- DL manuals

- Suzuki

- Automobile

- Wagon R Plus RB310

- Service Manual

Suzuki Wagon R Plus RB310 Service Manual

IMPORTANT

WARNING/CAUTION/NOTE

Please read this manual and follow its instructions carefully. To emphasize special information, the words

WARNING, CAUTION and NOTE have special meanings. Pay special attention to the messages highlighted by

these signal words.

The circle with a slash or a cross on illustllation in this manual means “Do not do this” or “Do not let this happen”.

WARNING:

Indicates a potential hazard that could result in death or injury.

CAUTION:

Indicates a potential hazard that could result in vehicle damage.

NOTE:

Indicates special information to make maintenance easier or instructions clearer.

WARNING:

This service manual is intended for authorized Suzuki dealers and qualified service mechanics only.

Inexperienced mechanics or mechanics without the proper tools and equipment may not be able to

properly perform the services described in this manual.

Improper repair may result in injury to the mechanic and may render the vehicle unsafe for the driver

and passengers.

WARNING:

For vehicles equipped with a Supplemental Restraint (Air Bag) System:

• Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

• If the air bag system and another vehicle system both need repair, Suzuki recommends that the air

bag system be repaired first, to help avoid unintended air bag system activation.

• Do not modify the steering wheel, instrument panel or any other air bag system component (on or

around air bag system components or wiring). Modifications can adversely affect air bag system

performance and lead to injury.

• If the vehicle will be exposed to temperatures over 93°C (200°F) (for example, during a paint baking

process), remove the air bag system components beforehand to avoid component damage or unin-

tended activation.

Summary of Wagon R Plus RB310

Page 1

Important warning/caution/note please read this manual and follow its instructions carefully. To emphasize special information, the words warning, caution and note have special meanings. Pay special attention to the messages highlighted by these signal words. The circle with a slash or a cross on il...

Page 2: Foreword

Foreword this supplementary service manual is a supplement to rb413 service manual. It has been pre- pared exclusively for the following applicable model. Applicable model: rb410/rb413 of and after the vehicle identification number below. If describes only different service information of the above ...

Page 4: Table Of Contents

Table of contents general information engine and emission control system (g10 engine) 6e1 0a 6e1 general information 0a 0b 6e2 maintenance and lubrication 0b engine and emission control system (m13 engine) 6e2 6f1 heating and air conditioning 1a 6f2 heater and ventilation 1a ignition system (g10 eng...

Page 6: Section 0A

General information 0a-1 0a section 0a general information contents how to use this manual.................................0a-2 precautions......................................................0a-3 precaution for vehicles equipped with a supplemental restraint (air bag) system.....0a-3 diagnosis.......

Page 7: How To Use This Manual

0a-2 general information how to use this manual 1) there is a “table of contents” on the third page of this manual, whereby you can easily find the section that offers the information you need. Also, there is a “contents” on the first page of each section, where the main items in that section are li...

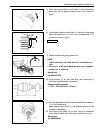

Page 8: Precautions

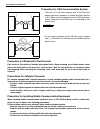

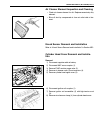

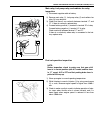

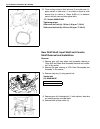

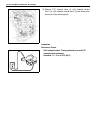

General information 0a-3 precautions precaution for vehicles equipped with a sup- plemental restraint (air bag) system warning: • the configuration of air bag system parts are as shown in the figure. When it is necessary to service (remove, reinstall and inspect) these parts, be sure to follow proce...

Page 9

0a-4 general information diagnosis • when troubleshooting air bag system, be sure to follow “diagnosis” in section 10b. Bypassing these procedures may result in extended diagnostic time, incorrect diagnosis, and incorrect parts replacement. • never use electrical test equipment other than that speci...

Page 10

General information 0a-5 servicing and handling warning: many of service procedures require disconnection of “air bag” fuse and all air bag (inflator) module(s) from initiator circuit to avoid an accidental deployment. Driver, passenger and side air bag (inflator) modules • for handling and storage ...

Page 11

0a-6 general information • even when the accident was light enough not to cause air bags to activate, be sure to inspect sys- tem parts and other related parts according to instructions under “repair and inspection required after an accident” in section 10b. • when servicing parts other than air bag...

Page 12

General information 0a-7 • warning / caution labels are attached on each part of air bag system components. Be sure to fol- low the instructions. • after vehicle is completely repaired, perform “air bag diagnostic system check” in section 10b. General precautions the warning and caution below descri...

Page 13

0a-8 general information • when removing the battery, be sure to disconnect the negative cable first and then the positive cable. When reconnecting the battery, connect the positive cable first and then the negative cable, and replace the terminal cover. • when removing parts that are to be reused, ...

Page 14

General information 0a-9 • when disconnecting vacuum hoses, attach a tag describing the correct installation positions so that the hoses can be reinstalled correctly. • after servicing fuel, oil, coolant, vacuum, exhaust or brake systems, check all lines related to the system for leaks. • for vehicl...

Page 15

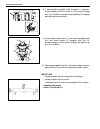

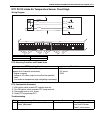

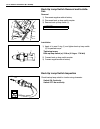

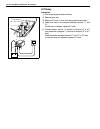

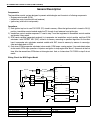

0a-10 general information precaution for can communication system • the loose (1) in the wire harnesses twist of the can lines except around the connector (3) should be within 100 mm (3.9 in.) refer to the wiring diagram for the can line discrim- ination. Excessive loosed lines may be influenced by ...

Page 16

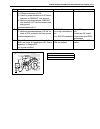

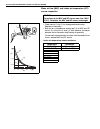

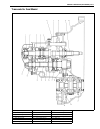

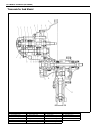

General information 0a-11 precaution in servicing full-time 4wd vehicle this full-time 4wd vehicle can not be converted to 2wd manually. Observe the following caution in servicing. Otherwise, front wheels drive rear wheels or vise-versa and vehicle accidents, drivetrain damage and personal injury ma...

Page 17

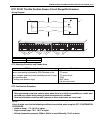

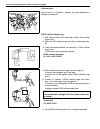

0a-12 general information precautions for electrical circuit service • when replacing a fuse, make sure to use a fuse of the specified capacity. Use of a fuse with a larger capacity will cause a damage to the electrical parts and a fire. • when disconnecting and connecting coupler, make sure to turn...

Page 18

General information 0a-13 • when installing the wiring harness, fix it with clamps so that no slack is left. • when installing vehicle parts, be careful so that the wir- ing harness is not interfered with or caught by any other part. • to avoid damage to the harness, protect its part which may conta...

Page 19

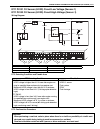

0a-14 general information • when taking measurements at electrical connectors using a tester probe, be sure to insert the probe (2) from the wire harness side (backside) of the connector (1). • when connecting meter probe (2) from terminal side of coupler (1) because it can’t be connected from harne...

Page 20

General information 0a-15 electrical circuit inspection procedure while there are various electrical circuit inspection methods, described here is a general method to check its open and short circuit by using an ohmmeter and a voltmeter. Open circuit check possible causes for the open circuit are as...

Page 21

0a-16 general information continuity check 1) measure resistance between connector terminals at both ends of the circuit being checked (between a-1 and c-1 in the figure). If no continuity is indicated (infinity or over limit), that means that the circuit is open between terminals a-1 and c-1. 2) di...

Page 22

General information 0a-17 short circuit check (wire harness to ground) 1) disconnect negative (–) cable at battery. 2) disconnect connectors at both ends of the circuit to be checked. 3) measure resistance between terminal at one end of circuit (a-1 terminal in the figure) and body ground. If contin...

Page 23

0a-18 general information • improperly formed or damaged terminals. Check each connector terminal in problem circuits carefully to ensure good contact tension by using the corresponding mating terminal. If contact tension is not enough, reform it to increase contact tension or replace. • poor termin...

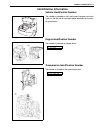

Page 24: Identification Information

General information 0a-19 identification information vehicle identification number the number is punched on front dash panel in engine room and it is also on the left side of instrument panel depending on the vehi- cle specification. Engine identification number the number is punched on cylinder blo...

Page 25

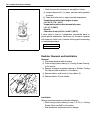

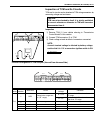

0a-20 general information warning, caution and information labels the figure below shows main labels among others that are attached to vehicle component parts. When servicing and handling parts, refer to warning/caution instructions printed on labels. If any warning/caution label is found stained or...

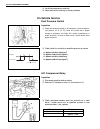

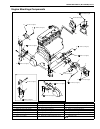

Page 26: Vehicle Lifting Points

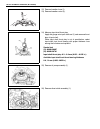

General information 0a-21 vehicle lifting points when using frame contact hoist warning: • before applying hoist to underbody, always take vehicle balance throughout service into consider- ation. Vehicle balance on hoist may change depending on what part to be removed. • before lifting up the vehicl...

Page 27

0a-22 general information when using floor jack when lifting front vehicle end with floor jack, be sure to put the wooden block (5) on the jack against front jacking bracket (1). When lifting rear vehicle end with floor jack, be sure to put the jack against the center portion of rear axle (2) (2wd v...

Page 28

General information 0a-23 abbreviations and symbols may be used in this manual abbreviations a abs anti-lock brake system e efe heater early fuel evaporation heater (positive temperature coeffi- cient, ptc heater) atdc after top dead center api american petroleum institute atf automatic transmission...

