- DL manuals

- Takeuchi

- Compact Excavator

- TB28FR

- Operator's Manual

Takeuchi TB28FR Operator's Manual

Summary of TB28FR

Page 1

Opera tor’s manual read and understand these instructions. Failure to do so can cause injury or death. Compact excavator tb53fr book no. Aj1e007 serial no. 15810675~ warning.

Page 2: Safety Alert Symbol

Safety alert symbol this symbol means attention! Be alert! Your safety is involved. The message that follows the symbol contains important information about safety. Read and understand the message to avoid personal injury or death. ■ it is the owner or employer’s responsibility to fully instruct eac...

Page 3

1 it is your responsibility to observe all pertinent laws and regulations and to follow the manufacturer’s instructions on machine operation, inspection and maintenance. Virtually all accidents occur as the result of a failure to observe basic safety rules and precautions. An accident can often be a...

Page 4

2 foreword this manual describes operation, inspection and maintenance of the machine, as well as safety instructions to be heeded during these operations. If you have any questions about the machine, please contact a takeuchi sales or service outlet. ■ manual storage compartment a compartment for s...

Page 5

3 ■ front, rear, ieft and right this manual refers the front, rear, left and right of the machine as seen when sitting in the operator’s seat with the dozer blade visible to the front. ■ designated operations use this machine primarily for the following operations: ¡ excavating ¡ digging ditches ¡ d...

Page 6

4.

Page 7: Contents

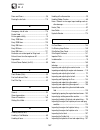

5 introduction .................................... 2 machine description ...................... 3 safety .............................................. 7 controls .........................................35 operation .......................................61 transport .................................

Page 8

6.

Page 9: Safety

7 general precautions .................................... 8 preparing precautions ............................... 12 starting precautions .................................. 14 operating precautions ............................... 16 stopping precautions ................................ 23 transport...

Page 10

8 safety general precautions observe all safety rules ¡ operation, inspection and maintenance of this machine must be performed only by a trained and qualified person. ¡ all rules, regulations, precautions and safety procedures must be understood and followed when performing operation, inspection an...

Page 11

9 safety general precautions use a signal person and flagman know and use the hand signals required for particular jobs and make sure who has the responsibility for signaling. ¡ all personnel must fully understand all the signals. ¡ the operator shall respond to signals only from the appointed signa...

Page 12

10 safety general precautions avoid fire and explosion hazards keep flames away from fuel, hydraulic fluid, oil, grease and antifreeze. Fuel is particularly flammable and dangerous. ¡ when handling these combustible materials, keep lit cigarettes, matches, lighters and other flames or sources of fla...

Page 13

11 safety general precautions exhaust fumes from the engine can kill ¡ do not operate the engine in an enclosed area without adequate ventilation. ¡ if natural ventilation is poor, install ventilators, fans, exhaust extension pipes or other artificial venting devices. Handling asbestos dust inhaling...

Page 14

12 safety preparing precautions know the working area before starting operation, know the working area to ensure safety. ¡ check the topography and ground condition of the working area, or the structure of the building when working indoors, and take the necessary safety measures in dangerous spots. ...

Page 15

13 safety preparing precautions perform inspection and maintenance daily failure to notice or repair machine irregularities or damage can lead to accidents. ¡ before operating, perform the prescribed inspections and make repairs immediately should any irregularities be found. ¡ if a failure that cau...

Page 16

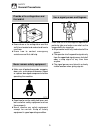

14 safety starting precautions maintain three point contact when mounting and dismounting ¡ do not jump on or off the machine. Never attempt to mount or dismount a moving machine. ¡ when mounting and dismounting the cab, first open the door fully to the locked position and check that it does not mov...

Page 17

15 safety starting precautions starting with jumper cables use jumper cables only in the recommended manner. Improper use of jumper cables can result in battery explosion or unexpected machine motion. Refer to the section titled “if the battery goes dead” for proper instructions. After starting the ...

Page 18

16 safety operating precautions check for safety in the surrounding area before starting ¡ understand the machine limitations. ¡ use a signal person where clearances are close or your vision is obstructed. ¡ never allow anyone to enter the slewing (swing) radius and machine path. ¡ signal your inten...

Page 19

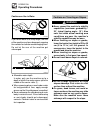

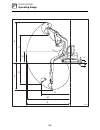

17 safety e4a040 operating precautions travel safety ¡ travel with the dozer blade up, the hoe attachment folded as shown on the diagram, and the bucket raised 30 to 40 cm (12 to 16 in.) from the ground. ¡ do not slew (swing) while traveling. If you must operate the hoe attachment while traveling, o...

Page 20

18 safety operating precautions cautions on traveling on slopes when traveling on slopes or grades, be careful that the machine does not tip (roll) over or slide. ¡ never exceed the machine’s stability capabilities (maximum gradeability –30 ° , lateral tipping angle –15 ° ). Also note that when actu...

Page 21

19 safety operating precautions ¡ maintain the maximum possible distance from power lines and never violate the minimum clearance. ¡ always contact the nearest electric utility and determine jointly what specific precautions must be taken to insure safety. ¡ consider all lines to be power lines and ...

Page 22

20 safety operating precautions watch out for hazardous working conditions ¡ never undercut a high bank. Be particularly alert for the possibility of a cave-in. ¡ do not operate in places where there is a danger of falling rocks. ¡ keep machine well back from the edge of an excavation. Avoid undercu...

Page 23

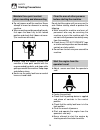

21 safety operating precautions never slew (swing) sideways with excessive weights the machine can tip over more easily in the lateral direction than in the longitudinal direction. ¡ do not slew (swing) sideways with excessive weight at the front. In particular do not slew sideways on slopes. ¡ the ...

Page 24

22 safety operating precautions danger of flying objects this machine is not equipped with protective guards to protect the operator from flying objects. Do not use the machine in places where there are risks of the operator being hit by flying objects. Cautions on towing when towing, selecting the ...

Page 25

23 safety stopping precautions park safely ¡ park the machine on firm, level ground and apply the parking device. ¡ when parking on streets, use barriers, caution signs, lights, etc., so that the machine can easily be seen even at night to avoid collision with other vehicles. ¡ before leaving the ma...

Page 26

24 safety transporting precautions load and unload the machine safely the machine may roll or tip over or fall while loading or unloading it. Take the following precautions: ¡ select a firm, level surface and keep sufficient distance from road shoulders. ¡ use loading ramps of adequate strength and ...

Page 27

25 safety maintenance precautions attach a “do not operate” tag severe injury could result if an unauthorized person should start the engine or touch controls during inspection or maintenance. ¡ stop the engine and remove the key before performing maintenance. ¡ attach a “do not operate” tag to the ...

