- DL manuals

- Swagelok

- Power Tool

- MS-BTB-1 series

- User Manual

Swagelok MS-BTB-1 series User Manual

Summary of MS-BTB-1 series

Page 1

Bench top tube bender user’s manual ■ electric and manual units ■ bends fractional and metric tubing ■ ce compliant.

Page 2

2 bench top bender user’s manual contents safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 tubing data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 bend layout . . . . . . ....

Page 3

Bench top bender user’s manual 3 tubing data ■ the swagelok bench top tube bender bends 1/4, 3/8, 1/2, 5/8, 9/16, 3/4, 7/8, 1 in ., and 1 1/4 in . And 6, 10, 12, 14, 15, 16, 18, 20, 22, 25, 28, and 30 mm outside diameter tubing in a variety of wall thicknesses . ■ tubing should be free of scratches ...

Page 4

4 bench top bender user’s manual bend layout this bender can be used to form single, offset, and other bends . This section contains information for measuring and marking the tube prior to bending . Note: make all marks 360° around the tube. Single bend 1 . Place a reference mark at the end of the t...

Page 5

Bench top bender user’s manual 5 reverse bends the measure-bend method sometimes a multiple bend layout will require that a bend be made in reverse . A reverse bend is made with the end of the tube opposite the reference mark inserted into the bend shoe rather than the end with the reference mark . ...

Page 6

6 bench top bender user’s manual manual bender product information bend shoe carrying handle bend degree wheel (2 1/2 ° increments) roller bracket assembly roller pins roller bracket lever roller knob hand crank high bend- speed selector drill yoke support medium bend- speed selector low bend- speed...

Page 7

Bench top bender user’s manual 7 caution when lifting the bender, first place one hand under the bender, then pick up the unit by grabbing the carrying handle with your other hand. Setup 1 . Place the hand crank on the high bend-speed selector . 2 . Rotate the hand crank until the zero reference mar...

Page 8

8 bench top bender user’s manual 10 . Align the bend mark on the tube with the reference mark on the bend shoe . Reference mark bend shoe tube bend mark 11 . Turn the roller bracket lever clockwise until the roller bracket assembly stop makes contact with the bracket post stop . Roller bracket assem...

Page 9

Bench top bender user’s manual 9 3 . Keep the hand crank still and rotate the bend degree wheel to zero . Caution releasing the hand crank while tube is under load may cause the hand crank to spin, possibly leading to injury. 4 . Rotate the hand crank until the bend wheel displays 5° less than the d...

Page 10

10 bench top bender user’s manual operation before operating the bender mark the tube (see bend layout) and follow the setup and calibration procedures . Caution - pinch points 1 . With the zero reference mark between the 2 and 3 o’clock position, place the hand crank on the desired speed selector ....

Page 11

Bench top bender user’s manual 11 roller bracket roller bracket lever roller knob bracket assembly stop bracket post bracket pin zero reference mark d pin d roller g roller g pin bend shoe reference mark clamp arm bracket post stop support bracket aluminum only, recommended when using 1 in . Or 25 m...

Page 12

12 bench top bender user’s manual electric bender must be operated in a safe environment to avoid risk of fire, explosion, or electric shock . Warning voltage greater than 30 v (ac) is present. Warning - keep dry. Do not expose the equipment to water or wet locations. Warning - fire or explosion. Do...

Page 13

Bench top bender user’s manual 13 8 . Carefully insert the tube into the bend shoe, past the clamp arm . Caution the end of the tube must extend past the right edge of the clamp arm to prevent potential damage to the tube during bending. Clamp arm tube bend shoe right edge 9 . Turn the roller bracke...

Page 14

14 bench top bender user’s manual calibration calibration is the process of accurately accounting for tube variables and mechanical play in the bender, which is typically observed as springback . Different materials, different lots of the same material, and different wall thicknesses of the same mat...

Page 15

Bench top bender user’s manual 15 note: do not force the roller bracket lever . Toggle switch roller bracket lever 2 . Hold the tube until the motor stops and the tube can be removed from the bender . Operation before operating the bender mark the tube (see bend layout) and follow the setup and cali...

Page 16

16 bench top bender user’s manual measuring the bend angle this is one of many methods that may be used to measure the bend angle . A protractor will be needed for this method . 1 . Place the bent tube on a piece of paper with the vertex of the bend on the paper . Tube vertex 2 . Hold the tube again...

Page 17

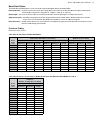

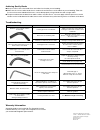

Bench top bender user’s manual 17 bend data tables the bend data provided reflects results achieved using the swagelok bench top tube bender . Bend deduction – the distance from the vertex of the angle back to the point where the tube breaks tangent and the bend actually begins . Sometimes referred ...