Page 29

0a-24 general information p psp switch power steering pressure switch (p/s pressure switch) pcm powertrain control module pcv positive crankcase ventilation r rh right hand s sae society of automotive engineers sdm sensing and diagnostic module (air bag controller, air bag control module) sfi sequen...

Page 30

General information 0a-25 symbols wire color symbols there are two kinds of colored wire used in this vehicle. One is single-colored wire and the other is dual-colored (striped) wire. The single-colored wire uses only one color symbol (i.E. “grn”). The dual-colored wire uses two color symbols (i.E. ...

Page 31: Fastener Information

0a-26 general information fastener information metric fasteners information most of the fasteners used for this vehicle are jis-defined and iso-defined metric fasteners. When replacing any fasteners, it is most important that replacement fasteners be the correct diame- ter, thread pitch and strength...

Page 32

General information 0a-27 fastener strength identification most commonly used metric fastener strength property classes are 4t, 6.8, 7t, 8.8 and radial line with the class identification embossed on the head of each bolt. Some metric nuts will be marked with punch, 6 or 8 mark strength identificatio...

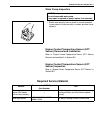

Page 33

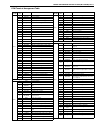

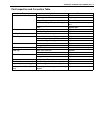

0a-28 general information tightening torque chart: thread diameter (nominal diameter) (mm) 4 5 6 8 10 12 14 16 18 strength a equivalent of 4t strength fastener n·m 1.5 3.0 5.5 13 29 45 65 105 160 kg-m 0.15 0.30 0.55 1.3 2.9 4.5 6.5 10.5 16 lb-ft 1.0 2.5 4.0 9.5 21.0 32.5 47.0 76.0 116.0 a equivalent...

Page 34: Section 0B

Maintenance and lubrication 0b-1 0b section 0b maintenance and lubrication contents maintenance schedule ...................................0b-3 maintenance schedule under normal driving conditions .........................................0b-3 maintenance recommended under severe driving conditions....

Page 35

0b-2 maintenance and lubrication transfer oil (4wd) and rear differential oil (4wd) inspection................................... 0b-19 transfer oil (4wd) and rear differential oil (4wd) replacement .............................. 0b-20 all latches, hinges and locks inspection...........................

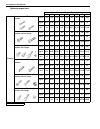

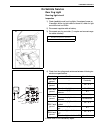

Page 36: Maintenance Schedule

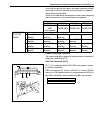

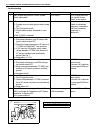

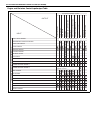

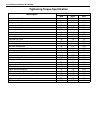

Maintenance and lubrication 0b-3 maintenance schedule maintenance schedule under normal driving conditions note: • this interval should be judged by odometer reading or months, whichever comes first. • this table includes service as scheduled up to 90,000 km (54,000 miles) mileage. Beyond 90,000 km ...

Page 37

0b-4 maintenance and lubrication interval km (x 1,000) 15 30 45 60 75 90 miles (x 1,000) 9 18 27 36 45 54 months 12 24 36 48 60 72 brake brake discs and pads (thickness, wear, damage) i i i i i i brake drums and shoes (wear, damage) – i – i – i brake hoses and pipes (leakage, damage, clamp) – i – i ...

Page 38

Maintenance and lubrication 0b-5 maintenance recommended under severe driving conditions if the vehicle is usually used under the conditions corresponding to any severe condition code given below, it is recommended that applicable maintenance operation be performed at the particular interval as show...

Page 39: Maintenance Service

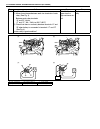

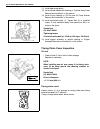

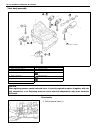

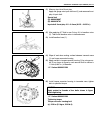

0b-6 maintenance and lubrication maintenance service drive belt inspection (m13 engine) water pump and generator drive belt inspection 1) disconnect negative (–) cable at battery. 2) inspect belt for cracks, cuts, deformation, wear and cleanli- ness. If any defect exists, replace. Check belt for ten...

Page 40

Maintenance and lubrication 0b-7 drive belt inspection (g10 engine) a/c compressor drive belt inspection (if equipped) 1) hoist vehicle and remove engine under cover of right side from vehicle body. 2) inspect belt for wear, deterioration and tension. Replace or adjust, if necessary. A/c compressor ...

Page 41

0b-8 maintenance and lubrication camshaft timing belt replacement (g10 engine) replace belt with new one. Refer to section 6a for replacement procedure. Valve lash (clearance) inspection (m13 engine) 1) inspect intake and exhaust valve lash and adjust as neces- sary. Refer to “valve lash (clearance)...

Page 42

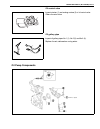

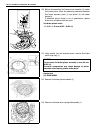

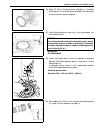

Maintenance and lubrication 0b-9 engine oil and oil filter replacement before draining engine oil, check engine for oil leakage. If any evi- dence of leakage is found, make sure to correct defective part before proceeding to the following work. 1) drain engine oil by removing drain plug. 2) after dr...

Page 43

0b-10 maintenance and lubrication 5) tighten the filter (1) 3/4 turn from the point of contact with the mounting surface using an oil filter wrench (2). Tightening torque oil filter (b): 14 n·m (1.4 kg-m, 10.5 lb-ft) (for reference) 6) replenish oil until oil level is brought to full level mark on d...

Page 44

Maintenance and lubrication 0b-11 engine coolant replacement change engine coolant with new one referring to “cooling system flush and refill” in section 6b or 6b2. Exhaust system inspection when carrying out periodic maintenance, or the vehicle is raised for other service, check exhaust system as f...

Page 45

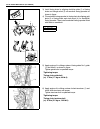

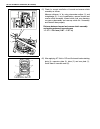

0b-12 maintenance and lubrication distributor cap and rotor inspection (g10 engine) • check distributor cap and rubber caps for cracks. • clean dusty and stained parts using a dry, soft cloth. • check center electrode and terminals for wear. • check rotor for cracks and its electrode for wear. Repai...

Page 46

Maintenance and lubrication 0b-13 fuel tank inspection check fuel tank damage, cracks, fuel leakage, corrosion and tank bolts looseness. If a problem is found, repair or replace. Pcv valve inspection check crankcase ventilation hose and pcv hose for leaks, cracks or clog, and pcv valve for stick or ...

Page 47

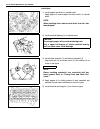

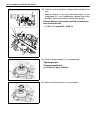

0b-14 maintenance and lubrication brake drums and shoes (rear) inspection 1) remove wheel and brake drum. 2) check rear brake drums and brake linings for excessive wear and damage, while wheels and drums are removed. At the same time, check wheel cylinders for leaks. Replace these parts as necessary...

Page 48

Maintenance and lubrication 0b-15 2) check tooth tip of each notch for damage or wear. If any damage or wear is found, replace parking lever. 3) check parking brake lever for proper operation and stroke, and adjust it if necessary. For checking and adjusting procedures, refer to “parking brake inspe...

Page 49

0b-16 maintenance and lubrication wheel discs inspection inspect each wheel disc for dents, distortion and cracks. A disc in badly damaged condition must be replaced. Wheel bearing inspection 1) check front wheel bearing for wear, damage, abnormal noise or rattles. For details, refer to “wheel disc,...

Page 50

Maintenance and lubrication 0b-17 3) check steering linkage for looseness and damage. Repair or replace defective parts, if any. 4) check boots (1) and (2) of steering linkage and steering gear case for damage (leak, detachment, tear, etc.). If damage is found, replace defective boot with new one. I...

Page 51

0b-18 maintenance and lubrication manual transmission oil inspection 1) inspect transmission case for evidence of oil leakage. Repair leaky point if any. 2) make sure that vehicle is placed level for oil level check. 3) remove oil filler/level plug (1) of transmission. 4) check oil level. Oil level ...

Page 52

Maintenance and lubrication 0b-19 automatic transmission fluid replacement 1) inspect transmission case for evidence of fluid leakage. Repair leaky point, if any. 2) make sure that vehicle is placed level for fluid level check. 3) change fluid. For its procedure, refer to “fluid change” in section 7...

Page 53

0b-20 maintenance and lubrication transfer oil (4wd) and rear differential oil (4wd) replacement change transfer oil and differential oil with new specified oil refer- ring to “transfer oil change” in section 7d or “rear differential oil change” in section 7f. All latches, hinges and locks inspectio...

Page 54: Final Inspection

Maintenance and lubrication 0b-21 final inspection seats check that seat slides smoothly and locks securely at any position. Also check that reclining mechanism of front seat back allows it to be locked at any angle. Seat belt inspect belt system including webbing, buckles, latch plates, retractors ...

Page 55

0b-22 maintenance and lubrication foot brake check the followings: • that brake pedal has proper travel, • that brake works properly, • that it is free from noise, • that vehicle does not pull to one side when brake is applied. • and that brake do not drag. Parking brake check that lever has proper ...

Page 56

Maintenance and lubrication 0b-23 recommended fluids and lubricants engine oil sg, sh, sj or sl grade (refer to “engine oil and oil filter replace- ment” in this section for engine oil viscosity.) engine coolant (ethylene glycol base coolant) “antifreeze / anticorrosion coolant” brake fluid dot 4 or...

Page 57

0b-24 maintenance and lubrication.

