Warning this product must be installed and serviced by a licensed plumber, a licensed gas fitter, or a professional service technician and/or in accordance with all local code. Improper installation and/or operation, or installation by an unqualified person, will void the warranty. Warning operation...

- 2 - contents specification …………. 2 introduction …………..3 for your safety …………..3-4 installation …………. 5 • general …………. 5 • accessories …………. 5 • outdoor installation ………….5-6 • indoor installation ………….6-7 • venting instructions …………..7 -9 • gas supply/gas pipe sizing………..10-11 • water connection ...

- 3 - introduction this manual provides information necessary for the installation, operation, and maintenance of the model t-m1 water heater. This unit includes a fan enabling sidewall (power) venting and an advanced electronic ignition system. The model description is listed on the rating plate wh...

- 4 - 6. Warning: do not disconnect the electrical supply if the ambient temperature will drop below freezing. The freeze prevention device only works if the unit has electrical power. The freeze prevention device is rated for temperatures down to 5 ºf (-15 ºc) in a wind free environment. Refer to t...

- 5 - installation general all gas water heaters require careful and correct installation to ensure safe and efficient operation. This manual must be followed exactly. Read the “for your safety” section at the beginning of this manual. 1. The gas regulator is preset at the factory; it is computer co...

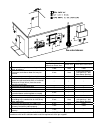

- 6 - warning: do not install this water heater under an overhang less than 3 feet from its top or eaves. The area under an overhang must be open to three sides warning: do not have the vent terminal pointing toward any opening into a building. Do not locate your heater in a pit or location where ga...

- 7 - combustible air supplied by mechanical fan or make up air device. The t-m1 water heater is equipped with a combustible air sensor that will shut off the unit when inadequate combustible air supply to unit is detected. If a mechanical fan or make up air device is used to supply air to the water...

- 8 - vent termination a sidewall vent terminator must be used when the water heater is vented through a sidewall. Takagi recommends the use of its part no.Tk- tv01. The vent terminator provides a means of installing vent pipe through the building wall and must be located in accordance with ansi z22...

- 9 - canada u.S.A direct vent and other than direct vent direct vent other than direct vent a clearance above grade, veranda, porch, deck, or balcony. 1 foot 1 foot 1 foot b clearance to window or door that may be opened. 3 feet 1 foot 4 feet from below or side opening. 1 foot from above opening. C...

- 10 - gas supply and gas pipe sizing check that the type of gas matches the rating plate located on the cover of your water heater. The minimum and maximum inlet gas pressures are: natural gas min. 5” wc - max. 10.5” wc propane gas min. 11” wc - max. 14” wc gas pressure below this specified range f...

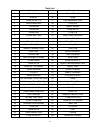

- 11 - natural gas supply piping maximum capacity of natural gas based on a 0.60 specific gravity at a 0.5” wc pressure drop pipe size kbtu of natural gas length 10’ 20’ 30’ 40’ 50’ 60’ 70’ 80’ 90’ 100’ 125’ 150’ 200’ ¾” 372 255 205 175 156 142 130 121 114 107 95 86 74 1” 702 482 387 331 293 266 245...

- 12 - to re-start your heater, follow these steps: 1. Make sure all hot water taps are closed and the drain plugs are securely attached. 2. Purge the water line of debris. 3. Open the manual water shut-off valve located on the water supply line. 4. Open all the hot water taps to verify water flows ...

- 13 - initial operation for your safety please read before operating the unit for the first time. Once you have properly installed the unit and before firing it for the first time, check the gas and water connections for leaks. Open the main gas supply valve to the unit using only your hand to avoi...

- 14 - temperature settings there are 4 preset temperatures that you can select from by adjusting the dipswitch settings on the computer board. The temperature has been preset at the factory to122ºf (50ºc). The computer will electronically control this temperature. At a fixture, mix cold water with ...

- 15 - wiring diagram a wiring diagram is located on the inside front panel of the appliance. Electrical rating: 120 vac, 60 hz, 0.8 a. Note: if any of the original wiring supplied with this appliance must be replaced, it must be replaced with appliance wiring material (180c) or its equivalent. Wire...

- 16 - freeze protection devices this unit comes equipped with heating blocks to prevent freezing which can damage the heat exchanger. For this freeze prevention system to operate, there has to be electrical power to the unit. Damage to the heat exchanger caused by freezing temperatures due to power...

