- DL manuals

- Taco

- Water Pump

- SKV SelfSensing

- Installation, Operation And Maintenance Manual

Taco SKV SelfSensing Installation, Operation And Maintenance Manual

© 201

7 Taco, Inc.

1

Installation, Operation, and Maintenance Manual

302-365

SKV SelfSensing

Vertical In-line Pump

SUPERSEDES:

January 14, 2014

EFFECTIVE:

June 5, 2017

Plant ID: 001-4208

Table of Contents

1 SAFETY REQUIREMENTS. . . . . . . . . . . . . . . . . . . . 2

2 GENERAL INSTALLATION REQUIREMENTS. . . . . 2

2.1 Receiving Pump. . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.3 Foundation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3.1 Routine Inspections . . . . . . . . . . . . . . . . . . . . . . 2

3.2 Close Coupled Pumps . . . . . . . . . . . . . . . . . . . . 3

3.3 Close Coupled Motors . . . . . . . . . . . . . . . . . . . . 3

3.4 Mechanical Seal. . . . . . . . . . . . . . . . . . . . . . . . . 3

4 DIS-ASSEMBLY AND RE-ASSEMBLY. . . . . . . . . . . 3

4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4.2 Dis-Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4.3 Re-Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5 PUMP PIPING - GENERAL. . . . . . . . . . . . . . . . . . . . 4

6 APPLICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

7 MECHANICAL INSTALLATION . . . . . . . . . . . . . . . . 4

7.1 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

7.2 VFD Mounting to Pump . . . . . . . . . . . . . . . . . . . 4

7.3 VFD Mounting to Wall . . . . . . . . . . . . . . . . . . . . 6

7.4 Pump Piping – Detailed . . . . . . . . . . . . . . . . . . . 6

8 ELECTRICAL CONNECTIONS. . . . . . . . . . . . . . . . . 9

8.1 Exploded Views . . . . . . . . . . . . . . . . . . . . . . . . . 9

8.2 Electrical Installation . . . . . . . . . . . . . . . . . . . . 10

8.3 Grounding Requirements. . . . . . . . . . . . . . . . . 12

8.4 Typical Terminal Wiring Configurations . . . . . . 18

9 USER INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . 28

9.1 Local Control Panel . . . . . . . . . . . . . . . . . . . . . 28

9.2 Backup and Copying Parameter Settings . . . . 30

9.3 Password Protection . . . . . . . . . . . . . . . . . . . . 31

10 PUMP CONTROL SET-UPS . . . . . . . . . . . . . . . . . 34

10.1 SelfSensing Description. . . . . . . . . . . . . . . . . 34

10.2 Set-up Menu . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.3 Variable Flow Control (Flow Compensation) . 35

10.4 Constant Flow Control . . . . . . . . . . . . . . . . . . 35

10.5 Constant Pressure Control. . . . . . . . . . . . . . . 36

10.6 Sequencing (Standby Pump Alternation). . . . 36

11 START-UP PROCEDURE . . . . . . . . . . . . . . . . . . 37

11.1 Check Points Before First Start . . . . . . . . . . . 37

11.2 Check Motor Rotation . . . . . . . . . . . . . . . . . . 37

11.3 Start Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . 37

11.4 Verify Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

12 SYSTEM BALANCING . . . . . . . . . . . . . . . . . . . . . 39

12.1 About SelfSensing ProBalance . . . . . . . . . . . 39

12.2 My Personal Menu for ProBalance . . . . . . . . 40

12.3 Balancing Procedure . . . . . . . . . . . . . . . . . . . 41

12.4 Additional Settings . . . . . . . . . . . . . . . . . . . . . 49

13 MENUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

14 WARNINGS AND ALARMS . . . . . . . . . . . . . . . . . 61

14.1 Supplemental Warning and Alarm Settings . . 70

15 CASING/IMPELLER WEAR RING CLEARANCES 73

16 SKS PUMP PROBLEM ANALYSIS . . . . . . . . . . . 74

17 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . 75

17.1 Power-dependent Specifications . . . . . . . . . . 75

17.2 Connection Tightening Torques. . . . . . . . . . . 77

A SET-UP FOR STANDBY PUMP ALTERNATION . 78

B ON-SITE DRIVE MOUNTING TO WALL OR PUMP 83

Summary of SKV SelfSensing

Page 1

? 201 7 taco, inc. 1 installation, operation, and maintenance manual 302-365 skv selfsensing vertical in-line pump supersedes: january 14, 2014 effective: june 5, 2017 plant id: 001-4208 table of contents 1 safety requirements. . . . . . . . . . . . . . . . . . . . 2 2 general installation requireme...

