- DL manuals

- Takagi

- Water Heater

- T-K3

- Service Manual

Takagi T-K3 Service Manual

Summary of T-K3

Page 1

T-k3 service manual ver. 1.05 1 confidential t-k3 instantaneous water heater service manual takagi industrial co. Usa inc. 5 whatney irvine, ca 92618 toll free: (888) 882-5244 usa toll free: (877) 877-4953 canada.

Page 2

T-k3 service manual ver. 1.05 2 confidential table of contents 1. Specifications of the t-k3, t-k3-os, and t-k3-sp……………..………………………… 3 2. Exterior view ……………………...…….…………………………………………………….. 4 3. Interior view …………………………….…………………………………………………….. 5 4. List of main components in the interior view …….……………...

Page 3

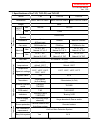

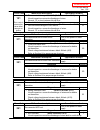

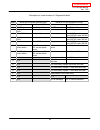

T-k3 service manual ver. 1.05 3 confidential 1. Specifications of the t-k3, t-k3-os, and t-k3-sp model t-k3 t-k3-os t-k3-sp dimensions h20.5"×w13.8"×d8.5" h20.5"×w13.8"×d8.5" h20.5"×w13.8"×d8.5" weight 40lbs. Max 199,000 190,000 input btu/h min 11,000 combustion system pow er vent installation indoo...

Page 4

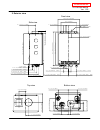

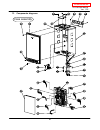

T-k3 service manual ver. 1.05 4 confidential 2. Exterior view top view bottom view side view front view 5 - 1 / 4 "( 1 3 2 .9 m m ) 4 - 7 / 8 "( 1 2 4 .3 m m ) 3 - 1 / 4 "( 8 4 m m ) 5-3/ 8" (13 6. 1mm) 2 -3/4" ( 72mm) 6-1/2 "(164. 4mm) 3-3 /4" (96 .5mm) 1 - 3 / 8 "( 3 6 m m ) 1 - 1 / 2 "( 3 7 .8 m ...

Page 5

T-k3 service manual ver. 1.05 5 confidential 3. Interior view 4. List of main components in the interior view no. Description t-k3 part# takagi part # common parts for other units 1 case assembly 001 ekk1d sp 2 combustion chamber 102 ekk1y sp 3 gas valve w ith proportional valve 105 ekk1w os, sp 4 c...

Page 6

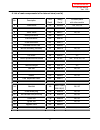

T-k3 service manual ver. 1.05 6 confidential 4. List of main components in the internal view (cont’d) no. Description t-k3 part# takagi part # common parts with other models 6 transformer 702 ekh09 th1, os, sp 7 water inlet 404 ekk1u os, sp 8 water outlet 405 ekk1v os, sp 9 mixing ther mistor 408 ek...

Page 7

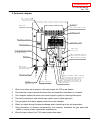

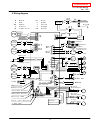

T-k3 service manual ver. 1.05 7 confidential 5. Schematic diagram 1. When a hot w ater tap is opened, cold w ater enters the t-k3 w ater heater. 2. The w ater flow sensor detects this w ater flow and sends this information to computer. 3. The computer initiates fan motor and sends signal to igniter ...

Page 8

T-k3 service manual ver. 1.05 8 confidential 6. Wiring diagram pr opor- ti onal v alve 3 9 53 73 g fi g bk w ac120v trans- former 3a g ground i g elect rod heater freeze protection thermostat heater ground b k b k m v s v 3 s v 2 s v 1 lb g o r o.H.C.F h i - l i m it s w i tc h bl bl b l b l bl bl b...

Page 9

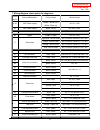

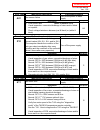

T-k3 service manual ver. 1.05 9 confidential 7. Wiring diagram check points for diagnosis check- point part and description color of wires normal range a, a1 100v power supply brown – brown (a1) white – black (a) ac 90~110v a2 120v power supply black - white ac 108~132v b1 heater black - black ac 90...

