- DL manuals

- Takeuchi

- Compact Excavator

- TB128FR

- Operator's Manual

Takeuchi TB128FR Operator's Manual

Summary of TB128FR

Page 1

C-1.

Page 2

C-2 safety alert symbol this symbol represents the safety alert. The message that follows the symbol contains important information about safety. Read and understand the message to avoid personal injury or death. It is the owner or employer’s responsibility to fully instruct each operator in the pro...

Page 3

0-1 signal words safety messages appearing in this manual and on machine decals are identified by the words “denger”, “warning” and “caution”. These signal words mean the following: danger danger indicates a hazard with a high level of risk which, if not avoided, will result in death or serious injur...

Page 4

0-2 foreword this manual describes operation, inspection and maintenance of the machine, as well as safety instructions to be heeded during these operations. If you have any questions about the machine, please contact a takeuchi sales or service outlet. Introduction manual storage compartment a comp...

Page 5

0-3 front, rear, left and right machine description this manual refers the front, rear, left and right of the machine as seen when sitting in the operator’s seat with the dozer blade visible to the front. Designated operations use this machine primarily for the following operations: • excavation • d...

Page 6

0-4 notes on reading this manual please note that the descriptions and diagrams included in this manual may not be applicable to your machine. The numbers used in the illustration are with circles around them. The same numbers appear between the parentheses in the text. (example: (1)) symbols used i...

Page 7

0-5 contents introduction .....................................0-2 machine description ........................0-3 safety ..............................................1-1 general precautions ................................ 1-2 precautions when preparing .................... 1-8 precautions when st...

Page 8

0-6 cautions after operations ................... 3-29 after the cold climate ......................... 3-29 handling rubber crawlers ....................... 3-30 prohibitions ........................................ 3-30 cautions ............................................ 3-31 preventing the rubb...

Page 9

0-7 inspecting and replacing the fuse ......... 6-6 inspecting the fusible link ..................... 6-7 restarting after adding fuel ...................... 6-8 bleeding air from the fuel system ......... 6-8 if a warning lamp flashes ......................... 6-9 other symptoms .......................

Page 10

0-8.

Page 11

1-1 safety.

Page 12

1-2 safety general precautions it is your responsibility to observe all pertinent laws and regulations and to follow the manufacturer’s instructions on machine operation, inspection and maintenance. Virtually all accidents occur as the result of a failure to observe basic safety rules and precaution...

Page 13

1-3 safety wear appropriate clothing and protective equipment general precautions • do not wear loose clothing or any accessory that can catch on controls or in moving parts. • do not wear oily or fuel stained clothing that can easily catch fire. • wear a hard hat, safety shoes, safety glasses, filter...

Page 14

1-4 safety use a signal person and a flag person learn how to use the hand signals required for particular jobs and make sure who has the responsibility for signaling. • all personnel must fully understand all the signals. • the operator must respond to signals only from the appointed signal person, ...

Page 15

1-5 safety avoid fire and explosion hazards keep flames away from fuel, oil, grease and antifreeze. Fuel is particularly flammable and dangerous. • when handling these combustible materials, keep lit cigarettes, matches, lighters and other flames or sources of flames away. • do not smoke or permit open fl...

Page 16

1-6 safety handling asbestos dust inhaling asbestos dust can cause lung cancer. When handling the materials which may contain asbestos, take the following precautions: • never use compressed air for cleaning. • avoid brushing or grinding parts containing asbestos. • for clean up, use a vacuum equipp...

Page 17

1-7 safety general precautions using optional products • consult with takeuchi before installing optional attachments. Depending on the type of attachments or the combination of them, the attachment may come into contact with the operator’s compartment or the other parts of the machine. Make sure th...

Page 18

1-8 safety precautions when preparing know the work area before starting operation, know the working area condition to ensure a safety operation. • inspect the topography and ground condition of the working area, or the structure of the building when working indoors, and take the safety precautions ...

Page 19

1-9 safety perform inspection and maintenance every day failure to identify or repair the irregularities or damage on machine can lead to accidents. • before operating, perform the specified inspection and make prompt repairs where necessary. • if a failure occurs and the operation becomes impossible...

Page 20

1-10 safety precautions when starting support your weight in a three point secure stance when getting on/off the machine • do not jump on or down from the machine. Never attempt to get on or off the moving machine. • when getting on or off the cab, first fully open the door to the locked position and...

Page 21

1-11 safety starting with jumper cables use jumper cables only in the recommended manner. Improper use of jumper cables can result in battery explosion or unexpected machine motion. Refer to “if the battery goes dead” for further instructions. Precautions when starting after starting the engine afte...

Page 22

1-12 safety precautions when operating ensure good visibility • when working in dark places, turn on the machine’s working lights and headlights and additional lighting equipment installed, as necessary. • when visibility is poor due to bad weather (fog, snow, rain or a cloud of dust), stop operatin...

Page 23

1-13 safety check the position of the undercarriage (tracks) before traveling before operating the travel levers/pedals, make sure that the dozer blade is to the front of the operator’s seat. Remember that when the dozer blade is to the rear of the operator’s seat, the travel levers/pedals must be o...

Page 24

1-14 safety cautions on traveling on slopes when traveling on slopes or grades, be careful that the machine does not tip (roll) over or slide. • never travel on slopes that are too steep for the machine to maintain its stability (maximum gradeability: 30°, lateral tipping angle: 15°). Note that in r...

Page 25

1-15 safety operate the machine on snow or ice with extra care • when traveling on snow or on frozen surfaces, drive at a low speed and avoid starting, stopping or changing directions abruptly. • in the snowy area, the road shoulder and objects placed beside the road are buried in the snow and canno...

Page 26

1-16 safety keep a safe distance from the overhead high-voltage cables never bring any part of the machine or loaded material to near to the high voltage cables unless all safety precautions required by the local and national authorities have been installed. If a person comes near to the machine tha...

Page 27

1-17 safety watch out for hazardous working conditions • do not come close to unstable grounds (cliffs, road shoulders, deep ditches). If the ground should collapse under the weight or vibration of the machine, there is a hazard that the machine may fall or tip over. · remember that the soil after h...

Page 28

1-18 safety • do not use the impact force of the hoe attachment for breaking work. There is a hazard of serious injury being caused by flying pieces of broken materials and by the damaged hoe attachment. Precautions when operating operating on slopes is dangerous when operating on slopes or grades, s...