Page 2: 1 Safety Requirements

Taco® skv 2 302-365, effective: june 5, 2017 © 2017 taco, inc. 1 safety requirements caution: these instructions should be read completely prior to installation of the equipment. A copy of these instructions should be retained on file for future refer- ence. Warning: electrical shock hazard. Discon-...

Page 3: 4 Dis-Assembly and Re-

Taco® skv 3 • check discharge gauge reading and confirm that it is normal. If gauge readings are abnormal find out why. Note: suction and discharge gauges should read the same with pump stopped. 3.2 close coupled pumps the pump section is attached directly to the motor shaft and does not contain bea...

Page 4: 5 Pump Piping - General

Taco® skv 4 302-365, effective: june 5, 2017 © 2017 taco, inc. 5 pump piping - general caution: never connect any pump to piping, unless extra care is taken to measure and align the piping flanges well. Always start piping from pump. Use as few bends as possible and preferably long radius elbows. Do...

Page 5

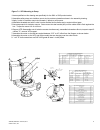

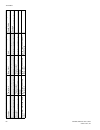

Taco® skv 5 302-365, effective: june 5, 2017 © 2017 taco, inc. Figure 7-1: vfd mounting to pump alternative bracket view skv or sks bom assembly item # description qty 1 vfd 1 2 bar bracket 2 3 wire harness - motor power 1 4 vibration isolation mount 4 5 safety strap 4 6 nut (vfd) 4 7 lock washer (v...

Page 6

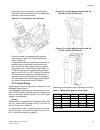

Taco® skv 6 302-365, effective: june 5, 2017 © 2017 taco, inc. 7.3 vfd mounting to wall 7.3.1 lifting • check the weight of the unit to determine a safe lift- ing method. • ensure that the lifting device is suitable for the task. • if necessary, plan for a hoist, crane, or forklift with the appropri...

Page 7

Taco® skv 7 302-365, effective: june 5, 2017 © 2017 taco, inc. Vertical in-line pumps may be installed directly in the system piping with no additional support. Pipe hangers are simply sized for the additional weight of the pumping unit. Many pumps are installed in this manner and are mounted at suf...

Page 8

Taco® skv 8 302-365, effective: june 5, 2017 © 2017 taco, inc. Pads must be used under the legs and monitored as pipe hangers are adjusted to ensure the pump flanges are not supporting the piping. Bolting to the floor or housekeep- ing pad is not recommended. If the stanchions are bolted down the bo...

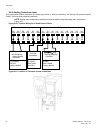

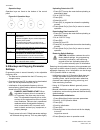

Page 9: 8 Electrical Connections

Taco® skv 9 302-365, effective: june 5, 2017 © 2017 taco, inc. 8 electrical connections 8.1 exploded views figure 8-1: exploded view a size 1 lcp 10 motor output terminals 96 (u), 97 (v), 98 (w) 2 rs-485 serial bus connector (+68, -69) 11 relay 1 (01, 02, 03) 3 analog i/o connector 12 relay 2 (04, 0...

Page 10

Taco® skv 10 302-365, effective: june 5, 2017 © 2017 taco, inc. Figure 8-2: exploded view b and c sizes 8.2 electrical installation this section contains detailed instructions for wiring the adjustable frequency drive. The following tasks are described. • wiring the motor to the adjustable frequency...

Page 11

Taco® skv 11 302-365, effective: june 5, 2017 © 2017 taco, inc. Figure 8-3 shows a basic electrical connection. Figure 8-3: basic wiring schematic drawing danger: equipment hazard! Rotating shafts and electrical equipment can be hazardous. All electri- cal work must conform to national and local ele...

