-do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance. -what to do if you smell gas . Do not try to light any appliance. Do not touch any electric switch, do not use any phone in your building. Immediately call your gas supplier from a nei...

Contents 2 │ page contents specifications…………………………………………………………………………………………..………………………... Introduction…………………………………………………………………………………………………..…………………. Safety guidelines…………….………………………………………………………………………………………..……….. Installation………………………………………………………………………………………………..…………………..…. General……………………………………………...

Specifications 3 │ page specifications model 110 indoor (t-kjr2-in) 110 outdoor (t-kjr2-os) 310 indoor (t-k4-in) 310 outdoor (t-k4-os) 510 indoor (t-d2-in) 510 outdoor (t-d2-os) natural gas input (operating range) min: 19,500 btu/h max: 140,000 btu/h min: 11,000 btu/h max: 190,000 btu/h min: 11,000 ...

Introduction 4 │ page introduction *this diagram illustrates tankless water heater design concepts only and does not accurately represent to the water heater’s physical description. This manual provides information necessary for the installation, operation, and maintenance of the water heater. The m...

Safety guidelines 5 │ page water temperatures over 125°f (52°c) can cause severe burns instantly or death from scalding. The water temperature is set at 122°f (50°c) from the factory to minimize any scalding risk. Before bathing or showering always check the water temperature. Do not store or use ga...

Installation 6 │ page installation general 1. Follow all local codes, or in the absence of local codes, follow the most recent edition of the national fuel gas code: ansi z223.1/nfpa 54 in the usa or can/csa b149.1 natural gas, propane installation code in canada. 2. All gas water heaters require ca...

Installation 7 │ page installation and service must be performed by a qualified installer (for example, a licensed plumber or gas fitter), otherwise the warranty will be void. The installer (licensed professional) is responsible for the correct installation of the water heater and for compliance wit...

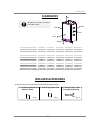

Installation 8 │ page clearances model top bottom front back sides 110 indoor* (t-kjr2-in)* 12” 12” 24” 1” 2 “ 110 outdoor (t-kjr2-os) 36” 12” 24” 1” 2 “ model top bottom front back sides 310 indoor* (t-k4-in)* 12” 12” 24” 1” 2 “ 310 outdoor (t-k4-os) 36” 12” 24” 1” 2 “ model top bottom front back s...

Installation 9 │ page optional items model 110 indoor (t-kjr2-in) 110 outdoor (t-kjr2-os) 310 indoor (t-k4-in) 310 outdoor (t-k4-os) 510 indoor (t-d2-in) 510 outdoor (t-d2-os) 9007666005 (tk-re02) ✔ ✔ ✔ ✔ 9007603005 (tm-re30) ✔ ✔ 9007678005 (tk-bf01) ✔ ✔ ✔ 9007667005 (tk-tv10) ✔ ✔ ✔ 9007670005 (tk-p...

Installation 10 │ page 5. Pipe covers: 9007670005 (tk-pc01) and 9007671005 (tk-pcjr2) the pipe cover protects the plumbing pipes to the water heater from unexpected adjustments. This pipe cover is fixed to the bottom of the water heater, which hides the plumbing and improves the visual aspects of th...

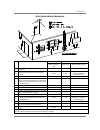

Installation 11 │ page do not adjust any dipswitches on the right bank for the 510 (t-d2) models. The dark squares indicate the direction the dipswitches should be set to. Dipswitches high-altitude installations check the elevation where your water heater is installed. Set dipswitches shown in the t...

Installation 12 │ page improper venting of this appliance can result in excessive levels of carbon monoxide which can result in severe personal injury or death. Improper installation can cause nausea or asphyxiation, severe injury or death from carbon monoxide and flue gases poisoning. Improper inst...

Installation 13 │ page -exhaust venting- for the 110 indoor (t-kjr2-in), 310 indoor (t-k4-in) and 510 indoor (t-d2-in) models this is a category iii appliance and must be vented accordingly. The vent system must be sealed air tight. All seams and joints without gaskets must be sealed with high heat ...

