste to the arma- ture shaft. 99000-25140: suzuki moly paste starter relay inspection remove the battery ho...

Page 132: Ignition System

6-14 electrical system ignition system description in the capacitor discharged ignition system, the battery’s electrical energy charges the capacitor. This en- ergy is released in a single surge at the specified ignition timing point and the current flows through the primary side of the ignition coi...

Page 133

Electrical system 6-15 correct incorrect measure the ignition coil primary peak voltage. Note: the ignition coil peak voltage inspection method is applicable only with the multi circuit tester and the peak volt adaptor. • faulty pickup coil incorrect • faulty cdi unit incorrect incorrect • faulty ig...

Page 134

6-16 electrical system w/bl cdi unit battery peak volt adaptor new spark plug inspection ignition coil primary peak voltage remove the left side leg shield. ( 5-3) remove the spark plug cap and spark plug. Connect a new spark plug to the spark plug cap and ground it to the crankcase. Note: make sure...

Page 135

Electrical system 6-17 ignition coil resistance remove the footboard. ( 5-3) disconnect the ignition coil coupler 1. Measure the ignition coil resistance in both the primary and sec- ondary windings using the multi circuit tester. If the resistance in both the primary and secondary windings is close...

Page 136

6-18 electrical system remove the trunk. ( 5-4) disconnect the generator coupler 1. Connect the multi circuit tester with the peak volt adaptor as follows. Brown (- probe) – white (+ probe) measure the pickup coil peak voltage in the same manner as on the cdi unit coupler. 09900-25008: multi circuit...

Page 137: Fuel Level Indicator Switch

Electrical system 6-19 fuel level indicator switch inspection remove the trunk. ( 5-4) turn the ignition switch to the “on” position, and disconnect the fuel level indicator coupler 1 going into the fuel level indi- cator switch, connect the lead wires from the main wiring har- ness with a jumper le...

Page 138: Oil Level Indicator Switch

6-20 electrical system connect a 12 v battery to the fuel level indicator switch and ground it through a 2 w bulb. The bulb should light up after several seconds if the switch is in good condition. When the switch is immersed in water under the above condi- tion, the bulb should go out. If the bulb ...

Page 139

Electrical system 6-21 thermoelement, carburetor heater, and thermoswitch inspection thermoelement remove the trunk. ( 5-4) disconnect the thermoelement coupler 1 and remove the thermoelement 2. Connect the thermoelement lead wires to a 12 v battery. Wait five minutes and feel the thermoelement to s...

Page 140

6-22 electrical system carburetor heater remove the trunk. ( 5-4) disconnect the carburetor heater lead wire and remove the carburetor heater 1. Measure the resistance between the terminals using the multi circuit tester. If the resistance is not within the specified value, replace the carburetor he...

Page 141: Speedometer

Electrical system 6-23 speedometer removal and disassembly remove the speedometer assembly. ( 5-23) disassemble the speedometer, as shown. Inspection check the continuity between the lead wires using the multi cir- cuit tester. If there is no continuity, replace the respective parts. 09900-25008: mu...

Page 142: Lamps

6-24 electrical system lamps headlight headlight bulb replacement remove the front leg shield. ( 5-3) remove the headlight bulb. If you touch the bulb with your bare hands, clean the bulb with a cloth moistened with alcohol or soapy wa- ter to prevent premature bulb failure. Headlight bulb: 12 v 35/...

Page 143

Electrical system 6-25 remove the front turn signal light bulb 3 and rear turn signal light bulb 4. If you touch the bulb with your bare hands, clean the bulb with a cloth moistened with alcohol or soapy wa- ter to prevent premature bulb failure. 1 2 3 4 front and rear turn signal light front and re...

Page 144

6-26 electrical system brake light/taillight remove the brake light/taillight bulb. If you touch the bulb with your bare hands, clean the bulb with a cloth moistened with alcohol or soapy wa- ter to prevent premature bulb failure. Brake light/taillight bulb replacement remove the brake light/taillig...