Page 12

Taco® skv 12 302-365, effective: june 5, 2017 © 2017 taco, inc. For your safety, comply with the following require- ments: • electronic controls equipment is connected to haz- ardous ac line voltage. Extreme care should be taken to protect against electrical hazards when applying power to the unit. ...

Page 13

Taco® skv 13 302-365, effective: june 5, 2017 © 2017 taco, inc. • use the clamps provided with on the equipment for proper ground connections. • do not ground one adjustable frequency drive to another in a “daisy chain” fashion. • keep the ground wire connections as short as possi- ble. • use of hig...

Page 14

Taco® skv 14 302-365, effective: june 5, 2017 © 2017 taco, inc. 8.3.5 motor connection danger: induced voltage! Run out- put motor cables from multiple adjustable frequency drives separately. Induced voltage from output motor cables run together can charge equipment capacitors even with the equipmen...

Page 15

Taco® skv 15 • depending on the configuration of the equipment, input power will be connected to the line power input terminals or the input disconnect. Figure 8-11: connecting to ac line power • ground the cable in accordance with grounding instructions provided in “8.3 grounding require- ments” on...

Page 16

Taco® skv 16 302-365, effective: june 5, 2017 © 2017 taco, inc. Control terminal types figure 8-14 shows the removable adjustable frequency drive connectors. Figure 8-14: control terminal locations • connector 1 provides four programmable digital inputs terminals, two additional digital terminals pr...

Page 17

Taco® skv 17 302-365, effective: june 5, 2017 © 2017 taco, inc. 50/60 hz ground loops with very long control cables, ground loops may occur. To eliminate ground loops, connect one end of the shield- toground with a 100 nf capacitor (keeping leads short). Avoid emc noise on serial communication to el...

Page 18

Taco® skv 18 302-365, effective: june 5, 2017 © 2017 taco, inc. 8.4 typical terminal wiring configurations the unit connection blocks are shown in “figure 8-14: control terminal locations” on page 16. Table 2: control terminal information terminal number parameter default setting description relay o...

Page 19

Taco® skv 19 302-365, effective: june 5, 2017 © 2017 taco, inc. Figure 8-18: control terminal connectors 1-4 and relay output locations drive 1 relay. Relay 1 is on the right in this view. Relay 2..

Page 20

Taco® skv 20 302-365, effective: june 5, 2017 © 2017 taco, inc. 8.4.1 factory default set-up this configuration makes use of the controller factory default settings for input/output. The factory default settings are configured for set-up 1, selfsensing system curve control without an external transd...

Page 21

Taco® skv 21 302-365, effective: june 5, 2017 © 2017 taco, inc. 8.4.2 relay outputs as shown above, each unit has two form c programmable relay outputs. The relay terminals can be found on the con- troller in various locations according to the frame size. Figure 8-19: wiring the relay terminals 01 c...

Page 22

Taco® skv 22 302-365, effective: june 5, 2017 © 2017 taco, inc. 8.4.3 adding transducer input this configuration adds a transducer for closed loop control or external monitoring. Use set-up 4 for pressure control (delta p) using a wired pressure transducer. Note: analog input configuration switches ...

Page 23

Taco® skv 23 302-365, effective: june 5, 2017 © 2017 taco, inc. The following wiring scheme is used with set-up 4 as shown in “10.1 selfsensing description” on page 34. Figure 8-22: terminal wiring for 0–10v sensor 39 com 42 aout 50 +10v 53 a in 55 com 54 a in 12 +24v 13 +24v 18 d in 19 d in 27 d in...

Page 24

Taco® skv 24 302-365, effective: june 5, 2017 © 2017 taco, inc. Table 5: settings for a wired sensor for external monitoring * to use ai 53, set parameters 6–14, 6–15, 6–17 and set 20-00 to “analog input 53.” parameter number description set to 0-24 display line 3 large ext. 1 feedback [unit] 21-14 ...

Page 25

Taco® skv 25 302-365, effective: june 5, 2017 © 2017 taco, inc. 8.4.4 speed control with external potentiometer this configuration allows an external potentiometer to control the speed of the motor.To use this set-up, the analog input must be configured as a voltage input. The following wiring schem...

