- DL manuals

- Takeuchi

- Excavators

- TB175W

- Workshop Manual

Takeuchi TB175W Workshop Manual

Summary of TB175W

Page 1

Tb 175 w hydraulic excavator book no. Cw3e001 work shop manual serial no. 17540001~.

Page 2

0-2 foreword this manual is intended for persons who engage in maintenance operations, and explains procedures for dis- assembly and reassembly of the machine, check and maintenance procedures, maintenance reference values, troubleshooting and outline specifications, etc. Please use this manual as a ...

Page 3: I .

0-3 i . General ii . Specifications iii . Machine configuration iv . Hydraulic units v . Troubleshooting vi . Engine.

Page 4

0-4.

Page 5: I .

1-1 i . General.

Page 6

General i-2 contents safety precautions 3 cautions during disassembly and assembly ........................................................................................................ ........................................................................................................ ..........

Page 7

I-3 general safety precautions safety alert symbol this symbol means attention! Be alert! Your safety is involved. The message that follows the symbol contains important information about safety. Read and understand the message to avoid personal injury or death. ■ signal words safety messages appear...

Page 8

I-4 general provide a fire extinguisher and first aid kit • know where a fire extinguisher and first aid kit are located and understand how to use them. • know how to contact emergency assistance and first aid help. Attach a “do not operate” tag severe injury could result if an unauthorized person should...

Page 9

I-5 general always clean the machine • clean the machine before performing mainte- nance. • cover electrical parts when washing the machine. Water on electrical parts could cause short-cir- cuits or malfunctions. Do not use water or steam to wash the battery, sensors, connectors or the operatorʼs se...

Page 10

I-6 general cautions on working on the machine • when performing maintenance on the machine, clean up the foot area and strictly observe the fol- lowing so as not to fall: • do not spill oil or grease. • do not leave tools laying around. • when walking, watch your step. • never jump off the machine....

Page 11

I-7 general be careful with fluids under pressure pressure can be maintained in the hydraulic circuit long after the engine has been shut down. • release all pressure before working on the hy- draulic system. • hydraulic fluid under pressure can penetrate the skin or eyes and cause injury, blindness o...

Page 12

I-8 general avoid battery hazards • batteries contain sulfuric acid which will damage eyes or skin on contact. • if acid contacts eyes, flush immediately with clean water and get prompt medical attention. • if acid is accidentally swallowed, drink large quantities of water or milk and call a physicia...

Page 13

I-9 general • when adding air to a tire, do so from a distance. Use a long hose with self-attaching chuck. Always stand behind tread when adjusting tire pressure. • do not inflate tires with flammable gases or from systems utilizing an alcohol injector. • never cut or weld on a wheel with an inflated t...

Page 14

I-10 general cautions during disassembly and assembly 1. Clean the machine before disassembly opera- tion. 2. Before disassembly, check the machine condi- tions and record them. • model, machine serial number, hourmeter • reason for repairs, repair history • dirtiness of filters • fuel and oil condi...

Page 15

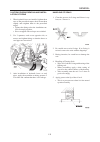

I-11 general cautions during removal and instal- lation of piping 1. When hydraulic hoses are installed, tighten them once to the prescribed torque, then loosen them slightly and retighten them to the prescribed torque. • tighten the fittings after the installation sur- faces fit snugly together. • pi...

Page 16

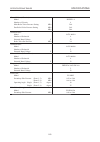

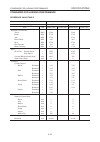

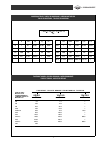

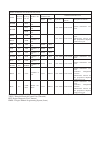

General i-12 tightening torques hydraulic hoses bite type pipe fitting for steel pipe pipe outer diameter (mm) torque n·m ft-lb 8 34.3 ±4.9 25.3 ±3.5 10 41.7 ±2.5 30.7 ±1.7 12 58.8 ±4.9 43.4 ±3.5 15 88.3 ±4.9 65.1 ±3.5 16 93.2 ±4.9 68.7 ±3.5 18 132.4 ±4.9 97.6 ±3.5 22 205.9 ±9.8 151.8 ±7.2 27.2 245....

Page 17

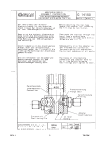

General i-13 joints for piping joints for piping (o-ring seal type) nominal thread diameter (r) torque steel cast steel n·m ft-lb n·m ft-lb 1/8 11.8 ±1.2 8.7 ±0.8 10.8 ±1.1 8.0 ±0.7 1/4 29.4 ±2.9 21.7 ±2.1 24.5 ±2.5 18.1 ±1.7 3/8 53.9 ±5.4 39.8 ±3.9 49 ±4.9 36.2 ±3.5 1/2 88.3 ±8.8 65.1 ±6.4 73.5 ±7....

Page 18

I-14 general bolts and nuts (for iso strength category 10.9) 1. General tightening points (non-lubricated) • all securing points other than the special tightening points. 2. Special tightening points (grease with molyb- denum disulfide applied.) • points where particularly necessary due to function. ...

Page 19: II .

Ii-1 ii . Specifications.

Page 20

Ii-2 specifications in regard to standard values and allowable values the terms used in the items “servicing standards” and “standards for judging performance” have the following meanings. Standard value ............ This indicates the standard value for the new machine at the time of shipping from ...

Page 21

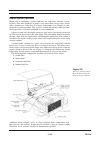

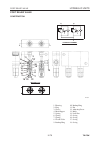

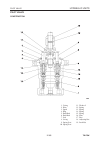

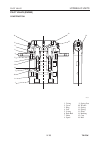

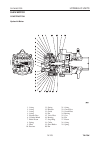

Ii-3 specifications names of components 1. Cab 2. Engine hood 3. Fuel tank 4. Hydraulic tank 5. Hydraulic pump 6. Slew motor 7. Pilot valve 8. Battery 9. Control valve 10. Axle lock cylinder 11. Engine 12. Tire 13. Axle 14. Hub 15. Swing cylinder 16. Undercarriage 17. Dozer blade 18. Steering wheel ...

Page 22

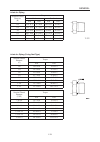

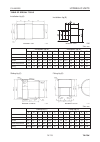

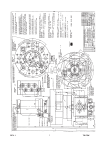

Ii-4 specifications dimensions dimensions 2-piece boom machine dimensions operating range unit: mm 2-piece boom mono-boom a 6260 6320 b 2110 ← c 2925 ← d 1720 ← e 1715 ← f 2100 ← g 2330 ← h 2300 ← j 515 ← k 335 ← l 2505 2620 m 1955 2060 n 2385 2495 p 690 ← q 730 ← r 1815 ← s 600 ← t 4380 4445 u 2895...

Page 23

Ii-5 specifications mono-boom dimensions operating range unit: mm mono-boom a 6945 b 6700 c 4055 d 3220 e 6780 f 4765 g 1330 h 4270 j 335 k 145.

Page 24

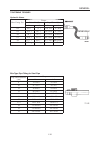

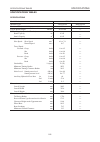

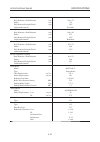

Ii-6 specifications specifications tables specifications specifications tables serial number 17540095 or later machine type 2-pice boom mono-boom machine mass (not including operator) kg 8130 7905 engine rated output kw/min –1 49.3/2300 ← bucket capacity (standard bucket) rated capacity m 3 0.245 ← ...

Page 25

Ii-7 specifications standards for judging performance serial number 17540095 or later machine type 2-pice boom mono-boom working equipment (hoe attachment) boom swing angle: l.H. Degree 80 ← r.H. Degree 50 ← maximum reach mm 7650 6945 maximum reach at grp mm 7430 6700 minimum level cut radius with b...

Page 26

Ii-8 specifications specifications of devides specifications tables serial number 17540095 or later engine model yanmar 4tnv98t-zstbw type 4-cycle, vertical, water-cooled, in-line, 4-cylinder diesel engine number of cylinders – bore × stroke mm 4-98 × 110 total displacement ml 3318 compression ratio...

Page 27

Ii-9 specifications specifications tables control valve (4-section) model kvse31-4 number of circuits 4 main relief valve pressure setting mpa 24.0 port relief valve pressure setting mpa 26.9 mpa 20.6 solenoid valve model 16521-00010 number of solenoids 4 solenoid rated voltage v 12 relief valve set...

Page 28

Ii-10 specifications specifications tables boom cylinder bore diameter × rod diameter mm 120 × 75 stroke mm 725 fully retracted length (pitch) mm 1207 cushion mechanism rod side arm cylinder bore diameter × rod diameter mm 100 × 65 stroke mm 875 fully retracted length (pitch) mm 1327 cushion mechani...

Page 29

Ii-11 specifications tire front tire: qty. 4 size 8.25-20-12pr tire pressure kpa 600 steering system type front setting system operation type hydraulically-operated breake device travel brake type front and rear wheel braking, direct acting hydraulic disk with brake lock parking brake type rear whee...

Page 30

Ii-12 specifications recommended lubricants select the appropriate fuel, lubricant and grease according to the temperature by referring to the table below. • regardless of the specified time, change the oil if it becomes too dirty or degraded. • when refilling, never mix oils of different brands. If a...

Page 31

Ii-13 specifications recommended lubricants diesel fuel standards use the diesel fuel that is compliant with any of the standards below. The table below shows the stan- dards from the various countries. Diesel fuel standards region no. 2-d, no. 1-d , astm d975-94 usa en590:96 eu part type capacity f...

Page 32

Ii-14 specifications standards for judging performance standards for judging performance reference value table serial number 17540095 or later machine type 2-piece boom mono-boom item unit standard values allowable values standard values allowable values hydraulic oil pressure travel mpa 31.00 31.00...

Page 33

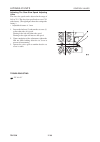

Ii-15 specifications standards for judging performance methods for inspecting perfor- mance hydraulic oil pressure (main relief valve set pressure) travel, boom, arm measuring method • engine : maximum r.P.M. • hydraulic oil temp. : 50~60°c • mount the pressure gauge on the pressure detec- tion port...

Page 34

Ii-16 specifications standards for judging performance dozer blade measuring method • engine : maximum r.P.M. • hydraulic oil temp. : 50~60°c • mount the pressure gauge on the pressure detec- tion port, operate the desired hydraulic circuit and measure the relief pressure. Adjusting method 1. Loosen...

Page 35

Ii-17 specifications standards for judging performance hydraulic oil pressure (slewing relief valve set pressure) measuring method • engine : maximum r.P.M. • hydraulic oil temp. : 50~60°c • mount the pressure gauge on the pressure de- tection port and set a solid obstacle so that the upperstructure...