Page 28

26 safety maintenance precautions prepare the work area ¡ select a firm, level work area. Make sure there is adequate light and, if indoors, ventilation. ¡ clear obstacles and dangerous objects. Eliminate slippery areas. Always clean the machine ¡ clean the machine before performing maintenance. ¡ s...

Page 29

27 safety maintenance precautions securely block the machine or any component that may fall ¡ before performing maintenance or repairs under the machine, set all working equipment against the ground or in the lowermost position. ¡ securely block the tracks. ¡ if you must work beneath the raised mach...

Page 30

28 safety maintenance precautions use caution when fueling ¡ do not smoke or permit open flames while fueling or near fueling operations. ¡ never remove the fuel cap or refuel with the engine running or hot. Never allow fuel to spill on hot machine components. ¡ maintain control of the fuel filler n...

Page 31

29 safety maintenance precautions release all pressure before working on the hydraulic system oil may spurt out if caps or filters are removed or pipes disconnected before releasing the pressure in the hydraulic system. ¡ gradually press the air breather button to relieve tank pressure. ¡ move all t...

Page 32

30 safety maintenance precautions be careful with grease under pressure the track adjuster contains highly pressurized grease. If the tension is adjusted without following the prescribed procedure, the grease discharge valve may fly off, resulting in injury. ¡ do not loosen the grease nipple. ¡ loos...

Page 33

31 safety maintenance precautions have a takeuchi service agent repair welding cracks or other damage ask a takeuchi service agent to repair any welding problems which are detected. If not feasible, make sure the welding is done by a qualified person in a properly equipped workplace. Checks after ma...

Page 34

32 safety safety signs (decals) the following safety signs (decals) have been placed on your machine in the areas indicated. They are intended for the personal safety of you, and those working with you. Please take this manual, walk around your machine and note the content and location of these safe...

Page 35: Warning

33 safety safety signs (decals) 1. No.03593-06500 2. No.03593-07400 3. No.03793-37300 4. No.03593-13700 6. No.05693-21980 5. No.03993-51406 d o n ot e n t e r i n t o sw i n g i n g a r e a warning warning 03793-37300 if the platform is raised or lowered while the engine is running, the machine may ...

Page 36: Warning

34 safety safety signs (decals) 8. No.03593-47010 warning 03593-47010 this excavator must not be used as a crane 9. No.03393-75040 caution 03393-75040 do not use ether usage of ether for starting purposes may cause internal engine damage. 10. No.03393-75050 caution 03393-75050 hydraulic tank must re...

Page 37: Controls

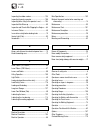

35 names of components .............................. 36 doors and covers ...................................... 38 seat and seat belt ...................................... 43 instrument cluster ..................................... 45 switches ..................................................... ...

Page 38

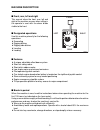

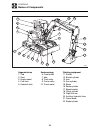

36 controls names of components upperstructure 1. Cab 2. Seat 3. Engine hood 4. Fuel tank 5. Hydraulic tank undercarriage 6. Crawler belt 7. Idler 8. Track roller 9. Carrier roller 10. Travel motor working equipment 11. Bucket 12. Bucket cylinder 13. Arm 14. Arm cylinder 15. Boom 16. Boom cylinder 1...

Page 39

37 controls names of components 1. Instrument cluster 2. Starter switch 3. Light switch 4. Horn switch 5. Travel speed switch 6. Wiper switch (cab) 7. Safety lock lever 8. Attachment interference switch 9. Throttle lever 10. Left operating lever 11. Right operating lever 12. Fuse box 13. Offset peda...

Page 40

38 controls doors and covers starter key the starter key is used not only to start and stop the engine, but also to lock and unlock the following places: ¡ fuel filler cap ¡ engine hood ¡ cab door ¡ tool case ¡ manual storage compartment lock and unlock 1. Insert and turn the starter key. Opening 1....

Page 41

39 controls doors and covers front window (cab) warning ¡ ¡ ¡ ¡ ¡ grasp the handles firmly with both hands when opening and closing the front window. Your head or hands may get caught if they slip. ¡ ¡ ¡ ¡ ¡ if you open the front window, be sure to lock it in place with the lock pins on the left and...

Page 42

40 controls lower front window (cab) removing 1. Open the front window and stow it in the ceiling. 2. Grasp the protruding parts (4) on the left and right with your fingers and slowly lift the lower front window off. 3. Hold the glass firmly, place the lower front window through the guides (5) at th...

Page 43

41 controls doors and covers engine hood warning ¡ ¡ ¡ ¡ ¡ before opening the engine hood, be sure to stop the engine. If your hands or tools should get caught in the fan or fan belt while the engine is running they may be severed. ¡ ¡ ¡ ¡ ¡ be sure to secure the engine hood or cover when opening it...

Page 44

42 controls doors and covers fuel filler cap warning ¡ ¡ ¡ ¡ ¡ do not smoke or permit open flames while fueling or near fueling operations. ¡ ¡ ¡ ¡ ¡ supply fuel in a well ventilated place and with the engine stopped. ¡ ¡ ¡ ¡ ¡ clean up spilled fuel immediately. ¡ ¡ ¡ ¡ ¡ do not fill the fuel tank t...

Page 45

43 controls seat and seat belt (b) fore-and-aft adjustment 1. Pull on lever (2) and slide the seat backward or forward to bring it to the optimum position for operating the machine. 2. Release the lever (2) at the desired position and the seat will be locked there. Adjustment stroke: 15 steps,150 mm...

Page 46

44 controls seat and seat belt seat belt caution always fasten the seat belt securely before starting the engine. Fastening the seat belt 1. Adjust the seat to the optimum position for operating, raise your torso, and sit back firmly into the seat. 2. Pull the seat belt to the desired length. 3. Mak...

Page 47

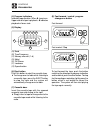

45 controls instrument cluster warning lamps important: if a warning lamp flashes and an alarm is sounded, stop all operations immediately and inspect and maintain the appropriate part. Refer to page 145 “troubleshooting”. 1. Engine emergency lamp this lamp flashes and an alarm is sounded if the eng...

Page 48

46 controls c4b013 c4b014 g4b011 indicators 6. Glow lamp this lamp turns off when engine preheating is completed. 7. Travel speed lamp this lamp lights when the travel speed is set to 2nd (high speed). 8. Decel. Lamp this lamp lights when decel. Switch pressed, the engine speed decreases. Instrument...

Page 49

47 controls horn switch press the switch on the right operating lever to blow the horn. Decel. Switch warning set the operating and travel levers to neutral before operating the decel. Switch. The machine’s operating speed will change abruptly if the switch is operated while the levers are engaged. ...