Page 26

Taco® skv 26 302-365, effective: june 5, 2017 © 2017 taco, inc. 8.4.5 control from external plc/bms through analog input this set-up allows an external control source such as a plc or bms controller to provide: a) the process variable, b) the setpoint or c) a speed reference. The output from the ext...

Page 27

Taco® skv 27 302-365, effective: june 5, 2017 © 2017 taco, inc. * to use ai 53, configure parameters 6-14, 6-15, 6-17 and set 20-00 to analog input 53 8.4.6 control from external plc/bms using communications port the controller can be controlled from a bms or plc through the communications port. In ...

Page 28: 9 User Interface

Taco® skv 28 302-365, effective: june 5, 2017 © 2017 taco, inc. 9 user interface 9.1 local control panel the local control panel (lcp) is the combined display and keypad on the front of the unit. The lcp is the user interface to the adjustable frequency drive. The lcp has several user functions. • s...

Page 29

Taco® skv 29 302-365, effective: june 5, 2017 © 2017 taco, inc. Navigation keys navigation keys are used for programming functions and moving the display cursor. The navigation keys also pro- vide speed control in local (hand) operation. Three adjustable frequency drive status indicators are also lo...

Page 30

Taco® skv 30 © 2017 taco, inc. Operation keys operation keys are found at the bottom of the control panel. Figure 9-4: operation keys 9.2 backup and copying parameter settings programming data is stored internally in the adjustable frequency drive. • the data can be uploaded into the lcp memory as a...

Page 31

Taco® skv 31 302-365, effective: june 5, 2017 © 2017 taco, inc. Manual initialization 1.Remove power to the unit and wait for the display to turn off. 2.Press and hold [status], [main menu], and [ok] at the same time and apply power to the unit. Factory default parameter settings are restored during...

Page 32

Taco® skv 32 302-365, effective: june 5, 2017 © 2017 taco, inc. 9.3.3 change password for main menu 1.Follow steps 1-4 in section 9.3.1 above. 2.Scroll down to parameter 0-60 main menu password. 3.Press [ok]. 4.Adjust/edit the password using the arrow keys. 5.Press [ok]. The main menu password is no...

Page 33

Taco® skv 33 302-365, effective: june 5, 2017 © 2017 taco, inc. 9.3.6 change password for personal menu 1.Follow steps 1-4 in in section 9.3.4 above. 2.Scroll down to parameter 0-65 personal menu password. 3.Press [ok]. 4.Adjust/edit the password using the arrow keys. 5.Press [ok]. The personal menu...

Page 34: 10 Pump Control Set-Ups

Taco® skv 34 302-365, effective: june 5, 2017 © 2017 taco, inc. 10 pump control set-ups 10.1 selfsensing description the taco selfsensing pump is a taco pump equipped with a variable frequency drive (vfd) with selfsensing control technology. Selfsensing control is an innovative concept in circulatin...

Page 35

Taco® skv 35 10.3 variable flow control (flow compensation) under variable flow control (otherwise known as flow compensation mode), the controller is set to control the pump speed according to a ‘control curve’ between max and min flow (see figure 10-1 below). This mode should be used for system di...

Page 36

Taco® skv 36 302-365, effective: june 5, 2017 © 2017 taco, inc. 10.5 constant pressure control selfsensing pumps can be configured to maintain a con- stant pump head in a system as the demand varies. This effectively simulates the mounting of a differential pres- sure sensor at, or near, the pump. F...

Page 37: 11 Start-Up Procedure

Taco® skv 37 302-365, effective: june 5, 2017 © 2017 taco, inc. 11 start-up procedure 11.1 check points before first start verify that motor is correctly wired for voltage available. Verify that the pump has been primed. The pump should never be run dry. Note: extra effort may be required to get the...

Page 38

Taco® skv 38 302-365, effective: june 5, 2017 © 2017 taco, inc. Menu.” 6.Scroll down to parameter 0-10 active set-up and press ok. 7.Change active set-up to “set-up 1”. A.Parameter 0-10 active set-up. B.You will know the change has happened when you see change to . 8.Press the [status] button to get...

Page 39: 12 System Balancing

Taco® skv 39 302-365, effective: june 5, 2017 © 2017 taco, inc. 12 system balancing 12.1 about selfsensing probalance the pump is equipped with selfsensing probalance tm technology. Selfsensing probalance tm technology is a revolutionary system balancing method that utilizes the vfd’s selfsensing ca...