Installation 14 │ page *backflow preventer (recommended for freezing weather conditions: 36°f and below) **vertical condensation drain must be installed accordance with local codes. Horizontal installation diagram with direct-vent concentric termination horizontal installation diagram (with direct-v...

Installation 15 │ page -vent termination clearances- canada u.S.A direct vent and other than direct vent direct vent other than direct vent a clearance above grade, veranda, porch, deck, or balcony. 1 foot 1 foot 1 foot b clearance to window or door that may be opened. 3 feet 1 foot 4 feet from belo...

Installation 16 │ page please follow all local and national codes in regards to proper termination clearances. In the absence of such codes, the following clearances can be used as guidelines. Local codes supersede these guidelines. For sidewall terminations exhaust termination 1ft. 1ft. 2ft. Inside...

Installation 17 │ page size the gas pipe appropriately to supply the necessary volume of gas required for the water heater using ansi233.1/nfpa 54 in the usa or can/csa b149.1 in canada or local codes. Otherwise, flow capabilities and output temperatures will be limited. Check that the type of gas m...

Installation 18 │ page -natural gas supply piping- maximum delivery capacity of cubic feet of gas per hour of ips pipe carrying natural gas of 0.60 specific gravity based on pressure drop of 0.5” wc based on energy content of 1,000 btu/cubic ft.: the water heater requires 140 cubic ft./hr for the 11...

Installation 19 │ page 1. Turn off all electric power to the water heater if service is to be performed. 2. Turn the manual gas valve located on the outside of the unit clockwise to the off position. -measuring inlet gas pressure- the water heater cannot perform properly without sufficient inlet gas...

Installation 20 │ page do not use this water heater if any part has been submersed under water. Immediately call a licensed professional to inspect the water heater to replace any damaged parts. Do not reverse the hot outlet and cold inlet connections to the water heater. This will not properly acti...

Installation 21 │ page follow the electrical code requirements of the local authority having jurisdiction. In the absence of such requirements, follow the latest edition of the national electrical code ansi/nfpa 70 in the u.S. Or the latest edition of csa c22.1 canadian electrical code, part 1, in c...

Installation 22 │ page remote controller connections 1. Disconnect power supply from the water heater. 2. Take off the water heater’s front cover. 3. Locate the remote controller terminal, pictured below (located around the lower right-hand side of the computer board). 4. Open the plastic cover of t...

Installation 23 │ page in an easy-link system, the pump must be connected to the “pump” connector in the “parent” unit only. If the pump is connected to any of the “child” units, the pump will not work. Pump control connections available on the 510 (t-d2) models only the 510 (t-d2) models water heat...

Installation 24 │ page the easy-link system is limited up to 4 units. If you connect more than 4 units, only the first 4 units will work as a part of the easy-link system. The other additional units will not work. All units within an easy-link system must be of the same exact model. Different models...

Installation 25 │ page the dark squares indicate the direction the dipswitches should be set to. 4. Between the “parent” and the “child-1” units connect the “parent” connector of the “parent” unit to the “[1]” connector of the “child-1” unit. 5. Between the “child-1” and the “child-2” units connect ...

Installation 26 │ page a remote controller is not required for the easy-link system. If running the easy-link system without a remote controller, please make sure the temperature settings on all the units are set to the same settings. Otherwise, the units will not operate properly. If a remote contr...

Installation 27 │ page connecting two “parent” connectors together from two separate units may damage the computer board. The communication cable has a female end and a male end so it’s impossible to have a parent -to- parent connection with the communication cable. Do not splice or modify connector...

Installation 28 │ page in order to purge air in water pipes within a closed-loop system, an air vent and air separator should be installed in to the system. Required circulation flow rates are labeled next to each application diagram. These flow rate requirements must be followed. Toxic chemicals us...