Page 50

48 controls switches auxiliary hydraulic switches press those switches to control the flow of the oil in the auxiliary hydraulic circuit. (a) .......... Hydraulic oil flows to left auxiliary line (b) .......... Hydraulic oil flows to right auxiliary line travel speed switch press this switch to set ...

Page 51

49 controls light switch when this switch is turned while the starter switch is at on, the lights turn on as follows: o ...... Off i ....... Meter light, front light and boom light turn on. Switches wiper switch (cab) important: if no washer fluid is discharged, do not operate the washer. Doing so m...

Page 52

50 controls levers and pedals operating levers warning ¡ ¡ ¡ ¡ ¡ be careful to check which pattern of lever control arrangement you are operating with before beginning operations. ¡ ¡ ¡ ¡ ¡ the explanations in this manual are for the iso pattern. Use these levers to operate the boom, arm, bucket and...

Page 53

51 controls levers and pedals offset pedal use this pedal to operate the boom offset. (a) .... Boom offset right (b) .... Boom offset left refer to page 75 “operating the boom offset”. Blade lever use this lever to operate the dozer blade. (a) .... Blade up (b) .... Blade down refer to page 75 “oper...

Page 54

52 controls accessories outlets move knob (1) up and down or left and right to adjust the direction of the air. Supplement: use the heater with care in warm seasons. Coolant circulates in the heater even when the heater switch is turned off. When the heater is no longer needed, stop coolant circulat...

Page 55

53 controls accessories battery switch warning never set this switch to the off (o) position while the engine is running. Doing so might cause damage to the electrical system. Off (o) .. Switches off the electrical circuit. Be sure to set this switch to the off (o) position when storing the machine ...

Page 56

54 controls auxiliary hydraulic lines warning oil may spurt out if caps or filters are removed or pipes disconnected before releasing the pressure in the hydraulic system. ¡ ¡ ¡ ¡ ¡ when disconnecting hoses, release the internal pressure before removing. These lines deliver the hydraulic oil necessa...

Page 57

55 controls 2. Stop the engine and open the selector valve (1) on the machine body. (the residual pressure is released from the (b) port line.) when equipped with accumulator (option): refer to page 177 “accumulator”. Selector valve o : open ....... When using a hydraulic breaker (1-way flow) s : cl...

Page 58

56 controls accessories cigarette lighter (cab) warning ¡ ¡ ¡ ¡ ¡ do not leave the cigarette lighter’s knob pressed in. Doing so heats up the lighter, and could be dangerous. ¡ ¡ ¡ ¡ ¡ if the knob does not pop out after 30 seconds, it may be broken. Pull it out by hand. ¡ ¡ ¡ ¡ ¡ do not use other ci...

Page 59

57 controls accessories radio (cab) operating precautions ¡ to ensure safe operation of the machine, always be sure to keep the volume of the radio down to a level where you can easily hear sounds from outside the machine. ¡ do not keep the radio playing for long periods of time with the engine stop...

Page 60

58 controls accessories (4) program indicators indicates tape direction. When s lamp is on. Upper side of a tape is playback, t indicates playback of lower side. (5) display (a) band (b) time/frequency (c) memory channel (1–6) (d) metal (e) fm stereo (f) loudness (g) tape direction (6) eject button ...

Page 61

59 controls accessories to change the program, press the fast- forward and rewind buttons simultaneously. The direction of tape feed will reverse. ¡ when the tape ends in one direction, the system automatically reverses the tape and plays the other side. ¡ to stop fast-forwarding or rewinding, light...

Page 62

60 controls accessories (15) disp (time / frequency) button this system is equipped with a clock which can show the accurate time. Even if the radio is off, the clock still shows the time. (16) ps / as switch push this button 2 sec below will automatically operates to show the memorized station from...

Page 63: Operation

61 before starting operation ......................... 62 starting and stopping the engine ............. 63 machine operation ..................................... 66 operating procedures ............................... 76 parking the machine .................................. 84 handling in cold we...

Page 64

62 operation before starting operation walk-around inspection perform the walk-around inspections before starting the engine the first time that day. Perform the inspections as described under “maintenance - walk-around inspection” (pages 103 and 104). Daily inspection perform the daily inspections ...

Page 65

63 operation starting and stopping the engine before starting the engine 1. Adjust the seat for a comfortable operating position. 2. Fasten the seat belt. 3. Check that the safety lock lever is in the locked position. 4. Check that all the levers and pedals are in the neutral position. 5. Insert the...

Page 66

64 operation starting and stopping the engine starting in cold weather 1. Pull the throttle lever to the middle position. 2. Turn the key to the preheat position and hold it there while the glow lamp is lit (about 15 seconds). 3. After the glow lamp turns off, then turn it to the start position and ...

Page 67

65 operation starting and stopping the engine stopping the engine important: do not stop the engine suddenly when operating with heavy loads or at maximum speed. Doing so may cause the engine to overheat or seize. Never bring the engine to a sudden stop except in the case of a true emergency. 1. Idl...

Page 68

66 operation machine operation lever pattern (iso pattern) warning ¡ ¡ ¡ ¡ ¡ be careful to check which pattern of lever control arrangement you are operating with before beginning operations. ¡ ¡ ¡ ¡ ¡ the explanations in this manual are for the iso pattern. Left crawler forward left crawler reverse...

Page 69

67 operation machine operation lever pattern (jcb pattern) warning ¡ ¡ ¡ ¡ ¡ be careful to check which pattern of lever control arrangement you are operating with before beginning operations. ¡ ¡ ¡ ¡ ¡ the explanations in this manual are for the iso pattern. Left crawler forward left crawler reverse...

Page 70

68 operation machine operation 3. Extend and retract each of the cylinders several times with no load. 4. Slew slowly left and right several times. 5. Travel slowly forward and backward several times. Warming up in cold weather 1. Perform the normal warm-up procedure. 2. Set the bucket cylinder at t...

Page 71

69 operation machine operation inspection after warm-up after warming up the engine and hydraulic oil, perform the checks and inspections described below, and repair if there is a problem. 1. Check that the warning lamps and meters are as follows: ¡ are all the warning lamps off? ¡ is the water temp...

Page 72

70 operation machine operation traveling forward and backward 1. Pull the throttle lever and increase the engine speed. 2. Fully lower the safety lock lever to disengage the lock. 3. Fold the hoe attachment and lower it to 30 to 40 cm(12 to 16 in.) above the ground. 4. Lift the dozer blade. Operatin...

Page 73

71 operation machine operation press the travel speed switch on the right travel lever to switch to 2nd (high) speed, and press it again to return to 1st speed (low speed). Pivot turn turning to the left when stopped: a to turn forward to the left: tilt the right lever forward. E to turn backward to...

Page 74

72 operation machine operation stopping travel warning ¡ ¡ ¡ ¡ ¡ park the machine on firm, level ground and apply the parking device. If you must park on a slope or incline, block the machine securely to prevent movement. ¡ ¡ ¡ ¡ ¡ if any controls should be touched accidentally when the safety lock ...