Page 29

1-19 safety never slew sideways with a heavy load the machine can tip over more easily in the lateral direction than in the longitudinal direction. • do not slew sideways with a heavy load at the tip of the hoe attachment. In particular, do not slew sideways on slopes. • the tip of the attachment is...

Page 30

1-20 safety be careful with flying objects this machine is not equipped with protective equipment to protect the operator from flying objects. Do not use this machine in places where there are risks of the operator being hit by flying objects. Cautions when towing when towing, serious injury or death c...

Page 31

1-21 safety precautions when stopping park safely • park the machine on a flat, rigid and safe ground. Set the parking brake. • if you must park on a slope or incline, park the machine securely and block the movement of the machine. • when parking on a street, use barriers, caution signs, lights, etc...

Page 32

1-22 safety precautions when transporting load/unload the machine safely the machine may roll or tip over or fall while being loaded or unloaded. Take the following precautions: • select a firm, level surface and keep sufficient distance from road shoulders. • secure ramps of adequate strength and siz...

Page 33

1-23 safety hoist the machine safely • know and use correct crane signals. • check the hoisting equipment for damaged or missing parts on a daily basis and replace as necessary. • when hoisting, use a wire rope capable of lifting the machine mass. • hoist the machine in such a manner described in th...

Page 34

1-24 safety precautions on maintenance display a “do not operate” alert sign severe injury could result if an unauthorized person should start the engine or touch controls during inspection or maintenance. • before performing maintenance, stop the engine, remove the key and take it with you. • displ...

Page 35

1-25 safety prohibit access by unauthorized persons do not allow unauthorized personnel in the work area while working. Be careful when grinding, welding or using a hammer. You could be injured by flying debris from the machine. Prepare work area • select a firm, level work area. Make sure there is ad...

Page 36

1-26 safety firmly secure the machine or any component that may fall • before performing maintenance or repairs under the machine, lower all moveable working equipment to the ground or in the lowermost position. • chock the tracks. • if you must work beneath the raised machine or equipment, always u...

Page 37

1-27 safety place heavy objects in a stable position when it is necessary to temporally place a heavy object or an attachment on the ground during removal or installation, be sure to place it in a stable position. Keep off unauthorized persons from the storage place for such object. Cautions when re...

Page 38

1-28 safety be careful with hot cooling systems do not remove the radiator cap or the drain plug when the cooling water is hot. Stop the engine and wait until the engine and the cooling water cool. Then, slowly loosen the radiator cap to release the internal pressure and remove it. Be careful with o...

Page 39

1-29 safety be careful with the high-pressure grease in the track adjuster, the grease has been injected under high pressure. If the tension is adjusted without following the prescribed procedure, the grease discharge valve may fly off, resulting in injury. • never loosen the grease fitting. • loosen ...

Page 40

1-30 safety disconnect the battery wiring disconnect the battery wiring before working on the electrical system or doing electric welding. Disconnect the negative (-) battery cable first. When reconnecting, connect the negative (-) battery cable last. Use caution when handling batteries • batteries c...

Page 41

1-31 safety periodically replace the safety-critical parts • to use the machine safely for a longer period, periodically add oil and perform inspection and maintenance. To improving the safely, replace the safety-critical parts like hoses and seat belts periodically. Refer to “list of safety-critica...

Page 42

1-32 safety have a takeuchi service agent repair welding if welding must be performed, make sure that it is done by a qualified person in a properly equipped workplace. To prevent any part from breaking down or being damaged due to overcurrent or sparks, observe the following. • disconnect the wiring...

Page 43

1-33 safety safety signs (decals) for the safety of the operator and the personnel working around the site, safety signs (decals) are placed at certain locations on the machine as shown below. Walk around the machine with this manual, and check the content and location of these safety signs. Review ...

Page 44

1-34 safety safety signs (decals).

Page 45

1-35 safety safety signs (decals).

Page 46

1-36 safety safety signs (decals).

Page 47

2-1 controls.

Page 48

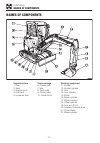

2-2 controls names of components upperstructure 1. Cab 2. Seat 3. Engine hood 4. Fuel tank 5. Hydraulic tank undercarriage 6. Crawler belt 7. Idler 8. Track roller 9. Carrier roller 10. Travel motor working equipment 11. Bucket 12. Bucket cylinder 13. Arm 14. Arm cylinder 15. Boom 16. Boom cylinder ...

Page 49

2-3 controls 1. Instrument cluster 2. Starter switch 3. Light switch 4. Horn button 5. Travel speed switch 6. Wiper switch (cab)* 7. Safety lock lever 8. Attachment interference prevention switch 9. Throttle lever 10. Left operating lever 11. Right operating lever 12. Travel levers/pedals 13. Auxili...

Page 50

2-4 controls covers starter key the starter key is used to start and stop the engine, as well as to lock and unlock the following components: • fuel filler cap • cab door • manual storage compartment • engine hood • covers covers storage box 1. To unlock this box, insert the starter key and turn it c...

Page 51

2-5 controls covers fuel filler port warning • do not smoke and keep away from heat or flame while filling the fuel tank. • fill the fuel tank in a well ventilated place, with the engine turned off. • clean up spilled fuel immediately. • do not fill the fuel tank to capacity. Allow room for oil expansi...

Page 52

2-6 controls covers tool case 1. Remove the wing bolt (1) and turn the cover (2). Fuse box this box is used to protect the electric system from over current. Opening 1. Push in the front tab on the fuse box cover (1), and then pull the cover (1) backward. Closing 1. Close the cover by engaging the b...

Page 53

2-7 controls insert the starter key and turn it. Opening 1. Pull the knob (1) towards you and open the door. Cab cab door warning when getting on or off the cab, first open the door all the way until it is secured in the catch and check that it does not move. Open the door fully and press it against ...

Page 54

2-8 controls cab front window warning • grasp the handles firmly with both hands when opening and closing the front window. It may hit your head or hands if it slips from your hands. • the front window comes closed to your head when you are opening or closing it. Be careful not to hit your head on th...

Page 55

2-9 controls lower front window removing 1. Open the front window and stow it in the ceiling. 2. Grasp the protruding parts (4) on the left and right with your fingers and slowly lift the lower front window. 3. Place the lower front window through the guides (5) at the rear, and then set it on the gu...

Page 56

2-10 controls seat and seat belt seat warning adjust and secure the seat. Seat and seat belt (a) adjusting the backrest warning • do not set the backrest to its maximum reclining position and slide the seat backwards at the same time. Doing so may damage the rear window or cause injury. • remember t...