Page 40

Taco® skv 40 302-365, effective: june 5, 2017 © 2017 taco, inc. 12.2 my personal menu for probalance the my personal menu is arranged in order to take you step by step through the selfsensing probalance system balancing process. Before you begin, it is recommended to acquaint yourself with the my pe...

Page 41

Taco® skv 41 302-365, effective: june 5, 2017 © 2017 taco, inc. 12.3 balancing procedure 12.3.1 measure system resistance figure 12-4 shows a typical system response at startup. Point a is programmed at the factory per the specifica- tion/equipment schedule and the pump is set to stay on the control...

Page 42

Taco® skv 42 302-365, effective: june 5, 2017 © 2017 taco, inc. 9.Scroll up to parameter 20-21 setpoint 1 and press ok. 10.Set the system’s flow at design point (flow value that was specified at the time of order is already displayed) and press [ok]. A.Parameter 20-21 setpoint 1. 11.Press the [auto ...

Page 43

Taco® skv 43 302-365, effective: june 5, 2017 © 2017 taco, inc. 5.Scroll down to parameter 20-00 feedback source and press ok. 6.Change feedback from “sensorless pressure” to “no function” then press ok. A.Parameter 20-00 = feedback 1 source. 7.Scroll down to parameter 1-00 configuration mode and pr...

Page 44

Taco® skv 44 302-365, effective: june 5, 2017 © 2017 taco, inc. 14.Change the configuration mode from “open loop” to “closed loop” and press ok. A.Parameter 1-00 = configuration mode. 15.Scroll down to parameter 20-12 reference/ feedback unit and press ok. 16.Change the reference/feedback unit to ft...

Page 45

Taco® skv 45 302-365, effective: june 5, 2017 © 2017 taco, inc. 24.Press the [ok] button to enter “my personal menu.” 25.Scroll down to parameter 22-89 flow at design point and press ok. A.Parameter 22-89 flow at design point. 26.Press the [status] button to get back to the main screen. 27.The progr...

Page 46

Taco® skv 46 302-365, effective: june 5, 2017 © 2017 taco, inc. A.Parameter 20-21 setpoint 1. 8.Press the [auto on] button. 9.Press the [status] button to get back to the main screen. A.Let the drive ramp up to the design flow point that was specified. B.Important: allow the pump enough time to sett...

Page 47

Taco® skv 47 302-365, effective: june 5, 2017 © 2017 taco, inc. A.Parameter 1-00 = configuration mode. 19.Scroll down to parameter 22-87 pressure at no-flow speed and press ok. 20.Set the desired pressure at no-flow in ft wg (control head) then press ok. A.Parameter 22-87 = pressure at no-flow speed...

Page 48

Taco® skv 48 302-365, effective: june 5, 2017 © 2017 taco, inc. A.Parameter 1-00 = configuration mode. 27.Scroll down to parameter 20-12 reference/ feedback unit and press ok. 28.Change the reference/feedback unit to ft wg (press the [down arrow] button to reach the setting faster). Important: due t...

Page 49

Taco® skv 49 302-365, effective: june 5, 2017 © 2017 taco, inc. 12.3.4 flow fine tuning after balancing is complete, if the flow at point c requires fine tuning, simply increase or decrease parameter 20-21 setpoint 1 until desired flow is achieved. Follow this pro- cedure to adjust the setpoint. 1.P...

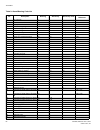

Page 50: 13 Menus

Taco® skv 50 302-365, effective: june 5, 2017 © 2017 taco, inc. 13 menus 13.0.1 quick menu structure - page 1 q3-1 general settings 0-24 display line 3 large 1-00 configuration mode q3-31 single zone ext. Setpoint 20-70 closed-loop type q3-10 adv. Motor settings 0-37 display text 1 20-12 reference/f...

Page 51

Taco® skv 51 302-365, effective: june 5, 2017 © 2017 taco, inc. 13.0.2 quick menu structure - page 2 0-21 display line 1.2 small 6-15 terminal 53 high ref./ feedb. Value 20-73 minimum feedback level 20-83 pid start speed [hz] 20-13 minimum reference/ feedb. 0-22 display line 1.3 small q3-3 closed-lo...