Page 18

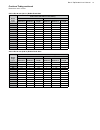

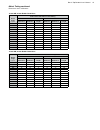

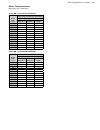

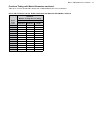

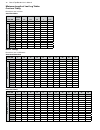

18 bench top bender user’s manual fractional tubing continued dimensions are in inches . 3/8 in. Od, 36 mm (1.42 in.) radius bend shoe bend angle degrees carbon steel and stainless steel tubing medium-pressure tubing aluminum bend shoe steel bend shoe steel bend shoe bend allowance bend deduction be...

Page 19

Bench top bender user’s manual 19 fractional tubing continued dimensions are in inches . 1/2 in. Od, 36 mm (1.42 in.) radius bend shoe bend angle degrees carbon steel and stainless steel tubing medium-pressure tubing aluminum bend shoe steel bend shoe steel bend shoe bend allowance bend deduction be...

Page 20

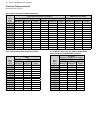

20 bench top bender user’s manual fractional tubing continued dimensions are in inches . 9/16 in. Od, ipt series, 82 mm (3.23 in.) radius bend shoe with effective bend radius of 3.47 in. Bend angle degrees ipt series medium- and high-pressure tubing steel bend shoe bend allowance bend deduction bend...

Page 21

Bench top bender user’s manual 21 fractional tubing continued dimensions are in inches . 5/8 in. Od, 46 mm (1.81 in.) radius bend shoe bend angle degrees carbon steel and stainless steel tubing aluminum bend shoe steel bend shoe bend allowance bend deduction bend length bend allowance bend deduction...

Page 22

22 bench top bender user’s manual fractional tubing continued dimensions are in inches . 7/8 in. Od, 67 mm (2.64 in.) radius bend shoe bend angle degrees carbon steel and stainless steel tubing aluminum bend shoe steel bend shoe bend allowance bend deduction bend length bend allowance bend deduction...

Page 23

Bench top bender user’s manual 23 fractional tubing continued dimensions are in inches . 1 1/4 in. Od, 112 mm (4.41 in.) radius bend shoe bend angle degrees standard tubing carbon steel and stainless steel tubing bend allowance bend deduction bend length 15 13/16 7/8 1 11/16 22 1/2 1 1/16 1 3/16 2 3...

Page 24

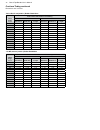

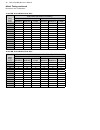

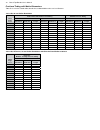

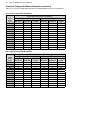

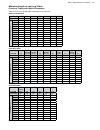

24 bench top bender user’s manual metric tubing dimensions are in millimeters . 6 mm od, 36 mm radius bend shoe bend angle degrees carbon steel and stainless steel tubing aluminum bend shoe steel bend shoe bend allowance bend deduction bend length bend allowance bend deduction bend length 15 –1 0 –1...

Page 25

Bench top bender user’s manual 25 metric tubing continued dimensions are in millimeters . 12 mm od, 36 mm radius bend shoe bend angle degrees carbon steel and stainless steel tubing aluminum bend shoe steel bend shoe bend allowance bend deduction bend length bend allowance bend deduction bend length...

Page 26

26 bench top bender user’s manual metric tubing continued dimensions are in millimeters . 15 mm od, 46 mm radius bend shoe bend angle degrees carbon steel and stainless steel tubing aluminum bend shoe steel bend shoe bend allowance bend deduction bend length bend allowance bend deduction bend length...

Page 27

Bench top bender user’s manual 27 metric tubing continued dimensions are in millimeters . 18 mm od, 56 mm radius bend shoe bend angle degrees carbon steel and stainless steel tubing aluminum bend shoe steel bend shoe bend allowance bend deduction bend length bend allowance bend deduction bend length...

Page 28

28 bench top bender user’s manual metric tubing continued dimensions are in millimeters . 22 mm od, 67 mm radius bend shoe bend angle degrees carbon steel and stainless steel tubing aluminum bend shoe steel bend shoe bend allowance bend deduction bend length bend allowance bend deduction bend length...

Page 29

Bench top bender user’s manual 29 metric tubing continued dimensions are in millimeters . 28 mm od, 112 mm radius bend shoe bend angle degrees carbon steel and stainless steel tubing steel bend shoe bend allowance bend deduction bend length 15 11 12 23 22 1/2 18 20 37 30 24 28 51 45 36 44 80 60 46 6...

Page 30

30 bench top bender user’s manual fractional tubing with metric dimensions tube od is in inches . Bend radius, bend shoe, and bend dimensions are in millimeters . 1/4 in. Od, 36 mm radius bend shoe bend angle degrees carbon steel and stainless steel tubing medium-pressure tubing aluminum bend shoe s...

Page 31

Bench top bender user’s manual 31 fractional tubing with metric dimensions tube od is in inches . Bend radius, bend shoe, and bend dimensions are in millimeters . 3/8 in. Od, 36 mm radius bend shoe bend angle degrees carbon steel and stainless steel tubing medium-pressure tubing aluminum bend shoe s...

