- DL manuals

- Takagi

- Water Heater

- 910

- Installation Manual And Owner's Manual

Takagi 910 Installation Manual And Owner's Manual - General Troubleshooting

- 35 -

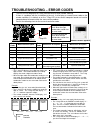

GENERAL TROUBLESHOOTING

~ TEMPERATURE and AMOUNT OF HOT WATER ~

PROBLEM

POSSIBLE SOLUTIONS

It takes long time to get hot water at

the fixtures.

• The time it takes to deliver hot water from the water

heater to your fixtures depends on the length of

piping between the two. The longer the distance or

the bigger the pipes, the longer it will take to get hot

water.

• If you would like to receive hot water to your fixtures

quicker, you may want to consider a hot water

recirculation system. (p. 40)

The water is not hot enough.

• Compare the flow and temperature. See the chart

on p. 51.

• Check cross plumbing between cold water lines

and hot water lines.

• Is the gas supply valve fully open? (p. 29)

• Is the gas line sized properly? (p. 17)

• Is the gas supply pressure enough? (p. 16)

• Is the set temperature set too low? (p. 30,33)

The water is too hot.

• Is the set temperature set too high? (p. 30,33)

The hot water is not available when

a fixture is opened.

• Make sure the unit has 120 VAC / 60 Hz power supply.

• If you are using the remote controller, is the power

button turned on? (p. 30)

• Is the gas supply valve fully open? (p. 29)

• Is the water supply valve fully open? (p. 29)

• Is the filter on cold water inlet clean? (p. 34)

• Is the hot water fixture sufficiently open to draw at

least 0.5 GPM through the water heater? (p. 30)

• Is the unit frozen?

• Is there enough gas in the tank / cylinder? (for Propane models)

The hot water gets cold and stays

cold.

• Is the flow rate enough to keep the water heater

running? (p. 30)

• If there is a recirculation system installed, does the

recirculation line have enough check valves?

• Is the gas supply valve fully open? (p. 29)

• Is the filter on cold water inlet clean? (p. 34)

• Are the fixtures clean of debris and obstructions?

Fluctuation in hot water temperature.

• Is the filter on cold water inlet clean? (p. 34)

• Is the gas line sized properly? (p. 17)

• Is the supply gas pressure enough? (p. 16)

• Check for cross connection between cold water

lines and hot water lines.

Summary of 910

Page 1

Gas tankless water heater 910 / 910 asme (t-m50 / t-m50 asme) models suitable for potable water heating and space-heating * *please refer to local codes for space-heating compliance. -do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance. -...

Page 2: Contents

- 2 - contents note *all references to the 910 (t-m50) also refer to the 910 asme (t-m50 asme) model *check the rating plate to ensure this product matches your specifications. *in accordance with ansi z21.10.3, co emission does not exceed 400 ppm for normal input. Specifications natural gas input (...

Page 3: Introduction

- 3 - introduction 1. A hot water tap is turned on. 2. Water enters the heater. 3. The water flow sensor detects the water flow. 4. The computer automatically ignites the burner. 5. Water circulates through the heat exchanger and then gets hot. 6. The computer will modulate the gas supply valve and ...

Page 4

- 4 - two combustion sections within the 910 (t-m50) the water heater contains two combustion sections. The section that turns on first is whichever section the water heater decides is the primary section. The moment at which the secondary section fires will depend on the total flow rate and set tem...

Page 5: Safety Guidelines

- 5 - safety guidelines • installation and service must be performed by a qualified installer (for example, a licensed plumber or gas fitter), otherwise the warranty by the manufacturer will be void. • the installer (licensed professional) is responsible for the correct installation of the water hea...

Page 6: Installation

- 6 - installation all gas water heaters require careful and correct installation to ensure safe and efficient operation. This manual must be followed exactly. Read the “safety guidelines” section at the beginning of this manual. • the warranty will not cover damage caused by water quality. Water ha...

Page 7: General

- 7 - general 1. The manifold gas pressure is preset at the factory.It is computer controlled and should not need adjustment. 2. Maintain proper space for servicing.Install the unit so that it can be connected or removed easily. Refer to p. 9 and p. 10 for proper clearances. 3. The electrical connec...

Page 8: Warning For Installations

- 8 - warning for installations for your safety, read before installation: do not install the heater where water, debris or flammable vapors may get into the flue terminal. This may cause damage to the heater and void the warranty. Do not have the vent terminal pointing toward any opening into a bui...