Page 57

2-11 controls seat and seat belt seat belt caution be sure to fasten the seat belt securely before starting the engine. Fastening the seat belt 1. Adjust the seat to the desired position for operation, sit up and sit back in the chair. 2. Pull the seat belt to the desired length. 3. Make sure that t...

Page 58

2-12 controls instrument cluster warning lamps important: if a warning lamp flashes and an alarm is sounded, immediately stop all operations and check the corresponding component. Refer to “troubleshooting” on page 6-9. 1. Battery charge warning lamp this lamp flashes and an alarm is sounded if a prob...

Page 59

2-13 controls indicators 5. Travel speed lamp this lamp lights up when the travel speed switch is set to 2nd (high) speed. 6. Glow lamp this lamp goes out when the engine preheating is completed. 7. Deceleration lamp when the deceleration button is pressed, this lamp lights up to indicate that the e...

Page 60

2-14 controls switches starter switch switches important: do not repeatedly switch the key from off to on and on to off over a short period. Doing so will cause engine breakdown. Preheat ......Position for preheating the engine. Off ...............Position for stopping the engine and inserting or re...

Page 61

2-15 controls horn button press the button situated on the right operating lever to blow the horn. Switches deceleration button warning before operating the deceleration button, set the operating and the travel levers to the neutral positions. If the button is operated while either lever has been en...

Page 62

2-16 controls switches auxiliary hydraulic buttons press those buttons to control the flow of the oil in the auxiliary hydraulic lines. • proportional control of the auxiliary hydraulic circuit is not possible. (a) ..................Hydraulic oil flows to left auxiliary line (a). (b) ....................

Page 63

2-17 controls switches light switch when this switch is turned while the starter switch is at on, the lights turn on as follows: o ....... Off i ......... Meter light, front light and boom light will be lit. Ad6b024 wiper switch important: if no washer fluid is discharged, do not operate the washer. ...

Page 64

2-18 controls switches attachment interference prevention switch warning • failure to properly set the attachment interference prevention switch can result in equipment damage, serious injury or death. • ensure that all buckets used in the s mode are standard buckets or those with shorter width than...

Page 65

2-19 controls levers and pedals safety lock lever warning • before standing up from the operator’s seat to open/close the window or remove/install the lower window, lower the working equipment to the ground, raise the safety lock lever to engage the lock and stop the engine. If any controls should b...

Page 66

2-20 controls operating levers warning • before starting operation, carefully check which lever pattern you are going to use. • it is described using the iso pattern in this manual. Use these levers to operate the boom, arm, bucket and upperstructure. Refer to “lever pattern” on page 3-6. Refer to “...

Page 67

2-21 controls travel levers/pedals warning • before operating the travel levers/ pedals, make sure that the dozer blade is to the front of the operator’s seat. Remember that when the dozer blade is to the rear of the operator’s seat, the travel levers/pedals must be operated in the reverse direction...

Page 68

2-22 controls accessories heater warning • always be sure to allow sufficient ventilation. • do not place combustible or explosive objects near the air outlets. Heater fan switch o ........Off i ..........Low ii .........High heater/defroster a ........Heater b ........Defroster ventilation/circulati...

Page 69

2-23 controls accessories heater valve coolant circulates in the heater even when the heater switch is turned off. When the heater is no longer needed, stop coolant circulation as follows: important: use the valve (1) either fully open or fully closed. Cooling water could leak when the valve is part...

Page 70

2-24 controls cigarette lighter warning • do not leave the cigarette lighter knob pushed in for a long time. Doing so heats up the lighter, and could be dangerous. • if the lighter knob does not pop out 30 seconds after it was pushed in, it may be broken. Pull it out by hand. • do not use any other ...

Page 71

2-25 controls interior light important: the battery capacity decreases if the interior light is left on for a long time when the engine is stopped. O ........Remains off all the time. I ..........Lights up all the time. Accessories external power sockets warning use only those electric products whic...

Page 72

2-26 controls radio (for cab) cautions on use • to ensure safe operation of the machine, always be sure to keep the volume of the radio down to a level where you can easily hear sounds from outside the machine. • do not use the radio for a long time when the engine is stopped. Doing so will drain th...

Page 73

2-27 controls (7) tune button use this button to tune to a radio station. Press and hold this button ( or ) for two seconds or more to start seeking the audible stations. The seeking stops when a station is found. To cancel tuning in progress, press the button again. Pressing the button will start s...

Page 74

2-28 controls presetting stations 1. Select the band (fm or am) and the station you want to preset. 2. To set the selected station to a preset button, choose the button to be set and then press and hold the button for three seconds or more. The number of the preset button chosen appears on the lcd. ...

Page 75

2-29 controls resetting the radio if there are any problems, such as the abnormal display of frequency or failure of selection, reset the radio by pressing the power button and the zero button together. Note: that the memory containing the clock setting and the channel setting is cleared after reset...

Page 76

2-30 controls auxiliary hydraulic lines these lines deliver the hydraulic oil necessary for operating a hydraulic breaker, crusher or other attachments. Stop valve (s): closed (o): open warning oil may spurt out if pipes disconnected before releasing the pressure in the hydraulic system. • immediate...

Page 77

2-31 controls connecting the hydraulic circuits to connect the attachment hydraulic lines, observe the following procedures: 1. Release the pressure remaining in the lines, and then close the stop valve. Refer to “releasing residual pressure” on page 2-32. 2. Remove the plugs. 3. Connect the attachm...

Page 78

2-32 controls operating selector valve accessories open ....... When using a hydraulic breaker (1-way flow) closed ..... When using a reversible attachment (2-way flow) change the direction of the hydraulic oil flow by opening or closing the selector valve on the machine body. 1. Loosen the bolts and r...

Page 79

3-1 operation.

Page 80

3-2 operation before starting operation getting on or off the machine warning • do not jump on or down from the machine. Never attempt to get on or off the moving machine. • when getting on or off the cab, first fully open the door to the locked position and check that it does not move. • climb up/do...

Page 81

3-3 operation 3. Check that the safety lock lever is in the locked position. Starting and stopping the engine before starting the engine 1. Adjust the seat for a comfortable operating position. 2. Fasten the seat belt. 4. Check that all levers and pedals are in the neutral position. 5. Insert the ke...

Page 82

3-4 operation starting the engine warning • clear all personnel from the work area. • sound the horn to warn people around the machine. Important: do not run the starter motor for more than 15 consecutive seconds. If the engine fails to start, wait for 30 seconds, and then try again to start the eng...