Page 10

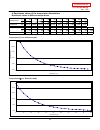

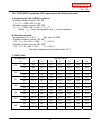

T-k3 service manual ver. 1.05 10 confidential 8. Resistance values of the temperature thermistors resistance values at different temperatures ºf 32 41 50 59 68 77 86 95 104 113 ºc 0 5 10 15 20 25 30 35 40 45 r esistance kΩ 23.76 19.08 15.43 12.56 10.28 8.47 7.02 5.85 4.90 4.12 t emperature ºf 122 13...

Page 11

T-k3 service manual ver. 1.05 11 confidential 9. Operational flow chart power supply on opeartion sw on open fav bv pre-check normal? Open the tap flow sensor above 0.5gpm? Fm speed (below 1,000rpm?) start fm pseudo-flame below dc0.15ƒÊ a? Iginiter on hi-limit normal? Ohcf normal? Mv on sv1 on gpv o...

Page 12

T-k3 service manual ver. 1.05 12 confidential 10. Component specifications 1. Burners p.13 2. Manifold p.14 3. Fan motor p.15 4. Gas valve assembly p.16 5. Flame rod p.17 6. Afr rod p.18 7. Heat exchanger p.19 8. Flow adjustment valve p.20 9. Flow sensor p.21 10. Bypass valve p.22 11. Thermistors p....

Page 13

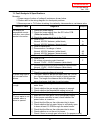

T-k3 service manual ver. 1.05 13 confidential 10-1. Burners t-k3 part # #101 takagi part # ekk1n checkpoint n/a function failure events effects on the t-k3 if burners fails error codes when the burners fail diagnostic color/number of wires n/a visual inspection: excessive dust deposit on the burner ...

Page 14

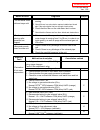

T-k3 service manual ver. 1.05 14 confidential 10-2. Gas manifold t-k3 part # #103 takagi part # ekk1f checkpoint n/a function failure events effects on the t-k3 if the manifold fails. Error codes when the manifold fails. Diagnostic color/number of wires blue -red dc 78~100v / 0.9~1.7kΩ 1. Visual ins...

Page 15

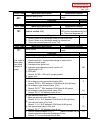

T-k3 service manual ver. 1.05 15 confidential 10-3. Fan motor t-k3 part # #104 takagi part # ekk25 checkpoint g function failure events effects on the t-k3 if fan motor fails error codes when the fan motor fails. Diagnostic red-blue yellow-blue orange-blue white-blue color/number of wires to provide...

Page 16

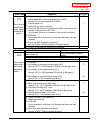

T-k3 service manual ver. 1.05 16 confidential 10-4. Gas valve assembly t-k3 part # #105 takagi part # ekk1w checkpoint c,h1 failure events effects on the t-k3 if valves fails. Error codes when the valves fail. 111 121 510 701 711 diagnostic dc 78~100v / 0.9~1.7kΩ dc 78~100v / 0.9~1.3kΩ dc 78~100v / ...

Page 17

T-k3 service manual ver. 1.05 17 confidential 10-5. Flame rod t-k3 part # #716 takagi part # ekk0e checkpoint i function failure event effects on the t-k3 if flame rod fails error codes when the flame rod fails. 111 121 721 diagnostic the flame rod is assembled with the afr rod. Orange(17) - flame r...

Page 18

T-k3 service manual ver. 1.05 18 confidential 10-6. Afr rod t-k3 part # #716 takagi part # ekk0e checkpoint i functions failure event effects on the t-k3 if the afr rod fails error codes when the afr rod fails. 101 991 391 diagnostic the afr rod is assembled with the flame rod. (during operation) 1μ...

Page 19

T-k3 service manual ver. 1.05 19 confidential 10-7. Heat exchanger t-k3 part # #401 takagi part # ekk1x checkpoint n/a function failure event effects on the t-k3 if the heat exchanger fails. Error codes when the heat exchanger fails. Diagnostic color/number of wires n/a 1. Visual inspection: soot de...

Page 20

T-k3 service manual ver. 1.05 20 confidential 10-8. Flow adjustment valve t-k3 part # #402 takagi part # ekk0t checkpoint j1 function failure event effects on the t-k3 if flow adjustment valve fails error codes when flow adjustment valve fails. Diagnostic color/number of wires black-red the flow adj...

Page 21

T-k3 service manual ver. 1.05 21 confidential 10-9. Flow sensor t-k3 part # #402 takagi part # ekk0t checkpoint h2 function failure event effects on the t-k3 if flow sensor fails error codes when the flow sensor fails. Diagnostic red-black white(85)-black the flow sensor is assembled with the flow a...