Page 36

Ii-18 specifications standards for judging performance hydraulic oil pressure (pilot relief valve set pressure) measuring method • engine : maximum r.P.M. • hydraulic oil temp. : 50~60˚c • mount pressure gauge on the pressure detection port and measure the pilot relief pressure. Pressure adjustment ...

Page 37

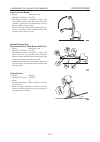

Ii-19 specifications standards for judging performance slew time • engine : maximum r.P.M. • hydraulic oil temp. : 50~60°c • measurement posture : completely retract the arm cylinder, fully extend the bucket cylinder and adjust so that boom foot pin and bucket pin are at matching height. Rest the do...

Page 38

Ii-20 specifications standards for judging performance arm cylinder speed • engine : maximum r.P.M. • hydraulic oil temp. : 50~60°c • measurement posture : completely retract the arm cylinder, fully extend the bucket cylinder, position the arm horizontally and rest the dozer blade on the ground. • t...

Page 39

Ii-21 specifications standards for judging performance adjust cylinder speed • engine : maximum r.P.M. • hydraulic oil temp. : 50~60°c • measurement posture : completely retract the arm cylinder, fully extend the bucket and boom cylinders, position the arm horizontally and rest the dozer blade on th...

Page 40

Ii-22 specifications standards for judging performance.

Page 41: III .

Iii- tb175w iii . Machine configuration.

Page 42

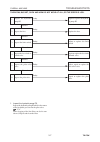

Iii- machine configuration tb175w contents drive system ...........................................................................................................................................................3 slew system ..............................................................................

Page 43

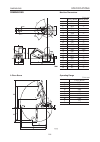

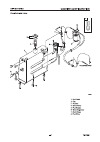

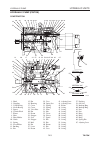

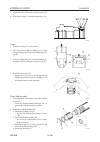

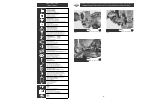

Machine configuration drive system iii- tb175w 1. Engine foot fl 2. Engine foot fr 3. Engine foot rl 4. Engine foot rr 5. Stopper 6. Stopper 7. Cushion rubber 8. Cushion rubber 9. Ground cable 10. Bracket 11. Exhaust pipe 12. Pipe 13. Bracket 14. Silencer 15. Gasket 16. Gasket b: 4 n·m c: 9 n·m d: 5...

Page 44

Machine configuration drive system iii-4 tb175w engine mount 2/2 a: .9 n·m a: 4.9 n·m 1. Bracket 2. Air cleaner 3. Hose 4. Hose 5. Pipe 6. Pipe 7. Pipe 8. Pipe 9. Hose 10. Hose 11. Drain vave 12. Hose 13. Hose 14. Hose 15. Sub tank 16. Bracket 17. Plate 18. Hose 19. Sensor 20. Joint 21. Hose iii-4 :...

Page 45

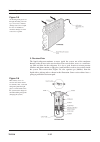

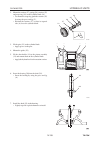

Machine configuration drive system iii-5 tb175w iii-5 radiator and oil cooler 1. Stay 2. Stay 3. Shroud 4. Plate 5. Plate 6. Plate 7. Net 8. Bracket 9. Bracket 10. Guard 11. Cushion rubber 12. Radiator and oil cooler 13. Cushion rubber 14. Guard :&( ; ;.

Page 46

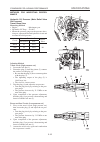

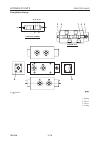

Machine configuration drive system iii- tb175w pump coupling 1. Engine housing 2. Hydraulic pump 3. Hab 4. Gear pump a: supply molybdenum disulfide grease. B: 8 n·m c: 54.9 n·m d: 55.8 n·m travel, bucket, boom[1], arm[2] travel, auxiliary, boom[2], arm[1], swing outrigger, slew, auxiliary steering, ...

Page 48

Machine configuration drive system iii-8 tb175w fuel supply pump a: 0.8 n·m b: “red” mark 1. Box 2. Resistor 3. Switch 4. Relay 5. Wire harness 6. Diode (3a, yellow) 7. Hose 8. Hose 9. Plug 10. Level switch 11. Strainer 12. Pump 13. Float iii-8 c:upon assembling, inspect the continuity using a teste...

Page 52

Iii-12 machine configuration travel system tb175w.

Page 54

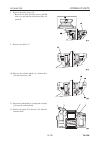

Machine configuration upper frame iii-14 tb175w floor plate 1. Floor plate 2. Floor mat 3. Cover 4. Stage 5. Tube 6. Tube 7. Rubber 8. Cover 9. Cover 10. Pipe w2c401 10 6 5 6 8 8 7 3 2 4 1 9.

Page 55

Machine configuration upper frame iii-15 tb175w heater d: grease with molybdenum disulfide applied. B: 23.5 n·m 1. Cover 2. Plate 3. Selector damper 4. Bracket 5. Panel 6. Cover 7. Wire 8. Wire 9. Filter 10. Cover 11. Hose 12. Hose 13. Heater assembly 14. Switch 15. Valve :&( '(7$,/$ $ % '(7$,/% ' %...

Page 56

Machine configuration upper frame iii-16 tb175w 1. Bracket 2. Box 3. Louver 4. Defroster hose 5. Parking brake switch 6. Site travel switch 7. Axle lock switch 8. Light switch 9. Hazard switch 10. Pilot lamp 11. Pilot lamp 12. Pilot lamp 13. Pilot lamp 14. Creeping travel switch 15. Ornament :&.

Page 57

Machine configuration upper frame iii-17 tb175w 1. Clamp 2. Box 3. Plate 4. Relay 5. Relay 6. Sheet 7. Battery 8. Bracket 9. Cable 10. Battery cable 11. Terminal 12. Clamp 13. Cover 14. Battery switch 15. Ecu 16. Ground cable a: acc relay b: air heat relay c: actuator relay d: main relay e: starter ...

Page 58

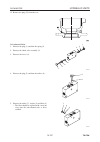

Machine configuration upper frame iii-18 tb175w radio 1. Cover r 2. Cover l 3. Bracket 4. Am/fm radio 5. Speaker r 6. Speaker l :& ; ;.

Page 59

Machine configuration upper frame iii-1 tb175w a: 54. N·m apply thread-locking compound. B: 26.5 n·m apply thread-locking compound. Covers 1. Engine food 2. Engine cover [front] 3. Side cover l 4. Side cover r 5. Front cover 6. Center cover f 7. Center cover t 8. Under cover 17. Lock plate 18. Link ...

Page 60

Machine configuration upper frame iii-20 tb175w.

Page 61

Iii-21 machine configuration control system tb175w control system construction steering unit 1. Washer 2. Telescopic device 3. Woodruff key 4. Nut 5. Spring 6. Shield 7. Covering 8. Spring 9. Shaft 10. Bracket 11. Ring 12. Covering 13. Washer 14. Half bowl 15. Substructure 16. Segment 17. Pin 18. Pi...

Page 62

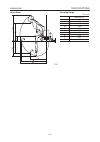

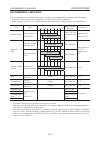

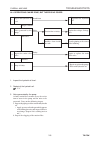

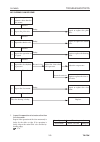

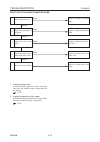

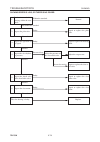

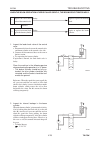

Machine configuration control system iii-22 tb175w tm4 tm6 tm2 tm1 pm1 a2 b2 c2 c1 sh t7 3a2 a2 b2 b1 a1 d pm2 3st 3st bst bsp ast pm5 pm4 pm3 tm3 tm5 ssp 5pa2 4pa3 4pa2 r1 r2 r3 r4 rt rp l1 l2 l3 l4 lt lp a mono boom 5pb2 4pb3 4pb2 w2c504e 11 21 1 13 a 4 5 8 7 9 16 10 24 2 20 :& $6 %5 %5 6 3 1 7 6 ...

Page 63

Machine configuration control system iii-23 tb175w ♦ table of connections ♦ r1 ↔ 4pb2 r2 ↔ 4pa3 r3 ↔ 4pa2 r4 ↔ 4pb3 rp ↔ pm2 rt ↔ tm2 l1 ↔ b2 l2 ↔ 5pb2 l3 ↔ a2 l4 ↔ c2 lp ↔ pm4 lt ↔ tm5 str ↔ 5 stl ↔ 6 stt ↔ t10 stp ↔ n as1 ↔ 4pa1 as2 ↔ 5pa5 ast ↔ tm1 asp ↔ a5 bs2 ↔ 5pb1 1. Right pilot valve 2. Left...

Page 64

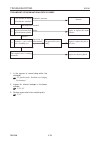

Machine configuration control system iii-24 tb175w control box r 1. Panel cover r 2. Cover 3. Cover 4. Panel cover r 5. Clamp 6. Cluster gauge 7. Starter switch 8. Slew speed switch 9. Light switch 10. Wiper switch 11. Safety lock button 12. Fuse box 13. Fuse box 14. Safety relay 1. Panel cover l 2....

Page 65

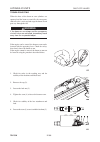

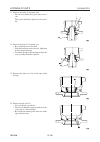

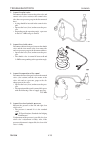

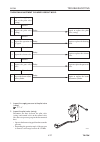

Machine configuration control system iii-25 tb175w dozer blade lever 1. Dozer blade lever 2. Bracket 3. Cover 4. Control cable 5. Yoke 6. Cigarette lighter swing pedal 7. Hinge 1. Bracket 2. Swing pedal 3. Cover 4. Bushing 5. Elbow 6. Pilot valve (swing) w2c508 3 1 7 6 2 4 5 w2c509e 4 5 1 b 3 6 2 vi...

Page 66

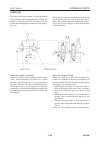

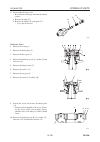

Machine configuration control system iii-26 tb175w pilot valve (brake) 1. Pilot valve (brake) 2. Adapter 3. Elbow 4. Adapter pilot valve (travel) 1. Pilot valve (travel) 2. Bushing 3. Elbow 4. Elbow w2c510 2 1 2 3 3 4 2 w2c511e 2 1 4 3 view a 2, 4 2, 3 a.

Page 67

Iii-27 machine configuration attachments tb175w attachments construction 2-piece boom 1 1. Boom 2. Bushing 3. Dust seal 4. Intermediate boom 5. Plate 6. Protector 7. Clamp 8. Cover 9. Wire harness 10. Rubber 11. Bracket 12. Pin 13. Pin 14. Pin 15. Pin 16. Shim 17. Grease nipple 18. Boom light 19. Bu...