Page 83

3-5 operation warming up the engine important: avoid racing the engine until it has warmed up. Do not warm up the engine for a long time (20 minutes or more). When idling is required, occasionally place a load or run the engine at medium speed. 1. Return the throttle lever, then run the engine at a ...

Page 84

3-6 operation operating the machine lever pattern (iso pattern) warning • before starting operation, carefully check which lever pattern you are going to use. • it is described using the iso pattern in this manual. Left crawler forward right crawler forward left crawler reverse right crawler reverse...

Page 85

3-7 operation lever pattern (jcb pattern) warning • before starting operation, carefully check which lever pattern you are going to use. • it is described using the iso pattern in this manual. Left crawler forward right crawler forward left crawler reverse right crawler reverse boom lower arm out bo...

Page 86

3-8 operation 5. Slew slowly to the left and the right several times. Warming up the machine (hydraulic oil) warning operating the working equipment without warming up the machine (hydraulic oil) is dangerous, as the working equipment cannot response to controls quickly or may move in unexpected way...

Page 87

3-9 6. Travel slowly forward and in reverse several times. Warm-up in cold climates 1. Perform the normal warm-up procedure. 2. Set the bucket cylinder at the stroke end and keep it there. Do not keep this condition for more than 30 seconds. 3. Repeat step 2 until the bucket operating speed becomes ...

Page 88

3-10 operation inspecting the attachment interference prevention system perform an inspection below to confirm that the bucket, arm and boom do not touch the cab if the boom or bucket is stopped by itself after moved very close to the cab. Operating the machine 1. Offset the boom to the front of the ...

Page 89

3-11 memo.

Page 90

3-12 operation 1. Pull the throttle lever and increase the engine speed. Operating the travel levers warning • never allow anyone to enter the machine’s slewing radius and path. • signal your intention to move by sounding the horn. • there is a blind spot in the rear of the machine. Before traveling...

Page 91

3-13 operation when the dozer blade is in front of the operator’s seat: to move forward: tilt the levers forward. To move backward: tilt the levers backward. When the dozer blade is behind the operator’s seat: to move forward: tilt the levers backward. To move backward: tilt the levers forward. Trav...

Page 92

3-14 operation pivot turn turning to the left when stopped: to turn forward to the left: tilt the right lever forward. To turn backward to the left: tilt the right lever backward. To turn to the right, operate the left lever in the same way as for the right lever. Turning to the left while traveling...

Page 93

3-15 operation stopping travel warning • park the machine on a flat, rigid and safe ground. Set the parking brake. If you must park on a slope, chock the tracks to block the machine. • if any control is accidentally touched when the safety lock lever is not locked, the machine may suddenly move and c...

Page 94

3-16 operation attachment interference prevention switch/interference prevention system warning • all attachments other than a bucket should be used with the aips set to the m mode. • failure to properly set the attachment interference prevention switch can result in equipment damage, serious injury...

Page 95

3-17 operation operating the machine operate excavator the minimal front radius feature is only available for the standard bucket attachment 460 mm (18.1 inches) or smaller..

Page 96

3-18 operation upperstructure slew left: tilt the left operating lever to the left. Upperstructure slew right: tilt the left operating lever to the right. Operating the boom operating the working equipment warning • before starting operation, carefully check which lever pattern you are going to use....

Page 97

3-19 operation arm in: tilt the left operating lever backward. Arm push: tilt the left operating lever forward. Operating the bucket bucket load: tilt the right operating lever to the left. Bucket dump: tilt the right operating lever to the right. Operating the boom offset boom offset left: step on ...

Page 98

3-20 operation do not extend the hydraulic cylinders to the stroke ends. Operate them with leeway. Operating procedures prohibited operations warning • do not operate on bedrock (hard or soft). • do not slew while traveling. If you must operate the hoe attachment while traveling, operate at speeds s...

Page 99

3-21 operation doing so will shorten the service life of the hoe attachment. Use the hydraulic force to dig. Do not perform operations using the machine’s dropping force putting excessive strain on the machine will shorten its service life. When digging, use the hydraulic force of the cylinders and ...

Page 100

3-22 operation pay attention to the dozer blade when digging when digging deeply with the dozer blade positioned at the front, be careful that the boom cylinder and bucket do not hit the dozer blade. Operate with the dozer blade at the rear whenever possible. Caution on digging down with the dozer b...

Page 101

3-23 operation cautions on using machine in water traveling over obstacles (rocks, stumps, etc.) may put a great load on the machine body and may cause damage to it. Avoid crossing over obstacles whenever possible. If you must do so, keep the hoe attachment near the ground, travel at a low speed, an...

Page 102

3-24 operation cautions on traveling on slopes warning • never travel on slopes that are too steep for the machine to maintain its stability (maximum gradeability: 30°, lateral tipping angle: 15°). Note that in reality, the machine’s stability becomes lower than the above values depending on the wor...

Page 103

3-25 operation when descending slopes, the brakes are applied automatically once the travel levers are returned to the neutral position. If the crawler slips if the crawler slips while climbing a slope and impossible to travel, use the pulling force of the arm to climb the slope. If the engine stops...

Page 104

3-26 operation getting out of mud if the machine gets stuck in mud, use the procedure below to get it out. If one crawler is stuck 1. Swing the bucket to the side of the crawler being stuck. 2. Set the arm and boom to an angle of 90 to 110°. 3. Press the bottom of the bucket (not the teeth) against ...

Page 105

3-27 operation leveling digging side drains use the boom offset function to dig side ditches as shown in the figure. Loading when loading dirt onto a truck bed, load from the back of the truck, as it is easier and able to load more load than doing it from the front. Also, use a small slewing angle fo...

Page 106

3-28 operation parking the machine parking warning • park the machine on a flat, rigid and safe ground. Set the parking brake. If you must park on a slope or incline, park the machine securely and block the movement of the machine. • when parking on a street, use barriers, caution signs, lights, etc....

Page 107

3-29 operation handling in cold climates preparing for cold climates starting engine in cold climates is not easy, and it becomes more difficult if the coolant freezes. Prepare for cold-climate problems as follows. Replacing the fuel and lubricant replace the hydraulic oil, engine oil and fuel with t...

Page 108

3-30 operation handling rubber crawlers rubber crawlers have an inherent weakness, lack of strength, due to their use of rubber. Be sure to observe the prohibitions and cautions below to prevent the crawlers from being damaged or coming off. Prohibitions do not travel or operate the machine in the f...