Page 145

Electrical system 6-27 license plate light remove the license plate light case. Remove the license plate light bulb. If you touch the bulb with your bare hands, clean the bulb with a cloth moistened with alcohol or soapy wa- ter to prevent premature bulb failure. License plate light bulb replacement...

Page 146: Relays

6-28 electrical system relays starter relay the starter relay is located behind the battery holder cover. ( 6-30) turn signal relay the turn signal relay is located behind the front leg shield. ( 5-3) if the turn signal light does not light, inspect the bulb or repair the circuit connection. If the ...

Page 147: Switches

Electrical system 6-29 switches measure each switch for continuity using the multi circuit tester. If there is no continuity, replace the respec- tive switch with a new one. Ignition switch position color b/r b/w bl/w o r on ( ) c ( • ) off ( ) lock ( ) lighting switch position color g/w gr y/w on (...

Page 148: Battery

6-30 electrical system battery removal remove the battery holder cover 1. Remove the battery. Note: disconnect the - battery lead wire, first. Remounting remount the battery in the reverse order of removal. 1.

Page 149

Electrical system 6-31 specifications type designation cb4l-b, fb4l-b capacity 12 v, 14.4 kc (4 ah)/10 hr standard electrolyte 1.280 at 20°c (specific gravity) when installing the battery onto the motorcycle, connect the breather tube to the battery vent. Initial charging filling electrolyte remove ...

Page 150

6-32 electrical system servicing visually inspect the surface of the battery container. If any signs of cracking or electrolyte leakage from the sides of the battery have occurred, replace the battery with a new one. If the battery terminals are found to be coated with rust or an acidic white powder...

Page 151

Electrical system 6-33 service life lead oxide is on the plates of the battery and will gradually come off of the plates during the life of the battery. When the bottom of the battery case becomes full of this sediment, replace the bat- tery. If the battery is not charged for a long period of time, ...

Page 152: Servicing Information

Servicing information 7-1 servicing information contents troubleshooting ...................................................................................... 7- 2 engine ........................................................................................................ 7- 2 carburetor ..........

Page 153: Troubleshooting

7-2 servicing information troubleshooting engine complaint symptom and possible causes remedy engine will not start or is hard to start. Compression too low 1. Worn cylinder. 2. Worn piston ring. 3. Gas leaks from the joint in crankcase, cylinder or cylin- der head. 4. Damaged reed valve. 5. Loose s...

Page 154

Servicing information 7-3 complaint symptom and possible causes remedy engine idles poorly. 1. Worn cylinder. 2. Worn piston rings. 3. Stiff piston ring. 4. Gas leaks from crankshaft oil seal. 5. Excessive spark plug gap. 6. Defective ignition coil. 7. Defective cdi unit. 8. Defective stator coil. 9...

Page 155

7-4 servicing information carburetor complaint symptom and possible causes remedy starting difficulty. 1. Defective thermoelement. 2. Air leaking from the joint between intake pipe and car- buretor. 3. Air leaking from carburetor joint or vacuum hose joint. 4. Clogged fuel pipe. Replace. Check intak...

Page 156

Servicing information 7-5 chassis complaint symptom and possible causes remedy steering is heavy. 1. Overtightened steering stem nut. 2. Broken bearing/race in steering stem. 3. Distorted steering stem. 4. Low tire pressure. Adjust. Replace. Replace. Adjust. Handlebar wobbles. 1. Loss of balance bet...

Page 157

7-6 servicing information brakes complaint symptom and possible causes remedy brake power insuffi- cient. 1. Leakage of brake fluid. 2. Worn brake pads. 3. Oil on brake pad surface. 4. Worn brake disc. 5. Air in hydraulic system. 6. Worn brake shoes. 7. Oil on brake shoe surface. 8. Worn brake drum....