Page 68

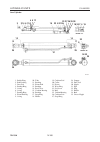

Iii-28 machine configuration attachments tb175w 2-piece boom 2 1. Pipe l 2. Pipe r 3. Clamp 4. Hose 5. Pipe 6. Hose 7. Clamp 8. Adapter 9. Pipe r 10. Pipe l 11. Pipe 12. Cap 13. Grease nipple 14. Hose 15. Hose 16. Hose 17. Cap • keep the clearance at the pin connecting section (excluding the bucket ...

Page 69

Iii-29 machine configuration attachments tb175w mono-boom 1. Boom 2. Bushing 3. Dust seal 4. Cover 5. Plate 6. Protector 7. Pipe r 8. Pipe l 9. Pipe 10. Wire harness 11. Rubber 12. Bracket 13. Clamp 14. Clamp 15. Pin 16. Pin 17. Pin 18. Pin 19. Pin 20. Shim 21. Adapter 22. Grease nipple 23. Boom lig...

Page 70

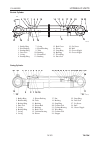

Iii-30 machine configuration attachments tb175w arm 1. Arm 2. Bushing 3. Bushing 4. Dust seal 5. Dust seal 6. Bucket link 7. Bushing 8. Bushing 9. Dust seal 10. Guide link l 11. Guide link r 12. Pin 13. Pin 14. Pin 15. Pin 16. Pin 17. Grease nipple 18. Elbow 19. Elbow 20. O-ring 21. Bucket cylinder ...

Page 71

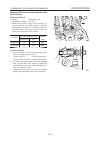

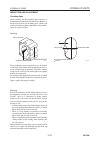

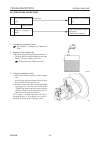

Iii-31 machine configuration attachments tb175w inspection and adjustment adjusting the clearance between the buck- et and arm adjust the clearance between the bucket and arm so that it is 0.5 mm. 1. Clean the bucket mount and the area around it thoroughly. 2. Slide the o-ring (1). 3. Measure the cl...

Page 72

Iii-32 machine configuration attachments tb175w.

Page 73

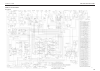

Hydraulic system hydraulic system hydraulic circuit diagram machine configuration iii-33 tb175w :& 2 piece boom.

Page 74

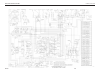

Mono-boom iii-34 tb175w hydraulic system machine configuration :&.

Page 75

Machine configuration hydraulic system iii-35 tb175w construction hydraulic tank 1. Tank 2. Air breather 3. Cover 4. Cover 5. Spring 6. Filter element 7. Check valve 8. Suction filter 9. O-ring 10. O-ring 11. Sight gauge 12. Plug 13. O-ring 14. Check valve 15. Snap ring 16. Adapter 17. Washer 18. Bu...

Page 76

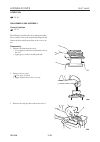

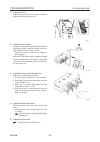

Iii-36 machine configuration hydraulic system tb175w bleeding the air important: after replacing the hydraulic oil, bleed the air from the hydraulic circuit and hy- draulic devices. Failure to do so may damage the hydraulic devices. Hydraulic pump 1. Open the engine hood. 2. Disconnect the drain hos...

Page 77

Electrical system electrical system electrical wiring diagram 1/3 machine configuration iii-37 tb175w :&.

Page 78

Iii-38 tb175w electrical system machine configuration 2/3 :&.

Page 79

Electrical system 3/3 machine configuration iii-39 tb175w :&.

Page 80

Iii-40 tb175w electrical system machine configuration.

Page 81

Machine configuration electrical system iii-41 tb175w 1. Wire harness 2. Short connector 3. Cap 4. Wire harness 5. Diode (3a yellow) 6. Plate 7. Resistor 8. Detector :& a $ $ % % h i j k d e f g 9. Relay 10. Controller 11. Flasher relay 12. Box 13. Buzzer 14. Fuse box 15. Bracket 16. Hour meter a: h...

Page 82

Machine configuration electrical system iii-42 tb175w w3c802 a a b b c b c 17540001~17540134 17540001~17540134 17540135~ 2 17540001~17540094 6 2 5 3 4 9 1 7 10 8 1. Wire harness 2. Fusible link 3. Short connector 4. Diode (3a yellow) 5. Short connector 6. Wire harness 7. Wire harness 8. Diode (3a ye...

Page 83

Machine configuration electrical system iii-43 tb175w :& /(9(5/,1. /(9(56:,7&+$1'/,0,76:,7&+.

Page 84

Iii-44 machine configuration electrical system tb175w :&.

Page 85

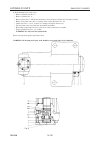

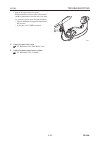

Machine configuration air conditioner system iii-45 tb175w air conditioner system construction compressor assembly 1. Bracket 2. Guard 3. Shaft 4. Collar 5. Compressor 6. Pulley 7. Hose 8. Hose 9. Bushing 10. Valve 11. Adaptor 12. Bushing 13. Elbow 14. V-belt a: allow a clearance. B: press on the ce...

Page 86

Machine configuration air conditioner system iii-46 tb175w air conditioner 1/2 1. Bracket 2. Cover 3. Condenser 4. Fun 5. Dryer 6. Bracket 7. Hose 8. Hose 9. Switch 10. Connector :& ; ;.

Page 87

Machine configuration air conditioner system iii-47 tb175w air conditioner 2/2 1. Hose 2. Guard 3. Wire harness 4. Air conditioner unit 5. Wire 6. Wire harness 7. Relay 8. Valve 9. Tube 10. Cover 11. Panel 12. Hose 13. Hose 14. Hose 15. Louver 16. Adaptor 17. Louver :&.

Page 88

Machine configuration air conditioner system iii-48 tb175w condenser, air conditioner unit, panel assembly 1. Adaptor 2. Evaporato 3. Heater core 4. Filter 5. Blowier motor 6. O-ring 7. O-ring 8. Expansion valve 9. Thermo stat 10. Air condiitioner switch 11. Knob 12. Cable control converter 13. Cabl...

Page 89: Overview of System Operation

Iii-48 tb175w overview of system operation • truck and heavy equipment systems • air conditioner-system operation • heater system operation • environmental effects on system operation • chapter review truck and heavy equipment systems a variety of hvac systems are in use today, some old and some new...

Page 90

Iii-49 tb175w air conditioner—system operation by law, all trucks have a heater/defroster as part of the standard equipment. When there is a reason to add air conditioning, there are options to meet different needs. The avail- able space in the cab, operating environment, and owner preference can al...

Page 91

Iii-50 tb175w system operation the following ac components are discussed in detail in this section: 1. Compressor/clutch assembly 2. Condenser 3. Receiver-drier 4. Expansion valve 5. Evaporator coil 1. Compressor/clutch assembly the compressor/clutch assembly is the heart of the system. When the clu...

Page 92

Iii-51 tb175w air conditioner—system operation the clutch is mounted on the shaft of the compressor and is engaged by electromag- netic action. Part of the clutch assembly is an electromagnetic wire coil. The coil is energized through a thermostat that senses the temperature in the evaporator coil. ...

Page 93

Iii-52 tb175w system operation 3. Receiver-drier the liquid refrigerant continues to move inside the system, out of the condenser through a tube or hose to the receiver-drier. The receiver-drier serves as a small stor- age tank and filter for the refrigerant. It is also a good location to mount pres...

Page 94

Iii-53 tb175w air conditioner—system operation 4. Expansion valve (refrigerant metering device) when refrigerant moves from the receiver-drier, it travels through another high pres- sure hose to a metering device at the inlet of the evaporator coil. The metering device can be an expansion valve, an ...

Page 95

Iii-54 tb175w system operation note: moisture in the air (humidity) condenses on the fins of the evaporator as water droplets which drain out of the evapora- tor through a drain hose. This action dehumidifies the air in the cab as part of system operation, and contributes to opera- tor comfort. Cab ...

Page 96

Iii-55 tb175w heater system operation heater and air conditioner systems both have the same basic function of mov- ing heat. They take advantage of nature’s laws where heat energy always moves from a warmer to a cooler area. In a heater system there is no “change of state” involved in system operati...

Page 97

Iii-56 tb175w 1. Heater core heater cores are like small radiators. The fin and tube construction is de - signed to route coolant flow for the best possible heat energy transfer from coolant to cab air. Hoses from and to the engine are connected to the core with clamps. The core outlet may be larger...

Page 98

Iii-57 tb175w • on a cold day the temperature can drop below zero. The engine may run cooler so the engine coolant is cooler when it circulates through the heater. The heat in the cab moves out of the cab faster (remember heat always moves to a cooler area until both are the same tempera- ture—natur...

Page 99: Without Gauges

Iii-58 tb175w inspection and maintenance- without gauges • discussion of inspection & maintenance survey results • visual inspection - system off • electrical system inspection • performance inspection - engine running • heater system inspection • preventive maintenance worksheet • chapter review di...

Page 100

Iii-59 tb175w visual inspection - system off your observations and the corrective measures you take may be different depend- ing on circumstances. The following inspection procedures are explained in more detail below: 1. Observe the system 2. Inspect parts 3. Check hoses and fittings 4. Check for r...

Page 101

Iii-60 tb175w a. Condenser – is it free of leaves, bugs, bird feathers or mud? The con- denser must be relatively clean to work well as a heat exchanger. How you clean the condenser depends on where it is mounted. The condenser fin comb, air hose and nozzle, or soap and water may be used. Where poss...

Page 102

Iii-61 tb175w c. Drive belt – the drive belt should be tight and in good condition. Use a belt tension gauge to check tension (120 pounds maximum). With experi- ence, you can feel belt tension by twisting the belt. Try feeling belt tension after using the gauge, when you know the tension is correct....

Page 103

Iii-62 tb175w you can feel for oil at the bottom of all connections (see figure 7-4) if the system is not too hot. Of course, a few minutes with an electronic leak de- tector is the best way to check for leaks. Keep in mind that pressure is dif- ferent in a system at rest, so small leaks may be hard...

Page 104

Iii-63 tb175w b. Turn the ac system on – this will power the thermostat and clutch. If it does not come on, use the ac mode switch to check the leads to the switch. You should be able to hear a “click” from the ther- mostat and hear the clutch drive plate “snap” against the clutch pul- ley. You can ...

Page 105

Iii-64 tb175w performance inspection – engine running the purpose of visual and electrical inspection is to detect obvious problems and assure ac system function for an accurate performance inspection. If you do the performance inspection first, you could be mislead. Problem areas discovered during ...

Page 106

Iii-65 tb175w these readings at the vents will be higher and temperature swing slow- er and not as obvious. Also blower speed will cause the temperature, levels to read higher (high air speed) or lower (low air speed) at the same thermostat setting. When you measure air temperature, an elec- tronic ...