Page 58: Section 1B

Air conditioning (optional) 1b-1 1b section 1b air conditioning (optional) contents diagnosis........................................................ 1b-2 wiring circuit (m13 engine model)............... 1b-2 a/c system inspection of ecm and its circuits (m13 engine model)......................... 1...

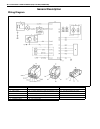

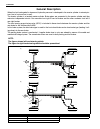

Page 59: Diagnosis

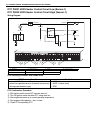

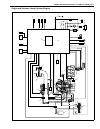

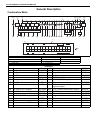

1b-2 air conditioning (optional) diagnosis wiring circuit (m13 engine model) 1. Main fuse box 7. A/c switch 13. A/c evaporator thermistor 2. Main relay 8. Dual pressure switch 14. Ect sensor 3. Radiator (and condenser) cooling fan motor relay 9. Blower fan motor relay 15. Compressor relay 4. Radiato...

Page 60

Air conditioning (optional) 1b-3 a/c system inspection of ecm and its cir- cuits (m13 engine model) ecm and its circuits can be checked at ecm wiring couplers by measuring voltage. Inspection 1) remove ecm (1) from vehicle. 2) connect ecm (1) couplers to ecm. 3) check voltage at each terminal of cou...

Page 61

1b-4 air conditioning (optional) terminal arrangement of ecm coupler (viewed from harness side) ecm voltage values table for relation of a/c control (m13 engine model) b. To “heater” fuse (25a) in circuit fuse box 2. Dual pressure switch 7. A/c evaporator thermistor 12. Radiator (and condenser) cool...

Page 62

Air conditioning (optional) 1b-5 compressor drive belt (m13 engine model) inspection • check compressor drive belt (6) for wear and cracks, and replace as required. • check compressor drive belt (6) tension by measuring how much it deflects when pushed at intermediate point between compressor pulley...

Page 63: On-Vehicle Service

1b-6 air conditioning (optional) 4) install new compressor drive belt. 5) adjust belt tension referring to above procedure. On-vehicle service dual pressure switch inspection 1) check dual pressure switch (1) for continuity at normal tempera- ture (approx. 25 º c (77 º f)) when a/c system has a prop...

Page 64

Air conditioning (optional) 1b-7 4) check that there is continuity between terminals “a” and “b” when battery is connected to terminals “c” and “d”. If found defective, replace. Compressor (m13 engine model) removal 1) run engine at idle speed with air conditioning on for 10 min- utes. After that, s...

Page 65

1b-8 air conditioning (optional).

Page 66: Section 3A

Front wheel alignment 3a-1 3a section 3a front wheel alignment contents general description ........................................3a-2 front wheel alignment specifications ..........3a-2 warning: do not removal all of the wheel bolts at once, because all the wheels of this vehicle are mounted by t...

Page 67: General Description

3a-2 front wheel alignment general description front wheel alignment specifications front alignment refers to the angular relationship between the front wheels, the front suspension attaching parts and the ground. Generally, the only adjustment required for front alignment is toe setting. Camber and...

Page 68: Section 3B

Manual rack and pinion 3b-1 3b section 3b manual rack and pinion contents on-vehicle service..........................................3b-2 tie rod end ..................................................3b-2 manual rack and pinion assembly (steering gear case) ....................................3b-3 ...

Page 69: On-Vehicle Service

3b-2 manual rack and pinion on-vehicle service tie rod end installation 1) install tie rod end lock nut (1) and tie rod end (2) to tie rod (3). Align lock nut with mark (4) on tie rod thread. 2) connect tie rod end to knuckle. Tighten new tie rod end nut (1) to specified torque. Tightening torque ti...

Page 70

Manual rack and pinion 3b-3 manual rack and pinion assembly (steering gear case) installation 1) apply grease to inside of pinion packing and install pinion packing onto pinion. Mount steering gear case (1) to body and tighten gear case mount bolts (2) and nuts (3) to speci- fied torque. Tightening ...

Page 71

3b-4 manual rack and pinion 7) reinstall cover (1) removed previously to steering shaft joint. 8) put back floor mat as it was. 9) install both wheels and tighten wheel bolts to specified torque. Tightening torque wheel bolt: 95 n·m (9.5 kg-m, 69.0 lb-ft) 10) lower hoist. 11) check toe setting. Adju...

Page 72: Section 3B1

Electrical power steering (eps) system (if equipped) 3b1-1 3b1 section 3b1 electrical power steering (eps) system (if equipped) contents general description ......................................3b1-2 wiring diagram ...........................................3b1-2 diagnosis.............................

Page 73: General Description

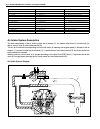

3b1-2 electrical power steering (eps) system (if equipped) general description wiring diagram 1. Main fuse box 8. Speedometer 15. Motor assembly (with clutch incorporated) 2. “eps” fuse (30 a) 9. “eps” warning lamp 16. Torque sensor 3. Ignition switch 10. To vehicle speed sensor (vss) for g10 engine...

Page 74: Diagnosis

Electrical power steering (eps) system (if equipped) 3b1-3 diagnosis “eps” warning lamp circuit check flow table for m13 engine model caution: be sure to perform “system check flow table” before starting diagnosis according to flow table. Step action yes no 1 1) make sure that battery voltage is abo...

Page 75

3b1-4 electrical power steering (eps) system (if equipped) table-b “eps” warning lamp remains on step action yes no 1 was “system check flow table” performed? Go to step 2. Go to “system check flow table” in this section. 2 1) with ignition switch off, disconnect 8 pin (“a”) connector from p/s contr...

Page 76: Section 3D

Front suspension 3d-1 3d section 3d front suspension contents general description ........................................3d-2 diagnosis.........................................................3d-3 wheel disc, bolt & bearing check................3d-3 on-vehicle service..................................

Page 77: General Description

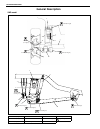

3d-2 front suspension general description the front suspension is the strut type independent suspension. The upper end of a strut is anchored to the vehi- cle body by a strut support. The strut and strut support are isolated by a rubber mount. A strut bearing is also installed a little lower to the ...

Page 78: Diagnosis

Front suspension 3d-3 diagnosis wheel disc, bolt & bearing check 1) inspect each wheel disc for dents, distortion and cracks. A disc in badly damaged condition must be replaced. 2) check wheel bolts for tightness and retighten them to specifi- cation as necessary. Tightening torque wheel bolt (a): 9...

Page 79: On-Vehicle Service

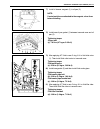

3d-4 front suspension on-vehicle service stabilizer bar and/or bushings components installation for installation, reverse removal procedure, observing the follow- ing instructions. • install stabilizer bar (1) so that paint mark (2) on it comes to the right side of vehicle. • align the outside edge ...

Page 80

Front suspension 3d-5 • install mounting bracket (1) so that its oblong hole side (2) comes to the rear. • tighten stabilizer bar bracket bolts to specified torque. Tightening torque stabilizer bar bracket bolt: 45 n · m (4.5 kg-m, 32.5 lb-ft) • after tightening castle nut (1) to specified torque, i...

Page 81

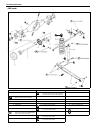

3d-6 front suspension • install wheel and tighten wheel bolts to specified torque. Tightening torque wheel bolt (a) 95 n · m (9.5 kg-m, 69.0 lb-ft) • confirm front end (wheel) alignment, referring to section 3a. Steering knuckle / bearing components 1. Wheel hub 5. Dust cover 9. Tie-rod end nut 13. ...

Page 82

Front suspension 3d-7 removal 1) hoist vehicle and remove wheel. 2) uncaulk drive shaft nut (1). 3) depress foot brake pedal and hold it there. Remove drive shaft nut. 4) remove caliper carrier bolts. 5) remove caliper with carrier. 6) remove brake disk screws. 7) pull brake disc (1) off by using tw...

Page 83

3d-8 front suspension 9) remove tie-rod end nut and disconnect tie-rod end (2) from knuckle (1) with puller. 10) remove wheel speed sensor (1) from knuckle (if equipped). 11) remove strut bracket bolts (1) from strut bracket and then control arm ball stud bolt (2). 12) remove knuckle (3). Disassembl...

Page 84

Front suspension 3d-9 2) remove circlip (1). Special tool (a): 09900-06108 3) remove wheel bearing using special tool and hydraulic press. Special tool (a): 09913-75810 (for gasoline engine model) (a): 09913-85210 (for diesel engine model) 4) remove wheel bearing outside inner race (1) as shown by h...

Page 85

3d-10 front suspension 2) install circlip (1). Special tool (a): 09900-06108 3) drive in dust cover (1) so that dimensions “a” and “b” become equal as shown. 4) caulk with a punch. Installation 1) using special tools and hydraulic press (1), drive wheel hub (2) into wheel bearing (3) as shown. Speci...

Page 86

Front suspension 3d-11 • apply grease lightly to contact part (1) of wheel bearing and drive shaft. “a”: grease 99000-25050 2) install knuckle (2) to ball stud (3) on suspension control arm (4) and strut bracket (1). Installing direction of each bolt is as shown. Align knuckle bolt hole with ball st...

Page 87

3d-12 front suspension 6) install brake disc. 7) tighten brake disc screws. Tightening torque brake disc screw (a): 9 nm (0.9 kg-m, 6.5 lb-ft) 8) install brake caliper/caliper carrier. 9) tighten caliper carrier bolts to specified torque. Tightening torque brake caliper carrier bolt (b): 95 n · m (9...

