- DL manuals

- T-Drill

- Tools

- T-60

- Instruction Manual And Spare Parts List

T-Drill T-60 Instruction Manual And Spare Parts List - 7. Maintenance

I N S T R U C T I O N M A N U A L

7. Maintenance

7.1 The maintenance of the T-DRILL T-60

The T-DRILL T-60 is prelubricated and does not need special attention for

maintenance. Clean dust and dirt from tool vents.

NOTE! All maintenance operations for the T-DRILL T-60 and

MILWAUKEE power unit sold in North America are to be carried out

only by T-DRILL Industries, Inc. in Norcross, Georgia, USA.

28

Summary of T-60

Page 2: Version

I n s t r u c t i o n m a n u a l version 3305-10-03 04.12.2002 lk 26.1.2004 /lk instruction manual this instruction manual includes a spare parts list and instructions for set- up for operation, operation and maintenance of the t-drill t-60 tee forming machine. Type code of manual is 3305-10-03 man...

Page 3: T-60

T e e f o r m i n g m a c h i n e t-60 table of contents 1. Notes on the use of the instruction manual ...................................... 5 1.1 symbols for warning used in this manual .................................... 5 1.2 symbolism ..............................................................

Page 4

I n s t r u c t i o n m a n u a l 4.

Page 5: T-60

T e e f o r m i n g m a c h i n e t-60 5 1. Notes on the use of the instruction manual 1.1 symbols for warning used in this manual important! Gray base color is used to emphasize an important detail note! May cause an accident or damage other property, if the right precautionary measures have not be...

Page 6

I n s t r u c t i o n m a n u a l 1.2 symbolism the following list defines the symbols on the tool. Read the instruction manual carefully before using this tool. Double insulated 130 ° thermally protected to 130 °c) warning! Do not throw to trash. Please recycle warning! Watch your fingers. Rotating...

Page 7: T-60

T e e f o r m i n g m a c h i n e t-60 2. General safety instructions read all the instructions before using the machine. Know your power tool - read the instruction manual carefully. Learn to know your own skill and limitations as well as the specific potential hazards peculiar to this tool. Danger...

Page 8

I n s t r u c t i o n m a n u a l 2.2 safety instructions for tool store idle tools – when not in use, tools should be stored in dry, high, or locked-up place, out of the reach of children. Don’t force tool – it will do the job better and safer at the rate for which it is intended. Dress properly – ...

Page 9: T-60

T e e f o r m i n g m a c h i n e t-60 moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its operation. A guard or other part that is damaged should be properly repaired or replaced by an authorised service unless otherwise indicated elsewhe...

Page 10

I n s t r u c t i o n m a n u a l 2.3. Safety instructions for tee forming do not touch the rotating tool when the work cycle is on. When fixing the machine to the tube, be careful not to leave your fingers between the machine and the tube when handling the tools, be careful with the cutting blades....

Page 11: T-60

T e e f o r m i n g m a c h i n e t-60 3. T-drill t-60, general 3.1 introduction the t-drill t-60 is a special tool intended for mechanically forming tees in copper tube typically found in domestic, commercial and industrial tubing systems. The t-60 extrudes in the run tube an outlet, to which the b...

Page 12

I n s t r u c t i o n m a n u a l 3.3 information about accessories for proper use of t-drill t-60 the following accessories are available: notcher nd-54 tube end notcher forms the end of branch pipe to match inner curve of the run tube. In this way maximum flow is achieved. The notcher also presses...

Page 13: T-60

T e e f o r m i n g m a c h i n e t-60 3.4 operating range of the machine the t-drill t-60 is intended for forming a tee in copper tube. The branch tube is joined to the run tube by brazing. The outlet size range of t-60 is ns 1/2" to 2" (10 – 54 mm). The diameter of the run tube can be 1/2 " to 4" ...

Page 14

I n s t r u c t i o n m a n u a l 4. Transport, handling and storage 4.1 t-60 the t-60 is delivered in a transport box, dimensions 25.2” (640mm) x 6.5” (165mm) x 14.2” (360mm) (w x h x d). The weight of the box is, depending on the accessories, between 29 - 49 lbs (13 and 23 kg) . Storage keep the t...

Page 15: T-60

T e e f o r m i n g m a c h i n e 15 t-60 5. Preparing before use 5.1 t-60, detachment and attachment of the connecting cord when delivered the t-60 power unit is fitted with a connecting cord, which allows quick changing in field conditions. Detachment of the cord turn the nut of the cord 1/2 turn ...

Page 16

I n s t r u c t i o n m a n u a l 6. The operation of the machine 6.1 description of the control devices 6.1.1 t-drill t-60 2 1 3 control devices: 1. Trigger, 2. Speed selector 3. Feed mechanism engagement lever note! Use maximum speed of rotation when drilling and forming the outlet - when working ...