Page 109

3-31 operation cautions observe the following cautions when operating the machine: • do not turn the undercarriage with the front of the machine body lifted using the hoe attachment (the upperstructure is not turned). Doing so will twist the crawlers with the load concentrated on a single point on t...

Page 110

3-32 operation • when climbing in reverse, do not change directions at the point where the slope starts. • avoid traveling by setting one crawler on a slope or projecting portion and the other crawler on a flat surface (with the machine at a tilt of 10° or more). Travel with both crawlers set on flat ...

Page 111

4-1 transport.

Page 112

4-2 transport loading and unloading warning the machine may roll or tip over or fall while being loaded or unloaded. Take the following precautions: • select a firm, level surface and keep sufficient distance from road shoulders. • secure ramps of adequate strength and size to the truck bed. The slope...

Page 113

4-3 transport 7. Drive the machine straight toward the ramps and travel up or down the ramps at 1st (low) speed, by following the signal from the signal person. 8. Load the machine at the specified position on the transporter. Refer to “transporting posture” on page 4- 6. Loading and unloading ag7f00...

Page 114

4-4 transport hoisting the machine warning • know and use the correct crane signals. • check the hoisting equipment for damaged or missing parts on a daily basis and replace as necessary. • when hoisting, use a wire rope capable of lifting the machine mass. • hoist the machine in such a manner descr...

Page 115

4-5 transport hoisting the machine.

Page 116

4-6 transport securing the machine after loading the machine at the specified position, secure it as described below. Transporting posture 1. Lower the dozer blade. 2. Extend the bucket cylinder and arm cylinder fully, and then lower the boom. 3. Raise the safety lock lever to the locked position. 4....

Page 117

5-1 maintenance.

Page 118

5-2 maintenance general maintenance overview to keep the machine in good condition and use if for a long period, perform the inspection and maintenance properly and safely following the procedures recommended by this manual. The inspection and maintenance items are divided into groups according to t...

Page 119

5-3 maintenance clean the installation surfaces when installing and removing parts, be sure that the surfaces of contact of the parts are clean. If the sealing grooves of the surface of contact are damaged, consult your sales or service dealer for repair or release. Seals and split pins • be sure to...

Page 120

5-4 maintenance service data fuel and lubricant table select the appropriate fuel, lubricant and grease according to the temperature by referring to the table below. • regardless of the specified time, change the oil if it becomes too dirty or degraded. • when refilling, never mix oils of different br...

Page 121

5-5 maintenance lubricant location type type by air temperature when to replace -4 14 32 50 68 86 104°f -20 -10 0 10 20 30 40°c engine oil pan diesel engine oil api: cd class acea: e-3, e-4 or e-5 every 250 hrs. After the initial 50 hrs. Hydraulic oil tank takeuchi genuine hydraulic oil 46 every 400...

Page 122

5-6 maintenance volume engine oil pan engine cooling system hydraulic oil tank fuel tank travel reduction gear upper limit 3.6 l (3.8 us qt.) lower limit 2.4 l (2.5 us qt.) 4.3 l (4.5 us qt.) system 70 l (18.5 us gal.) tank 44 l (11.6 us gal.) 39 l (10.3 us gal.) 0.5 l x 2 (0.53 us qt.) x 2 service ...

Page 123

5-7 maintenance list of consumables periodically replace consumables such as filters and elements according to the table below. System item part name part no. When to replace hydraulic system hydraulic oil return filter element 15511-03300 every 500 hrs after the initial 50 hrs. Engine lubrication sys...

Page 124

5-8 maintenance list of tools code part name part no. Remarks 1 spanner 19100-47081 10 - 12 2 spanner 19100-47082 14 - 17 3 screwdriver 19100-06112 (+) (–) replaceable shank 4 filter wrench 19100-65081 5 hammer 16903-00330 3/4 6 monkey wrench 16904-00250 250 mm 7 pliers 16905-00200 200 mm 8 spanner ...

Page 125

5-9 maintenance list of tightening torques nuts and bolts (for iso strength category 10.9) tighten nuts and bolts at the torques shown on the table below, unless otherwise specified. • the tightening torques used for the mounted plastic covers are not listed in the table below. Consult your sales or ...

Page 126

5-10 maintenance safety-critical parts to use the machine safely, periodically perform inspection and maintenance. The safety-critical parts listed below must be periodically replaced for an increased safety. Serious injury or a fire could result if they are worn or damaged. List of safety-critical p...

Page 127

5-11 maintenance the material of the safety-critical part listed on the left tends to change over time and cause wear or deterioration. It is difficult to determine the degree of deterioration at the periodic inspection, and thus they need to be replaced with new ones after a certain time to maintain...

Page 128

5-12 maintenance maintenance list inspection and maintenance item page walk-around inspection inspecting by opening the engine hood and covers 5-14 inspecting by walking around the machine 5-15 inspecting while sitting in the operator’s seat 5-15 daily inspection (every 10 hours) inspecting and repl...

Page 129

5-13 maintenance inspection and maintenance item page every 500 hours replacing the hydraulic oil return filter 5-35 replacing the fuel filter 5-35 every 1000 hours replacing the travel motor gear oil * 5-36 cleaning the engine cooling system 5-36 replacing the air cleaner element 5-38 inspecting and ...

Page 130

5-14 maintenance walk-around inspection perform the following inspections every day before starting the engine for the first time. Warning • before operating, perform the walk-around inspections and make repairs immediately where necessary. • be sure to secure the engine hood or cover before working ...

Page 131

5-15 maintenance inspecting by walking around the machine 4. Check lights for dirt, damage and burnt out bulbs. 5. Check attachments and hoses for damage. 6. Check the bucket, bucket teeth and side cutter for wear, damage and looseness. 7. Check the hook, slip stopper and hook mount of buckets with ...

Page 132

5-16 maintenance daily inspection (every 10 hours) perform the following inspections every day before starting the engine for the first time. Warning • before operating, perform the daily inspections and make repairs immediately where necessary. • be sure to secure the engine hood or cover before wor...

Page 133

5-17 maintenance inspecting and replenishing the engine oil warning stop the engine and allow the machine to cool down before performing maintenance. Inspection 1. Open the engine hood. 2. Take out the dipstick (1) and wipe the oil off with a rag. 3. Fully reinsert the dipstick (1), and then pull it...