Page 75

73 operation machine operation attachment interference switch / interference prevention system warning ¡ ¡ ¡ ¡ ¡ all attachments other than a bucket should be used with the ais set to the m mode. ¡ ¡ ¡ ¡ ¡ ensure that all buckets used in the standard position are no longer than a standard bucket whe...

Page 76

74 operation machine operation slewing warning check the surrounding area for safety before slewing. A to slew left: tilt the left operating lever to the left. E to slew right: tilt the left operating lever to the right. Operating the boom a to lower the boom: tilt the right operating lever forward....

Page 77

75 operation machine operation operating the arm a to contract the arm: tilt the left operating lever backward. E to extend the arm: tilt the left operating lever forward. Operating the bucket a to dig: tilt the right operating lever to the left. E to dump: tilt the right operating lever to the righ...

Page 78

76 operation operating procedures be gentle on the hydraulic cylinders do not extend the hydraulic cylinders to the stroke ends. Operate them with leeway. Do not support the machine body with the hoe attachment as it is lowering with the arm cylinder fully extended. Doing so concentrates the load on...

Page 79

77 operation operating procedures do not perform operations using the machine’s dropping force putting excessive strain on the machine will shorten its service life. Use the hydraulic force of the cylinders and always dig with shallow, long strokes. Digging base rock for hard base rock, break the ro...

Page 80

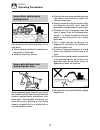

78 operation e4a040 operating procedures pay attention to the dozer blade when digging when digging deeply with the dozer blade positioned at the front, be careful that the boom cylinder and bucket do not hit the dozer blade. Operate with the dozer blade at the rear whenever possible. Caution on dig...

Page 81

79 operation operating procedures cautions on use in water if you leave water at a sharp angle, the rear of the machine may be submerged, exposing the radiator fan to water and damaging them. Do not let the rear of the machine get submerged. ¡ allowable water depth in water, only use the machine up ...

Page 82

80 operation operating procedures braking when traveling down slopes when traveling down slopes, the brakes are applied automatically when the travel levers are returned to the neutral position. If the crawlers slip if the crawlers slip while traveling up a slope, use the pulling force of the arm to...

Page 83

81 operation operating procedures getting out of mud if the machine gets stuck in mud, use the procedure below to get it out. If one crawler is stuck 1. Slew the bucket to the side which is stuck. 2. Set the arm and boom to an angle of 90 to 110 ° . 3. Press the bottom of the bucket (not the teeth) ...

Page 84

82 operation operating procedures operations possible with this machine excavating 1. Set the dozer blade on the side opposite the side you want to dig on. 2. Use the arm and bucket and dig with shallow, long strokes. The digging force is strongest when the boom and arm angle is 80 to 120 ° . Use th...

Page 85

83 operation operating procedures leveling 1. Bring the hoe attachment close to the body. 2. Gradually remove the dirt from the side of the mound. 3. Once the mound is low, remove the dirt from the top. If the load on the body is too heavy, adjust by raising or lowering the dozer blade. E4d053.

Page 86

84 operation parking the machine inspection and checks after stopping the engine 1. Check for oil and water leakage and inspect the working equipment, covers and lower body. If any irregularities are found, repair. 2. Fill the fuel tank. Refer to page 107 “inspecting the fuel level”. 3. Remove any p...

Page 87

85 operation handling in cold weather preparing for cold weather in cold weather, it may be difficult to start the engine and the coolant may freeze. Make the preparations described below. Changing the fuel and lubricant change the fuel, hydraulic oil and engine oil to types suited for cold conditio...

Page 88

86 operation handling rubber crawlers ¡ do not let fuel, oil, salt or chemical solvents get on the crawlers. These substances may corrode the couplings of the crawlers’ metal cores, resulting in rust or peeling. If these substances should get on the crawlers, wipe them off immediately using water. ¡...

Page 89

87 operation handling rubber crawlers cautions heed the following cautions when operating the machine: ¡ avoid changing course abruptly and spinning on concrete surfaces whenever possible. Doing so may wear or damage the rubber crawlers. ¡ avoid drops that may expose the rubber crawlers to strong sh...

Page 90

88 operation handling rubber crawlers ¡ do not change directions when the crawler belts are slack as shown in the diagram..

Page 91: Transport

89 transport loading and unloading ............................. 90 securing the machine ................................ 91 cautions on transporting .......................... 92.

Page 92

90 transport loading and unloading 1. Apply the truck’s parking brake and place stoppers against its tires. 2. Fasten the ramps securely to the truck bed so that they will not come off. Set the ramps to an angle of 15 ° or less. 3. Line up the center of the truck bed with the center of the machine a...

Page 93

91 transport securing the machine after loading the machine in the designated position, secure it as described below. Transporting posture 1. Lower the dozer blade. 2. Fully extend the bucket and arm cylinders, then lower the boom. 3. Stop the engine and remove the starter key. 4. Raise the safety l...

Page 94

92 transport cautions on transporting warning ¡ ¡ ¡ ¡ ¡ know and follow the safety rules, vehicle code and traffic laws when transporting the machine. ¡ ¡ ¡ ¡ ¡ consider the length, width, height and weight of the truck with the machine loaded on it when determining the best route..

Page 95: Maintenance

93 maintenance general ....................................................... 94 service data ............................................... 96 important parts ........................................ 100 maintenance chart ................................... 101 walk-around inspection ...............

Page 96

94 maintenance general cautions on maintenance do not perform inspection and maintenance procedures not prescribed in this manual. Have inspection and maintenance procedures not prescribed in this manual performed by a takeuchi sales or service outlet. Always keep the machine clean. ¡ always keep th...

Page 97

95 maintenance general disposing of wastes ¡ collect spent fluids from the machine in containers. Disposing of wastes irresponsibly damages the environment. ¡ dispose of oil, fuel, cooling water, coolant, filters, batteries and other harmful substances as prescribed by law. Check after maintenance ¡...

Page 98

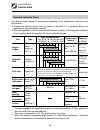

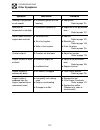

96 maintenance service data fuel and lubricant chart use different fuels, lubricants and greases according to the temperature, referring to the chart below. ¡ change the lubricant earlier than as shown in the table if it is extremely dirty or its performance has deteriorated severely. ¡ whenever pos...

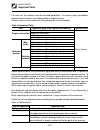

Page 99

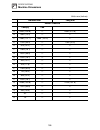

97 maintenance service data expendables replace expendables such as filters and elements periodically, referring to the table below. Replace the hydraulic oil regularly! Replacement interval (hours) item hydraulic oil return filter 1st time 25 2nd time 100 periodically 600 200 when the breaker opera...