Page 32

32 bench top bender user’s manual fractional tubing with metric dimensions continued tube od is in inches . Bend radius, bend shoe, and bend dimensions are in millimeters . 1/2 in. Od, 36 mm radius bend shoe bend angle degrees carbon steel and stainless steel tubing medium-pressure tubing aluminum b...

Page 33

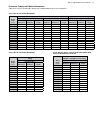

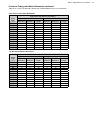

Bench top bender user’s manual 33 fractional tubing with metric dimensions continued tube od is in inches . Bend radius, bend shoe, and bend dimensions are in millimeters . 9/16 in. Od, ipt series, 82 mm. Radius bend shoe with effective bend radius of 88 mm bend angle degrees ipt series medium- and ...

Page 34

34 bench top bender user’s manual fractional tubing with metric dimensions continued tube od is in inches . Bend radius, bend shoe, and bend dimensions are in millimeters . 5/8 in. Od, 46 mm radius bend shoe bend angle degrees carbon steel and stainless steel tubing aluminum bend shoe steel bend sho...

Page 35

Bench top bender user’s manual 35 fractional tubing with metric dimensions continued tube od is in inches . Bend radius, bend shoe, and bend dimensions are in millimeters . 7/8 in. Od, 67 mm radius bend shoe bend angle degrees carbon steel and stainless steel tubing aluminum bend shoe steel bend sho...

Page 36

36 bench top bender user’s manual fractional tubing with metric dimensions continued tube od is in inches . Bend radius, bend shoe, and bend dimensions are in millimeters . 1 1/4 in. Od, 112 mm radius bend shoe bend angle degrees carbon steel and stainless steel tubing steel bend shoe bend allowance...

Page 37

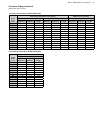

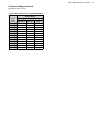

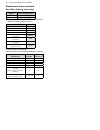

Bench top bender user’s manual 37 minimum length of last leg during bending, both rollers must remain on the tube until the desired bend angle is achieved . If the length of tube is too short, the bend may not reach its desired angle or the end of the tube may be damaged . Specifying a final leg len...

Page 38

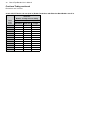

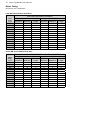

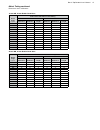

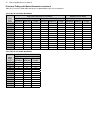

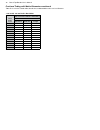

38 bench top bender user’s manual minimum length of last leg tables fractional tubing dimensions are in inches . Metric tubing dimensions are in millimeters . Aluminum bend shoe tube od 6 10 12 14 15 16 18 20 22 25 bend radius 36 36 36 46 46 46 56 67 67 82 bend angle, degr ees 15 63 65 69 88 87 89 1...

Page 39

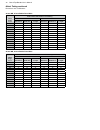

Bench top bender user’s manual 39 minimum length of last leg tables fractional tubing with metric dimensions tube od is in inches . Bend radius and length are in millimeters . Aluminum bend shoe tube od 1/4 3/8 1/2 5/8 3/4 7/8 1 bend radius 36 36 36 46 56 67 82 bend angle, degr ees 15 65 64 69 89 10...

Page 40

40 bench top bender user’s manual maintenance all models using the supplied grease gun, grease the two points on the upper gearbox of the bender after every 24 hours of operation . Grease points the grease must be a high-grade, multipurpose grease meeting castrol ® molub-alloy-860/220-1 es or tribol...

Page 41

Bench top bender user’s manual 41 replacement parts tube bender components description ordering number qty metal box with trays (manual model) ms-btb-cc-m 1 metal box with trays (electric model) ms-btb-cc-e 1 roller bracket ➀ ms-btb-rs 1 g pin 16685 1 d pin 16686 1 roller-bracket lever ms-btb-rah 1 ...

Page 42

42 bench top bender user’s manual bend shoe ordering information material fractional and metric sizes basic ordering number aluminum ms-btt-b-xx ➀ steel ms-btt-b-sxx ➀ ➀ the following sizes require an additional designator be added to the basic ordering number: size designator 6 mm -r36 10 mm -r36 1...

Page 43

Bench top bender user’s manual 43 ms-btb-a-tc torque clutch: allows 1/2 in . Electric or pneumatic drill motor to be used in place of hand crank on manual bender . Ms-btb-a-sa support arm: must be used with torque clutch to support drill motor . Ms-btb-a-fs foot switch operates the electric bender i...

Page 44

Warranty information swagelok products are backed by the swagelok limited lifetime warranty . For a copy, visit swagelok .Com or contact your authorized swagelok representative . Achieving quality bends ■ always use the correct size bend shoes and rollers for the tube you are bending . ■ make sure t...