Page 107

Iii-66 tb175w note: a roof mounted condenser or ac unit assembly often in- cludes a roof mounted receiver-drier (and sight glass) close to the condenser. Heater system inspection a heater system inspection is really a combination engine cooling system and heater inspection. All heater/cooling system...

Page 108

Iii-67 tb175w b. Warm up engine – next, let the engine warm up to normal operat- ing temperature and set both fan and temperature on high. Feel both heater supply and return hoses. If there is a noticeable difference in their temperature, it indicates a low flow of coolant through the heater core (a...

Page 109

Iii-68 tb175w chapter review the purpose of these brief inspection procedures is for vehicle system mainte- nance and to determine if further, more detailed service is required. The uses of a manifold gauge set, system troubleshooting, recovery, flushing, evacuating and charging are explained in the...

Page 110

Iii-69 tb175w.

Page 111: Troubleshooting

Iii-70 tb175w troubleshooting & service procedures • troubleshooting overview • understanding system function • a troubleshooting example • manifold gauge set installation • troubleshooting by manifold gauge set readings • review of frequent problem areas • conclusion can you fix an air conditioner ...

Page 112

Iii-71 tb175w experienced troubleshooters talk to the operator if they can, then personally verify the symptoms of the problem whenever possible. They attempt quick fixes on the basis of their knowledge of common system problems and causes when appropriate. They know where components are located, an...

Page 113

Iii-72 tb175w when you turn on the air conditioner at the control panel (1), the thermostat (2), is supposed to sense a warm temperature at the evaporator. A circuit in the ther- mostat should close, allowing current to flow through the thermostat to the com - pressor clutch field coil (3). When thi...

Page 114

Iii-73 tb175w use your knowledge and experience. Ask yourself what could have caused a lack of cooling in that rig! Did the compressor drive belt break? Did a pressure switch or relief valve cutout the compressor because of high or low system pressure? Does the switch or valve in this type of system...

Page 115

Iii-74 tb175w • have you had other service problems in the last few months? Answer: no. • (if the answer was yes, you should ask—when? Where? What was fixed or replaced?). • finally, ask the operator if he or she has a wiring diagram for the system. Now let’s look at the information you have gathere...

Page 116

Iii-75 tb175w if your ac and heater visual, electrical and leak inspections don’t turn up any problems, save time by hooking up the manifold gauge set before you make the performance test. If you find a leak and can correct it easily by tightening a con - nection, do so. But if too much refrigerant ...

Page 117

Iii-76 tb175w 1. Purging air from gauge set hoses environmental regulations require that all service hoses have a shutoff valve within 12 inches of the service end. These valves are required to ensure only a minimal amount of refrigerant is lost to the atmosphere. R-12 gauge set hoses have a valve n...

Page 118

Iii-77 tb175w before adding refrigerant to the system you should study the sight glass while the engine is running and the air conditioner is on. Even if you found a leak during the system inspection and corrected it, you have no way of knowing how much refrigerant has leaked. You will not be able t...

Page 119

Iii-78 tb175w 3. Add refrigerant until the gauges read in the normal range and the sight glass appears clear. The sight glass may not be clear for a moment just before or after the clutch cycles on and off but should generally be clear. Gauge readings will fluctuate as the compres - sor cycles on an...

Page 120

Iii-79 tb175w start the engine and set to a fast idle of 1200 to 1500 rpm. Turn on the air conditioner. After a quick in-cab performance test of control function, blow- er speeds and air flow, set the ac system controls to maximum cooling and blower speed on high. All windows must be closed. If cab ...

Page 121

Iii-80 tb175w repair procedure: check for leaks with your leak detector. If you find a leak at a connection, tighten it then add refrigerant as necessary. If a component or line is leaking (defective), recover all refrigerant from the system. Replace the de- fective part and then check the compresso...

Page 122

Iii-81 tb175w after finding a leak, recover all refrigerant from the system and repair the leak. Check the compressor and replace any refrigeration oil lost due to leakage. Evacu- ate and recharge the system with refrigerant, then check ac operation and performance. Air and/or moisture in the system...

Page 123

Iii-82 tb175w excessive air and/or moisture in the system tip: there may be occasional bubbles in the sight glass. Air from vents in the cab is only slightly cool. Cause: system contains excessive air and/or moisture. Repair procedure: test for leaks, recover refrigerant from the system and repair t...

Page 124

Iii-83 tb175w cause: an expansion valve malfunction could mean the valve is stuck in the closed position, the filter screen is clogged (block type expansion valves do not have filter screens), moisture in the system has frozen at the expansion valve orifice, or the sensing bulb is not oper - ating. ...

Page 125

Iii-84 tb175w note: if the expansion valve tests did not cause the low pressure gauge needle to rise and drop, and if the oth- er procedures described did not correct the problem, the expansion valve is defective. You must recover all refrigerant from the system again, and replace the expansion valv...

Page 126

Iii-85 tb175w 3. If the low side gauge shows a drop again, the valve is not stuck. Clean the surfaces of the evaporator outlet and the capillary coil or bulb. Make sure the coil or bulb is securely fastened to the evaporator outlet and covered with insulation material. Operate the system and check p...

Page 127

Iii-86 tb175w repair procedure: after you locate the defective component containing the restriction, recover all of the refrigerant. Replace the defective component and the receiver-drier. Evacu- ate and recharge the system with refrigerant, then check ac operation and performance. Compressor malfun...

Page 128

Iii-87 tb175w if you find particles of desiccant in the compressor, remove and replace it and the receiver-drier. Before do- ing so, back flush other system components (except the expansion valve) using a flushing kit. If there are stem type valves and you isolate the compressor, the rest of the sys...

Page 129

Iii-88 tb175w cause: the condenser is not functioning correctly or there may be an overcharge of refrigerant inside the system. An- other possibility is lack of (ram) air flow through the condenser fins during testing. Engine cooling system component malfunction can cause high pressure by blocking a...

Page 130

Iii-89 tb175w thermostatic switch malfunction tip: the low side gauge needle may fluctuate in a very nar - row range compared to a normal range. The compressor clutch may be cycling on and off more frequently than it should. The low side gauge needle may fluctuate in an above normal range as the clu...

Page 131

Iii-90 tb175w note: see the thermostat section in chapter 10 . Fan clutch, radiator shutter, condenser, compressor, and the new- er air and water valve control systems are covered in chapter 10 . Review of frequent problem areas in hvac systems a limited number of things can go wrong. Moving parts o...

Page 132

Iii-91 tb175w 2. Condenser condensers get dirty and the dirt reduces heat movement by insulating the condenser. The fittings come loose or break from stress if the condenser or connecting hoses are not secured properly to keep the effects of vibration at a minimum. Heat transfer efficiency and press...

Page 133

Iii-92 tb175w technicians frequently add refrigerant to a system, replacing refrigerant seepage through system connections or fittings. If the system has been main - tained regularly (every three to six months), adding a small amount of re- frigerant may result in normal system function. However, th...

Page 134

Machine configuration iii-93 tb175w.

Page 135: IV .

Iv-1 tb175w iv . Hydraulic units.

Page 136

Hydraulic units iv-2 tb175w contents hydraulic pump (piston) ....................................................................................................................................... 3 hydraulic pump (gear) ..................................................................................

Page 137

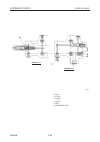

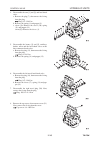

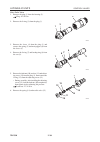

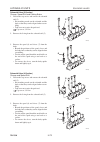

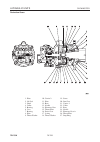

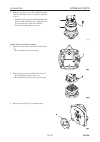

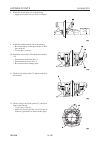

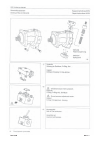

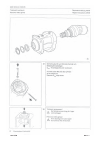

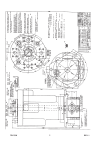

Hydraulic units hydraulic pump iv-3 tb175w hydraulic pump (piston) construction 1. Shaft 2. Coupling 3. Collar bearing 4. Needle bearing 5. Spacer 6. Cylinder block 7. Piston 8. Shoe 9. Shoe holder 10. Guide 11. Spring 12. Swash plate 13. Bushing 14. Pin 15. Pin 16. Housing 17. Cover 18. Cover 19. V...

Page 138

Hydraulic units hydraulic pump iv-4 tb175w operation piston pump this pump is a variable displacement piston pump with a single cylinder block, which discharges two equal volumes. Ten pistons (2) are installed in the cylinder block (1), and the end surface is in contact with the valve plate (3). The...

Page 139

Hydraulic units hydraulic pump iv-5 tb175w when the discharge pressure from pump p1 or p2 exceeds the setting value, the average pressure of the discharges from pumps p1 and p2, (p1 + p2)/2, acts on the piston (9). Then, the spool (6) is pushed and moved to the right until this operating pressure ba...

Page 140

Hydraulic units hydraulic pump iv-6 tb175w disassembly and assembly general cautions • carry out disassembly and assembly operations in a clean place and provide clean containers to place the disassembled parts in. • before disassembly, clean around the ports and remove the paint from each joint usi...

Page 141

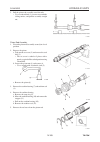

Hydraulic units hydraulic pump iv-7 tb175w 5. Remove the valve plate. 6. Disassemble the cylinder block. A. Remove the cylinder block from the shaft. B. Remove the guide (3), the springs (4), the holder (5), and the pistons (6) from the cylinder block (7). • disassemble the inside of the cylinder bl...

Page 142

Hydraulic units hydraulic pump iv-8 tb175w 9. Remove the shaft while tapping its rear end with a plastic hammer. 10. Remove the cap screws and remove the cover. 11. Remove the two springs [inside, outside]. 12. Remove the spring seat. 13. Remove the cap screws and remove the cover. 14. Remove the le...

Page 143

Hydraulic units hydraulic pump iv-9 tb175w 16. Remove the plug and the pin. 17. Remove the piston. • screw the bolt into the screw hole (m4) at the end face of the piston, and grab the bolt to pull out the piston. 18. Loosen the lock nut (3) and remove the adjusting screw (2). • record the length of...

Page 144

Hydraulic units hydraulic pump iv-10 tb175w assembly 1. Install the adjusting screw (2). • fix the adjusting screw (2) to the same length as previously assembled using the lock nut (3). Lock nut: 98 n·m 2. Install the piston. 3. Install the drain plug (1). 4. Install the oil seal. 5. Install the sha...

Page 145

Hydraulic units hydraulic pump iv-11 tb175w 6. Fit the pin r and l on the swash plate. 7. Install the swash plate in the housing. • insert the bushing into the swash plate. • apply grease on the sliding surfaces of the swash plate, pin r and pin l. 8. Mount the pin and tighten the plug. Plug: 29.4 n...

