135 270 01 .En /ma s /© 1 2 .0 4 ce declaration of conformity we declare that the machine a391 is in conformity with the following standard or standardised documents: 98/37/eec fromm holding ag hinterbergstrasse 26 ch - 6330 cham 03.04 2002 r.Fromm director operation manual / spare parts list pneuma...

2 index page 1 safety instructions 3 2 warranty conditions and liability 4 3 appropriate use 4 4 chart of types a391.0002 4 5 tecnical data 5 5.1 sound information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 5.2 vibration information . . . . . . . . . . . ...

3 1 safety instructions read these instructions carefully. Failure to follow these instructions can result in severe personal injury. Eye injury hazard failure to wear safety glasses with side shields can result in severe eye injury or blindness. Always wear safety glasses with side shields which co...

4 a3910002en.Teil1 2 warranty conditions and liability fromm holding ag warrants all its strapping tools and machine heads during a period of 24 months from the date of installation at the end-user's sight by the distributor, however, not later than 30 months from the date of shipment to the distrib...

5 a3910002en.Teil1 5 tecnical data dimensions tool: package: length: 385 mm / 15.16" 460 mm / 18.11" width: 175 mm / 6.89" 240 mm / 9.45" height: 140 mm / 5.51" 185 mm / 7.28" weight: 5.1 kg/11.2 lbs 0.9 kg/2.0 lbs compressed air joining thread: g 1/4" tube: min. Inside diameter = 8 mm / 5/16" maxim...

6 a3910002en.Teil1 7 components 8 use feeding the strap around the package the strap is fed around the package in the direction as shown in the illustration. The end of the strap is held tightly with the left hand and pulled firmly towards the operator with the right hand. Loading the strap lift and...

7 a3910002en.Teil1 tensioning the strap tensioning the strap by pressing the valve button. It is possible to change tensioning force by adjusting the pressure regulator at the air unit. Attention! Never exceed the maximum air pressure of 6 bar / 87 psi. Sealing the strap the sealing handle is moved ...

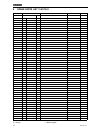

A33.1137 a33.2121 2 3 1 a b c d e a33.1174 a48.1220 n3.2314 n2.3317 n2.3317 n2.3318 n2.3318 a39.3327 n1.7301 a39.3313 a39.3314 n2.2148 n3.4307 n3.4102 n3.3131 n2.4902 n4.9159 a33.1161 n2.5807 n1.3120 n2.2230 n1.1168 n1.6103 a33.1176 n1.1182 n2.4902 n41.9134 a39.3316 a33.1181 n2.5170 a33.1163 n1.3203...

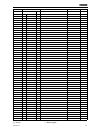

4 5 6 7 n41.9128 n41.9129 a39.3312 n1.6318 n2.1109 n4.5112 n1.5134 a39.3311 a39.3325 l2.1111 n6.6205 a39.3308 n2.5185 a39.3306 a39.3307 2 x n2.2441 n1.1184 n1.5124 a39.3301 n2.4906 a39.3326 a33.1177 n3.2313 n3.1131 a39.3303 a48.1226 n3.3110 n3.2308 a39.3302 n1.1168 n1.1168 n2.2167 n1.6103 n1.6103 n2...

[ ] = group * = wearing parts 10 13527001.Een 9 spare parts list 13.5270.01 13.5270.01 a391/12.7/0.38-0.58 a391.0001.01 26/06/98 item-no. Pcs. Description dimension field a33.1120 * 1 shear blade d4 a33.1137 * 1 die half e3 a33.1138 * 1 die half e3 a33.1158 1 stop c3 a33.1161 1 bush c2 a33.1163 1 so...

[ ] = group * = wearing parts 11 13527001.Een [l2.1212] ->[l2.1111] 1 housing -- l2.1213 ->[a39.3325] 1 button -- l2.1214 ->[a39.3325] 1 valve piston -- l2.1301 ->[l2.1111] 1 end plate -- l2.1302 ->[l2.1111] 1 parallel pin -- l2.1303 ->[l2.1111] 1 cylinder -- l2.1304 * ->[l2.1111] 5 vane -- l2.1308 ...

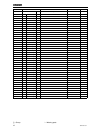

[ ] = group * = wearing parts 12 13527001.Een n2.2167 1 parallel pin 10 h8 x 58 b6 n2.2216 ->[a39.3334] 1 parallel pin 5 h8 x 16 b6 n2.2230 1 parallel pin 5 h8 x 60 c2 n2.2401 1 dowel pin 3 x 10 e5 n2.2414 ->[a39.3325] 1 dowel pin 2 x 12 mm -- n2.2441 2 dowel pin 6 x 20 mm a4 n2.3317 ->[a39.3336] 2 ...

13 a3910002en.Teil2 10 seal control a regular control of the seal is necessary. The seal can be checked visually and the person controlling can easily judge the quality of the seal. When checking the seal the following illustrations must be compared. Correct seal a correct seal must be conform to th...

14 a3910002en.Teil2 11 seal adjustment the sealing mechanisms stamping and cutting depth can be adjusted with the socket wrench n4.1408 delivered with the tool. Procedure: • place the tool as shown. • loosen both screws n1.1168 and unscrew them about three rotations. • if sealing mechanism is adjust...

15 a3910002en.Teil2 13 accessories 13.1 suspension a33.0113 it is possible to suspend the tool for strapping in vertical position. Order the suitable suspension separately under item no. A33.0113. 13.2 using tool with horizontal handle upon request the tool can be supplied with a bolt a33.4101 and a...

16 a3910002en.Teil2.