Page 52

Taco® skv 52 302-365, effective: june 5, 2017 © 2017 taco, inc. 13.0.3 main menu structure - page 1 0-** operation / display 0-37 display text 1 0-77 dst/summertime end 1-36 iron loss resistance (rfe) 1-82 min speed for function at stop [hz] 0-0* basic settings 0-38 display text 2 0-79 clock fault 1...

Page 53

Taco® skv 53 302-365, effective: june 5, 2017 © 2017 taco, inc. 13.0.4 main menu structure - page 2 0-32 custom readout max value 0-76 dst/summertime start 1-35 main reactance (xh) 1-81 min speed for function at stop [rpm] 3-0* reference limits 3-02 minimum reference 3-92 power restore 4-6* speed by...

Page 54

Taco® skv 54 302-365, effective: june 5, 2017 © 2017 taco, inc. 13.0.5 main menu structure - page 3 3-81 quick stop ramp time 4-54 warning reference low 5-18 terminal x30/4 digital input 5-65 pulse output max freq #29 6-2* analog input 54 3-82 starting ramp up time 4-55 warning reference high 5-3* d...

Page 55

Taco® skv 55 302-365, effective: june 5, 2017 © 2017 taco, inc. 13.0.6 main menu structure - page 4 6-47 term. X30/12 live zero 8-32 baud rate 8-85 slave timeout errors 9-71 profibus save data values 10-21 cos filter 2 6-5* analog output 42 8-33 parity / stop bits 8-89 diagnostics count 9-72 profibu...

Page 56

Taco® skv 56 302-365, effective: june 5, 2017 © 2017 taco, inc. 13.0.7 main menu structure - page 5 13-1* comparators 14-23 typecode setting 15-04 overtemps 15-47 power card ordering no 16-01 reference [unit] 13-10 comparator operand 14-25 trip delay at torque limit 15-05 overvolts 15-48 lcp id no 1...

Page 57

Taco® skv 57 302-365, effective: june 5, 2017 © 2017 taco, inc. 13.0.8 main menu structure - page 6 16-38 sl controller state 16-77 analog out x30/8 [ma] 18-35 analog out x42/11 [v] 20-33 user-defined refrigerant a3 21-01 pid performance 16-39 control card temp. 16-8* fieldbus & fc port 18-36 analog...

Page 58

Taco® skv 58 302-365, effective: june 5, 2017 © 2017 taco, inc. 13.0.9 main menu structure - page 7 21-32 ext. 2 maximum reference 21-64 ext. 3 dif. Gain limit 22-43 wake-up speed [hz] 22-90 flow at rated speed 23-64 timed period stop 21-33 ext. 2 reference source 22-** appl. Functions 22-44 wake-up...

Page 59

Taco® skv 59 302-365, effective: june 5, 2017 © 2017 taco, inc. 13.0.10 main menu structure - page 8 24-90 missing motor function 25-26 destage at no-flow 25-8* status 26-20 terminal x42/3 low volt- age 26-54 terminal x42/9 timeout preset 24-91 missing motor coeffcient 1 25-27 stage function 25-80 c...

Page 60

Taco® skv 60 302-365, effective: june 5, 2017 © 2017 taco, inc. 35-06 temperature sensor alarm function 35-17 term. X48/4 high temp. Limit 35-27 term. X48/7 high temp. Limit 35-37 term. X48/10 high temp. Limit 35-45 term. X48/2 high ref./ feedb. Value 35-1* temp. Input x48/4 35-2* temp. Input x48/7 ...

Page 61: 14 Warnings and Alarms

Taco® skv 61 14 warnings and alarms 14.0.1 system monitoring the adjustable frequency drive monitors the condition of its input power, output, and motor factors as well as other system performance indicators. A warning or alarm may not necessarily indicate a problem internal to the adjust- able freq...