Page 146

Hydraulic units hydraulic pump iv-12 tb175w 10. Mount the sleeve and spool. 11. Install the lever on the housing. 12. Install the cover and install the cap screws. Cap screw: 29.4 n·m 13. Install the spring seat. • apply grease to the spherical part of the spring seat. 14. Install the two springs [i...

Page 147

Hydraulic units hydraulic pump iv-13 tb175w 16. Install the cylinder block matching the spline of the shaft. • apply grease to the sliding surfaces of the piston shoes and the plate. 17. Apply grease to the rear of the valve plate and install it to the cover, matching the knock hole. 18. Install a l...

Page 148

Hydraulic units hydraulic pump iv-14 tb175w parts judgment criteria treatment • a clearance s of 0.05 mm or more between the piston and the cylinder block • occurrence of scratches, scoring, abnormal wear, etc. On sliding parts piston and cylinder block assembly slack of the piston shoe shaft and oi...

Page 149

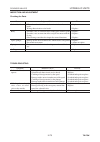

Hydraulic units hydraulic pump iv-15 tb175w troubleshooting symptom probable causes remedy • remove the dirt or eliminate the pinched condition of the hose. • retighten each joint. • replace the hydraulic oil with oil of the proper viscosity. • center the pump with respect to the engine. • investiga...

Page 150

Hydraulic units hydraulic pump iv-16 tb175w.

Page 151

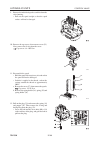

Hydraulic units hydraulic pump iv-17 tb175w hydraulic pump (gear) construction 1. Flange 2. Housing 3. Drive gear 4. Driven gear 5. Bushing 6. Adapter plate 7. Rear cover 8. Drive gear 9. Driven gear 10. Bushing 11. Bushing 12. Bushing 13. Gasket 14. Gasket 15. Buckup ring 16. Gasket 17. Gasket 18. ...

Page 152

Hydraulic units hydraulic pump iv-18 tb175w disassembly and assembly general cautions • carry out disassembly and assembly operations in a clean place and provide clean containers to place the disassembled parts in. • before disassembly, clean around the ports and remove the paint from each joint us...

Page 153

Hydraulic units hydraulic pump iv-19 tb175w 4. Remove the gasket (2) from the flange (1). 5. Remove the backup ring (5) and gasket (6) from the flange (1). 6. Remove the bushing (7), the bushing (8), the drive gear (9), and the driven gear (10) from the housing. • be careful to keep the bushings sep...

Page 154

Hydraulic units hydraulic pump iv-20 tb175w 9. Remove the rear cover (17). 10. Remove the gasket (12) from the adapter plate (11). 11. Remove the bushing (13), bushing (14), the drive gear (15), and the driven gear (16). • be careful to keep the bushings separated and in their original places. • be ...

Page 155

Hydraulic units hydraulic pump iv-21 tb175w inspection and adjustment checking parts after checking the disassembled parts for dirt or discoloration, clean them with diesel fuel. However, do not let diesel fuel get on rubber parts. Check each part for the following points and if there is any trouble...

Page 156

Hydraulic units hydraulic pump iv-22 tb175w other likely causes are as follows. • excessive load due to damage to the relief valve. • cavitaion or aeration. • hydraulic oil temperature is too high. • hydraulic oil is deteriorated. • hydraulic oil’s viscosity is low. If it is necessary to replace the...

Page 157

Hydraulic units hydraulic pump iv-23 tb175w measuring the discharge volume after completing the test operation, measure the discharge volume. 1. Connect a tester (1) to the discharge side of the pump (2). • there should be no mistakes made in the tester’s pipe installation. 2. Open the tester’s load...

Page 158

Hydraulic units hydraulic pump iv-24 tb175w troubleshooting symptom probable causes remedy pump won’t discharge. • direction of rotation is reversed. • oil level in the tank is low. • suction side pipe or suction filter is clogged. • hydraulic oil’s viscosity is too high. • speed is low. • run the p...

Page 159

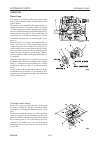

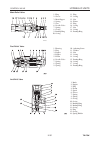

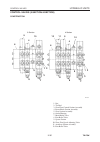

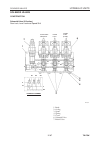

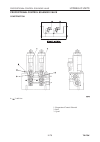

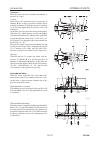

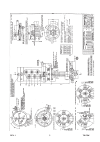

Hydraulic units control valve iv-25 tb175w control valve (mono-block) construction 1. Right travel section 2. Bucket section 3. Boom [1] section 4. Arm [2] section 5. Left travel section 6. Auxiliary section 7. Boom [2] section 8. Arm [1] section 9. Swing section w2d200e a a b c b d e f g h k j c z ...

Page 160

Hydraulic units control valve iv-26 tb175w 1. Cover 2. Spool end 3. Holder 4. Spring 5. Spring 6. O-ring 7. Cover 8. O-ring 9. Shuttle 10. Spring 11. O-ring 12. Plug 13. Poppet 14. O-ring 15. Plug 16. Spring.

Page 161

Hydraulic units control valve iv-27 tb175w 1. Housing 2. O-ring 3. Spring holder 4. Spring 5. Spool end 6. Port relief valve 7. O-ring 8. Plug 9. Spring 10. Poppet.

Page 162

Hydraulic units control valve iv-28 tb175w 1. O-ring 2. Plug 3. Spring 4. Poppet 5. Spring 6. Poppet 7. Sleeve 8. Port relief valve 9. O-ring 10. Plug 11. Backup ring 12. O-ring 13. Spring 14. Poppet 15. Sleeve 16. Plug 17. O-ring 18. Spring 19. Poppet 20. Anti-drift valve 21. Spacer 22. Spring 23. ...

Page 163

Hydraulic units control valve iv-29 tb175w 1. Port relief valve 2. Plug 3. O-ring 4. Spring 5. Poppet 6. Port relief valve 7. Poppet 8. Spring 9. O-ring 10. Backup ring 11. Plug 12. O-ring 13. Plug 14. Sleeve 15. Spring 16. Poppet.

Page 164

Hydraulic units control valve iv-30 tb175w 1. Plug 2. O-ring 3. Poppet 4. Spring 5. Plug 6. Main relief valve w2d205e 6 2 1 3 4 5 section “j-j” section “k-k”.

Page 165

Hydraulic units control valve iv-31 tb175w main relief valve port relief valve anti-drift valve 1. Plug 2. Sleeve 3. Main poppet 4. Spring 5. Seat 6. Needle valve 7. Spring 8. O-ring 9. Backup ring 10. O-ring 11. Plug 12. O-ring 13. Nut 14. Piston 15. Plug 16. O-ring 17. Nut 18. O-ring 19. Backup ri...

Page 166

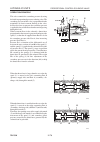

Hydraulic units control valve iv-32 tb175w operation this control valve has a structure incorporating a 4- section and a 5-section part. When all spools are in the neutral positions center bypass passage the oil supplied from the pump p1 flows through the center bypass passage (1) and the tank passa...

Page 167

Hydraulic units control valve iv-33 tb175w independent operation travel spool switching switching the spool (1) on the right travel lever closes the center bypass passage (2), and the oil supplied from the pump p1 passes through the center bypass passage (2) and bridge passage (3), and flows into th...

Page 168

Hydraulic units control valve iv-34 tb175w boom spool switching 1. When the spool is in the neutral position the poppet (1) of the anti-drift valve mounted on the cylinder head of the boom [1] is seated by the pressure from the port 4b3. This pressure is applied through the passage (2), spool (3), p...

Page 169

Hydraulic units control valve iv-35 tb175w 3. Lower switching the spool (6) of the boom [1] by pressuriz- ing the port 4pa3 closes the center bypass passage (7). The oil supplied from the pump p1 passes through the parallel passages (8), load check valve (9), passage (10), and the head of the spool ...

Page 170

Hydraulic units control valve iv-36 tb175w arm spool switching 1. Dump switching the spool (1) of the arm [1] by pressurizing the port 5pb2 closes the center bypass passage (2). The oil supplied from the pump p2 passes through the center bypass passage (2), tandem check valve (3), passage (4), and t...

Page 171

Hydraulic units control valve iv-37 tb175w switching the spool (1) of the arm [1] by pressurizing the port 5pa2 closes the center bypass passage (2). The oil supplied from the pump p2 passes through the center bypass passage (2), tandem check valve (3), passage (4), and the head of the spool (1) of ...

Page 172

Hydraulic units control valve iv-38 tb175w anti-drift valve this valve is installed in the boom cylinder head line to prevent the oil from leaking at the boom cylinder head line so that the boom will not fall down sponta- neously when the boom spool is in the neutral posi- tion. 1. Neutral the press...

Page 173

Hydraulic units control valve iv-39 tb175w main relief valve relieving operation when the pressure in the circuit is low with respect to the set value, the relief valve is maintained at equilib- rium. Hydraulic oil from the pump passes through the orifice from chamber b and arrives at the spring cha...

Page 174

Hydraulic units control valve iv-40 tb175w port relief valve relieving operation when the pressure in the circuit is low with respect to the set value, the relief valve is maintained at equilib- rium. Pressure from the pump passes from chamber b to the orifice in piston (4), then reaches chamber c a...

Page 175

Hydraulic units control valve iv-41 tb175w suction operation when the cylinder is operated at high speed, and the supply of oil cannot keep up with it, creating a vacuum in chamber b, oil is supplied from the tank side, preventing the occurrence of cavitation. When the pressure in chamber b is lower...

Page 176

Hydraulic units control valve iv-42 tb175w disassembly and assembly general cautions • since all parts in control valves are precision machined, carry out disassembly and assembly operations in a clean place. • before disassembly, clean the outside surfaces around the valves. • clean all disassemble...

Page 177

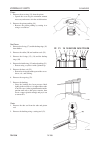

Hydraulic units control valve iv-43 tb175w l3d226 7 8 9 10 11 12 1 9 8 7 l3d227 15 14 13 15 14 13 l3d228 20 19 1817 16 4. Disassemble the arm [1] and [2] and load check valve. A. Remove the plug (7), then remove the o-ring from the plug. Plug: 167~196 n·m b. Remove the spring (8) and poppet (9). C. ...

Page 178

Hydraulic units control valve iv-44 tb175w l2d232 27 28 29 28 l3d230 l3d231 23 9. Remove the individual spool assemblies from the valve housing. • pull out the spool straight so that the spool surface will not be damaged. 10. Remove the cap screws, then remove cover (23). Next, remove the o-ring fro...

Page 179

Hydraulic units control valve iv-45 tb175w anti-drift valve 1. Remove the plug (1), then remove the o-ring from the plug. Plug: 69~78 n·m 2. Remove the piston (2), spool (3) and spring (4). 3. Remove the plug (5), then remove the o-ring from the plug. Plug: 69~78 n·m 4. Remove the sleeve (6). Then r...