Page 9: Outdoor Installation

- 9 - the dark square is the direction the dipswitch should be set to. Keep the clearances. Outdoor installation 1. Follow all local codes, or in the absence of local codes, follow the most recent edition of the national fuel gas code: ansi z223.1/nfpa 54 in the usa or can/csa b149.1 natural gas, pr...

Page 10: Indoor Installation

- 10 - keep the clearances. Indoor installation 1. Follow all local codes, or in the absence of local codes, follow the most recent edition of the national fuel gas code: ansi z223.1/nfpa 54 in the usa or can/csa b149.1 natural gas, propane installation code in canada. 2. When installed indoors, the...

Page 11: Direct Intake Vent System

- 11 - the dark square is the direction the dipswitch should be set to. Direct intake vent system this water heater may be converted to a direct-vent (sealed combustion) appliance by installing an adapter (part no. 9007669005 (tm-dv50)) which will bring all required combustible air from outside the ...

Page 12: Venting Instructions

- 12 - venting instructions warning: improper venting of this appliance can result in excessive levels of carbon monoxide which can result in severe personal injury or death. This water heater must be vented in accordance with the section “venting of equipment" of the latest edition of the natural f...

Page 13: Vent Termination

- 13 - vent termination warning: improper installation can cause nausea or asphyxiation, severe injury or death from carbon monoxide and flue gases poisoning. Improper installation will void product warranty. • the vent termination provides a means of installing vent pipe through the building wall a...

Page 14

- 14 - horizontal installation diagram vertical installation diagram • regarding the clearance from the terminal to the air inlet or opening, refer to the next page. • install a condensation drain in the venting. • follow the vent manufacturer’s instructions and local codes. • do not common vent or ...

Page 15: Vent Clearances

- 15 - vent clearances canada u.S.A direct vent and other than direct vent direct vent other than direct vent a clearance above grade, veranda, porch, deck, or balcony. 1 foot 1 foot 1 foot b clearance to window or door that may be opened. 3 feet 1 foot 4 feet from below or side opening. 1 foot from...

Page 16: -Gas Connections-

- 16 - size the gas pipe appropriately to supply the necessary volume of gas required for the water heater using ansi z223.1/nfpa 54 in the usa or can/csa b149.1 in canada or local codes. Otherwise, flow capabilities and output temperatures will be limited. Gas supply and gas pipe sizing 1. Turn off...

Page 17: Natural Gas Supply Piping

- 17 - natural gas supply piping maximum delivery capacity of cubic feet of gas per hour of ips pipe carrying natural gas of 0.60 specific gravity based on pressure drop of 0.5” wc based on energy content of 1,000 btu/cubic ft.: 910 (t-m50) requires 380 cubic ft./hr. Unit: cubic feet per hour pipe s...

Page 18

- 18 - 1. Turn off all electric power to the water heater if service is to be performed. 2. Turn the manual gas valve located on the outside of the unit clockwise to the off position. -measuring inlet gas pressure- the water heater cannot perform properly without sufficient inlet gas pressure. Bel...

Page 19: Water Connections

- 19 - water connections ・ do not use this water heater if any part has been submersed under water. Immediately call a licensed professional to inspect the water heater and to replace any damaged parts. ・do not reverse the hot outlet and cold inlet connections to the water heater. This will not acti...

Page 20: Electrical Connections

- 20 - electrical connections warning: follow the electrical code requirements of the local authority having jurisdiction. In the absence of such requirements, follow the latest edition of the national electrical code ansi/nfpa 70 in the u.S. Or the latest edition of csa c22.1 canadian electrical co...

Page 21

- 21 - remote controller connection 1) disconnect power supply from the water heater. 2) take off the water heater’s front cover. 3) please find the remote control terminal using the diagram below (located around the lower right-hand side of the water heater). 4) open the plastic cover of the remote...

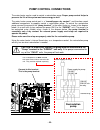

Page 22: Pump Control Connections

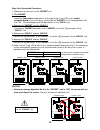

- 22 - pump control connections the water heater can be used to control a recirculation pump. Proper pump control helps to preserve the life of the system and saves energy as well. The water heater pump control port is a “normally-open dry contact”, and therefore needs additional components to prope...

Page 23: Pump Control Mode

- 23 - the dark squares indicate the direction the dipswitches should be set to. Pump control mode the water heater provides the four types of the pump control modes. The pump control modes are selected by changing dipswitch settings. The dipswitches are located in the upper bank of dipswitches in t...