Installation 29 │ page -dual-purpose hot water heating- (domestic and space heating): priority control devices such as a flow switch, an aquastat or other electronic controller can be used to prioritize the domestic water system over the heating system. Follow all local codes, or in the absence of l...

Initial operation 30 │ page check the gas and water connections for leaks before firing unit for the first time. Open the main gas supply valve to the unit using only your hand to avoid any spark. Never use tools. If the knob will not turn by hand, do not try to force it; call a qualified service te...

Operating safety 31 │ page operating safety for your safety read before operating warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. A. This water heater does not have a pilot. It is equipped with an igni...

Operating safety 32 │ page danger vapors from flammable liquids will explode and catch fire causing death or severe burns. Do not use or store flammable products such as gasoline, solvents or adhesives in the same room or area near the water heater. Keep flammable products: 1. Far away from heater 2...

Normal operation 33 │ page flow rate to activate the water heater : 0.5 gallons per minute at the default set temperature flow rate to keep the water heater running : 0.4 gallon per minute hot water temperatures over 125 f (52°c) can cause severe burns instantly or death from scalding. The outlet ho...

Normal operation 34 │ page do not set to 185 °f if you use your water heater in a recirculation system. This will cause damage to the heater and void the warranty. (this temperature setting is only available on the 510 (t-d2) models.) do not adjust the left bank of dipswitches. For the 510 (t-d2) mo...

Normal operation 35 │ page only pipes within the water heater are protected by the freeze protection system. Any water pipes (hot or cold) located outside the unit will not be protected. Properly protect and insulate these pipes from freezing. Household flow rates taken from upc 2006 flow the flow r...

Normal operation 36 │ page turn off the electrical power supply and close the manual gas shutoff valve and the manual water control valve before servicing. Maintenance and service clean the cold-water inlet filter. (refer to diagram below) be sure that all openings for combustion and ventilation air...

Troubleshooting 37 │ page general troubleshooting -t em pe ra tu re a nd a m o u n t o f ho t w at er - problem solutions it takes long time to get hot water at the fixtures. The time it takes to deliver hot water from the water heater to your fixtures depends on the length of piping between the two...

Troubleshooting 38 │ page - w at er h ea te r - problem solutions unit does not ignite when water goes through the unit. Is the flow rate over 0.5 gpm? (p. 33) check for the filter on cold water inlet. (p. 36) check for reverse connection and cross connection. If you use the remote controller, is th...

Troubleshooting 39 │ page error codes the units are self diagnostic for safety and convenience when trouble shooting. If there is a problem with the installation or the unit, depending on the model or if there is a remote controller installed, it will either display a numerical error code on the 7-s...

Troubleshooting 40 │ page -fault analysis of error codes- 110 (t-kjr2) and 310 (t-k4) 510 (t-d2) malfunction description diagnosis red led remote remote one time 03 031 incorrect dipswitch setting check the dipswitch settings on the pcb. (part #701) five times 10 101 warning for the “991” error code...

Troubleshooting 41 │ page 110 (t-kjr2) and 310 (t-k4) 510 (t-d2) malfunction description diagnosis red led remote remote n/a n/a 441 flow sensor failure (easy-link system only) check for connection/breakage of wires and/or debris on the flow sensor impeller. (part #402, 717) six times 51 510 abnorma...

Components diagram 42 │ page components diagram case assembly 110 indoor (t-kjr2-in) 110 outdoor (t-kjr2-os) 310 and 510 indoor (t-k4-in and t-d2-in) 310 and 510 outdoor (t-k4-os and t-d2-os) 0 0 2 0 5 0 7 0 2 0 5 2 0 0 7 7 0 4 0 0 6 0 0 5 0 5 3 0 6 6 0 5 3 0 5 2 0 5 2 0 0 1 0 0 4 0 5 6 0 0 4 0 0 1 ...