Page 88

Front suspension 3d-13 7) remove bushing. Place suspension control arm onto flat surface side of spe- cial tool and push out bushing with special tool and oil hydraulic press as shown. Special tool (a): 09943-77910 installation 1) place suspension control arm onto flat surface side of spe- cial tool...

Page 89

3d-14 front suspension 3) install ball stud (2) to knuckle (1). Align ball stud groove with knuckle bolt hole as shown. Then install ball stud bolt from the direction as shown. Tighten control arm ball stud bolt to specified torque. Tightening torque control arm ball stud bolt (a): 60 n · m (6.0 kg-...

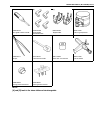

Page 90: Required Service Material

Front suspension 3d-15 required service material special tool material recommended suzuki product (part number) use lithium grease (should be applicable for –40 c° – 130 °c or –40 °f – 266 °f) suzuki super grease (e) (99000-25050) • wheel bearing 09943-17912 09942-15511 09900-06108 09913-75810 front...

Page 91

3d-16 front suspension.

Page 92: Section 3E

Rear suspension 3e-1 3e 3f 4 4b 5 5a 5b 5c 6-2 6a2 6b2 section 3e rear suspension contents general description ........................................3e-2 diagnosis.........................................................3e-4 wheel disc, bolt and bearing check ............3e-4 on-vehicle service......

Page 93: General Description

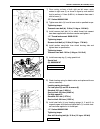

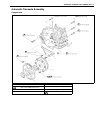

3e-2 rear suspension general description 2wd model 1. Rear coil spring 4. Rear shock absorber 7. Rear axle 10. Circlip 2. Rear bump stopper 5. Lateral rod 8. Wheel bearing tightening torque 3. Rear spring upper seat 6. Trailing arm 9. Brake drum 6 7 5 2 1 3 4 90 n·m(9.0 kg-m) 63 n·m(6.3 kg-m) 63 n·m...

Page 94

Rear suspension 3e-3 4wd model a: with abs 4. Rear shock absorber 9. Brake drum 14. Wheel bearing retainer ring or rear wheel sensor ring (if equipped with abs) b: without abs 5. Lateral rod 10. Rear axle shaft 15. Spacer 1. Rear coil spring 6. Trailing arm 11. Breather cap tightening torque 2. Rear...

Page 95: Diagnosis

3e-4 rear suspension diagnosis wheel disc, bolt and bearing check • inspect each wheel disc for dents, distortion and cracks. A disc in badly damaged condition must be replaced. • check wheel bolts for tightness and, as necessary, retighten to specification. Tightening torque wheel bolt (a): 95 n · ...

Page 96: On-Vehicle Service

Rear suspension 3e-5 on-vehicle service 2wd model “a”: body outside 7. Lateral rod outer washer 14. Lspv bracket (only vehicle with lspv) 21. Trailing arm rear bolt: insert from vehicle inside. 1. Rear coil spring 8. Rear axle 15. Brake back plate: apply water tight sealant 99000-31090 to joint of p...

Page 97

3e-6 rear suspension 4wd model “a”: body outside 11. Oil seal 22. Brake back plate bolt 1. Rear coil spring 12. Spacer: the tapered side of spacer inner diameter directed toward outside (brake drum side). 23. Bearing retainer ring (without abs) 2. Rear bump stopper: apply soap water, when installing...

Page 98

Rear suspension 3e-7 lateral rod installation 1) install lateral rod (1) or (2) to rear axle (or axle housing) (3) and vehicle body (4) referring to figure for proper installing direction of bolt (5) and washer (6). Tighten nuts (7) temporarily at this step. 2) lower hoist. 3) tighten lateral rod nu...

Page 99

3e-8 rear suspension coil spring installation 1) install coil springs (1) (right & left) on spring seat (2) of rear axle as shown in figure and then raise rear axle. 2) install shock absorber (1) lower side to rear axle (or axle housing). Tighten shock absorber lower bolt (2) temporarily by hand at ...

Page 100

Rear suspension 3e-9 8) lower hoist and vehicle in non-loaded condition, tighten absorber lower bolt (1) and lateral rod body side nut (2) to specified torque. Tightening torque rear shock absorber lower bolt (a): 63 n·m (6.3 kg-m, 45.5 lb-ft) lateral rod nut (body side) (b): 100 n·m (10.0 kg-m, 72....

Page 101

3e-10 rear suspension 2) install wheel speed sensor lead wire clamp, if equipped. 3) install parking brake cable clamp (1). 4) install shock absorber (1) to rear axle (2). 5) tighten shock absorber lower bolt (3) temporarily by hand. 6) remove floor jack from rear axle. 7) install wheel and tighten ...

Page 102

Rear suspension 3e-11 rear axle (for 2wd model) installation install removed parts in reverse order of removal, noting the fol- lowing points. 1) place rear axle on floor jack. Then install lateral rod to rear axle and tighten nut temporarily by hand. 2) install trailing arm rear bolts (1) (right & ...

Page 103

3e-12 rear suspension 7) install brake back plates (1) and tighten back plate bolts (2) to specified torque. Tightening torque brake back plate bolt (a): 23 n · m (2.3kg-m, 16.5 lb-ft) 8) connect wheel speed sensor and lead wire clamps (right & left) (if equipped). 9) connect brake pipes to wheel cy...

Page 104

Rear suspension 3e-13 12) install brake drums (right & left). For details, refer to steps 3) to 8) of “brake drum installation” in section 5c. 13) fill reservoir with brake fluid and bleed brake system. (for bleeding operation, refer to section 5.) 14) install wheel and tighten wheel bolts to specif...

Page 105

3e-14 rear suspension 2) remove circlip (1). Special tool (a): 09900-06108 3) remove wheel bearing by using special tool and hydraulic press. Special tool (a): 09913-76010 installation 1) install new wheel bearing (1) by using special tool and hydraulic press. Special tool (a): 09913-75810 2) instal...

Page 106

Rear suspension 3e-15 rear axle shaft and wheel bearing (for 4wd model) removal 1) hoist vehicle and remove rear wheels. 2) remove brake drum screw and rear brake drum by using 8 mm bolts. For details referring to section 5c. 3) drain gear oil from rear axle housing by loosening drain plug (1). 4) r...

Page 107

3e-16 rear suspension 10) in order to remove the retainer ring (1) from the axle shaft (2), grind (3) with a grinder two parts of the bearing retainer ring as illustrated till it becomes thin. 11) break with a chisel the thin ground retainer ring, and it can be removed. 12) using special tools, remo...

Page 108

Rear suspension 3e-17 installation install removed parts in reverse order of removal, noting the fol- lowing points. 1) install wheel bearing spacer (1) with the tapered side of its inner diameter directed toward outside, or brake drum side. 2) press in a new bearing (2) and retainer ring (3) in ord...

Page 109

3e-18 rear suspension 6) install rear axle shaft to rear axle housing and tighten brake back plate bolts to specified torque. Tightening torque brake back plate bolt (a): 23 n·m (2.3 kg-m, 17.0 lb-ft) 7) connect brake pipe to wheel cylinder and tighten brake pipe flare nut to specified torque. Tight...

Page 110

Rear suspension 3e-19 rear axle housing (for 4wd model) removal 1) hoist vehicle and remove rear wheels referring to “wheel removal and installation” in section 3f. 2) remove rear axle shafts (right & left) referring to steps 2) – 9) of “rear axle shaft and wheel bearing (for 4wd model)” in this sec...

Page 111

3e-20 rear suspension 11) loosen trailing arm rear mounting nuts (3) (right & left) from axle housing, but don’t remove bolts. 12) remove shock absorber lower mounting bolts (1). 13) lower floor jack until tension of suspension coil spring becomes a little loose and remove trailing arm rear mounting...

Page 112

Rear suspension 3e-21 installation install removed parts in reverse order of removal, noting the fol- lowing. 1) place rear axle housing on floor jack. Then install rear trail- ing arm bolts (1) (right & left) in proper direction as shown. Then tighten nuts (2) temporarily by hand. 2) install coil s...

Page 113

3e-22 rear suspension 5) clean mating surfaces of axle housing (1) and differential carrier and apply sealant to housing side. “a”: sealant 99000-31110 6) install differential carrier assembly to axle housing and tighten carrier bolts to specified torque. Tightening torque rear differential carrier ...

Page 114

Rear suspension 3e-23 15) install rear axle shaft (right & left) to rear axle housing. 16) tighten brake back plate bolts to specified torque. Tightening torque brake back plate bolt (a): 23 n·m (2.3 kg-m, 17.0 lb-ft) 17) connect brake pipes (3) to wheel cylinders (1) (right & left) and tighten brak...

Page 115

3e-24 rear suspension 26) tighten right and left trailing arm nuts (1) and shock absorber lower bolts (2) to specified torque. Tighten lateral rod nuts (3) to specified torque. Tightening torque trailing arm rear nut (a): 80 n·m (8.0 kg-m, 58.0 lb-ft) rear shock absorber lower bolt (b): 63 n·m (6.3 ...

Page 116: Required Service Material

Rear suspension 3e-25 required service material material recommended suzuki product (part number) use lithium grease suzuki super grease (a) (99000-25010)···(for 4wd model) • axle shaft oil seal sealant suzuki bond no. 1215 (99000-31110)···(for 4wd model) • joint seam of differential carrier and axl...