Page 24: Easy-Link System

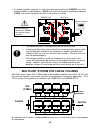

- 24 - easy-link system the water heater can be connected with other heaters of the same model with communication cables to work as a multiple manifold system. • the easy-link system can connect up to 4 units. • a communication cable (gray color) comes with each unit. The cables use 18 gage wire and...

Page 25

- 25 - the dark squares indicate the direction the dipswitches should be set to. Easy-link connection procedures 1. Choose one of your units as the “parent” unit. 2. “the parent” locate the lower bank of dipswitches to the right of the 7-seg. Led on the central computer board of the unit that you se...

Page 26

- 26 - caution • if you connect the “[1] (or [2]) connector” of the “parent” unit to the “parent (or [1]) connector” of the “child-1” unit, the system will not work as the easy-link system. The units will operate as individual units. • if you connect the “parent connector” of the “child-1” unit to t...

Page 27

- 27 - communication cable p a r e n t p a r e n t connectors connectors lower bank of dipswitch off on lower bank of dipswitch off on 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 11 22 11 22 • if a remote controller (optional) is used, it has to be connected to the “parent” unit. If the remote controller is con...

Page 28

- 28 - multi-unit system connection diagram the water heaters with a multi-unit controller and a remote controller wiring: • the above connection diagram is an example of how to connect 4 water heaters together in a multi-unit system. Up to 10 water heaters can be connected in this fashion. • make s...

Page 29: Initial Operation

- 29 - initial operation • check the gas and water connections for leaks before firing it for the first time. • open the main gas supply valve to the unit using only your hand to avoid any spark. Never use tools. If the knob will not turn by hand, do not try to force it; call a qualified service tec...

Page 30: Normal Operation

- 30 - (unit: °f) temperatures available under the high temperature mode* (refer to p. 31 for details.) (unit: °f) 2. Press the hot/cold button to set the water temperature up to 120 °f (50 °c). Normal operation • flow rate to activate the 910 (t-m50) : 0.5 gallon per minute • flow rate to keep the ...

Page 31

- 31 - *to change the remote controller’s mode from default mode to high temperature mode, please follow the procedures below (the remote controller must be installed prior to operating these procedures): do not set to 185ºf if you use your water heater in a recirculation system. This will cause dam...

Page 32: Flow

- 32 - flow • the flow rate through the water heater is limited to a maximum of 14.5 gpm. • the temperature setting, along with the supply temperature of the water will determine the flow rate output of the unit. • please refer to the temperature vs. Gallons per minute chart on p.51 to determine the...

Page 33: Temperature Settings

- 33 - the dark squares indicate the direction the dipswitches should be set to. Temperature settings • the temperature has been preset at the factory to 120 ºf (50 ºc). • there are 8 preset temperatures that you can select from by changing the dipswitch settings on the computer board. If you want t...

Page 34: Maintenance And Service

- 34 - maintenance and service warning: turn off the electrical power supply and close the manual gas control valve and the manual water control valve before servicing. • clean the cold-water inlet filter. (refer to diagram below) • be sure that all openings for combustion and ventilation air are no...

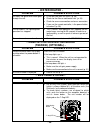

Page 35: General Troubleshooting

- 35 - general troubleshooting ~ temperature and amount of hot water ~ problem possible solutions it takes long time to get hot water at the fixtures. • the time it takes to deliver hot water from the water heater to your fixtures depends on the length of piping between the two. The longer the dista...

Page 36: ~ Water Heater ~

- 36 - ~ water heater ~ problem possible solutions unit does not ignite when water goes through the unit. • is the flow rate over 0.5 gpm? (p. 30) • check for the filter on cold water inlet. (p. 34) • check for reverse connection and cross connection. • if you use the remote controller, is the power...

Page 37

- 37 - troubleshooting – error codes • the units are self diagnostic for safety and convenience when trouble shooting. • if there is a problem with the installation or the unit, it will display a numerical error code on the remote controller (if installed) or on the 7-seg led of the central computer...

Page 38: Operating Safety

- 38 - operating safety for your safety read before operating warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. A. This water heater does not have a pilot. It is equipped with an ignition device that aut...

Page 39: Danger

- 39 - danger vapors from flammable liquids will explode and catch fire causing death or severe burns. Do not use or store flammable products such as gasoline, solvents or adhesives in the same room or area near the water heater. Keep flammable products: 1. Far away from heater 2. In approved contai...