Page 100

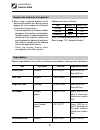

98 maintenance service data tools j1g017 1 2 3 4 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 23 22 13 hammer 16903-00330 3/4 14 hex. Wrench 16906-00400 4mm 15 hex. Wrench 16906-00500 5mm 16 hex. Wrench 16906-00600 6mm 17 hex. Wrench 16906-00800 8mm 18 hex. Wrench 16906-01000 10mm 19 hex. Wrench 1690...

Page 101

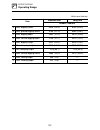

99 maintenance service data tightening torques nuts and bolts (for iso strength category 10.9) tighten nuts and bolts at the torques shown on the table below, unless otherwise specified in the text. ¡ tightening torques when mounting plastic covers differ from the values on the table below. Consult ...

Page 102

100 maintenance important parts for safe use, the machine must be serviced periodically. To increase safety, periodically replace the parts listed in the following table of important parts. Serious injury or a fire could result if they deteriorate or are damaged. Table of important parts above impor...

Page 103

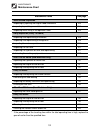

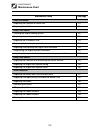

101 maintenance maintenance chart * if the percentage of the traveling time within the total operating time is high, replace the gear oil earlier than the specified time. Maintenance items see page walk-around inspection inspecting by opening the engine hood and covers 103 inspecting by walking arou...

Page 104

102 maintenance maintenance chart maintenance items see page every 500 hours replacing the hydraulic oil return filter 121 replacing the fuel filter 121 every 1000 hours cleaning the engine cooling system 122 replacing the air cleaner element 123 replacing the air breather filter 124 replacing the t...

Page 105

103 maintenance walk-around inspection inspecting by opening the engine hood and covers 1. Check for any twigs, leaves, oil or other combustible materials around the engine and battery. 2. Check for oil or engine coolant water leakage around the engine. 3. Check for oil leakage from the hydraulic ta...

Page 106

104 maintenance walk-around inspection inspecting while sitting in the operator’s seat 13. Check the windshield for dirt or damage. 14. Check the seat and seat belt for dirt or damage. Check the operator’s seat for dirt, oil or other combustible materials. 15. Check the monitor, instruments and swit...

Page 107

105 maintenance daily inspection (every 10 hours) perform the following inspections once every day before starting the engine the first time. Warning ¡ ¡ ¡ ¡ ¡ before operating, perform the daily inspections and make repairs immediately should any irregularities be found. ¡ ¡ ¡ ¡ ¡ be sure to secure...

Page 108

106 maintenance daily inspection (every 10 hours) inspecting the water separator warning stop the engine and allow the machine to cool down before performing inspection and maintenance. S : closed 1. Open the engine hood. 2. Inspect the water separator (1). If the red indicator ring (6) is sunk to t...

Page 109

107 maintenance daily inspection (every 10 hours) inspecting the fuel level warning ¡ ¡ ¡ ¡ ¡ do not smoke or permit open flames while fueling or near fueling operations. ¡ ¡ ¡ ¡ ¡ stop the engine in a well-ventilated place when adding fuel. ¡ ¡ ¡ ¡ ¡ clean up spilled fuel immediately. ¡ ¡ ¡ ¡ ¡ do ...

Page 110

108 maintenance daily inspection (every 10 hours) replenishing 1. Remove cap nut (3) on the air breather (2). 2. Press button (4) and bleed the air from the tank. 3. Tighten securely by hand with cap nut (3). 4. Remove the plug (1). 5. Add hydraulic oil up to the middle of the sight gauge (7). 6. Ti...

Page 111

109 maintenance daily inspection (every 10 hours) lubricating the working equipment 1. Set the machine to the lubrication posture shown in the diagram above, ground the working equipment, then stop the engine. 2. Use the grease gun to lubricate the grease nipples. 3. Wipe off the expelled grease. J1...

Page 112

110 maintenance after first 50 hours (new machines only) 1. Remove cap nut (3) on the air breather (2). 2. Press button (4) and bleed the air from the tank. 3. Tighten securely by hand with cap nut (3). 4. Loosen the bolts, and remove the flange (5). 5. Remove the return filter (6). 6. Install the n...

Page 113

111 maintenance after first 50 hours (new machines only) 4. Open the engine hood. 5. Using a filter wrench, turn the filter (4) counterclockwise and remove it. 6. Clean the surface of installation of the filter stand. 7. Apply a thin layer of oil to the packing of the new filter. 8. Install the new ...

Page 114

112 maintenance after first 50 hours (new machines only) adjustment 1. Tilt up the platform. Refer to page 133 “tilting up the platform”. 2. Loosen the adjustment bolt (5) and locking nut (6). 3. Using a lever (7), move the alternator (8) and adjust the slack. 4. Tighten the adjustment bolt (5) and ...

Page 115

113 maintenance every 50 hours 2. Use the operating devices to lift the body. Operate the levers slowly. 3. Inspect the gap (a or b) between the bottom surface of the frame at the center of the crawler frame and the top surface of the crawler. The gap (a or b) should be within the following range: (...

Page 116

114 maintenance every 50 hours 2. Using the grease gun, insert grease through the grease nipple (3) in the grease discharge valve (2). 3. Inspect the crawler tension. Decreasing the tension 1. Remove the cover (1). 2. Using the spanner, slowly loosen the grease discharge valve (2) and drain the grea...

Page 117

115 maintenance every 50 hours inspecting the battery fluid level and replenishing danger ¡ ¡ ¡ ¡ ¡ do not use the battery when the fluid level is below the lower level. Doing so will hasten the deterioration of the internal portions of the battery and shorten the battery life, and can also cause ru...

Page 118

116 maintenance every 50 hours draining the fuel tank warning ¡ ¡ ¡ ¡ ¡ do not smoke or permit open flames while handling fuel or working on the fuel system. ¡ ¡ ¡ ¡ ¡ stop the engine in a well-ventilated place and allow it to cool down before performing maintenance. ¡ ¡ ¡ ¡ ¡ clean up spilled fuel ...

Page 119

117 maintenance after first 250 hours (new machines only) replacing the travel motor gear oil warning ¡ ¡ ¡ ¡ ¡ stop the engine and allow the machine to cool down before performing maintenance. • the travel motors are hot directly after the engine is stopped. Touching them will cause burns. • the ge...

Page 120

118 maintenance 1. Open the engine hood. 2. Loosen the clamp (1) and remove the dust cup (2). 3. Clean the inside of the dust cup (2). 4. Remove the element (3). 5. Cover the intake hole at the back of the body (4) with cloth or tape to prevent dirt from getting in. 6. Clean the inside of the body (...