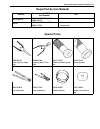

Page 117: Special Tool

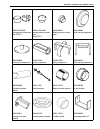

3e-26 rear suspension special tool 09913-75810 09913-76010 09927-18411 09900-06108 bearing installer (for 2wd model) rear wheel bearing installer (for 2wd model) universal puller (for 4wd model) snap ring pliers (for 2wd model) 09942-15511 09943-17912 09921-57810 09913-50121 sliding hammer brake dru...

Page 118: Section 3F

Wheels and tires 3f-1 3f section 3f wheels and tires contents general description ....................................... 3f-2 tires ............................................................. 3f-2 maintenance and minor adjustments........... 3f-2 wheel maintenance ...................................

Page 119: General Description

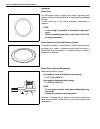

3f-2 wheels and tires general description tires this vehicle is equipped with the following tire. Tire specification 165/60r14 75t ········ gasoline engine model 165/60r14 79t ····························· diesel engine model the tire is of tubeless type. The tire is designed to operate satisfactori...

Page 120: On-Vehicle Service

Wheels and tires 3f-3 on-vehicle service service operations wheel bolts all models use metric lug wheel bolts. Metric lug bolt size (1): m12 x 1.5 wheel removal 1) loosen wheel bolts by approximately 180 ° (half a rotation). 2) hoist vehicle. 3) make sure that the vehicle will not fall off by trying...

Page 121

3f-4 wheels and tires tightening order “a” – “b” – “c” – “d”: tightening torque wheel bolt (a): 95 n · m (9.5 kg-m, 69.0 lb-ft) tightening torque specifications fastening part tightening torque n•m kg-m lb-ft wheel bolt 95 9.5 69.0

Page 122: Section 4A

Front drive shaft (g10/m13 engines) 4a-1 4a 4b 5 5a 5b 5c 6-2 6a2 6b2 section 4a front drive shaft (g10/m13 engines) contents general description ....................................... 4a-1 diagnosis........................................................ 4a-1 on-vehicle service.......................

Page 123: On-Vehicle Service

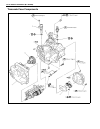

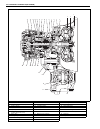

4a-2 front drive shaft (g10/m13 engines) on-vehicle service front drive shaft assembly construction 1. Transaxle 7. Oil filler/level plug : apply sealant 99000-31260 to plug thread 13. Drive shaft washer 2. Drive shaft assembly 8. Oil drain plug : apply sealant 99000-31260 to plug thread 14. Center ...

Page 124

Front drive shaft (g10/m13 engines) 4a-3 front drive shaft assembly removal and installation removal 1) undo caulking (1) and remove drive shaft nut (2). 2) loosen wheel bolts. 3) hoist vehicle. 4) remove wheel. 5) drain transaxle oil as follows. • for m/t model with g10 engine refer to “oil change”...

Page 125

4a-4 front drive shaft (g10/m13 engines) 9) pull out drive shaft joint (2) as follows. • for left side of all model and right side of g10 engine model using tire lever (1), pull out drive shaft joint (2) so as to release snap ring fitting of joint spline at differential side. • for right side of 2wd...

Page 126

Front drive shaft (g10/m13 engines) 4a-5 installation reverse removal procedure for installation noting the following. • install wheel side joint to steering knuckle first, and then dif- ferential side joint to transaxle. • tighten each bolt and nut to the specified torque referring to “front drive ...

Page 127

4a-6 front drive shaft (g10/m13 engines) front drive shaft components [a]: tripod joint type 6. Wheel side joint (constant velocity ball joint) : apply black grease included in spare part to joint. 14. Circlip [b]: doj type 7. Boot (wheel side) 15. Center bearing support [c]: center shaft for 2wd mo...

Page 128

Front drive shaft (g10/m13 engines) 4a-7 front drive shaft disassembly and assembly disassembly for doj type 1) remove differential side boot big band (1) as follows. • for boot big band without joint remove boot big band by tapping boot and band with plastic hammer. If it is hard to remove boot big...

Page 129

4a-8 front drive shaft (g10/m13 engines) c) remove cage (1) with retaining ring (2) from housing (3) if necessary. 3) remove differential side boot small band, and then pull out differential side boot from shaft. 4) pull out damper through shaft. 5) remove wheel side boot big band (1) as follows. • ...

Page 130

Front drive shaft (g10/m13 engines) 4a-9 1) remove differential side boot big band (1) as follows. • for boot big band without joint remove boot big band by tapping boot and band with plastic hammer. If it is hard to remove boot big band, cut it using a nipper or a iron saw with care not to damage t...

Page 131

4a-10 front drive shaft (g10/m13 engines) 7) remove wheel side boot big band (1) as follows. • for boot big band without joint cut boot big band using a iron saw or a nipper with care not to damage wheel side joint housing. • for boot big band with joint draw hooks of boot big band together and remo...

Page 132

Front drive shaft (g10/m13 engines) 4a-11 3) install new wheel side boot on shaft temporarily. 4) apply grease in the supplied parts to the inside of joint hous- ing. Grease color: black grease amount: approx. 70 g (2.5 oz) 5) fit wheel side boot onto grooves of housing and shaft. 6) place new wheel...

Page 133

4a-12 front drive shaft (g10/m13 engines) 10) install damper (1) on left side drive shaft according to dimen- sion specified below. Damper installation position for m/t model with m13 engine “a”: 134 – 140 mm (5.28 – 5.51 in.) for a/t model with m13 engine “a”: 157 – 163 mm (6.18 – 6.42 in.) 11) ins...

Page 134

Front drive shaft (g10/m13 engines) 4a-13 15) install boot on joint housing. • for right side when fixing boot (1) to joint housing (2) with differential side boot big band (3), adjust so that measurements become as indicated below. • for left side fit boot to grooves of shaft and housing and adjust...

Page 135

4a-14 front drive shaft (g10/m13 engines) for tripod joint type judging from abnormality noted before disassembly and what is found through visual check of component parts after disassembly, prepare replacing parts and proceed to reassembly. Make sure that wheel side joint (1) and differential side ...

Page 136

Front drive shaft (g10/m13 engines) 4a-15 5) place new wheel side boot small band (1) onto boot putting band outer end (2) against forward rotation (3) as shown in figure. 6) install wheel side boot small band (1), putting its lower edge against projected end (4) of boot (3) so that clearance “a” is...

Page 137

4a-16 front drive shaft (g10/m13 engines) 11) apply grease to inside of joint housing (1), then install hous- ing, joint it with boot and fit boot to joint housing. After fitting boot, insert screwdriver into boot on joint housing side and allow air to enter boot so that air pressure in boot becomes...

Page 138

Front drive shaft (g10/m13 engines) 4a-17 center shaft and center bearing support dis- assembly and assembly (2wd model with m13 engine) disassembly 1) for m/t model, go to the next step. For a/t model, remove wheel side oil seal and circlip from center bearing support bracket (3). 2) using hydrauli...

Page 139

4a-18 front drive shaft (g10/m13 engines) • when installing left oil seal (1) and right oil seal (2) to center bearing support bracket (3) by using special tools, use care so that the oil seals installed in proper direction and position as shown figure. Special tool (a): 09913-76010 (for a/t model) ...

Page 140: Requirped Service Material

Front drive shaft (g10/m13 engines) 4a-19 requirped service material special tools material recommended suzuki product (part number) use lithium grease suzuki super grease a (99000-25010) • oil seal lip sealant suzuki bond no. 1217g (99000-31260) • oil drain and filler/level plugs for manual transmi...

Page 141

4a-20 front drive shaft (g10/m13 engines).

Page 142: Section 4B

Propeller shafts 4b-1 4b section 4b propeller shafts contents on-vehicle service..........................................4b-2 tightening torque specification...................4b-6 note: for the descriptions (items) not found in this section, refer to the same section of the service manual mentione...

Page 143: On-Vehicle Service

4b-2 propeller shafts on-vehicle service on-vehicle inspection • check propeller shaft connecting bolts for looseness. If looseness is found, tighten to specified torque. • check propeller shaft joints for wear, rattle and damage. If any defect is found, replace. • check propeller shaft center suppo...

Page 144

Propeller shafts 4b-3 removal 1) hoist vehicle. 2) before removing propeller shafts, give match marks (1) on propeller shaft no.2 (4) and companion flange (2) of rear dif- ferential as shown. Also give match marks (1) on propeller shaft no.2 yoke (5), dynamic damper (3), viscous coupling with center...

Page 145

4b-4 propeller shafts 4) if disassembling propeller shaft assembly is necessary, loosen propeller shaft no.2 bolts (1) and viscous coupling nuts (2) to facilitate subsequent disassembling, but keeping each connection provisionally. 5) loosen center support bolts (1), then remove propeller shaft no.1...

Page 146

Propeller shafts 4b-5 installation reverse removal procedure to install propeller shafts noting the following points. • when installing propeller shafts, dynamic damper and vis- cous coupling with center support, align the match marks (1). Otherwise, vibration may occur during driving. • apply threa...

Page 147

4b-6 propeller shafts tightening torque specification fastening portion tightening torque n•m kg-m lb-ft propeller shaft bolt 23 2.3 17.0 propeller shaft no.2 bolt 23 2.3 17.0 center support bolt 55 5.5 40.0 viscous coupling nut 23 2.3 17.0

Page 148: Section 5

Brakes 5-1 5 section 5 brakes contents general description .......................................... 5-2 check and adjustment ..................................... 5-3 bleeding brakes.............................................. 5-3 brake shoe check .......................................... 5-5 t...

