- DL manuals

- TA

- Measuring Instruments

- Q Series

- Getting started manual

TA Q Series Getting started manual

Summary of Q Series

Page 1

Tma q series getting started guide 1 q series getting started guide tma thermomechanical analyzer revision d issued november 2006.

Page 2

Tma q series getting started guide 2 ©2003, 2004 by ta instruments—waters llc 109 lukens drive new castle, de 19720 notice the material contained in this manual, and in the online help for the software used to support this instrument, is believed adequate for the intended use of the instrument. If t...

Page 3

Tma q series getting started guide 3 important: ta instruments manual supplement please click on the links below to access important information supplemental to this getting started guide: • ta instruments trademarks • ta instruments patents • other trademarks • ta instruments end-user license agree...

Page 4: Table of Contents

Tma q series getting started guide 4 important: ta instruments manual supplement ........................................................................................................ 3 table of contents .................................................................................................

Page 5

Tma q series getting started guide 5 connecting cables and lines ............................................................................................................................... 26 ports .....................................................................................................

Page 6

Tma q series getting started guide 6 notes, cautions, and warnings this manual uses notes, cautions, and warnings to emphasize important and critical instructions. A note highlights important information about equipment or procedures. A caution emphasizes a procedure that may damage equipment or cau...

Page 7: Regulatory Compliance

Tma q series getting started guide 7 regulatory compliance safety standards for canada: can/csa-22.2 no. 1010.1-92 safety requirements for electrical equipment for measurement, control, and laboratory use, part 1: general requirements + amendments. Can/csa-22.2 no. 1010.2.010-94 particular requireme...

Page 8: Safety

Tma q series getting started guide 8 safety caution: the operator of this instrument is advised that if the equipment is used in a manner not specified in this manual, the protection provided by the equipment may be impaired. Instrument symbols the following labels are displayed on the tma instrumen...

Page 9

Tma q series getting started guide 9 sample decomposition the tma is capable of heating samples to 1000°c. Many materials may decompose during the heating, which can generate hazardous byproducts. Warning: if you are using samples that may emit harmful gases, vent the gases by placing the instrument...

Page 10

Tma q series getting started guide 1 0 warning: potential asphyxiant liquid nitrogen can cause rapid suffocation without warning. Store and use in an area with adequate ventilation. Do not enter confined spaces where nitrogen gas may be present unless the area is well ventilated. The warning above a...

Page 11: Overview

Tma q series getting started guide 1 1 overview the thermomechanical analyzer (tma) is an analytical instrument used to test the physical properties of many different materials. The tma instrument works in conjunction with a controller and associated software to make up a thermal analysis system. Yo...

Page 12

Tma q series getting started guide 1 2 • the weight tray, located behind the weight tray door, holds the weights to exert an additional known force on the sample. • the chromel®*/alumel®* sample thermocouple senses the temperature of the sample. The tma was developed by ta instruments with the follo...

Page 13

Tma q series getting started guide 1 3 the qtma touch screen with qnx/platinum tm the tma q400 instrument has a built-in integrated display and keypad in the form of a touch screen for local operator control. The functions on the screen change depending upon the menu you are using. This section brie...

Page 14

Tma q series getting started guide 1 4 display accesses the display screen, which displays the signals from the instrument such as signal display, real-time plot, instrument information, etc. Calibrate displays the calibration functions available for this instrument. Qnx/platinum tm control menu the...

Page 15

Tma q series getting started guide 1 5 control command description probe down used to “close” the probe, this key lowers the probe 3 mm, the range of the lvdt, when pressed one time. When the key is pressed a second time, mechanical action occurs, centering the lvdt coil. If the probe is moving up a...

Page 16

Tma q series getting started guide 1 6 qnx/platinum tm display touch screen options the display options are accessed by touching the display key at the bottom of the touch screen. The keys shown in the figure to the right are displayed. A brief description of the function of each key is provided in ...

Page 17

Tma q series getting started guide 1 7 qnx/platinum tm calibration options the calibration options are accessed by touching the calibrate key at the bottom of the touch screen. The keys shown in the figure below are displayed. A brief description of the function of each key is provided in the table ...

Page 18

Tma q series getting started guide 1 8 the tma touch screen (original) the tma q400 instruments have a built-in integrated display and keypad in the form of a touch screen for local operator control. The functions shown on the screen change depending upon the menu you are using. This section briefly...

Page 19

Tma q series getting started guide 1 9 tma control menu keys the control menu is accessed by touching the control menu key at the bottom of the touch screen. The keys shown in the figure here are displayed. A brief descrip- tion of the function of each key is provided in the table below. The availab...

Page 20

Tma q series getting started guide 2 0 display menu keys the display menu is accessed by touching the display menu key at the bottom of the touch screen. The menu shown in the figure here will be displayed. A brief description of the function of each key is provided in the table below. Key name desc...