Page 62

Taco® skv 62 302-365, effective: june 5, 2017 © 2017 taco, inc. Table 9: alarm/warning code list no. Description warning alarm/trip alarm/trip lock parameter reference 1 10 volts low x 2 live zero error (x) (x) 6-01 4 mains phase loss (x) (x) (x) 14-12 5 dc link voltage high x 6 dc link voltage low ...

Page 63

Taco® skv 63 302-365, effective: june 5, 2017 © 2017 taco, inc. (x) dependent on parameter 1) cannot be auto reset via 14-20 reset mode no. Description warning alarm/ trip alarm/trip lock parameter reference 54 ama motor too small x 55 ama parameter out of range x 56 ama interrupted by user x 57 ama...

Page 64

Taco® skv 64 302-365, effective: june 5, 2017 © 2017 taco, inc. 14.0.5 fault messages the warning/alarm information below defines the warn- ing/alarm condition, provides the probable cause for the condition, and details a remedy or troubleshooting proce- dure. Warning 1, 10 volts low the control car...

Page 65

Taco® skv 65 302-365, effective: june 5, 2017 © 2017 taco, inc. Display the thermal drive load on the lcp and monitor the value. When running above the adjustable frequency drive continuous current rating, the counter should increase. When running below the adjustable frequency drive continuous curr...

Page 66

Taco® skv 66 302-365, effective: june 5, 2017 © 2017 taco, inc. 15-42 voltage 15-43 software version 15-45 actual typecode string 15-49 sw id control card 15-50 sw id power card 15-60 option mounted 15-61 option sw version warning/alarm 16, short circuit there is a short circuit in the motor or moto...

Page 67

Taco® skv 67 302-365, effective: june 5, 2017 © 2017 taco, inc. Warning/alarm 30, motor phase u missing motor phase u between the adjustable frequency drive and the motor is missing. Remove power from the adjustable frequency drive and check motor phase u. Warning/alarm 31, motor phase v missing mot...

Page 68

Taco® skv 68 302-365, effective: june 5, 2017 © 2017 taco, inc. For x30/7, check the load connected to x30/7 or remove short-circuit connection. Check 5-33 term x30/7 digi out (mcb 101). Warning/alarm 45, ground fault 2 ground fault on start-up. Troubleshooting • check for proper grounding and loose...

Page 69

Taco® skv 69 troubleshooting • check that the ambient operating temperature is within limits. • check for clogged filters. • check fan operation. • check the control card. Warning 66, heatsink temperature low the adjustable frequency drive is too cold to operate. This warning is based on the tempera...

Page 70

Taco® skv 70 302-365, effective: june 5, 2017 © 2017 taco, inc. Warning 203, missing motor with an adjustable frequency drive operating multi- motors, an underload condition was detected. This could indicate a missing motor. Inspect the system for proper operation. Warning 204, locked rotor with an ...

Page 71

Taco® skv 71 302-365, effective: june 5, 2017 © 2017 taco, inc. • manual reset alarm [3] dry-run settings 1.Press [main menu]. 2.Scroll down to parameter 22-** appl. Func- tions. 3.Press [ok]. 4.Scroll down to parameter 22-2* no-flow detection. 5.Press [ok]. 6.Scroll down to parameter 22-26 dry pump...

Page 72

Taco® skv 72 302-365, effective: june 5, 2017 © 2017 taco, inc. 4.Scroll down to parameter 22-5* end of curve. 5.Press [ok]. 6.Press [ok] to change parameter 25-50 end of curve function. 7.Change parameter 22-50 to desired feature. 8.Press [back]. 9.Scroll down to parameter 25-51 end of curve delay....

Page 73

Taco® skv 73 302-365, effective: june 5, 2017 © 2017 taco, inc. 15 casing/impeller wear ring clearances pump size wear ring-suction side dia d1 dia d2 clearance max min max min max min 1506 2.363 2.361 2.377 2.375 .016 .012 1507 2.738 2.736 2.752 2.750 .016 .012 2006 2.863 2.861 2.877 2.875 .016 .01...

Page 74: 16 Skv Pump Problem Analysis

Taco® skv 74 302-365, effective: june 5, 2017 © 2017 taco, inc. 16 skv pump problem analysis 16.0.1 no discharge 1.Pump not primed. 2.Speed too low. 3.System head too high. 4.Suction lift higher than pump is designed. 5.Impeller completely clogged. 6.Incorrect direction of rotation. 7.Air leak in su...