Page 149: General Description

5-2 brakes general description when the foot brake pedal is depressed, hydraulic pressure is developed in the master cylinder to actuate pis- tons (two in front and four in rear). The master cylinder is a tandem master cylinder. Brake pipes are connected to the master cylinder and they make two inde...

Page 150: Check And Adjustment

Brakes 5-3 check and adjustment bleeding brakes bleeding operation is necessary to remove air whenever it entered hydraulic brake system. Hydraulic lines of brake system are based on the diagonal split system. When a brake pipe or hose was disconnected at the wheel, bleeding operation must be perfor...

Page 151

5-4 brakes 3) depress brake pedal several times, and then while holding it depressed, loosen bleeder plug about one-third to one half turn. 4) when fluid pressure in the cylinder is almost depleted, retighten bleeder plug. 5) repeat this operation until there are no more air bubbles in hydraulic lin...

Page 152

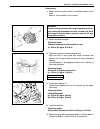

Brakes 5-5 brake shoe check inspection should be carried out on the following points after brake pedal travel “c” (pedal to silencer clearance) check as described on previous page of this section, even when it is more than specification. Amount of brake shoe wear can be checked as follows. 1) hoist ...

Page 153

5-6 brakes.

Page 154: Section 5A

Brakes pipe/hose/master cylinder 5a-1 5a section 5a brakes pipe/hose/master cylinder contents on-vehicle service..........................................5a-2 rear brake hose/pipe ..................................5a-2 warning: for vehicles equipped with supplemental restraint (air bag) system: • se...

Page 155: On-Vehicle Service

5a-2 brakes pipe/hose/master cylinder on-vehicle service rear brake hose/pipe removal 1) raise and suitably support vehicle. Remove tire and wheel. 2) clean dirt and foreign material from both hose end or pipe end fittings. Remove brake hose or pipe. Installation 1) reverse removal procedure for bra...

Page 156

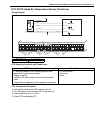

Brakes pipe/hose/master cylinder 5a-3 [a]: with abs vehicle 1. Rear brake hose 4. Top side 7. Right side [b]: without abs vehi- cle (2wd) 2. Lspv assembly 5. Out side tightening torque a – g: clamp 3. E–ring (insert delection) 6. Front side [a] [b] view a a detail b view c b c d e f g 3 1 c 3 2 2 3 ...

Page 157

5a-4 brakes pipe/hose/master cylinder [c]: without abs vehicle (4wd) 3. Rear brake hose 7. From master cylinder (secondary) 11. Front side a – g: clamp 4. To left rear wheel cylinder 8. Top side 12. E–ring (insert delection) 1. E–ring 5. To right rear wheel cylinder 9. Left side tightening torque 2....

Page 158: Section 5B

Front brake 5b-1 5b section 5b front brake contents on-vehicle service..........................................5b-2 front disc brake pad ....................................5b-2 front disc brake caliper ...............................5b-3 front brake disc ..............................................

Page 159: On-Vehicle Service

5b-2 front brake on-vehicle service front disc brake pad installation 1) install pads (1). Caution: lubricate parts as specified. Do not use lubricated shop air on brake parts as damage to rubber com- ponents may result. If any component is removed or line disconnected, bleed the brake system. Repla...

Page 160

Front brake 5b-3 2) install caliper (1) and tighten caliper pin bolts (2) to specifica- tion. Tightening torque caliper pin bolt (a): 30 n·m (3.0 kg-m, 22.0 lb-ft) 3) tighten front wheel bolts to specification. Tightening torque wheel bolt (b): 95 n·m (9.5 kg-m, 69.0 lb-ft) 4) upon completion of ins...

Page 161

5b-4 front brake 4) torque wheel bolts to specification. Tightening torque wheel bolt (c): 95 n · m (9.5 kg-m, 69.0 lb-ft) 5) after completing installation, fill reservoir with brake fluid and bleed brake system. Perform brake test and check each installed part for oil leakage. Front brake disc remo...

Page 162

Front brake 5b-5 3) torque caliper carrier bolts (1) to specification. Tightening torque caliper carrier bolt (a): 95 n · m (9.5 kg-m, 69.0 lb-ft) 4) torque front wheel bolts to specifications. Tightening torque wheel bolt (b): 95 n · m (9.5 kg-m, 69.0 lb-ft) 5) upon completion of installation, perf...

Page 163

5b-6 front brake.

Page 164: Section 5C

Parking and rear brake 5c-1 5c section 5c parking and rear brake contents on-vehicle service..........................................5c-2 parking brake cable component location ...5c-4 brake drum (for 2wd model)........................5c-5 brake drum removal and installation (for 4wd model)...........

Page 165: On-Vehicle Service

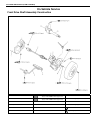

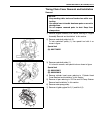

5c-2 parking and rear brake on-vehicle service caution: • replace all components included in repair kits to service this drum brake. Lubricate parts as speci- fied. • if any hydraulic component is removed or brake line disconnected, bleed the brake system. • the torque values specified are for dry, ...

Page 166

Parking and rear brake 5c-3 1. Brake back plate: clean back plate and apply thin coat of bentonite base brake grease (anti-squeal agent) to six surfaces on which shoe rims rest. 9. Piston assembly 17. Parking brake cable 2. Brake shoe 10. Cover 18. Wheel speed sensor ··· if equipped with abs 3. Retr...

Page 167

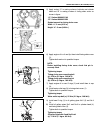

5c-4 parking and rear brake parking brake cable component location 1. Parking brake lever assembly 4. Parking cable bracket 7. Parking brake cable bolt 2. Equalizer 5. Parking brake cable: apply water tight sealant 99000-31090 to plate and cable contact. 8. Parking brake lever bolt 3. Adjusting nut ...

Page 168

Parking and rear brake 5c-5 brake drum (for 2wd model) removal 1) hoist vehicle and remove wheel referring to “wheel” removal in section 3f. 2) remove spindle cap (1) as shown (by hammering lightly at 3 locations around it so as not to deform or cause damage to seating part of cap). 3) uncaulk spind...

Page 169

5c-6 parking and rear brake e) pull brake drum (1) off by hand. If it is hard to remove, use special tools. Special tool (a): 09942-15511 (b): 09943-17912 6) remove sensor ring (1) from brake drum (2) using special tool (if equipped with abs). Special tool (a): 09913-75520 (b): 09913-65135 installat...

Page 170

Parking and rear brake 5c-7 3) install brake drum after making sure that inside of brake drum and brake shoes are free from dirt and oil. 4) install new spindle nut (1). 5) tighten spindle nut (1) to specified torque. Tightening torque spindle nut (a): 175 n·m (17.5 kg-m, 126.5 lb-ft) 6) calk spindl...

Page 171

5c-8 parking and rear brake 2) remove brake drum screw (1) and release parking brake lever. 3) remove brake drum. If brake drum can not be removed easily, increase clearance between brake shoes and drum, referring to step a) – d) in “brake drum (for 2wd model)”. A) pull brake drum off by using 8 mm ...

Page 172

Parking and rear brake 5c-9 6) install wheel and tighten wheel bolts to specified torque. Tightening torque wheel bolt (b): 95 n·m (9.5 kg-m, 69.0 lb-ft) 7) check to ensure that brake drum is free from dragging and proper braking is obtained. Then remove vehicle from hoist and perform brake test (fo...

Page 173

5c-10 parking and rear brake installation 1) apply water tight sealant to mating surfaces of brake back plate and rear axle. “a”: sealant 366e, 99000-31090 2) install brake back plate and tighten back plate bolts to speci- fied torque. Tightening torque brake back plate bolt (a): 24 n·m (2.4 kg-m, 1...

Page 174: Required Service Material

Parking and rear brake 5c-11 8) install wheel and tighten wheel bolts to specified torque. Tightening torque wheel bolt (a): 95 n·m (9.5 kg-m, 69.0 lb-ft) 9) upon completion of all jobs, depress brake pedal with about 300 n (30 kg, 66 lbs) load at least 10 – 15 times until adjuster actuator clicking...

Page 175: Special Tools

5c-12 parking and rear brake special tools 09942-15511 09943-17912 09913-75520 sliding hammer brake drum remover (front wheel hub remover) bearing installer (for 2wd model) snap-on part no. B3404b or equivalent 09913-65135 09926-68310 09950-78230 bearing puller (for 2wd model) bearing installer (for...

Page 176: Section 6-2

Engine general information and diagnosis (m13 engine) 6-2-1 6-2 section 6-2 engine general information and diagnosis (m13 engine) contents general information ....................................... 6-2-3 statement on cleanliness and care ............ 6-2-3 precaution ..................................

Page 177

6-2-2 engine general information and diagnosis (m13 engine) dtc p0113 intake air temperature sensor circuit high .................................... 6-2-73 dtc p0117 engine coolant temperature circuit low............................ 6-2-76 dtc p0118 engine coolant temperature circuit high.............

Page 178: General Information

Engine general information and diagnosis (m13 engine) 6-2-3 general information statement on cleanliness and care an automobile engine is a combination of many machined, honed, polished and lapped surfaces with tolerances that are measured in the thousands of an millimeter (ten thousands of an inch)...

Page 179

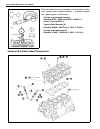

6-2-4 engine general information and diagnosis (m13 engine) precaution precaution on engine service the following information on engine service should be noted carefully, as it is important in preventing damage, and in contributing to reli- able engine performance. • when raising or supporting engin...