Page 134

5-18 maintenance inspecting the fuel level warning • do not smoke or permit open flames while handling fuel or working on the fuel system. • never remove the fuel cap or add fuel when the engine is running or still hot. Do not spill fuel on the hot surface of the machine. • fill the fuel tank in a we...

Page 135

5-19 maintenance daily inspection (every 10 hours) replenishing important: .Do not fill up to the level higher than the upper limit (h). It will damage the hydraulic circuits or result in oil spurting. If accidentally done, stop the engine and wait the hydraulic oil to cool, and then let the excessiv...

Page 136

5-20 maintenance daily inspection (every 10 hours) lubricating the working equipment 1. Keep the machine configuration as shown in the diagram above, lower the working equipment to the ground, and then stop the engine. 2. Use the grease gun to lubricate the grease fittings. 3. Wipe off the excess grea...

Page 137

5-21 maintenance after the initial 50 hours (only for new machines) replacing the engine oil and the oil filter warning stop the engine and allow the machine to cool down before performing maintenance. • the engine, muffler, radiator, hydraulic lines, sliding parts and many other parts of the machine...

Page 138

5-22 maintenance after the initial 50 hours (only for new machines) inspecting and adjusting the fan belt warning stop the engine and allow the machine to cool down before performing maintenance. • the engine, muffler, radiator, hydraulic lines, sliding parts and many other parts of the machine are h...

Page 139

5-23 maintenance after the initial 50 hours (only for new machines) replacing the hydraulic oil return filter warning • stop the engine and allow the machine to cool down before performing maintenance. · the engine and the hydraulic system and many other parts of the machine are hot immediately afte...

Page 140

5-24 maintenance every 50 hours inspecting and adjusting the crawler tension warning • if you must work beneath the raised machine or working equipment, always use wood blocks, jack-stands or other rigid and stable supports. Never get under the machine or working equipment if they are not sufficientl...

Page 141

5-25 maintenance adjustment increasing the tension decreasing the tension 1. Remove the cover (1). 2. Slowly loosen (one turn) the grease discharge valve (2) with a spanner to discharge grease. If grease does not come out well, move the machine back- and-forth. 3. Tighten the grease discharge valve ...

Page 142

5-26 maintenance lubricating the slew bearing warning do not slew while lubricating. Doing so is dangerous, as you may get caught in the machine. Every 50 hours 1. Stop the engine with the machine in the posture shown on the figure above. 2. Use the grease gun to grease the grease fitting (1). 3. Star...

Page 143

5-27 maintenance draining the water from the fuel tank warning • do not smoke or permit open flames while handling fuel or working on the fuel system. • never remove the fuel cap or add fuel when the engine is running or still hot. Do not spill fuel on the hot surface of the machine. • fill the fuel ...

Page 144

5-28 maintenance 3. Pull out the battery and inspect the indicator (5). · blue: good · white: charging needed · red: insufficient battery fluid 4. Inspect the fluid level. The fluid level must be between the upper level (h) line and lower level (l) line. If not, add distilled water up to the line (h). I...

Page 145

5-29 maintenance • if the fluid level cannot be checked by fluid level lines: remove the caps (2) and look into the fluid filler holes to check the fluid level. If the fluid is below the sleeve (3), be sure to add distilled water up to the bottom edge of the sleeve (3). Proper level (a) if the fluid reache...

Page 146

5-30 maintenance every 100 hours cleaning the water separator warning • do not smoke or permit open flames while handling fuel or working on the fuel system. • stop the engine in a well-ventilated place and allow it to cool down before performing maintenance. • clean up spilled fuel immediately. (s):...

Page 147

5-31 maintenance after the initial 250 hours (only for new machines) replacing the travel motor gear oil warning • stop the engine and allow the machine to cool down before performing maintenance. · the travel motor is hot immediately after the engine is stopped. Touching it will cause burns. · the ...

Page 148

5-32 maintenance every 250 hours replacing the engine oil and the oil filter refer to “replacing the engine oil and the oil filter” on page 5-21. Inspecting and adjusting the fan belt refer to “inspecting and adjusting the fan belt” on page 5-22. Cleaning the air cleaner warning • stop the engine and...

Page 149

5-33 maintenance 7. Clean the primary element (3) with dried compressed air (294 to 490 kpa or 43 to 71 psi). First blow the air from the inside of the element along the pleats. Then blow the air from the outside and finally from the inside again. 8. Light up the inside of the primary element (3) wit...

Page 150

5-34 maintenance cleaning the radiator fins and oil cooler fins warning wear required appropriate equipment such as protective goggle and filter mask when using compressed air, as metal fragments or other objects can fly and cause serious injury. Important: be careful not to damage the fins when cleani...

Page 151

5-35 maintenance every 500 hours every 500 hours replacing the hydraulic oil return filter refer to “replacing the hydraulic oil return filter” on page 5-23. Replacing the fuel filter warning • do not smoke or permit open flames while handling fuel or working on the fuel system. • stop the engine in a...

Page 152

5-36 maintenance every 1000 hours replacing the travel motor gear oil refer to “replacing the travel motor gear oil” on page 5-31. Cleaning the engine cooling system warning • stop the engine and allow the machine to cool down before performing maintenance. · the engine, muffler, radiator and many ot...

Page 153

5-37 maintenance 4. Place a pan for catching the waste coolant under the drain plug (4), and then loosen the drain plug (4) to drain the coolant. 5. Tighten the drain plug (4). 6. Add tap water to the radiator through the coolant fill port up to the top of the port. Take time and slowly add water, so...

Page 154

5-38 maintenance replacing the air cleaner element warning stop the engine and allow the machine to cool down before performing maintenance. • the engine, muffler, radiator and many other parts of the machine are hot immediately after the engine is stopped. Touching these parts will cause burns. Impo...

Page 155

5-39 maintenance every 1000 hours inspecting and adjusting the engine valve clearance this operation requires experience. Ask your sales or service dealer for it. Retightening the engine cylinder head bolt this operation requires experience. Ask your sales or service dealer for it..

Page 156

5-40 maintenance every 1500 hours inspecting and cleaning the engine fuel injectors this operation requires experience. Ask your sales or service dealer for it. Inspecting the crankcase breather system this operation requires experience. Ask your sales or service dealer for it. Every 1500 hours.

Page 157

5-41 maintenance every 2000 hours lapping the engine valve seats this operation requires experience. Ask your sales or service dealer for it. Every 2000 hours.