Page 180

Hydraulic units control valve iv-46 tb175w main relief valve 1. Remove the sleeve (2), spring (3) and main pop- pet (4) from the plug assembly (1). • the pilot seat (5) is caulked by the tip of the plug and cannot be disassembled. 2. Remove the o-ring (6) and backup ring (7) from the pilot seat (5)....

Page 181

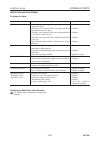

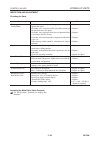

Hydraulic units control valve iv-47 tb175w inspection and adjustment checking the parts adjusting the main relief valve pressure “ii. Specifications, standards for judging per- formance” parts judgment criteria treatment • replace • replace • replace • replace • replace housing • scratches, rust, co...

Page 182

Hydraulic units control valve iv-48 tb175w troubleshooting the following items are a list of all the problems that might occur individually, but in actual practice, 2 or 3 of these problems might occur simultaneously to compound the trouble. It is therefore desirable to proceed so that the causes ca...

Page 183

Hydraulic units control valve iv-49 tb175w • check if it isn't just the cylinder’s natu- ral drop when the cylinder is held. If the problem is in the cylinder, disassemble and repair it. • replace the spool or replace the valve block assembly. • manually operated : check if there is something interf...

Page 184

Hydraulic units control valve iv-50 tb175w.

Page 185

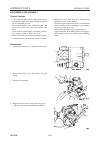

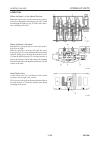

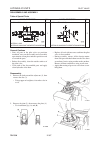

Hydraulic units control valves iv-51 tb175w control valves (3-section/4-section) construction 1. Nut 2. Tie rod 3. Slew flow control section assembly 4. Dozer blade section assembly 5. Slew section assembly 6. Outlet housing 7. Main relief valve 8. Port relief valve 9. Spacer section 10. Slow slew s...

Page 186

Hydraulic units control valves iv-52 tb175w slew flow control section 1. Screw 2. Sleeve 3. Pin 4. O-ring 5. Piston 6. Spring holder 7. Spring 8. Cover 9. O-ring 10. Cover 11. O-ring 12. Cap screw 13. O-ring dozer blade section 1. Cover 2. Screw 3. Spring holder 4. Spring 5. Cover 6. Load check valv...

Page 187

Hydraulic units control valves iv-53 tb175w outlet housing 1. Filter 2. Orifice spacer section 1. Plug 2. Adjusting screw 3. Nut 4. O-ring 5. O-ring 6. O-ring l3d253 1 2 l3d254 6 3 4 1 2 5 1. Cover 2. Screw 3. Spring holder 4. Spring 5. Cover 6. Load check valve 7. Spring 8. O-ring 9. O-ring auxilia...

Page 188

Hydraulic units control valves iv-54 tb175w 11. Lock nut 12. O-ring 13. Backup ring 14. O-ring 15. Backup ring 16. O-ring 17. O-ring 18. Wave washer 19. O-ring 9. Lock nut 10. Spring 11. Spring 12. O-ring 13. Backup ring 14. O-ring 15. O-ring 16. O-ring main relief valve 1. Housing 2. Plug 3. Sleeve...

Page 189

Hydraulic units control valves iv-55 tb175w operation when the spool is in the neutral position when the control valve spool is not moving, hydrau- lic oil flows through the center bypass passage (1) and then through the tank passage (t) in the arrow direc- tion, returning to the tank. When the spoo...

Page 190

Hydraulic units control valves iv-56 tb175w slew flow control function this function switches the quantity of hydraulic oil flowing to the slew motor to change the slewing speed between normal and slow. It also keeps the flow to the motor steady even when the supply pressure changes during slow spee...

Page 191

Hydraulic units control valves iv-57 tb175w main relief valve a main relief valve is mounted between the pump circuit and tank circuit of each inlet housing and serves to maintain the circuit pressure at the set value. When the relief valve is not operating when the pressure in the circuit is low wi...

Page 192

Hydraulic units control valves iv-58 tb175w port relief valve a port relief valve is located between the actuator port and the tank circuit and when abnormal pressure due to shock pressure or external pressure generated when the actuator port is suddenly blocked by the spool or when there is an over...

Page 193

Hydraulic units control valves iv-59 tb175w suction operation when the cylinder is operated at high speed, and the supply of oil cannot keep up with it, creating a vacuum in chamber b, oil is supplied from the tank side, preventing the occurrence of cavitation. When the pressure in chamber b is lowe...

Page 194

Hydraulic units control valves iv-60 tb175w disassembly and assembly general cautions • since all parts in control valves are precision machined, carry out disassembly and assembly operations in a clean place. • before disassembly, clean the outside surfaces around the valves. • clean all disassembl...

Page 195

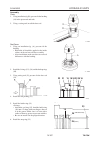

Hydraulic units control valves iv-61 tb175w 4. Remove the load check valve. • remove the spring (3), then remove the poppet (4). Manually operated section 1. Remove the cap screws (5), the cover (6) and the spool assembly (7). Cap screw: 7.3 n·m 2. Loosen the screw (8) from the spool assembly (7). S...

Page 196

Hydraulic units control valves iv-62 tb175w 4. Remove the seal holder (12), then remove the backup ring (13) and o-ring (14). 5. Remove the screws on the spool yoke end side of the section, then remove the seal holder, backup ring and o-ring. Screw: 2.5 n·m pilot operated section 1. Take out the cap...

Page 197

Hydraulic units control valves iv-63 tb175w 3. Take out the screw (17) and remove the spring holder (18), spring (19) and spring holder (18). Screw: 4.9 n·m 4. Take out the cap screws (5) and remove the cover (21). 5. Remove the o-ring (16) from the cover (21). Cap screw: 7.3 n·m disassembling the s...

Page 198

Hydraulic units control valves iv-64 tb175w main relief valve 1. Remove the plug (1) from the housing (2). Plug: 49~54 n·m 2. Remove the o-ring (3) from the plug (1). 3. Remove the sleeve (4) from the plug (1) and remove the spring (5) and main poppet (6) from the sleeve (4). 4. Remove the o-ring (7...

Page 199

Hydraulic units control valves iv-65 tb175w inspection and adjustment checking the parts adjusting the main relief valve pressure “ii. Specifications, standards for judging per- formance” parts judgment criteria treatment • replace • replace • replace • replace • replace housing, section body • scra...

Page 200

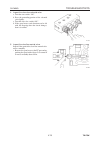

Hydraulic units control valves iv-66 tb175w l3d255 84.4 a 1 2 adjusting the slow slew speed adjusting valve the slow slew speed can be adjusted in the range of 38% to 71%. The slow slew speed has been set to 71% at the factory. (the right figure shows the setting at the factory.) • adjustable distan...

Page 201

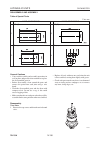

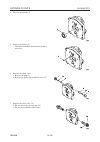

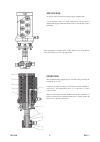

Hydraulic units solenoid valves iv-67 tb175w solenoid valves construction solenoid valve (3-section) ram lock, lever lock and speed shift 1. Body 2. O-ring 3. Spool 4. Spring 5. Cover 6. Solenoid valve 7. Relief valve w2h100e 7 1 3 t t a4 a4 p p p1 p1 a3 a3 a2 a2 a1 a1 4 2 5 6 hydraulic symbol outri...

Page 202

Hydraulic units solenoid valves iv-68 tb175w solenoid valve (3-section) change, speed shift and parking brake 1. Spring 2. Sleeve 3. Body 4. Rod 5. Plate 6. Solenoid valve 7. Spool 8. Stopper 9. Plug 10. Washer 11. O-ring 12. O-ring hydraulic symbol w2h101e c b a a p t b c parking brake swing/adjust...

Page 203

Hydraulic units solenoid valves iv-69 tb175w solenoid valve (4-section) change and speed shift 1. Spring 2. Sleeve 3. Body 4. Rod 5. Plate 6. Solenoid valve 7. Spool 8. Stopper 9. Plug 10. Washer 11. O-ring 12. O-ring hydraulic symbol w2h102e c d b a a p t b c d swing/adjust change speed shift (low)...

Page 204

Hydraulic units solenoid valves iv-70 tb175w operation solenoid valve when current is not flowing oil at port p is blocked by the spool (1). Also, since port a and port t are connected, the pressure in the pilot circuit downstream becomes the same as the tank pressure. When current is flowing a magn...

Page 205

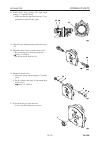

Hydraulic units solenoid valves iv-71 tb175w disassembly and assembly general cautions • carry out disassembly and assembly operations in a clean place and place disassembled parts in clean containers. • before disassembly, clean thoroughly around the ports and remove paint or thread lock, etc. From...

Page 206

Hydraulic units solenoid valves iv-72 tb175w solenoid valve (3-section) change, speed shift and parking brake 1. Loosen the cap screws and remove the solenoid coil (5). • put matching marks on the solenoid and the body so that they can be aligned when assem- bling. • take care not to miss the push r...

Page 207

Hydraulic units solenoid valves iv-73 tb175w • replace • replace • overhaul and repair or replace. • overhaul and repair or replace. • overhaul and repair or replace. • overhaul and repair or replace. Inspection and adjustment checking the parts parts • replace • replace troubleshooting symptom sole...

Page 208

Hydraulic units solenoid valves iv-74 tb175w.

Page 209

Hydraulic units proportional control solenoid valve iv-75 tb175w proportional control solenoid valve construction a: 7 ± 0.5 n·m 1. Proportional control solenoid 2. Bolt 3. Spool.

Page 210

Hydraulic units proportional control solenoid valve iv-76 tb175w t9h201 s 1 2 4 a1 a p t b1 s=a1-b1 fk paxs paxs fk fs fks fs fks t9h202 1 5 p a t t9h203 1 6 p a t operation principle this valve controls the secondary pressure by using the built-in proportional pressure reducing valve. The secondary...

Page 211

Hydraulic units proportional control solenoid valve iv-77 tb175w iv-76-1 disassembly and assembly general cautions • carry out disassembly and assembly operations in a clean place and place disassembled parts in clean containers. • before disassembly, clean thoroughly around the ports and remove pai...

Page 212

Hydraulic units proportional control solenoid valve iv-78 tb175w inspection and adjustment checking the parts part judgment criteria treatment • when the solenoid is burned, short-circuited, or has a wire break • wiring short-circuit or wire break • scratches, rust, or corrosion at the sliding parts...

Page 213

Hydraulic units selector valve iv-77 tb175w selector valve construction pilot change 1. Body 2. Plug 3. Connector 4. Spool 5. Spring 6. Retainer 7. O-ring 8. O-ring w2h300 pl t p hydraulic symbol a 3 7 1 4 6 5 8 2 a b pl t p a a: 26.5 n·m b: 70.6 n·m.