Page 22

T-k3 service manual ver. 1.05 22 confidential 10-10. Bypass valve t-k3 part # #403 takagi part # ekk0u checkpoint j2 failure event effects on the t-k3 if the bypass valve fails error codes when bypass valve fails. Diagnostic color/number of wires red - black the physical appearance of the bypass val...

Page 23

T-k3 service manual ver. 1.05 23 confidential 10-11. Thermistors t-k3 part # #406 (inlet) #407 (outlet) #408 (mixing) takagi part # ekk38 (inlet) ekk2t (outlet) ekk1a (mixing) checkpoint e1 (mixing) e2 (outlet) e3 (inlet) function failure event effects on the t-k3 if thermistor fails error codes whe...

Page 24

T-k3 service manual ver. 1.05 24 confidential 10-12. Hi-limit switch t-k3 part # #409 takagi part # ekn34 checkpoint c1 function failure event effects on the t-k3 if hi-limit switch fails. 111 121 diagnostic color/number of wires blue-blue when temperatures exceed 194˚f (90˚c), the reset button trip...

Page 25

T-k3 service manual ver. 1.05 25 confidential 10-13. Overheat cutoff fuse t-k3 part # #411 takagi part # ekk0s checkpoint c2 function failure event effects on the t-k3 if the overheat cutoff fuse fails. Error codes when the fuse fails. 111 121 diagnostic color/number of wires blue-blue solder will m...

Page 26

T-k3 service manual ver. 1.05 26 confidential 10-14. Freeze protection heaters t-k3 part # #412 #418(inlet) takagi part # ekk2r ekk2p(inlet) checkpoint b1 function failure event effects on the t-k3 if heaters fail. Error codes when heaters fail. Diagnostic color/number of wires white - white prevent...

Page 27

T-k3 service manual ver. 1.05 27 confidential 10-15. Computer board t-k3 part # #701 takagi part # ekk1l checkpoint n/a function failure event effects on the t-k3 if the computer board fails. Error codes when the computer board fails. Diagnostic color/number of wires controls the functions of most o...

Page 28

T-k3 service manual ver. 1.05 28 confidential 10-16. Tran sfo rmer t-k3 part # #702 takagi part # ekh09 checkpoint a1, a2 function failure event effects on the t-k3 if transformer fails error codes when transformer. Diagnostic white -black brown-brown -to transform input voltage from 120vac to 100va...

Page 29

T-k3 service manual ver. 1.05 29 confidential 10-17. Gfi t-k3 part # #703 takagi part # ekn73 checkpoint a, a1 function failure event effects on the t-k3 if the gfi fails. Error codes when the gfi fails. Diagnostic color/number of wires n/a 1. Visual inspection: connection/breakage of wires and/or s...

Page 30

T-k3 service manual ver. 1.05 30 confidential 10-18. Igniter t-k3 part # #704 takagi part # ekn74 checkpoint b2 function failure event effects on the t-k3 if the igniter fails error codes when igniter fails. Diagnostic color/number of wires 1. Visual inspection: connection/breakage of wires and/or a...

Page 31

T-k3 service manual ver. 1.05 31 confidential 10-19. Freeze protection thermostat t-k3 part # #705 takagi part # ekj59 checkpoint b1 function failure event effects on the t-k3 if the freeze protection thermostat fails. Error codes when the freeze protection thermostat fails. Diagnostic color/number ...

Page 32

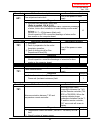

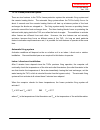

T-k3 service manual ver. 1.05 32 confidential 11. Fault analysis & specifications remarks: 1 proper range of values of voltage & resistance shown below. 2 please refer to the wiring diagram for checkpoint positions. 3 remove power to t-k3 when checking for continuity, disconnections, resistance valu...

Page 33

T-k3 service manual ver. 1.05 33 confidential checkpoint 1 2 3 check that the filter on the cold water inlet is clean. 4 1 1 2 check if there is any blockage of the exhaust pipe. 3 check the manifold pressure in the unit. -fault of flow adjustment valve checkpoint 1 check whether the filter in cold ...