Page 17: T-60

T e e f o r m i n g m a c h i n e 17 t-60 t h e s p e e d s 1. Speed selector 2. The feed mechanism lever the speed selector knob is on the top of the gearbox of the t-60. Slow speed is marked “i” and fast speed is marked “ii”. To shift from fast to slow speed, turn the selector knob 180 degrees. Dr...

Page 18

I n s t r u c t i o n m a n u a l 6.2 selection and adjustment of the t-drill heads 6.2.1 the identification of the t-drill head the size of the t-drill head is stamped on the cover plate: 5310401 15 1/2 1 2 3 identification: 1. Actual size in millimetres, 2. Nominal size in inches (ns), 3. The orde...

Page 19: T-60

T e e f o r m i n g m a c h i n e 19 t-60 6.2.2 the fine adjustment of the outlet diameter note! When adjusting the outlet diameter, extend the forming pins first. Each t-drill head is adjusted at the factory to correspond to the nominal size stamped on the cover of each t-drill head. Changing the t...

Page 20

I n s t r u c t i o n m a n u a l depending on the size of the t-drill head, the forming pin span t should be 0,020” – 0,055” (0,5 – 1,4mm) bigger than the branch pipe outer diameter (o.D.) 1. Loosen the screws on the cover plate by about one circle using a 3 mm hexagon wrench, that is supplied with...

Page 21: T-60

T e e f o r m i n g m a c h i n e t-60 6.3 chucking the t-drill head 6.3.1 chucking to insert the t-drill head into the chuck, rotate the locking ring (1) clockwise and slide the t-drill head shaft into the chuck(2). Release the locking ring. Rotate the t-drill head (3) in the chuck until it locks. ...

Page 22

I n s t r u c t i o n m a n u a l 6.3.3 fitting the old t-drill heads to the t-60 –machine if you have old 42/1½ or 54 /2 t-drill heads, you can use them in t-drill t-60 after shortening the drill core as described below. Without shortening the drill cores of old t-drill heads do not fit in the chuc...

Page 23: T-60

T e e f o r m i n g m a c h i n e t-60 6.4 the tee forming process with the t-drill t-60 since the process may be new to you, we recommend that you read the following instructions carefully and then practice a few times on some pieces of scrap tubing. Note! Before forming any tee always make sure th...

Page 24

I n s t r u c t i o n m a n u a l 6. Check that the speed selector knob is in position ii and the feed mechanism lever in “off”-position. 7. Pull the support legs out and place the tube support firmly onto the point where the tee is to be formed on the tube, as shown on the illustration. Press the t...

Page 25: T-60

T e e f o r m i n g m a c h i n e t-60 10. Select low speed i by turning the selector knob. (always use low speed (i) when forming the outlet, consult capacity chart in section 11.1 for options.) engage the feed mechanism as shown. If it does not engage smoothly, rotate the motor by “bumping” the tr...

Page 26

I n s t r u c t i o n m a n u a l 6.5 annealing of tube danger! The annealed work piece is extremely hot after annealing. When working with the tube protective gloves should be used. 1. Anneal the area where outlet is to be formed to a dull red.The area will remain annealed even when cool. It is not...

Page 27: T-60

T e e f o r m i n g m a c h i n e t-60 4. Retract forming pins on t-drill head and attach t-drill t-60 to counterplate. Notches on tube support fit on tabs of counterplate. 5. Drill pilot hole, extend forming pins, reduce speed, engage feed mechanism, pull trigger to form the outlet. Release trigger...

Page 28: 7. Maintenance

I n s t r u c t i o n m a n u a l 7. Maintenance 7.1 the maintenance of the t-drill t-60 the t-drill t-60 is prelubricated and does not need special attention for maintenance. Clean dust and dirt from tool vents. Note! All maintenance operations for the t-drill t-60 and milwaukee power unit sold in ...

Page 29: T-60

T e e f o r m i n g m a c h i n e t-60 7.2 the replacement of the forming pins 1. Loosen the two screws on the cover plate one turn and rotate the conical cover with respect to the cover plate so that the conical cover can be removed. When the conical cover is removed rotate the cone so that the for...

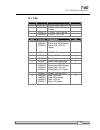

Page 30: 8. Trouble-Shooting

I n s t r u c t i o n m a n u a l 8. Trouble-shooting problem cause remedy the power unit doesn’t run. The connection cord loose, or the plugs do not make contact with the wires inside the cord. Trigger not fully pressed. Insert the cord into the bracket, or substitute the cord with a new one. Press...

Page 31: T-60

T e e f o r m i n g m a c h i n e t-60 problem cause remedy the forming pins break off or the drill shank breaks lack of annealling when called for in instructions. Burrs in the pilot hole -drill bit dull the wall-thickness of the tube exceeds the max. Allowable thickness. Not enough lubricant durin...