Components diagram 43 │ page burner assembly 110 (t-kjr2) models burner assembly manifold assembly 1 0 6 1 0 7 1 0 8 1 0 9 1 1 0 0 6 5 7 1 2 7 0 1 0 5 3 1 2 0 0 5 3 7 1 2 7 1 1 0 5 3 7 1 4 0 6 2 0 5 5 1 1 9 1 5 1 1 1 8 0 5 2 1 2 1 7 0 3 0 5 3 7 0 4 7 0 5 4 0 1 1 0 4 1 0 5 1 0 1 7 0 9 1 1 1 0 5 2 0 5...

Components diagram 44 │ page 310 (t-k4) models and 510 (t-d2) models fan motor section for outdoor models power control section burner assembly fan motor section for indoor models manifold assembly 1 1 6 1 1 7 0 5 3 1 0 3 0 5 4 1 1 5 0 5 7 0 5 8 7 1 3 1 0 6 1 0 7 1 0 8 1 0 9 1 1 0 0 6 5 7 1 2 1 2 1 ...

Components diagram 45 │ page water way assembly 110 (t-kjr2) models 310 (t-k4) models 510 (t-d2) models 110 (t-kjr2) and 310 (t-k4) models 510 (t-d2) models 7 0 7 7 1 0 7 0 8 7 1 5 1 0 3 7 1 7 7 1 8 7 01 7 0 9 7 1 9 7 1 6 7 01 7 0 7 7 0 9 7 1 4 7 1 0 7 0 8 1 03 4 0 2 4 0 2 4 0 7 4 08 7 1 9 computer ...

Output temperature chart 46 │ page parts list item# description part# 110, 310, 510 models t-kjr2, t-k4, t-d2 models 001 case assembly for 110 indoor (t-kjr2-in) for 110 outdoor (t-kjr2-os) for 310 and 510 indoor (t-k4-in and t-d2-in) for 310 and 510 outdoor (t-k4-os and t-d2-os) 319143-159 319143-1...

Output temperature chart 47 │ page item# description part# 110, 310, 510 models t-kjr2, t-k4, t-d2 models 104 burner holder gasket for 110 (t-kjr2) models burner holder gasket for 310 (t-k4) and 510 (t-d2) models 319143-341 319143-032 ex00v ekk0g 105 106 107 burner gasket burner window rod holder ga...

Output temperature chart 48 │ page item# description part# 110, 310, 510 models t-kjr2, t-k4, t-d2 models 408 outlet thermistor for 110 (t-kjr2) and 310 (t-k4) models mixing thermistor for 510 (t-d2) models 319143-218 319143-190 ekk55 ekk1a 409 410 411 water outlet outlet drain plug output thermisto...

Output temperature chart 49 │ page output temperature chart output temperature vs. Gpm (max. 6.6 gpm) with various inlet water temperature 0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 o u t p u t h o t w a te r g p m 40 f 50 f 60 f 70 f 40 f 3.8 3.5 3.3 3.1 2.9 2.7 2.5 2.4 2.3 2.1 1.9 1.8 50 f 4.6 4.2 3.8 3.5 3....

Output temperature chart 50 │ page output temperature vs. Gpm (max. 8.0 gpm) with various inlet water temperature 0.0 2.0 4.0 6.0 8.0 10.0 o u t p u t h o t w a te r g p m 40 f 50 f 60 f 70 f 40 f 5.2 4.8 4.4 4.1 3.9 3.7 3.5 3.3 3.1 2.8 2.6 2.5 50 f 6.2 5.7 5.2 4.8 4.4 4.1 3.9 3.7 3.5 3.1 2.8 2.7 60...

Warranty 51 │ page limited warranty 1. General terms of limited warranty: this limited warranty gives you specific legal rights, and you may also have other rights which vary from state to state. The manufacturer will honor the warranty to the original retail buyer at the original location only, and...

Warranty 52 │ page (3) limited labor coverage the manufacturer will provide for reasonable labor charges associated with warranty repairs or replacements within one (1) year from the date of purchase. The manufacturer will only pay directly to the service provider. Warranty service must be performed...