Page 34

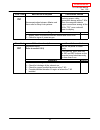

T-k3 service manual ver. 1.05 34 confidential error code checkpoint check the dipswitch settings on pcb warning for the "991" error code (refer to section 12-3) checkpoint 1 check if there is any blockage in the air inlet of the unit. 2 check if there is any blockage along the exhaust run. 3 check t...

Page 35

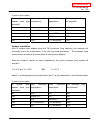

T-k3 service manual ver. 1.05 35 confidential checkpoint 6 c1 normal:1Ω or less between blue & blue 7 inspect flame rod i ① check for any soot on the rod. ② (in this case, the wire is contacted to the manifold surface.) ③ pcb fault ④ flame rod fault (insulated resistance) normal: 40khz~60khz (betwee...

Page 36

T-k3 service manual ver. 1.05 36 confidential 5 disconnected/damaged o.H.C.F. (refer to section 10-13) c2 visual inspection:connection/breakage of wires. Normal: 1Ω or less between blue & blue 6 check if hi-limit switch is properly functioning. 7 c1 normal: 1Ω or less between blue & blue checkpoint ...

Page 37

T-k3 service manual ver. 1.05 37 confidential checkpoint 1 flow sensor fault (refer to section 10-9) checkpoint 1 visual inspection of gas valves: connection/breakage of wires. Normal: dc78~100v between com (blue) & #3 (light blue) normal: dc78~100v between com (blue) & #9 (green) normal: dc78~100v ...

Page 38

T-k3 service manual ver. 1.05 38 confidential checkpoint 1 pcb and flow adjustment valve fault. (refer to section 10-8 & 10-15) normal: dc 7~16v between (black-red) 1 pcb fault ① ② checkpoint 1 check the pcb (refer to section 10-15) checkpoint 1 false flame detection (5 sec.) flame rod (insulated re...

Page 39

T-k3 service manual ver. 1.05 39 confidential checkpoint 1 2 check for signs of power surges. Abnormal burning (refer to section 12-3) checkpoint 1 check for blockage on the air inlet of the t-k3. 2 check for blockage of the exhaust run. 3 check for proper manifold pressure in the t-k3. 4 761 consid...

Page 40

T-k3 service manual ver. 1.05 40 confidential 12. Controls and settings 12-1. (a)diagnosing the t-k3 using the tm- re10………………………………..……….…. 41 12-1. (b)diagnosing the t-k3 using the tm- re30…………..…………………..……….…. 42 12-2. The error-code button: verifing functionality of computer board, displaying err...

Page 41

T-k3 service manual ver. 1.05 41 confidential 12-1. (a) diagnosing the t-k3 using the tm-re10 1. Press and hold the "hot" and "cold" buttons simultaneously for at least 5 seconds to enter “diagnostics mode”. 2. Number "0" w ill be displayed. (fig.1) 3. Scroll through the mode #’s by pressing the "ho...

Page 42

T-k3 service manual ver. 1.05 42 confidential 12-1. (b) diagnosing the t-k3 using the tm-re30 1. Press the " hot" button and the "cold" button simultaneously for at least 5 seconds to enter “diagnostic mode”. 2. Scroll up or dow n to the needed information (mode #) of the t-k3 by pressing the “ hot”...

Page 43

T-k3 service manual ver. 1.05 43 confidential 1. Press and hold the " hot" and "cold" buttons simultaneously for at least 5 seconds to enter “diagnostics mode”. 2. "0" w ill be displayed on the tm-re30. (see fig. 1) 3. Scroll to the desired t-k3 unit # in the easy-link system by pressing the " hot" ...

Page 44

T-k3 service manual ver. 1.05 44 confidential description of mode numbers in “diagnostics mode” mode # whole multi-unit system inf ormation (#0) individual t-k3 unit information (#1 to #4) 1 total system flow rate 0 - 999 ( × 0.1 gpm) total operation time 0 to 9999 (hours) 2 on/off cycles 0 to 9999 ...

Page 45

T-k3 service manual ver. 1.05 45 confidential 12-2. The error-code button: verifying functionality of computer board, displaying error code history, and clearing error code history memory the t-k3 has as error-code button on the computer board that provides three main functions. The button is locate...

Page 46

T-k3 service manual ver. 1.05 46 confidential 12-3. Clearing the “991” error code the t-k3’s “991” error code signifies imperfect (abnormal) combustion, caused by insufficient intake air and/or obstructions in the exhaust. A. If the “991” error code occurs, please check the follow ing: 1. What is th...