Page 121

119 maintenance every 250 hours 8. Light up the inside of the element (3) with a bulb, inspect it, and replace it if there are small holes or thin spots. 9. Remove the cloth or tape applied in step 5. 10. Install the element (3). 11. Install the dust cup (2) with the “top” mark at the top, then fast...

Page 122

120 maintenance every 250 hours cleaning the radiator and oil cooler fins warning wear required appropriate equipment such as safety glasses and filter mask when using compressed air, as metal fragments or other objects can fly and cause serious personal injury. Important: be careful not to damage t...

Page 123

121 maintenance every 500 hours replacing the fuel filter warning ¡ ¡ ¡ ¡ ¡ do not smoke or permit open flames while handling fuel or working on the fuel system. ¡ ¡ ¡ ¡ ¡ stop the engine in a well-ventilated place and allow it to cool down before performing maintenance. ¡ ¡ ¡ ¡ ¡ clean up spilled f...

Page 124

122 maintenance every 1000 hours 1. Open the engine hood. 2. Remove the cover (5) on the radiator cap (3). 3. Gradually loosen the radiator cap (3) to release the internal pressure, then remove. 4. Place a pan for catching the spent coolant under the drain plug (4), then loosen the drain plug (4) an...

Page 125

123 maintenance every 1000 hours 6. Run the engine at a low idle for about 30 minutes. For the first 5 minutes after starting it, pay attention to the level of the cleaning fluid, and add tap water if the level drops. 7. Stop the engine and drain the cleaning fluid. 8. Tighten the drain plug (4), ad...

Page 126

124 maintenance every 1000 hours inspecting and adjusting the engine valve clearance this operation requires experience. Have it performed by a takeuchi sales or service outlet. Retightening the engine cylinder head bolts this operation requires experience. Have it performed by a takeuchi sales or s...

Page 127

125 maintenance every 2000 hours replacing the hydraulic oil and cleaning the suction strainer warning ¡ ¡ ¡ ¡ ¡ stop the engine and allow the machine to cool down before performing maintenance. • the engine, hydraulic lines and many other parts of the machine are hot directly after the engine is st...

Page 128

126 maintenance every 2000 hours 21. Set the machine to the hydraulic oil level inspection posture and inspect the level once the temperature of the oil has dropped. Refer to page 107 “inspecting the hydraulic oil level and replenishing”. Bleeding the air important: after replacing the hydraulic oil...

Page 129

127 maintenance when required 3. Remove the key, then check that the bucket is stable. 4. Place a rod against the locking pin (1) and knock the locking pin out by hammering against the rod. The rod should be round and thinner than the locking pin. 5. Remove the tooth point (2). Some tooth points (2)...

Page 130

128 maintenance when required installation 1. Clean the adapter nose (3). If there is gravel or mud on the adapter nose, the tooth point will not go in all the way and the pin cannot be driven in. 2. Put the tooth point (2) in the adapter nose (3). Push in firmly until the tooth point (2) touches th...

Page 131

129 maintenance when required ¡ ¡ ¡ ¡ ¡ side cutter installation 1. Insert the bolts from the inner of the bucket and tighten the nuts. Tightening torque: 241 n·m (178 ft-lb) 2. Caulk the bolts with a punch at three spots along the periphery of the screw to prevent the nuts from coming loose. G4g026...

Page 132

130 maintenance when required 2. Set the safety lock lever to the locked position and stop the engine. 3. Remove the bolt (1). 4. Hammer pin (2) out of the bucket. 5. Remove the bucket. Inspect the pin seal (3) and replace it if it is deformed or damaged. (see next page.) installation 1. Set the buc...

Page 133

131 maintenance when required 3. Operate the cylinder, line up pin hole (b) in the bucket with the pin hole in the link arm (6), and install the pin (2). 4. Line up the turn prevention holes, install the bolt (1), and the nuts. Be sure to leave a gap of about 0.5 ~ 1 mm (0.02 ~ 0.04 in.) between the...

Page 134

132 maintenance lubricating the levers warning set the machine to the parking posture, stop the engine, remove the starter key and store it. Failure to do so may result in the machine moving abruptly, leading to serious injury or death. If the levers or pedals no longer move smoothly, supply grease....

Page 135

133 maintenance when required tilting up the platform for inspection and maintenance, the platform is designed so that it can be tilted up. Warning ¡ ¡ ¡ ¡ ¡ raising or lowering the platform while the engine is running may cause the machine to move, and cause serious injury or death. Lower the worki...

Page 136

134 maintenance (3) metal core replace if even one metal core is off. (4) rubber repair if there are cracks of 60 mm (2.4 in.) or greater in length. If the steel cord is visible, repair as soon as possible, regardless of the length of the crack. E4g064 3 e4g065 60 mm or greater when required inspect...

Page 137

135 maintenance when required replacing the rubber crawlers warning ¡ ¡ ¡ ¡ ¡ if you must work beneath the raised machine or equipment, always use wood blocks, jack-stands or other rigid and stable supports. Never get under the machine or working equipment if they are not sufficiently supported. Thi...

Page 138

136 maintenance when required 6. Check that the rubber crawler is securely engaged on the sprocket and idler. 7. Tighten the rubber crawler to the standard tension. Refer to page 113 “inspecting and adjusting the crawler tension”. 8. Install the other rubber crawler using the same procedure. Cleanin...

Page 139

137 maintenance long-term storage during storage warning ¡ ¡ ¡ ¡ ¡ do not operate the engine in an enclosed area without adequate ventilation. ¡ ¡ ¡ ¡ ¡ if natural ventilation is poor, install ventilators, fans, exhaust extension pipes or other artificial venting devices. 1. To prevent rusting, oper...

Page 140

138.

Page 141: Troubleshooting

139 symptoms that are not malfunctions ...... 140 if the engine overheats ........................... 141 if the battery goes dead .......................... 142 after the fuel runs out ........................... 143 if a fuse blows ......................................... 144 if a warning lamp fl...

Page 142

140 troubleshooting symptoms that are not malfunctions the following symptoms are not malfunctions: ¡ when the arm reaches the vertical position while contracting it while the engine is running at low speed, the contracting speed slows down momentarily. ¡ when the bucket teeth reach the horizontal p...

Page 143

141 troubleshooting if the engine overheats 3. If there is steam, stop the engine immediately and contact a takeuchi sales or service outlet for repairs. If there is no steam, run the engine at low idle and let the water temperature decrease. 4. Once the water temperature gauge drops to the green zo...

Page 144

142 troubleshooting if the battery goes dead connecting the jumper cables important: set the starter keys of both the rescue vehicle and problem vehicle to the off position. Refer to page 40 “battery access cover”. 1. Connect the clip of jumper cable (r) to the problem vehicle’s “+” terminal. 2. Con...