Page 158

5-42 maintenance every 4000 hours replacing the hydraulic oil and cleaning the suction strainer warning • stop the engine and allow the machine to cool down before performing maintenance. · the engine and the hydraulic system and many other parts of the machine are hot immediately after the engine i...

Page 159

5-43 maintenance 15. Tighten the drain plug (5). 16. Add hydraulic oil from the hole of plug (1) up to the level between the upper limit (h) and the lower limit (l) in the sight gauge (4). 17. Tighten the plug (1). 18. Bleed air from the hydraulic oil circuit by following “bleeding air” below. 19. S...

Page 160

5-44 maintenance when required replacing the bucket teeth and the side cutters replace the bucket teeth and the side cutters when the tooth points or the side cutters are worn. Do not wait until the adapter or bucket is damaged. Warning • before performing maintenance or repairs under the machine, l...

Page 161

5-45 maintenance installation 1. Clean the adapter nose (3). If there is gravel or mud on the adapter nose, the tooth point will not go in all the way and the pin cannot be driven in. When required 2. Put the tooth point (2) in the adapter nose (3). Push in firmly until the tooth point (2) touches th...

Page 162

5-46 maintenance when required • side cutter installation 1. Insert the bolts from the inner of the bucket and tighten the side cutterwith nuts. Tightening torque: 241 n·m (178 ft-lb) 2. Caulk the bolts with a punch at three spots along the periphery of the screw to prevent the nuts from coming loos...

Page 163

5-47 maintenance replacing the bucket warning • before performing maintenance or repairs under the machine, lower all working equipment to the ground or in the lowermost position. • if maintenance must be performed with the engine running, always work as a two person team communicating each other. ·...

Page 164

5-48 maintenance installation 1. Set the o-ring (4) on the bucket as shown on the figure above. 2. Align the pin hole (a) on the bucket with the pin hole on the arm (5), and install the pin (2). 3. Operate the cylinder, align the pin hole (b) on the bucket with the pin hole on the link arm (6), and i...

Page 165

5-49 maintenance inspecting and replenishing the windshield washer fluid warning choose ethyl alcohol as washer solution. Do not use methyl alcohol as washer solution. It could damage the eyes. Use a windshield washer fluid designed specifically for motor vehicles. Follow the instructions included wit...

Page 166

5-50 maintenance lubricating the levers warning set the machine to the parking posture, stop the engine, remove the starter key and store it. Failure to do so may result in the machine moving abruptly, leading to serious injury or death. If the levers or pedals no longer move smoothly, grease them. ...

Page 167

5-51 maintenance (3) metal core inspecting the rubber crawlers repair or replace the rubber crawlers if their condition becomes as described below. Consult your sales or service dealer for repair or replacement. Rubber crawler replace the crawler if the entire crawler is stretched and cannot be adju...

Page 168

5-52 maintenance replacing the rubber crawlers warning • if you must work beneath the raised machine or working equipment, always use wood blocks, jack-stands or other rigid and stable supports. Never get under the machine or working equipment if they are not sufficiently supported. • if maintenance ...

Page 169

5-53 maintenance 2. Set the rubber crawler on the sprocket. 3. Set an iron pipe (1) in the rubber crawler and turn the sprocket slowly in the reverse direction. 4. Turn until the iron pipe (1) is directly next to the idler and the rubber crawler lifts away from the idler, then stop turning the sproc...

Page 170

5-54 maintenance tilting up the platform tilting up the platform for inspection and maintenance, the platform is designed so that it can be tilted up. Warning • raising or lowering the platform while the engine is running may cause the machine to move, resulting in serious injury or death. Stop the ...

Page 171

5-55 maintenance maintenance during extended storage period storage procedures if the machine is to be stored for 30 days or more, store it indoors. If it must be stored outdoors, park the machine on a surface laid with lumber on a flat ground, and place a waterproof cover over it so that it stays dr...

Page 172

5-56.

Page 173

6-1 troubleshooting.

Page 174

6-2 troubleshooting symptoms that are not malfunctions the symptoms listed below are not malfunctions. • the arm retracting speed momentarily slows down when it reaches an almost vertical position while the engine is running at low speed. • the bucket teeth moving speed momentarily slows down when i...

Page 175

6-3 troubleshooting if the engine overheats warning • do not open the engine hood when steam is coming from it. The steam or hot water may spurt out and cause burns. • do not try to remove the radiator cap or the drain plug when the cooling water is hot. Stop the engine, wait until the engine and th...

Page 176

6-4 troubleshooting if the battery goes dead the symptoms below indicate that the battery is dead. • the starter motor does not turn or fails to start the engine. • the horn is too weak. Remedy procedure start the engine using the booster battery on the other vehicle (booster vehicle) and the jumper...

Page 177

6-5 troubleshooting disconnecting the jumper cables once the dead machine is successfully running, remove the jumper cables by following the same steps as for connection in the reverse order. 1. Disconnect the clip of jumper cable (b) from the engine block of the dead machine. 2. Disconnect the othe...

Page 178

6-6 troubleshooting if a fuse blows if a light does not come on or the electrical system does not work, a fuse may be blown. Inspect the fuses. Inspecting and replacing the fuse warning if the fuse blows again soon after replacement, then the electric system is likely faulty. It may pose a fire hazar...

Page 179

6-7 troubleshooting inspecting the fusible link if the machine is not turned on after turning the starter switch to the on position, the cartridge type fusible link (1) is likely blown. Open the cover and inspect. If the fusible link is blown, please contact your sales or service dealer. Note: fusib...

Page 180

6-8 troubleshooting restarting after adding fuel bleeding air from the fuel system 1. Add fuel. 2. Open the valve (2) of the water separator. Note: air in the fuel system causes the engine to fail to start or to have other problems. Always bleed air when the fuel tank is emptied or when there is air...

Page 181

6-9 troubleshooting if a warning lamp flashes if an alarm is sounded or a warning lamp starts flashing during operation, park the machine in a safe place and perform the remedy procedures described below. Warning lamp lamp name causes and remedies battery charge warning lamp there is a problem with t...

Page 182

6-10 troubleshooting other symptoms for symptoms not included in the table below or if the problem persists after the proper remedies have been taken, consult your sales or service dealer. Symptoms major causes remedies left and right operating levers do not move smoothly • insufficient grease on the...

Page 183

6-11 troubleshooting symptoms major causes remedies slewing is not possible or not smooth. • insufficient grease on slew bearing • grease the bearing. Refer to page 5-26. Hydraulic oil temperature is too high • hydraulic oil level too low • add up to the specified level. Refer to page 5-18. Starter mo...