Page 47

T-k3 service manual ver. 1.05 47 confidential 12-4. Dipswitch settings there are tw o banks of dipsw itches (upper and low er bank) on the t-k3 computer board. The upper bank has certain special functions as shown on the follow ing table and generally should not need adjustment. Carefully verify the...

Page 48

T-k3 service manual ver. 1.05 48 confidential 12-5. Assigning unit numbers in the easy-link system • each t-k3 in an easy-link system is assigned a random unit #, except for the master unit, w hich is alw ays assigned as unit #1. This is w hy the t-k3’s w ill not necessarily be numbered in order fro...

Page 49

T-k3 service manual ver. 1.05 49 confidential 12-6. T-k3 on/off conditions: overview the t-k3 has tw o modes of on/off conditions. Select either mode by changing dipsw itch 3 on the upper bank of dipsw itches as shown in the picture to the right. Intermittent mode this mode is the nor mal, default m...

Page 50

T-k3 service manual ver. 1.05 50 confidential 12-7. T-k3 on/off conditions: btu requirements for intermittent mode a. Calculating the t-k3’s on/off conditions 【 condition needed to turn the t-k3 on】 ( t set – t in ) × gpm × 500 > 14,880 【 condition needed to turn the t-k3 off】 ( t set – t in ) × gpm...

Page 51

T-k3 service manual ver. 1.05 51 confidential 12-8. T-k3 on/off conditions: btu requirements for continuous mode a. Calculating the t-k3’s on/off conditions 【 condition needed to turn the t-k3 on】 ( t set – t in ) × gpm × 500 > 11,900 【 condition needed to turn the t-k3 off】 ( t set – t in ) × gpm ×...

Page 52

T-k3 service manual ver. 1.05 52 confidential 12-9. Pump control on/off conditions: overview dipsw itch 3 on the upper bank of dipsw itches (shown in the picture to the right) also sets the mode for the pump control on/off conditions. Again, there are tw o modes of on/off conditions for the pump con...

Page 53

T-k3 service manual ver. 1.05 53 confidential 12-10. Pump control on/off conditions: btu requirements for intermittent mode a. Calculating the pump’s on/off condition 【 condition needed to turn the pump on】 ( t set – t in ) × gpm × 500 > 18,600 【 condition needed to turn the pump off】 4 minutes afte...

Page 54

T-k3 service manual ver. 1.05 54 confidential 12-11. Pump control on/off conditions: btu requirements for continuous mode (non-stop pump operation) a. Calculating the pump’s on/off condition 【 condition needed to turn the pump on】 ( t set – tin ) × gpm × 500 > 11,900 【 there are no conditions w hich...

Page 55

T-k3 service manual ver. 1.05 55 confidential 12-12 multi-unit system on/off conditions in easy-link multi-unit systems, the amount of t-k3’s called on to activate depends on the flow rat e and the output set t emperat ure. 1. Condition required to activate an additional t-k3: flow rate required to ...

Page 56

T-k3 service manual ver. 1.05 56 confidential 12-13. Relay selection for the pump control connection the maximum current capacity of t-k3’s pump control connection is 1 amp. Before using any relay w ith the pump control, please check the specifications of that particular relay to ensure that the cur...

Page 57

T-k3 service manual ver. 1.05 57 confidential 12-14. Adjusting manifold gas pressure the manifold gas pressure on the t-k3 can be adjusted by follow ing the procedures below. Adjusting the manifold pressure can cause unexpected combustion conditions during operation, w hich can cause a health hazard...

Page 58

T-k3 service manual ver. 1.05 58 confidential figure 1 manifold port figure 2 to manometer tube t-k3 computer board figure 3 max button min button increase button decrease button.

Page 59

T-k3 service manual ver. 1.05 59 confidential figure 2 12-15. Manually adjusting the fan motor speed while the fm+ dipsw itch will automatically increase the fan speed by 6%, the fan motor speed on the t-k3 can also be manually adjusted. In order to perform manual adjustments to the speed, a tm-re10...

Page 60

T-k3 service manual ver. 1.05 60 confidential 12-16. Freeze protection system there are tw o features to the t-k3’s freeze protection system: the automatic firing system and the ceramic heating blocks. The automatic firing system allow s the t-k3 to briefly fire on for about 4 seconds and the cerami...