Page 158

Servicing information 7-7 electrical complaint symptom and possible causes remedy no sparking or poor sparking. 1. Defective ignition coil. 2. Defective spark plug. 3. Defective stator coil or pickup coil. 4. Defective cdi unit. 5. Loose connection of lead wire. Replace. Replace. Replace. Replace. C...

Page 159

7-8 servicing information battery complaint symptom and possible causes remedy sulfation, acidic white powdery substance or spots on surfaces of cell plates. 1. Insufficient electrolyte. 2. Cracked battery case. 3. Battery has been left in a run-down condition for a long time. 4. Foreign matter has ...

Page 160: Wiring Diagram

Servicing information 7-9 wiring diagram fu hi tl tr oi sp off on • push on off on off speedometer diode lighting switch starter button rear brake light switch front brake light switch resistor turn signal relay ignition coil fuel level switch oil level switch on off thermoswitch cdi unit on off the...

Page 161

7-10 servicing information wire harness, cable, and hose routing wire harness 1 set the wires under the bracket seat striker and the tube frame..

Page 162

Servicing information 7-11.

Page 163

7-12 servicing information cable routing 1 p ass the throttle cab le behind the front br a k e hose . 2 p ass the throttle cab le and the rear br a k e cab le through the cab le guide . 3 p ass the throttle cab le through the cab le guide ..

Page 164

Servicing information 7-13.

Page 165

7-14 servicing information b a fuel v a lv e fuel hose v acuum hose t o the carb u retor t o the carb u retor clamp clamp air v ent hose fuel hose fuel v a lv e v acuum hose engine oil hose clamp oil dr ain hose oil dr ain hose view a view b fuel hose fuel system hose routing.

Page 166

Servicing information 7-15 battery breather hose routing breather hose battery forward forward cushion 65 mm 15 mm slit position note: the slit on the breather hose must face battery side..

Page 167

7-16 servicing information front brake hose routing 1 p ass the br a k e hose in front of the wire har ness and each cab le . 2 p ass the br a k e hose through the hose guide . 3 clamp the slee v e fir mly . 4 tighten the br a k e hose union bolt so that the hose is par allel to the handlebar . 5 ti...

Page 168: Special Tools

Servicing information 7-17 09920-13120 crankcase separat- ing tool 09921-20210 bearing remover special tools 09900-00401 hexagon wrench set 09900-06107 snap ring pliers 09900-06108 snap ring pliers 09900-09003 impact driver set 09900-20101 vernier calipers (150 mm) 09900-20202 micrometer (25 – 50 mm...

Page 169

7-18 servicing information 09923-73210 bearing remover 09923-74510 bearing remover 09924-84521 bearing installer set 09930-30102 sliding hammer 09930-40113 rotor holder 09940-52860 front fork oil seal installer 09941-34513 steering inner race installer 09941-50111 bearing remover 09941-74910 bearing...

Page 170: Tightening Torque

Servicing information 7-19 tightening torque engine item n·m kgf-m cylinder head nut 10 1.0 spark plug 28 2.8 exhaust pipe mounting nut and bolt 10 1.0 engine mounting bracket nut 65 6.5 engine mounting nut 60 6.0 clutch housing nut 50 5.0 kick starter nut 50 5.0 generator rotor nut 40 4.0 clutch sh...

Page 171

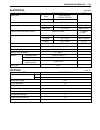

7-20 servicing information tightening torque chart for other nuts and bolts not listed in the preceding page, refer to this chart: bolt diameter conventional or “4” marked bolt “7” marked bolt a (mm) n·m kgf-m n·m kgf-m 4 1.5 0.15 2.3 0.23 5 3 0.3 4.5 0.45 6 5.5 0.55 10 1.0 8 13 1.3 23 2.3 10 29 2.9...

Page 172: Service Data

Servicing information 7-21 service data cylinder + piston + piston ring unit: mm item standard limit piston to cylinder clearance 0.06 – 0.07 0.120 cylinder bore 41.005 – 41.020 measure at 20 mm from the top surface 41.075 piston diameter 40.940 – 40.955 measure at 15 mm from the skirt end 40.885 cy...