Page 180

Engine general information and diagnosis (m13 engine) 6-2-5 • fuel or fuel vapor hose connection varies with each type of pipe. When reconnecting fuel or fuel vapor hose, be sure to connect and clamp each hose correctly referring to the figure hose connection. After connecting, make sure that it has...

Page 181

6-2-6 engine general information and diagnosis (m13 engine) 3) disconnect fuel pump relay (1) from relay box (2). 4) remove fuel filter cap to release fuel vapor pressure in fuel tank and then reinstall it. 5) start engine and run it till it stops for lack of fuel. Repeat cranking engine 2-3 times f...

Page 182: Diagnosis

Engine general information and diagnosis (m13 engine) 6-2-7 diagnosis engine diagnosis general description this vehicle is equipped with an engine and emission control system which are under control of ecm. The engine and emission control system in this vehicle are controlled by ecm. Ecm has an on-b...

Page 183

6-2-8 engine general information and diagnosis (m13 engine) driving cycle a “driving cycle” consists of engine startup and engine shutoff. 2 driving cycle detection logic the malfunction detected in the first driving cycle is stored in ecm memory (in the form of pending dtc) but the malfunction indi...

Page 184

Engine general information and diagnosis (m13 engine) 6-2-9 in the 2nd through the 4th frames, the freeze frame data of each malfunction is stored in the order as the malfunction is detected. These data are not updated. Shown in the table below are examples of how freeze frame data are stored when t...

Page 185

6-2-10 engine general information and diagnosis (m13 engine) precaution in diagnosing trouble for engine • don’t disconnect couplers from ecm, battery cable from bat- tery, ecm ground wire harness from engine or main fuse before confirming diagnostic information (dtc, freeze frame data, etc.) stored...

Page 186

Engine general information and diagnosis (m13 engine) 6-2-11 engine and emission control system check refer to the following items for the details of each step. Step action yes no 1 customer complaint analysis 1) perform customer complaint analysis referring to “customer complaint analysis” in follo...

Page 187

6-2-12 engine general information and diagnosis (m13 engine) 1. Customer complaint analysis record details of the problem (failure, complaint) and how it occurred as described by the customer. For this purpose, use of such an inspection form will facilitate collecting information to the point requir...

Page 188

Engine general information and diagnosis (m13 engine) 6-2-13 customer problem inspection form (example) note: the above form is a standard sample. It should be modified according to conditions characteristic of each market..

Page 189

6-2-14 engine general information and diagnosis (m13 engine) malfunction indicator lamp (mil) check 1) turn on ignition switch (but the engine at stop) and check that mil (1) lights. If mil does not light up (or mil dims), go to “malfunction indi- cator lamp does not come “on” at ignition switch on ...

Page 190

Engine general information and diagnosis (m13 engine) 6-2-15 note: dtc and freeze frame data stored in ecm memory are also cleared in the following cases. Be careful not to clear them before keeping their record. • when power to ecm is cut off (by disconnecting bat- tery cable, removing fuse or disc...

Page 191

6-2-16 engine general information and diagnosis (m13 engine) dtc table dtc no. Detecting item detecting condition (dtc will set when detecting:) mil p0010 camshaft position actuator circuit actual valve timing fails to become close to target advance level of each function although advance control fu...

Page 192

Engine general information and diagnosis (m13 engine) 6-2-17 p0134 o2 sensor (ho2s) circuit no activity detected (sensor–1) output voltage of ho2s–1 fails to go above specifica- tion. (or ho2s–1 circuit open or short) 2 driving cycles p0136 o2 sensor (ho2s) circuit (sensor–2) maximum output voltage ...

Page 193

6-2-18 engine general information and diagnosis (m13 engine) p1601 can communication error transmitting or receiving error detected to ecm for specified time continuously. 1 driving cycle p1603 tcm trouble code detected when ecm receives a trouble code from tcm, which indicates that some problem occ...

Page 194

Engine general information and diagnosis (m13 engine) 6-2-19 fail-safe table when any of the following dtcs is detected, ecm enters fail-safe mode as long as malfunction continues to exist but that mode is canceled when ecm detects normal condition after that. Dtc no. Detected item fail-safe operati...

Page 195

6-2-20 engine general information and diagnosis (m13 engine) visual inspection visually check the following parts and systems. Inspection item referring section • engine oil – level, leakage “engine oil and oil filter” in section 0b. • engine coolant – level, leakage “engine coolant” in section 0b. ...

Page 196

Engine general information and diagnosis (m13 engine) 6-2-21 engine basic inspection this check is very important for troubleshooting when ecm has detected no dtc and no abnormality has been found in visual inspection. Follow the flow table carefully. Step action yes no 1 was “engine and emission co...

Page 197

6-2-22 engine general information and diagnosis (m13 engine) 11 check ignition spark as follows: 1) disconnect injector couplers. 2) remove spark plugs and connect them to high-ten- sion cords or ignition coils. 3) ground spark plugs. 4) crank engine and check if each spark plug sparks. Is it in goo...

Page 198

Engine general information and diagnosis (m13 engine) 6-2-23 engine symptom diagnosis perform troubleshooting referring to following table when ecm has detected no dtc and no abnormality has been found in visual inspection and engine basic inspection previously. Condition possible cause reference it...

Page 199

6-2-24 engine general information and diagnosis (m13 engine) low oil pressure improper oil viscosity “engine oil and oil filter replacement” in section 0b. Malfunctioning oil pressure switch “oil pressure switch inspection” in sec- tion 8c. Clogged oil strainer “oil pan and oil pump strainer” in sec...

Page 200

Engine general information and diagnosis (m13 engine) 6-2-25 overheating inoperative thermostat “thermostat inspection” in section 6b2. Poor water pump performance “water pump inspection” in section 6b2. Clogged or leaky radiator “radiator inspection” in section 6b2. Improper engine oil grade “engin...

Page 201

6-2-26 engine general information and diagnosis (m13 engine) excessive engine oil consumption blown cylinder head gasket “valves and cylinder head inspection” in section 6a2. Leaky camshaft oil seals “camshaft, tappet and shim” in sec- tion 6a2. Sticky piston ring “pistons, piston rings, connecting ...

Page 202

Engine general information and diagnosis (m13 engine) 6-2-27 surge (engine power vari- ation under steady throttle or cruise. Feels like vehicle speeds up and down with no change in accelera- tor pedal.) leaky or loosely connected high-tension cord “high-tension cords inspection” in sec- tion 6f2. F...

Page 203

6-2-28 engine general information and diagnosis (m13 engine) engine has no power faulty spark plug “spark plugs inspection” in section 6f2. Faulty ignition coil with ignitor “ignition coil assembly (including igni- tor) inspection” in section 6f2. Leaks, loose connection or disconnection of high-ten...

Page 204

Engine general information and diagnosis (m13 engine) 6-2-29 improper engine idling or engine fails to idle faulty spark plug “spark plugs inspection” in section 6f2. Leaky or disconnected high-tension cord “high-tension cords inspection” in sec- tion 6f2. Faulty ignition coil with ignitor “ignition...

Page 205

6-2-30 engine general information and diagnosis (m13 engine) excessive hydrocar- bon (hc) emission or carbon monox- ide (co) faulty spark plug “spark plugs inspection” in section 6f2. Leaky or disconnected high-tension cord “high-tension cords inspection” in sec- tion 6f2. Faulty ignition coil with ...

Page 206

Engine general information and diagnosis (m13 engine) 6-2-31 scan tool data as the data values given below are standard values estimated on the basis of values obtained from the normally operating vehicles by using a scan tool, use them as reference values. Even when the vehicle is in good condi- ti...

Page 207

6-2-32 engine general information and diagnosis (m13 engine) ✱ maf (mass air flow rate) at specified idle speed with no load after warm- ing up 1.0 – 4.0 g/s 0.14 – 0.52 lb/min at 2500 r/min with no load after warming up 4.0 – 12.0 g/s 0.53 – 1.58 lb/min ✱ calc load (calculated load value) at specif...

Page 208

Engine general information and diagnosis (m13 engine) 6-2-33 scan tool data definitions coolant temp (engine coolant temperature, °c, °f) it is detected by engine coolant temp. Sensor. Intake air temp. (°c, °f) it is detected by intake air temp. Sensor. Engine speed (rpm) it is computed by reference...

Page 209

6-2-34 engine general information and diagnosis (m13 engine) long ft b1 (long term fuel trim, %) long term fuel trim value represents long term corrections to the air/fuel mixture computation. A value of 0 indi- cates no correction, a value greater than 0 means an enrichment correction, and a value ...

Page 210

Engine general information and diagnosis (m13 engine) 6-2-35 ignition advance (ignition timing advance for no.1 cylinder, °) ignition timing of no.1 cylinder is commanded by ecm. The actual ignition timing should be checked by using the timing light. Battery voltage (v) this parameter indicates batt...

Page 211

6-2-36 engine general information and diagnosis (m13 engine) inspection of ecm and its circuits ecm and its circuits can be checked at ecm wiring couplers by measuring voltage, pulse signal and resistance. Voltage check 1) remove ecm (1) from vehicle body referring to “engine control module (ecm) re...

Page 212

Engine general information and diagnosis (m13 engine) 6-2-37 terminal number wire color circuit normal voltage condition e23-1 blk/yel ground for ecm below 0.3 v ignition switch turned on e23-2 blk/yel ground for ecm below 0.3 v ignition switch turned on e23-3 blu/red heater output of heated oxygen ...