Page 61

T-k3 service manual ver. 1.05 61 confidential to sum it up in a chart: 5 minutes have elapsed since prior operation? Inlet ther mistor temperature outlet ther mistor temperature will automatic firing be activated? No any any no yes above 39°f any no yes any above 50°f no yes 39°f and below 50°f and ...

Page 62

T-k3 service manual ver. 1.05 62 confidential ceramic heating blocks the blocks w ill only activate based on w hat the freeze protection thermostat senses. The thermostat is located on the fan motor, close in vicinity to the inlet and outlet pipes w ithin the t-k3. Electrical pow er is required for ...

Page 63

T-k3 service manual ver. 1.05 63 confidential 12-17. Freeze protection for recirculation systems if the t-k3 pump control is used to control a recirculation pump, w hen needed, the computer w ill activate this pump to provide flow and prevent freezing throughout the recirculation system. For instruc...

Page 64

T-k3 service manual ver. 1.05 64 confidential drain plug with f ilter gas valve water valve drain plug 12-18. Draining the t-k3 and cleaning the inlet water filter 1. Close the manual gas shut off valve. 2. Turn off pow er to the t-k3, and then turn on again. 3. Wait 30 seconds for water valves to c...

Page 65

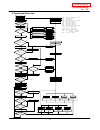

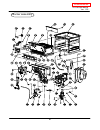

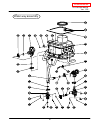

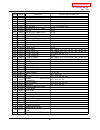

T-k3 service manual ver. 1.05 65 confidential 13. Components diagrams 0 0 1 0 0 5 0 0 3 0 5 1 0 5 0 7 0 2 0 5 1 0 5 1 0 0 4 0 5 2 0 5 2 0 0 2 0 5 2 0 5 2 7 0 6 7 0 7 0 5 3 0 5 2 0 5 4 0 5 3 7 0 8 7 0 1 7 0 9 7 1 0 7 1 1 7 1 3 7 1 4 7 1 5 7 1 6 7 1 7 0 5 0 7 1 2 case assembly.

Page 66

T-k3 service manual ver. 1.05 66 confidential 1 0 2 1 5 1 1 0 9 1 0 7 1 1 2 7 1 6 1 0 1 1 1 4 1 1 7 1 1 5 1 0 6 1 5 1 1 5 1 1 1 6 7 0 3 1 2 1 1 1 0 1 5 0 1 5 0 7 1 8 7 0 9 1 5 0 1 5 0 1 0 3 1 5 2 1 5 1 1 5 1 1 1 9 1 2 0 1 2 3 1 5 9 1 0 5 1 1 8 1 5 0 1 5 6 1 1 1 1 0 4 1 5 7 7 0 5 7 1 1 1 5 3 1 1 3 1 ...

Page 67

T-k3 service manual ver. 1.05 67 confidential 4 09 45 1 403 452 459 413 4 12 454 458 460 401 411 415 410 402 457 452 404 052 418 4 56 407 4 17 416 45 3 412 454 458 405 456 408 450 4 06 45 0 052 419 455 4 56 414 4 58 454 water way assembly.

Page 68

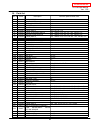

T-k3 service manual ver. 1.05 68 confidential 14. Parts list item # part # description common parts for other units 1 ekk1d case assembly 2 ekk1j front cover 3 ekj62 air blockage plate tkjr 4 ekj09 bracket tkjr 5 ekj64 junction box tkjr 50 ew000 screw m4x12 tkjr, os, sp, th1 51 ew001 screw w/w asher...

Page 69

T-k3 service manual ver. 1.05 69 confidential item # part # description common parts for other units 406 ekk38 inlet thermisor 407 ekk2t outlet thermistor 408 ekk1a mixing thermistor 409 ekn34 hi-limit switch tkjr, tk1s, os, sp, th1 410 ekn50 silicon ring t-k1s,t-k3,t-k3-sp,t-h1 411 ekk0s over heat ...

Page 70

T-k3 service manual ver. 1.05 70 confidential 15. Revisions version description of changes date 1.00 sample evaluation 10/19/07 1.01 revision of w rong information in the section 10,11 and 12 10/28/07 1.02 revision of w rong information in all section 11/28/07 1.03 revised by p.P. 1/14/08 1.04 revis...