Page 173

7-22 servicing information transmission unit: mm except ratio item standard limit reduction ratio variable 2.975 – 1.033 — final reduction ratio 13.812 (51/15 × 65/16) — drive belt width 18.4 17.4 driven face spring free length 110 104.5 carburetor item specification carburetor type keihin pws14 bor...

Page 174

Servicing information 7-23 electrical unit: mm item specification note spark plug type ngk: bpr7hs denso: w22fpr gap 0.6 – 0.7 spark performance over 8 at 1 atm. Ignition coil resistance primary 0.2 – 1.5 Ω w/bl – b/w generator coil resistance lighting 0.3 – 1.5 Ω y/w – ground pickup 120 – 250 Ω w –...

Page 175

7-24 servicing information brake + wheel unit: mm item standard/specification limit brake lever play rear 15 – 25 — brake drum i.D. Rear — 120.7 brake disc thickness front 4.0 ± 0.2 3.5 brake disc runout front — 0.30 master cylinder bore front 11.000 – 11.043 — master cylinder piston diameter front ...

Page 176

Servicing information 7-25 fuel + oil item specification note fuel type use only gasoline that is graded 91 octane or higher. Unleaded gasoline is recommended. Fuel tank capacity 6.0 l engine oil type use suzuki cci super oil. If not available, use a good quality 2-stroke oil rated fc under jaso cla...

Page 177

Uf50k1 and uf50zk1 (’01-model) 8-1 uf50k1 and uf50zk1 (’01-model) 8 contents specifications ............................................................................................ 8- 2 service data ................................................................................................ ...

Page 178: Specifications

8-2 uf50k1 and uf50zk1 (’01-model) specifications dimensions and dry mass overall length ................................................... 1 840 mm overall width .................................................... 650 mm overall height ................................................... 1 095 mm ...

Page 179

Uf50k1 and uf50zk1 (’01-model) 8-3 chassis front suspension ............................................. Inverted telescopic, coil spring rear suspension .............................................. Swingarm type, coil spring, oil damped steering angle ...............................................

Page 180: Service Data

8-4 uf50k1 and uf50zk1 (’01-model) cylinder + piston + piston ring unit: mm item standard limit piston to cylinder clearance 0.06 – 0.07 0.120 cylinder bore 41.005 – 41.020 measure at 20 mm from the top surface 41.075 piston diam. 40.940 – 40.955 measure at 15 mm from the skirt end 40.885 cylinder d...

Page 181

Uf50k1 and uf50zk1 (’01-model) 8-5 carburetor item specification carburetor type keihin pws14 bore size 14 mm i.D. No. 30f0 idle r/min. 1 900 ± 200 r/min. Float height 5.1 ± 0.5 mm main jet (m.J.) #65 jet needle (j.N.) n5gj-2nd slow jet (s.J.) #42 air screw (a.S.) 2 turns back throttle cable play 2 ...

Page 182

8-6 uf50k1 and uf50zk1 (’01-model) brake + wheel unit: mm item standard/specification limit brake lever play rear 15 – 25 ——— brake drum i.D. Rear ——— 120.7 brake disc thickness front 4.0 ± 0.2 3.5 brake disc runout front ——— 0.30 master cylinder bore front 11.000 – 11.043 ——— master cylinder piston...

Page 183: Wire Harness Routing

Uf50k1 and uf50zk1 (’01-model) 8-7 brake light/taillight brake light/taillight coupler license plate light coupler w (white) lead wire gr (gray) lead wire b/w (black with white tracer) lead wire fuel level indicator switch coupler cdi unit thermoswitch coupler clamp clamp clamp air vent hose generat...

Page 184

188 prepared by motorcycle service department 2nd ed. March, 2001 1st ed. April, 2000 part no. 99500-10491-01e printed in japan.

Page 185

Printed in japan y k1.