Page 213

6-2-38 engine general information and diagnosis (m13 engine) e23-16 blk/red egr valve (stepper motor coil 3) output 10 – 14 v ignition switch is turned on *0 – 2 v ↑↓ 8 – 14 v (reference wave- form no.5) ignition switch is turned to st (cranking) position. (output signal is active low duty pulse. Pu...

Page 214

Engine general information and diagnosis (m13 engine) 6-2-39 e23-34 grn/blk egr valve (stepper motor coil 2) output 10 – 14 v ignition switch turned on *0 – 2 v ↑↓ 8 – 14 v (reference wave- form no.5) ignition switch is turned to st (cranking) position. (output signal is active low duty pulse. Pulse...

Page 215

6-2-40 engine general information and diagnosis (m13 engine) e22-9 wht knock sensor signal *2 – 3 v (reference wave- form no.15 and no.16) ignition switch turned on engine running at idling with after warm- ing up e22-10 orn reference (classified cylinder) signal for cmp sensor *0 – 0.6 v ↑↓ 4 – 5 v...

Page 216

Engine general information and diagnosis (m13 engine) 6-2-41 e22-21 – – – – e22-22 – – – – e22-23 – – – – e22-24 – – – – e22-25 – – – – e22-26 – – – – e22-27 – – – – e22-28 brn/wht ground for sensors below 0.3 v ignition switch turned on e22-29 – – – – e22-30 pnk ckp sensor signal 0 – 1 v ignition s...

Page 217

6-2-42 engine general information and diagnosis (m13 engine) e21-9 grn/wht electric load signal for stop lamp 0 – 1 v ignition switch turned on, stop lamp not lighted up 10 – 14 v ignition switch turned on, stop lamp lighted up e21-10 – – – – e21-11 wht/blk serial communication line of data link con...

Page 218

Engine general information and diagnosis (m13 engine) 6-2-43 e21-30 lt grn/ red a/c request signal (if equipped) 10 – 14 v (high input) ignition switch turned on, blower fan selector selected off position or a/c switch turned off or a/c evaporator temp. Less than 2.5°c, 36.5°f 0 – 1 v (low input) ig...

Page 219

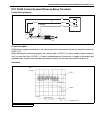

6-2-44 engine general information and diagnosis (m13 engine) 1. Reference waveform no.1 heated oxygen sensor–2 heater signal at engine idling 2. Reference waveform no.2 heated oxygen sensor–1 signal at engine idling 3. Reference waveform no.3 heated oxygen sensor–1 heater signal at engine idling mea...

Page 220

Engine general information and diagnosis (m13 engine) 6-2-45 4. Reference waveform no.4 iac valve signal 5. Reference waveform no.5 egr valve signal 6. Reference waveform no.6 ignition coil no.2 and no.3 signal at engine idling measurement terminal ch1: e23-8 to e23-1 oscilloscope setting ch1: 5 v/d...

Page 221

6-2-46 engine general information and diagnosis (m13 engine) 7. Reference waveform no.7 ignition coil no.1 and no.4 signal at engine idling 8. Reference waveform no.8 oil control valve signal at engine idling 9. Reference waveform no.9 oil control valve signal at vehicle driving measurement terminal...

Page 222

Engine general information and diagnosis (m13 engine) 6-2-47 10. Reference waveform no.10 fuel injector signal at engine racing 11. Reference waveform no.11 no.4 fuel injector signal at engine idling 12. Reference waveform no.12 no.3 fuel injector signal at engine idling measurement terminal ch1: e2...

Page 223

6-2-48 engine general information and diagnosis (m13 engine) 13. Reference waveform no.13 no.2 fuel injector signal at engine idling 14. Reference waveform no.14 no.1 fuel injector signal at engine idling 15. Reference waveform no.15 knock sensor signal at engine speed 4000 r/min. 16. Reference wave...

Page 224

Engine general information and diagnosis (m13 engine) 6-2-49 17. Reference waveform no.17 cmp sensor signal at engine idling 18. Reference waveform no.18 mass air flow sensor signal at engine racing 19. Reference waveform no.19 manifold absolute pressure sensor signal at ignition switch turned on me...

Page 225

6-2-50 engine general information and diagnosis (m13 engine) 20. Reference waveform no.20 manifold absolute pressure sensor signal at engine racing 21. Reference waveform no.21 vss signal at 30 km/h (19 mil/h) 22. Reference waveform no.22 ignition pulse (engine revolution) signal at engine idling me...

Page 226

Engine general information and diagnosis (m13 engine) 6-2-51 23. Reference waveform no.23 ignition pulse (engine revolution) signal at engine idling 24. Reference waveform no.24 engine coolant temperature signal at engine idling 25. Reference waveform no.25 evap canister purge valve signal measureme...

Page 227

6-2-52 engine general information and diagnosis (m13 engine) resistance check 1) disconnect ecm couplers (1) from ecm with ignition switch off. 2) check resistance between each pair of terminals of discon- nected couplers as listed in the following table. Caution: never touch terminals of ecm itself...

Page 228

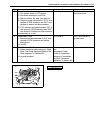

Engine general information and diagnosis (m13 engine) 6-2-53 component location information sensors control devices others 1. Maf and iat sensor a: fuel injector a: ecm 2. Tp sensor b: evap canister purge valve b: combination meter 3. Stop lamp switch c: fuel pump relay c: evap canister 4. Ect senso...

Page 229

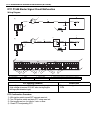

6-2-54 engine general information and diagnosis (m13 engine) table a-1 malfunction indicator lamp circuit check – lamp does not come “on” with ignition switch on (but engine stops) wiring diagram circuit description when the ignition switch is turned on, ecm causes the main relay to turn on (close t...

Page 230

Engine general information and diagnosis (m13 engine) 6-2-55 3 mil power supply check 1) disconnect ignition switch connector. 2) remove “meter” fuse. 3) measure resistance between “blu/blk” wire terminal of ignition switch connector and “blu/blk” wire terminal of “meter” fuse connector. Is resistan...

Page 231

6-2-56 engine general information and diagnosis (m13 engine) table a-2 malfunction indicator lamp circuit check-lamp remains “on” after engine starts wiring diagram circuit description when the ignition switch is turned on, ecm causes the main relay to turn on (close the contact point). Then, ecm be...

Page 232

Engine general information and diagnosis (m13 engine) 6-2-57 2 mil circuit check 1) turn ignition switch to off position. 2) remove combination meter referring to “combination meter removal and installation” in section8. 3) disconnect connectors from ecm. 4) measure resistance between “ppl/wht” wire...

Page 233

6-2-58 engine general information and diagnosis (m13 engine) table a-3 ecm power and ground circuit check-mil doesn’t light with igni- tion switch on and engine doesn’t start though it is cranked up wiring diagram circuit description when the ignition switch tuned on, the main relay turns on (the co...

Page 234

Engine general information and diagnosis (m13 engine) 6-2-59 3 main relay circuit check 1) turn ignition switch to off position. 2) check for fuse blow at fi fuse (20 a). (see fig. 1.) 3) if ok, measure voltage between “e23-15” wire terminal of ecm connector and body ground. Is voltage 10 – 14 v? Go...

Page 235

6-2-60 engine general information and diagnosis (m13 engine) 9 main relay check 1) measure resistance between each two terminals of main relay. (see fig. 3). Between main relay terminals “a” and “b”: infinity “c” and “d”: 160 – 240 Ω at 20°c (68°f) 2) check that there is continuity between terminals...

Page 236

Engine general information and diagnosis (m13 engine) 6-2-61 dtc p0010 camshaft position actuator circuit wiring diagram circuit description actual valve timing fails to become close to target advance level of each function although advance control func- tion or retarded advance control function is ...

Page 237

6-2-62 engine general information and diagnosis (m13 engine) dtc confirmation procedure 1) clear dtc. Refer to “dtc clearance”. 2) start engine and keep it at idle for 10 seconds. 3) check dtc. Refer “dtc check”. Troubleshooting step action yes no 1 was “engine and emission control system check” per...

Page 238

Engine general information and diagnosis (m13 engine) 6-2-63 8 check wire circuit. 1) disconnect connectors from ecm with ignition switch turned off. 2) measure resistance between “e22-3” terminal of ecm con- nector and “blk/yel” wire terminal of oil control valve con- nector. Is resistance 1 Ω or l...

Page 239

6-2-64 engine general information and diagnosis (m13 engine) dtc p0011 camshaft position – timing over-advanced or system perfor- mance dtc p0012 camshaft position – timing over-retarded description actual value of advanced valve timing does not reach target value. Valve timing is advanced although ...

Page 240

Engine general information and diagnosis (m13 engine) 6-2-65 4 vvt signal check 1) drive vehicle the following condition. • vehicle speed at 80 km/h (50 mile/h). • gear position at 5th or d range. 2) check that the vvt gap displayed on suzuki scan tool is 0 – 5°. Is it ok? Substitute a known-good ec...

Page 241

6-2-66 engine general information and diagnosis (m13 engine) dtc p0102 mass air flow circuit low input wiring diagram dtc detecting condition and trouble area dtc confirmation procedure 1) with ignition switch turned off, connect scan tool. 2) turn on ignition switch and clear dtc using scan tool. 3...

Page 242

Engine general information and diagnosis (m13 engine) 6-2-67 troubleshooting step action yes no 1 was “engine and emission control system check” per- formed? Go to step 2. Go to “engine and emission control system check” in this section. 2 maf sensor check. 1) connect scan tool to dlc with ignition ...

Page 243