Page 21: Options And Accessories

Tma q series getting started guide 2 1 options and accessories several optional probes and a cooling accessory are available from ta instruments to be used with the tma. A brief description of each one follows. For more information refer to the online documentation. Probes • film/fiber probe : the t...

Page 22: Instrument Specifications

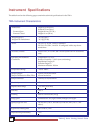

Tma q series getting started guide 2 2 instrument specifications the tables found on the following pages contain the technical specifications for the tma. Tma instrument characteristics dimensions depth 55.9 cm (22 in.) width 45.5 cm (18 in.) furnace open height 64.8 cm (25.5 in.) furnace closed hei...

Page 23: Unpacking/repacking The Tma

Tma q series getting started guide 2 3 unpacking/repacking the tma the instructions needed to unpack and repack the instrument are found as separate unpacking instructions in the shipping box and in the online documentation associated with the instrument control software. You may wish to retain all ...

Page 24

Tma q series getting started guide 2 4 choosing a location because of the sensitivity of tma experiments, it is important to choose a location for the instrument using the following guidelines. The tma should be: in ... A temperature-controlled area. ... A clean, vibration-free environment. ... An a...

Page 25

Tma q series getting started guide 2 5 fuse fuse holder fuse voltage configuration unit power entry module captive fasteners replace fuses for 230 vac only voltage configuration unit a voltage configuration/safety isolation unit is required for 230 vac or 120 vac. It is shipped in a separate contain...

Page 26

Tma q series getting started guide 2 6 connecting cables and lines to connect the cables and gas lines, you will need access to the tma instrument’s rear panel. All directional descriptions are written on the assumption that you are facing the back of the instrument. Note: connect all cables before ...

Page 27

Tma q series getting started guide 2 7 port function base purge this port is not used with the tma. Gas 1 gas inlet port controlled by the mass flow controller. Used for the sample purge gas. Gas 2 this port is not used with the tma. Cooling gas provides the furnace with air for cooling (830 kpa gau...

Page 28

Tma q series getting started guide 2 8 the purge gas flows through the instrument and is channeled internally to the sample purge line shown in the figure to the left. 3. Make sure that the pressure of your purge gas source is regulated between 100 and 140 kpa gauge (15 and 20 psig). Connecting the ...

Page 29

Tma q series getting started guide 2 9 installing the stage to install the stage on the tma, check to make sure the furnace is raised and off to the side. Then follow these steps (refer to the figure here for illustration of the parts): 1. Remove the stage shield by lifting it straight up. (this is ...

Page 30

Tma q series getting started guide 3 0 installing the expansion/penetration probes when you first receive the tma, you will need to install a probe. Later, if a different sample form is used, you can change to the appropriate probe for the experiment. (refer to chapter 3 for details on probe selecti...

Page 31

Tma q series getting started guide 3 1 ethernet switch setup in order to connect the instrument to a network, you will need to make the necessary cable connections as described below. The instrument and controller will be connected to an ethernet switch. In addition, there are instructions for conne...

Page 32

Tma q series getting started guide 3 2 ethernet connection yellow light green light connecting the controller to a lan before you can connect the controller to a lan, you will need to have already installed a network interface card into the computer. 1. Locate the second ethernet port on the back of...

Page 33

Tma q series getting started guide 3 3 power entry module reset button power switch the power switch is located at the rear of the instrument. It is part of the assembly called the power entry module, which also contains the power cable connection and fuses. The power switch is used to turn the inst...

Page 34: Starting The Tma

Tma q series getting started guide 3 4 starting the tma 1. Check all connections between the tma and the controller. Make sure each component is plugged into the correct connector. 2. Set the instrument power switch to the on (1) position. After the proper power up sequence, the ta instruments logo ...

Page 35: Using The Tma

Tma q series getting started guide 35 using the tma all of your tma experiments will have the following general outline. In some cases, not all of these steps will be performed. The majority of these steps are performed using the instrument control software. The instructions needed to perform these ...

Page 36: Calibrating The Tma

Tma q series getting started guide 36 calibrating the tma to obtain accurate experimental results, calibrate the tma when you first install it. To keep your tma working to the highest level of performance possible, you should calibrate periodically thereafter. A brief description of each calibration...

Page 37

Tma q series getting started guide 37 when to calibrate: the sample thermocouple should be calibrated in the following situations: • when the tma is first installed • when the sample thermocouple is changed • when the tma is serviced or repaired • periodically (approximately once a month) • if you a...

Page 38: Running A Tma Experiment

Tma q series getting started guide 38 running a tma experiment caution: drying out the instrument may be needed, if it has been exposed to humid conditions. Certain ceramic materials used in this equipment may absorb moisture, causing leakage currents to exceed those specified in the applicable stan...

Page 39

Tma q series getting started guide 39 probe type contactdiameter pressure exerted by types of tests yielded mm (in.) 0.01 n load flexure 5.08 (0.2) 0.49 kpa deflection temperature flexibility dilatometer 6.07 (0.239) 0.34 kpa expansion coefficient parallel plate 9.52 (0.375) 0.14 kpa viscosity-tempe...