Page 32: 9. Disposing

I n s t r u c t i o n m a n u a l 9. Disposing disposing of the t-drill machine in the manufacturing of the t-drill machines various kinds of metals, plastic and lubricants have been used. Dispose of your t-drill machine according to federal, state and local regulations. 32.

Page 33: T-60

T e e f o r m i n g m a c h i n e t-60 10. Warranty t-drill guarantees that every t-drill t-60 tee forming machine is free from defects in materials and workmanship (other than normal wear and tear) for a period of one (1) year from date of shipment. Should within this period any t-60 be proved to t...

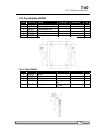

Page 34: 11. Supplement

I n s t r u c t i o n m a n u a l 11. Supplement capacity and instruction chart for t-drill t-60 on m, l, & k tubing run tube size 1 / 2 ” 3 / 4 ” 1” 1- 1 / 4 ” 1- 1 / 2 ” 2” 2-½” 3” 4” nominal outlet size notch and dimple all branch tubes. Place dimples in line with the run of the tube.Braze all jo...

Page 35: T-60

T e e f o r m i n g m a c h i n e t-60 engage the feed mechanism, pull the trigger to form outlet. Notch and dimple branch tube. Insert branch tube into outlet, align dimples with the run of the tube – braze the joint. ** if motor slows during drilling of pilot hole, shift to slow speed. Note: lubri...

Page 36

I n s t r u c t i o n m a n u a l 36 capacity chart in millimeters use the capacity charts to determine the maximum wall-thickness of the tube and to select the right t-drill head. Instructions for the use of the capacity charts: 1. Use the unit of measure that is correct for you: the measures of th...

Page 37: T-60

T e e f o r m i n g m a c h i n e t-60 37.

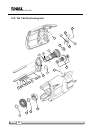

Page 38: 12. Spare Parts List

I n s t r u c t i o n m a n u a l 38 12. Spare parts list 12.1. T-60 1 6 7 3 2 4 5 8.

Page 39: T-60

T e e f o r m i n g m a c h i n e t-60 12.1. T-60 part no. Complete assembly 5330161 t-drill t-60 120v usa 5330163 t-drill t-60 230v europe 5330110 t-drill t-60 110v uk 5330209 t-drill t-60 110v japan item part no. Description qty 1 5330158 5330160 5330109 power unit 120v usa power unit 230v europe ...

Page 40

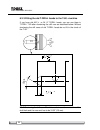

I n s t r u c t i o n m a n u a l 12.2. The t-60 tee forming unit 14 6 5 18 9 17 16 2 1 18 17 19 15 10 7 23 4 13 3 20 24 21 8 11 9 23 12 40

Page 41: T-60

T e e f o r m i n g m a c h i n e t-60 part no. Complete assembly 5330154 t-60 tee forming unit item part no. Description qty 1 5330156 housing 1 2 5330117 lead screw 1 3 5330097 nut assy complete 1 4 5540031 reduction gear 1 5 3330178 gear changer 1 6 5330115 shift knob 1 7 4330099 push rod 2 8 333...

Page 42

I n s t r u c t i o n m a n u a l 12.3 t-drill head 7 5 6 3 4 2 1 8 9 6 11 10 2 9 tee size ∅ mm 10 12 15 18 22 28 35 42 54 nominal tee size ∅ inch 1/4 3/8 1/2 5/8 3/4 1 1/1/4 1/1/2 2 order no. 5310399 5310400 5310401 5310402 5310403 5310404 5310411 5310412 5310413 item description qty part no. 1 dri...

Page 43: T-60

T e e f o r m i n g m a c h i n e t-60 12.4 counterplate 5540085 item part no. Name size/type std./manuf. Qty 1 3540011 counterplate 1 2 3540012 counter plate mask. 1 3 3540013 counterplate fem. 1 5 5540201 chain 1 6 9018038 parallel pin Ø3m6x20 din 6325 4 7 4540070 pin 1 12.4.1 chain 5540201 item p...

Page 44

I n s t r u c t i o n m a n u a l 12.5 optional equipment item part no. Description qty 1 5090294 notcher nd-54 1 2 3310461 gauge block 1 3 5540085 counter plate 1 5 9010205 lubricant for copper 1l-bottle 1 44.

Page 45: T-60

T e e f o r m i n g m a c h i n e t-60 13. Ordering spare parts when ordering spare parts, please state the following details: -the type code of the machine -manufacturing code of the machine -the part number -a description of the part -the quantity of the parts required the type code and the manufa...

Page 46

I n s t r u c t i o n m a n u a l i n s t r u c t i o n m a n u a l 46 46.