Page 145

143 troubleshooting disconnecting the jumper cables once the engine starts, disconnect the jumper cables following the connection procedure in reverse order. 1. Disconnect the clip of jumper cable (b) from the problem vehicle’s engine block. 2. Disconnect the other clip of jumper cable (b) from the ...

Page 146

144 troubleshooting if a light does not turn on or the electric system does not operate, a fuse may be blown. Inspect the fuses. Inspecting and replacing the fuse warning if the fuse blows as soon as it is replaced, there is a problem with the electric system. Continued use may lead to fire. Consult...

Page 147

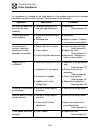

145 troubleshooting if a warning lamp flashes if an alarm is sounded or a warning lamp starts flashing during operation, park the machine in a safe place and perform the procedures described below. Warning lamp lamp name procedure the coolant temperature has risen irregularly and the engine is overh...

Page 148

146 troubleshooting other symptoms for symptoms not included on the table below or if the problem persists after the proper procedures have been taken, consult a takeuchi sales or service outlet. Symptom main cause procedure left and right operating levers do not move smoothly ¡ insufficient grease ...

Page 149

147 troubleshooting other symptoms slewing is not possible or not smooth ¡ insufficient grease on slew bearing ¡ add grease. Refer to page 114. Symptom main cause procedure hydraulic oil temperature is too high ¡ insufficient hydraulic oil ¡ replenish to the prescribed level. Refer to page 107. Star...

Page 150

148 troubleshooting 4 3 m 2 j1j004 to lower the boom 2. Put mark (m) on the plug of the port relief valve (2) and set screw (3). 3. Gripping the set screw (3) with a hexagonal wrench so that it does not turn together with the lock nut (4), loosen the lock nut (4). 4. Turn the set screw (3) slowly 1 ...

Page 151

149 troubleshooting towing warning when towing, selecting the wrong wire rope, inspecting improperly, or towing in the wrong way could lead to accidents resulting in serious injury or death. ¡ ¡ ¡ ¡ ¡ the wire rope breaking or coming detached could be extremely dangerous. Use a wire rope suited for ...

Page 152

150

Page 153: Specifications

151 specifications main specifications ................................. 152 machine dimensions ............................... 154 operating range ...................................... 156 lifting capacities ..................................... 159.

Page 154

152 specifications main specifications sound-power level l wa 99 sound-pressure level l pa 82 mass machine mass kg (lb.) (not including operator) rubber crawlers 5115 (11270) 5200 (11460) performance bucket capacity m 3 (cu.Ft.) (standard bucket) heaped 0.141 (4.98) struck 0.102 (3.60) 9.7 (9.7) sle...

Page 155

153 specifications engine manufacturer and model yanmar 4tnv88-qtbz rated output kw / min –1 (hp / rpm) 27.4 / 2300 (36.8 / 2300) displacement mi (cu.In.) 2189 (133.6) starter v – kw 12 – 2.5 alternator v – kw 12 – 0.48 battery v – a·h 12 – 72 main specifications type canopy cab.

Page 156

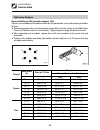

154 specifications machine dimensions j1k0011 n l m d q p j h k c f g a s e b r t u.

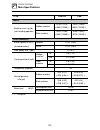

Page 157

155 specifications machine dimensions units: mm (inches) canopy cab a 5330 (209.8) ← 5350 (210.6) b 1860 (73.2) ← ← c 2580 (101.7) 2565 (100.9) ← d 1000 (39.4) ← 1050 (41.3) e 615 (24.2) ← ← f 1985 (78.1) ← ← g 2500 (98.5) ← ← h 2000 (78.7) ← ← j 400 (15.7) ← ← k 300 (11.8) ← ← l 1285 (50.6) ← ← m 7...

Page 158

156 specifications operating range j1k0021 d j h k c f g a e b.

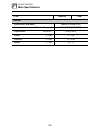

Page 159

157 specifications operating range units: mm (inches) item standard arm long arm rubber crawlers a max. Digging radius 5905 (232.4) 6195 (243.9) b max. Ground digging radius 5765 (227.0) 6065 (238.7) c max. Digging depth 3590 (141.3) 3900 (153.5) d max. Vertical digging depth 2735 (107.7) 3030 (119....

Page 160

158 memo.

Page 161

159 specifications lifting capacities rated lift capacity chart ¡ the loads in the charts do not exceed 87% of hydraulic lift capacity or 75% of tipping load. ¡ rated lift capacities limited by rated hydraulic lift capacity are identified by an asterisk(*) ¡ the mass of slings and any auxiliary lift...

Page 162

160 specifications lifting capacities equipped with standard arm m6 .0 5. 0 4.0 3.0 2.0 1.0 0 ft. (19.7) (16.4) (13.1) (9.8) (6.6) (3.3) 6.0 (19.7) 5.0 (16.4) 4.0 (13.1) 3.0 (9.8) 2.0 (6.6) 1.0 (3.3) 0( 0) –1.0 (–3.3) –2.0 (–6.6) –3.0 (–9.8) m ft. J1k0031e over front ; dozer blade up 873 (1925) 1299...

Page 163

161 specifications equipped with standard arm lifting capacities m6 .0 5. 0 4.0 3.0 2.0 1.0 0 ft. (19.7) (16.4) (13.1) (9.8) (6.6) (3.3) 6.0 (19.7) 5.0 (16.4) 4.0 (13.1) 3.0 (9.8) 2.0 (6.6) 1.0 (3.3) 0( 0) –1.0 (–3.3) –2.0 (–6.6) –3.0 (–9.8) m6 .0 5. 0 4.0 3.0 2.0 1.0 0 ft. (19.7) (16.4) (13.1) (9.8...

Page 164

162 specifications lifting capacities equipped with standard arm and extra weight m 6.0 5.0 4.0 3.0 2.0 1.0 0 ft. (19.7) (16.4) (13.1) (9.8) (6.6) (3.3) 6.0 (19.7) 5.0 (16.4) 4.0 (13.1) 3.0 (9.8) 2.0 (6.6) 1.0 (3.3) 0 (0) –1.0 (–3.3) –2.0 (–6.6) –3.0 (–9.8) m ft. J1k0051e over front ; dozer blade up...

Page 165

163 specifications equipped with standard arm and extra weight lifting capacities m 6.0 5.0 4.0 3.0 2.0 1.0 0 ft. (19.7) (16.4) (13.1) (9.8) (6.6) (3.3) 6.0 (19.7) 5.0 (16.4) 4.0 (13.1) 3.0 (9.8) 2.0 (6.6) 1.0 (3.3) 0 (0) –1.0 (–3.3) –2.0 (–6.6) –3.0 (–9.8) m 6.0 5.0 4.0 3.0 2.0 1.0 0 ft. (19.7) (16...