Page 184

6-12 troubleshooting 2. Put marks (m) on the port relief valve (2), lock nut (4) and adjuster screw (3). 3. Loosen the lock nut (4) while holding the adjuster screw (3) in place with a hexagonal wrench. 4. Turn the adjuster screw (3) slowly 1 and 1/3 turns to lower the boom. 5. Check safety and stab...

Page 185

6-13 troubleshooting towing warning when towing, serious injury or death could result, if performed incorrectly or the wire rope being used is inappropriate or not properly inspected. • it becomes dangerous if the wire rope breaks or becomes disengaged. Use a wire rope appropriate for the required t...

Page 186

6-14.

Page 187

7-1 specifications.

Page 188

7-2 specifications basic specifications type canopy cab mass operating mass kg (lb) rubber crawlers 3315 (7310) 3410 (7520) steel crawlers 3400 (7495) 3500 (7715) performance bucket capacity (standard bucket) m 3 (cu. Ft.) heaped 0.068 (2.4) struck 0.051 (1.8) slew speed min -1 (rpm) 10 (10) travel ...

Page 189

7-3 memo.

Page 190

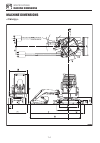

7-4 specifications machine dimensions machine dimensions.

Page 191

7-5 specifications unit: mm (inch) item standard arm rubber crawlers a overall length 4275 (168.3) b upperstructure overall width 1505 (59.3) c overall height 2545 (100.2) d slew radius 865 (34.1) e clearance height under upperstructure 600 (23.6) f crawler base 1545 (60.8) g crawler overall length ...

Page 192

7-6 specifications machine dimensions.

Page 193

7-7 specifications unit: mm (inch) item standard arm rubber crawlers a overall length 4275 (168.3) b upperstructure overall width 1505 (59.3) c overall height 2530 (99.6) d slew radius 865 (34.1) e clearance height under upperstructure 600 (23.6) f crawler base 1545 (60.8) g crawler overall length 2...

Page 194

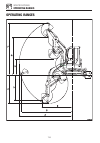

7-8 specifications operating ranges operating ranges.

Page 195

7-9 specifications unit: mm (inch) item standard arm rubber crawlers a maximum reach 4785 (188.4) b maximum reach at ground reference plane 4655 (183.3) c maximum digging depth 2575 (101.4) d maximum vertical digging depth 2150 (84.6) e reach at maximum vertical digging depth 2775 (109.3) f maximum ...

Page 196

7-10 memo.

Page 197

7-11 specifications lifting capacities rated lift capacity chart • the loads in the charts do not exceed 87% of hydraulic lift capacity or 75% of tipping load. • figures marked with an asterisk (*) are hydraulically-limited capacities. • the mass of slings and any other lifting devices shall be dedu...

Page 198

7-12 specifications standard arm lifting capacities.

Page 199

7-13 specifications standard arm lifting capacities.

Page 200

7-14.

Page 201

8-1 options.

Page 202

8-2 options general precautions safety precautions warning when removing or installing an attachment or optional part, take the following precautions. • consult with takeuchi before installing an optional attachment. • do not use any attachments not approved by takeuchi. Doing so may cause safety pr...

Page 203

8-3 options cautions when operating attachments warning long attachments reduce stability of the machine. The machine may tip over if it loses the balance when traveling or slewing on slopes. Never perform the operations listed below as they are extremely dangerous. • traveling down the slopes with ...

Page 204

8-4 options attachment combination table the table below shows which bucket should be installed when the machine is using a standard arm. Select a proper bucket by following the table. Warning • consult with takeuchi before installing an optional attachment. • do not use any attachments not approved...

Page 205

8-5 options selecting a lever pattern the operating pattern of the left and right operating levers can be selected. Warning before starting the engine, check the selector to see which operating pattern the left and right operating levers are set. Selecting a lever pattern switching the lever pattern...

Page 206

8-6 options • do not pound with the arm placed perpendicular to the ground surface. • do not pry with the chisel or do not pry while pounding. • do not move the chisel while pounding. • do not pound continuously for over 30 seconds on the same surface. Hydraulic breaker for handling of the breaker, ...

Page 207

8-7 options • do not drop the breaker itself on the object to be broken in order to break it. • do not move objects to be broken or rocks with the breaker itself. • slew the machine occasionally to cool the engine. • if a hydraulic hose is vibrating abnormally, nitrogen gas may be leaking from the a...

Page 208

8-8 options arm load safety device the load safety devices include an emergency shut-off valve and an overload warning device. The emergency shut-off valve prevents the boom or arm from falling. The overload warning device sounds an alarm when an excessive load is detected. Emergency shut-off valve ...

Page 209

8-9 options overload warning device if a weight greater than the lifting capacity is applied or lifted, the overload warning device is activated and the horn sounds. (when the overload warning switch is turned on.) warning if the overload is not removed after the overload warning horn is sounded, th...

Page 210

8-10 options 6. Press the auxiliary hydraulic buttons several times to release the residual pressure in the circuitry. 7. Move all the control levers and pedals several times in all directions to release the pressure from the working equipment circuitry. 8. Raise the safety lock lever to engage the ...

Page 211

8-11 options travel alarm the alarm sounds while the machine is traveling and stops when the machine stops traveling. If the alarm does not sound when the machine travels, the fuse may be blown. Inspect the fuses. Warning if the fuse blows again soon after replacement, then the electric system is li...

Page 212

8-12 options optional equipment mass standard machine mass (rubber crawlers, not including operator) canopy cab 3250 (7165) 3335 (7350) option steel crawlers 80 (175) rubber pads 180 (395) emergency shut-off valve boom + arm 15 (35) units: kg (lb) *: mass of optional equipment is added to the standa...

Page 213

8-13 options biodegradable oil biodegradable oil is a new type of hydraulic oil that is decomposed into carbon dioxide and water by microorganisms in the soil and water. It is highly safe for living organisms and offers advantages in term of environmental protection. • recommended biodegradable oil:...

Page 214

8-14 first published july 2009 second published may 2010 printed in japan by station m co., ltd. Operator’s manual no.32482 mini excavator tb128fr edited and issued by takeuchi mfg. Co., ltd..

Page 215

C-3 california proposition 65 warning diesel engine exhaust and some of its constituents are known to the state of california to cause cancer, birth defects, and other reproductive harm. Battery posts, terminals and related accessories contain lead and lead compounds, chemicals known to the state of...