Page 40: Applications

- 40 - check valve check valve air separator recirculation pump hot water outlet to fixtures air vent unions gas supply ball valves expansion tank y-strainer cold water inlet hot water outlet s cold water inlet gas inlet applications space heating applications warning • in order to purge air in wate...

Page 41

- 41 - dual-purpose hot water heating (domestic and space heating): priority control devices such as a flow switch, an aquastat or other electronic controller can be used to prioritize the domestic water system over the heating system. Warning: follow all local codes, or in the absence of local code...

Page 42: Additional Clearances

- 42 - additional clearances please follow all local and national codes in regards to proper termination clearances. In the absence of such codes, the following clearances can be used as guidelines. Local codes supersede these guidelines. For sidewall terminations exhaust termination 1ft. 1ft. 2ft. ...

Page 43: Optional Items

- 43 - optional items 1. Temperature remote controller: 9007603005 (tm-re30) the temperature remote controller has two functions. It allows the output temperature from the water heater to be adjusted within the range of 100 °f to 185 °f, and it also works as a diagnostic tool that will give a concis...

Page 44: Components Diagram

- 44 - components diagram computer board assembly case assembly the 910 (t-m50) and the 910 asme (t-m50 asme) models share the same components. 3 7 6 13 3 11 4 10 1 12 3 3 3 4 2 4 2 3 5 9 8 4 718 709 416 705 707 706 708 704 418 703 715 701 719 113 708 702 710 712 713 711 714 113 711 113 113 716 416 ...

Page 45

- 45 - burner assembly 114 115 116 705 113 113 117 707 707 102 121 119 118 707 707 109 112 106 111 105 113 113 104 103 108 107 113 110 101 114 115 116 113 113 117 707 707 102 121 119 118 707 707 109 112 106 111 105 113 113 104 103 108 107 113 110 101 123 124 126 125 3 123 122 120 705 the 910 (t-m50)...

Page 46

- 46 - combustion and exhaust assembly other than part# 444, part# 445, part# 446 and part# 447, the 910 (t-m50) and the 910 asme (t-m50 asme) models share the same components. 3 132 133 136 135 137 402 401 403 404 406 407 408 409 410 411 113 412 413 414 415 113 416 405 402 401 403 404 406 407 408 4...

Page 47

- 47 - water way assembly 910 (t-m50) 910 asme (t-m50 asme) 422 419 411 419 411 424 406 407 419 411 425 427 423 407 406 425 427 411 419 411 419 422 411 419 411 439 440 441 442 443 429 425 421 411 419 406 407 424 429 425 432 419 411 407 406 430 434 3 433 425 438 437 436 435 113 411 420 419 427 426 41...

Page 48: Parts List

- 48 - parts list item# description part# 910 models t-m50 models 001 002 003 004 005 case assembly brackets screw m4x10 (w/washer) screw m4x10 (coated) back guard panel 319143-265 319143-012 319143-325 319143-026 319143-237 em305 em335 ew001 ew002 em264 006 007 008 009 010 power supply code assembl...

Page 49

- 49 - item# description part# 910 models t-m50 models 136 137 138 139 140 duct gasket screw m4x10 fan damper screw m3x6 freeze protection thermostat 319143-240 319143-060 319143-147 319143-330 319143-252 em268 ew003 ek270 ew00b em286 401 402 403 404 405 heat exchanger assembly for 910 (t-m50) overh...

Page 50

- 50 - item# description part# 910 models t-m50 models 447 448 449 450 451 connecting pipe for 910 asme (t-m50 asme) left cold pipe for 910 asme (t-m50 asme) left hot pipe for 910 asme (t-m50 asme) right hot pipe for 910 asme (t-m50 asme) right cold pipe for 910 asme (t-m50 asme) 319143-278 319143-3...

Page 51: Output Temperature Chart

- 51 - output temperature chart output temperature vs. Gpm (max. 14.5 gpm) with various ground water temperature 0.0 2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 output hot water temperature o u tp u t h o t w a te r g p m 40 f 50 f 60 f 70 f 40 f 10.1 9.3 8.7 8.1 7.6 7.1 6.7 6.4 6.1 5.5 5.1 4.9 4.7 4.5 4.3 ...

Page 52

- 52 - 3. General terms of limited warranty: this limited warranty gives you specific legal rights, and you may also have other rights which vary from state to state. The manufacturer will honor the warranty to the original retail buyer at the original location only, within the united states or cana...