Page 214

Hydraulic units selector valve iv-78 tb175w swing/adjust change 1. Spring 2. Cover 3. Cover 4. O-ring ) ) 22 * * 6 6 2 2 x x 9 0!- hydraulic symbol a a 1 2 3 4 4 section “x-x” pp t p 1 b 1 a 1 b 2 a 2 p 2 a: 9.8 n·m.

Page 215

Hydraulic units port relief valve iv-79 tb175w port relief valve construction 1. Housing 2. Plug 3. Sleeve 4. Main poppet 5. Spring 6. Spring 7. Spring 8. Needle valve 9. Backup ring 10. Backup ring 11. Pin 12. Adjusting screw 13. Body 14. Lock nut 15. O-ring 16. O-ring 17. O-ring 18. O-ring w2h400e...

Page 216

Hydraulic units port relief valve iv-80 tb175w operation “iv-58~59” disassembly and assembly genaral cautions “iv-60” following is an explanation of the relief valve disas- sembly procedure. Follow the procedure used to disassemble the relief valve in reverse order when reassembling it. Disassembly ...

Page 217

Hydraulic units shut-off valves iv-81 tb175w 1. Body 2. Relief valve 3. Plug 4. Screw 5. Plug 6. Plug 7. Lock nut 8. Adjusting screw 9. Spring 10. Spool shut-off valves construction.

Page 218

Hydraulic units shut-off valves iv-82 tb175w operation the isolation valve prevents the boom or arm being raised from falling. If the hydraulic hose breaks, the valve blocks and isolates the hydraulic oil flowing to the cylinder head. When the boom or arm is raised, the pressure oil from the hydraul...

Page 219

Hydraulic units shut-off valves iv-83 tb175w inspection and adjustment never adjust the adjuster screws on the isolation valve. Otherwise, the valve may not work properly, or the boom or arm may fall. Iv-8 3.

Page 220: Warning

Hydraulic units shut-off valves iv-84 tb175w iv-8 4 trouble shooting when the hose of the boom or arm cylinders are ruptured and the boom or arm falls, the emergency shut-off valve is activated and stops the boom or arm part way through the fall. If the boom or arm drops and the emergency shut-off v...

Page 221

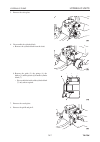

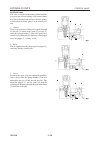

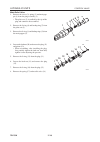

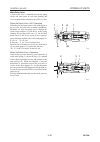

Hydraulic units pilot valve iv-97 tb175w pilot valve construction 1. Casing 2. Plate 3. Spool 4. Plug 5. Push rod 6. Push rod 7. Seal 8. O-ring 9. Spring seat 10. Spring seat 11. Washer 2 12. Spring 13. Spring 14. Spring 15. Spring 16. Joint 17. Disc 18. Adjusting nut 19. Lock nut iv- 85.

Page 222

Hydraulic units pilot valve iv-87 tb175w operation the pilot valve casing contains a vertical shaft hole with a reducing valve incorporated into it. When the handle is tilted, the push rod and spring seat are pushed down changing the secondary pressure spring’s pressure. The casing also contains an ...

Page 223

Hydraulic units pilot valve iv-98 tb175w disassembly and assembly table of special tools general cautions • since all parts in the pilot valve are precision machined, carry out disassembly and reassembly operations in a clean place and take special care not to scratch the parts. • before disassembly...

Page 224

Hydraulic units pilot valve iv-99 tb175w 3. Take out the plug (5) then remove the push rod (6) from the plug (5). • if the plug is difficult to remove, use (–) screw driver to remove it. • be careful not to let the plug fly out from the spring’s force. 4. Remove the o-ring (7) and seal (8) from the ...

Page 225

Hydraulic units pilot valve iv-100 tb175w b. Remove the spring seat (14), spring (15) and washer 2 (16) from the spool (17). Assembly 1. Assemble the reducing valve (12). A. Install the washer 2 (16), spring (15) and spring seat (14) on the spool (17). B. Push in the spring sheet (14) to contract th...

Page 226

Hydraulic units pilot valve iv-101 tb175w 2. Install the spring (13) and reducing valve (12). • install them in the positions they were in be- fore disassembly. 3. Install the o-ring (7) and seal (8) in the plug (5). 4. Install the push rod (9) in the plug (5). • apply hydraulic oil to the push rod....

Page 227

Hydraulic units pilot valve iv-102 tb175w 6. Install the disc (2), the adjust nut (1) and the lock nut. • tighten the adjust nut to the point where all 4 push rods are uniformly making contact. • during tightening, the disc should not be moved. Adjust nut: 68.6 ± 4.9 n·m 7. Apply grease to the conta...

Page 228

Hydraulic units pilot valve iv-94 tb175w • replace inspection and adjustment checking the parts t n e m ta e r t ai r et ir c t n e m g d u j st r a p o-ring ⎯⎯ seal seal washer ⎯⎯ ⎯⎯ • wear on sliding portions is 10 μ m or greater compared to non- sliding portions • scratches on sliding portions • ...

Page 229

Hydraulic units pilot valve iv-10 tb175w pilot valve (swing) construction 1. Casing 2. Cover 3. Plug 4. Seal 5. O-ring 6. Push rod 7. Shim 8. Spool 9. Spring seat 10. Washer 11. Spring 12. Spring 13. Shaft 14. Bushing 15. Cam 16. Ball l3d350 16 6 4 3 2 5 9 12 11 7 10 8 1 13 15 14 iv 3 iv-9 3.

Page 230

Hydraulic units pilot valve iv-104 tb175w operation “iv-86” disassembly and assembly general cautions “iv-87” the following describes the disassembly procedure. For assembly, refer to the construction diagram and follow the disassembly procedure in the reverse or- der. Disassembly 1. Remove the boot...

Page 231

Hydraulic units pilot valve iv-105 tb175w 4. Loosen the cap screws and remove the cover (2). • the cover and plug will rise from the surface if the rebound spring is too strong, so loosen the cap screws alternately so that the cover is flat. • mark the cover and casing so that they can be reassemble...

Page 232

Hydraulic units pilot valve iv-9 6 tb175w • replace inspection and adjustment checking the parts t n e m ta e r t ai r et ir c t n e m g d u j st r a p o-ring ⎯⎯ seal seal washer ⎯⎯ ⎯⎯ • wear on sliding portions is 10 μ m or greater compared to non- sliding portions • scratches on sliding portions •...

Page 233

Hydraulic units pilot valve iv-95 tb175w secondary pressure doesn’t rise • primary pressure is insufficient • spring is damaged or permanently deformed • the clearance between the spool and casing is abnormally large • there is looseness in the handle • keep the primary pressure • replace the spring...

Page 234

Hydraulic units pilot valve iv-106 tb175w iv-98.

Page 235

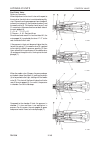

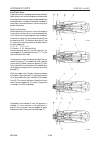

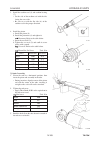

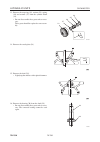

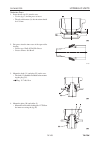

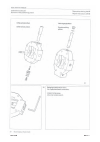

Hydraulic units cylinders iv-99 tb175w cylinders construction boom cylinder 1. Buffer ring 2. Rod packing 3. Dust seal 4. O-ring 5. Backup ring 6. O-ring 7. Backup ring 8. Piston packing 9. O-ring 10. Tube 11. Bushing 12. Piston rod 13. Bushing 14. Rod cover 15. Cushion bearing 16. Bushing 17. Snap ...

Page 236

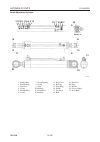

Hydraulic units cylinders iv-100 tb175w arm cylinder 1. Buffer ring 2. Rod packing 3. Dust seal 4. Backup ring 5. O-ring 6. O-ring 7. Backup ring 8. Piston packing 9. O-ring 10. Tube 11. Bushing 12. Piston rod 13. Bushing 14. Rod cover 15. Cushion bearing 16. Bushing 17. Snap ring 18. Holder 19. Cus...

Page 237

Hydraulic units cylinders iv-101 tb175w bucket cylinder 1. Buffer ring 2. Rod packing 3. Backup ring 4. Dust seal 5. O-ring 6. Backup ring 7. O-ring 8. O-ring 1. Buffer ring 2. Rod packing 3. Backup ring 4. Dust seal 5. O-ring 6. Backup ring swing cylinder 7. O-ring 8. Piston packing 9. Tube 10. Bus...

Page 238

Hydraulic units cylinders iv-102 tb175w boom adjustment cylinder 1. Buffer ring 2. Rod packing 3. Dust seal 4. O-ring 5. Backup ring 6. O-ring 7. Piston packing 8. O-ring 9. Tube 10. Bushing 11. Piston rod 12. Bushing 13. Rod cover 14. Bushing 15. Snap ring 16. Piston 17. Set screw 18. Ball 19. Dust...

Page 239

Hydraulic units cylinders iv-103 tb175w operation hydraulic oil flowing alternately in and out of the oil outlet and inlet on both sides (head and rod sides) of the piston acts on the piston and its force causes the piston to move back and forth. In cylinders equipped with a cushion mechanism, the s...

Page 240

Hydraulic units cylinders iv-104 tb175w disassembly and assembly special tools see the table of special tools at the back of this section for the jigs and tools used for disassembly and assem- bly. General cautions • carry out disassembly and assembly operations in a clean place and provide clean co...

Page 241

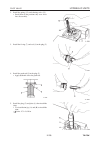

Hydraulic units cylinders iv-105 tb175w 5. Pull the piston rod assembly out of the tube. • use a wooden block (1) so as not to scratch the sliding surface, and pull the assembly straight out. Piston rod assembly 1. Fasten the piston rod assembly securely in a level position. 2. Remove the piston. A....

Page 242

Hydraulic units cylinders iv-106 tb175w piston 1. Remove the wear ring (13) from the piston. • spread the wear ring the minimum amount necessary and remove it in the axial direction. 2. Remove the piston packing (14). • remove the piston packing by cutting it or using a screwdriver. Rod cover 1. Rem...

Page 243

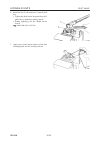

Hydraulic units cylinders iv-107 tb175w assembly clevis 1. Using installation jig (b), pressure fit the bushing (44) in the piston rod and tube. 2. Using a setting tool, install the dust seal. Rod cover 1. Using an installation jig (a), pressure fit the bushing. • hydraulic oil should be applied to ...