Page 40

Tma q series getting started guide 40 guidelines for handling samples sample preparation sample preparation will vary based on the selected probe type. Guidelines for samples used for penetration and expansion studies are detailed below: • they should be as flat as possible, with parallel ends, to e...

Page 41

Tma q series getting started guide 41 starting an experiment before you start the experiment, ensure that the tma is connected with the controller, the sample is loaded, the furnace is closed, and you have entered all necessary information through the instrument control soft- ware. Note: once the ex...

Page 42: Maintaining The Instrument

Tma q series getting started guide 42 maintaining the instrument the primary maintenance procedures described in this section are the customer’s responsibility. Any further maintenance should be performed by a representative of ta instruments or other qualified service personnel. Consult the online ...

Page 43

Tma q series getting started guide 43 cleaning the stage dirt or sample residue left on the top of the stage may interfere with the next sample placed on the stage. To maintain proper experimental conditions, clean the stage as follows: for small amounts of residue: 1. Use industrial cleaner or acet...

Page 44

Tma q series getting started guide 44 cleaning the thermocouple sample residue and dirt may interfere with the accuracy of the thermocouple readings. To clean the thermo- couple: 1. Raise the furnace and rotate it clockwise to move it off to the side. 2. Remove the stage shield by lifting it straigh...

Page 45: Replacements

Tma q series getting started guide 45 replacements occasionally, you may need to replace a broken or worn-out part of the tma. Any replacements needed, other than those discussed in this manual, must be supplied and installed by qualified ta instruments service personnel. Call (302) 427-4050 for ser...

Page 46

Tma q series getting started guide 46 4. Slide the balance enclosure into position. 5. Replace the screws, two on each side, that hold the balance enclosure in place. 6. Reposition the thermocouple so that the tip of the thermo- couple bends at a 90° angle and lies flat against the sample platform. ...

Page 47

Tma q series getting started guide 47 replacing fuses warning: always unplug the instrument before you examine or replace the fuses. Replacing the tma fuses the tma contains internal fuses that are not user serviceable. If any of the internal fuses blows, a hazard may exist. Call your ta instruments...

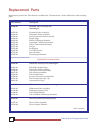

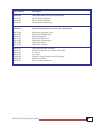

Page 48: Replacement Parts

Tma q series getting started guide 48 replacement parts replacement parts for the tma that are available from ta instruments. See the table below when ordering parts. Part number description 944200.901 standard tma accessory kit consisting of: 944122.901 expansion probe assembly 944126.901 penetrati...

Page 49

Tma q series getting started guide 49 part number description 944203.902 tma q400 em accessory kit consisting of: 944127.901 flexure probe assembly 941054.000 flexure sample platform 945045.901 3-point bend calibration jig 944204.901 parallel plate rheometer accessory kit consisting of: 943125.000 r...

Page 50

Tma q series getting started guide 50

Page 51: Index

Tma q series getting started guide 5 1 index a accessories 12 standard 12 expansion probes 12 penetration probes 12 air cool key 15 air cool line installing 28 air source 28 auto measure system zeroing 39 b balance enclosure 11 installing 46 removing 45 c cable ethernet 31 cables connecting 26 calib...

Page 52

Tma q series getting started guide 5 2 computer connecting to ethernet hub 31 connecting to lan 32 connecting cables 26 gas lines 26 contamination 9 control menu touch screen keys - qnx/platinum 14 controller description 11 cooling gas line 28 cooling gas port 27 d dilatometer accessory description ...

Page 53

Tma q series getting started guide 5 3 flexure accessory 21 operation 21 furnace assembly 11 fuses 47 replacement for voltage configuration unit 25 replacing on the tma 47 g gas lines connecting 26 gases use of 27 h hazardous products 9 hemispherical probe 21 i installation 23 to 33 voltage configur...

Page 54

Tma q series getting started guide 5 4 mass flow controller 27 mass flow controller (mfc) 27 measure length key 40 mechanical cooling accessory (mca) 21 moisture 24, 38 n networking 31 p parallel plate rheometer accessory 21 operation 21 sample loading 21 parallel plate rheometer accessorydescriptio...

Page 55

Tma q series getting started guide 5 5 probes, expansion installation 30 probes, penetration installation 30 purge gas 27 purge gases recommended 22 purge line 27 q qnx/platinum touch screens 13 r regulatory compliance 7 remote key. See also system key repacking 23 replacement parts 45, 48 running e...

Page 56

Tma q series getting started guide 5 6 stage nut installation 29 stage retainer ring installation 29 stage shield installation 29, 46 starting experiment 41 instrument 34 status line 18 stopping instrument 34 stopping an experiment 41 t ta instruments service 45 technical specifications 22 thermal s...

Page 57

Tma q series getting started guide 5 7 u unpacking 23 v voltage configuration unit installing 25 w weight tray function 12 z zero length key 39.

Page 58

Tma q series getting started guide 5 8.