Page 166

164 specifications lifting capacities equipped with long arm m 6.0 5.0 4.0 3.0 2.0 1.0 0 ft. (19.7) (16.4) (13.1) (9.8) (6.6) (3.3) 6.0 (19.7) 5.0 (16.4) 4.0 (13.1) 3.0 (9.8) 2.0 (6.6) 1.0 (3.3) 0 (0) –1.0 (–3.3) –2.0 (–6.6) –3.0 (–9.8) –3.5 (–1 1.5) m ft. J1k0071e over front ; dozer blade up units:...

Page 167

165 specifications equipped with long arm lifting capacities m 6.0 5.0 4.0 3.0 2.0 1.0 0 ft. (19.7) (16.4) (13.1) (9.8) (6.6) (3.3) 6.0 (19.7) 5.0 (16.4) 4.0 (13.1) 3.0 (9.8) 2.0 (6.6) 1.0 (3.3) 0 (0) –1.0 (–3.3) –2.0 (–6.6) –3.0 (–9.8) –3.5 (–1 1.5) m ft. M 6.0 5.0 4.0 3.0 2.0 1.0 0 ft. (19.7) (16....

Page 168

166.

Page 169: Options

167 options general precautions ................................ 168 safety signs (decals) ............................... 170 switching the lever pattern .................... 173 hydraulic breaker .................................... 174 travel alarm ............................................. 17...

Page 170

168 options general precautions precautions on safety warning heed the following when removing or installing an attachment or option: ¡ ¡ ¡ ¡ ¡ consult with a takeuchi dealer before installing optional attachments. ¡ ¡ ¡ ¡ ¡ do not use attachments that have not been approved by takeuchi or a takeuch...

Page 171

169 options general precautions precautions on operating attachments warning long attachments reduce machine stability. When traveling down steep slopes or slewing on slopes, the machine may loose its balance and tip over. The following operations are particularly dangerous. Do not perform them. ¡ ¡...

Page 172

170 options safety signs (decals) keep all safety signs clean and legible. Replace all missing, illegible or damaged safety and warning signs. There are other safety signs in addition to the ones listed here. Treat them in the same way..

Page 173: Warning

171 options safety signs (decals) 1. No.03593-32200 2. No.03593-32300 g a (iso) 03593-32200 03593-32300 check what type of lever control arrangement you are operating with before beginning operations. Warning.

Page 174

172 memo.

Page 175

173 options switching the lever pattern the operating pattern of the left and right operating levers can be changed. Warning before starting the engine, check the selector to see which operating pattern the left and right operating levers are set for. Switching the lever pattern 1. Park the machine ...

Page 176

174 options hydraulic breaker for handling of the breaker, read the hydraulic breaker ’s manual, provided separately. Important: when mounting devices, select devices suited for this machine. For advice on selecting device, contact a takeuchi sales or service outlet. Precautions on operating ¡ pull ...

Page 177

175 options hydraulic breaker replace the hydraulic oil regularly! ¡ when using a hydraulic breaker, the oil deteriorates quicker than during normal digging. Be sure to replace the hydraulic oil and return filter element. • failure to replace these in time can lead to damage to the machine and break...

Page 178

176 options factory option an alarm is sounded when the machine travels and stops when traveling is stopped. If the alarm does not sound when the machine travels, the fuse may be blown. Inspect the fuse. Warning if the fuse which has just been replaced should blow again, there is a problem in the el...

Page 179

177 options accumulator operating the machine with accumulator on machines equipped with an accumulator, the residual pressure in the auxiliary hydraulic circuits can be released within a specific amount of time after the engine is stopped. Releasing the residual pressure after using the machine, pr...

Page 180

178 options load safety device the load safety devices include an emergency shut-off valve and an overload warning device. The emergency shut-off valve stops the boom or arm part way through a fall. The overload warning device sounds an alarm when an excessive load is applied. Emergency shut-off val...

Page 181

179 options overload warning device if a weight greater than the machine is designed to lift is lifted, the overload warning device is activated and a horn is sounded (when the overload warning switch is turned on). Warning continuing to apply the load after the overload warning horn sounds could re...

Page 182

180 options second auxiliary hydraulics second auxiliary hydraulic lines warning oil may spurt out if caps or filters are removed or pipes disconnected before releasing the pressure in the hydraulic system. ¡ ¡ ¡ ¡ ¡ when disconnecting hoses, release the internal pressure before removing. These line...

Page 183

181 options second auxiliary hydraulics lubricating if the pedal no longer move smoothly, supply grease. 1. Remove the lower mount section of the boot (1) and turn it upwards. 2. Wipe off the old grease. 3. Supply grease to points (a) and (b). 4. Set the boot (1) back as it was. T7g0271 b a b 1.

Page 184

182 options third auxiliary hydraulics third auxiliary hydraulic lines warning oil may spurt out if caps or filters are removed or pipes disconnected before releasing the pressure in the hydraulic system. ¡ ¡ ¡ ¡ ¡ when disconnecting hoses, release the internal pressure before removing. These lines ...

Page 185

183 options third auxiliary hydraulics third auxiliary hydraulic switch and button operating press those switch and button to control the flow of the oil in the third auxiliary hydraulic lines. When the safety lock lever is released after the engine is started, hydraulic oil constantly flows in pipe...

Page 186

184.

Page 187: Index

185 index.

Page 188

186 index a ~ d a accessories ................................................................ 52 accumulator ............................................................. 177 after cold weather is over ........................................ 85 after first 250 hours (new machines only) ..............

Page 189

187 index d ~ i doors and covers ...................................................... 38 draining the fuel tank ............................................... 116 e emergency shut-off valve ........................................ 178 engine hood .....................................................

Page 190

188 index i ~ o inspecting the rubber crawlers ................................. 134 inspecting the water separator ................................. 106 inspecting while sitting in the operator’s seat .......... 104 inspection after warm-up .......................................... 69 inspection a...

Page 191

189 index p ~ s p park safely ................................................................. 23 parking ....................................................................... 84 parking the machine .................................................. 84 perform inspection and maintenance daily ......

Page 192

190 index s ~ w switching the lever pattern ..................................... 173 switching the lever pattern ..................................... 173 symptoms that are not malfunctions ........................ 140 t third auxiliary hydraulic lines ................................. 182 third au...

Page 193: Operator’S Manual

First published october 2000 no. 22536 seventh published september 2005 operator’s manual tb53fr compact excavator edited and issued by takeuchi mfg. Co., ltd. Printed in japan by station m co., ltd..

Page 194: California

California proposition 65 warning diesel engine exhaust and some of its constituents are known to the state of california to cause cancer, birth defects, and other reproductive harm. Battery posts, terminals and related accessories contain lead and lead compounds, chemicals known to the state of cal...