- 17 - common trouble shooting the t-m1 can burn gas at a maximum input rate of 235,000 btuh. This puts a limit on the possible output temperature and flow capabilities. If the water doesn’t seem hot enough, compare the flow and temperature that is being attained to the t-m1 flow vs. Temperature cha...

- 18 - operating instructions 1. Stop! Read the safety information above or in the owners manual. 2. Turn off all electric power to the water heater. 3. Do not attempt to light the burner by hand. 4. Turn the gas manual gas valve located on the outside of the unit clockwise ↻ to the off position. 5....

- 19 - vapors from flammable liquids will explode and catch fire causing death or severe burns. Do not use or store flammable products such as gasoline, solvents or adhesives in the same room or area near the water heater. Warning: do not install water heater where flammable products will be stored....

- 20 - applications space heating applications the t-m1 can be used for potable hot water heating applications as well as space heating applications. Warning • toxic chemicals used in boiler treatments such as alcohol, glycerol and glycol group must not be introduced into the system when used for op...

- 21 - dual-purpose hot water heating (domestic and space heating) priority control devices such as a flow switch, an aquastat or other electronic controller can be used to prioritize the domestic water system over the heating system. Warning: follow all local codes, or in the absence of local codes...

- 22 - t-m1 with storage tank this illustration is a concept design only. The maximum flow rate through the t-m1 is 9.6 gpm. If it is necessary to achieve higher flow rates with full pressure for longer periods of time, then it can be installed in conjunction with a storage tank. A pump will be nece...

- 23 - optional items 1. Tm-re10 temperature remote controller the tm-re10 temperature remote controller has two functions. It allows the output temperature from the t-m1 to be adjusted within the range of 99 °f to 182 °f, and it also works as a diagnostic tool that will give a concise error code wh...

- 24 - manifold multi-system application for large volume. Mobius water heater has full capability of manifolding multi-systems, with multi-system computer control (part tm-re20 and part tm-re10). This multi-system computer controller, you can manifold from 2 units to 20 units for commercial and res...

- 25 - for tm-re10 port. Use 18 gage wire. No polarity it has four ports. Each port can connect up to five t-m1. No polarity. This connects “201” connecter in the first t-m1 lp or natural gas, please don’t change these switch, factory already set it correctly. When unit is firing, this red led will ...

- 26 - pump connection : a) not remove “store” and “re-cir” jumper. Normal pump re-circulation control if “operation switch” of re20 is on, “pump control port” is always turned on. The water in piping is circulated and temperature is kept constant. B) remove “re-cir” jumper. Instant re-circulation c...

- 27 - component diagram 50 49 48 46 47 35 44 20 29 45 34 42 31 40 39 31 43 41 37 38 26 60 30 29 28 32 33 34 35 36 20 27 52 40 34 58 18 51 53 54 55 57 56 56 61 40 62 63 65 66 48 64 40 60 59 34 26 23 25 24 18 22 21 20 19 18 17 16 15 14.

- 28 - 128 127 126 123 9 125 124 122 119 120 117 121 118 115 116 115 114 111 18 112 113.

- 30 - 1 2 3 4 5 6 2 3 7 8 9 10 11 12 13 3.

- 31 - parts list part no. Description part no. Description 1 case assembly 35 screw m4 x 12 2 brackets 36 flange 3 screw (w) m4 x 10 37 flow adjustment valve 4 back guard panel 38 o-ring p16 5 transformer 39 bypass junction 6 transformer 40 screw m4 x 6 7 junction box 41 o-ring p18 8 junction box c...

- 32 - 69 burner assembly 99 igniter 70 screw m4- 12 100 screw m4 x 6 71 wire holder 101 solenoid valve wire 72 spark electrode holder packing 102 proportional valve wire 73 spark electrode holder 103 gas valve unit 74 screw m4 x 10 104 o-ring p22 75 silicon cap 105 o-ring p18 76 spark electrode fix...

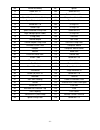

- 3 3 - o ut pu t t em pe ra tu re v s. G pm (m ax . 9 .6 g p m ) w ith v ar io us g ro un d w at er t em pe ra tu res c or re ct g as p ip e si ze c an b e as su m ed 0. 0 2. 0 4. 0 6. 0 8. 0 10 .0 12 .0 o ut pu t h ot w at er t em pe ra tu re output hot water gpm 40 f 50 f 60 f 70 f 40 f 7. 7 7. 0...

- 33 - mm1097 126.