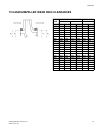

Page 75: 17 Specifications

Taco® skv 75 302-365, effective: june 5, 2017 © 2017 taco, inc. 17 specifications 17.1 power-dependent specifications table 10: line power supply 200-240 v ac table 11: line power supply 3 x 200-240 v ac table 12: line power supply 3 x 200-240 v ac table 13: line power supply 3 x 380-480 v ac line p...

Page 76

Taco® skv 76 302-365, effective: june 5, 2017 © 2017 taco, inc. Table 14: line power supply 3 x 380-480 v ac table 15: line power supply 3 x 380-480 v ac table 16: with brake and load sharing 95 / 4/0 table 17: with brake and load sharing 95 / 4/0 line power supply 3 x 380-480 v ac - normal overload...

Page 77

Taco® skv 77 302-365, effective: june 5, 2017 © 2017 taco, inc. 17.1.1 line power supply 3 x 525-690 v ac table 18: line power supply 3 x 525-690 v ac table 19: line power supply 3 x 525-690 v ac ip20-chassis/ip21-ip55/nema 1-nema12 table 20: line power supply 3 x 525-690 v ac ip21-ip55/nema 1-nema ...

Page 78

Taco® skv 78 302-365, effective: june 5, 2017 © 2017 taco, inc. Appendix a: set-up for standby pump alternation this section describes how to alternate taco skv pump units based on elapsed time and how to configure the standby pump to energize in the event that the duty pump fails. A.1 overview two ...

Page 79

Taco® skv 79 302-365, effective: june 5, 2017 © 2017 taco, inc. During system commissioning and other situations, the user may want to force pump alternation rather than rely on the setting in parameter 13-20.0. • logic rule 1 allows the user to override the timer by pressing the [ok] and [>] keys o...

Page 80

Taco® skv 80 302-365, effective: june 5, 2017 © 2017 taco, inc. 5.The standby drive (drive b) should display in the upper right hand corner of the screen (set-up 2). 6.If drive b remains in set-up 1 , check the fol- lowing: a.Check that wire connections comply with figure a-1. B.Check that both driv...

Page 81

Taco® skv 81 302-365, effective: june 5, 2017 © 2017 taco, inc. A.3 parameters table 22: lead and lag drive parameters parameter number parameter name parameter value set-up 1 set-up 2 0–01 language [22] english us [22] 0–03 regional settings [1] north america [1] north america 0–10 active set-up [9...

Page 82

Taco® skv 82 302-365, effective: june 5, 2017 © 2017 taco, inc. 13–52.2 sl controller action [3] select set-up 2 [3] select set-up 2 13–52.3 sl controller action [30] start timer 1 [30] start timer 1 13–52.4 sl controller action [29] start timer 0 [29] start timer 0 13–52.5 sl controller action [2] ...

Page 83

Taco® skv 83 302-365, effective: june 5, 2017 © 2017 taco, inc. Appendix b: on-site drive mounting to wall or pump follow the steps below for on-site drive mounting to wall or to pump. B.1 match pump and drive tags important: ensure the pump tag matches the vfd tag. The pump and drive will have iden...

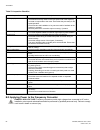

Page 84

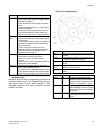

Taco® skv 84 302-365, effective: june 5, 2017 © 2017 taco, inc. Table 23: inspection checklist b.5 applying power to the frequency converter danger: high voltage! Frequency converters contain high voltage when connected to ac mains. Installation, start-up and maintenance should be performed by quali...

Page 85

Taco® skv 85 302-365, effective: january 14, 2014 © 2017 taco, inc. Warning: unintended start! When the frequency converter is connected to ac mains, the motor may start at any time. The frequency converter, motor, and any driven equipment must be in operational readiness. Failure to comply could re...

Page 86

Taco® skv printed in the usa © 2017 taco, inc. Taco, inc. (taco) will repair or replace without charge (at the company's option) any product or part which is proven defective under normal use within one (1) year from the date of start-up or one (1) year and six (6) months from date of shipment (whic...