Page 244

Hydraulic units cylinders iv-108 tb175w 7. Install the collar (30) and the cushion seals (29). 8. Install the o-ring (17) and the backup rings (18). Piston 1. Install the o-ring (27) on the piston. 2. Cover the piston with the sliding jig (c), then, using the fitting jig (d), insert the slipper ring...

Page 245

Hydraulic units cylinders iv-109 tb175w 3. Install the cushion seal (8) and cushion bearing (7). • set the side of the cushion seal with the slits facing the screw side. • be sure to set with the flat side (a) of the cushion seal in the proper direction. 4. Install the piston. A. Install the piston ...

Page 246

Hydraulic units cylinders iv-110 tb175w measuring the bend a. Support the portion of the rod with the same diameter at both ends on v-blocks. B. Set a dial gauge at the center between the two blocks. C. Rotate the rod and take a reading of the maximum and minimum runout indicated by the dial gauge. ...

Page 247

Hydraulic units cylinders iv-111 tb175w inspection after assembly no load operation test 1. Place the cylinder in a horizontal position with no load. 2. Apply gentle pressure alternately to the ports at both ends, operating the piston rod 5 or 6 times. 3. Make sure there is no abnormality in the ope...

Page 248

Hydraulic units cylinders iv-112 tb175w • remove the foreign matter. • replace the affected parts. Troubleshooting symptom probable causes remedy oil leaks from piston rod sliding surface (an oil ring forms on the piston and this enlarges and drips off). • foreign matter is caught in the inner diame...

Page 249

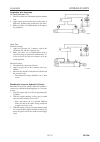

Hydraulic units cylinders iv-113 tb175w table of special tools installation jig (b) installation jig (a) material: ss41 material: ss41 unit: mm installation jig (a) installation jig (b) a 79 69 59 59 79 boom arm bucket boom adjustment swing b 75 65 55 55 75 c 43 43 32 32 43 d 12 12 12 12 12 e 75 75 ...

Page 250

Hydraulic units cylinders iv-114 tb175w corrective jig (e) unit: mm boom arm bucket boom adjustment swing a 133 113 98 103 133 b 120 100 85 90 120 material: stkm13c.

Page 251

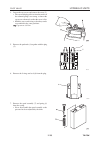

Hydraulic units dozer blade cylinder iv-115 tb175w dozer blade cylinder construction 1. Dust seal 2. Joint 3. Guide band 4. O-ring 5. Backup ring 6. Pipe 7. Piston rod 8. Rod cover 9. Piston 10. Nut 11. Screw 12. Bearing 13. Ring w2d409 12 13 11 1 2 8 5 4 3 7 6 9 10

Page 252

Hydraulic units dozer blade cylinder iv-116 tb175w.

Page 253

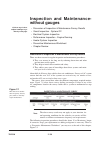

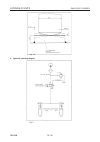

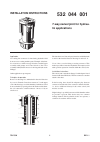

Hydraulic units ram lock cylinder iv-117 tb175w ram lock cylinder contents 1. Functional description 2. Hydraulic connection plan 3. Start-up and bleeding 4. Fault-finding 5. Repair instructions 1. Functional description designed as plunger cylinder with integrated non-return valve. The non-return v...

Page 254

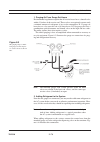

Hydraulic units ram lock cylinder iv-118 tb175w figs 1-6 2. Hydraulic switching diagram fig. 2.

Page 255

Hydraulic units ram lock cylinder iv-119 tb175w 3. Start-up and bleeding at start-up, all components must be filled with oil and bled of air. This is done as follows: • remove lock bolts from cylinder (pos. 10). • press rod down as far as bearing. Warning! Regardless of cylinder type, the check valv...

Page 256

Hydraulic units ram lock cylinder iv-120 tb175w fig. 3 b) demounting the non-return valve • remove cylinder bolts, pos. 9. • remove cylinder, pos. 4. • remove piston, pos. 5. The piston should move freely in the non-return valve and in the cylinder. • remove non-return valve, pos. 3, from the inside...

Page 257

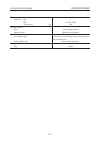

Hydraulic units ram lock cylinder iv-121 tb175w torque: pos. Ma (nm) 9 10 11 12 16 180 10 40 seal set if part in pos. O-ring ∗∗ d if part in pos. O-ring ∗ d back-up ring ∗ d o-ring ∗ d o-ring ∗ d lock bolt lock bolt lock bolt cylinder bolt o-ring d grooved ring d scraper ring d piston cylinder non-r...

Page 258

Hydraulic units ram lock cylinder iv-122 tb175w.

Page 259

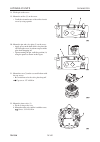

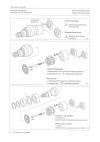

Hydraulic units slew motor iv-123 tb175w 1. O-ring 2. O-ring 3. O-ring 4. O-ring 5. Friction disc 6. Cylinder block 7. Brake piston 8. Spring 9. Shaft 10. Retainer slew motor construction hydraulic motor 11. Spring 12. Retainer 13. Guide 14. Pin 15. Valve plate 16. Bearing 17. Snap ring 18. Collar 1...

Page 260

Hydraulic units slew motor iv-124 tb175w 1. Plate 2. Oil seal 3. Shaft 4. Collar 5. Bearing 6. Case 7. Bearing 8. Plate 9. Thrust washer reduction gears 10. Carrier 2 11. Plate 12. Race 13. Needle 14. Planetary gear 15. Thrust plate 16. Drive gear 17. O-ring 18. Thrust washer 19. Screw 20. Sun gear ...

Page 261

Hydraulic units slew motor iv-125 tb175w brake valve 1. Cover 2. Poppet 3. O-ring 4. Spring 5. Housing 6. Poppet 7. Seat 8. Seat 9. Spring 10. Plug 11. O-ring 12. Piston 13. O-ring 14. Backup ring 15. Guide 16. O-ring 17. O-ring 18. Backup ring 19. O-ring 20. Backup ring 21. Body 22. Check valve ass...

Page 262

Hydraulic units slew motor iv-126 tb175w operation hydraulic motor 9 pistons (2) are fitted in the cylinder block (1) and there is a valve plate (3) with two half moon ports, b and c in the end. Also, the cylinder block (1) rotates freely and is joined to the shaft (4) via the spline. On the other b...

Page 263

Hydraulic units slew motor iv-127 tb175w operation 2 since this relief valve has a shockless mechanism, it operates in 2 steps. 1st step when relief valve operation starts, the pressure in chamber b (p1) is kept at a pressure which is lower than that in chamber c while the pressure in chamber a (p) ...

Page 264

Hydraulic units slew motor iv-128 tb175w the rebound pressure also pushes the check valve (1) to the left, which is the opposite direction of pushing at the time of braking. The flux control valve built in the check valve (2) (that is now on the lower pressure side) releases the oil in the damper ch...

Page 265

Hydraulic units slew motor iv-129 tb175w powers the spring force and moves the brake piston (5) to the right. This generates a clearance between the center discs (1) and friction discs (2) to release the parking brake. When the motor stops, the spool re- turns to the neutral position to close the pa...

Page 266

Hydraulic units slew motor iv-130 tb175w disassembly and assembly table of special tools jig (a) name, dimensions name, dimensions jig (c) 1 3 jig (b) jig (d) 2 4 unit: mm general cautions • carry out disassembly and assembly operations in a clean place and provide clean containers to place the disa...

Page 267

Hydraulic units slew motor iv-131 tb175w 2. Remove the cap screws to disassemble the motor into the hydraulic motor (1) and the reduction gear (2). • mark the mating position on both the hydraulic motor and the reduction gear so that they can be mated correctly when reassembling. • fix the hydraulic...

Page 268

Hydraulic units slew motor iv-132 tb175w 4. Remove the bearing (4). 5. Remove the orifice (5). • the orifice is caulked. Do not remove it unless necessary. 6. Remove the check valve. A. Remove the plug (9). B. Remove the spring (10) and check valve (11). 7. Remove the relief valve (12). • do not loo...

Page 269

Hydraulic units slew motor iv-133 tb175w 8. Remove the brake piston (15). • blow the air from the brake release port pb with care such that the brake piston does not protrude. 9. Remove the collar (17). 10. Remove the cylinder block (18), friction discs (19) and center discs (20). 11. Remove the sho...

Page 270

Hydraulic units slew motor iv-134 tb175w 13. Remove the snap ring (24), retainer (25), spring (26) and retainer (27) from the cylinder block (18). • do not disassemble these parts unless neces- sary. These parts should be replaced as one assem- bly. 14. Remove the swash plate (28). 15. Remove the sh...

Page 271

Hydraulic units slew motor iv-135 tb175w 17. Disassemble the timer valve. • be careful not to damage or deform the contact surface. A. Remove the plug (31). B. Remove the spring (32) and spool (33). • use a pair of tweezers. Reduction gears 1. Remove the o-ring (1). 2. Remove the thrust plate (2). 3...

Page 272

Hydraulic units slew motor iv-136 tb175w 11. Remove the collar (9) and plate (10). • do not disassemble these parts unless neces- sary. These parts should be replaced as one assem- bly. 12. Remove the shaft (11) from the case. • be careful not to miss the shaft. • if the shaft will not come out easi...

Page 273

Hydraulic units slew motor iv-137 tb175w 15. Remove the plug (25) from the case. Anti-rebound valve 1. Remove the plug (1) and then the spring (2). 2. Remove the check valve assembly (3). 3. Remove the sleeve (4). 4. Remove the plug (5) and then the orifice (6). 5. Remove the orifice (7), washer (8)...

Page 274

Hydraulic units slew motor iv-138 tb175w assembly anti-rebound valve 1. Mount the filter (9), washer (8) and orifice (7) on the body. • use a new filter. Orifice: 4.9 n·m 2. Mount the orifice (6) on the body. Orifice: 2.45 n·m 3. Fit the o-ring to the plug (5), and mount them on the body. Plug: 61.8...

Page 275

Hydraulic units slew motor iv-139 tb175w 2. Mount the retainer (27), spring (26), retainer (25) and snap ring (24) on the cylinder block (18). • to mount the snap ring, push the retainer (25) by using the press and jig (c). • position the retainer (27) so that its tapered side (a) faces the cylinder...

Page 276

Hydraulic units slew motor iv-140 tb175w 8. Install the switch plate (28) in the housing. • apply grease to the side (a) of the swash plate. 9. Install the cylinder block (18) in the housing. • be careful not to let the shoe holder or other parts drop off. • use the press to insert. 10. Mount the ce...

Page 277

Hydraulic units slew motor iv-141 tb175w 13. Install twelve large springs (16), eight small springs (17), and the o-ring. • make sure that the eight small springs (17) are positioned as shown in this figure. 14. Fit the o-rings and backup rings to the relief valve (12). 15. Mount the relief valve as...

Page 278